Comparative Analysis of Scientific Papers on LCA Applied to Nanoparticulated Building Materials

Abstract

1. Introduction

- Goal and scope definition: The goal and scope definition phase outlines the purpose of the study, the rationale for conducting the analysis, and other technical aspects, such as the impact categories, the system boundary (both geographical and temporal), and the functional unit for the analysis, are determined [18,25].

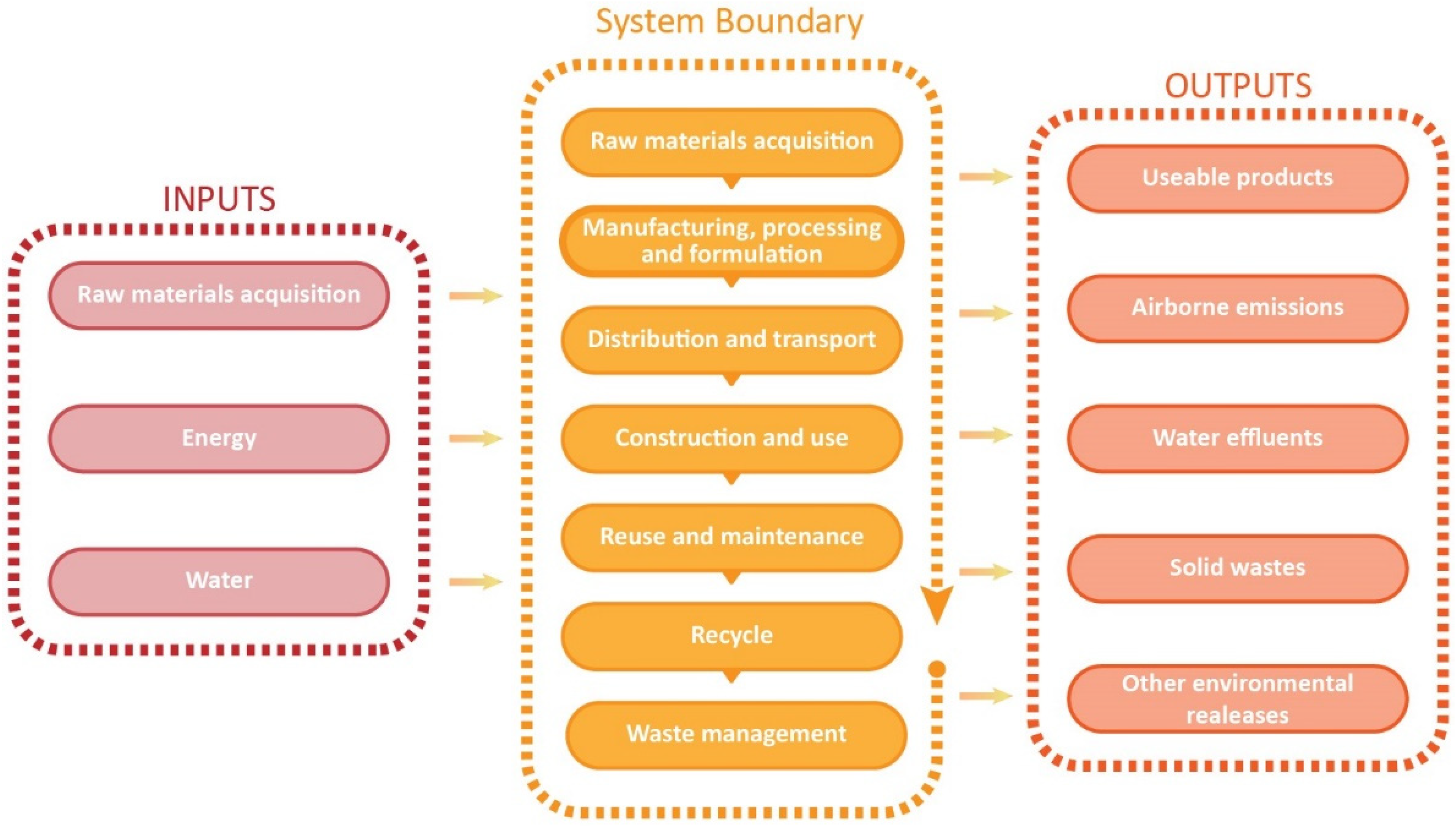

- Inventory analysis: The second phase, referred to as the Life Cycle Inventory (LCI), entails gathering data or compiling an inventory of all inputs (such as raw materials and energy) and outputs (such as waste and emissions) across the product’s entire life cycle (Figure 2). The data collected are essential for calculating the environmental impact of the product. This inventory analysis phase is both the most iterative and time-intensive step in the LCA process [18,25].

- 3.

- Impact Assessment: This third phase, also known as the Life Cycle Impact Assessment (LCIA), focuses on evaluating the potential environmental consequences originating from the inputs and outputs quantified during the inventory analysis phase, as well as the estimated resource usage. The impact assessment is achieved by translating the environmental loads into environmental impacts, such as climate change, acidification, eutrophication, etc. [18,25].

- 4.

- Interpretation: In the interpretation step, the focus is on identifying major issues, interpreting the results to draw conclusions, addressing limitations, and providing recommendations from the impact assessment, ensuring that the conclusions are thoroughly substantiated. The standard ISO 14044 provides several checks for data quality and procedures followed during the LCA study to support the conclusions [18,25].

- Identification of the problem and contextualization of basic concepts, thoroughly explained in the introduction, to know the origin and the theoretical foundations of nanomaterials, as well as the environmental impact of the current production system. This section will answer two main questions: what nanomaterials are, and how a sustainable building is designed, which are both closely related.

- Identification of the advantages of LCA, defining its different phases and the challenges in its applicability to nanoparticles. This section will address the primary question of how to evaluate and quantify the environmental impact of a building.

- Identification of the advantages that nanoproducts offer in the construction sector, with the purpose of distinguishing materials with specific and advanced properties, thus identifying their environmental and health impacts during the construction process to select the construction materials that incorporate nanoparticles and generate the least impact. This will allow for informed decision-making and the prioritization of materials that align with sustainability and health considerations.

2. Materials and Methods

2.1. Life-Cycle Assessment Fundamentals

2.2. Nanoproducts in the Construction Sector

- one or more external dimensions of the particle are in the size range 1 nm to 100 nm.

- the particle has an elongated shape, such as a rod, fibre, or tube, where two external dimensions are smaller than 1 nm and the other dimension is larger than 100 nm.

- the particle has a plate-like shape, where one external dimension is smaller than 1 nm and the other dimensions are larger than 100 nm” [35].

- “Particle” refers to a minute portion of matter with distinct physical boundaries, excluding single molecules.

- “Aggregate” describes a particle composed of strongly bound or fused smaller particles.

- “Agglomerate” pertains to a group of loosely bound particles or aggregates, with an external surface area comparable to the sum of its individual components [35].

- The surface layer, which is the outermost layer and can be functionalized with various small molecules, metal ions, surfactants, or polymers.

- The shell layer, a material chemically distinct from the core.

- The core, which is the innermost layer and serves as the central structure of the NP, generally identified as the nanoparticle itself [36].

2.2.1. Environmental Risks Associated

2.2.2. Associated Health Risks

3. Results and Discussion

3.1. Environmental and Methodological Challenges in the LCA of Nanomaterials

3.2. Definition of Objectives and Scope of the Study

3.3. Development of an Inventory of Consumption and Emissions

- Production stage:

- Inputs and outputs during the production stage; consumption- and emission-associated.

- Emissions of nanoparticles during the production stage; exposure of workers.

- Releases during the production stage; compartment of the emission.

- Transformation of the particle after the emission.

- Use stage:

- Lifespan and services obtained from the product.

- Inputs and outputs produced during use; maintenance, cleaning, consumption, and emissions associated with use.

- Emissions of nanoparticles during the use stage; exposure of workers.

- Releases during the production stage; compartment of the emission. Transformation of the particles after the emission.

- Possibility of nanoparticle emissions during use. Environmental compartment of the emission. Transformation of the particle after the emission.

- End-of-life stage:

- Characteristics of nanoproduct waste generated at the end-of-life stage.

- Treatment and final disposal of nanoproduct waste.

- Recycling: Type of recycling process. Emissions of nanoparticles during recycling. Quantity of nanoparticles in recycled products.

- Disposed to landfill: Degradation or transformation of nanoproducts. Environmental compartment for the final fate of nanoproduct waste.

- Incineration: Transformation of nanoparticles after incineration. Nanoparticles included in resulting ashes. Environmental compartment for the final fate of nanoproducts included in the resulting ashes.

3.4. Selection and Quantification of Environmental Impact Categories

3.5. Interpretation of Results

- Measurement of the releases of nanoparticles over the entire life cycle of the product, from its inception to its disposal (cradle to grave).

- Identification of the specific environmental compartments associated with each instance of nanoparticle release.

- Anticipation of the long-term destiny of the released nanoparticles, encompassing an understanding of the transformations that these nanoparticles undergo in the environment following emission.

- Evaluation of the toxicity impact on both humans and the environment resulting from the emissions of produced nanoparticles.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dräger, P.; Letmathe, P. Value losses and environmental impacts in the construction industry—Tradeoffs or correlates? J. Clean. Prod. 2022, 336, 130435. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy use in the life cycle of conventional and low-energy buildings: A review article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Intergovernmental Panel on Climate Change. IPCC Report. Climate Change 2021: The Physical Science Basis, the Working Group I Contribution to the Sixth Assessment Report; IPCC: Geneva, Switzerland, 2022. [Google Scholar]

- UN. 2022 Global Status Report for Buildings and Construction; UN: New York, NY, USA, 2023. [Google Scholar]

- Bribián, I.Z.; Usón, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520. [Google Scholar] [CrossRef]

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394. [Google Scholar] [CrossRef]

- Vasilca, I.; Nen, M.; Chivu, O.; Radu, V.; Simion, C.; Marinescu, N. The Management of Environmental Resources in the Construction Sector: An Empirical Model. Energies 2021, 14, 2489. [Google Scholar] [CrossRef]

- Açıkkalp, E.; Hepbasli, A.; Yucer, C.; Karakoc, T. Advanced life cycle integrated exergoeconomic analysis of building heating systems: An application and proposing new indices. J. Clean. Prod. 2018, 195, 851–860. [Google Scholar] [CrossRef]

- Bernal, E.; Edgar, D.; Burnes, B. Building Sustainability on Deep Values Through Mindfulness Nurturing. Ecol. Econ. 2017, 146, 645–657. [Google Scholar] [CrossRef]

- Guardigli, L.; Bragadin, M.; Della Fornace, F.; Mazzoli, C.; Prati, D. Energy retrofit alternatives and cost-optimal analysis for large public housing stocks. Energy Build. 2018, 166, 48–59. [Google Scholar] [CrossRef]

- Singh, A.; Berghorn, G.; Joshi, S.; Syal, M. Review of life-cycle assessment applications in building construction. J. Archit. Eng. 2011, 17, 15–23. [Google Scholar] [CrossRef]

- Cattaneo, A.; Gornati, R.; Sabbioni, E.; Chiriva-Internati, M.; Cobos, E.; Jenkins, M.; Bernardini, G. Nanotechnology and human health: Risks and benefits. J. Appl. Toxicol. 2010, 30, 730–744. [Google Scholar] [CrossRef]

- Salieri, B.; Turner, D.; Nowack, B.; Hischier, R. Life cycle assessment of manufactured nanomaterials: Where are we? NanoImpact 2018, 10, 108–120. [Google Scholar] [CrossRef]

- Khan, I.; Saeed, K. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Som, C.; Berges, M.; Chaudhry, Q.; Dusinska, M.; Fernandes, T.; Olsen, S.; Nowack, B. The importance of life cycle concepts for the development of safe nanoproducts. Toxicology 2010, 269, 160–169. [Google Scholar] [CrossRef] [PubMed]

- Fay, R.; Treloar, G.; Iyer-Raniga, U. Life-cycle energy analysis of buildings: A case study. Build. Res. Inf. 2000, 28, 31–41. [Google Scholar] [CrossRef]

- Wu, J.-G.; Meng, X.; Liu, X.; Liu, X.; Zheng, Z.; Xu, D.; Sheng, G.; Yu, H. Life Cycle Assessment of a Wastewater Treatment Plant Focused on Material and Energy Flows. Environ. Manag. 2010, 46, 610–617. [Google Scholar] [CrossRef]

- Rochester Institute of Technology. What Is Life Cycle Assessment (LCA)? 2020. Available online: https://www.rit.edu/sustainabilityinstitute/blog/what-life-cycle-assessment-lca (accessed on 20 October 2023).

- Fava, J.; Baer, S.; Cooper, J. Increasing Demands for Life Cycle Assessments in North America. J. Ind. Ecol. 2009, 13, 491–494. [Google Scholar] [CrossRef]

- Ortiz, O.; Castells, F.; Sonnemann, G. Sustainability in the construction industry: A review of recent developments based on LCA. Constr. Build. Mater. 2009, 23, 28–39. [Google Scholar] [CrossRef]

- Han, G.; Srebric, J. Life-Cycle Assessment Tools for Building Analysis; The Pennsylvania Housing Research Center: State College, PA, USA, 2011. [Google Scholar]

- Rebitzer, G.; Ekvall, T.; Frischknecht, R.; Hunkeler, D.; Norris, G.; Rydberg, T.; Schmidt, W.; Suh, S.; Weidema, B.; Pennington, D. Life cycle assessment: Part 1: Framework, goal and scope definition, inventory analysis, and applications. Environ. Int. 2004, 30, 701–720. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization (ISO): Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 12 September 2023).

- Baumann, H.; Tillman, A. The Hitch Hiker’s Guide to LCA: An Orientation in Life Cycle Assessment Methodology and Application; Studentlitteratur AB: Lund, Sweden, 2004. [Google Scholar]

- Ecochain, Life Cycle Assessment (LCA)—Complete Beginner’s Guide. Available online: https://ecochain.com/blog/life-cycle-assessment-lca-guide/ (accessed on 5 September 2023).

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Hauschild, M.Z.; Huijbregts, M.A.J. Life Cycle Impact Assessment; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar]

- Ding, G. Life cycle assessment (LCA) of sustainable building materials: An overview. In Eco-Efficient Construction and Building Materials; Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: Sawston/Cambridge, UK, 2014; pp. 38–58. [Google Scholar]

- Yahya, K.; Boussabaine, H.; Alzaed, A. Using life cycle assessment for estimating environmental impacts and eco-costs from the metal waste in the construction industry. Manag. Environ. Qual. 2016, 27, 227–244. [Google Scholar] [CrossRef]

- Tool, S.F. Life Cycle Assessment. Available online: https://sftool.gov/plan/400/life-cycle-assessment#:~:text=Life%20Cycle%20Assessment%20(LCA)%20aims,that%20will%20benefit%20the%20environment (accessed on 5 September 2023).

- Buyle, M.; Braet, J.; Audenaert, A. Life cycle assessment in the construction sector: A review. Renew. Sustain. Energy Rev. 2013, 26, 379–388. [Google Scholar] [CrossRef]

- Greening, L.; Greene, D.; Difiglio, C. Energy efficiency and consumption—The rebound effect—A survey. Energy Policy 2000, 28, 389–401. [Google Scholar] [CrossRef]

- Ortiz-Rodríguez, O.; Castells, F.; Sonnemann, G. Life cycle assessment of two dwellings: One in Spain, a developed country, and one in Colombia, a country under development. Sci. Total Environ. 2010, 408, 2435–2443. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Mahendra, S.; Alvarez, P.J.J. Nanomaterials in the Construction Industry: A Review of Their Applications and Environmental Health and Safety Considerations. ACS Nano 2010, 4, 3580–3590. [Google Scholar] [CrossRef] [PubMed]

- Wohlleben, W.; Mielke, J.; Bianchin, A.; Ghanem, A.; Freiberger, H.; Rauscher, H.; Gemeinert, M.; Hodoroaba, V. Reliable nanomaterial classification of powders using the volume-specific surface area method. J. Nanoparticle Res. 2017, 19, 61. [Google Scholar] [CrossRef]

- Shin, W.; Cho, J.; Kannan, A.; Lee, Y.; Kim, D. Cross-linked Composite Gel Polymer Electrolyte using Mesoporous Methacrylate-Functionalized SiO2 Nanoparticles for Lithium-Ion Polymer Batteries. Sci. Rep. 2016, 6, 26332. [Google Scholar] [CrossRef]

- Garzón, M.G. Nanomateriales, nanopartículas y síntesis verde. Revista Repertorio de Medicina y Cirugía. Fundación Universitaria de Ciencias de la Salud—FUCS. Rev. Repert. Med. Cirugía 2018, 27, 2. [Google Scholar]

- David, M.; Ion, R.; Grigorescu, R.; Iancu, L.; Andrei, E. Nanomaterials Used in Conservation and Restoration of Cultural Heritage: An Up-to-Date Overview. Materials 2020, 13, 2064. [Google Scholar] [CrossRef]

- Sierra-Fernandez, A.; Gomez-Villalba, L.; Rabanal, M.; Fort, R. New nanomaterials for applications in conservation and restoration of stony materials: A review. Mater. Construcción 2017, 67, 107. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.; Kurmus, H.; Milas, J.; Arulrajah, A.; Horpibulsuk, S.; Kadir, A. Nanoparticles in Construction Materials and Other Applications, and Implications of Nanoparticle Use. Materials 2019, 12, 3052. [Google Scholar] [CrossRef]

- Boostani, H.; Modirrousta, S. Review of Nanocoatings for Building Application. Procedia Eng. 2016, 145, 1541–1548. [Google Scholar] [CrossRef]

- European Union Observatory for Nanomaterials. Regulation. Available online: https://euon.echa.europa.eu/regulation (accessed on 22 September 2023).

- European Chemicals Agency. Nanomaterials. Available online: https://echa.europa.eu/regulations/nanomaterials (accessed on 22 September 2023).

- Nizam, N.; Hanafiah, M.; Woon, K. A Content Review of Life Cycle Assessment of Nanomaterials: Current Practices, Challenges, and Future Prospects. Nanomaterials 2021, 11, 3324. [Google Scholar] [CrossRef]

- European Chemicals Agency. Risk Assessment of Nanomaterials—Further Considerations. June 2017. Available online: https://euon.echa.europa.eu/documents/2435000/3268584/nano_in_brief_en.pdf/295c5f46-0f1e-4ad5-72a5-81c44b45bdd5?t=1531477424187 (accessed on 22 September 2023).

- REACHnano Consortium. Guidance for Applying Life Cycle Assessment Methodology to Nanomaterials. Available online: https://invassat.gva.es/documents/161660384/162311778/02+Guidance+for+applying+Life+Cycle+Assessment+methodology+to+nanomaterials/f40ee359-a279-4464-b2d0-c35c17d5922f (accessed on 25 September 2023).

- European Commission; Joint Research Centre; Institute for Environment and Sustainability. ILCD Handbook: General Guide for Life Cycle Assessment—Detailed Guidance; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- European Chemicals Agency. Study of the EU Market for Nanomaterials, Including Substances, Uses, Volumes and Key Operators; European Chemicals Agency: Helsinki, Finland, 2022. [Google Scholar]

- European Comission. Toxicological Impact of Nanomaterials Derived from Processing, Weathering and Recycling of Polymer Nanocomposites Used in Various Industrial Applications. 2016. Available online: https://cordis.europa.eu/project/id/247899 (accessed on 25 September 2023).

| Nanoparticle Type | Material/Application | Expected Benefits |

|---|---|---|

| SiO2 nanoparticles | Concrete Ceramic Windows | Reinforcement in mechanical strength, rapid hydration Coolant; light transmission; fire-resistant Flame-proofing; anti-reflection |

| TiO2 nanoparticles | Cement Windows Solar cell | Rapid hydration; increased degree of hydration; self-cleaning Superhydrophilicity; anti-fogging; fouling resistance Non-utility electricity generation |

| Carbon nanotubes | Concrete Ceramic NEMS/MEMS Solar cell | Mechanical durability, crack prevention Enhanced mechanical and thermal properties Real-time structural health monitoring Effective electron mediation |

| Fe2O3 nanoparticles | Concrete | Increased compressive strength, abrasion-resistant |

| Cu nanoparticles | Steel | Weldability, corrosion resistance, formability |

| Ag nanoparticles | Coating/painting | Biocidal activity |

| Clay nanoparticles | Bricks and mortars | Increased compressive strength and surface roughness |

| Al2O3 nanoparticles | Asphalt, concrete, timber | Increased serviceability |

| ZnO nanoparticles | Cement | Enhanced performance |

| CaCO3 nanoparticles | Concrete | Accelerated hydration, increased flowability, and increased compressive strength |

| MgO nanoparticles | Coating/painting | Energy-saving |

| Nanoparticle Type | Affected Cell/Organ/System |

|---|---|

| Silver nanoparticles (Ag NPs) | Immune system Lungs Liver Brain Carcinogenesis |

| Titanium dioxide (TiO2) | Vascular system Reproductive organs Fibroblast Inflammation in lungs DNA damage Metabolic changes |

| Zinc oxide nanoparticles (ZnO NPs) | Carcinogenesis Cell death Cell proliferation |

| Iron oxide (Fe3O4) | Oxidative DNA damage |

| Copper zinc ferrite (CuZnFe2O4) | DNA damage Oxidative DNA damage |

| Carbon nanotubes (CNTs) | DNA damage Oxidative stress |

| Copper dioxide (CuO) | Inflammation DNA damage |

| Silica nanoparticles (SiO2) | Oxidative DNA damage Bronchoalveolar carcinoma |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sánchez-Burgos, M.A.; Blandón-González, B.; Conradi-Galnares, E.; Porras-Pereira, P.; Mercader-Moyano, P. Comparative Analysis of Scientific Papers on LCA Applied to Nanoparticulated Building Materials. Constr. Mater. 2025, 5, 37. https://doi.org/10.3390/constrmater5020037

Sánchez-Burgos MA, Blandón-González B, Conradi-Galnares E, Porras-Pereira P, Mercader-Moyano P. Comparative Analysis of Scientific Papers on LCA Applied to Nanoparticulated Building Materials. Construction Materials. 2025; 5(2):37. https://doi.org/10.3390/constrmater5020037

Chicago/Turabian StyleSánchez-Burgos, Marco Antonio, Begoña Blandón-González, Esperanza Conradi-Galnares, Paula Porras-Pereira, and Pilar Mercader-Moyano. 2025. "Comparative Analysis of Scientific Papers on LCA Applied to Nanoparticulated Building Materials" Construction Materials 5, no. 2: 37. https://doi.org/10.3390/constrmater5020037

APA StyleSánchez-Burgos, M. A., Blandón-González, B., Conradi-Galnares, E., Porras-Pereira, P., & Mercader-Moyano, P. (2025). Comparative Analysis of Scientific Papers on LCA Applied to Nanoparticulated Building Materials. Construction Materials, 5(2), 37. https://doi.org/10.3390/constrmater5020037