Segregation Sensitivity of Concrete—Quantification by Concrete Density

Abstract

1. Introduction

2. Literature Review

3. Investigation

3.1. Investigation Concept

3.2. Test Procedures

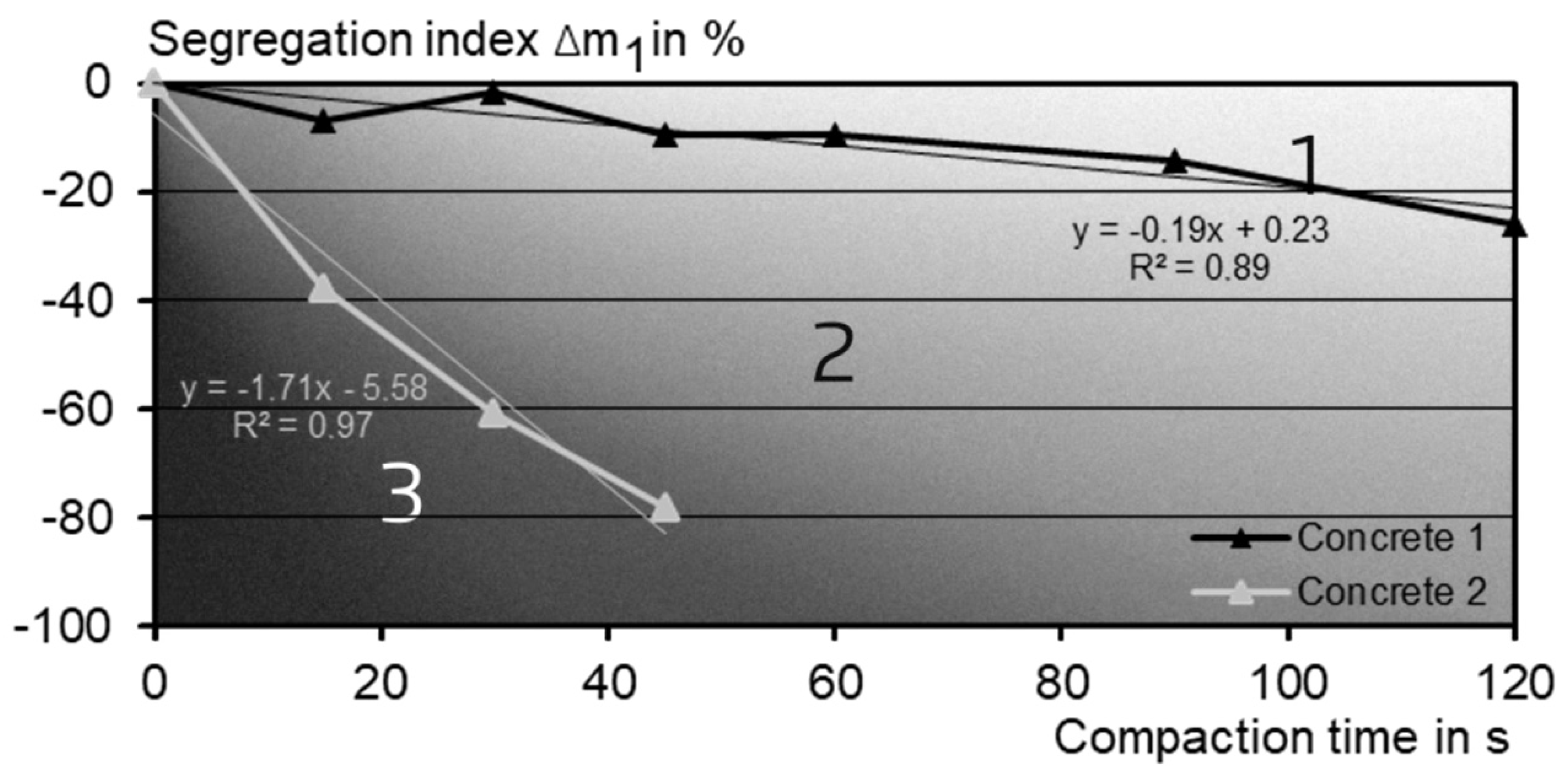

3.2.1. Wash-Out Test According to “BAW-Code of Practice MESB” [11]

3.2.2. Density Method

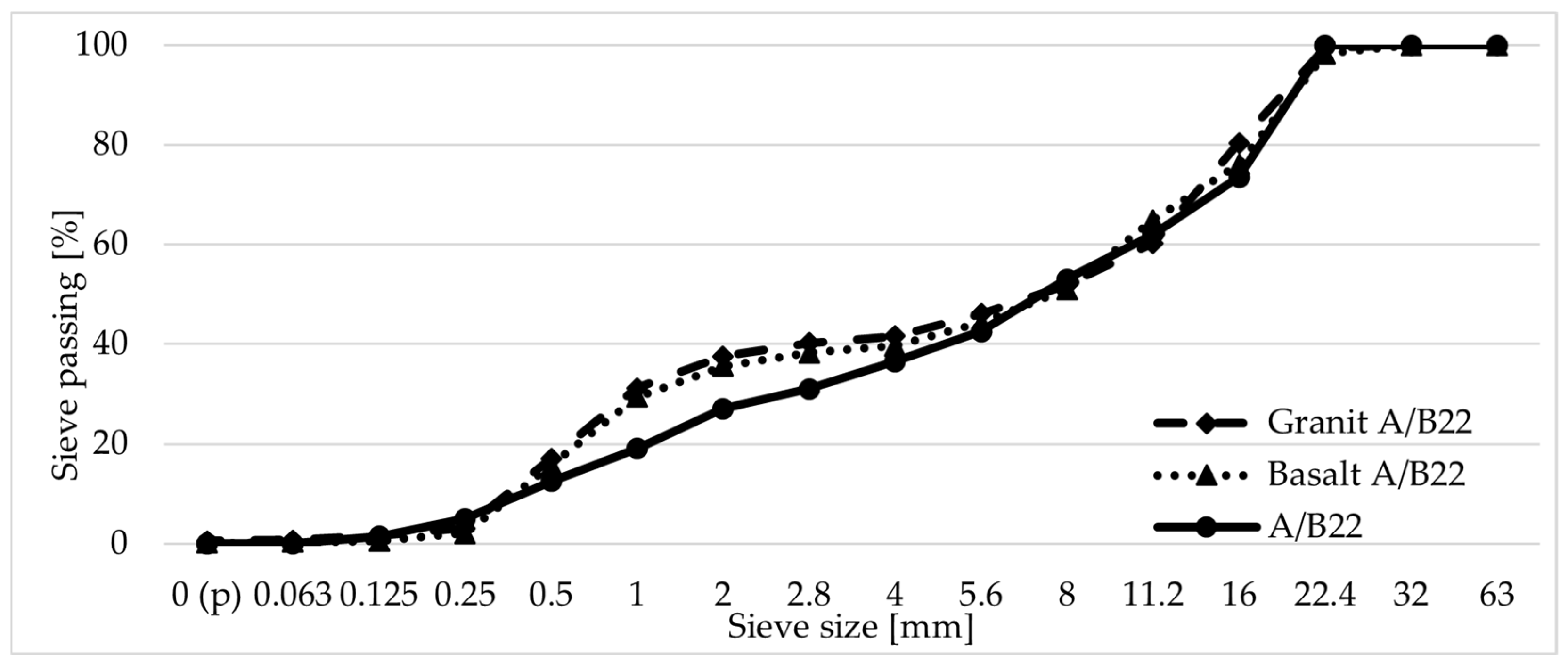

3.3. Concrete Mix Design

3.4. Experimental Procedure

4. Test Results

4.1. Fresh Concrete Properties

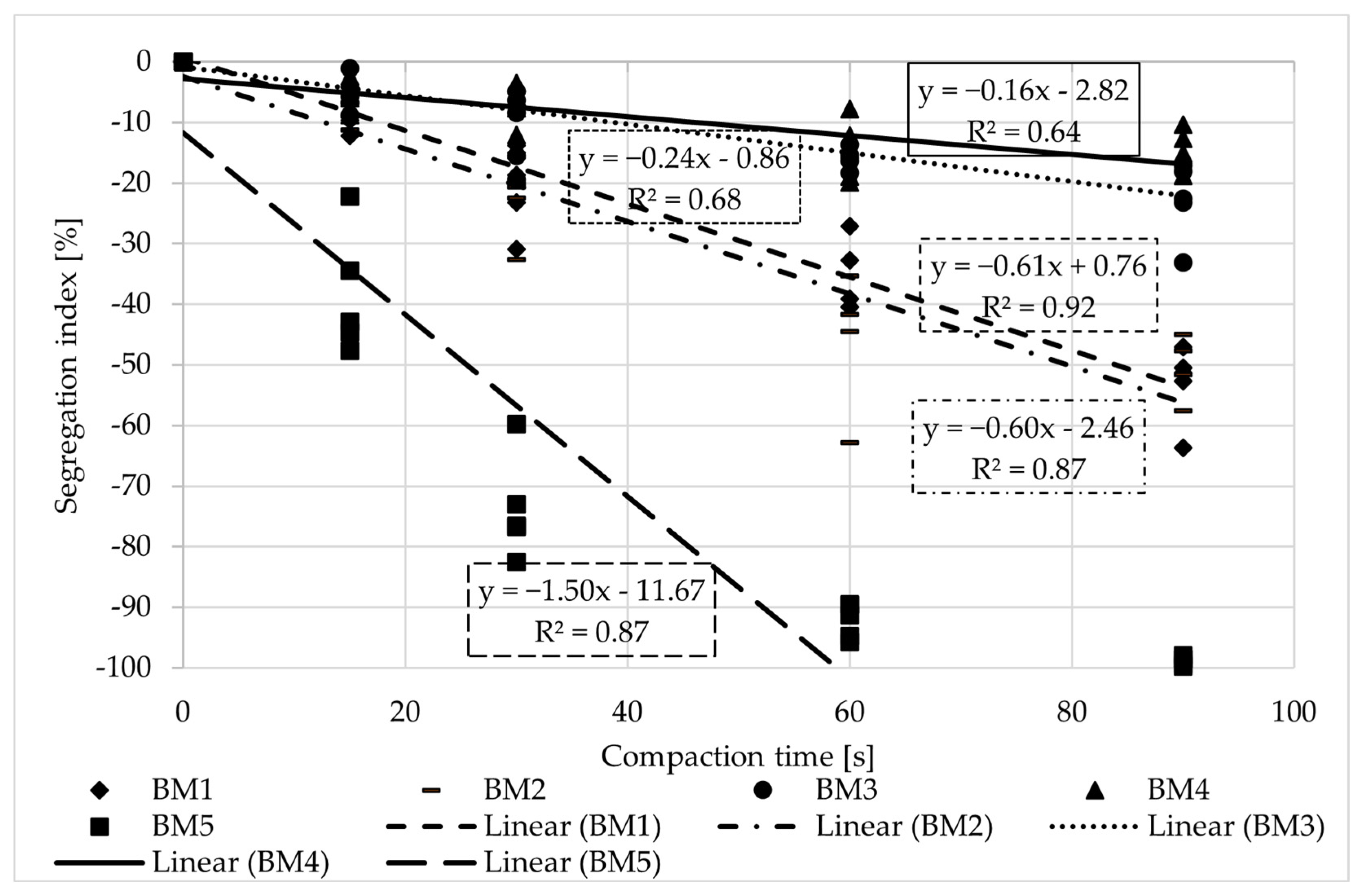

4.2. Wash-Out Test

4.3. Density Method

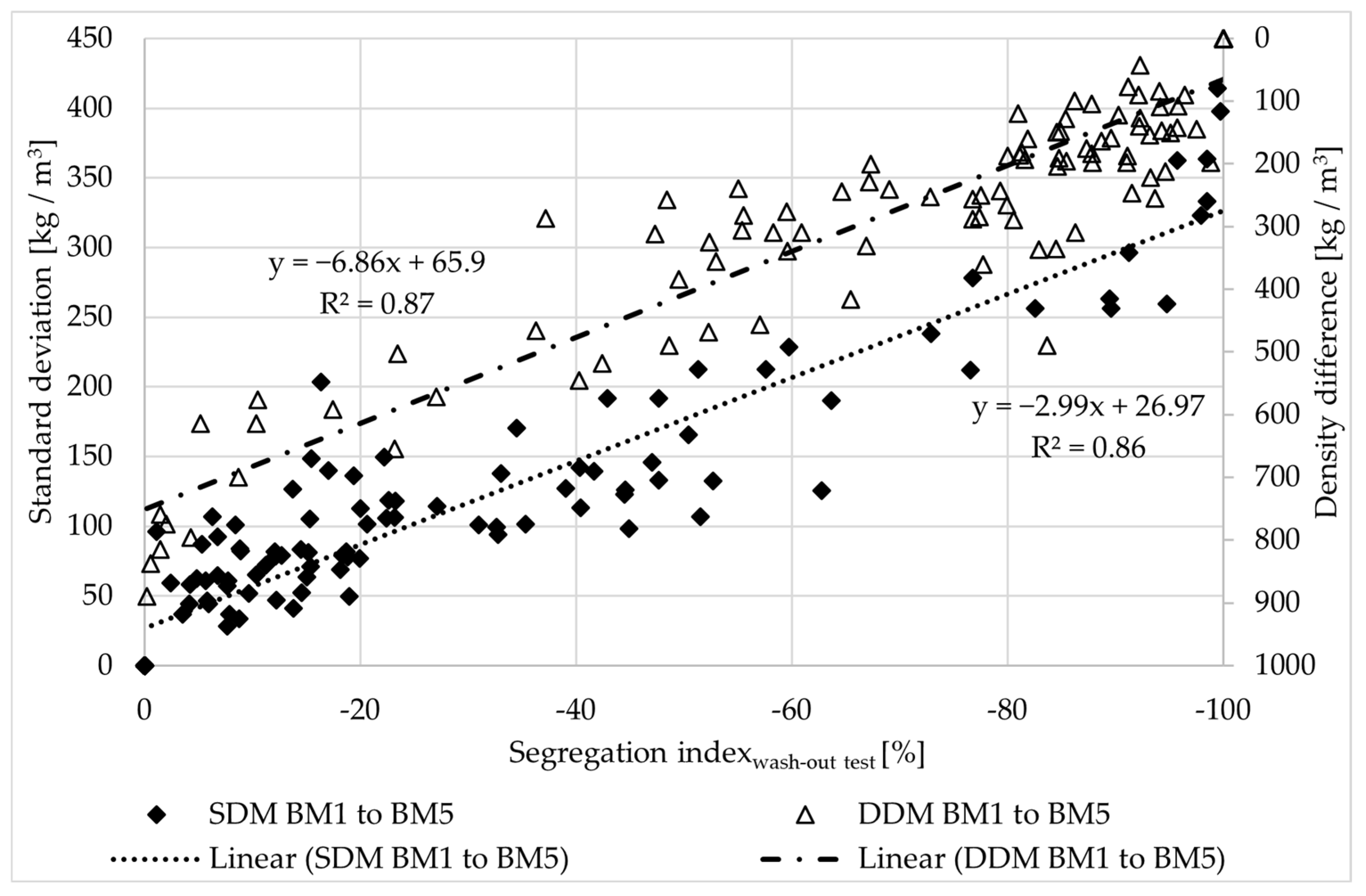

4.3.1. Standard Deviation Method (SDM)

4.3.2. Density Difference Method (DDM)

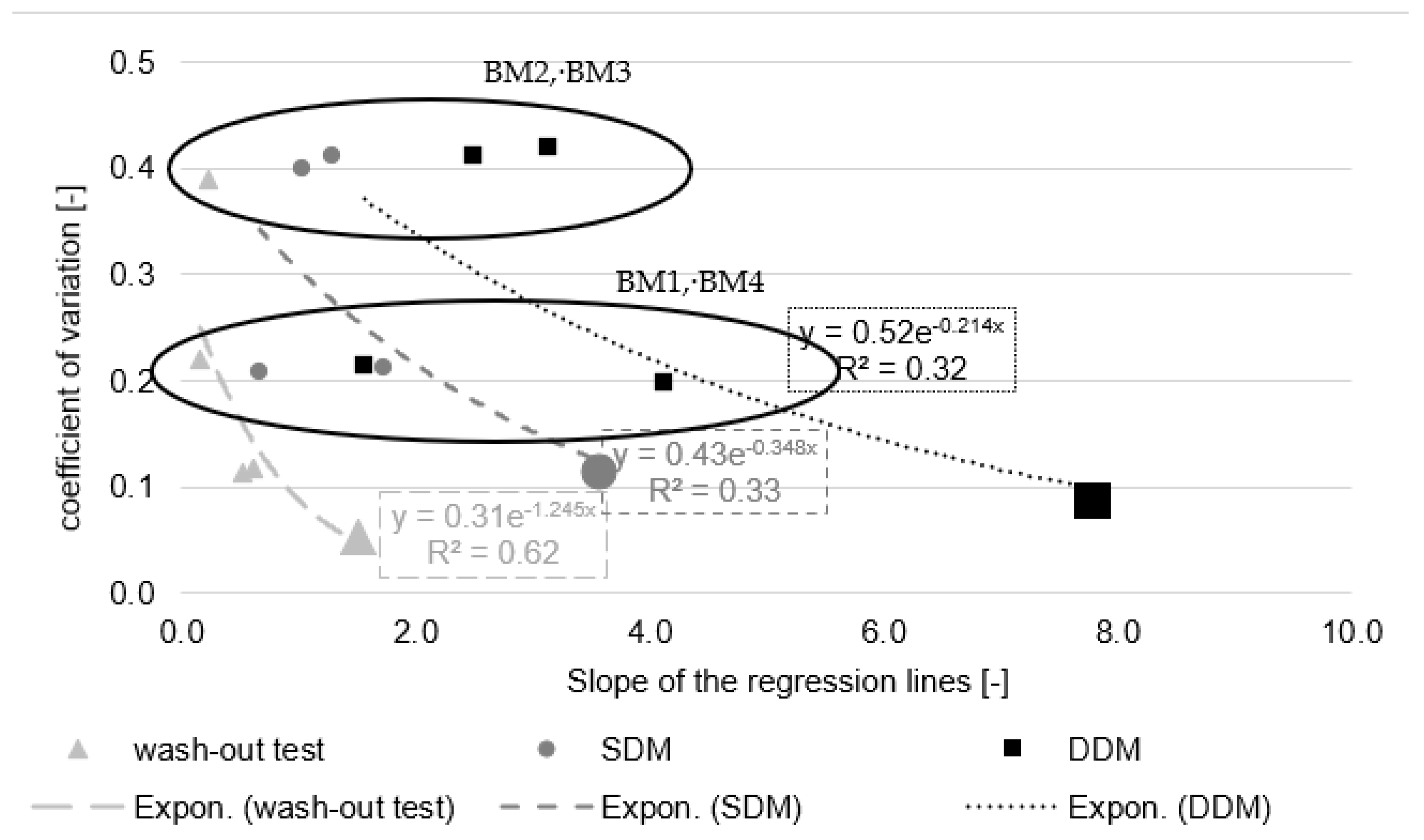

4.4. Correlation of All Methods

4.5. Test Result Scatter

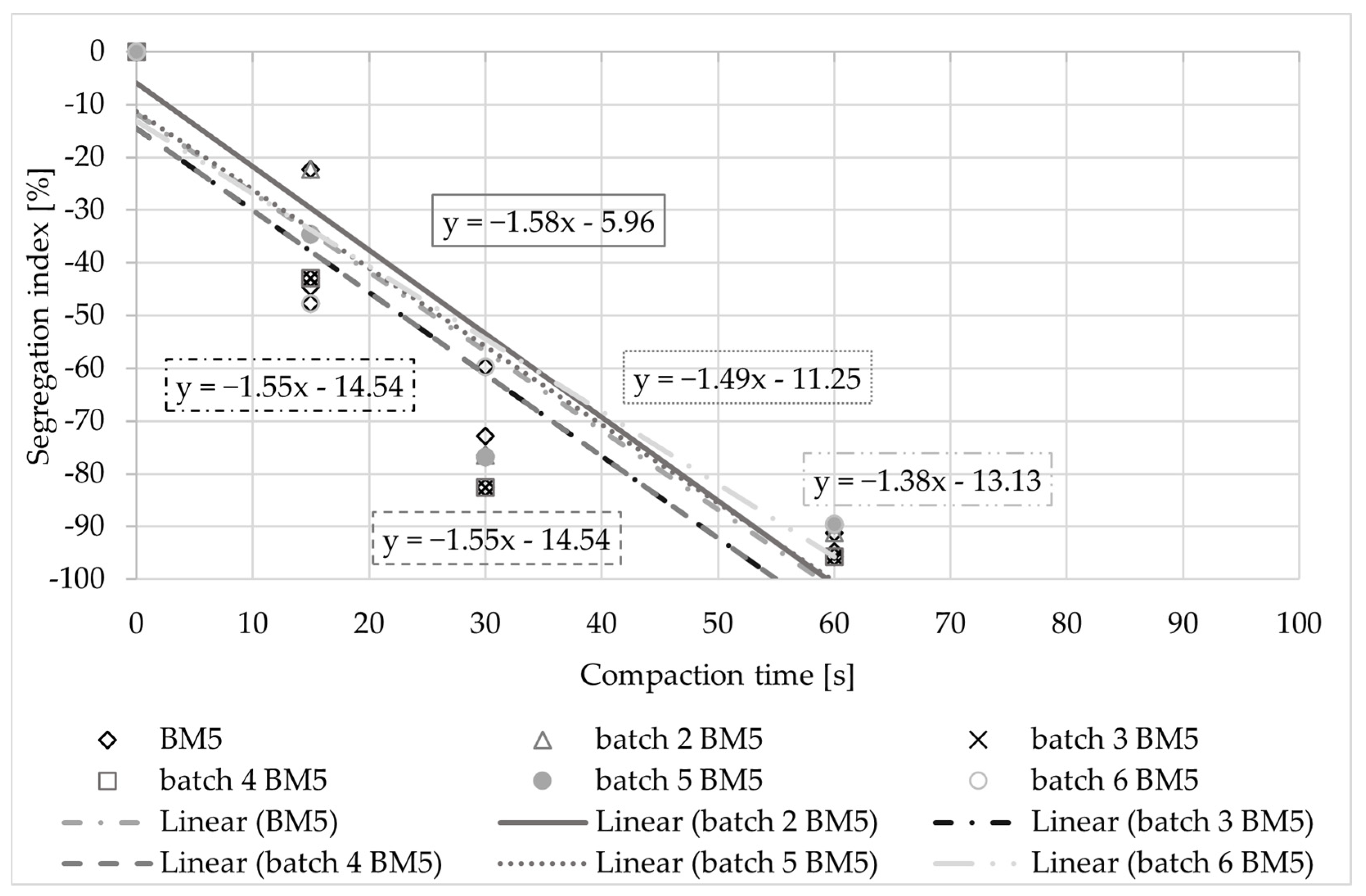

4.5.1. Regression Function

4.5.2. Segregation Index at a Certain Compaction Time

4.5.3. Slope of Regression Function

4.6. Comparison of the Evaluation of the Concretes with the Three Methods

4.7. Practicability of the Three Methods

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Wash-Out Test | |||||

|---|---|---|---|---|---|

| Slope | BM1 | BM2 | BM3 | BM4 | BM5 |

| Batch 2 | −0.57 | −0.44 | −0.16 | −0.16 | −1.58 |

| Batch 3 | −0.56 | −0.58 | −0.26 | −0.16 | −1.55 |

| Batch 4 | −0.54 | −0.55 | −0.13 | −0.21 | −1.55 |

| Batch 5 | −0.65 | −0.55 | −0.35 | −0.15 | −1.49 |

| Batch 6 | −0.71 | - | −0.3 | −0.12 | −1.38 |

| Mean Value | −0.61 | −0.53 | −0.24 | −0.16 | −1.51 |

| Standard Deviation | 0.072 | 0.062 | 0.093 | 0.032 | 0.080 |

| Coefficient of Variation | 0.12 | 0.12 | 0.39 | 0.20 | 0.05 |

| SDM | |||||

|---|---|---|---|---|---|

| Slope | BM1 | BM2 | BM3 | BM4 | BM5 |

| Batch 2 | 2.22 | 2.03 | 1.36 | 0.73 | 3.39 |

| Batch 3 | 1.23 | 0.96 | 1.28 | 0.76 | 3.94 |

| Batch 4 | 1.56 | 1.35 | 0.34 | 0.77 | 3.69 |

| Batch 5 | 1.79 | 0.85 | 1.19 | 0.60 | 2.92 |

| Batch 6 | 1.87 | - | 0.97 | 0.45 | 3.82 |

| Mean Value | 1.74 | 1.30 | 1.03 | 0.66 | 3.55 |

| Standard Deviation | 0.37 | 0.53 | 0.41 | 0.14 | 0.41 |

| Coefficient of Variation | 0.21 | 0.41 | 0.40 | 0.21 | 0.11 |

| DDM | |||||

|---|---|---|---|---|---|

| Slope | BM1 | BM2 | BM3 | BM4 | BM5 |

| Batch 2 | 5.05 | 4.97 | 3.27 | 1.56 | 7.71 |

| Batch 3 | 2.91 | 2.33 | 3.36 | 1.81 | 8.77 |

| Batch 4 | 3.83 | 3.25 | 0.81 | 1.96 | 8.04 |

| Batch 5 | 4.21 | 2.04 | 2.65 | 1.42 | 7.00 |

| Batch 6 | 4.59 | - | 2.38 | 1.10 | 7.40 |

| Mean Value | 4.12 | 3.14 | 2.49 | 1.57 | 7.78 |

| Standard Deviation | 0.81 | 1.32 | 1.03 | 0.34 | 0.67 |

| Coefficient of Variation | 0.20 | 0.42 | 0.41 | 0.21 | 0.09 |

References

- Ojala, T.; Ahmed, H.; Vehmas, T.; Chen, Y.; Tauqir, A.; Oey, T.; Al-Neshawy, F.; Leivo, M.; Punkki, J. ‘Factors of Compactibility and Risk of Segregation for Concrete’, Science + Technology, Helsinki, Finland, May 2021. Available online: https://aaltodoc.aalto.fi/items/06bb53ef-fe67-4b4a-959a-587d44e1f6dd (accessed on 1 April 2025).

- Navarrete, I.; Lopez, M. Understanding the relationship between the segregation of concrete and coarse aggregate density and size. Constr. Build. Mater. 2017, 149, 741–748. [Google Scholar] [CrossRef]

- Alfes, C.; Assbrock, O.; Begemann, C.; Breitenbücher, R.; Cokovik, A.; Cotardo, D. Sachstandbericht Frischbeton—Eigenschaften, Einflüsse und Prüfungen; Deutscher Ausschuss für Stahlbeton, Ed.; Beuth Verlag GmbH: Berlin, Germany; Vienna, Austria; Zürich, Switzerland, 2020; Heft 637; ISBN 978-3-410-65843-6. [Google Scholar]

- Ojala, T.; Al-Neshawy, F.; Punkki, J. Good Vibrations Project; Aalto University Scholl of Engineering: Espoo, Finland, 2019. [Google Scholar]

- Begemann, C.; Haist, M.; Lohaus, L. Prüfverfahren zur Bewertung der Mischungsstabilität von Beton unter Rütteleinwirkung; Institutionelles Repositorium der Leibniz Universität Hannover: Hannover, Germany, 2019. [Google Scholar] [CrossRef]

- Westendarp, A. Probleme mit Mischungsstabilität von Beton, Bundesanstalt für Wasserbau, Karlsruhe, BAWBrief, January 2015. Available online: https://hdl.handle.net/20.500.11970/100468 (accessed on 1 April 2025).

- Lohaus, L.; Begemann, C.; Breitenbücher, R.; Neumann, J. “Beurteilung der Sedimentationsstabilität von Frischbeton”. Gemeinsamer Abschlussbericht zur Phase 1 des Forschungsvorhabens; Leibniz Universität Hannover Institut für Baustoffe; Ruhr-Universität Bochum Lehrstuhl für Baustofftechnik. 2019. Available online: https://www.baustoff.uni-hannover.de/de/forschung/forschungsprojekte/forschungsprojekte-detailansicht/projects/beurteilung-der-sedimentationsstabilitaet-von-frischbeton-teil-1-sedimentationsversuch (accessed on 1 April 2025).

- Wagner, J.-P. Baustellenrelevante Betoneigenschaften—ein Weg zur Qualitätsverbesserung. In Tagungsbericht Ibausil; Finger-Institut für Baustoffe, Bauhaus-Universität: Weimar, Germany, 2018. [Google Scholar]

- Haist, M.; Breitenbücher, R.; Lohaus, L.; Moffat, J.; Vogel, C.; Neumann, J. Beurteilung der Sedimentationsstabilität von Frischbeton, Gemeinsamer Abschlussbericht zur Phase 2 des Forschungsvorhaben; Leibniz Universität Hannover Institut für Baustoffe; Ruhr-Universität Bochum Lehrstuhl für Baustofftechnik. 2021. Available online: https://www.baustoff.uni-hannover.de/de/lohaus/forschungsprojekte/projects/beurteilung-der-sedimentationsstabilitaet-von-frischbeton-teil2-viskowaage (accessed on 1 April 2025).

- Spörel, F. Anwendung eines Prüfverfahrens zur Ermittlung der Sedimentationssensibilität von Rüttelbeton. In Tagungsbericht Ibausil; Finger-Institut für Baustoffe, Bauhaus-Universität: Weimar, Germany, 2018; Available online: https://henry.baw.de/server/api/core/bitstreams/00a203c9-ae47-4c8a-96b3-3f34c3faddfd/content (accessed on 12 December 2023).

- Bundesanstalt für Wasserbau. Entmischungssensibilität von Beton (MESB). In BAW-Merkblatt; Bundesanstalt für Wasserbau: Karlsruhe, Germany, 2019. [Google Scholar]

- DAfStb—Richtlinie: Selbstverdichtender Beton (SVB-Richtlinie); Deutscher Ausschuss für Stahlbeton (DAfStb): Berlin, Germany, 2003.

- Jakob, O. Sedimentationsstabilität von Rüttelbeton; Masterarbeit, Karlsruher Institut für Technologie: Karlsruhe, Germany, 2018. [Google Scholar]

- Lohaus, L.; Begemann, C.; Cotardo, D.; Schack, T. Mischungsstabilität und Robustheit fließfähiger Betone; Researchgate: Dresden, Germany, 2017; Available online: https://www.researchgate.net/publication/325896517_Mischungsstabilitat_und_Robustheit_fliessfahiger_Betone (accessed on 1 April 2025).

- Siebert, B. Besondere Verfahren zur Prüfung von Frischbeton (Special Test Methods for Fresh Concrete), Deutscher Beton- und Bautechnik-Verein E.V., Berlin, DBV-Merkblatt, January 2014. Available online: https://www.dinmedia.de/de/technische-regel/dbv-merkblatt-frischbetonpruefungen/203502883 (accessed on 1 April 2025).

- DIN EN ISO 3219-2:2021-08; Rheologie Teil 2: Allgemeine Grundlagen der Rotations- und Oszillationsrheometrie. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Hoang, Q.G.; Kaci, A.; Kadri, E.-H.; Gallias, J.-L. A new methodology for characterizing segregation of cement grouts during rheological tests. Constr. Build. Mater. 2015, 96, 119–126. [Google Scholar] [CrossRef]

- Ojala, T.; Ahmed, H.; Kuusela, P.; Seppänen, A.; Punkki, J. Monitoring of concrete segregation using AC impedance spectroscopy. Constr. Build. Mater. 2023, 384, 131453. Available online: https://www.sciencedirect.com/science/article/pii/S0950061823011662 (accessed on 1 April 2025).

- Ahmed, H. Evaluation of Segregation in Hardened Concrete; Aalto University Scholl of Engineering: Espoo, Finland, 2022. [Google Scholar]

- DIN EN 12390-7:2021-01; Prüfung von Festbeton—Teil 7: Rohdichte von Festbeton. Beuth Verlag GmbH: Berlin, Germany, 2021.

- DIN 1045-2:2023-08; Tragwerke aus Beton, Stahlbeton und Spannbeton—Teil 2: Beton. Beuth Verlag GmbH: Berlin, Germany, 2023.

- DIN EN 197-1:2011-11; Zement Teil 1: Zusammensetzung, Anforderungen und Konformitätskriterien von Normalzement. Beuth Verlag GmbH: Berlin, Germany, 2011.

- DIN EN 12350-5:2019-09; Prüfung von Frischbeton—Teil 5: Ausbreitmaß; Deutsche Fassung EN 12350-5:2019-09. Beuth Verlag GmbH: Berlin, Germany, 2019.

- DIN EN 12350-7:2022-05; Prüfung von Frischbeton—Teil 7: Luftgehalt Druckverfahren; Deutsche Fassung EN 12350-7:2019 + AC:2022. Beuth Verlag GmbH: Berlin, Germany, 2022.

- DIN EN 12350-6:2019-09; Prüfung von Frischbeton—Teil 6: Frischbetonrohdichte; Deutsche Fassung EN 12350-6:2019. Beuth Verlag GmbH: Berlin, Germany, 2019.

| Unit | BM1 | BM2 | BM3 | BM4 | BM5 | |

|---|---|---|---|---|---|---|

| CEM III/A 42.5 N | [kg/m3] | 260 | 320 | 260 | 270 | 350 |

| Fly ash | [kg/m3] | 67 | 70 | 67 | 70 | 68 |

| Coarse aggregate | [-] | basalt | granite | basalt | granite | basalt |

| Grading curve | [-] | A/B | ||||

| Maximum aggregate size | [mm] | 22 | 22 | 22 | 22 | 22 |

| Aggregate content | [kg/m3] | 1997 | 1607 | 2089 | 1882 | 1647 |

| Water | [kg/m3] | 149 | 191 | 149 | 155 | 207 |

| Concrete density calculated | [kg/m3] | 2449 | 2218 | 2565 | 2378 | 2272 |

| (w/c)eq. | [-] | 0.52 | 0.55 | 0.52 | 0.52 | 0.55 |

| Target air content | [Vol.-%] | 5 | 5 | 1 | 1 | 8 |

| Paste content pc | [L/m3] | 265 | 328 | 265 | 275 | 351 |

| Paste content incl. air pc, air | [L/m3] | 315 | 378 | 275 | 285 | 431 |

| Paste density incl. air | [kg/m3] | 1512 | 1537 | 1732 | 1737 | 1404 |

| Air-entraining admixture based on root resin | [% of c.] | 0.13 | 0.11 | 0.00 | 0.00 | 0.80 |

| SP type | [-] | PCE | PCE | PCE | PCE | PCE |

| SP dosage | [% of c.] | 0.75 | 0.11 | 1.45 | 1.13 | 0.00 |

| Unit | BM1 | BM2 | BM3 | BM4 | BM5 | |

|---|---|---|---|---|---|---|

| Measured air content (mean) | [Vol.-%] | 6.8 | 4.0 | 1.8 | 1.8 | 4.1 |

| Flow table test spread (mean) | [mm] | 460 | 500 | 440 | 480 | 550 |

| Density (mean) | [kg/m3] | 2390 | 2270 | 2570 | 2370 | 2410 |

| Wash-Out Test | Standard Deviation Method (SDM) | Density Difference Method (DDM) | |||

|---|---|---|---|---|---|

| Range According to Figure 1 | Concrete | Classification | Ranking | Classification | Ranking |

| 1 | BM4 and BM3 | 1 | BM4 | 1 | BM4 |

| 2 | BM1 and BM2 | 2 | BM1, BM2, and BM3 | 2 | BM1, BM2, and BM3 |

| 3 | BM5 | 3 | BM5 | 3 | BM5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Denu, M.; Spörel, F.; Alós Shepherd, D.; Ahmed, H.; Punkki, J.; Dehn, F. Segregation Sensitivity of Concrete—Quantification by Concrete Density. Constr. Mater. 2025, 5, 22. https://doi.org/10.3390/constrmater5020022

Denu M, Spörel F, Alós Shepherd D, Ahmed H, Punkki J, Dehn F. Segregation Sensitivity of Concrete—Quantification by Concrete Density. Construction Materials. 2025; 5(2):22. https://doi.org/10.3390/constrmater5020022

Chicago/Turabian StyleDenu, Maureen, Frank Spörel, David Alós Shepherd, Hassan Ahmed, Jouni Punkki, and Frank Dehn. 2025. "Segregation Sensitivity of Concrete—Quantification by Concrete Density" Construction Materials 5, no. 2: 22. https://doi.org/10.3390/constrmater5020022

APA StyleDenu, M., Spörel, F., Alós Shepherd, D., Ahmed, H., Punkki, J., & Dehn, F. (2025). Segregation Sensitivity of Concrete—Quantification by Concrete Density. Construction Materials, 5(2), 22. https://doi.org/10.3390/constrmater5020022