Abstract

This study examines the effects of steel fibers (SF) and carbon nanotubes (CNTs) on the performance of cementitious composites. Three types of mixes were analyzed: a reference mix (REF), a steel fiber-reinforced concrete (SFRC), and a hybrid mix containing both CNTs and SFs. The investigation included physicomechanical property evaluations, microstructural analysis, and ultrasonic pulse velocity (UPV) tests. Results indicate significant improvements in performance across the mixes, with the hybrid mix achieving the highest flexural and compressive strengths, highlighting a synergistic interaction between CNTs and SF to enhance load-bearing capacity. Additionally, the mixtures displayed reduced porosity and water absorption, signifying improved density and lower permeability. SEM analysis further confirmed a denser microstructure with enhanced crack-bridging capabilities due to the presence of CNTs and SF. UPV measurements supported these findings, demonstrating superior internal integrity and stiffness in the hybrid mix. These experimental results underscore the potential of hybrid reinforcement strategies for producing high-performance fiber concrete with enhanced durability, making it suitable for demanding construction applications.

1. Introduction

Incorporating steel fibers into concrete has been proven to significantly enhance its mechanical properties, particularly tensile strength, ductility, toughness, and impact resistance [1] (Khan, Hashmi et al., 2023). Steel fibers act as reinforcements that distribute stress more uniformly throughout the material, reducing the likelihood of cracking and improving the overall durability of concrete. This increased toughness makes fiber-reinforced concrete (FRC) more resistant to physical stresses such as impacts and dynamic loads. The quantity, length and distribution of steel fibers can be adjusted to control specific properties of the composite material, allowing for tailored performance in various applications, such as buildings, bridges, and pavements.

The addition of steel fibers also has a notable effect on the compressive strength of concrete [2]. This enhancement is primarily due to the high tensile strength and stiffness of steel fibers, which reinforce the concrete matrix and reduce microcrack formation. However, the effectiveness of steel fibers in improving compressive strength is influenced by factors such as fiber length, aspect ratio, dispersion, orientation, and content [3]. Typically, longer and thinner fibers provide better enhancement, but an excessive volume of fibers can cause issues such as fiber balling and segregation, which can negatively affect strength [4]. Steel fiber-reinforced concrete (SFRC) is commonly used in applications where high compressive strength and durability are required, such as bridge decks, tunnels, and pavements. Additionally, SFRC can reduce the required thickness of concrete elements while increasing their load-carrying capacity, potentially offering cost savings and environmental benefits.

Steel fibers are especially beneficial in enhancing the tensile strength of concrete. While concrete has excellent compressive strength, its tensile strength is relatively low, making it vulnerable to cracking under tensile loads [5,6]. Incorporating steel fibers into the concrete matrix can significantly increase its tensile strength and toughness, resulting in a more durable and reliable material. Typically, steel fibers are added at a low volume fraction, ranging from 0.5% to 2.5% by volume, and are uniformly distributed throughout the concrete to effectively bridge cracks under tensile stress. This reduces crack propagation and improves the material’s ductility. Research has shown that steel fibers can significantly increase the strength of concrete, depending on fiber content and other parameters [7]. As a result, steel fiber-reinforced concrete exhibits significantly improved tensile properties and toughness, making it suitable for a wide range of demanding structural applications. The incorporation of dispersed steel fibers significantly enhances the flexural tensile strength of concrete by improving its ability to resist cracking and deformation under applied loads [8]. This improvement is primarily attributed to the bridging effect provided by steel fibers, which helps control crack propagation and increases the energy absorption capacity of the material [9]. At the same time, the volume fraction and aspect ratio of steel fibers lead to an increase in flexural tensile strength due to improved fiber-matrix interaction and mechanical anchorage. Additionally, the hybridization of macro and micro steel fibers has been observed to further enhance flexural properties by synergistically combining their respective benefits—macro fibers contribute to crack bridging at larger scales, while micro fibers improve resistance at finer scales. However, it is important to note that excessive fiber content beyond an optimal threshold can reduce workability and increase porosity, potentially offsetting some of these benefits.

The elastic modulus of concrete, which measures the stiffness of the material, is also influenced by the addition of steel fibers [10]. While the primary purpose of steel fibers is to improve toughness and ductility, their incorporation also enhances the crack-bridging mechanisms and reduces stress concentrations, which leads to an increase in the elastic modulus. The effect on the elastic modulus depends on fiber properties such as length, diameter, volume fraction, and the characteristics of the matrix material [11]. Typically, a higher fiber volume fraction increases the elastic modulus by reinforcing the matrix. However, excessively high fiber content may lead to fiber clustering, reducing matrix density and potentially having a negative impact on the elastic modulus. Overall, steel fibers increase the modulus of elasticity of the concrete-steel fiber composite, making it more resistant to deformation, cracking, and other forms of mechanical damage, which enhances its performance in construction applications.

Despite these advantages, there are drawbacks associated with the use of steel fibers in concrete. One of the main issues is the susceptibility of steel fibers to corrosion when exposed to moisture and oxygen. Corrosion can lead to the formation of rust, which causes the concrete to crack, spall, and ultimately lose structural integrity [12]. This issue is particularly critical in environments rich in chlorides or pollutants, such as coastal regions or industrial areas. The additional cost of steel and the protective measures required to prevent corrosion, such as coatings or cathodic protection, can also increase project expenses. Furthermore, steel production has a high environmental impact, involving significant energy consumption and greenhouse gas emissions. Transporting steel fibers also contributes to increased energy usage and CO2 emissions. Although carbon nanotubes (CNTs) have a significantly lower coefficient of thermal expansion (CTE) compared to concrete, their nanoscale dimensions minimize stress concentrations caused by thermal mismatches. Additionally, their high aspect ratio enables effective crack-bridging mechanisms within the cement matrix. The strong interfacial bond between CNTs and hydration products further mitigates potential issues arising from CTE differences while enhancing overall mechanical performance [13,14]. Proper design measures, such as expansion joints or careful reinforcement detailing, are necessary to mitigate these risks. However, recent research has shown that these negative effects are not always observed, as advancements in mix design strategies, protective coatings for fibers, and improvements in UHPC formulations help mitigate environmental impacts on SFRC structures; for instance, [15] found that dispersed reinforcement with steel fibers at appropriate dosages (20–25 kg/m3) enhances corrosion resistance in acidic environments by mitigating crack propagation and reducing open porosity. Similarly, another study observed that steel fibers improve axial compressive strength and inhibit microstructural damage caused by acidic attack [16]. These findings suggest that SFRC’s performance depends heavily on environmental factors and material composition, warranting a more nuanced discussion in this context.

An alternative to steel fibers is the use of carbon nanotubes (CNTs) in cement concretes [17]. CNTs exhibit extraordinary mechanical properties, including high tensile strength, stiffness, and a low weight-to-strength ratio [18,19,20]. When incorporated into concrete, CNTs can enhance both its tensile and compressive strengths [21,22]. Additionally, CNTs are highly resistant to environmental degradation, such as corrosion, moisture, and chemical attack, making them a more durable reinforcement option [23,24]. CNTs also effectively bridge microcracks in the concrete matrix, preventing crack propagation and improving the overall durability of the material. Their high surface area and aspect ratio contribute to better load transfer between the cement particles and the reinforcement, enhancing the hydration process. Furthermore, CNTs provide nucleation sites for hydration products, improving the dispersion of cement particles and, ultimately, the mechanical properties of the composite. Being lightweight and easily dispersible, CNTs can improve structural performance without adding excessive weight to the material.

The aim of this research was to investigate the influence of steel fibers (SFs) and carbon nanotubes (CNTs) on the strength, porosity, and microstructural behavior of cementitious composites. Specifically, the study examines their effects on compressive strength and flexural performance while also analyzing microstructural modifications and porosity characteristics using advanced characterization techniques. Furthermore, the research explores the synergistic effects of SF and CNTs in hybrid composites to optimize mechanical performance. Steel fibers serve as macro-scale reinforcements that control crack propagation and enhance load-bearing capacity, while CNTs provide nanoscale reinforcement, refining the microstructure and reducing porosity. This combined reinforcement strategy improves material densification, enhances strength, and contributes to a more refined and durable cementitious matrix.

2. Experimental Procedure

2.1. Materials and Mixtures Composition

The materials used in this study included CEM I 42.5 N as the binder, calcareous ag-gregates, and water from the supply network. Functionalized multi-walled carbon nanotubes (MWCNTs) and straight steel fibers (0.2 mm in diameter and 12 mm in length) were incorporated into specific mixtures to enhance their properties; the carbon nanotubes had a diameter of 2–10 nm, a length of 10–30 μm, and a surface-specific area greater than 500 m2/g.

The w/c ratio of all mixtures was maintained consistently across all batches (w/c = 0.65). The proportions and physical properties of the materials used in the study are summarized in Table 1. The experimental procedure involved fabricating specimens of various sizes and shapes to assess their physical and mechanical properties. Lubricated metal molds were used for casting, as illustrated in Figure 1, while Figure 2 shows the additives (SFs and CNTs) used in the study; Figure 3 represents the sieve analyses of aggregates (coarse and fine). Fresh concrete was poured into these molds and compacted using a jolting table. The flow test for the mixes was performed according to ASTM C1437, which evaluates the consistency and workability of cement mortars, including those reinforced with fibers such as steel fibers [25]. After 24 h, the test specimens were demolded and then submerged in water for a 28-day curing period. To enhance the workability of mixtures containing carbon nanotubes and steel fibers, a small quantity of SIKA VISCOCRETE 4000 plasticizer was incorporated. This plasticizer also facilitated the effective dispersion of CNTs within the mixture.

Table 1.

Material properties and mix proportions of fiber-reinforced concrete mixtures.

Figure 1.

Experimental methodology: (A) concrete mix preparation, (B) specimen casting, and (C) test specimen after compression testing.

Figure 2.

Images of (A) steel fibers and (B) dispersed multi-walled carbon nanotubes (MWCNTs).

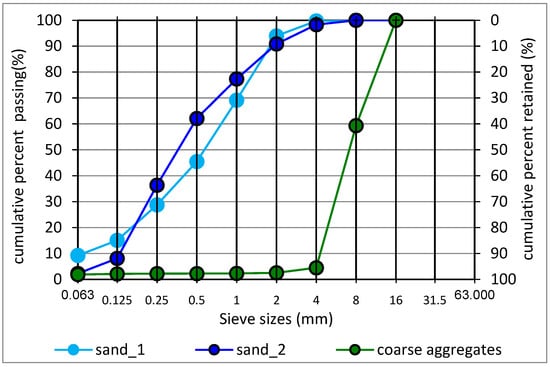

Figure 3.

Particle size distribution curves of sand (two types) and coarse aggregates.

In our laboratory, three distinct batches were prepared for each experimental group (REF, SF, and MIX): 12 cubes were designated for compression testing, and 9 prisms were allocated for bending testing. A total of 93 L of fresh concrete was produced for each group. Additionally, 329 g (2 wt.% by cement weight) of steel fibers (SF) and 70 g (0.2 wt.% by cement weight) of multi-walled carbon nanotubes (CNTs) were incorporated into the respective mixtures in equal proportions. The experimental groups were categorized as follows: (a) SF Group: this batch consisted of concrete containing steel fibers, (b) MIX Group: specimens in this category included a combination of steel fibers at a volume fraction of 2.0 wt.% and multi-walled carbon nanotubes (MWCNTs) at a concentration of 0.2 wt.%, and (c) REF Group: this served as the control mixture without any additives, providing a baseline for comparative analysis.

2.2. Techniques Adopted

2.2.1. Ultrasonic Pulse Velocity (UPV) Testing

In this study, the ultrasonic pulse velocity (UPV) testing method was employed to assess the uniformity, quality, and consistency of the cementitious materials. This technique is widely used to detect cracks and voids in porous materials. Furthermore, it enables the calculation of the dynamic modulus of elasticity, as described in Equation (1), by measuring the ultrasonic pulse velocity through the concrete mass, in accordance with ASTM C597-02. Importantly, the UPV method is non-destructive and relies on the material’s elastic properties. However, factors such as humidity, temperature, and the shape or size of the test specimens can significantly influence the accuracy of elastic modulus measurements. The tests were conducted at three distinct time intervals: 28 days, 70 days, and 100 days after casting. For these measurements, the PUNDIT Plus device PUNDIT (Proceq, Zurich, Switzerland). was used, equipped with two 54 kHz sensors operating in direct transmission mode. To ensure effective transmission of the ultrasonic pulse between the transducers and the specimen’s surface, an appropriate coupling agent was applied. Prior to each measurement, the specimens were removed from the curing tank and oven-dried at 105 °C for 24 h. For the UPV measurements, concrete cubes (100 × 100 × 100 cm3) were used. The total number of samples tested was three (3) for each group and age, ensuring statistical reliability for our results. Tests were performed on two opposing surfaces, depending on the experimental requirements. The dynamic modulus of elasticity (E) was then calculated using the following equation:

where

V represents the ultrasonic pulse velocity (m/s),

E is the dynamic modulus of elasticity (GPa),

ρ is the density of the concrete (kg/m3),

μ is the dynamic Poisson’s ratio (≈0.2 for concrete).

2.2.2. Porosity Assessment and Sorptivity Testing

In this study, the porosity of cement concretes produced in the laboratory was assessed using the vacuum saturation method. The 100 × 100 × 100 mm3 cubes were subjected to vacuum saturation following the methodology outlined by Hall and Hoff (2012) [26]. The tests were conducted at intervals of 7, 28, 90, 120, and 240 days after the initial casting of the specimens. Prior to each test, the specimens were oven-dried until they reached a constant mass. Subsequently, the samples were placed in a vacuum desiccator under reduced pressure for 2 to 2.5 h before being immersed in water at atmospheric pressure for 24 h. Using the liquid-saturated mass (wsat), the immersed liquid-saturated mass (wa), and the dry mass (wd) of each sample, the bulk density (b), bulk volume (Vb), and porosity (fo) were calculated.

For the absorption test, 100 × 100 × 100 mm3 cubes were utilized to evaluate the sorptivity of the cementitious materials. The tests were performed at 28 and 90 days. The oven-dried samples were positioned on polymeric spacers within a shallow container filled with methanol. At regular intervals, the amount of liquid absorbed by each specimen was recorded using a precision balance with an accuracy of 0.1 mg. To ensure unidirectional flow, the liquid level was maintained at 2–3 mm above the lower surface of each specimen. Throughout the test, the temperature of the methanol was carefully monitored to maintain consistent testing conditions. The sorptivity (S) of the specimens was calculated as the slope of the graph plotting absorption intensity against time, following Equations (2) and (3) [27]. This method provided a precise evaluation of the capillary absorption properties of the materials, yielding valuable insights into their porosity and durability.

where

i: cumulative absorption per unit surface area (mm)

Δw: mass of liquid absorbed (g)

A: absorbing surface area (mm2)

ρ: density of methanol (g/cm3)

t: time (min)

S: sorptivity (mm/min)

2.2.3. Mechanical Properties Assessment of Cementitious Composites

The performance of cementitious composites is primarily governed by their mechanical properties, notably their tensile and compressive strengths [28,29]. While direct uniaxial tensile stress application offers the most accurate measurement of tensile strength in cement-based materials, it demands meticulous specimen preparation and careful handling compared to commonly employed indirect methods. Consequently, alternative approaches, such as the splitting (Brazilian) test or bending tests, are frequently utilized. These methods induce tensile stresses at the failure surfaces, enabling the indirect measurement of the tensile resistance of cementitious specimens [30].

In this research, the flexural strength of concrete was evaluated using a three-point bending test conducted on specimens measuring 600 mm × 150 mm × 150 mm (EN 12390-5). Additionally, the axial compressive strength was assessed on cubic specimens with dimensions of 100 mm × 100 mm × 100 mm (EN 12390-3). For each experimental group and testing age, three specimens were prepared and tested to ensure reliability and consistency in the results. These evaluations were conducted at predetermined intervals following the casting of the specimens to systematically monitor their properties.

2.2.4. Scanning Electron Microscopy (SEM) Analysis

To examine the surfaces of cementitious materials after a laboratory exposure period of 56 days, scanning electron microscopy (SEM) was utilized for detailed optical analysis. The analysis was performed using a Philips XL 30 (Philips, Eindhoven, Netherlands). high-resolution SEM, which offers a maximum resolution of 2.0 nm at an accelerating voltage of 30 kV and supports magnifications ranging from 20× to 1,000,000×. Optical observations were conducted with the backscattered electron detector (BSE), enabling precise identification of constituent phases by analyzing their brightness and coloration characteristics.

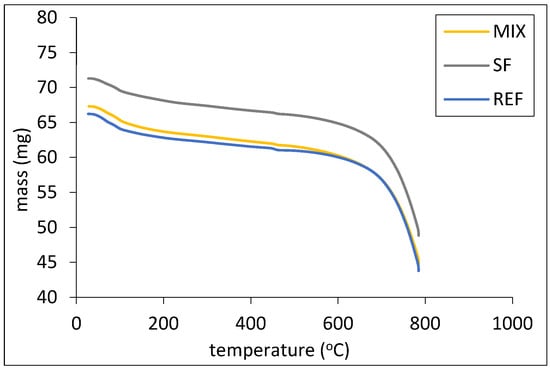

2.2.5. Thermogravimetric Analysis

Thermogravimetric analysis (TGA) was employed to investigate the thermal stability of different cementitious composite samples. The TGA analysis was conducted after 28 days of water curing to assess the thermal stability of the composites following a sufficient curing period. The thermal analysis was performed using a Schimadzu DTA-TG thermal analyzer (Shimadzu Corporation, Kyoto, Japan). The TGA experiments were performed under an air atmosphere with a constant gas flow rate of 20 mL/min. Samples weighing between 67 and 71 mg were placed in Alumina pans and subjected to a controlled temperature program. The temperature was increased from 35.0 °C to 800.0 °C at a heating rate of 5.00 °C/min. A final hold time of 1 min at 800.0 °C was included to ensure complete thermal decomposition or any desired reactions.

3. Results and Discussion

3.1. Ultrasonic Pulse Velocity and Elastic Modulus

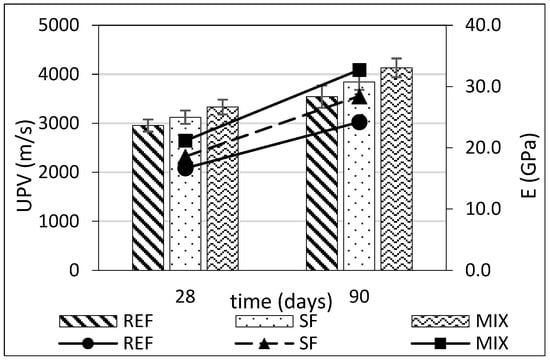

Figure 4 presents data on ultrasonic pulse velocity (UPV) and Young’s modulus (E) for three concrete mix groups. UPV results, reported in meters per second (m/s), were measured at 28 and 90 days for all three mixtures. At 28 days, the REF group exhibits an UPV of 2954 m/s, while the SF group demonstrates an increased velocity of 3124 m/s. The MIX group achieves the highest UPV at 3332 m/s, indicating superior wave propagation speed and suggesting improved internal integrity or fewer defects within the concrete. This trend persists at 90 days, with UPV values increasing for all groups. Notably, the REF group registers velocity values that are 8.5% lower than the SF group and 16.6% lower than the MIX group. Regarding Young’s modulus, the REF group exhibits a value 11.5% lower than the SF group at 28 days and 27% lower when compared to the MIX group. The UPV measurements indicate that the MIX group demonstrates the highest stiffness and structural integrity among the examined mixes, highlighting its superior resistance to deformation under load. Overall, the data suggest that the MIX group, incorporating both CNTs and steel fibers, exhibits the best performance in terms of UPV and Young’s modulus at both 28 and 90 days. These findings indicate improved concrete quality, enhanced internal integrity, and higher stiffness, all highly desirable characteristics for construction materials. The SF group, containing only steel fibers, also outperforms the REF group, underscoring the positive impact of steel fibers on concrete properties.

Figure 4.

Ultrasonic pulse velocity (UPV) and Young’s modulus (E) of concrete specimens at 28 and 90 days of curing.

The enhancement of the elastic modulus through concurrent incorporation of steel fibers (SFs) and carbon nanotubes (CNTs) arises from their synergistic reinforcement mechanisms operating across macro- and nanoscales. Steel fibers primarily address macro-level fracture toughness through micro-crack bridging, load redistribution, and enhanced ductility, while CNTs refine the microstructure by filling voids, strengthening interfacial bonds, and bridging nano-cracks. Together, they create a multi-scale reinforcement hierarchy that improves crack resistance, stress distribution uniformity, and matrix density—ultimately elevating the elastic modulus [31,32].

3.2. Porosity Analysis of Concretes

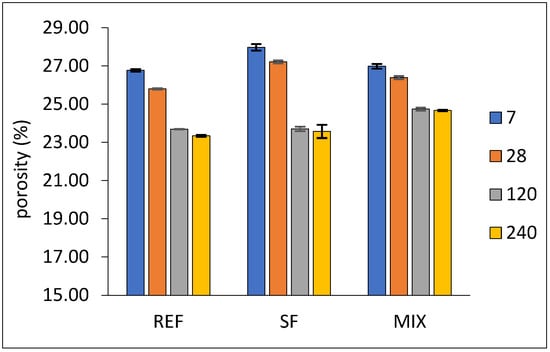

Figure 5 represents the porosities of various concrete specimens, providing insights into the impact of these mixtures on porosity and their effectiveness in reducing permeability and enhancing concrete densification. The REF mixture exhibits a gradual decrease in porosity over time. At seven days, porosity is measured at 26.8%, decreasing to 25.8% at 28 days. This downward trend continues, reaching 23.6% at 120 days. Notably, at 240 days, porosity stabilizes at 23.3%, indicating that the REF mixture maintains relatively low porosity with a prolonged curing time. The addition of steel fibers to the mixture exhibits variable effects on porosity compared to the REF mixture. At seven days, the SF mixture shows a porosity of 28%, slightly higher than the REF mixture. However, at 28 days, the porosity of the SF mixture increases to 27%. By 120 days and 240 days, porosity decreases to 23.7% and 23.6%, respectively, suggesting that incorporating steel fibers contributes to reducing porosity in the cement concrete. The MIX, incorporating both carbon nanotubes and steel fibers, presents varying results in terms of porosity compared to the REF and SF mixtures. At seven days, the MIX has a porosity of 27%, similar to the REF mixture. However, this value slightly decreases to 26.4% at 28 days. The trend continues at 120 days, with a porosity of 24.8%. At 240 days, porosity remains stable at 24.7%, indicating the potential of carbon nanotubes and steel fibers to reduce porosity and enhance densification in cement concrete. Data analysis reveals several key findings regarding the correlations between mixtures and porosity. Time significantly influences porosity, as all mixtures demonstrate a decrease in porosity with extended curing periods. This trend indicates ongoing densification and reduced permeability within the cement concretes. Among the three mixtures, specimens without additives (REF) exhibit lower porosity values compared to the other two mixes. While carbon nanotubes (CNTs) improve porosity by densifying the cementitious matrix through crack bridging and void filling effects, steel fibers can marginally increase porosity depending on factors like mix design and fiber content. However, despite potential increases in porosity from steel fibers, they significantly enhance crack resistance and post-cracking behavior through stress transfer mechanisms; the latter explains the improvement in the strength of SF concrete compared with the ordinary Portland cement (OPC) mixture without steel fibers.

Figure 5.

Porosity of concrete specimens at different ages (days) for the reference (REF), steel fiber-reinforced (SF), and hybrid (MIX) mixtures.

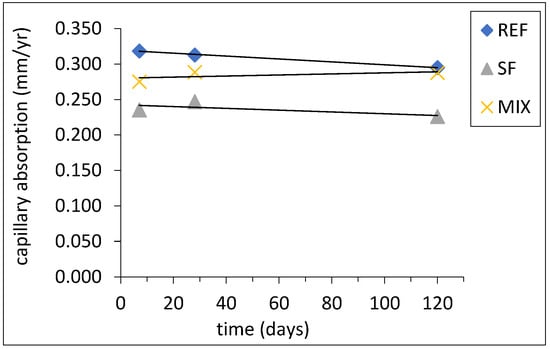

3.3. Capillary Absorption

Figure 6 illustrates the water absorption rate (i) of three concrete groups: reference (REF), steel fiber-reinforced (SF), and a hybrid mixture incorporating both steel fibers and carbon nanotubes (MIX), over a period of exposure time. The data reveal distinct trends in water absorption behavior for each group. Overall, the graph demonstrates a general trend of decreasing water absorption rate with increasing exposure time for all three groups. This observation aligns with the expected densification process of cementitious materials. As the hydration reaction progresses, new hydration products are formed, filling the voids within the matrix and reducing the available space for water absorption. Consequently, as the porosity of the concrete decreases, its capacity for water absorption is also reduced.

Figure 6.

Capillary absorption of the three groups at different ages.

A closer examination reveals interesting differences in the water absorption behavior among the three groups. The reference group exhibits a significant decrease in water absorption rate with increasing exposure time. This indicates a strong correlation between exposure time and water absorption rate, suggesting a consistent and significant reduction in water absorption over time due to the ongoing densification and pore refinement within the reference concrete matrix as the hydration reaction proceeds.

The SF group also exhibits a decreasing trend in water absorption rate with increasing exposure time. However, the rate of decrease is less pronounced compared to the reference group. This suggests that the presence of steel fibers might introduce some complexities into the densification process. While steel fibers can contribute to crack bridging and improve overall mechanical properties, they may also introduce some microcracks or voids around the fiber–matrix interface. However, the graph indicates that the SF group consistently exhibits lower water absorption rates compared to the MIX group across all exposure times. This suggests that the presence of steel fibers might have a more pronounced beneficial effect on reducing water absorption compared to the combination of steel fibers and carbon nanotubes.

The MIX group, incorporating both steel fibers and carbon nanotubes, exhibits the least significant decrease in water absorption rate among the three groups. This suggests a weaker correlation between exposure time and water absorption rate. This behavior might be attributed to the complex interactions between the steel fibers, carbon nanotubes, and the cement matrix. While carbon nanotubes can contribute to densification and pore refinement, their presence within the matrix might introduce localized variations in the microstructure, potentially affecting the water absorption behavior. Furthermore, the graph indicates that the MIX group consistently exhibits the highest water absorption rates among the three groups, suggesting that the combination of steel fibers and carbon nanotubes might not have a significant beneficial effect on reducing water absorption.

In conclusion, the analysis of the water absorption behavior of the three concrete groups reveals distinct trends. While all groups exhibit a general decrease in water absorption rate with increasing exposure time, the SF group appears to exhibit the lowest water absorption rates across all exposure times, suggesting that the incorporation of steel fibers might have a more pronounced beneficial effect on reducing water absorption compared to the other two groups. The MIX group, despite incorporating both steel fibers and carbon nanotubes, exhibits the highest water absorption rates. These observations provide valuable insights into the influence of steel fibers and carbon nanotubes on the microstructural development and water absorption behavior of cementitious materials. Further research is needed to fully understand the underlying mechanisms and to investigate the long-term implications of these findings for the durability and performance of these materials in real-world applications.

In summary, a general trend of decreasing water absorption rate with increasing exposure time was observed across all three concrete groups. This observation aligns with the expected densification process inherent to cementitious materials [33]. As hydration reactions progress, new hydration products are generated within the concrete matrix. These products occupy voids and reduce the available pore space, leading to a decrease in material porosity [34]. Consequently, this reduction in porosity results in a diminished capacity for water absorption.

A closer analysis reveals that the reference group exhibited a significant decrease in water absorption rate with increasing exposure time, demonstrating a strong correlation between these two variables. This reduction can be attributed to the ongoing densification and refinement of the pore structure within the reference concrete matrix as hydration reactions continue over time. Although not explicitly detailed in this excerpt, it is reasonable to infer that the inclusion of steel fibers (SFs) or a hybrid combination of steel fibers and carbon nanotubes (MIX) likely influences the rate at which voids are filled during hydration [35,36]. These additives may enhance pore structure refinement or introduce additional mechanisms that reduce porosity more effectively than in the REF group alone.

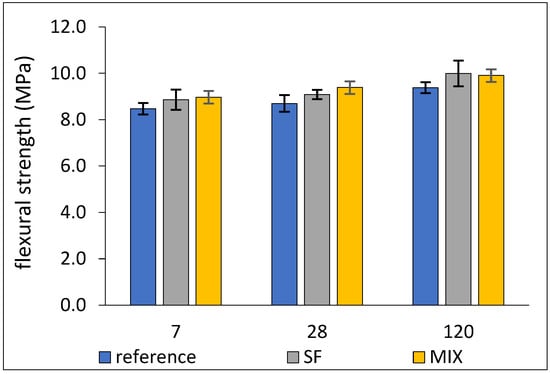

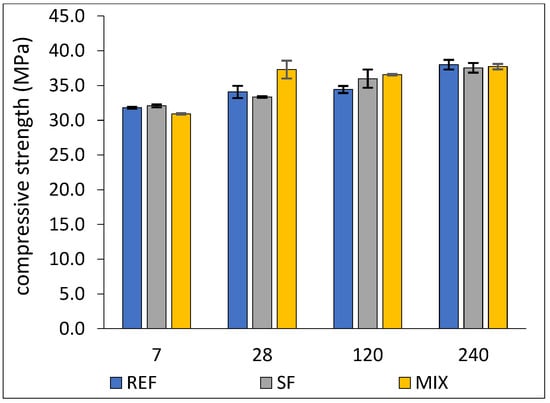

3.4. Flexural and Compressive Strength Analysis

The experimental results for the mechanical strength of composites are presented in Figure 7 and Figure 8. For the measurements, three (3) test samples for each group and age were tested. From Figure 7, it is observed that the flexural strength of all mixtures exhibits a progressive increase over time. At seven days of curing, the flexural strength of the reference concrete is approximately 8.5 MPa. The SF concrete exhibits a slightly higher flexural strength of around 8.9 MPa, while the MIX concrete shows a comparable value of approximately 9.0 MPa. The error bars at this early stage suggest a relatively small dispersion of results for all three mixtures. As the curing period extends to 28 days, all three concrete types demonstrate an increase in flexural strength. The reference concrete reaches approximately 8.7 MPa and the SF concrete attains a value of around 9.1 MPa, whilst the MIX concrete achieves a flexural strength of approximately 9.4 MPa. Notably, the SF and MIX concretes continue to outperform the reference concrete at this intermediate age. The error bars remain relatively small, indicating consistent performance within each mixture group. Upon reaching 120 days of curing, a further increase in flexural strength is observed for all concrete mixtures. The reference concrete achieves a flexural strength of approximately 9.4 MPa. The SF concrete exhibits a significantly higher strength of around 10.0 MPa, and the MIX concrete reaches a peak flexural strength of approximately 9.905 MPa. At this later stage, both the SF and MIX concretes show a substantial improvement in flexural strength compared to the reference concrete. The error bars at 120 days appear slightly larger for the SF and MIX concretes compared to the earlier ages, suggesting potentially greater variability in the long-term flexural strength development of these modified mixtures. In summary, the data presented in Figure 7 indicate that the incorporation of steel fibers (SFs) positively influences the flexural strength development of concrete over time. Both the SF and MIX concretes consistently exhibit higher flexural strength compared to the reference concrete at all tested curing ages. The most significant improvements are observed at the later curing stage of 120 days. This suggests that the bridging of SFs and the synergistic effects with the CNTs contribute to a denser microstructure and enhanced flexural performance over the long term.

Figure 7.

Flexural strength of concretes up to 120 days.

Figure 8.

Compressive strength of concretes up to 240 days.

Regarding compressive strength (Figure 8), the REF mixture exhibits a consistent increase over time, with a notable improvement of 7.2% observed between days seven and 28. The addition of steel fibers further enhances compressive strength compared to the REF mixture. At 120 and 240 days, the SF mixture achieves compressive strengths of 36 MPa and 37.5 MPa, respectively, demonstrating the reinforcing effect of steel fibers on the concrete’s ability to withstand compressive loads.

The MIX, incorporating both CNTs and steel fibers, exhibits varying compressive strength results compared to the REF and SF mixtures. At seven days, the MIX shows a slightly lower compressive strength of 31 MPa relative to the REF and SF mixtures. However, by 28 days, the MIX’s compressive strength increases significantly to 37.3 MPa, surpassing both the REF and SF mixtures. This positive trend continues at 120 days, where the MIX achieves a compressive strength of 36.6 MPa. By 240 days, the compressive strength of the MIX remains relatively stable, further emphasizing the synergistic benefits of CNTs and steel fibers in enhancing the concrete’s resistance to compressive loads.

Furthermore, while the addition of steel fibers improves the compressive strength of concrete during early curing periods, as evidenced by notable gains up to 28 days, the results indicate diminishing returns in terms of strength improvement at later ages (e.g., beyond 120 days). Similarly, although incorporating CNTs alongside steel fibers in the MIX enhances early-age compressive strength and contributes to improved microstructural properties, Figure 7 and Figure 8 suggest that these enhancements do not translate into significant differences in bending or compressive strength at extended curing durations (e.g., up to 240 days). These findings highlight that while steel fibers and CNTs can optimize early structural integrity and performance, their impact on long-term mechanical properties may be limited under certain conditions. This nuanced understanding provides valuable insights for engineers and researchers aiming to balance short-term performance gains with long-term durability when designing resilient infrastructure systems.

It is worth noting that at later stages of curing (120–240 days), concrete specimens incorporating carbon nanotubes (CNTs) and steel fibers (SFs) demonstrate compressive and flexural strengths that are comparable to the SF group. This convergence in mechanical performance is primarily attributed to the near completion of the hydration process across all concrete mixes. By this stage, the additional benefits provided by CNT-induced nucleation become less pronounced, as the hydration reactions responsible for strength development have largely stabilized [37,38]. Moreover, natural microstructural densification occurs progressively in the reference concrete over time. This densification reduces the distinction between modified mixes containing CNTs and SFs and their unmodified counterparts. As concrete matures, crack formation becomes less frequent, which diminishes the relative importance of crack-bridging mechanisms offered by CNTs and SFs. Additionally, the potential for agglomeration in inadequately dispersed CNTs may further limit their effectiveness during long-term performance. Poor dispersion can hinder the uniform distribution of CNTs within the cement matrix, thereby reducing their ability to enhance mechanical properties consistently over time. These findings align with prior research indicating that nanomaterials such as CNTs significantly improve early-age properties of concrete through mechanisms like nucleation and crack control [39,40,41]. However, their influence tends to diminish as concrete evolves beyond its standard curing period due to reduced hydration activity and natural improvements in unmodified mixes.

As a result, Figure 7 and Figure 8 do not exhibit significant differences among the tested groups at 120 and 240 days, highlighting that the combined effects of hydration, steel fiber reinforcement, and dispersion challenges collectively moderate the influence of CNTs on ultimate bending and compressive strength over time.

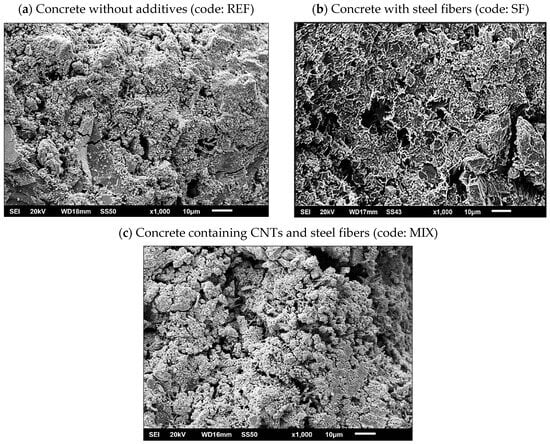

3.5. Microstructural Analysis

The analysis of cementitious composites reinforced with carbon nanotubes (CNTs) and steel fibers (SFs) reveals distinct microstructural and mechanical property differences, which significantly influence their overall performance (Figure 9). Scanning electron microscopy (SEM) images of the MIX group, incorporating both CNTs and SFs, demonstrate a highly refined microstructure characterized by enhanced particle density and a notable reduction in porosity. This improved microstructural integrity arises from the unique morphology of CNTs, which act as nanoscale bridges across microcracks, thereby enhancing flexural strength and durability. Experimental results corroborate these observations, indicating that the MIX formulation exhibits superior mechanical performance compared to the reference mixture (REF). In contrast, SEM images of samples reinforced solely with SFs reveal a smoother texture with elongated fiber shapes uniformly distributed throughout the cement matrix. This configuration effectively bridges cracks, improving both tensile and flexural strength. Experimental data confirm that the SF mixture consistently outperforms the REF mixture in terms of flexural and compressive strength, underscoring the reinforcing efficacy of steel fibers.

Figure 9.

Scanning electron microscopy (SEM) images of (a) reference (REF), (b) steel fiber-reinforced (SF), and (c) hybrid (MIX) concrete microstructures.

While both CNTs and SFs enhance the performance of cementitious materials, they operate through distinct mechanisms. CNTs primarily reduce porosity and increase matrix density, whereas SFs focus on crack bridging and load distribution. The synergistic combination of these materials in the MIX group yields superior structural integrity and durability. Furthermore, microscopy images indicate that samples containing only SFs exhibit larger voids compared to those with CNTs. Although these voids may raise concerns regarding permeability, the crack-bridging action of SF mitigates crack formation and propagation, complementing the benefits provided by CNTs.

The SEM analysis of the REF sample reveals a microstructure characterized by higher porosity and a less cohesive particle arrangement. The presence of visible voids and surface irregularities underscores the absence of reinforcing additives, resulting in lower density and compromised mechanical properties. The lack of reinforcement in the REF sample diminishes its ability to resist tensile and flexural stresses, rendering it more susceptible to crack initiation and propagation. This microstructural analysis highlights the critical role of fibers in enhancing interparticle bonding and overall durability.

In summary, the SEM findings illustrate how the absence of reinforcements leads to a less favorable microstructure, contributing to the inferior mechanical performance observed in the REF sample. This emphasizes the importance of incorporating additives such as CNTs and SFs to optimize the properties of cementitious materials for construction applications. The SEM analysis underscores the complementary roles of CNTs and SFs in enhancing mechanical properties and durability: CNTs refine the microstructure by reducing porosity and increasing density, while SFs reinforce the material by bridging cracks and improving tensile strength. Collectively, these findings highlight the potential of hybrid reinforcement strategies to advance the performance of concrete in demanding structural applications.

The decrease in porosity observed in SEM analysis compared to opposite results using other methods arises primarily from the limitations of surface-level imaging in capturing internal voids and interconnected pore networks, as well as differences in measurement principles between analytic techniques (MIP, vacuum saturation, etc.) that assess bulk material properties more comprehensively.

3.6. TGA Analyses

All three thermogravimetric analysis (TGA) curves demonstrate a consistent downward trajectory, signifying progressive mass loss as temperature was elevated (Figure 10). This phenomenon is predominantly ascribed to the dehydration of chemically bound water within cement hydrates, particularly calcium silicate hydrate (C-S-H), the principal component governing the structural integrity of the cement matrix. The reference sample, devoid of additives, displayed a characteristic mass loss profile consistent with the dehydration kinetics of C-S-H gel, as documented in conventional cementitious systems. The calcium silicate hydrate (C-S-H) phases are usually determined on TGA/DTG curves within a temperature range of approximately 100–200 °C, where most chemically bound water is released during decomposition. However, in some cases, structural water may continue to be released up to ~600 °C depending on experimental conditions [42,43].

Figure 10.

Thermogravimetric analysis (TGA) curves of REF, SF, and MIX concrete specimens.

The incorporation of steel fibers into the cementitious matrix may influence hydration kinetics, thereby modulating its thermal behavior. Steel fibers could alter the rate and degree of hydration, inducing microstructural modifications in the C-S-H gel. Such structural alterations may consequently modulate the bound water content within the matrix, directly impacting the mass loss observed during TGA. Notably, the MIX sample, which integrates both steel fibers and CNTs, exhibited a more intricate thermal response. The inclusion of nanomaterials introduces multifactorial influences on the TGA profile. First, CNTs, as carbon-based nanomaterials, undergo oxidative degradation at elevated temperatures, contributing to pronounced mass loss at higher temperature regimes. Furthermore, if CNTs exhibit pozzolanic reactivity, they may participate in secondary reactions with calcium hydroxide (Ca(OH)2) liberated during cement hydration, yielding supplementary C-S-H gel. This pozzolanic interaction could refine the matrix porosity and microstructure, thereby altering its thermal decomposition characteristics. Additionally, the elevated surface area of CNTs may alter water adsorption dynamics within the composite, potentially affecting the initial mass loss phase in the TGA curve.

In summary, TGA provides critical insights into the thermal decomposition mechanisms of cementitious composites and elucidates the role of additives such as steel fibers and CNTs in microstructural evolution. The observed variations in mass loss profiles underscore the interplay among additive-induced hydration modifications, oxidative processes, and nanoscale interactions. To advance these findings, complementary characterization techniques—including scanning electron microscopy (SEM) for microstructural imaging and X-ray diffraction (XRD) for phase identification—are recommended. Such an integrated analytical approach would facilitate a holistic understanding of the additive-mediated effects on the thermomechanical properties of cement-based materials, enabling tailored optimization of composite performance.

4. Discussion

The experimental results demonstrate that the incorporation of steel fibers (SFs) and carbon nanotubes (CNTs) significantly enhances the mechanical properties and microstructural characteristics of cementitious composites, surpassing the performance of the reference mixture (REF).

The observed enhancement in flexural strength in the SF mixture can be attributed to several key mechanisms. The dispersed steel fibers act as internal reinforcement, effectively bridging microcracks that inevitably arise during loading [44,45]. This bridging action effectively transfers stresses across the crack faces, impeding crack propagation and significantly improving the load-bearing capacity of the concrete (Trevor and Frank). The effectiveness of this mechanism is evident in the sustained improvement in the flexural strength of the SF mixture throughout the testing period. The addition of CNTs to the MIX group resulted in a further significant enhancement in flexural strength, particularly in the early stages. This can be attributed to several interconnected mechanisms. The high aspect ratio and large surface area of CNTs provide numerous nucleation sites for the formation of hydration products, such as calcium silicate hydrate (C-S-H) gel [46,47,48]. This accelerated hydration leads to a denser and more homogeneous microstructure with improved interfacial bonding between the matrix and the reinforcement. The exceptional mechanical properties of CNTs, including their high tensile strength and stiffness, enable them to effectively transfer stresses within the matrix [49,50]. This improved stress distribution minimizes localized stress concentrations and enhances the overall load-bearing capacity of the composite. Furthermore, while steel fibers bridge larger cracks, CNTs can effectively bridge and reinforce microcracks and nano-sized defects within the cement matrix, further enhancing the overall resistance to crack propagation [51,52].

The incorporation of steel fibers significantly improved compressive strength, particularly at later ages [53,54]. This enhancement can be attributed to several factors. The steel fibers effectively share the applied load with the cement matrix, reducing the stress concentration on the matrix and improving its overall load-bearing capacity [55]. The presence of steel fibers within the matrix can create a confinement effect, restricting the lateral expansion of the matrix during compressive loading and thereby increasing its compressive strength [56,57]. The MIX group, incorporating both CNTs and SFs, exhibited the highest compressive strength at later ages, suggesting a synergistic effect between the two reinforcement materials. The CNTs, with their high aspect ratio and excellent mechanical properties, contribute to load transfer and stress distribution within the matrix, while the steel fibers provide additional reinforcement and crack-bridging capabilities. This synergistic interaction leads to a significant enhancement in the compressive strength of the composite [58,59,60].

The observed decrease in porosity over time for all mixtures is attributed to the ongoing hydration process, which leads to the formation of new hydration products and the filling of pores within the matrix. The incorporation of CNTs in the MIX group further reduced porosity, likely due to several mechanisms. The high aspect ratio and large surface area of CNTs can effectively fill the voids within the cement matrix, leading to a denser and more homogeneous microstructure. Furthermore, CNTs act as nucleation sites for the formation of hydration products, leading to a finer pore structure and reduced porosity [61]. This primarily stems from CNTs’ triple role in bridging, pore filling, and nucleation. Notably, MWCNTs exhibit a higher propensity for agglomeration and adhesion due to their strong van der Waals forces, extremely high aspect ratio, and hydrophobicity.

The significant increase in ultrasonic pulse velocity (UPV) and Young’s modulus observed in the MIX group provides strong evidence of improved internal integrity, higher stiffness, and enhanced resistance to deformation [62]. The high aspect ratio and stiffness of CNTs significantly increase the overall stiffness of the composite. This increased stiffness is reflected in the higher UPV values, as the ultrasonic pulse travels faster through a stiffer material. Moreover, the presence of CNTs can improve the interfacial bond between the matrix and the reinforcement, leading to more efficient stress transfer and improved load-bearing capacity [63,64]. This enhanced interfacial bonding contributes to the observed increase in Young’s modulus.

The results demonstrate that the synergistic combination of CNTs and SF offers significant advantages in enhancing the mechanical properties and microstructural characteristics of cementitious composites. Steel fibers primarily contribute to improved flexural and compressive strength through crack-bridging, load-transfer, and confinement mechanisms [65,66]. On the other hand, carbon nanotubes contribute to early strength gain, improved microstructural refinement, enhanced load transfer, increased stiffness, and reduced porosity [67,68,69,70]. These findings provide valuable insights relevant to the development of high-performance construction materials with improved durability, sustainability, and resistance to various loading conditions. Further research should focus on optimizing the content and dispersion of these additives, investigating the long-term durability and environmental impact of these materials, and exploring potential applications in various civil engineering structures.

5. Conclusions

This study investigated the influence of steel fibers (SFs) and carbon nanotubes (CNTs) on the physicomechanical properties and quality characteristics of cementitious composites. From the experimental results, the following conclusions can be drawn:

- The simultaneous addition of CNTs and SFs in the MIX group resulted in slight yet consistent improvements over the SF group at all ages. Notably, at 28 days of curing, the simultaneous inclusion of CNTs and SFs increased flexural strength by approximately 8.0% relative to the REF group and by 3.5% compared to the SF group. However, at seven and 120 days, the flexural strength of both the SF and MIX groups remained nearly identical, showing an improvement of 5–6% over that of the REF group.

- The combined incorporation of carbon nanotubes (CNTs) and steel fibers (SFs) resulted in the highest compressive strength at both 28 and 120 days compared to other groups. At 28 days, the MIX group demonstrated a notable increase in compressive strength, surpassing the REF group by 9.5% and the SF group by 11.8%. However, as curing progressed to later ages (120 days), differences among all groups diminished, with variations in compressive strength reduced to approximately 6%.

- The results showed a gradual decrease in porosity for all mixtures over time, indicating ongoing densification. While the REF mixture exhibited the lowest porosity, the incorporation of CNTs in the MIX group also contributed to a significant reduction in porosity, likely due to the filling effect of CNTs within the matrix and their ability to refine the pore structure.

- The MIX group, incorporating both CNTs and steel fibers, exhibited the highest UPV and Young’s modulus, indicating superior wave propagation speed, improved internal integrity, and higher stiffness compared to the other groups. This suggests that the combined use of CNTs and steel fibers can significantly enhance the overall performance of cementitious materials, making them more suitable for demanding construction applications.

In summary, the incorporation of CNTs and SFs in cementitious composites offers substantial advantages, including enhanced flexural and compressive strength, reduced porosity, and improved mechanical properties. The MIX group, which combines the benefits of both additives, demonstrated the most promising results, highlighting a synergistic effect that enhances the overall performance of cementitious materials.

These findings have significant implications for the development of high-performance construction materials with improved durability and load-bearing capacity. Future research should focus on optimizing the content and combination of CNTs and SFs to maximize performance benefits while considering cost-effectiveness and long-term durability under various environmental conditions. Additionally, further investigations using advanced characterization techniques, such as scanning electron microscopy (SEM) and X-ray diffraction (XRD), are recommended to gain deeper insights into the microstructural mechanisms driving these performance enhancements.

While this study demonstrates significant improvements in strength characteristics through the incorporation of steel fibers (SFs) and carbon nanotubes (CNTs), further research is required to comprehensively evaluate their impact on durability parameters such as shrinkage reduction, crack resistance under environmental stressors, frost resistance in freeze–thaw cycles, abrasion resistance under mechanical wear conditions, and long-term corrosion resistance in aggressive environments. The observed enhancements in microstructural density due to SF bridging effects and CNT-induced pore refinement suggest promising potential for improving these durability aspects. Future studies should aim to quantify these parameters systematically through experimental testing under real-world exposure conditions.

Funding

This research received no external funding.

Data Availability Statement

Some or all data, models, or code that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Khan, M.; Hashmi, A.F.; Shariq, M.; Ibrahim, S. Effects of incorporating fibres on mechanical properties of fibre-reinforced concrete: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mahadik, S.; Kamane, S.; Lande, A. Effect of steel fibers on compressive and flexural strength of concrete. Int. J. Adv. Struct. Geotech. Eng. 2014, 3, 388–392. [Google Scholar]

- Le Hoang, A.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high-performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Hung, C.-C.; Chen, Y.-T.; Yen, C.-H. Workability, fiber distribution, and mechanical properties of UHPC with hooked end steel macro-fibers. Constr. Build. Mater. 2020, 260, 119944. [Google Scholar] [CrossRef]

- Tantawi, H. Introduction to Concrete Technology; Department of Civil Engineering, Fahad Bin Sultan University: Tabuk, Saudi Arabia, 2015; pp. 143–188. [Google Scholar]

- Wee, T.; Lu, H.; Swaddiwudhipong, S. Tensile strain capacity of concrete under various states of stress. Mag. Concr. Res. 2000, 52, 185–193. [Google Scholar] [CrossRef]

- Abbass, W.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Grynyova, I. Research of Strength, Frost Resistance, Abrasion Resistance and Shrinkage of Steel Fiber Concrete for Rigid Highways and Airfields Pavement Repair. Appl. Sci. 2022, 12, 1174. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Strength, Frost Resistance, and Resistance to Acid Attacks on Fiber-Reinforced Concrete for Industrial Floors and Road Pavements with Steel and Polypropylene Fibers. Materials 2022, 15, 8339. [Google Scholar] [CrossRef]

- Ali, A.M.; Falah, M.W.; Hafedh, A.A.; Al-Khafaji, Z.S.; Radhi, S. Evaluation the influence of steel-fiber on the concrete characteristics. Period. Eng. Nat. Sci. (PEN) 2022, 10, 368–379. [Google Scholar] [CrossRef]

- Shimoda, K.; Hinoki, T. Effects of fiber volume fraction on the densification and mechanical properties of unidirectional SiCf/SiC-matrix composites. J. Eur. Ceram. Soc. 2021, 41, 1163–1170. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.P.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

- Raoufi, K.; Schlitter, J.; Bentz, D.; Weiss, J. Parametric Assessment of Stress Development and Cracking in Internally Cured Restrained Mortars Experiencing Autogenous Deformations and Thermal Loading. Adv. Civ. Eng. 2011, 2011, 870128. [Google Scholar] [CrossRef]

- Zhao, J.; Zong, G.; Sun, R.; Zhu, J. Research on damage and failure mechanism of concrete and steel structures caused by temperature. SYLWAN 2024, 168. [Google Scholar] [CrossRef]

- Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Comparison of the Corrosion Resistance of Fiber-Reinforced Concrete with Steel and Polypropylene Fibers in an Acidic Environment. Constr. Mater. 2025, 5, 6. [Google Scholar] [CrossRef]

- Marcos-Meson, V.; Fischer, G.; Edvardsen, C.; Skovhus, T.L.; Michel, A. Durability of Steel Fibre Reinforced Concrete (SFRC) exposed to acid attack—A literature review. Constr. Build. Mater. 2019, 200, 490–501. [Google Scholar] [CrossRef]

- Chousidis, N.; Constantinides, G. Fire endurance and corrosion resistance of nano-modified cement mortars exposed to elevated temperatures. Ceram. Int. 2023, 49 Pt B, 19182–19193. [Google Scholar] [CrossRef]

- Can, R.J.; Grimsley, B.W.; Czabaj, M.W.; Siochi, E.J.; Hull, B. Processing and characterization of carbon nanotube composites. In Proceedings of the Society for the Advancement of Material and Process Engineering (SAMPE TECH 2014), Seattle, WA, USA, 2–5 June 2014. [Google Scholar]

- Mostofizadeh, A.; Li, Y.; Song, B.; Huang, Y. Synthesis, Properties, and Applications of Low-Dimensional Carbon-Related Nanomaterials. J. Nanomater. 2011, 2011, 685081. [Google Scholar] [CrossRef]

- Wu, T.; Wang, J.N. Carbon nanotube springs with high tensile strength and energy density. RSC Adv. 2016, 6, 38187–38191. [Google Scholar] [CrossRef]

- Mosallam, S.J.; Behbahani, H.P.; Shahpari, M.; Abaeian, R. The effect of carbon nanotubes on mechanical properties of structural lightweight concrete using LECA aggregates. Structures 2022, 35, 1204–1218. [Google Scholar] [CrossRef]

- Zhang, P.; Su, J.; Guo, J.; Hu, S. Influence of carbon nanotube on properties of concrete: A review. Constr. Build. Mater. 2023, 369, 130388. [Google Scholar] [CrossRef]

- Jayakumari, B.Y.; Swaminathan, E.N.; Partheeban, P. A review on characteristics studies on carbon nanotubes-based cement concrete. Constr. Build. Mater. 2023, 367, 130344. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- Dawood, E.T.; Ramli, M. Development of high strength flowable mortar with hybrid fiber. Constr. Build. Mater. 2010, 24, 1043–1050. [Google Scholar] [CrossRef]

- Hall, C.; Hoff, W.D. Water Transport in Brick, Stone and Concrete, 2nd ed.; Spon Press: London, UK, 2012. [Google Scholar]

- Gummerson, R.J.; Hall, C.; Hoff, W.D. Water movement in porous building materials—II. Hydraulic suction and sorptivity of brick and other masonry materials. Build. Environ. 1980, 15, 101–108. [Google Scholar] [CrossRef]

- Chousidis, N.; Polymenis, S.; Batis, G. Impact of high volume EMD residue on the corrosion resistance and mechanical properties of construction materials in sulfate environment. Mater. Res. Express 2023, 10, 056508. [Google Scholar] [CrossRef]

- Chousidis, N.; Zacharopoulou, A.; Zeris, C.; Batis, G. Corrosion resistance and physical-mechanical properties of reinforced mortars with and without carbon nanotubes. J. Mater. Sci. Chem. Eng. 2022, 10, 1–23. [Google Scholar] [CrossRef]

- Pereira, E.B.; Fischer, G.; Barros, J.A. Direct assessment of tensile stress-crack opening behavior of strain hardening cementitious composites (SHCC). Cem. Concr. Res. 2012, 42, 834–846. [Google Scholar] [CrossRef]

- Kim, W.; Jeong, K.; Lee, T.; Park, S. A Study on Correlation between Ultrasonic Pulse Velocity Method and Coarse Aggregate for Estimating Residual Modulus of Elasticity of Concrete Exposed to High Temperatures. Appl. Sci. 2022, 12, 6644. [Google Scholar] [CrossRef]

- Estévez, E.; Martín, D.A.; Argiz, C.; Sanjuán, M.Á. Ultrasonic Pulse Velocity—Compressive Strength Relationship for Portland Cement Mortars Cured at Different Conditions. Crystals 2020, 10, 133. [Google Scholar] [CrossRef]

- Zhang, S.P.; Zong, L. Evaluation of Relationship between Water Absorption and Durability of Concrete Materials. Adv. Mater. Sci. Eng. 2014, 2014, 650373. [Google Scholar] [CrossRef]

- Castro, J.; Bentz, D.; Weiss, J. Effect of sample conditioning on the water absorption of concrete. Cem. Concr. Compos. 2011, 33, 805–813. [Google Scholar] [CrossRef]

- Usman Rashid, M. Experimental investigation on durability characteristics of steel and polypropylene fiber reinforced concrete exposed to natural weathering action. Constr. Build. Mater. 2020, 250, 118910. [Google Scholar] [CrossRef]

- Enfedaque, A.; Paradela, L.S.; Sánchez-Gálvez, V. An alternative methodology to predict aging effects on the mechanical properties of glass fiber reinforced cements (GRC). Constr. Build. Mater. 2012, 27, 425–431. [Google Scholar] [CrossRef]

- Del Carmen Camacho, M.; Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Mechanical Properties and Durability of CNT Cement Composites. Materials 2014, 7, 1640–1651. [Google Scholar] [CrossRef]

- Şahin, Y.; Köksal, F. The influences of matrix and steel fibre tensile strengths on the fracture energy of high-strength concrete. Constr. Build. Mater. 2011, 25, 1801–1806. [Google Scholar] [CrossRef]

- Balasubramaniam, B.; Mondal, K.; Ramasamy, K.; Palani, G.S.; Iyer, N.R. Hydration Phenomena of Functionalized Carbon Nanotubes (CNT)/Cement Composites. Fibers 2017, 5, 39. [Google Scholar] [CrossRef]

- Park, B.; Choi, Y.C. Investigating the Effect of CNTs on Early Age Hydration and Autogenous Shrinkage of Cement Composite. Appl. Sci. 2021, 11, 5545. [Google Scholar] [CrossRef]

- Jung, S.-H.; Oh, S.; Kim, S.-W.; Moon, J.-H. Effects of CNT Dosages in Cement Composites on the Mechanical Properties and Hydration Reaction with Low Water-to-Binder Ratio. Appl. Sci. 2019, 9, 4630. [Google Scholar] [CrossRef]

- Zhang, Q.; Ye, G. Dehydration kinetics of Portland cement paste at high temperature. J. Therm. Anal. Calorim. 2012, 110, 153–158. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B.; Press, C. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: London, UK, 2006. [Google Scholar]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- MacLeod, A.J.N.; Collins, F.G.; Duan, W. Effects of carbon nanotubes on the early-age hydration kinetics of Portland cement using isothermal calorimetry. Cem. Concr. Compos. 2021, 119, 103994. [Google Scholar] [CrossRef]

- Makar, J.M.; Chan, G.W. Growth of cement hydration products on single-walled carbon nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Carriço, A.; Bogas, J.; Hawreen, A.; Guedes, M. Durability of multi-walled carbon nanotube reinforced concrete. Constr. Build. Mater. 2018, 164, 121–133. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Z.; Fu, J.; Liang, Z.; Ramakrishnan, K.R. Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review. Nanotechnol. Rev. 2021, 10, 1438–1468. [Google Scholar] [CrossRef]

- Sahu, R.; Harursampath, D.; Ponnusami, S.A. Mechanical behaviour of carbon nanotube composites: A review of various modelling techniques. J. Compos. Mater. 2024, 58, 791–825. [Google Scholar] [CrossRef]

- Gnanasaravanan, S.; Ayeshamariam, A.; Saravanakkumar, D.; Nagarani, N.; Baraneedharan, P.; Mohamed, S.B. Effects of MWCNTs on the Improved Mechanical Characteristics of Cementitious Composite. Curr. Phys. Chem. 2024, 15, 69–80. [Google Scholar] [CrossRef]

- Chiadighikaobi, P.C.; Noor, A.A.A.; Paul, V.J.; Markovich, A.S.; Saad, L.A.; Ewa, D.E.; Aderomose, S.K. Physicomechanical Properties of Carbon Nanotubes Reinforced Cementitious Concrete–A Review. Open Constr. Build. Technol. J. 2023, 17, 1. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Properties of concrete with addition carbon nanotubes: A review. Constr. Build. Mater. 2023, 393, 132066. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, P.; Wang, J.; Hu, S. Influence of fibers on the mechanical properties and durability of ultra-high-performance concrete: A review. J. Build. Eng. 2022, 52, 104370. [Google Scholar] [CrossRef]

- Liu, K.; Song, R.; Li, J.; Guo, T.; Li, X.; Yang, J.; Yan, Z. Effect of steel fiber type and content on the dynamic tensile properties of ultra-high performance cementitious composites (UHPCC). Constr. Build. Mater. 2022, 342, 127908. [Google Scholar] [CrossRef]

- Hu, X.; Su, T.-H.; Zeng, J.-J.; Long, Y.-L.; Wang, J.-S.; Liao, J.; Ouyang, Y. Effect of steel fibres and expansive agents on compressive behaviour of circular CFST columns. Case Stud. Constr. Mater. 2024, 20, e02789. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Z.; Zhong, W.; Wang, S.; Zhang, R.; Yao, X. Effects of steel fibers on the dynamic properties and failure process of ultra high-performance concrete. J. Build. Eng. 2022, 62, 105415. [Google Scholar] [CrossRef]

- Si, T.; Xie, S.; Ji, Z.; Ma, C.; Wu, Z.; Wu, J.; Wang, J. Synergistic effects of carbon black and steel fibers on electromagnetic wave shielding and mechanical properties of graphite/cement composites. J. Build. Eng. 2022, 45, 103561. [Google Scholar] [CrossRef]

- Kim, G.M.; Yang, B.J.; Yoon, H.N.; Lee, H.K. Synergistic effects of carbon nanotubes and carbon fibers on heat generation and electrical characteristics of cementitious composites. Carbon 2018, 134, 283–292. [Google Scholar] [CrossRef]

- Li, S.; Yan, J.; Ma, H.; Lyu, X.; Zhang, Y.; Du, S. Hybrid effects of carbon nanotubes and steel fiber on dynamic mechanical properties of ultra high-performance concrete. Mater. Res. Express 2023, 10, 025503. [Google Scholar] [CrossRef]

- Liew, K.; Kai, M.; Zhang, L. Carbon nanotube reinforced cementitious composites: An overview. Compos. Part A Appl. Sci. Manuf. 2016, 91, 301–323. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, S.; Yun, H.; Chung, W. Correlation Analysis between Strength and Defect of Nano-Cementitious Composites using Ultrasonic Pulse Velocity. Nanomaterials 2023, 13, 1183. [Google Scholar] [CrossRef]

- Zhang, Y.; Xia, W. Enhancing effect of carbon nanotubes on the performance of concrete containing surface-treated fly ash cenosphere. Constr. Build. Mater. 2023, 406, 133322. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X. Interfacial bonding characteristics of multi-walled carbon nanotube/ultralight foamed concrete. Sci. Eng. Compos. Mater. 2024, 31, 20240028. [Google Scholar] [CrossRef]

- Mujalli, M.A.; Dirar, S.; Mushtaha, E.; Hussien, A.; Maksoud, A. Evaluation of the tensile characteristics and bond behaviour of steel fibre-reinforced concrete: An overview. Fibers 2022, 10, 104. [Google Scholar] [CrossRef]

- Raza, S.S.; Qureshi, L.A.; Ali, B.; Raza, A.; Khan, M.M. Effect of different fibers (steel fibers, glass fibers, and carbon fibers) on mechanical properties of reactive powder concrete. Struct. Concr. 2021, 22, 334–346. [Google Scholar] [CrossRef]

- Reis, E.D.; Resende, H.F.; Christoforo, A.L.; Costa, R.M.; Gatuingt, F.; Poggiali, F.S.J.; Bezerra, A. Assessment of physical and mechanical properties of concrete with carbon nanotubes pre-dispersed in cement. J. Build. Eng. 2024, 89, 109255. [Google Scholar] [CrossRef]

- Silvestro, L.; Gleize, P.J.P. Effect of carbon nanotubes on compressive, flexural and tensile strengths of Portland cement-based materials: A systematic literature review. Constr. Build. Mater. 2020, 264, 120237. [Google Scholar] [CrossRef]

- Trevor, D.H.; Frank, J.V. Behavior of Steel Fiber-Reinforced Concrete Slabs under Impact Load. ACI Struct. J. 2014, 111, 1213–1224. [Google Scholar]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).