Incorporation of Phase Change Materials in Buildings

Abstract

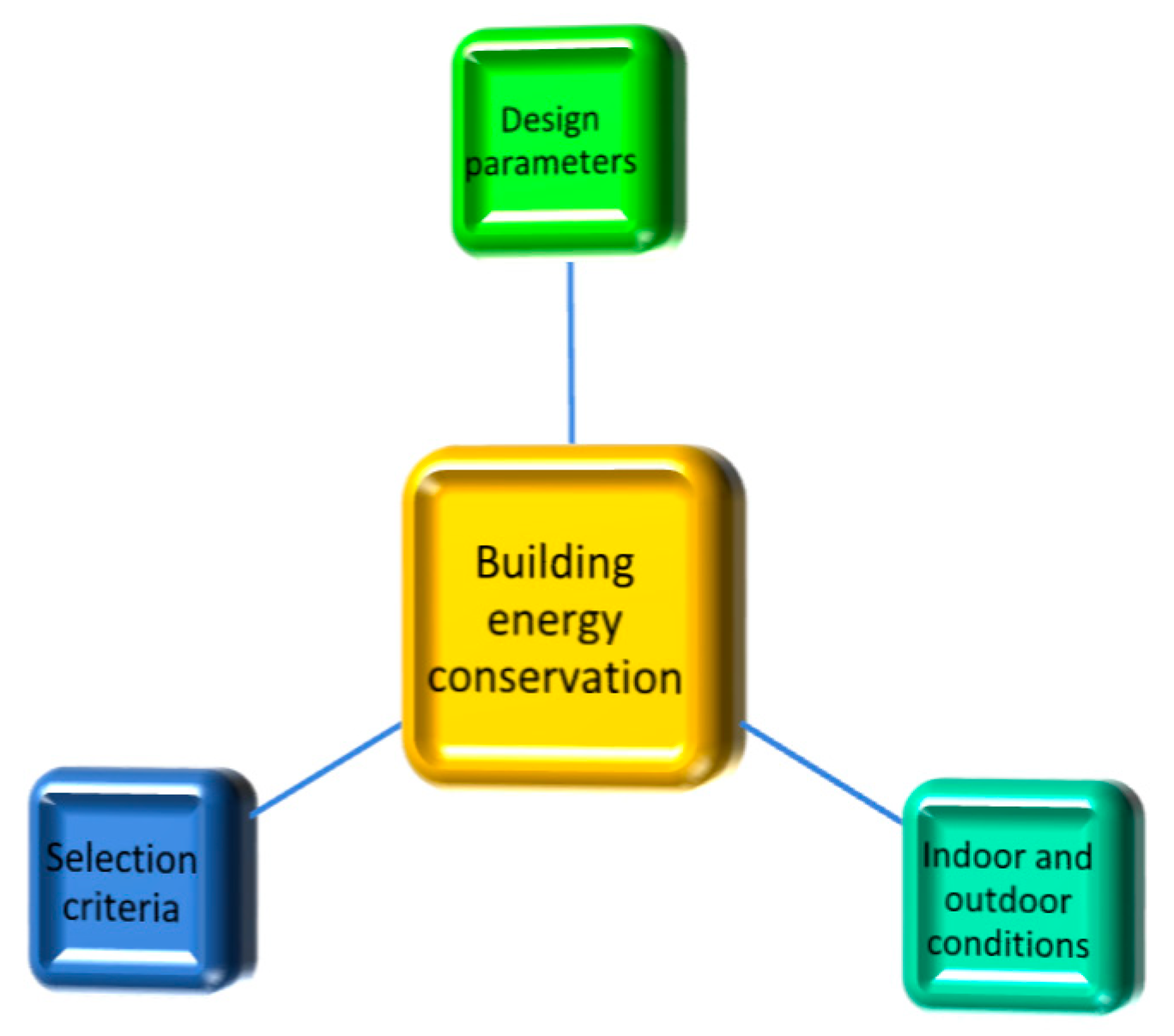

1. Introduction

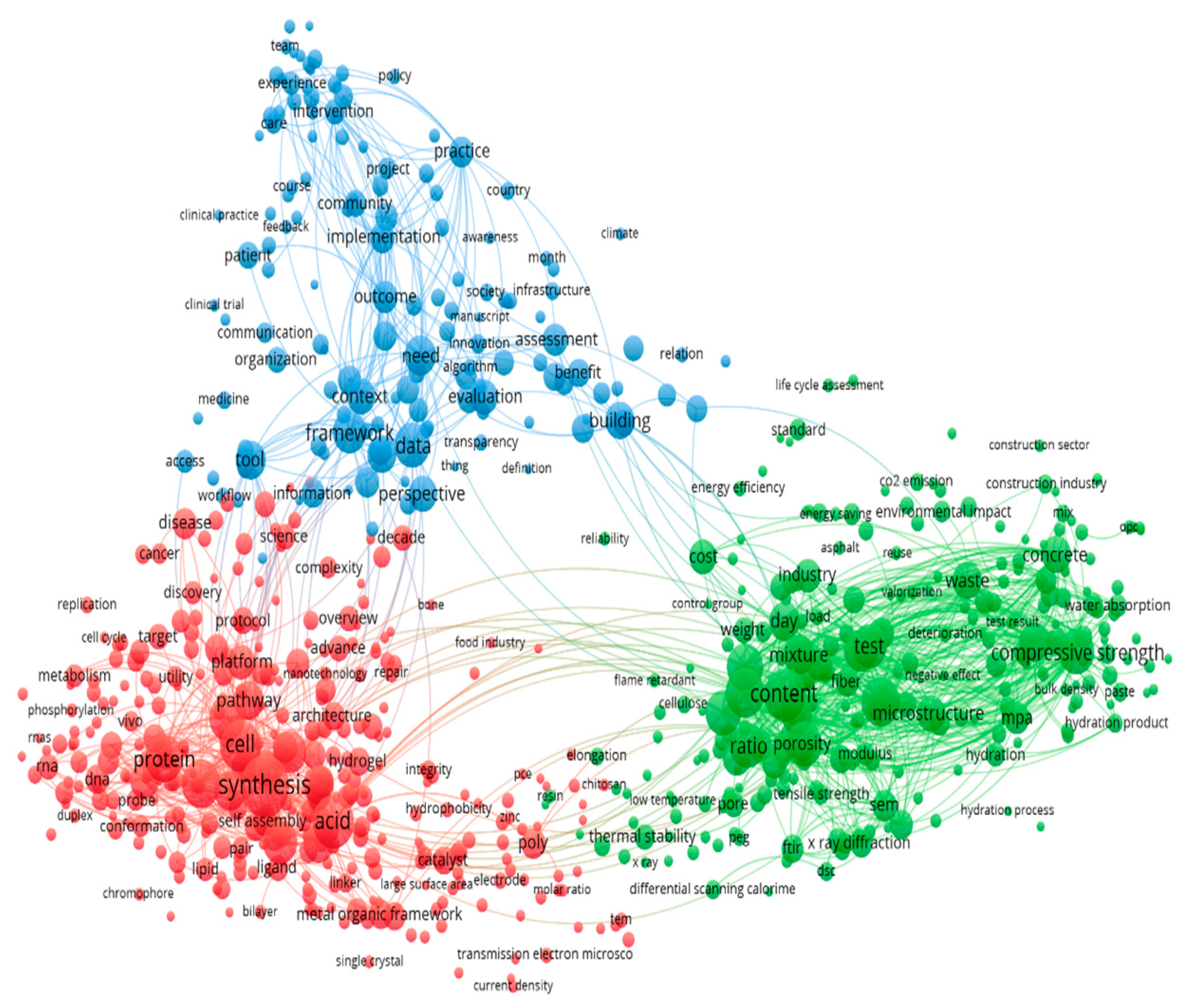

2. Methodology

3. Thermal Energy in Buildings

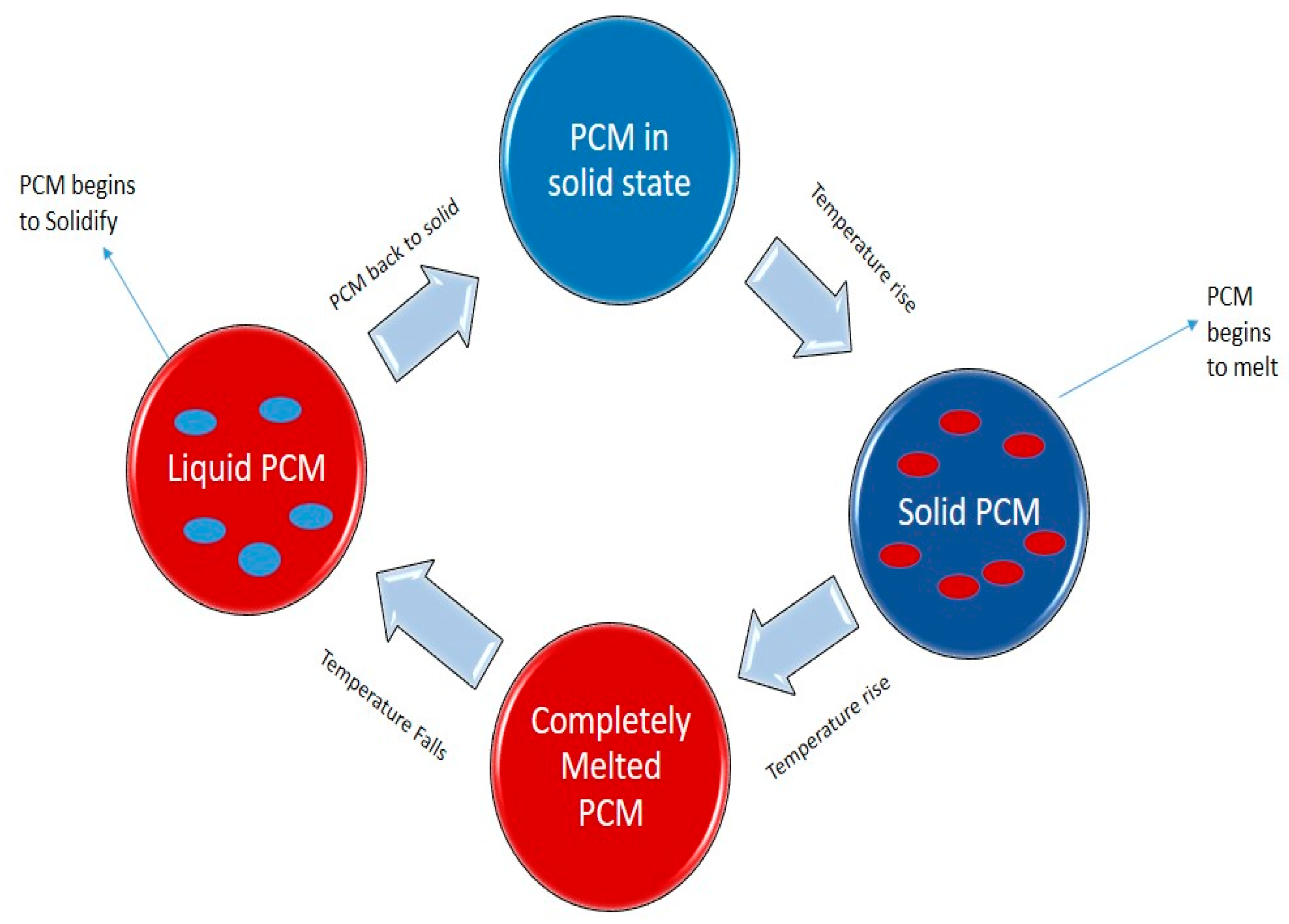

4. Phase Change Material

4.1. Concept of PCMs

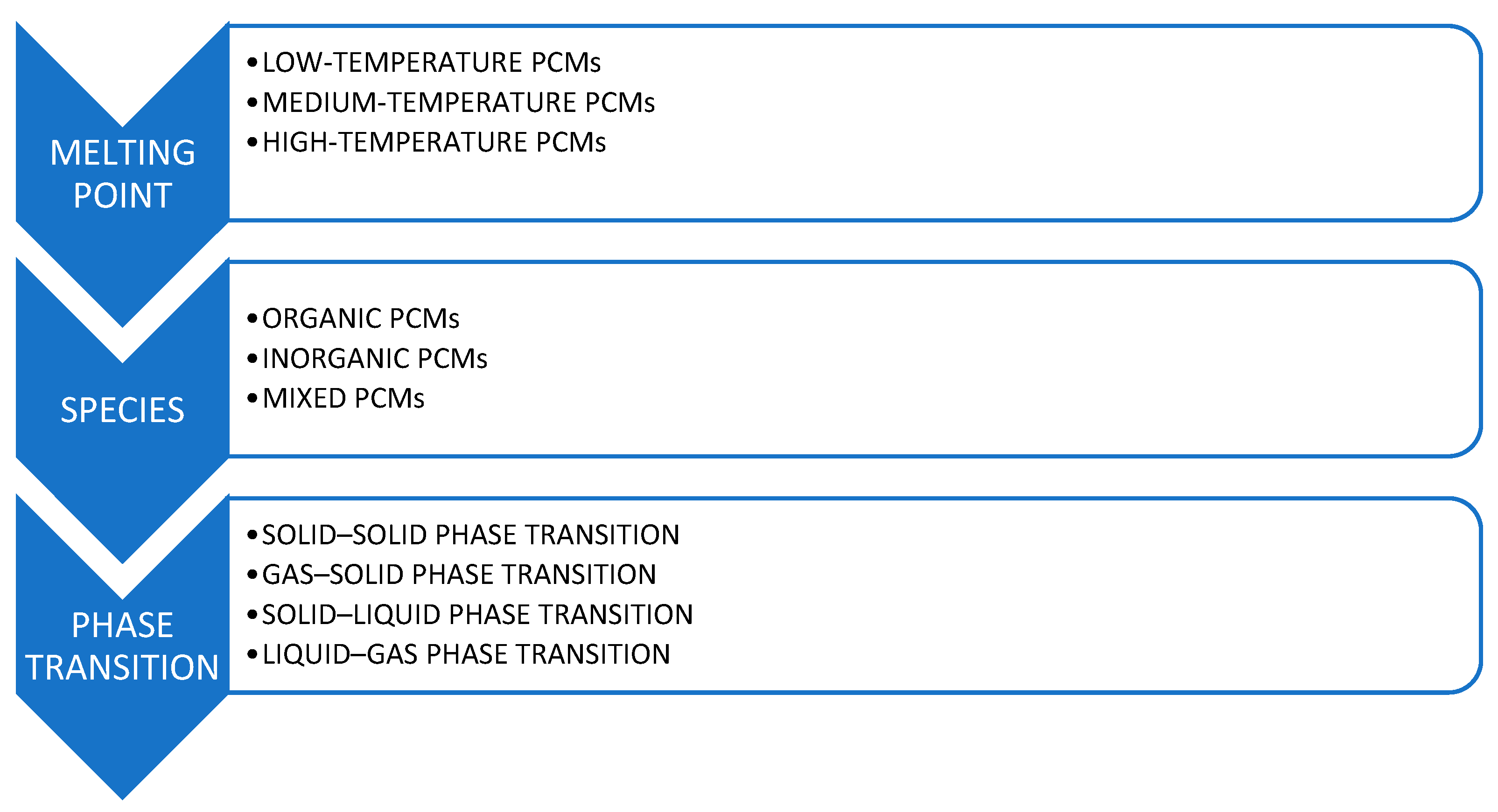

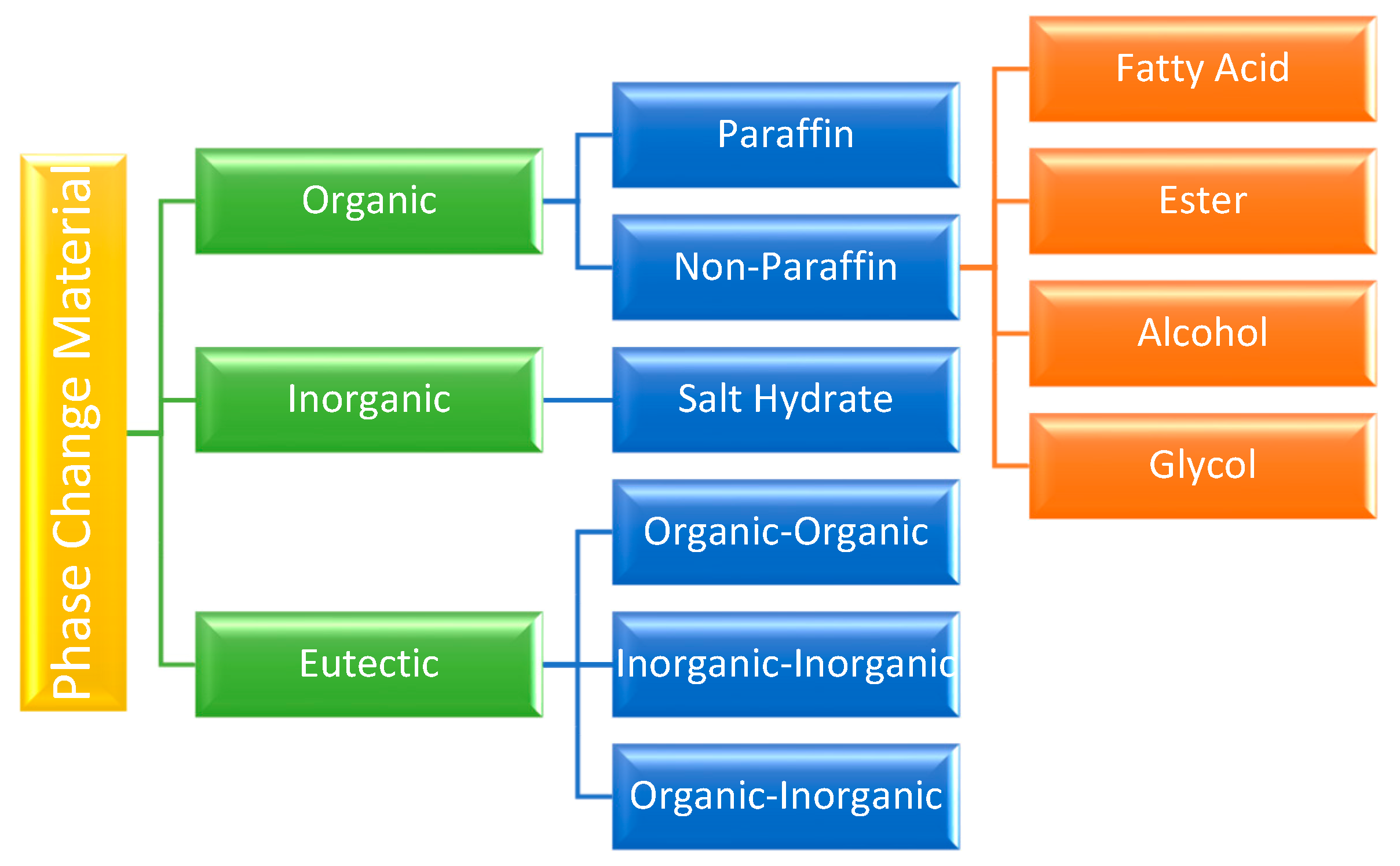

4.2. Types and Characteristics of PCMs

- Low-temperature PCM, with a phase transition temperature below 15 °C, is typically used in air conditioning applications and the food industry [42].

- Medium-temperature PCM, which is the most popular, has a phase transition temperature between 15 and 90 °C and has applications in solar energy, medical, textile, and electronic fields [43].

- High-temperature PCM, with a phase transition temperature greater than 90 °C, is primarily used in industry and aerospace fields [44].

4.2.1. Organic PCMs

- Paraffins

- Non-paraffins

- Fatty acids

4.2.2. Inorganic PCMs

4.2.3. Eutectic PCMs

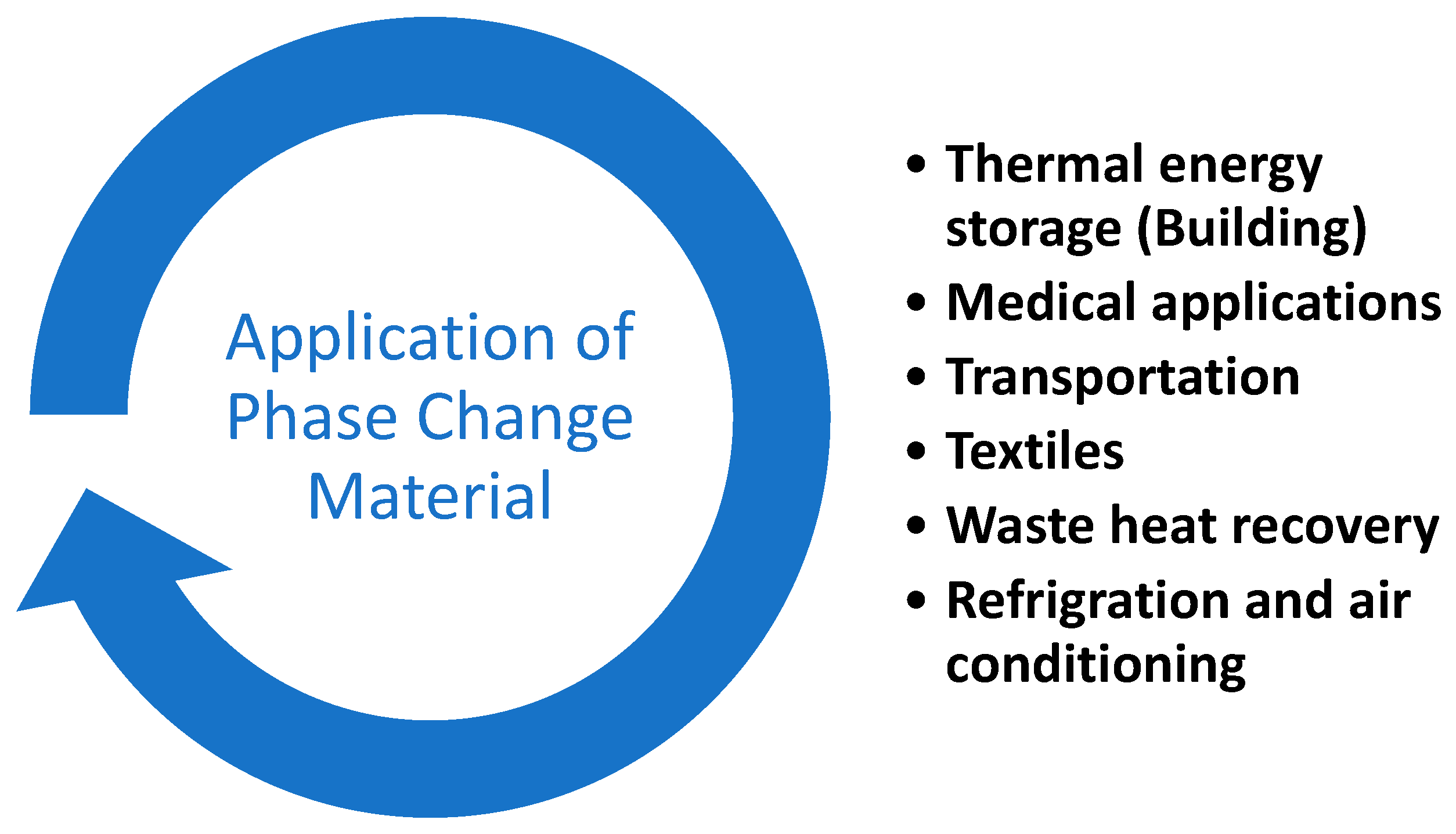

4.3. Applications of PCMs

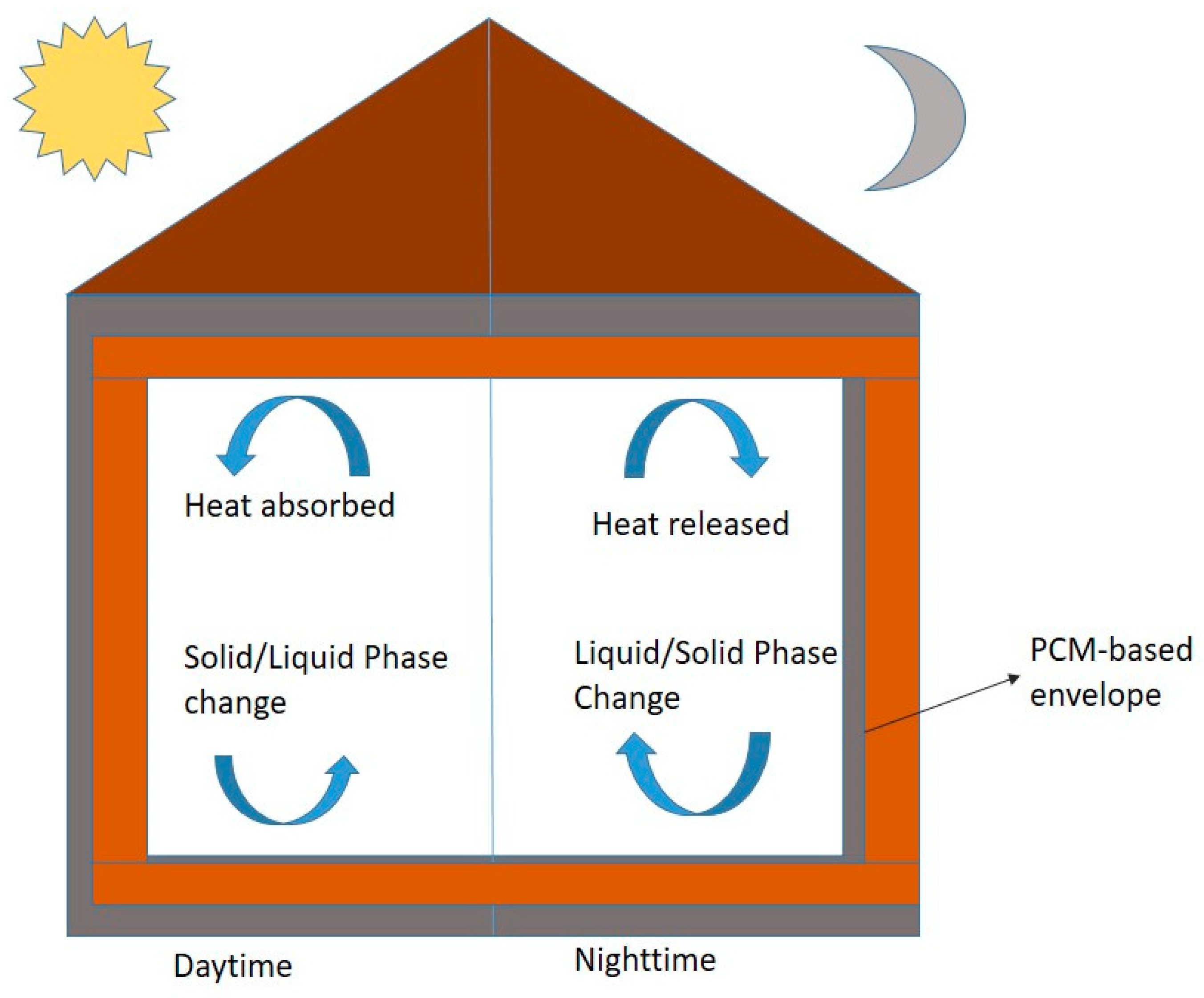

5. PCM-Incorporated Building Envelope

- Lower peak temperatures: PCMs have the ability to lower peak temperatures by as much as 4 °C, which can support summertime thermal comfort.

- Enhanced thermal inertia: PCMs have the ability to enhance a building envelope’s thermal inertia, hence enhancing comfort and thermal performance.

- Less energy wastage: PCM installation inside walls can cut down on energy wastage [77].

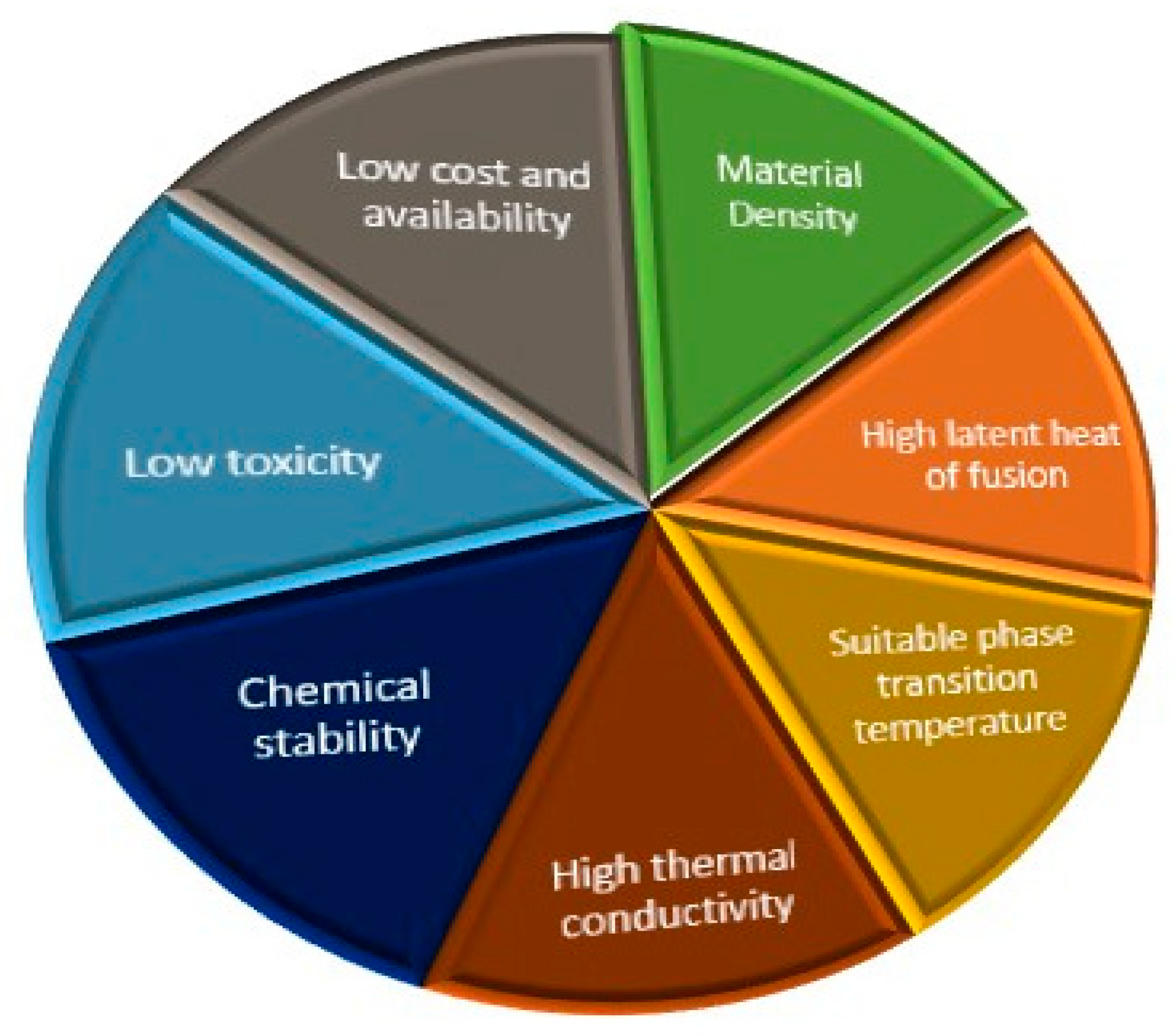

5.1. Selection Criteria of PCMs

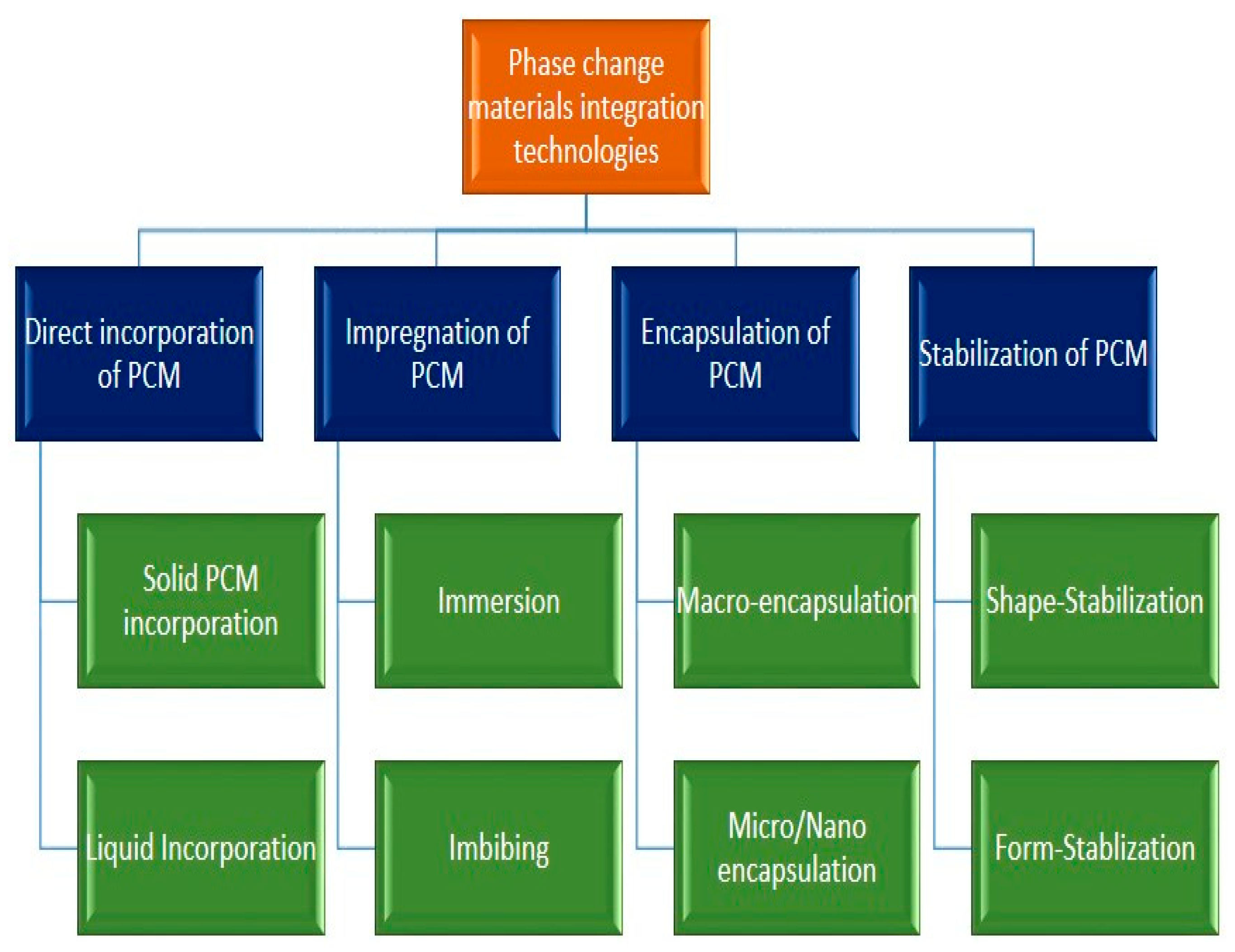

5.2. Various Incorporation Methods of PCMs in Buildings

- Direct incorporation:

- Encapsulation (Micro and Macro):

- Microencapsulation: Encases PCMs in microscopic polymer shells, allowing them to be mixed with building materials without leakage.

- Macroencapsulation: Involves larger containers or shells that can be integrated into walls, floors, or ceilings [81].

- Advantages:

- Prevents leakage and chemical interaction with the building material.

- Can be easily incorporated into existing structures.

- Challenges:

- Increased cost due to encapsulation materials and processes.

- Potential for reduced thermal conductivity due to encapsulating shell.

- Shape-stabilized PCMs:

- Advantages:

- Eliminates the risk of leakage.

- Maintains structural integrity during phase transitions.

- Challenges:

- Form-stable PCMs composite:

- Advantages:

- Good mechanical strength and stability. For example, the enhancement of PCM stability and mechanical properties for different applications is a subject of interest to many researchers, such as the polyethylene glycol/graphene oxide composite, in order to ensure reliable performance during repeated thermal cycles [84].

- Versatile application in different construction elements.

- Challenges:

- Potential for reduced PCM content, impacting overall thermal storage capacity.

- Complex manufacturing and higher costs.

- Immersion:

- Advantages:

- Simple method for impregnating porous materials.

- Enhances thermal storage capacity of the material.

- Challenges:

- Limited to porous materials.

- Potential for uneven distribution of PCMs within the material.

5.3. Parameters for PCMs’ Performance in Buildings

- (a)

- Melting Temperature of PCMs

- Factors to consider:

- Climate and seasonal variations: The melting temperature must align with the local climate conditions to maximize the efficiency of thermal energy storage.

- Building usage: Different types of buildings (e.g., residential, commercial, industrial) have varying thermal comfort requirements influencing the choice of PCM with an appropriate melting temperature [88].

- (b)

- Thickness of PCMs

- Factors to consider:

- Thermal conductivity: The material in which the PCM is encapsulated or incorporated can affect the optimal thickness. Materials with higher thermal conductivity allow for better heat transfer.

- Space constraints: Building designs often have space limitations that can restrict the thickness of PCM layers that can be practically applied.

- Cost-effectiveness: Thicker layers of PCM can be more expensive so a balance between performance and cost must be achieved.

- (c)

- Location of PCMs

- Factors to consider:

- Thermal loads: Placing PCMs in areas with high thermal loads (external walls, roofs) can enhance their efficiency in absorbing excess heat during the day and releasing it at night.

- Integration with building systems: PCMs can be integrated with radiant heating systems, passive solar designs, or HVAC systems to maximize energy savings.

- Occupant comfort: The placement should ensure that the thermal regulation provided by PCMs contributes to the comfort of building occupants without causing unwanted thermal variations.

5.4. Modeling of PCM Incorporated Building Envelope

- Key Concepts in PCM Modeling for Building Envelopes

- (a)

- Thermal Properties and Phase Change Behavior

- Latent Heat Storage: PCMs can store large amounts of heat during the phase change process. When the ambient temperature rises above the PCM’s melting point, the material absorbs heat and melts. Conversely, when the temperature drops, the PCM solidifies and releases the stored heat [94].

- Thermal Conductivity: The efficiency of heat transfer through PCMs is a critical factor in their performance. Higher thermal conductivity facilitates quicker energy absorption and release which can be advantageous in dynamic thermal environments [95].

- Specific Heat Capacity: This property measures the amount of heat required to change the temperature of the PCM. A higher specific heat capacity increases the thermal inertia of the building envelope, stabilizing indoor temperatures against external fluctuations [96].

- (b)

- Numerical Modeling Approaches

- Finite Difference Method (FDM): FDM is used to discretize the heat transfer equations governing PCM behavior. By breaking down the building envelope into a grid, FDM can simulate the transient heat flow and phase transitions within PCMs [97].

- Finite Element Method (FEM): FEM divides the building envelope into smaller, finite elements and solves the heat transfer equations iteratively. This method is particularly useful for complex geometries and heterogeneous material properties [98].

- Computational Fluid Dynamics (CFD): CFD simulations provide detailed analysis of airflow and thermal distribution in spaces where PCMs are used. CFD models can capture the interaction between the PCM and the surrounding air, offering insights into thermal comfort levels and energy savings [99].

- (c)

- Simulation Tools

- Energy Plus: Developed by the U.S. Department of Energy, Energy Plus is a robust building energy simulation tool that incorporates PCM models. It can simulate the thermal performance of buildings with PCM-enhanced envelopes, predicting energy consumption and thermal comfort under various climatic conditions [100].

- TRNSYS: A transient systems simulation program widely used for modeling energy systems in buildings. TRNSYS includes components for PCM modeling, enabling detailed analysis of their impact on building energy performance and indoor climate [101].

5.5. Practical Implementation and Case Studies

| Study | PCM Types/Incorporation | Key Findings |

|---|---|---|

| Ahangari and Maerefat (2019) [103] | Innovative PCM system | Improved thermal comfort, reduced energy demand, effective indoor temperature management, lowered HVAC reliance |

| Al-Rashed et al. (2022) [109] | RT-31, RT-35, RT-42 | Higher melting temperatures correlated with better thermal performance, importance of PCM type selection based on climate |

| Cascone et al. (2018) [105] | PCM-enhanced opaque building envelope components | Significant enhancement of energy efficiency in retrofitted buildings |

| Liu et al. (2021) [87] | PCM with melting temperature of 24 °C and latent heat of 219 kJ/kg | Reduced energy consumption for heating and cooling across seasons |

| Rathore and Shukla (2020) [106] | Macroencapsulated PCM | Significant reduction in indoor temperature fluctuations, enhanced energy savings during peak load periods |

| Halimov et al. (2019) [107] | Latent heat storage model | Reduced primary energy consumption, operational costs, and CO2 emissions, contributing to sustainable practices |

| Souayfane et al. (2016) [108] | PCM for passive cooling | Helped maintain indoor thermal comfort without active cooling systems, saving energy and enhancing sustainability |

| Tyagi et al. (2020) [110] | Bio-based PCMs | Improved energy efficiency, reduced environmental impact, biodegradable, cost-effective for sustainable building solutions |

| Zhu et al. (2021) [111] | Microencapsulated PCM in concrete | Enhanced thermal mass and energy savings in buildings, improved durability of building materials |

| Zhang et al. (2022) [112] | Paraffin-based PCM in roof insulation | Reduced indoor temperature peaks, contributing to significant energy savings in hot climates |

| Sari and Karaipekli (2017) [113] | Nanoparticle-enhanced PCMs | Enhanced heat transfer, improved thermal energy storage capacity, reduced material degradation over multiple cycles |

| Huang et al. (2021) [114] | Organic PCMs incorporated into gypsum boards | Improved thermal regulation, better indoor air quality, and significant reduction in heating/cooling loads |

| Fan et al. (2017) [115] | Composite PCM with graphite | Improved thermal conductivity, faster energy storage and release, better temperature regulation in buildings |

5.6. Assessment of PCM-Incorporated Buildings

5.6.1. Thermal Performance Assessment

5.6.2. Energy Efficiency Analysis

5.6.3. Indoor Comfort Evaluation

5.6.4. Sustainability Assessment

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ürge-vorsatz, D.; Cabeza, L.F.; Serrano, S.; Barreneche, C. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- Morrey, H.S.; Ghosh, A. Energy assessment of gasochromic smart windows for a high-rise apartment block in a temperate climate. J. Build. Eng. 2024, 84, 108625. [Google Scholar] [CrossRef]

- Field, E.; Ghosh, A. Energy assessment of advanced and switchable windows for less energy-hungry buildings in the UK. Energy 2023, 283, 128999. [Google Scholar] [CrossRef]

- Mohammad, A.K.; Ghosh, A. Exploring energy consumption for less energy-hungry building in UK using advanced aerogel window. Sol. Energy 2023, 253, 389–400. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Urge-Vorsatz, D.; Petrichenko, K.; Staniec, M.; Eom, J. Energy use in buildings in a long-term perspective. Curr. Opin. Environ. Sustain. 2013, 5, 141–151. [Google Scholar] [CrossRef]

- Feng, G.; Sha, S.; Xu, X. Analysis of the Building Envelope Influence to Building Energy Consumption in the Cold Regions. Procedia Eng. 2016, 146, 244–250. [Google Scholar] [CrossRef]

- Iluyemi, D.C.; Nundy, S.; Shaik, S.; Tahir, A.; Ghosh, A. Building energy analysis using EC and PDLC based smart switchable window in Oman. Sol. Energy 2022, 237, 301–312. [Google Scholar] [CrossRef]

- Ghosh, A. Investigation of vacuum-integrated switchable polymer dispersed liquid crystal glazing for smart window application for less energy-hungry building. Energy 2023, 265, 126396. [Google Scholar] [CrossRef]

- Mirrahimi, S.; Mohamed, M.F.; Haw, L.C.; Ibrahim, N.L.N.; Yusoff, W.F.M.; Aflaki, A. The effect of building envelope on the thermal comfort and energy saving for high-rise buildings in hot-humid climate. Renew. Sustain. Energy Rev. 2016, 53, 1508–1519. [Google Scholar] [CrossRef]

- Gaetani, I. A Strategy for Fit-for-Purpose Occupant Behavior Modelling in Building Energy and Comfort Performance Simulation Modelling. Ph.D. Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 27 June 2019. [Google Scholar]

- Charles, A.; Maref, W.; Ouellet-Plamondon, C.M. Case study of the upgrade of an existing office building for low energy consumption and low carbon emissions. Energy Build. 2019, 183, 151–160. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Memon, R.A.; Bhayo, B.A. A critical review for formulation and conceptualization of an ideal building envelope and novel sustainability framework for building applications. Clean. Eng. Technol. 2022, 11, 100555. [Google Scholar] [CrossRef]

- Saffari Tabalvandani, M.; Gracia, A.D.; Ushak, S.; Cabeza, L.F. Economic impact of integrating PCM as passive system in buildings using Fanger comfort model. Energy Build. 2016, 112, 159–172. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, M.E.; Fernández Renna, A.I.; Cabeza, L.F. Improvement of the thermal inertia of building materials incorporating PCM. Evaluation in the macroscale. Appl. Energy 2013, 109, 428–432. [Google Scholar] [CrossRef]

- Zalba, B.; Marin, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 318–345. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Passive thermal control in residential buildings using phase change materials. Renew. Sustain. Energy Rev. 2016, 55, 371–398. [Google Scholar] [CrossRef]

- Farid, M.M.; Khudhair, A.M.; Razack, S.A.K.; Al-Hallaj, S. A review on phase change energy storage: Materials and applications. Energy Convers. Manag. 2004, 45, 1597–1615. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castell, A.; Barreneche, C.; De Gracia, A.; Fernández, A.I. Materials used as PCM in thermal energy storage in buildings: A review. Renew. Sustain. Energy Rev. 2011, 15, 1675–1695. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Castell, A.; Solé, C.; Medrano, M.; Roca, J.; Cabeza, L.F.; García, D. Natural convection heat transfer coefficients in Phase Change Material (PCM) modules with external vertical fins. Appl. Therm. Eng. 2010, 28, 1676–1686. [Google Scholar] [CrossRef]

- Al-Saadi, S.N. PHASE CHANGE MATERIALS FOR AUTONOMOUS ENERGY STORAGE IN BUILDINGS. In Proceedings of the 12th Conference of International Building Performance Simulation Association, Hyderabad, India, 7–9 December 2015; Available online: https://publications.ibpsa.org/proceedings/bs/2015/papers/bs2015_2965.pdf (accessed on 7 October 2024).

- Smith, J.; Johnson, L.; Gupta, R.; Brown, M. AMS Operative Temperature. In Van Nostrand’s Scientific Encyclopedia; Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 20, pp. 319–325. [Google Scholar]

- Simone, A.; Babiak, J.; Bullo, M.; Landkilde, G.; Olesen, B.W. Operative temperature control of radiant surface heating and cooling systems. In Proceedings of the Clima 2007 WellBeing Indoors, Helsinki, Finland, 10–17 June 2007; Seppaenen, O., Saeteri, J., Eds.; FINVAC: Helsinki, Finland, 2007; Volume 2, pp. 1–8. [Google Scholar]

- Saadatian, O.; Sopian, K.; Lim, C.H.; Asim, N.; Sulaiman, M.Y. Trombe walls: A review of opportunities and challenges in research and development. Renew. Sustain. Energy Rev. 2012, 16, 6340–6351. [Google Scholar] [CrossRef]

- Duan, S.; Jing, C.; Zhao, Z. Energy and exergy analysis of different Trombe walls. Energy Build. 2016, 126, 517–523. [Google Scholar] [CrossRef]

- Szyszka, J. From Direct Solar Gain to Trombe Wall: An Overview on Past. Energy Build. 2022, 15, 8586. [Google Scholar]

- Omrany, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy effciency in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Wang, X.; Xi, Q.; Ma, Q. A review of current work in research of Trombe walls. In E3S Web of Conferences, Proceedings of the 3rd International Conference on Civil Architecture and Energy Science, Hangzhou, China, 19–21 March 2021; EDP Sciences: Les Ulis, France, 2021; Volume 248, pp. 1–5. [Google Scholar]

- Du, Q. Phase change materials. In Storing Energy, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2022; Volume 2, ISBN 9781000772593. [Google Scholar]

- Koohi-Fayegh, S.; Rosen, M.A. A review of energy storage types, applications and recent developments. J. Energy Storage 2020, 27, 101047. [Google Scholar] [CrossRef]

- Cárdenas, B.; León, N. High temperature latent heat thermal energy storage: Phase change materials, design considerations and performance enhancement techniques. Renew. Sustain. Energy Rev. 2013, 27, 724–737. [Google Scholar] [CrossRef]

- Sarbu, I. Review on heat transfer analysis in thermal energy storage using latent heat storage systems and phase change materials. Int. J. Energy Res. 2018, 43, 1–36. [Google Scholar] [CrossRef]

- Baker, J. New technology and possible advances in energy storage. Energy Policy 2008, 36, 4368–4373. [Google Scholar] [CrossRef]

- Kumar, N.; Gupta, S.K.; Sharma, V.K. Application of phase change material for thermal energy storage: An overview of recent advances. Mater. Today Proc. 2021, 44, 368–375. [Google Scholar] [CrossRef]

- Yang, X.; Guo, Z.; Liu, Y.; Jin, L.; He, Y.L. Effect of inclination on the thermal response of composite phase change materials for thermal energy storage. Appl. Energy 2019, 238, 22–33. [Google Scholar] [CrossRef]

- Huang, X.; Zhu, C.; Lin, Y.; Fang, G. Thermal properties and applications of microencapsulated PCM for thermal energy storage: A review. Appl. Therm. Eng. 2019, 147, 841–855. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S.; Harikrishnan, S.; Elayaperumal, A. Sustainable thermal energy storage technologies for buildings: A review. Renew. Sustain. Energy Rev. 2012, 16, 2394–2433. [Google Scholar] [CrossRef]

- Zhou, Y.; Wu, S.; Ma, Y.; Zhang, H.; Zeng, X.; Wu, F.; Liu, F.; Ryu, J.E.; Guo, Z. Recent Advances in Organic/Composite Phase Change Materials for Energy Storage. ES Energy Environ. 2020, 9, 28–40. [Google Scholar] [CrossRef]

- Guarda, D.; Righetti, G.; Longo, G.A.; Zilio, C.; Mancin, S. Experimental assessment of low temperature phase change materials (PCM) for refrigerating and air conditioning applications. Int. J. Refrig. 2023, 154, 33–42. [Google Scholar] [CrossRef]

- Yang, L.; Jin, X.; Zhang, Y.; Du, K. Recent development on heat transfer and various applications of phase-change materials. J. Clean. Prod. 2020, 287, 124432. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Oró, E.; Miró, L.; Farid, M.M.; Cabeza, L.F. Thermal analysis of a low temperature storage unit using phase change materials without refrigeration system. Int. J. Refrig. 2012, 35, 1709–1714. [Google Scholar] [CrossRef]

- Du, X.; Wang, H.; Du, Z.; Cheng, X. Synthesis and thermal properties of novel solid-solid phase change materials with comb-polyurethane block copolymer structure for thermal energy storage. Thermochim. Acta 2017, 651, 58–64. [Google Scholar] [CrossRef]

- Pielichowska, K.; Pielichowski, K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Huang, J.; Luo, Y.; Weng, M.; Yu, J.; Sun, L.; Zeng, H.; Liu, Y.; Zeng, W.; Min, Y.; Guo, Z. Advances and Applications of Phase Change Materials (PCMs) and PCMs-based Technologies. ES Mater. Manuf. 2021, 13, 23–39. [Google Scholar] [CrossRef]

- Nie, B.; Palacios, A.; Zou, B.; Liu, J.; Zhang, T.; Li, Y. Review on phase change materials for cold thermal energy storage applications. Renew. Sustain. Energy Rev. 2020, 134, 513–533. [Google Scholar] [CrossRef]

- Jebasingh, B.E.; Arasu, A.V. A detailed review on heat transfer rate, supercooling, thermal stability and reliability of nanoparticle dispersed organic phase change material for low-temperature applications High density Polyethylene. Mater. Today Energy 2020, 16, 100408. [Google Scholar] [CrossRef]

- Huang, X.; Alva, G.; Jia, Y.; Fang, G. Morphological characterization and applications of phase change materials in thermal energy storage: A review. Renew. Sustain. Energy Rev. 2017, 72, 128–145. [Google Scholar] [CrossRef]

- Gasia, J.; Miró, L.; de Gracia, A.; Barreneche, C.; Cabeza, L.F. Experimental evaluation of a paraffin as phase change material for thermal energy storage in laboratory equipment and in a shell-and-tube heat exchanger. Appl. Sci. 2016, 6, 112. [Google Scholar] [CrossRef]

- Dincer, I. On thermal energy storage systems and applications in buildings. Energy Build. 2002, 34, 377–388. [Google Scholar] [CrossRef]

- Rathod, M.K.; Banerjee, J. Thermal stability of phase change materials used in latent heat energy storage systems: A review. Renew. Sustain. Energy Rev. 2013, 18, 246–258. [Google Scholar] [CrossRef]

- Sharma, A.; Won, L.D.; Buddhi, D.; Park, J.U. Numerical heat transfer studies of the fatty acids for different heat exchanger materials on the performance of a latent heat storage system. Renew. Energy 2005, 30, 2179–2187. [Google Scholar] [CrossRef]

- Al-Ahmed, A.; Mazumder, M.A.J.; Salhi, B.; Sari, A.; Afzaal, M.; Al-Sulaiman, F.A. Effects of carbon-based fillers on thermal properties of fatty acids and their eutectics as phase change materials used for thermal energy storage: A Review. J. Energy Storage 2021, 35, 102329. [Google Scholar] [CrossRef]

- Sahan, N.; Paksoy, H.O. Thermal enhancement of paraffin as a phase change material with nanomagnetite. Sol. Energy Mater. Sol. Cells 2014, 126, 56–61. [Google Scholar] [CrossRef]

- Sarier, N.; Onder, E. Organic phase change materials and their textile applications: An overview. Thermochim. Acta 2012, 540, 7–60. [Google Scholar] [CrossRef]

- da Cunha, S.R.L.; de Aguiar, J.L.B. Phase change materials and energy efficiency of buildings: A review of knowledge. J. Energy Storage 2020, 27, 101083. [Google Scholar] [CrossRef]

- Ghadim, H.B.; Shahbaz, K.; Al-Shannaq, R.; Farid, M.M. Binary mixtures of fatty alcohols and fatty acid esters as novel solid-liquid phase change materials. Int. J. Energy Res. 2019, 43, 8536–8547. [Google Scholar] [CrossRef]

- Wang, J.; Liu, F. Low-Cost, Robust Microcapsules of Phase Change Materials for Thermal Active Concrete Structures. In Proceedings of the Fourth International Conference on Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar] [CrossRef]

- Mofijur, M.; Meurah, T.; Mahlia, I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2007, 12, 1–20. [Google Scholar] [CrossRef]

- Gupta, B.; Bhalavi, J.; Sharma, S.; Bisen, A. Materials Today: Proceedings Phase change materials in solar energy applications: A review. Mater. Today Proc. 2020, 46, 5550–5554. [Google Scholar] [CrossRef]

- Oró, E.; De Gracia, A.; Castell, A.; Farid, M.M.; Cabeza, L.F. Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl. Energy 2012, 99, 513–533. [Google Scholar] [CrossRef]

- Calati, M.; Hooman, K.; Mancin, S. Thermal storage based on phase change materials (PCMs) for refrigerated transport and distribution applications along the cold chain: A review Accord du Transport Perissable. Int. J. Thermofluids 2022, 16, 100224. [Google Scholar] [CrossRef]

- Maranda, S.; Sponagle, B.; Worlitschek, J.; Groulx, D. Experimental Investigation of Thin PCM Packages and Thermal Spreader for Thermal Management of Portable Electronic Devices. Appl. Sci. 2019, 9, 4613. [Google Scholar] [CrossRef]

- Dhumal, A.R.; Kulkarni, A.P.; Ambhore, N.H. A comprehensive review on thermal management of electronic devices. J. Eng. Appl. Sci. 2023, 70, 1–18. [Google Scholar] [CrossRef]

- Hossain, T.; Shahid, M.A.; Ali, M.Y.; Saha, S.; Salman, M.S.I.; Habib, A. Fabrications, Classifications, and Environmental Impact of PCM- Incorporated Textiles: Current State and Future Outlook. ACS Omega J. 2023, 8, 45164–45176. [Google Scholar] [CrossRef] [PubMed]

- Niu, Z.; Yuan, W. Smart Nanocomposite Nonwoven Wearable Fabrics Embedding Phase Change Materials for Highly Efficient Energy Conversion−Storage and Use as a Stretchable Conductor. ACS Appl. Mater. Interfaces 2021, 13, 4508–4518. [Google Scholar] [CrossRef] [PubMed]

- Shukla, A.; Sharma, A.; Shukla, M.; Chen, C.R. Development of thermal energy storage materials for biomedical applications Development of thermal energy storage materials for biomedical applications. J. Med. Eng. Technol. 2015, 39, 363–368. [Google Scholar] [CrossRef] [PubMed]

- Prajapati, D.G.; Kandasubramanian, B. A review on Polymeric-Based Phase Change Material for Thermo-Regulating Fabric Application A review on Polymeric-Based Phase Change Material for Thermo-Regulating Fabric Application. Polym. Rev. 2019, 70, 1–31. [Google Scholar] [CrossRef]

- Faruk, M.O.; Ahmed, A.; Abdul, M.; Islam, M.T.; Mojnun, A.; Adak, B.; Hossain, M.; Mukhopadhyay, S. Functional textiles and composite based wearable thermal devices for Joule heating: Progress and perspectives. Appl. Mater. Today 2021, 23, 101025. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K. An experimental evaluation of thermal behavior of the building envelope using macroencapsulated PCM for energy savings. Renew. Energy 2020, 149, 1300–1313. [Google Scholar] [CrossRef]

- Zhang, B.; Yang, H.; Xu, T.; Tang, W.; Cui, H. Mechanical and Thermo-Physical Performances of Gypsum-Based Pcm Composite Materials Reinforced with Carbon Fiber. Appl. Sci. 2021, 11, 1–20. [Google Scholar] [CrossRef]

- Yang, L.; Liu, Y.; Qiao, Y.; Liu, J.; Wang, M. Building Envelope with Phase Change Materials. In Zero and Net Zero Energy; IntechOpen: Rijeka, Croatia, 2019; pp. 1–24. [Google Scholar]

- Abu-Hamdeh, N.H.; Melaibari, A.A.; Alquthami, T.S.; Khoshaim, A.; Oztop, H.F.; Karimipour, A. Efficacy of incorporating PCM into the building envelope on the energy saving and AHU power usage in winter. Sustain. Energy Technol. Assess. 2021, 43, 100969. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Vitorino, N.; Abrantes, J.C.; Frade, J.R. Quality criteria for phase change materials selection. Energy Convers. Manag. 2016, 124, 598–606. [Google Scholar] [CrossRef]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A review on phase change material application in building. Adv. Mech. Eng. 2017, 9, 1–15. [Google Scholar] [CrossRef]

- Ghosh, A. Diffuse transmission dominant smart and advanced windows for less energy-hungry building: A review. J. Build. Eng. 2023, 64, 105604. [Google Scholar] [CrossRef]

- Wijesuriya, S.; Tabares-Velasco, P.C. Empirical validation and comparison of methodologies to simulate micro and macro-encapsulated PCMs in the building envelope. Appl. Therm. Eng. 2021, 188, 116646. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Lin, K.P.; Yang, R.; Di, H.F.; Jiang, Y. Preparation, thermal performance and application of shape-stabilized PCM in energy efficient buildings. Energy Build. 2006, 38, 1262–1269. [Google Scholar] [CrossRef]

- Meng, D.; Zhao, K.; Wang, A.; Wang, B. Preparation and Properties of Paraffin/PMMA Shape-stabilized Phase Change Material for Building Thermal Energy Storage. J. Wuhan Univ. Technol. Sci. Ed. 2020, 35, 231–239. [Google Scholar] [CrossRef]

- Rakkappan, S.R.; Sivan, S.; Pethurajan, V.; Aditya, A.; Mittal, H. Preparation and thermal properties of encapsulated 1-Decanol for low- temperature heat transfer fluid application. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 614, 126167. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, G.; Lin, K.; Zhang, Q.; Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 2007, 42, 2197–2209. [Google Scholar] [CrossRef]

- Cárdenas-Ramírez, C.; Jaramillo, F.; Gómez, M. Systematic review of encapsulation and shape-stabilization of phase change materials. J. Energy Storage 2020, 30, 101495. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Alam, M.; Sanjayan, J.; Wilson, J. Parametric analysis for performance enhancement of phase change materials in naturally ventilated buildings. Energy Build. 2016, 124, 35–45. [Google Scholar] [CrossRef]

- Saffari, M.; De Gracia, A.; Fernández, C.; Cabeza, L.F. Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Appl. Energy 2017, 202, 420–434. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Li, D.; Zhou, Y.; Wang, Z.; Liu, X. Effect of PCM thickness and melting temperature on thermal performance of double glazing units. J. Build. Eng. 2017, 11, 87–95. [Google Scholar] [CrossRef]

- Li, Z.X.; Al-Rashed, A.A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. On the importance of the location of PCMs in building walls for enhanced thermal performance. Appl. Energy 2013, 106, 72–78. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. Numerical analysis for the optimal location of a thin PCM layer in frame walls. Appl. Therm. Eng. 2016, 103, 1057–1063. [Google Scholar] [CrossRef]

- Al-mudhafar, A.H.; Hamzah, M.T.; Tarish, A.L. Potential of integrating PCMs in residential building envelope to reduce cooling energy consumption. Case Stud. Therm. Eng. 2021, 27, 101360. [Google Scholar] [CrossRef]

- Kenisarin, M.M. Thermophysical properties of some organic phase change materials for latent heat storage. A review. Sol. Energy 2014, 107, 553–575. [Google Scholar] [CrossRef]

- Sari, A.; Karaipekli, A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl. Therm. Eng. 2007, 27, 1271–1277. [Google Scholar] [CrossRef]

- Jamil, N.; Kaur, J.; Pandey, A.K.; Shahabuddin, S.; Hassani, S.; Saidur, R.; Ali, R.R.; Sidik, N.A.C.; Naim, M. A review on nano enhanced phase change materials: An enhancement in thermal properties and specific heat capacity. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 57, 110–120. [Google Scholar]

- Brano, V.L.; Ciulla, G.; Piacentino, A.; Cardona, F. On the Efficacy of PCM to Shave Peak Temperature of Crystalline Photovoltaic Panels: An FDM Model and Field Validation. Energies 2013, 6, 6188–6210. [Google Scholar] [CrossRef]

- Aguayo, M.; Das, S.; Maroli, A.; Kabay, N.; Mertens, J.C.E.; Rajan, S.D.; Sant, G.; Chawla, N.; Neithalath, N. The influence of microencapsulated phase change material (PCM) characteristics on the microstructure and strength of cementitious composites: Experiments and finite element simulations. Cem. Concr. Compos. 2016, 73, 29–41. [Google Scholar] [CrossRef]

- Dabiri, S.; Mehrpooya, M.; Nezhad, E.G. Latent and sensible heat analysis of PCM incorporated in a brick for cold and hot climatic conditions, utilizing computational fluid dynamics. Energy 2018, 159, 160–171. [Google Scholar] [CrossRef]

- Pandey, B.; Banerjee, R.; Sharma, A. Coupled EnergyPlus and CFD analysis of PCM for thermal management of buildings. Energy Build. 2021, 231, 110598. [Google Scholar] [CrossRef]

- Ibanez, M.; Lázaro, A.; Zalba, B.; Cabeza, L.F. An approach to the simulation of PCMs in building applications using TRNSYS. Appl. Therm. Eng. 2005, 25, 1796–1807. [Google Scholar] [CrossRef]

- Karthick, A.; Kalidasa Murugavel, K.; Ghosh, A.; Sudhakar, K.; Ramanan, P. Investigation of a binary eutectic mixture of phase change material for building integrated photovoltaic (BIPV) system. Sol. Energy Mater. Sol. Cells 2020, 207, 110360. [Google Scholar] [CrossRef]

- Ahangari, M.; Maerefat, M. An innovative PCM system for thermal comfort improvement and energy demand reduction in building under different climate conditions. Sustain. Cities Soc. 2019, 44, 120–129. [Google Scholar] [CrossRef]

- Ehms, J.H.N.; Oliveski, R.D.C.; Rocha, L.A.O.; Biserni, C.; Garai, M. Phase Change Materials (PCM) for Building Envelope applications: A review of numerical models. In Proceedings of the 74th Conference of the Italian Thermal Machines Engineering Association (ATI), Modena, Italy, 11–13 September 2019. [Google Scholar]

- Cascone, Y.; Capozzoli, A.; Perino, M. Optimisation analysis of PCM-enhanced opaque building envelope components for the energy retrofitting of office buildings in Mediterranean climates. Appl. Energy 2018, 211, 929–953. [Google Scholar] [CrossRef]

- Feng, F.; Fu, Y.; Yang, Z.; O’Neill, Z. Enhancement of phase change material hysteresis model: A case study of modeling building envelope in EnergyPlus. Energy Build. 2022, 276, 112511. [Google Scholar] [CrossRef]

- Halimov, A.; Lauster, M.; Müller, D. Validation and integration of a latent heat storage model into building envelopes of a high-order building model for Modelica library AixLib. Energy Build. 2019, 202, 109336. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renew. Sustain. Energy Rev. 2020, 119, 109579. [Google Scholar] [CrossRef]

- Al-Rashed, A.A.A.A.; Alnaqi, A.A.; Alsarraf, J. Energy-Saving of Building Envelope Using Passive PCM Technique: A Case Study of Kuwait City Climate Conditions. Sustain. Energy Technol. Assess. 2021, 46, 101254. [Google Scholar] [CrossRef]

- Okogeri, O.; Stathopoulos, V.N. What about Greener Phase Change Materials? A Review on Biobased Phase Change Materials for Thermal Energy Storage Applications. Int. J. Thermofluids 2021, 10, 100081. [Google Scholar] [CrossRef]

- Zhu, L.; Dang, F.; Xue, Y.; Jiao, K.; Ding, W. Multivariate Analysis of Effects of Microencapsulated Phase Change Materials on Mechanical Behaviors in Light-Weight Aggregate Concrete. J. Build. Eng. 2021, 42, 102783. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, J.; Fang, X.; Ling, Z.; Zhang, Z. Optimal Roof Structure with Multilayer Cooling Function Materials for Building Energy Saving. Int. J. Energy Res. 2020, 44, 1594–1606. [Google Scholar] [CrossRef]

- Dsilva Winfred Rufuss, D.; Suganthi, L.; Iniyan, S.; Davies, P.A. Effects of Nanoparticle-Enhanced Phase Change Material (NPCM) on Solar Still Productivity. J. Clean. Prod. 2018, 192, 9–29. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Incorporation of Phase Change Materials into Building Envelope for Thermal Comfort and Energy Saving: A Comprehensive Analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Khushnood, S.; Jabbal, M. Experimental Investigation of PCM Based Round Pin-Fin Heat Sinks for Thermal Management of Electronics: Effect of Pin-Fin Diameter. Int. J. Heat Mass Transf. 2018, 117, 861–872. [Google Scholar] [CrossRef]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance assessment of phase change material integrated cementitious composites in buildings: Experimental and numerical approach. Appl. Energy 2017, 207, 654–664. [Google Scholar] [CrossRef]

- Uriarte, I.; Erkoreka, A.; Giraldo-soto, C.; Martin, K.; Uriarte, A.; Eguia, P. Mathematical development of an average method for estimating the reduction of the Heat Loss Coefficient of an energetically retrofitted occupied office building. Energy Build. 2019, 192, 101–122. [Google Scholar] [CrossRef]

- Souayfane, F.; Biwole, P.H.; Fardoun, F.; Achard, P. Energy performance and economic analysis of a TIM-PCM wall under different climates. Energy 2019, 169, 1274–1291. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings’ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2020, 33, 101913. [Google Scholar] [CrossRef]

- Nienborg, B.; Gschwander, S.; Munz, G.; Fröhlich, D.; Helling, T.; Horn, R.; Weinläder, H.; Klinker, F.; Schossig, P. Life Cycle Assessment of thermal energy storage materials and Life Cycle Assessment of components thermal energy storage materials and a Assessing feasibility of heat temperature function for district heat Pina. Energy Procedia 2018, 155, 111–120. [Google Scholar] [CrossRef]

- Rahimi, M.; Tajbakhsh, K. Reducing temperature stratification using heated air recirculation for thermal energy saving Wall-2. Energy Build. 2011, 43, 2656–2661. [Google Scholar] [CrossRef]

| Cluster 1 (Red) | Cluster 2 (Blue) | Cluster 3 (Green) |

|---|---|---|

| Thermal Energy Storage | Energy Efficiency | Building Envelope |

| Phase Change Material (PCM) | Renewable Energy | Insulation |

| Latent Heat | Energy Consumption | Thermal Comfort |

| Melting Point | Energy Saving | Heat Transfer |

| Solidification | Sustainable Building | Thermal Conductivity |

| Heat Capacity | Energy Performance | Passive Design |

| Encapsulation | Smart Materials | Temperature Regulation |

| PCM Integration | Energy Management | Building Materials |

| Thermal Regulation | Environmental Impact | Construction Techniques |

| Energy Optimization | Energy Policy | Durability |

| Property | Thermal Characteristics | Chemical Characteristics | Economics |

|---|---|---|---|

| Melting Point | Within the preferred operating temperature range | Stable chemical structure within operating temperature | Lower energy costs due to optimal temperature range |

| Latent Fusion Heat Capacity | High latent fusion heat capacity per volume | Consistent phase change properties over multiple cycles | Reduces the amount of material needed, lowering costs |

| Specific Heat Capacity | High specific heat capacity for significant additional sensible heat storage | Chemical stability under varying thermal loads | Enhances energy efficiency, reducing operational costs |

| Thermal Conductivity | Both solid and liquid phases have high thermal conductivity | Non-reactive with encapsulating materials | Minimizes material degradation, reducing replacement costs |

| Vapor Pressure | Minimal vapor pressure at operating temperature and minimal volume change during phase transformation | Non-volatile, ensuring safety and longevity | Low maintenance costs due to stability |

| Uniform Melting/Freezing | Uniform melting and freezing points, maintaining the material’s storage capacity | Consistent phase change temperatures | Reliability reduces operational disruptions |

| Reversibility | Ensures efficient thermal energy storage and release | Full reversible cycle of freezing and melting | Long-term cost savings through reusable cycles |

| Durability | Long-term thermal stability | No deterioration even after numerous freeze/melt cycles | Reduces replacement frequency, saving costs |

| Non-corrosive | Compatible with thermal systems | The materials used in construction and encapsulation are not corrosive | Low maintenance and replacement costs |

| Safety | Safe under operating conditions | Not explosive, flammable, or toxic | Reduces safety management costs |

| Availability | Widely available for various applications | Chemical composition easily sourced | Abundantly available and reasonably priced |

| Treatment and Recycling | Easily integrated into existing systems | Simple chemical treatment and recycling processes | Simple treatment and recycling |

| Environmental Performance | Environmentally friendly thermal properties | Non-toxic and environmentally safe | Good environmental performance based on life cycle assessment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jha, S.K.; Sankar, A.; Zhou, Y.; Ghosh, A. Incorporation of Phase Change Materials in Buildings. Constr. Mater. 2024, 4, 676-703. https://doi.org/10.3390/constrmater4040037

Jha SK, Sankar A, Zhou Y, Ghosh A. Incorporation of Phase Change Materials in Buildings. Construction Materials. 2024; 4(4):676-703. https://doi.org/10.3390/constrmater4040037

Chicago/Turabian StyleJha, Subodh Kumar, Advaith Sankar, Yue Zhou, and Aritra Ghosh. 2024. "Incorporation of Phase Change Materials in Buildings" Construction Materials 4, no. 4: 676-703. https://doi.org/10.3390/constrmater4040037

APA StyleJha, S. K., Sankar, A., Zhou, Y., & Ghosh, A. (2024). Incorporation of Phase Change Materials in Buildings. Construction Materials, 4(4), 676-703. https://doi.org/10.3390/constrmater4040037