Abstract

This paper investigates the viability of using a commercially available liquid polymer (LP) in lieu of ordinary cement to stabilize soil during rammed earth (RE) construction. The scope of this study includes modifying and testing the locally available natural soil with two different LPs at various percentages. Once the optimum moisture content (OMC) of the soil with LPs was determined using the Proctor test, test samples were prepared by chemical and mechanical stabilizations. Following the curing process in an unconfined open-air laboratory environment for 7 days, soil samples were tested to determine the unconfined compressive strength (UCS) and California bearing ratio (CBR) values. The results demonstrate that the lubrication effect of polymers is different than that of water. The first polymer type yields a lower OMC compared to water, while the second polymer achieves a higher OMC. The CBR and UCS values of polymer-stabilized soils are improved for both polymer types at all dosages. The CBR values of polymer-modified soils showed as high as a 10-times improvement compared to Portland cement (PC) stabilization. A similar trend is observed for the UCS results as well. The UCS value of polymer-stabilized soils reached over 1900 psi (13 MPa), which was over 3-times higher than the UCS of PC-stabilized soil.

1. Introduction

Earthen construction is ubiquitous. It is estimated that at least 30% of the world’s population lives in some kind of earthen building [1]. Earthen construction implies a variety of methods, including cob, adobe, wattle, and daub. Another technique, rammed earth (RE) has a history dating back millennia. For example, the walls of the Pingliangtai settlement are over 4000 years old [2]. Due to readily available and inexpensive material stocks, and the relative simplicity of the technique [3], RE construction methods continue to be widely used throughout the developing world; although, the inconsistent enforcement of building codes and the common practice of folk building techniques in these areas often results in less-than-desirable outcomes [4].

Recently, RE construction methods have regained some popularity in the area of sustainability, since the materials are comparatively inexpensive, largely inert, locally sourced [5], and well suited for the integration of alternative materials, such as lime [6,7], guar gum, and fiberglass [8]; waste materials and industrial by-products, such as fly ash [9,10]; or mixtures of these [11,12,13,14,15,16,17]. Additionally, RE has a comparatively low embodied energy level [18,19]. Alternative admixtures have also been studied as stabilizers in historical masonry, including polyvinyl alcohol, polypropylene, chopped basalt, carbon fiber, and copper-coated stainless steel, with polyvinyl alcohol and copper-coated stainless-steel fiber samples yielding promising results [20].

Often, RE is used for structural purposes, but this material has fundamental mechanical limitations [21]. Consequently, RE is often stabilized with Portland cement (PC) and referred to as cement-stabilized rammed earth (CSRE). The integration of PC detracts from the environmental profile of the material considerably, as the production of clinker (the raw materials of PC) is extremely energy- and water-intensive, accounting for 9% of global industrial water consumption [22], and 5% of greenhouse gas emissions each year [23], hence the appeal of alternative stabilizers.

While RE construction techniques have a long history, the mechanical properties of the technique are not perfectly understood. Soil selection [24,25,26], mixing procedures, compaction effort, and aspect ratio [27] are of utmost importance, and variations from site to site necessitate a more consistent process and quality control [28]. The unconfined compressive strength of samples is often used as an indicator of the vertical load-carrying capacity of RE, with noted variations in local soil samples [29]. To this end, it has been determined that stabilized rammed earth specimens have higher shear and energy dissipation capacities, but a weaker deformation capacity than un-stabilized rammed earth [30].

From a practical standpoint, RE construction techniques involve the vigorous compaction of a soil matrix within a formwork assembly. However, it should be noted that Raju and Venkatarama searched for ways to minimize the need for such a vigorous compaction with the use of plasticizers [31]. More generally, compaction is performed in several lifts, and soils with a relatively high (upward of 20%) cohesive clay content are preferred. Samples have been recorded with unconfined compressive strengths in the range of 150 to 1500 psi, or 1 to 10.15 MPa [32]. Generally, samples with higher unconfined compressive strengths have been “stabilized” with Portland cement, another additive, or combinations of these. Even though it is very limited, some researchers studied the use of polymers in RE construction. Lu et al. examined the use of polymers in the restoration of aging and weathered monuments [33]. Additional studies have focused on the use of biopolymers, such as lignin sulfonate, tannin, sheep wool fibers, citrus pomace, and grape-seed flour, with wool, lignin sulfate, and tannin exhibiting improvements to the unconfined compressive strength of samples [34]. As the use of polymers in the construction industry increases, this study can provide a better understanding of the use of so-called liquid polymers in RE construction.

2. Objectives and Scope

One of the objectives of this research was to examine the viability of commercially available “so-called” liquid polymers (LPs) in RE construction. Another objective was to investigate the impact of compaction effort on the polymer modification of RE. Yet, another objective was to check the suitability of the local soil for RE construction. For this purpose, soil local to Panhandle Florida and South Alabama was used as the virgin/base material. The samples were prepared at different ratios of water, PC, and two types of LPs as stabilizers. The impact of LP percent on the California bearing ratio (CBR) and unconfined compressive strength was investigated, as well as the effect of compaction on the compressive strength. The impact of compaction effort was studied using readily available standard and modified Proctor laboratory equipment, which correlated well with the field without additional equipment. To gain a broader perspective of the mechanical properties and to achieve the objectives, the following analyses were conducted on original and modified soil samples.

- Sieve and hydrometer analyses for gradation.

- Atterberg limit determination.

- AASHTO and USCS soil classifications.

- Standard Proctor.

- California bearing ratio.

- Unconfined compressive strength.

- Impact of compaction effort on rammed earth.

3. Materials and Methods

3.1. Soil Properties and Gradation

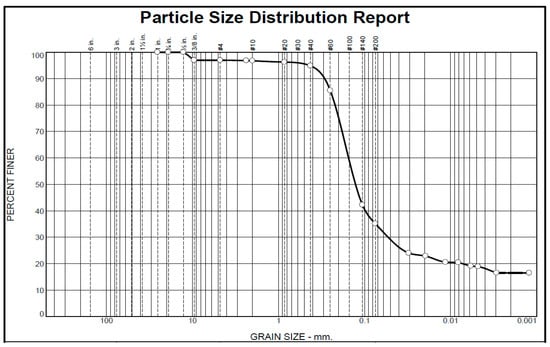

The soil used in this research was native to Panhandle Florida and South Alabama, USA. It has a distinctive grayish-yellow appearance with a high amount of fines. To determine the soil classification, a mechanical gradation of the soil was performed. Since the soil sample had a high percentage of fines, a hydrometer test was conducted to further determine the distribution of particle sizes smaller than 0.075 mm by the sedimentation process. The gradation of the soil was performed as per ASTM D 422 [35]. Figure 1 illustrates the particle size distribution graph created from the mechanical gradation and hydrometer analysis of the soil.

Figure 1.

Particle size distribution graph of virgin soil.

Once the gradation of the soil was established, Atterberg limits tests were conducted to determine the liquid limit, plastic limit, and plasticity index of finer particles. The ASTM D 4318 standard was followed to determine the Atterberg limits [36]. Based on the results of the gradation and Atterberg limits tests, the soil was classified as silty sand (SM) according to the unified soil classification system (USCS) and A-2-4 according to the AASHTO soil classification system. The specific gravity of the soil was also determined by the water pycnometer method as per the ASTM D 854 standard [37].

3.2. Liquid Polymers and Portland Cement

The liquid polymers used in this study were commercially available polyurethanes with the chemical name diphenylmethane di-isocyanates. Since they were patented products, only certain information was available. Some of the chemical and physical properties provided by the manufacturer are given in Table 1. They are used to improve the material rheology, enhance the strength of construction materials, provide water barrier/waterproofing, coat the construction materials for protection, and deliver economical alternatives to various construction materials. The Portland cement used in this study as a soil stabilizer was an ordinary type I/II PC. It was only used at 4% by the weight of the soil mixture as per common practice in the field.

Table 1.

Properties of liquid polymers.

4. Sample Preparation and Performance Tests

4.1. Modified Proctor Test

A modified Proctor (MP) test was conducted to determine the optimum moisture content (OMC) and maximum dry density (MDD) of the virgin, PC-stabilized, and polymer-stabilized soil samples as per ASTM D 1557 [38]. Since the lubrication effects of water and liquid polymers were different, each stabilized soil was tested to discover the OMC and MDD values. Liquid polymers used in this study behaved differently to each other during the modified Proctor test. While liquid polymer#1 (LP1) stabilization yielded a lower OMC compared to water, modification with liquid polymer#2 (LP2) resulted in a higher OMC than water. To find the measured moisture content of the polymer-stabilized soil mixes, the polymer amount had to be removed mathematically since the polymer did not evaporate completely in the forced-air draft oven as in the case of water as a lubricant. Moreover, the results of the mathematical calculations were confirmed using an ignition oven where the polymer was completely burnt.

4.2. California Bearing Ratio Test

California bearing ratio (CBR) tests of the virgin, PC-stabilized, and liquid polymer-stabilized soil samples were performed as per the ASTM D 1883 standard [39]. In simple terms, the CBR of a material can be defined as a ratio of stress required to penetrate a 3-inch area plunged 0.1 inches (or 0.2″) into the soil sample divided by the stress needed to penetrate the same plunge 0.1 inches (or 0.2″) into standard crushed rock after conditioning under water for 4 days and a surcharge of 10 lbs. The CBR test was conducted at an OMC for all virgin and stabilized soil samples. In addition, another set of CBR tests was performed at an OMC +2% for polymer-stabilized soil samples. While the CBR at 95% MDD was only tested for water samples, more CBR tests were conducted for all soil samples at higher compaction levels to observe the impact of mechanical densification.

4.3. Unconfined Compressive Strength Test

Unconfined compression strength (UCS) tests were conducted on virgin, PC-stabilized, and liquid polymer-stabilized soil samples as well. The UCS test was performed as per ASTM D 2166 [40]. There were two sets of UCS samples tested. Both sets were prepared at OMC-MDD values obtained from the MP test. In addition, the polymer-stabilized samples were prepared at a different LP content than OMC to observe the impact of changing the polymer content. The first set of soil samples was manufactured using a modified Proctor apparatus and compacted as per standard specifications. The second set of samples was prepared by increasing the compaction numbers per layer. The goal of manufacturing and testing two sets of soil samples at different compaction levels was to observe the effect of mechanical compaction on the polymer-stabilized soil samples since the compaction effort is the key to RE construction. Soil samples were cured for 7 days in an open-air environment after they were extruded from the molds following the 24 h in-mold conditioning time. The reason for selecting a 7-day curing duration was mainly to determine the rapid strength gain properties of RE construction with polymer stabilization since this would allow for providing faster RE housing when needed, instead of waiting long periods for cement stabilization. The samples had an approximate diameter-to-height ratio of 0.5. Once the soil samples were extruded from the molds, they were maintained in a room with a temperature of 77 ± 3 °F and 40 ± 5% relative humidity (RH). At least 3 samples were tested to ensure the repeatability of the soil modification and testing. The average value of replicates was calculated and recorded as the USC value of the virgin or stabilized soil mixtures. The soil samples experienced almost no shrinkage cracks during open-air environment curing. This could be attributed to the relatively high RH value in the environment.

5. Results and Discussions

The results of the basic property tests, including sieve analysis, hydrometer, specific gravity, and Atterberg limits, and performance tests, including modified Proctor, California bearing ratio, and unconfined compression strength, are discussed in this section. A mechanical sieve analysis was conducted to discover the particle size distribution of the soil. A total of 100% of the soil passed through the #4 sieve and only approximately 5% was retained in the #40 sieve. Fine sand composed nearly 60% of the soil, while almost 35% was silt and clay. To further assess the particle size distribution of soil passing through a #200 sieve, a hydrometer analysis was performed to determine silt (particle sizes between 0.075 and 0.002 mm) and clay (particle sizes smaller than 0.002 mm) fractions of the soil. The results show that around 19% of the soil is clay and 16% of it is silt. Even though the clay portion of the soil was slightly less compared to common RE soil types, no adjustments were performed to the gradation to check the suitability of local soil for RE construction. Table 2 summarizes the findings of the gradation, specific gravity, Atterberg limits, and soil classification tests. The specific gravity of the soil was determined using a water pycnometer. The specific gravity of the soil was found to be 2.65. Plastic limit and liquid limit tests of the soil were conducted on the soil with water and liquid polymers. The results reveal that there are no considerable changes in the plastic and liquid limits.

Table 2.

Gradation summary, classification, specific gravity, and Atterberg limits.

5.1. Modified Proctor Test and Compaction Effort

A modified Proctor test was performed to find the OMC and MDD of virgin and stabilized soils. While the virgin and PC-stabilized soil had OMCs of 10.3% and MDDs of 121.8 pcf (1951 kg/m3), these values were 5.9% and 113 pcf (1810 kg/m3) for the LP1 stabilization and 14.4% and 112.8 pcf (1807 kg/m3) for the LP2 stabilization, respectively. Table 3 summarizes the modified Proctor test results in a tabular form. It was observed that the maximum dry densities of both LP1- and LP2-modified soils were almost equal and approximately 7.5% less than the maximum dry density of water.

Table 3.

Modified Proctor test results.

The MP test was performed using mechanical compaction equipment capable of dropping a 10 lb hammer from an 18-inch free-fall height. The same equipment was used to compact Proctor, CBR, and UCS samples. While the compaction of the first set of CBR and UCS samples followed the standards, the second set of samples was compacted at a higher compaction rate to investigate the impact of the compaction level, which is critical for RE construction. The second set of samples was densified using the same mechanical Proctor compaction equipment and compacted them at 5 layers and 75 blows per layer, which yielded approximately a three-greater more compaction effort than the first set of samples.

5.2. California Bearing Ratio Results

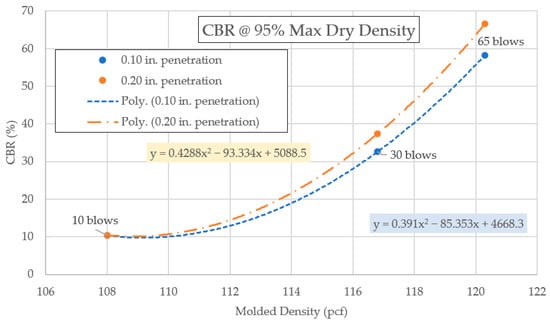

California bearing ratio tests were conducted on virgin, PC-stabilized, and two different liquid polymer-stabilized soil samples for both ordinary and high-level compaction efforts. CBR tests of virgin and PC-stabilized soils were performed at a 10.3% optimum moisture content and 121.8 pcf (1951 kg/m3) maximum dry density for both compaction levels. Moreover, the CBR at a 95% maximum dry density for the virgin soil was also conducted and it was calculated as 27.1% for a 0.10 in (2.54 mm) penetration and 29.9% for a 0.2 in (5.08 mm) penetration.

While the results of the CBR tests are provided in Table 4, the percent CBR versus molded density graphs are presented in Figure 2. The CBR tests for polymer-stabilized soils were conducted at three different polymer contents. The first polymer content was selected as the optimum moisture content obtained from the modified Proctor test, while the second polymer content was taken as the optimum moisture content obtained from the modified Proctor test plus 2% by the weight of dry soil. The third liquid polymer content was chosen as the optimum moisture content of water, which was 10.3%. The goal of selecting the third polymer content at an OMC of water was to obtain a common base for all the prepared samples, as is generally conducted in the literature.

Table 4.

CBR at 95% maximum dry density results for virgin soil.

Figure 2.

CBR% versus molded density graph.

As stated in Table 3, the OMC for the first liquid polymer type was obtained at 5.9% and the second polymer type was 14.4%. Thus, the CBR samples for LP1 stabilization were prepared at 5.9%, 7.9%, and 10.3%, while the CBR samples for the LP2 modification were produced at 10.3%, 14.4%, and 16.4% polymer contents.

While those samples were compacted as per the corresponding standards, another set of CBR samples for the virgin and stabilized soils was prepared just at OMC-MDD values with a higher level of compaction, as explained in detail in the previous section. The results of the CBR tests are provided in Table 5.

Table 5.

CBR values of virgin and stabilized soil samples at different compaction levels.

The results show that any chemical and mechanical stabilizations increase the CBR value. Since the common practice for RE construction has been to incorporate Portland cement into the soil, PC stabilization was selected as the control group in this study, and polymer stabilizations were compared with it. As the LP1 content was increased, the CBR values improved as well up to a level and then started to decrease. This can be explained by the increased liquidity of the samples well above the OMC. The increase in the CBR value from OMC to a 7.9% polymer content was over 100%. It was observed that LP1 worked the best and made the soil very cohesive, slightly on the wet side. LP2 stabilization was also better than PC stabilization at any polymer content. The CBR values improved with the increasing polymer content at both deflection measurements. However, the LP2 modifications did not yield results as good as the LP1 modifications. At the higher compaction level, the CBR values showed even better improvements. While the CBR of the PC stabilization almost doubled with a greater compaction effort, it increased by approximately five times for the LP1 stabilization and over 800% for the LP2 stabilization at their OMC levels. Although the LP1 stabilization yielded higher CBR values at the ordinary compaction level, LP2 outperformed any other stabilization at a higher compaction level. This implies that the CBR of the liquid polymer-modified soil can show different performances at different compaction levels. The increase in the CBR value of the soil with the addition of the polymers complies with the findings of the previous researchers [41,42].

5.3. Unconfined Compressive Strength Results

Unconfined compressive strength tests were performed on the same CBR test soil mixture ratios, other than LP1-10.3%, at both compaction levels. The reason for omitting the LP1-10.3% soil was the drop in value it experienced after CBR testing. UCS test samples were prepared in the Proctor molds and kept in the molds for 24 h. Once the confinement period was over, the samples were extruded and cured in an open-air environment for 7 days prior to testing. After the curing period, it was visually observed that the polymer-stabilized samples did not have any shrinkage cracks, while there were negligible surface cracks in the virgin and PC-stabilized soil samples.

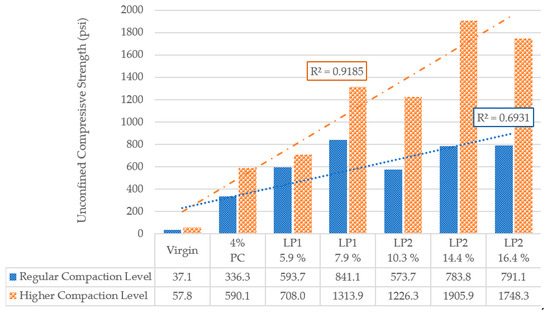

The results of the UCS test are provided in Figure 3. It was observed that any polymer-stabilized soil performed better than the virgin and PC-stabilized soils. Regardless of the stabilization and stabilization type, the UCS values of any soil sample enhanced as the compaction effort increased. The impact of compaction level was more dominant for LP2 polymer-stabilized soils. While the UCS values of virgin and PC-stabilized soils improved by approximately 56% and 75% with the higher compaction level, those of LP1 and LP2 increased on average by 38% and 126%, respectively. The maximum strength gain was obtained for the LP1-7.9% stabilization achieving 841.1 psi at a regular compaction level, and with LP2 at a 14.4% stabilization achieving 1905.9 psi (13.1 MPa) at a higher compaction level.

Figure 3.

UCS values of virgin and stabilized soils at regular and high compaction levels.

At the regular compaction level, both polymer types progressively improved the UCS value as the polymer content increased. While the UCS for LP1 at 5.9% was 593.7 psi (4.1 MPa), which was 77% stronger than the PC stabilization, the value for LP1 at 7.9% was 841.1 psi (5.8 MPa), which was 150% stronger than the regular PC stabilization and 42% stronger than LP1 at 5.9%. Similarly, LP2 achieved a UCS of 573.7 psi (5.2 MPa) at 10.3%, 783.8 psi (5.4 MPa) at 14.4%, and only 791.1 psi (5.45 MPa) at 16.4% polymer content. At the higher compaction level, the improvement of the UCS values followed a similar trend to that of a regular compaction level other than the LP2-16.4% stabilization. LP1 at 5.9% improved the UCS by 20%, whereas LP1 at 7.9% enhanced by 123% compared to the PC stabilization at the higher compaction level. Likewise, LP2 achieved a UCS of 1226.3 psi (8.45 MPa) at 10.3%, 1905.9 psi (13.1 MPa) at 14.4%, and 1748.3 psi (12.1) at a 16.4% polymer content. When the UCS results are compared at regular and higher compaction levels, the LP2 polymer provides better UCS values than the LP1 polymer at the higher compaction level. The change in the UCS for LP2 at 14.4% compared to PC stabilization at a higher compaction level was 223% higher in favor of polymer modification. Even though the LP2-16.4% stabilization was expected to exceed all LP2 modifications due to its higher polymer content, the UCS value was approximately 8% less than that of the LP2-14.4% stabilization. This can be explained by not allowing enough curing time for the moisture to evaporate and full polymerization to be completed. This phenomenon was observed by several researchers as well. Kolay et al. and Geiman et al. observed that the moisture of the polymer-stabilized soil samples cured in a confined environment was not able to evaporate properly. This resulted in no significant strength gain by preventing the bonding process during polymerization [43,44]. Hence, the curing time and curing conditions have a vital role in the strength gain of polymer-stabilized soils.

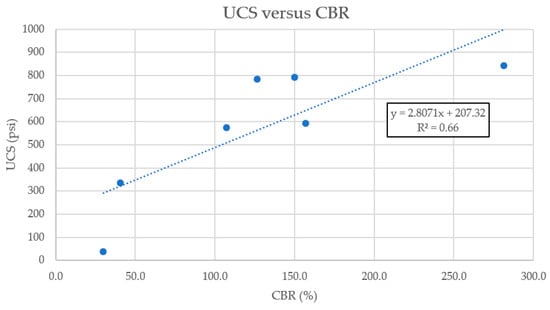

Since the CBR value is commonly used as a strength parameter for most virgin and modified soils by geotechnical and road/highway engineers, the correlation between the CBR and UCS values is constructed and provided in Figure 4. It should be noted that the correlation is provided to present an overall idea about the relationship between UCS and CBR values and to compare the findings of this research work with previous studies, even though the dataset is very limited to draw solid conclusions. The positive linear correlation between CBR and UCS results with R2 = 66% complies with the findings of researchers in the literature. Saputra et al. found a similar positive correlation between UCS and CBR values with an R2 value of 0.92 [45]. The correlation is only established for a regular compaction level since it is the common practice.

Figure 4.

UCS versus CBR values for virgin and stabilized soils.

6. Conclusions and Discussions

While the main goal of this study was to examine the viability of commercially available “so-called” liquid polymers in RE construction, the other objectives were to investigate the impact of compaction effort on the polymer and to check the suitability of the local soil for RE construction. The following conclusions can be drawn from the findings of this experimental study.

- The OMC of soils changed with the use of different lubricants. The OMC of soil was 10.3% with water. The first LP resulted in a lower OMC than the water with only a 5.9% polymer content; the second LP attained a higher OMC than water with a 14.4% polymer content.

- Although the OMCs of the polymer-modified soils showed a significant difference, the MDD values were almost the same with less than a 0.2% difference. The impact of compaction on the polymer stabilization of soil was determined with two different levels of compaction, namely, regular and higher compaction levels. As the compaction level increased, both the CBR and UCS values enhanced for all soil samples tested.

- The polymer stabilization of the soil improved the CBR values, regardless of the polymer type and content. In general, the highest CBR value was obtained at 0.2 in penetration. The first LP stabilization at 2% more than OMC achieved almost a 281% CBR value compared to about the 41% CBR achieved by a 4% PC stabilization.

- Each polymer stabilization achieved over a 100% CBR at a regular compaction level. Moreover, the second liquid polymer stabilization achieved a CBR value of over 1000% at the higher compaction level.

- The UCS values of any polymer-stabilized soil samples showed an improvement. The first LP stabilization improved the UCS of the soil by around 77% at its optimum moisture content when compared to the PC stabilization. The improvement was more pronounced for the second LP stabilization at its OMC. The UCS of a 14.4% stabilization with the second LP was enhanced by 133% compared to the same PC-stabilized soil.

- The improvement of the UCS was higher at the higher compaction level for the second polymer type with a 223% increase in strength. However, the improvement at a higher compaction level was not as good for the first polymer type. It only achieved approximately a 20% better unconfined compressive strength than the control stabilization. This implied that the second polymer type was a better alternative than the first one at a higher compaction level in terms of the CBR and UCS values.

- A positive linear correlation between the CBR and UCS results with R2 = 66% was achieved with a limited dataset.

7. Limitations and Future Work

This research study had some limitations. One of them was the use of a single-source soil native to Panhandle, FL. Another limitation was the use of commercially available “so-called” liquid polymers with limited production and performance information. The data collected were also limited to a single soil type and two liquid polymers. The statistical data analysis was performed using these limited data. This research study suggests the use of different soil types and liquid polymers, especially bio-engineered ones, which are environmentally sustainable and friendly. In addition, different levels of compaction efforts should be investigated and quantified to improve RE construction.

Author Contributions

Conceptualization, visualization, methodology, data curation, data analysis, formal analysis, writing—original draft preparation, writing—review and editing: S.K.; writing—introduction: A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank Southern Earth Sciences (SES) laboratories for their support and assistance during the testing of the samples.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| UCS | Unconfined compressive strength |

| OMC | Optimum moisture content |

| CSRE | Cement-stabilized rammed earth |

| MP | Modified Proctor |

| MDD | Maximum dry density |

| LP | Liquid polymer |

| LP1(2) | Liquid polymer 1(2) |

| RE | Rammed earth |

| PC | Portland cement |

| SM | Silty sand |

| RH | Relative humidity |

| USCS | Unified soil classification system |

| ASTM | American Society for Testing and Materials |

| AASHTO | American Association of Highway and Transportation Officials |

References

- Keefe, L. Earth Building Methods & Materials, Repair & Conservation; Taylor & Francis: London, UK, 2005; p. 7. [Google Scholar]

- Jaquin, P.A.; Augarde, C.; Gerrard, C.M. A chronological description of the spatial development of rammed earth techniques. Int. J. Archit. Herit. 2008, 2, 377–400. [Google Scholar] [CrossRef]

- McHenry, P.G. Adobe, and Rammed Earth Building: Design and Construction; John Wiley and Sons: New York, NY, USA, 1984. [Google Scholar]

- Gautam, D.; Chaulagain, H. Structural performance and associated lessons to be learned from world earthquakes in Nepal after 25 April 2015 (MW 7.8) Gorkha earthquake. Eng. Fail. Anal. 2016, 68, 222–243. [Google Scholar] [CrossRef]

- Lovec, V.B.; Jovanovic-Popovic, M.D.; Zivkovic, B.D. The Thermal Behaviour of Rammed Earth Wall in Traditional House in Vojvodina: Thermal Mass as a Key Element for Thermal Comfort. Therm. Sci. 2018, 22, 1143–1155. [Google Scholar] [CrossRef]

- Ciancio, D.; Beckett, C.T.S.; Carraro, J.A.H. Optimum lime content identification for lime-stabilized rammed earth. Constr. Build. Mater. 2014, 53, 59–65. [Google Scholar] [CrossRef]

- Martin-del-Rio, J.J.; Canivell, J.; Falcon, R.M. The use of non-destructive testing to evaluate the compressive strength of a lime-stabilized rammed-earth wall: Rebound index and ultrasonic pulse velocity. Constr. Build. Mater. 2020, 242, 118060. [Google Scholar] [CrossRef]

- Toufigh, V.; Kianfar, E. The effects of stabilizers on the thermal and the mechanical properties of rammed earth at various humidities and their environmental impacts. Constr. Build. Mater. 2019, 200, 616–629. [Google Scholar] [CrossRef]

- Saranya, R.S.; Sharma, A.K.; Anand, K.B. Performance appraisal of coal ash stabilized rammed earth. J. Build. Eng. 2018, 18, 51–57. [Google Scholar]

- Islam, M.S.; Elahi, T.E.; Shahriar, A.R.; Mumtaz, N. Effectiveness of fly ash and cement for compressed stabilized earth block construction. Constr. Build. Mater. 2020, 255, 119392. [Google Scholar] [CrossRef]

- Da Rocha, C.G.; Consoli, N.C.; Johan, A.D.R. Greening stabilized rammed earth: Devising more sustainable dosages based on strength controlling equations. J. Clean. Prod. 2014, 66, 19–26. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilized rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Radwan, M.K.H.; Lee, F.W.; Woon, Y.B.; Yew, M.K.; Mo, K.H.; Wai, S.H. A Study of the Strength Performance of Peat Soil: A Modified Cement-Based Stabilization Agent Using Fly Ash and Polypropylene Fiber. Polymers 2021, 13, 4059. [Google Scholar] [CrossRef] [PubMed]

- Darsi, B.P.; Molugaram, K.; Madiraju, S.V.H. Subgrade Black Cotton Soil Stabilization Using Ground Granulated Blast Furnace Slag (GGBS) and Lime, an Inorganic Mineral. Environ. Sci. Proc. 2021, 6, 15. [Google Scholar]

- Siddiqua, S.; Barreto, P.N.M. Chemical stabilization of rammed earth using calcium carbide residue and fly ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Gomes, M.I.; Faria, P.; Goncalves, T.D. Earth-based mortars for repair and protection of rammed earth walls. Stabilization with mineral binders and fibers. J. Clean. Prod. 2018, 172, 2401–2414. [Google Scholar] [CrossRef]

- Gu, K.; Chen, B. Loess stabilization using cement, waste phosphogypsum, fly ash and quicklime for self-compacting rammed earth construction. Constr. Build. Mater. 2020, 231, 117195. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Leuzinger, G.; Sreeram, V.S. Low embodied energy cement stabilised rammed earth building—A case study. Energy Build. 2014, 68, 541–546. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Prasanna Kumar, P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385. [Google Scholar] [CrossRef]

- Dollente, I.J.R.; Valerio, D.N.R.; Quiatchon, P.R.J.; Abulencia, A.B.; Villoria, M.B.D.; Garciano, L.E.O.; Prometilla, M.A.B.; Guades, E.J.; Onpeng, J.M.C. Enhancing the Mechanical Properties of Historical Masonry Using Fiber-Reinforced Geopolymers. Polymers 2023, 15, 1017. [Google Scholar] [CrossRef]

- Maniatidis, V.; Walker, P. Structural capacity of rammed earth in compression. J. Mater. Civ. Eng. 2008, 20, 230–238. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Impacts of booming concrete production on water resources worldwide. Nat. Sustain. 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Mahasenan, N.; Smith, S.; Humphreys, K. The Cement Industry and Global Climate Change: Current and Potential Future Cement Industry CO2 Emissions. In Proceedings of the 6th International Conference on Greenhouse Gas Control Technologies, Kyoto, Japan, 1–4 October 2002; Elsevier: Amsterdam, The Netherlands, 2003; Volume II, pp. 995–1000. [Google Scholar]

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the assessment of soil suitability for rammed earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- Narloch, P.; Woyciechowski, P.; Kotowski, J.; Gawriuczenkow, I.; Wojcik, E. The Effect of Soil Mineral Composition on the Compressive Strength of Cement Stabilized Rammed Earth. Materials 2020, 13, 224. [Google Scholar] [CrossRef] [PubMed]

- Burroughs, S. Soil Property Criteria for Rammed Earth Stabilization. J. Mater. Civ. Eng. 2008, 20, 264–273. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Suresh, V.; Nanjunda Rao, K.S. Characteristic Compressive Strength of Cement-Stabilized Rammed Earth. J. Mater. Civ. Eng. 2017, 29, 04016203. [Google Scholar] [CrossRef]

- Ciancio, D.; Gibbings, J. Experimental investigation on the compressive strength of cored and molded cement-stabilized rammed earth samples. Constr. Build. Mater. 2012, 28, 294–304. [Google Scholar] [CrossRef]

- Jayasinghe, C.; Kamaladasa, K. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, B.; Zhao, X.; Mu, J. Experimental testing of the in-plane behavior of bearing modern rammed earth walls. Adv. Struct. Eng. 2018, 21, 2045–2055. [Google Scholar] [CrossRef]

- Raju, L.; Venkatarama, R. Influence of Layer Thickness and Plasticizers on the Characteristics of Cement-Stabilized Rammed Earth. J. Mater. Civ. Eng. 2018, 30, 04018314. [Google Scholar] [CrossRef]

- Khadka, B.; Shakya, M. Comparative compressive strength of stabilized and un-stabilized rammed earth. Mater. Struct. 2016, 49, 3945–3955. [Google Scholar] [CrossRef]

- Lu, Y.M.; Chiu, Y.P.; Shiau, Y.C. Study on applying inorganic polymers to restore rammed earth brick monuments. Emerg. Mater. Res. 2018, 7, 200–205. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Woloszyn, M.; Lavrik, L.; Moletti, C.; Dotelli, G.; Caruso, M. Mechanical and Microstructural Characterization of Rammed Earth Stabilized with Five Biopolymers. Materials 2022, 15, 3136. [Google Scholar] [CrossRef] [PubMed]

- ASTM D 422; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 1998.

- ASTM D 4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D 1557; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D 1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D 2166/D 2166M; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2013.

- Kavak, A.; Bilgen, G.; Mutman, U. In-situ modification of a road material using a special polymer. Sci. Res. Essays 2010, 5, 2547–2555. [Google Scholar]

- Mousavi, F.; Abdi, E.; Rahimi, H. Effect of polymer stabilizer on swelling potential and CBR of forest road material. KSCE J. Civ. Eng. 2014, 18, 2064–2071. [Google Scholar] [CrossRef]

- Kolay, P.K.; Dhakal, B. Geotechnical properties and microstructure of liquid polymer amended fine-grained soils. Geotech. Geol. Eng. 2019, 38, 2479–2491. [Google Scholar] [CrossRef]

- Geiman, C.M.; Filz, G.; Brandon, T.L. Final Contract Report Stabilization of Soft Clay Subgrades in Virginia: Phase I Laboratory Study; Report No. VTRC 05-CR16; Department of Civil and Environmental Engineering, Virginia Tech: Blacksburg, VA, USA, 2005. [Google Scholar]

- Norseta, A.S.; Rutra, R. The Correlation Between CBR (California Bearing Ratio) and UCS (Unconfined Compression Strength) Laterite Soils in Palangka Raya as Heap Material. IOP Conf. Ser. Earth Environ. Sci. 2020, 469, 012093. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).