1. Introduction

An immersed tunnel is an underwater structure composed of prefabricated elements, which are constructed onshore, floated to the site, and then submerged and installed in a prepared trench. These structures are typically shallow, which minimizes hydrostatic pressures, reduces overall tunnel length, and allows for gentler approach gradients compared to bored tunnels. Their adaptable cross-section profiles make them suitable for a range of applications, including highways and combined rail-road systems. Moreover, they are appropriate for diverse geological conditions, including soft alluvial soils and loose permeable sediments found in riverbeds or seabeds—environments where tunnel boring machines have limitations. The off-site (onshore) construction of tunnel elements also facilitates enhanced quality control. Overall, immersed tunnels often represent a viable alternative from both economic and safety standpoints, as noted in [

1].

The seismic behavior of immersed tunnels is strongly influenced by the properties of the surrounding soil, particularly its stiffness [

2]. Seismic-induced displacements may be amplified by soil liquefaction, potentially leading to ground failure if the soil experiences significant strength loss. Liquefaction may result in a loss of lateral or vertical support, differential movements or rotations, shake-down settlement effects (caused by densification of granular materials), or flotation of the tunnel. Likewise, uncontrolled movement of the tunnel can lead to overstressing of the structure and joint leakage, making the implementation of appropriate ground improvement measures essential.

Additionally, the spatial variability of the input motion on a long immersed tunnel, arising from factors like wave passage, site amplification, and differing ground properties along the tunnel’s length, significantly affects its seismic response by inducing longitudinal bending, axial stresses, and uneven shear forces in its joints, which are critical for its structural integrity. In particular, it is worth noting that the ground properties spatial variability along the tunnel’s length can lead to non-uniform ground motion and foundation response.

A number of immersed tunnels have been constructed in seismically active regions. Notable examples include the BART Tunnel in San Francisco [

3], several tunnels in Japan, the Aktio-Preveza Tunnel in Western Greece, and, more recently, the Bosphorus Tunnel in Istanbul and the Busan Tunnel in South Korea [

4]. A future immersed tunnel crossing the Tagus River is also planned in a seismically active area. One of the principal challenges in the design of such tunnels is ensuring adequate seismic resistance, as structural damage from seismic events is particularly difficult to repair due to the nature and location of the tunnel.

This paper investigates the seismic performance of immersed tunnels. It begins by exploring the deformation mechanisms affecting immersed tunnels, including those arising from ground shaking and failure. Given its relevance in inducing large deformations to the tunnel foundation and its structural consequences, liquefaction and related mitigation strategies are addressed in detail. We then review the seismic design process for immersed tunnels, encompassing analytical approaches, numerical modeling techniques (such as the finite element and finite difference methods), and physical modeling. Several case studies are also presented, including the Offshore Transbay Tube, the Posey and Webster Street Tubes, the Waihuan Tunnel, the George Massey Tunnel, and the Hong Kong–Zhuhai–Macau immersed tunnel. Finally, a brief case study is provided on a proposed immersed tunnel crossing the Tagus River downstream of the 25 de Abril Bridge in Lisbon, Portugal, between Algés and Trafaria, with an approximate length of 2.4 km.

This paper advances understanding of immersed tunnel seismic behavior by synthesizing lessons from analytical, numerical, and experimental studies, together with case histories, into a practitioner-oriented framework for design and retrofitting. It highlights that tunnel performance is displacement-controlled, emphasizes the governing role of soil–structure interaction and liquefaction, and critically reviews the effectiveness of available mitigation measures. Special emphasis is placed on tunnel joints, identified as the key elements of seismic resilience. The review also outlines gaps in current knowledge—such as soil constitutive modeling, optimal mitigation layouts, and advanced joint protection concepts—thereby pointing to future research needs for more resilient and safe immersed tunnel design.

2. Types of Deformation

The effects of earthquakes on underground structures generally arise from two main mechanisms: ground shaking and ground failure. As seismic waves arrive at a site, ground shaking induces displacement of the foundation ground and may reduce its strength, thereby imposing additional loads on the tunnel support system. This shaking can lead to structural damage such as cracking, spalling, and, in extreme cases, structural failure [

5,

6].

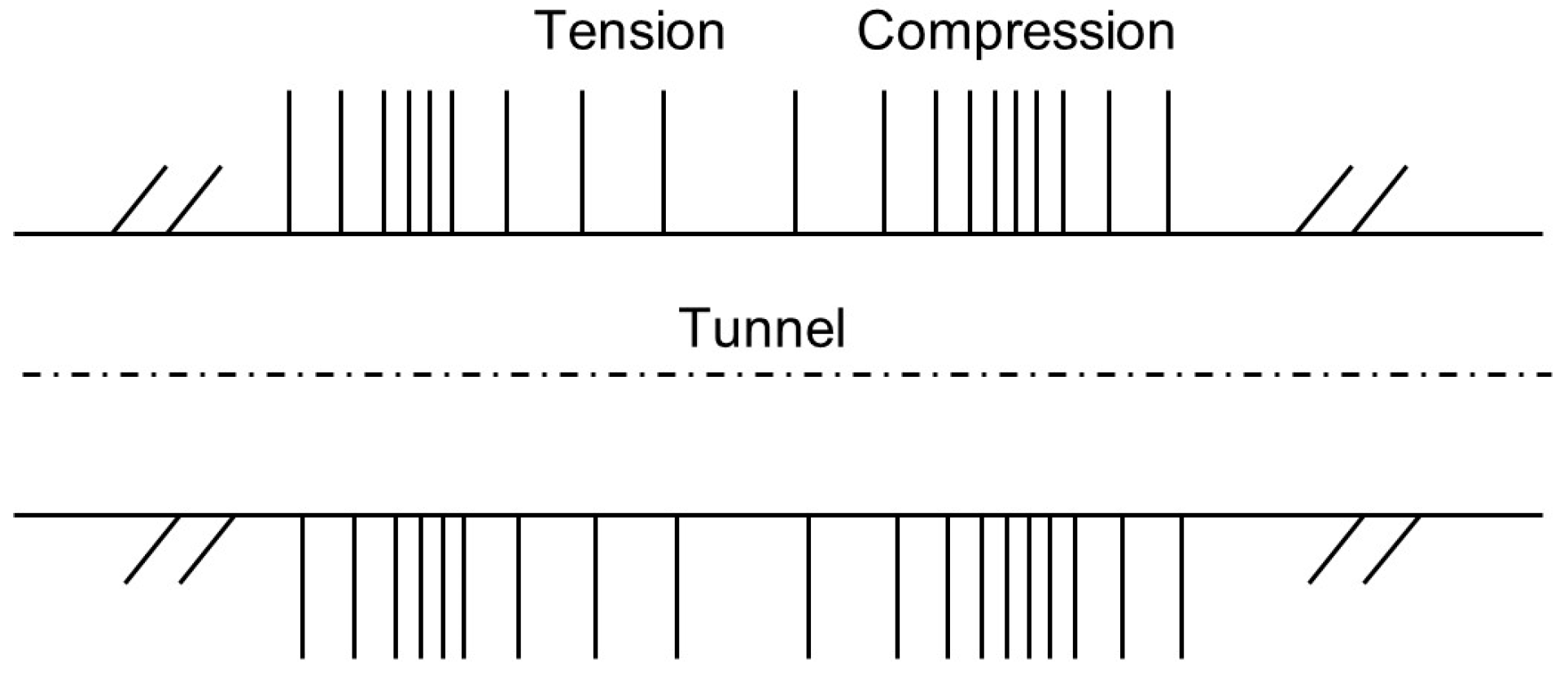

The simplest analytical case of ground shaking involves a P-wave propagating parallel to the tunnel axis, assuming soil–structure interaction is neglected. P-waves can generate longitudinal compression and tension as they travel along the tunnel, inducing axial strains, tensile and compressive forces in the structure, and the opening or closing of tunnel joints (

Figure 1). This loading scenario is one of the most critical for immersed tunnels, as it may lead to decompression of joint gaskets, potentially compromising the tunnel’s watertightness.

P-waves may also propagate normal or at a certain angle to the tunnel axis, producing lateral compression and consequently inducing axial, normal, and shear strains within the structure. When the angle of incidence ranges between 0° and 90°, relative to the tunnel alignment, a time delay occurs in wave arrival between opposite ends of the structure. This asynchronous excitation can lead to horizontal bending, with tensile and compressive zones developing on opposite sides of the tunnel (

Figure 2).

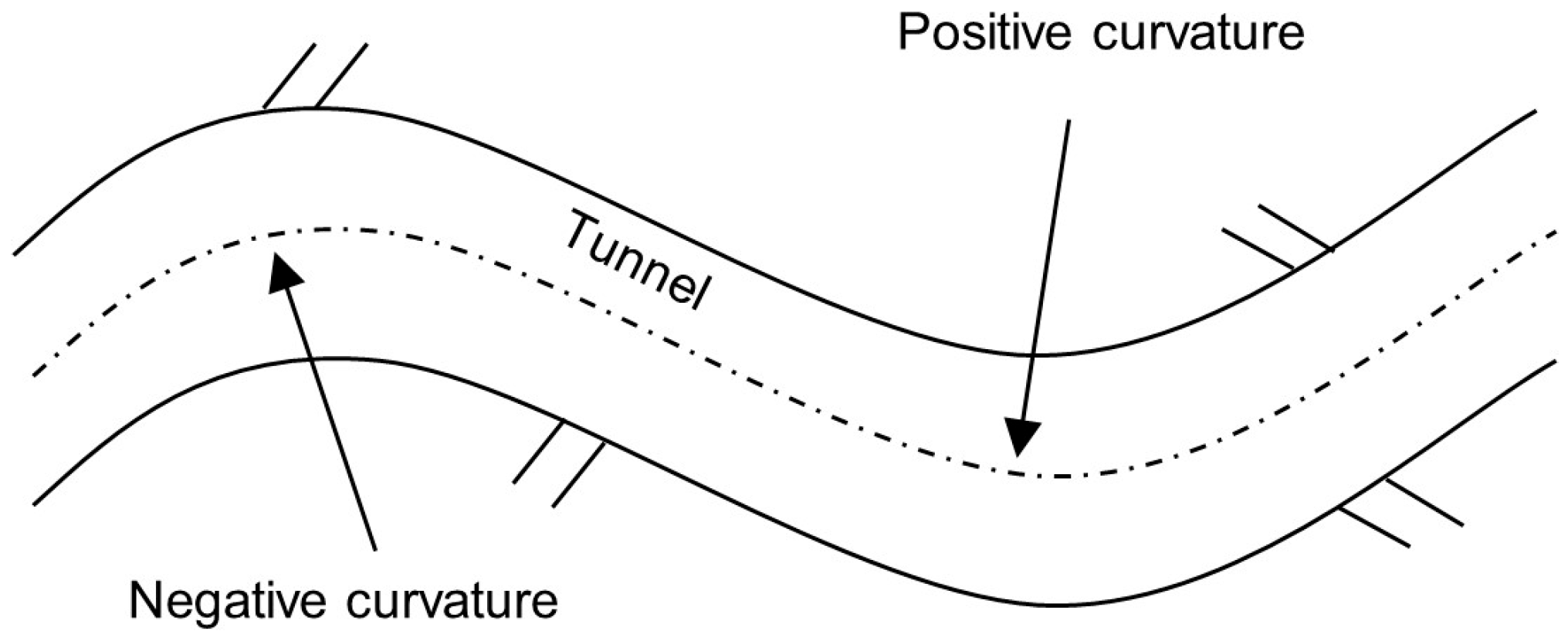

S-waves, which possess both vertical and horizontal components, deform the tunnel according to their direction of propagation and angle of incidence. These waves can induce longitudinal, normal, and shear strains, as well as vertical and horizontal bending moments in the tunnel. Furthermore, the curvature of the structure may result in joints opening and closing, similar to the effects of P-waves.

St. John and Zahrah [

5] presented analytical methods for estimating longitudinal, normal, and shear strains—and their corresponding stresses—as function of the wave incidence angle. These were evaluated for P-, S-, and Rayleigh (R-) waves, both with and without considering soil–structure interaction. The latter case is especially pertinent for immersed tunnels, which are generally stiffer than the surrounding soils (generally soft deposits) and therefore do not conform to free-field ground deformations. Shear waves are typically responsible for generating the largest bending moments, shear forces, and axial loads in the tunnel.

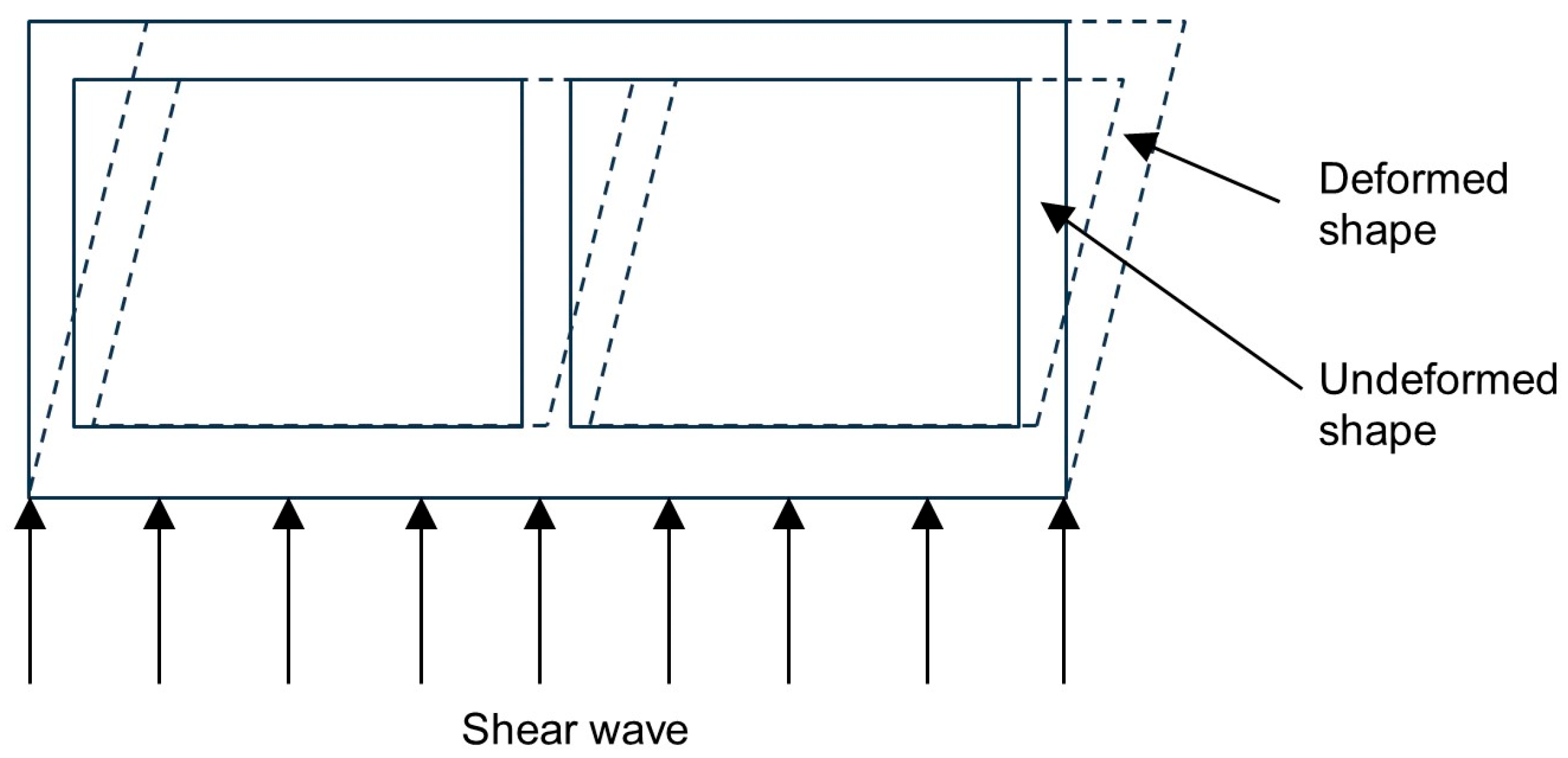

Racking deformation arises from SH-waves propagating vertically through the soil, perpendicular to the tunnel axis. Due to inertial effects within the ground layers, this produces horizontal distortion of the ground mass [

7]. The racking deformation imposed on the structure corresponds to the relative displacement between the soil at the top and bottom of the tunnel. For a rectangular tunnel cross-section, such distortion (

Figure 3) generates significant bending moments and shear forces—especially at rigid wall–slab connections—that must be accounted for in the design. If the tunnel is considerably stiffer than the surrounding soil, as is typical for immersed tunnels, numerical analysis incorporating soil–structure interaction is essential. In such cases, the actual racking deformation is expected to be less than that predicted from free-field deformation [

5].

Immersed tunnels are usually embedded in soft ground near the surface, which significantly influences their dynamic response. In some cases, the limit friction may be exceeded at the soil–structure interface, leading to slippage. Additionally, soft surface layers may experience amplified motion due to earthquake-induced liquefaction, which can result in a severe loss of soil strength and lead to ground failure. The tunnel’s behavior is further influenced by variations in subsurface topography and geology, changes in overburden thickness, the presence of fault lines or dislocations, slope movements, and shear zones [

2]. Thus, the most critical ground failure mechanisms for immersed tunnels include liquefaction, fault displacement, and slope instability.

Liquefaction may cause the immersed tunnel to either float or sink, depending on the net pore pressures in the soils beneath the structure. Fault displacements or shear movements in the bedrock may be mitigated by maintaining a sufficient thickness of soft soil between the tunnel and the underlying rock [

8]. Furthermore, increasing joint flexibility can help accommodate fault-induced offsets and reduce structural damage. Slope instability can also be triggered by either ground shaking or liquefaction. This is particularly relevant near tunnel portals located on inclined riverbanks or coastal slopes, as well as underwater slopes, all of which may become susceptible to seismic-induced sliding.

3. Liquefaction and Mitigation Measures

Liquefaction of soils surrounding an immersed tunnel can have severe consequences, including the loss of lateral or vertical support and significant displacements or rotations of the tunnel. In extreme cases, such as the 1964 Niigata earthquake in Japan, horizontal displacements of 6 to 8 m were recorded. Additional movement may occur due to shake-down settlement, a phenomenon where granular soils densify naturally as their structure collapses under seismic loading. Any uncontrolled movement of the tunnel structure is undesirable, as it can lead to overstressing and joint leakage.

Buoyancy represents a critical concern in liquefaction conditions, as uplift is governed by the loss of effective stress in the surrounding soil. When liquefaction occurs, excess pore water pressures reduce the soil’s effective stress to nearly zero, and the soil mass effectively behaves as a fluid. In such conditions, the upward force in the lower slab of the tunnel, resulting from this excess pore pressure, combined with the existing buoyant force from the pore water in saturated soil (equal to the weight of fluid displaced by the tunnel), can overcome the weight of the tunnel and, consequently, cause uplift. Additionally, a proper buoyancy assessment must consider not only the tunnel’s self-weight but also the contributions of engineered backfill and any ground improvement measures. While a simple balance of weights might indicate that the tunnel would float, such an approach neglects the spatial variability of liquefaction and the restraining effects provided by soil–structure interaction. Furthermore, the mechanical interaction between the tunnel and the selected backfill—which is often designed to resist liquefaction—introduces additional complexity, as the degree to which the backfill behaves monolithically with the tunnel is difficult to quantify.

According to [

9], a secondary uplift mechanism, driven by pore water migration under hydraulic gradients during or after shaking, can also occur. Excess pore pressure generated beneath the tunnel by contractive soils can cause water to flow both beneath the tunnel and toward the surface. Post-shaking continued water flow may lead to volumetric soil expansion beneath the tunnel and residual uplift. As pore pressures equalize, water flows out from beneath the tunnel and it partially settles, reversing much of the post-earthquake uplift.

In some scenarios, high shear stresses resulting from differential weight between the structure and surrounding soil, combined with severe liquefaction-induced strength loss, could generate a net upward force on the structure, resulting in large, uncontrolled uplift—suggesting the presence of a force-based uplift mechanism.

In summary, uplift is primarily influenced by:

the extent and thickness of liquefiable soil (particularly beneath the structure);

the soil’s relative density;

the weight differential between the tunnel and the surrounding ground;

the amplitude and duration of seismic shaking;

volumetric dilation due to pore water migration and heaving of soft soils.

Liquefaction can also trigger submarine landslides, particularly in foreshore areas, where shallow material may flow into the deeper channel and increase overburden on the tunnel. Such effects can lead to increased post-earthquake settlement, which must be anticipated and accounted for in design.

Given the complexity and unpredictability of ground behavior during liquefaction, preventing its occurrence is essential. This requires a comprehensive assessment of the potential for liquefaction in the supporting ground, followed by appropriate ground improvement measures. Since it is often not feasible to alter the tunnel alignment to avoid liquefiable materials, strengthening the soil through increased density, shear strength, or improved drainage usually becomes the only viable solution [

4].

Several well-established ground improvement techniques have been used successfully for immersed tunnels, which are briefly described next.

3.1. Stone Columns and Vibro-Replacement Techniques

Stone columns improve seismic behavior by increasing the shear modulus of the soil and limiting the buildup of pore water pressure. When combined with vertical drains, they facilitate rapid consolidation, reduce differential settlement, and provide escape paths for excess pore water during seismic shaking [

4]. Typically, stone columns have diameters ranging from 0.6 to 1.0 m and are installed on a grid with approximately 2 m spacing, arranged in square or diamond patterns, depending on design objectives regarding bearing capacity, density, or relief of excess pore water pressures.

To ensure effectiveness, gravel used in the columns must be narrowly graded to promote self-compaction and maintain permeability. Some clogging from silt and some sediment infiltration may occur, but due to the column’s large diameter, water flow paths are generally preserved. However, vertical drains may be included to enhance performance. Crucially, the stone columns must be connected to a permeable layer, such as a gravel foundation bed, extending through a coarse backfill to the seabed or riverbed surface, enabling dissipation of pore water pressure.

Vibro-replacement techniques densify and reinforce liquefiable soils. The drainage capacity of the columns—and its variability along their length—significantly influences their effectiveness and must be accounted for in the design [

10].

3.2. In Situ Soil Mixing

In situ soil mixing allows for deep ground improvement by using a set of augers to penetrate the ground and, during their withdrawal, injecting and mixing cement with the soil to form stiffened columns. This method can create treated panels or walls and is particularly useful in high liquefaction potential zones. It enhances bearing capacity and stiffness of the ground, reduces settlements, and can be adapted for deep offshore conditions (up to 70 m below seabed level) [

4].

In-ground walls formed through this technique also [

10]:

Reduce earthquake-induced shear strains in the treatment zone;

Limit pore pressure generation;

Contain untreated soil and contribute to overall shear strength;

Act as barriers to excess pore pressure migration from untreated soils;

Help mitigate flotation by confining liquefied soil beneath the tunnel.

3.3. Sand Compaction Piles (SCPs)

SCPs are installed by vibrating a sleeve filled with sand into the ground and releasing the sand during withdrawal. This displacement method densifies loose deposits and has proven effective for increasing bearing capacity and reducing settlement. SCPs are suitable for marine environments and can treat depths up to 70 m. Commonly, they are arranged on triangular or rectangular grids with diameters of 1.5 to 2 m for offshore applications.

3.4. Colloidal Silica Grouting

This more recent method involves injecting a colloidal silica gel that binds sand particles and fills pore spaces, reducing permeability. Colloidal silica gel also encapsulates the soil structure, significantly enhancing resistance to cyclic loading. It decreases its volume upon compression, allowing less excess pore water pressure to develop, and it does not significantly increase soil stiffness, thus avoiding amplification of seismic waves. Under suitable seepage conditions, colloidal silica can be injected upstream and transported via groundwater to the target liquefiable zone beneath the tunnel—either before or after the installation of tunnel elements.

3.5. Expansive Polyurethane Resin Injections

Expansive polyurethane resin injections are another recent method, used to densify the ground, as additional material is injected into a relatively constant soil volume, filling voids and increasing soil stiffness. This technique also enhances composite stiffness, induces cementation, and increases horizontal stresses. For immersed tunnels, this method is best applied before trench excavation, up to the base of the tunnel, so that a minimum confining stress—provided by the weight of overlying sand and foundation and protection layers—is present at the injection zone.

4. Seismic Design

The seismic hazard at a tunnel site can be quantified through a project-specific seismic hazard assessment. This involves estimating bedrock motion by evaluating historical seismicity, relevant seismic data, ground motion characteristics, regional seismic hazard assessments, site geology, and the activity of nearby faults with the potential to generate significant seismic events.

Seismic design of tunnel structures differs fundamentally from that of aboveground structures. Tunnel behavior is primarily displacement-controlled, as the structure tends to move in concert with the surrounding ground. The tunnel’s inertia is generally negligible relative to that of the soil, except at portals with above ground elements such as buildings or ventilation shafts. In immersed tunnels, the structure is typically stiffer than the surrounding soil, making soil–structure interaction a key consideration.

Thus, the dynamic behavior and stability of the surrounding ground are crucial to the seismic design of immersed tunnels. Ground displacement—particularly vertical differential displacements along the tunnel axis during earthquakes—is the dominant design consideration.

Site-specific amplification or attenuation effects due to topography and geology can be assessed using numerical modeling. These analyses provide estimates of the effective ground motions at the tunnel, from which structural strains can be determined. Applying appropriate stress–strain relationships enables the derivation of corresponding internal forces [

2]. Accurate conversion of strains into forces requires a clear understanding of the tunnel’s structural response. Since both steel and concrete immersed tunnels typically contain similar volumes of concrete, the tensile behavior of concrete—particularly its tendency to crack under large seismic loads, unless heavily compressed or prestressed—plays a critical role in overall structural performance [

2].

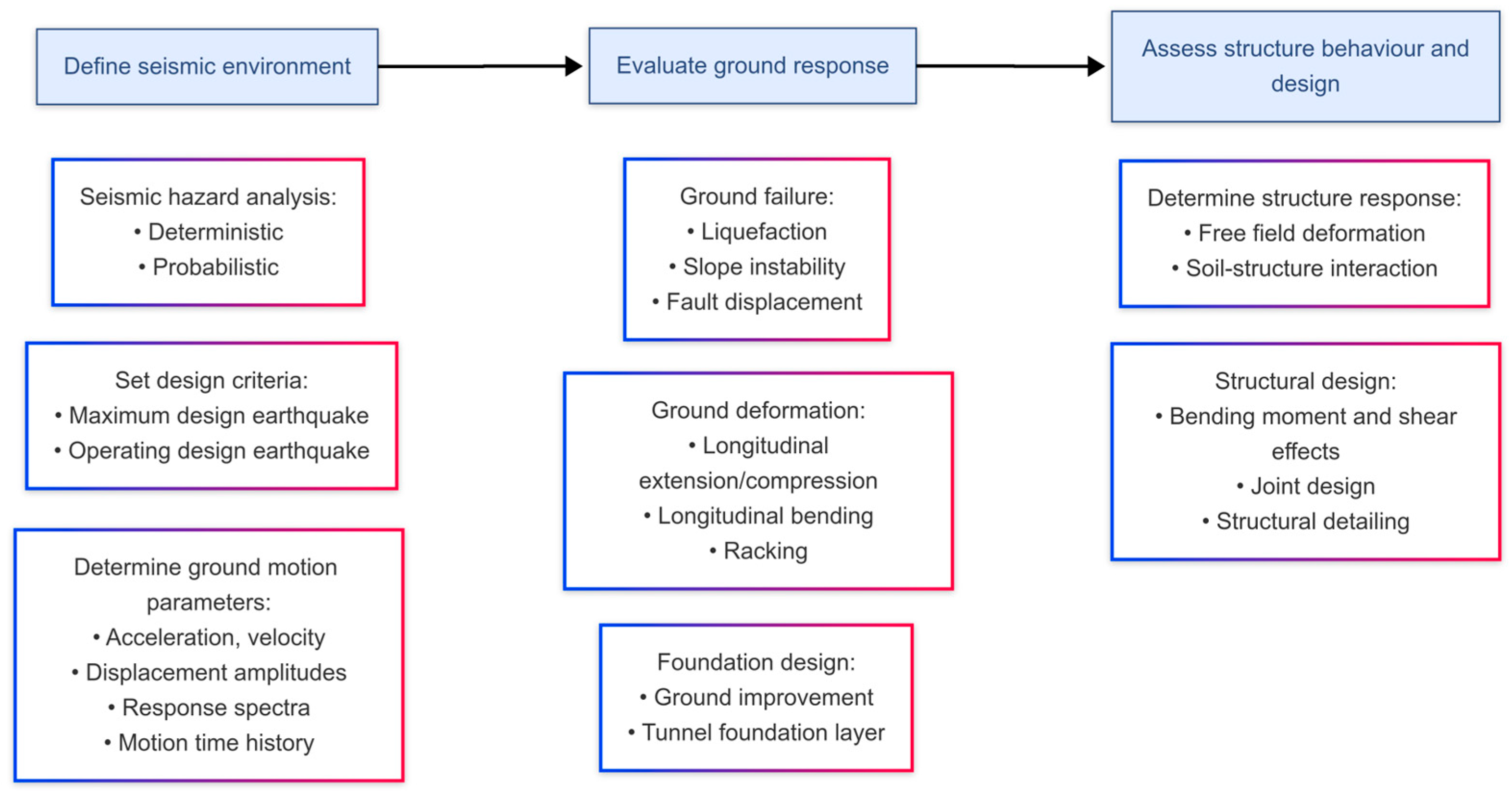

Seismic loading induces horizontal and vertical bending in the tunnel, resulting in reciprocal shear forces at the joints. Differential settlements between adjacent tunnel segments can further introduce vertical shear. These shear forces must be transferred across the joints—primarily through shear keys. Therefore, joint design must account for both compressive and shear forces. The general steps in the seismic design process are outlined in

Figure 4.

Kiyomiya [

11] identified three main approaches used in Japan for the seismic design of immersed tunnels: (1) the seismic coefficient method, (2) the seismic deformation method (both analytical), and (3) dynamic response analysis (numerical method). According to [

11], the internal forces and displacements in tunnel components should be evaluated using both the seismic coefficient and seismic deformation methods (for cross-sectional behavior), and dynamic response analysis (for longitudinal behavior), incorporating the effects of the surrounding ground, topography, and geology. Structural deformations, ground response, inertial effects due to the tunnel’s dead weight, and additional earth pressures must also be considered.

The study of dynamic soil–structure interaction for linear underground structures under seismic loading is a complex engineering challenge. Hashash et al. [

7] and Nam et al. [

12] reviewed various methodologies for quantifying seismic effects on underground structures and investigated soil–structure interaction. These include analytical approaches and numerical modeling techniques, primarily based on finite element or finite difference methods. In addition, physical modeling is used to study immersed tunnel responses—particularly in critical components such as joints.

4.1. Analytical Approaches

Analytical methods for estimating strains and stresses in structures subjected to ground motion are typically based on the theory of wave propagation in an infinite, homogeneous, isotropic, elastic medium, coupled with the theory of an elastic beam on an elastic foundation to incorporate soil–structure interaction effects [

5]. This approach, only applicable to a limited range of problems, requires the definition of a foundation modulus—introducing a degree of subjectivity in its application.

St. John and Zahrah [

5] applied this analytical method to the Offshore Transbay Tube (TBT) of the Bay Area Rapid Transit (BART) system in San Francisco. The analysis involved calculating the maximum internal forces (bending moments, shear forces, and axial forces) due to both horizontal and vertical shear waves, then combining these to obtain the total design forces. When soil–structure interaction was considered, the maximum bending moment and shear force were reduced by factors of approximately 3 and 2, respectively.

Kuesel [

3], using the theory of wave propagation, derived an analytical expression for the maximum axial strain (

) induced by an oblique shear wave in the TBT, travelling across the structure at an angle χ of around 32° to the structure axis. This wave includes both transverse (producing bending) and longitudinal (producing compression-tension distortion) components:

where

is the critical wavelength, assumed to be six times the immersed tunnel width in the bending plane (deep beam action), and

is the amplitude associated with

, derived from the design earthquake response spectrum. The design earthquake was derived from the 1940 El Centro earthquake and adjusted for a peak horizontal acceleration of 0.33 g in rock and shallow overburden (depth under 21.3 m) and of 0.50 g in deep overburden (depth over 21.3 m). Peak vertical accelerations were taken as 2/3 of the peak horizontal accelerations.

The tunnel was also designed to resist racking. The shear distortion magnitude was estimated using:

where

is the shear distortion angle (in radians),

is the overburden depth (m) and

is the average shear wave velocity (m/s). This expression approximates the shear deformation of a vertically cantilevered soil column subjected to a horizontal base excitation, assuming a linear variation in shear modulus with depth. The first six modes of vibration of the column were considered, with the expression resulting from a linear approximation of the computed soil response curves, with an accuracy greater than 90%.

Okamoto et al. [

13] developed a mathematical model for the seismic analysis of immersed tunnels, treating the structure as a beam supported by elastic or inelastic springs, both transversely and longitudinally. Ground motion resulted from shear wave vibration of the surface layer, with only the fundamental vibration mode considered. The ground at each point along the tunnel axis was modeled as a mass–spring system, with mass and spring stiffness values chosen to match the natural period of the system to that of the ground. Ground displacements were obtained by multiplying the mass displacement by the corresponding participation factor for the fundamental vibration mode.

In the seismic coefficient method [

11], a force-based approach, inertial forces in three orthogonal directions are computed by multiplying the structure and soil masses by the respective design seismic coefficients. Higher coefficients are used for critical elements such as ventilation towers, with large inertial forces. Seismic earth pressures are calculated using the Mononobe–Okabe method. Vertical overburden pressures are adjusted by multiplying the weight of the soils by (1 ± k

v), where k

v is the vertical design seismic coefficient. This approach can be used for the design of the ventilation tower and approach structures.

In contrast, in the seismic deformation method [

11], a displacement-based approach, the ground displacement

is estimated at the tunnel longitudinal axis depth

using:

where

is the normalized response velocity per unit seismic coefficient,

is the natural period of the surface ground,

is the horizontal seismic coefficient at the bedrock, and

is the surface layer thickness. The tunnel is assumed to follow ground movement, with minimal excitation or resonance.

For transverse analysis, the tunnel cross-section is modeled as an elastic frame. Slabs and walls are idealized as beams. When soil–structure interaction is considered, the tunnel is modeled as a beam connected to the ground with a series of idealized springs in both longitudinal and transverse directions. The following differential equations are formed, allowing one to determine the maximum axial force and bending moment, respectively:

where

is the Young’s modulus,

is the cross-sectional area, and

is the moment of inertia of the lining;

and

are the longitudinal (axial) and transverse (shear) spring constants, respectively;

is the ground displacement and

is the immersed tunnel displacement;

is the maximum ground displacement; and

is the wavelength.

Neglecting soil–structure interaction, the maximum axial force occurs at a 45° wave incidence angle, and the maximum bending moment and shear force occur with wave propagation parallel to the tunnel axis. Assuming harmonic motion, the peak forces are as follows:

Vrettos [

14] noted that this method is conservative, as it assumes a single, critically oriented shear wave and a value of

independent of wavelength, while actual ground displacement amplitude typically decreases with increasing wavelength. Thus, as a reliable and physically sound estimate of the wavelength of the relevant incident seismic wave is usually difficult to determine, he proposed simplified, wavelength-independent upper bound estimates of peak forces by seeking the wavelengths that maximize axial force and bending moment (it is assumed that

and

are independent of

):

While various methods exist for estimating spring constants, reliable analytical evaluation remains difficult. Vrettos [

14] recommends finite element (FE) analysis with nonlinear soil models for realistic assessment. Nevertheless, St. John and Zahrah [

5] derived a closed-form expression, from a 2D plane–strain solution for a static sinusoidal point load in an infinite elastic, isotropic, and homogeneous medium:

where

and

are the shear modulus and Poisson’s ratio of the soil, respectively, and

is the tunnel’s equivalent diameter.

4.2. Numerical Methods

Numerical methods offer a powerful tool for analyzing and designing complex structures, serving as a key approach for evaluating the seismic performance of immersed tunnels. These methods enable the investigation of spatial variation effects in ground motion and the dynamic interaction between soil and structure.

In the finite element method (FEM), the continuum is discretized into finite elements, each assigned specific material and constitutive properties. The state equations for each element are then assembled into a global system of equations representing the entire structure [

5]. In contrast, the finite difference method involves discretizing the equations of motion of the soil–structure system by approximating derivatives with finite difference expressions. For ground modeling, block elements or two-dimensional plane–strain elements are typically used, while beam elements represent the immersed tunnel. Despite the availability of 3D models, simplified numerical approaches such as mass–spring equivalent models are often employed due to the high computational cost and memory demands of full 3D simulations.

Kiyomiya [

11] introduced a 2D multi-mass–spring model in which the surface soil layer is divided into vertical slices, each represented by a mass–spring–dashpot system. Springs and dashpots connect the masses to the bedrock, and they are also interconnected along the tunnel axis via springs and dashpots, simulating the longitudinal soil behavior. The dynamic response is governed by the following equation:

where

,

, and

represent the mass, damping, and stiffness matrixes, respectively;

,

, and

are the acceleration, velocity, and displacement vectors; and

is the vector of input accelerations. The tunnel is modeled as a beam connected to the ground via springs, which transmit ground motion to the tunnel ends. One end of each spring is assumed to be displaced to the same extent as the ground, allowing the seismic response of the tunnel to be calculated. This formulation also enables the inclusion of elements such as joints and ventilation towers in the seismic analysis.

Building upon this model, a quasi-3D approach was developed for more complex ground conditions. Here, the surface layer is represented by plate elements and masses, and each mass is connected to the bedrock through springs/dashpots, allowing for improved simulation of three-dimensional effects.

Anastasopoulos et al. [

15] applied a finite element model to study joint deformations in an immersed tunnel subjected to combined longitudinal and lateral seismic vibrations. The model was based on a 70 m deep tunnel located in a seismically active region of Greece and simulated using beams linked to the ground via calibrated springs, dashpots, and sliders. Free-field acceleration time histories were applied at spring supports with time lags to simulate wave passage effects. Tunnel elements were modeled using shear-flexible beam elements, while joints were represented by 64-node perimeter frames connected by single-degree-of-freedom nonlinear springs, representing the stiffness of the joint. Gina gaskets and shear keys were modeled using axial springs in the longitudinal direction and gap elements in the transverse and vertical directions, respectively. The nonlinear dynamic analysis of the tunnel highlighted the influence of joint characteristics—such as Gina gasket deformation and shear key allowance—and tunnel segment length in the transverse and vertical deformation of the tunnel. The results indicated that appropriately designed joint gaskets with increased thickness and shorter tunnel elements reduce the risk of excessive tension or compression in the joints during seismic loading. In fact, while the modern trend is to go for longer elements, on the order of 150–200 m, smaller lengths may be dictated by seismic considerations. Furthermore, longitudinal hydrostatic prestressing of the tunnel and the end supports provide, respectively, a restoring force and a substantial constraint, which mitigate longitudinal sliding.

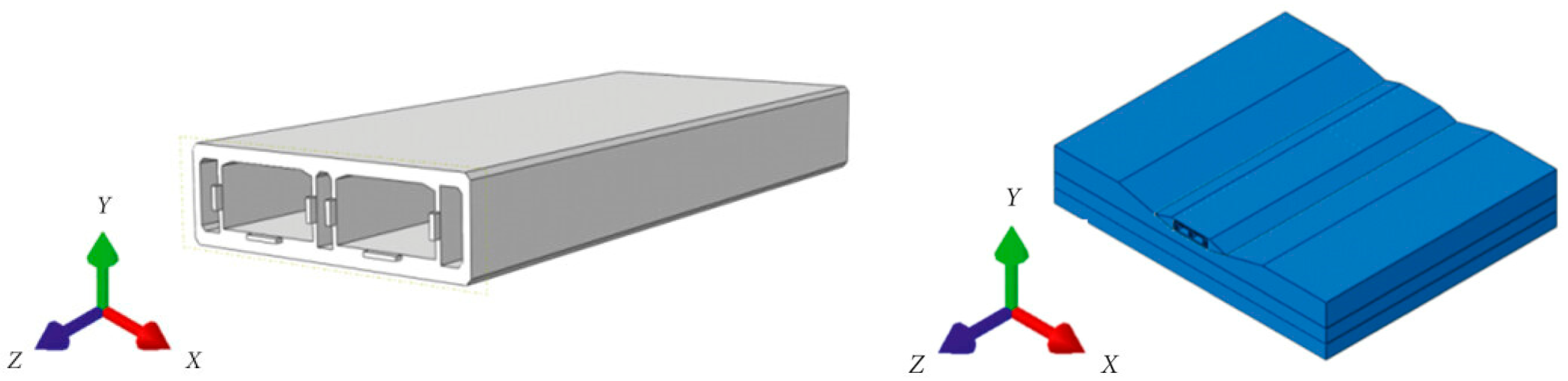

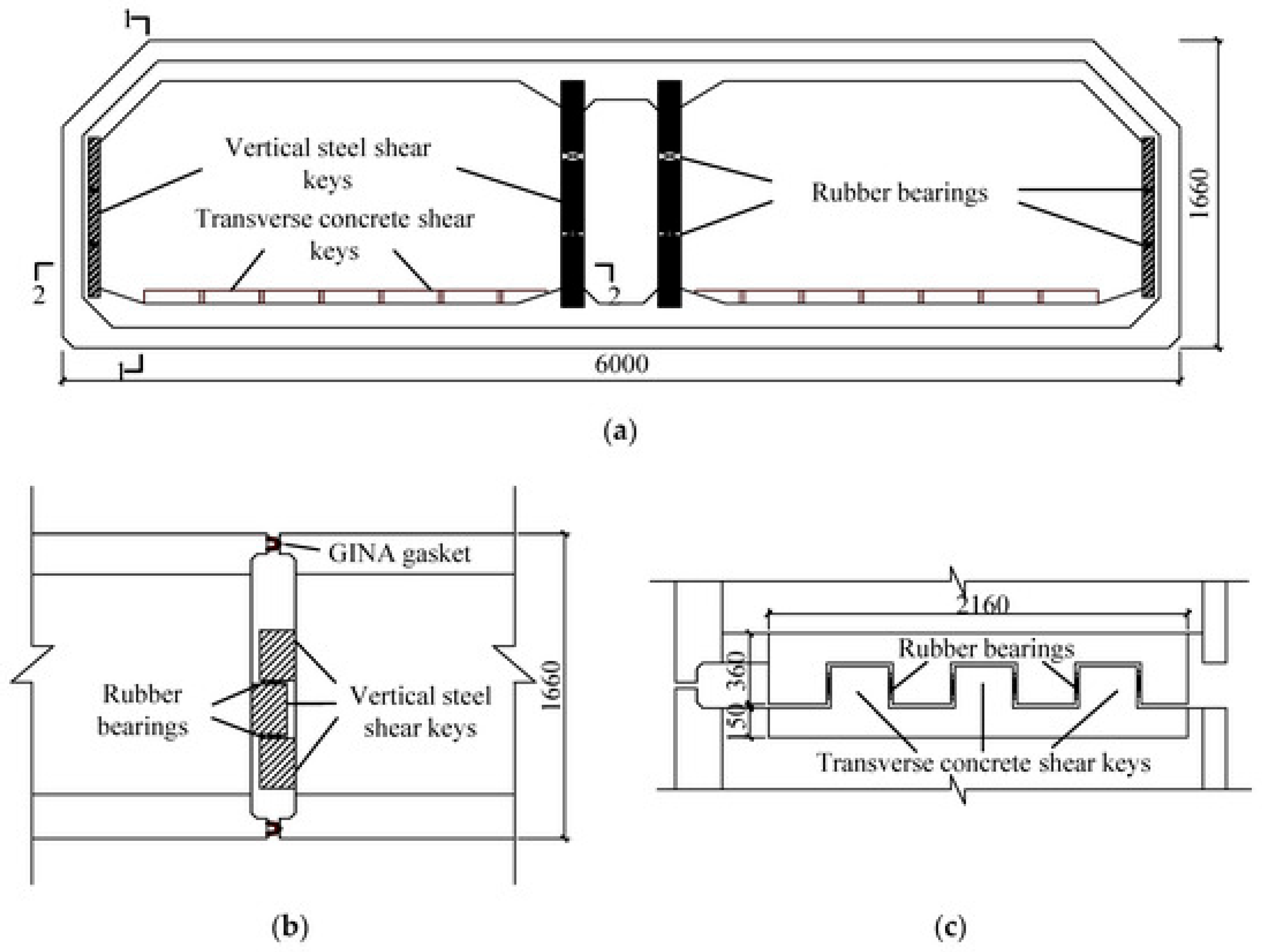

Expanding on this methodology, Zhang et al. [

16] developed a spatial nonlinear mass–spring model to investigate the seismic behavior of an immersed tunnel–foundation system. The behavior of the joints between elements and segments was simulated using distributed multi-node frame elements, including shear pins in segment joints (

Figure 5). The study examined the influence of temperature and prestressing on the tunnel seismic response. The results showed that cooling (temperature decrease) had a more adverse effect on joint deformation and segment internal forces than heating by reducing compression. While axial forces were sensitive to temperature variation, bending moments were largely unaffected. Retaining prestress cables improved segment joint sealing but negatively affected immersion joint sealing, as Gina gasket compression is higher when the cables are cut.

Oorsouw [

17] studied the “worming and snaking” effects using simplified beam models, without considering soil–structure interaction, to assess the impact of parameters such as seismic wavelength, construction depth, tunnel element length, and rubber gasket stiffness in segment and immersion joints. He concluded that gasket properties and seismic wavelength were the most influential factors. The Gina gasket’s compressibility and the segment water sealing profile’s elongation capacity dictated axial deformation, while rotational capacity and Gina gasket quantity affected snaking behavior. The segment joints were found to act relatively stiff until their moment capacity was reached.

Zhang et al. [

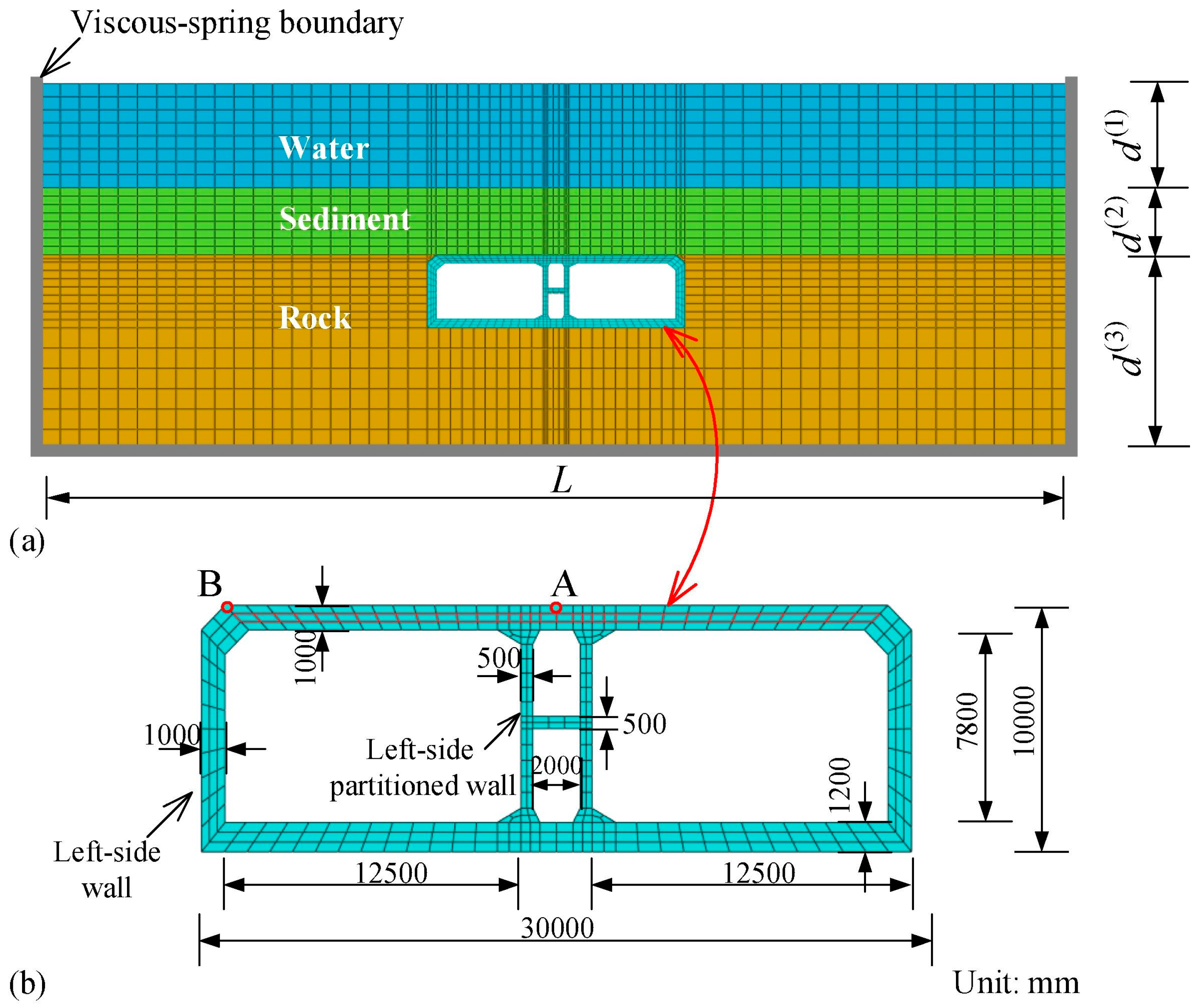

18] proposed a structure–water–sediment–rock interaction model to evaluate a linear elastic immersed tunnel response to obliquely incident seismic waves, considering the dynamic interaction between the structure and the surrounding ground. A viscous-spring absorbing boundary simulated the wave radiation effect of the far field domain, and the free field response was calculated through site earthquake response analysis and translated into equivalent boundary loads. Their model had a width L of 120 m, a water depth d

(1) of 17 m, a variable sediment thickness d

(2) of between 0 m and 9 m, and a rock thickness d

(3) of 37 m (

Figure 6). The effects of the thickness, porosity, and permeability of the surrounding ground and of the seismic wave incident angle were studied. The results showed that greater sediment thickness and lower porosity increased peak horizontal displacement, while peak stress rose with the angle of wave incidence.

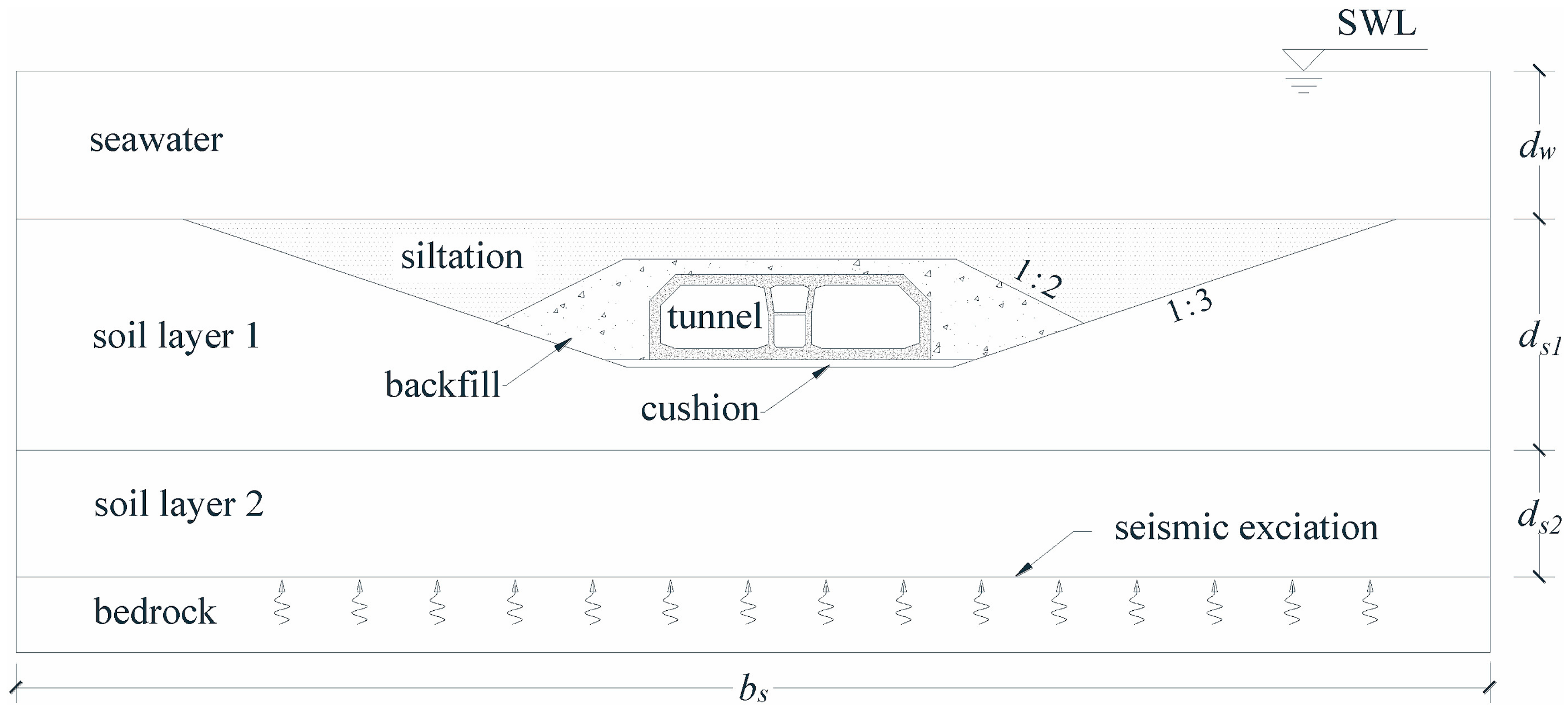

Chen et al. [

19] developed a 2D integrated model for time-history analysis of an immersed tunnel in a marine environment under bidirectional seismic excitation (

Figure 7). The width of the model was 800 m, and the thicknesses of the soil layer 1 (clay), of the soil layer 2 (sand), and of the bedrock were 40 m, 30 m, and 10 m, respectively. The depth of the seawater was considered to be 20 m. The model incorporated nonlinear soil behavior using the Davidenkov model and employed the Coupled Acoustic–Structure (CAS) method for dynamic soil–water interaction. The influence of soil–tunnel contact technique, seismic input, seawater effects, and ground reinforcement via sand compaction piles (SCPs) on the performance of an immersed tunnel was studied under three peak bedrock accelerations, ranging from 0.2 to 0.4 g. The distribution of tensile damage, of the maximum drift ratio between the top and bottom slabs of the tunnel, of the maximum bending moment, and of the tunnel inclination angle in the transverse direction were analyzed. Findings indicated that bidirectional input led to more severe tunnel responses, except for the maximum drift ratio. Additionally, the overlying seawater increased the tensile damage and amplified the uneven settlement of the tunnel for higher peak bedrock accelerations. While SCPs can effectively reduce settlement and deformation, they may make the tunnel more susceptible to damage and failure during seismic events. The bending moments and tensile damage increased at critical corner locations of the tunnel section, especially under higher seismic intensities. Also, the maximum drift ratio increased with the implementation of SCPs, and this increase became more pronounced for higher seismic input intensities. The uneven settlement of the tunnel cross-section was amplified only for lower seismic input intensities.

Chen et al. [

20] analyzed the dynamic response of the Zhoutouzui immersed tunnel using a 3D finite–infinite element model, varying the stiffness of the joints. The mesh near the boundaries of the model was formed by infinite elements, and the immersion joints were simulated with springs. They found that increasing joint stiffness led to higher axial forces and bending moments in the joints.

Zhou et al. [

21] modeled the nonlinear seismic response of a three-element immersed tunnel subjected to obliquely incident SV waves in a horizontally layered site (

Figure 8). Using an accurate dynamic stiffness matrix and viscous-spring boundary conditions, they observed increased overall displacement with increasing incident angle. Maximum stress on the shear keys and deformation of the immersion joints occurred near the critical wave angle. Crack analysis of the tunnel cross-section suggested reinforcement was needed at the corners, midspan of the top slab, and horizontal shear key connections with the base slab.

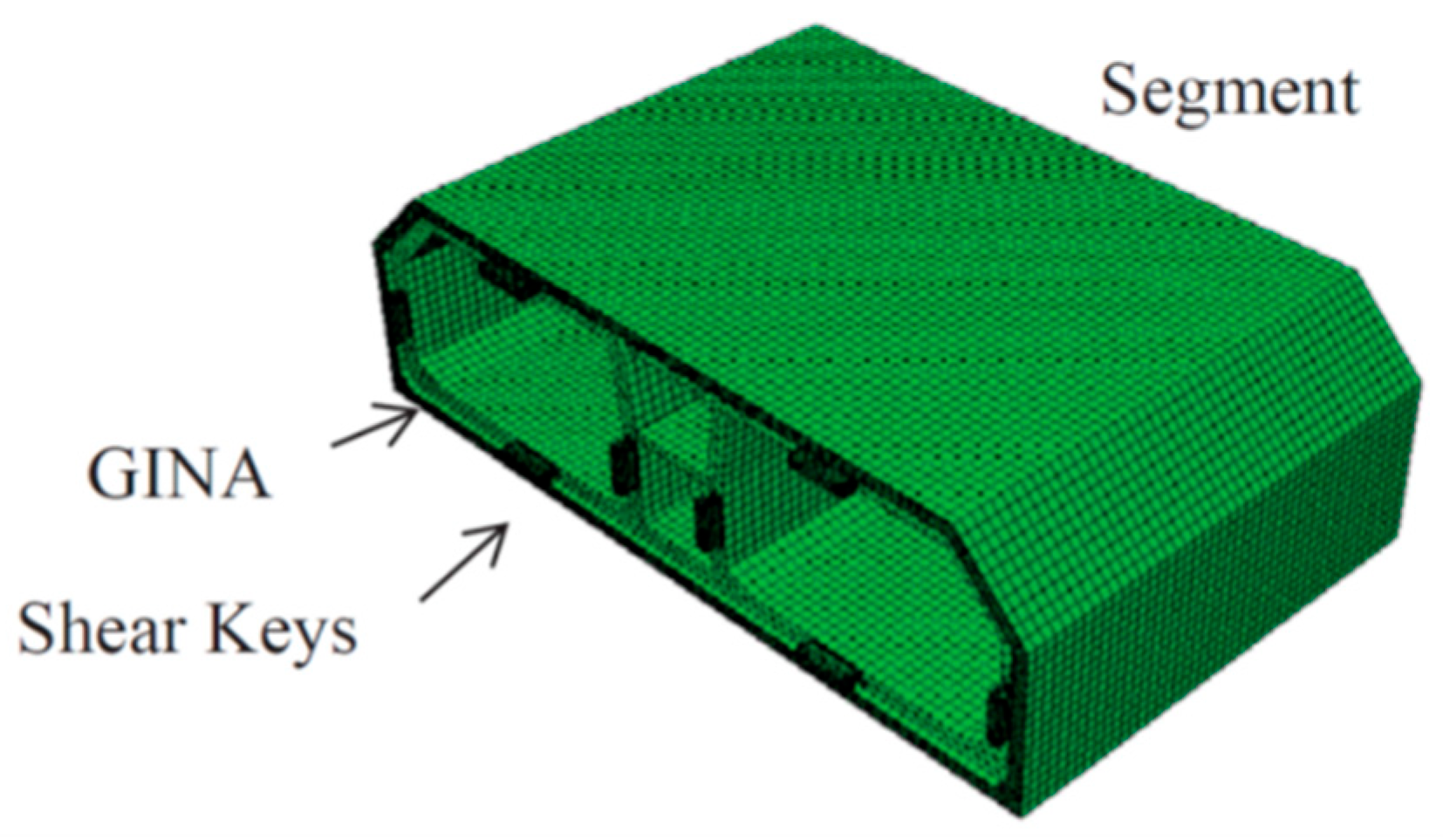

Xiao et al. [

22] conducted a pseudo-static numerical analysis of an immersion joint (

Figure 9), modeling steel shear key behavior with a bilinear elastic–plastic model and Gina gasket response with the Mooney–Rivlin model. The vibration isolation bearings between shear keys were indirectly simulated using gap closure tolerance, and the anchor bolts connecting the steel shear keys to the concrete elements were substituted by an equivalent elasto-plastic layer. The results showed that joint flexural stiffness increased nonlinearly with axial force. Under cyclic shear loading, higher axial forces promoted elastic-like behavior of the Gina gasket, as its compressive stiffness increased, while lower axial forces led to hysteresis.

Lyngs [

23] investigated the seismic response of an immersed tunnel and gasket damage using a closed-form solution, a Winkler-type model (without considering ground elements), and a full 3D continuum model. While the Winkler model was deemed unsuitable for the seismic design of tunnels with non-uniform cross-sections, comparative analysis revealed that soil properties and stratification, together with the earthquake magnitude, significantly influence tunnel damage. Interestingly, tunnel joint modeling had minimal impact on gasket deformation.

The use of 2D and 3D finite element models to evaluate immersed tunnel seismic performance is further illustrated in the case studies presented in

Section 5.

4.3. Physical Models

Physical models have been extensively employed to investigate the seismic performance of immersed tunnels, focusing on tunnel flotation, the influence of the overlying water layer, and the mechanical behavior of tunnel joints.

Uplift of buried structures in liquefiable soils, including immersed tunnels, has been observed during large earthquakes [

24,

25], and it has also been documented in shaking table tests [

24,

26,

27] and centrifuge experiments [

28,

29,

30]. Significant uplift typically occurs under strong shaking conditions.

For example, Yasuda et al. [

27] analyzed the flotation of buried pipes, demonstrating that uplift magnitude and rate decreased with increasing pipe unit weight and soil relative density. Uplift was more pronounced when a larger volume of liquefiable soil surrounded and underlay the pipe, while allowing pore pressure dissipation substantially reduced uplift. Sasaki and Tamura [

29] further found that uplift was predominantly accumulated during shaking. They observed that increased liquefiable soil thickness beneath the structure and a larger volume ratio between liquefiable soil and structure led to greater uplift. Conversely, higher soil relative density reduced uplift, while structure weight and groundwater level had minimal influence.

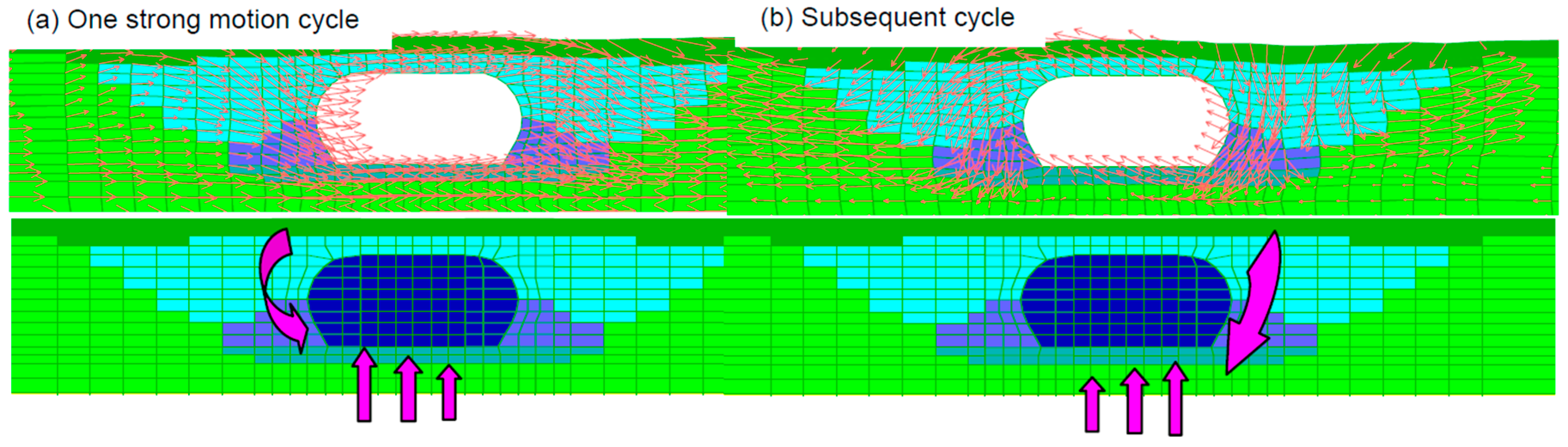

Travasarou et al. [

30], through centrifuge testing, identified uplift as a displacement-limited ratcheting mechanism governed primarily by co-seismic soil movement beneath the tunnel. The liquefied soil, softened and heavier, pushed the tunnel upward and laterally (

Figure 10). Displacements from shear deformation during strong shaking were not recovered post-earthquake.

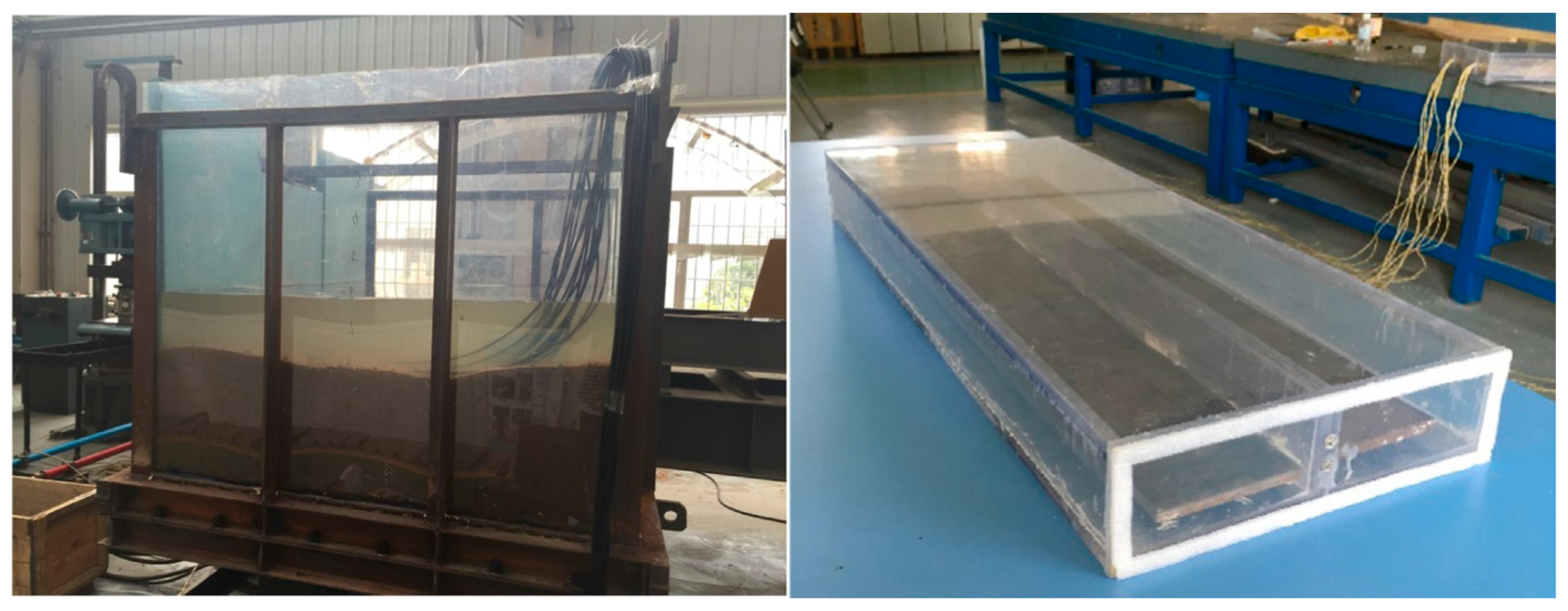

Cheng et al. [

31] conducted a series of shaking-table tests to assess the influence of foundation soil and overlying water layer on the seismic response of immersed tunnels. Considering the common placement of such tunnels beneath rivers or seas, the study was based on the Hong Kong–Zhuhai–Macau (HZM) project, which includes an immersed tunnel with 33 elements, divided into 8 segments each. The scaled model (1:30) comprised three segmented elements and two simplified flexible joints, omitting scaled shear keys due to strength limitations.

Tests were performed in dry sand, saturated sand, and saturated sand with a 0.20 m thick overlying water layer placed inside a laminar shear container under identical horizontal seismic excitations (PGA ranged from 0.1 to 0.4 g). The results indicated that liquefaction significantly altered seismic wave propagation and tunnel dynamic response by dissipating energy and reducing acceleration amplification. However, the overlying water layer had negligible impact on the dynamic performance of the ground or tunnel. Simplified joints reduced acceleration transmission between elements and were found to be significant for seismic design, despite lacking shear keys and gaskets. Additionally, stronger excitations generated excess pore pressures more rapidly, peaking at the ground surface. Soil below the structure exhibited slower particle movement and reduced liquefaction, attributed to increased consolidation stress due to the additional structural load.

Chen et al. [

32] also examined an immersed tunnel response under uniform seismic excitation, both in the longitudinal and transverse directions, using a four-shaking-table array with a 1:60 scale model, placed inside a rigid container that spanned the four tables. The tunnel model joints included prestress cables, Gina gaskets, and shear keys. Testing involved stepwise excitation up to 1.5 g. As shaking intensity increased in free-field tests, soil stiffness decreased, and soil gradually softened. Tunnel seismic responses were clearly affected by surrounding ground conditions, and immersion joint forces grew with input intensity.

Wang et al. [

33] investigated the seismic responses of two immersed tunnel elements under varying seismic waves (PGA: 0.1–0.4 g) and water levels (

Figure 11) using a single DOF shaking-table and a rigid container with polystyrene foam boards glued to its walls to absorb the seismic waves and avoid their reflection. The tunnel polystyrene model, scaled at 1:100, included ballast steel plates and simplified joints, constituted by flexible plastic foam Gina and Omega gaskets and shear keys made with snap fasteners (

Figure 12). Soil was pre-treated via drainage consolidation and vibration to prevent liquefaction. The results showed that seismic wave amplitude and other characteristics influenced tunnel response, which increased with the amplitude. Water presence amplified earthquake waves, with water level influencing this amplification and especially affecting tunnel transverse strains, which were higher near joints.

Xiao [

34] conducted experimental studies on an immersion joint subjected to axial, shear, and bending loads. The model included two tunnel elements, with an immersion joint in between, with a rubber seal and two types of shear keys (steel and concrete). Both the axial stiffness and the flexural stiffness of the joint were derived through load–deformation curves. Increasing axial force in the joint, also subjected to bending, enhanced its flexural stiffness and reduced differential displacements. Static and dynamic shear stiffness also increased with axial load, particularly under dynamic loading due to the Gina gasket rubber compression. Nonetheless, the increase in dynamic stiffness varied with the input frequency. In both cases, the stiffness of the joint increased when compared with the element.

Additionally, Xiao [

34] determined the failure mode and the shear capacity of the joint. However, experimental shear capacities differed from design values due to staggered shear key failure. Rubber bearings improved shear force distribution in steel keys, while asymmetric installation of the shear keys led to racking in concrete keys. The Gina rubber gasket significantly contributed to shear resistance.

To mitigate seismic effects, Buckling Energy Dissipation Devices (BEDDs) can be installed at tunnel joint sidewalls. These steel plate core devices, encased in silicone and concrete-filled steel tubes to restrain buckling, are designed to be activated prior to the occurrence of non-elastic deformations or structural damage, with the goal of dissipating most of the earthquake energy. Large-scale tests, conducted on an immersion joint subjected to compression-bending, showed that BEDDs improved joint hysteretic behavior, bending resistance, and flexural stiffness, though rubber seals remained the primary load-bearing component under bending.

Yuan et al. [

35] studied the vertical shear behavior of an immersion joint model with steel shear keys under multidirectional loading (

Figure 13). A custom loading system enabled testing under various load combinations: compression–vertical shear with increasing longitudinal compression, or increasing vertical shear until failure at constant compression; bidirectional shear, with increasing vertical shear, and fixed longitudinal compression and transverse shear. The results showed that vertical shear stiffness increased with longitudinal compression due to enhanced Gina gasket friction. Transverse shear loads further contributed to this increase due to the friction generated by shear force sharing among horizontal keys. However, the ultimate vertical shear capacity of the joint was lower than the theoretical sum of individual vertical keys shear capacities, indicating non-simultaneous load sharing.

5. Immersed Tunnels’ Seismic Performance

The seismic performance of six immersed tunnel projects is examined in detail: the Offshore Transbay Tube (TBT), the Posey and Webster Street Tubes, the Waihuan Tunnel, the George Massey Tunnel, the Hong Kong–Zhuhai–Macau (HZM) immersed tunnel, and the proposed Algés–Trafaria crossing.

5.1. The Offshore Transbay Tube (TBT)

The Offshore Transbay Tube (TBT), part of the Bay Area Rapid Transit (BART) system, is a 5.8 km long immersed railway tunnel connecting San Francisco to Oakland. Located in the seismically active San Francisco Bay Area (

Figure 14), it was constructed in the late 1960s.

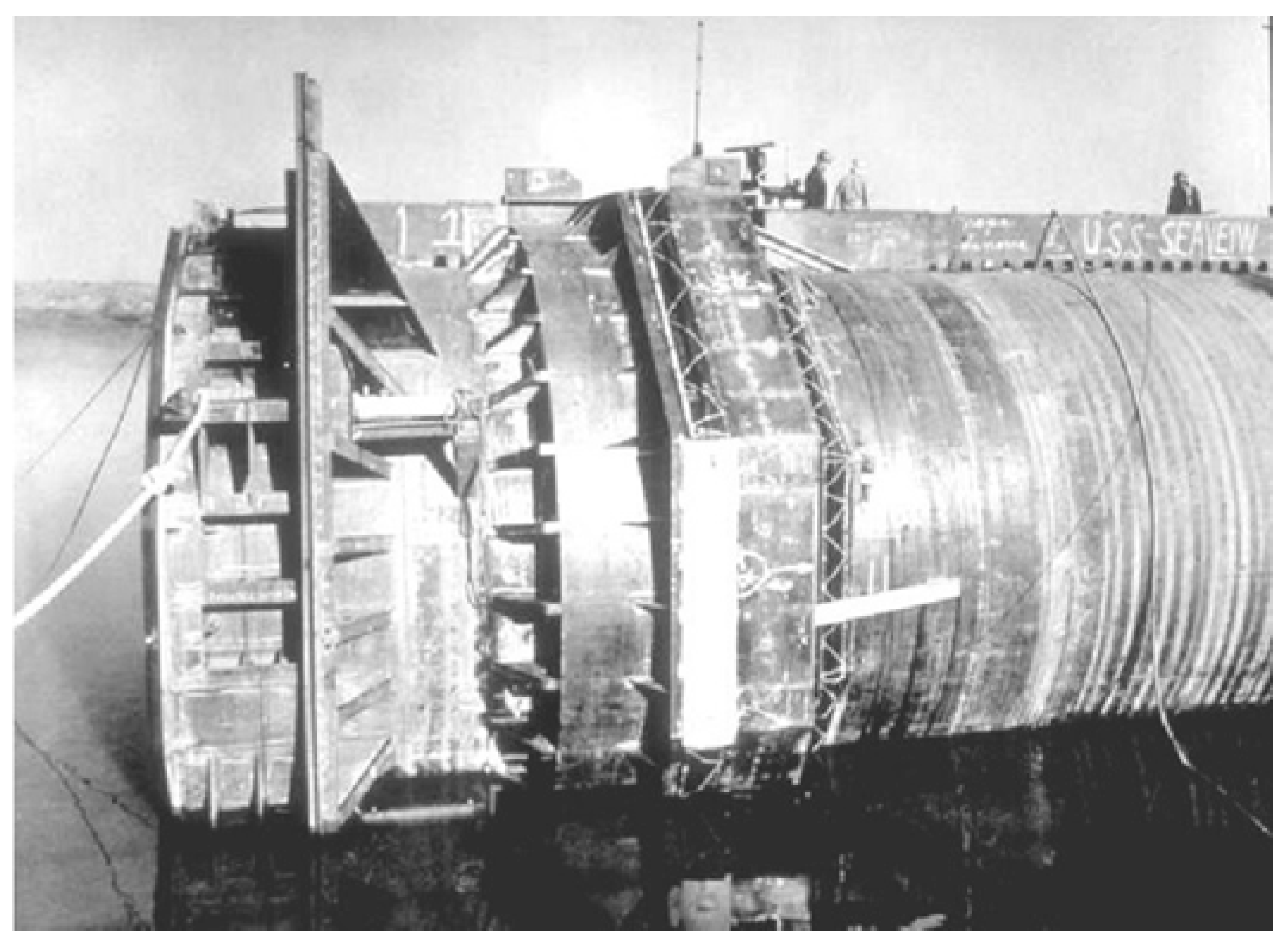

The tunnel was installed in a trench excavated in natural soil, reaching a maximum depth of approximately 40 m. After trench excavation, a 1.2 m thick gravel bedding layer was placed and levelled (

Figure 15). A total of 58 composite tunnel elements—each 100 m long and composed of an external steel shell with internal reinforced concrete—were then immersed and joined. Gravel backfill was tremied around the tunnel up to mid-height, followed by the placement of sand fill to provide a minimum cover of 1.5 m above the structure. Over time, natural sedimentation led to the formation of a soft, impermeable, surficial mud layer [

30].

Although the TBT does not intersect any active faults directly, it lies in close proximity to major fault systems. Specifically, it is situated approximately 14 km from the San Andreas Fault and 9 km from the Hayward Fault, both of which are capable of generating magnitude 7–8 earthquakes.

To accommodate potential seismic displacements from nearby fault activity, a specially designed terminal joint was implemented at both ends of the tunnel [

4]. This telescopic sliding joint allows for triaxial movement while maintaining watertight integrity (

Figure 16). It was engineered to accommodate longitudinal displacements of 0.08 m and vertical or transverse displacements of 0.15 m. Precompressed rubber gaskets slide on Teflon-coated radial and circumferential bearing surfaces to permit movement. Tensioned cables and spherical bearings ensure proper alignment and load transfer. Seals are incorporated to prevent leakage during joint articulation. The movement capability integrates allowance for creep, which is likely to occur over time with repeated seismic movements. The joint also includes mechanical stops to limit excessive displacement and mitigate the risk of joint opening.

The tunnel demonstrated its seismic resilience during the 1989 Loma Prieta earthquake (magnitude 6.9), which had a peak ground acceleration (PGA) of approximately 0.2 g at the surface of the tunnel site and an epicenter 95 km away. Despite widespread infrastructure damage across the region, the TBT remained operational and was reopened only three hours after the earthquake, making it the only functional public transit link at the time.

While liquefaction of the backfill was anticipated under design-level seismic events due to its loose placement, no instances have been reported to date. The gravel backfill is relatively permeable, facilitating rapid dissipation of excess pore pressures. However, the presence of low-permeability surficial soils may result in localized entrapment of pore water.

Dongdong et al. [

37] investigated the vulnerability of the TBT to uplift induced by liquefaction of surrounding soils. Two centrifuge model tests were conducted at the University of California, Davis [

38], simulating representative trench geometries and soil conditions along the TBT alignment, including both stiff and soft clay substrates. The results were used to calibrate numerical models for seismic design.

Each centrifuge model was subjected to a suite of earthquake ground motions with PGA values in the range of 0.01–0.66 g. Before the full amplitude events, smaller amplitude versions were applied to the models in order to calibrate the shaker controllers. The full amplitude events included the 090-horizontal component of the Yerba Buena Island (YBI) recording from the 1989 Loma Prieta earthquake (PGA of 0.14 g for model 1 and of 0.07 g for model 2); the TCU078 recording from the 1999 Chi-Chi earthquake (magnitude 7.6, PGA of 0.65 g for model 1 and of 0.66 g for model 2); and a processed signal from the 1992 Landers earthquake (magnitude 7.3, PGA of 0.36 g for model 1), referred to as the Joshua Tree motion.

Three uplift mechanisms were identified: (1) a ratcheting mechanism involving sand migration beneath the tunnel with each cycle of relative movement, (2) pore water migration driven by pressure gradients, and (3) bottom heave due to soft clay deformation below the trench [

38].

Under the YBI motion, negligible uplift occurred despite excess pore pressures reaching 70–80% of the initial effective stress beneath the tunnel. In contrast, the stronger TCU078 motion caused modest co-seismic uplift (~0.25 m). The limited uplift was attributed to the thin gravel foundation layer, which restricts soil and water migration, and the high permeability of the surrounding soil, which facilitates rapid drainage. In the centrifuge tests corresponding to TCU078 and Joshua Tree motions, water flow accounted for 20–25% of the total uplift, while ratcheting contributed 65–80%.

Numerical simulations using the UBCSAND model in FLAC2D [

39] and the PressureDependMultiYield01 model in OpenSees were able to reproduce key features of the TBT behavior, involving nonlinear dynamic soil response, liquefaction, water flow, and soil–structure interaction. These included tunnel uplift, excess pore pressure dissipation rates, and deformation patterns such as inward and upward movement of liquefied soil beneath the tunnel.

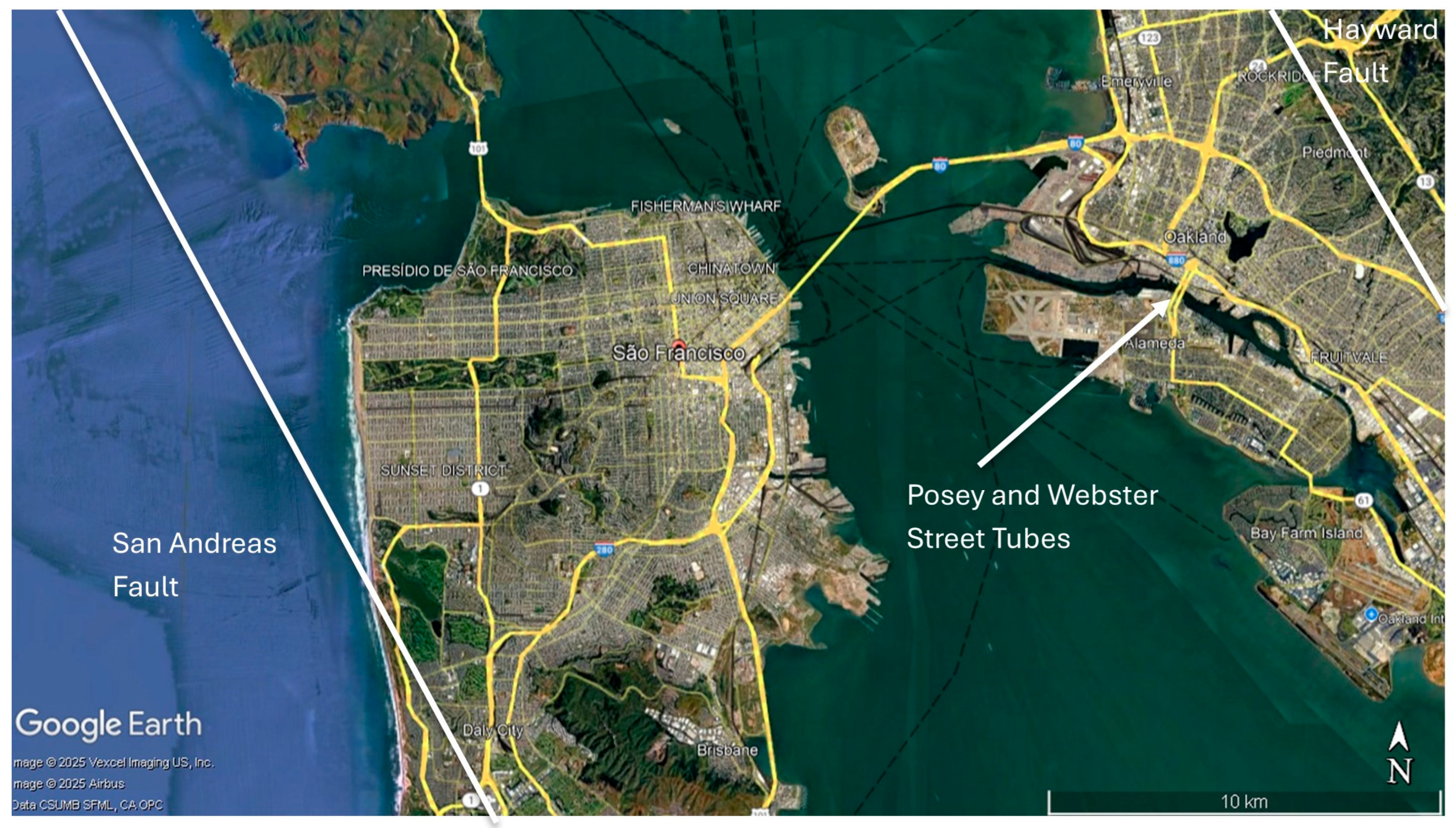

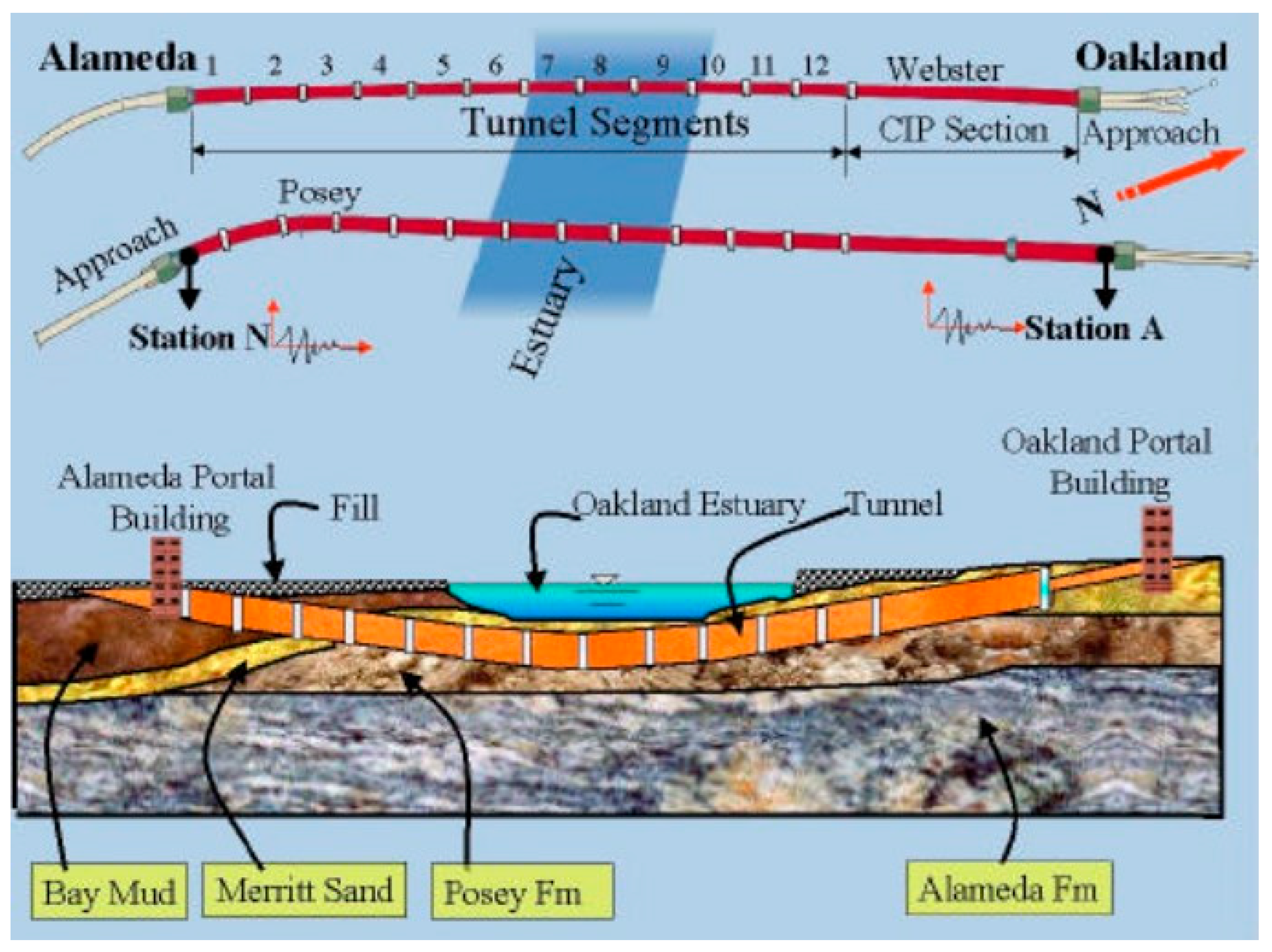

5.2. The Posey and Webster Street Tubes

The Posey and Webster Street Tubes, built in 1928 and 1962, respectively, are immersed reinforced concrete tunnels that connect Alameda Island to the city of Oakland, California (

Figure 17). These tunnels reach a maximum depth of approximately 20 m below the water surface. The Posey Tunnel consists of precast concrete elements, each about 60 m in length. A typical tunnel section features a circular cross-section with an external diameter of approximately 11 m and a wall thickness of 0.75 m.

Following placement in a pre-excavated trench at the Bay floor, the joints were sealed with steel and concrete. The sub-tunnel space was filled with loose sand, while the trench backfill was composed of soft clay and loose sand from the Bay. The local subsurface stratigraphy comprises five major layers (

Figure 18). Beneath the ground surface, the Alameda Formation—consisting of dense medium to coarse gravelly sand interbedded with sandy silt to clayey silt—overlies bedrock at about 180 m depth. Above this lies the Posey Formation, composed of stiff to very stiff sandy silt to clayey silt, followed by very dense Merritt sand, and capped by soft Bay mud.

Seismically, the site lies approximately 22 km from the San Andreas Fault and only 6 km from the Hayward Fault (

Figure 17). The Hayward Fault presents the primary seismic hazard, capable of generating a magnitude 7.25 earthquake, with peak horizontal rock outcrop accelerations up to 0.76 g and surface horizontal ground accelerations exceeding 0.5 g. The anticipated duration of such an event may exceed 45 s, allowing significant pore pressure buildup that could induce widespread liquefaction and potential tunnel flotation [

40].

The most recent major seismic event impacting the area was the 1989 Loma Prieta earthquake. This event caused liquefaction in Alameda and in the vicinity of the tunnels. In response, a seismic retrofit plan was implemented in 1997. The retrofit strategy focused on mitigating flotation risk and improving structural performance through ground improvement of the backfill and structural upgrades, respectively.

Ground improvement measures included the installation of stone columns on both sides of the Webster Street Tube to densify the backfill and facilitate pore pressure dissipation during seismic events. Jet grouting was applied adjacent to the Posey Street Tube to laterally isolate it from the backfill. Structural retrofits included the modification of existing full-perimeter joints between tunnel elements to accommodate expansion and the addition of special joints at the connections to the portal buildings. These modifications were aimed at improving flexibility, reducing internal forces, and maintaining watertightness during seismic loading.

As part of the retrofit project, Kozak et al. [

41] conducted advanced nonlinear finite element analyses to assess soil–structure interaction effects under earthquake loading. Their models incorporated wave passage, scattering, and reflection phenomena. The use of detailed three-dimensional global models, including nonlinear material behavior and realistic boundary conditions, provided critical insights into tunnel response under strong ground motion. These global models were supplemented with two-dimensional local analyses for evaluating ultimate load capacity due to racking effects. A specialized three-dimensional model was also developed for the Posey Tube’s transition element and subjected to racking to investigate the impact of geometric changes under seismic loading.

In the global 3D finite element model, the tunnels were represented with beam and truss elements, while nonlinear springs were used to simulate soil behavior. Seismic excitations were applied as displacement time histories at the soil boundaries. A comparative analysis was conducted for both the original and retrofitted tunnel configurations. In the retrofitted model, inter-element joints were modified to eliminate tensile force transmission, significantly reducing axial forces, shear forces, and bending moments to within acceptable limits.

Parametric studies explored the effects of varying soil spring spacing, torsional spring stiffness, and element length on tunnel response. It was concluded that modeling soil springs at 15 m intervals, with at least two finite elements between them, provided a reliable approximation of seismic response. The results demonstrated that the proposed retrofit measures significantly improved tunnel performance, particularly in reducing joint displacements. Furthermore, the analyses underscored the importance of modeling the nonlinear behavior of surrounding soils when assessing tunnel deformation and joint responses.

A separate two-dimensional racking analysis of the Posey Tube was also carried out, incorporating site stratigraphy, backfill, jet grout, tunnel walls, slabs, and reinforcement (

Figure 19). The construction sequence of the immersed tunnel was included in the model. Racking displacement was applied incrementally using inelastic static analysis. Outputs included stress distributions in soil and tunnel, reinforcement bar stresses, and crack development in walls and slabs. These results helped identify critical shear zones at the backfill/soil interface and at the walls of the tunnel, and they provided further validation of the jet grout’s effectiveness in enhancing soil–structure performance.

Finally, a specialized three-dimensional model for the transition element of the Posey Tube was subjected to a racking displacement using linear elastic incremental static analysis. The results revealed that stress concentrations diminished rapidly beyond the transition zone, suggesting that abrupt geometric changes primarily affected localized tunnel behavior.

5.3. The Waihuan Tunnel

The Waihuan Tunnel is a 2888 m long bi-directional immersed tunnel beneath the Huangpu River in Shanghai, China [

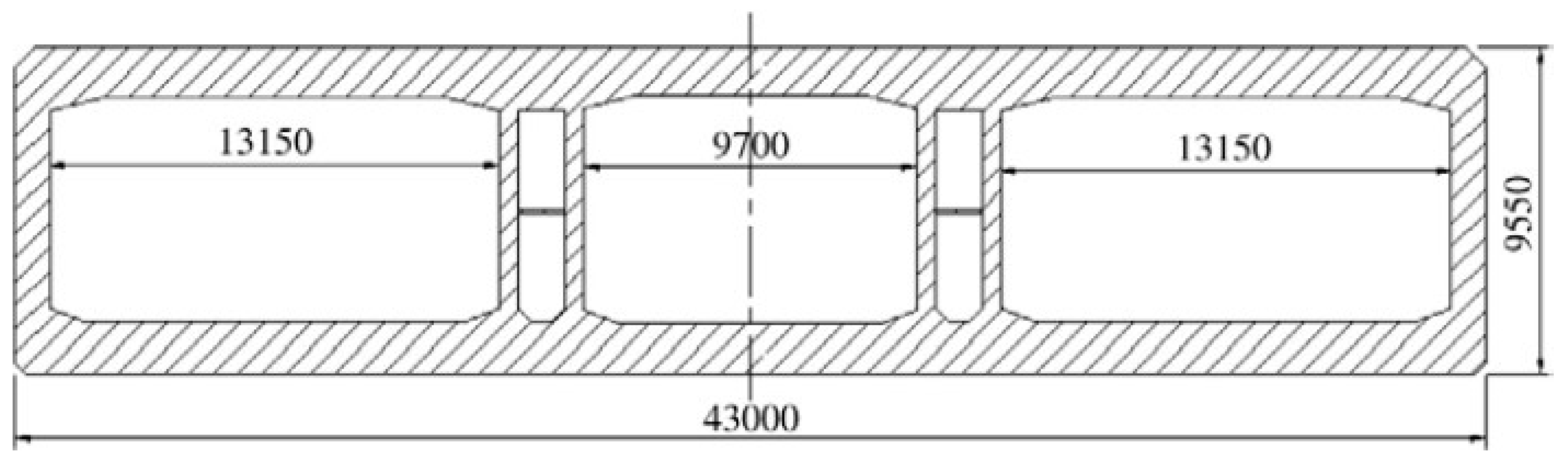

42]. It features a large cross-section (43 m × 9.55 m) accommodating eight traffic lanes (

Figure 20) and consists of seven immersed elements, each 100–108 m in length, connected by eight flexible joints.

Ding et al. [

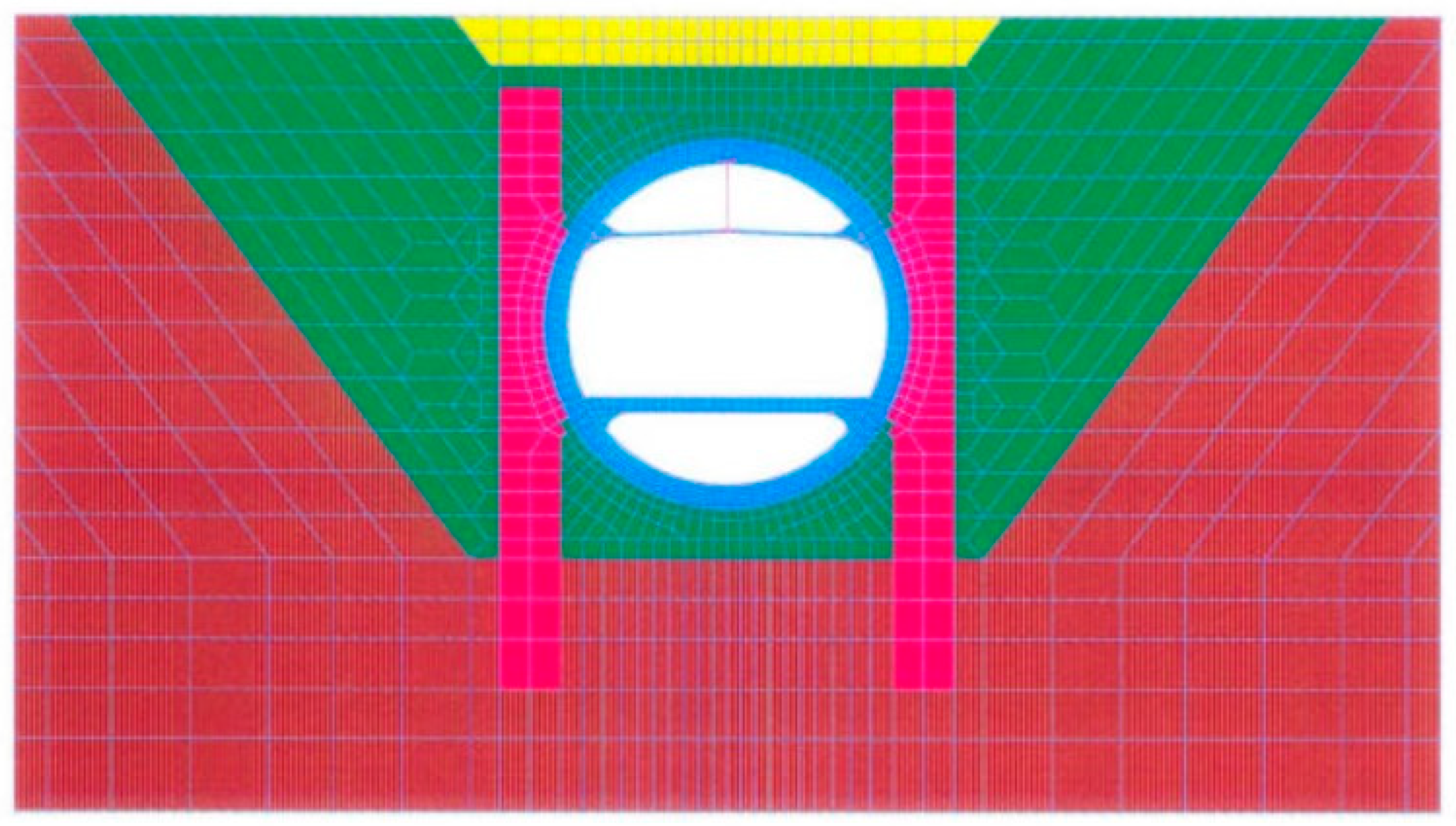

42] developed a large-scale numerical simulation method to assess the seismic response of the tunnel, employing a three-dimensional dynamic finite element model executed on a high-performance computing system. The analysis used LS-DYNA, a general-purpose finite element code capable of modeling dynamic large-deformation structural responses. The finite element mesh included four-node tetrahedral elements for the surrounding soil, eight-node hexahedral solid elements for the tunnel structure, and beam elements to represent prestressed cables. The model boundaries were placed at a distance exceeding four times the tunnel’s cross-sectional width to minimize boundary effects (

Figure 21).

The site’s subsurface conditions comprise multiple layers of cohesive silts and clays. Their mechanical behavior was modeled using an elastoplastic constitutive relation based on the Drucker–Prager yield criterion. The tunnel’s flexible joints include Gina gaskets and vibration isolation bearings, both composed of rubber exhibiting nonlinear geometric and material behavior (

Figure 22). The rubber components were modeled using the Mooney–Rivlin hyperelastic formulation [

43]. The steel shear key was simulated with a constitutive model incorporating isotropic and kinematic hardening plasticity, as well as strain-rate effects.

Seismic input was based on ground motions from the 1976 Tangshan earthquake (magnitude 7.6), applied independently both in the longitudinal and transverse directions at the bedrock level. The vertical and orthogonal (transverse or longitudinal, respectively) displacements were constrained accordingly. The amplitude of the seismic record was modulated so that the peak ground acceleration (PGA) at the bedrock of the tunnel site was approximately 0.1 g. To prevent spurious reflections at the model boundaries, normal viscous boundary conditions were applied. The dynamic analysis employed an explicit time integration scheme with a parallel domain decomposition algorithm [

44].

The analysis revealed that the largest relative displacements between adjacent tunnel elements occurred at the tunnel extremities, with a maximum value of 0.024 m. Gina gaskets experienced compressive deformations ranging from 0.005 m to 0.023 m, while the vibration isolation bearings atop the shear keys displaced between 0.004 m and 0.007 m. The results confirmed that the incorporation of eight flexible joints effectively reduced stress concentrations along the tunnel walls and enhanced the overall seismic resilience of the structure. Consequently, flexible joints play a critical role in the earthquake-resistant design of immersed tunnels, preventing unacceptable deformation. Their performance depends on the behavior of internal components such as Gina gaskets and shear keys made of steel and concrete.

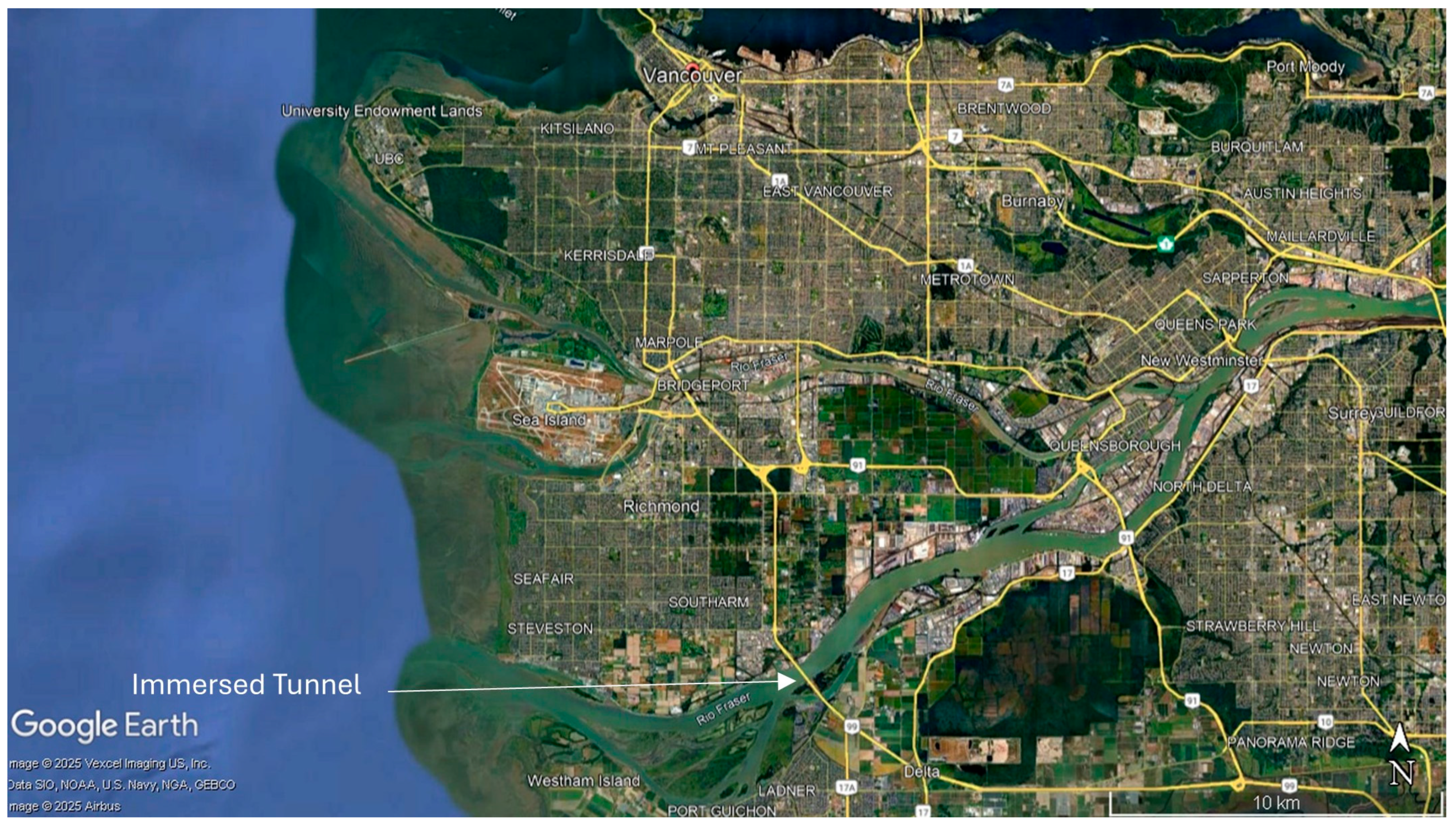

5.4. The George Massey Tunnel

The George Massey Tunnel, completed in 1959, connects Vancouver, British Columbia, Canada, with Washington State, USA. The tunnel spans 1.3 km beneath the Fraser River, comprising a 370 m north approach, a 629 m immersed section, and a 335 m south approach (

Figure 23). The immersed portion includes two traffic shafts, each carrying two lanes, and two external ventilation ducts (

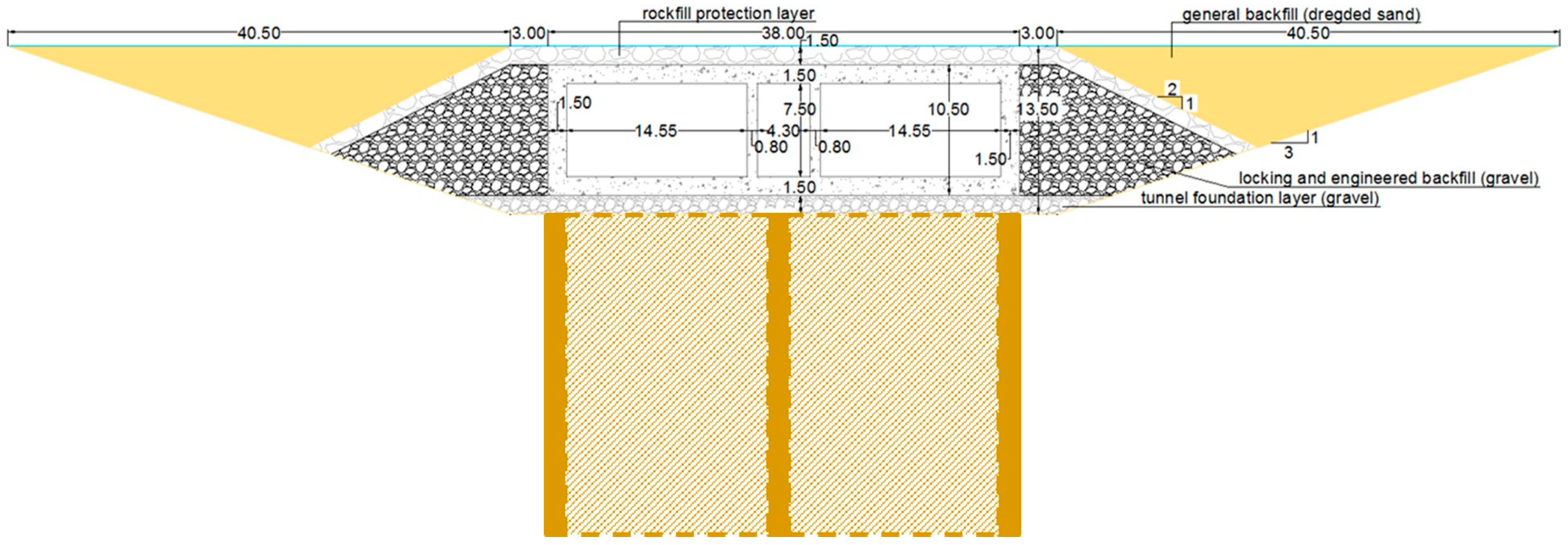

Figure 24). Tunnel elements were precast in 105 m segments within a graving dock, floated into position, and submerged into a shallow trench on the riverbed. After placement, sand was jetted to fill the space beneath the tunnel, and gravel and rockfill were placed around and above the structure to ensure stability against buoyancy and to protect against scour [

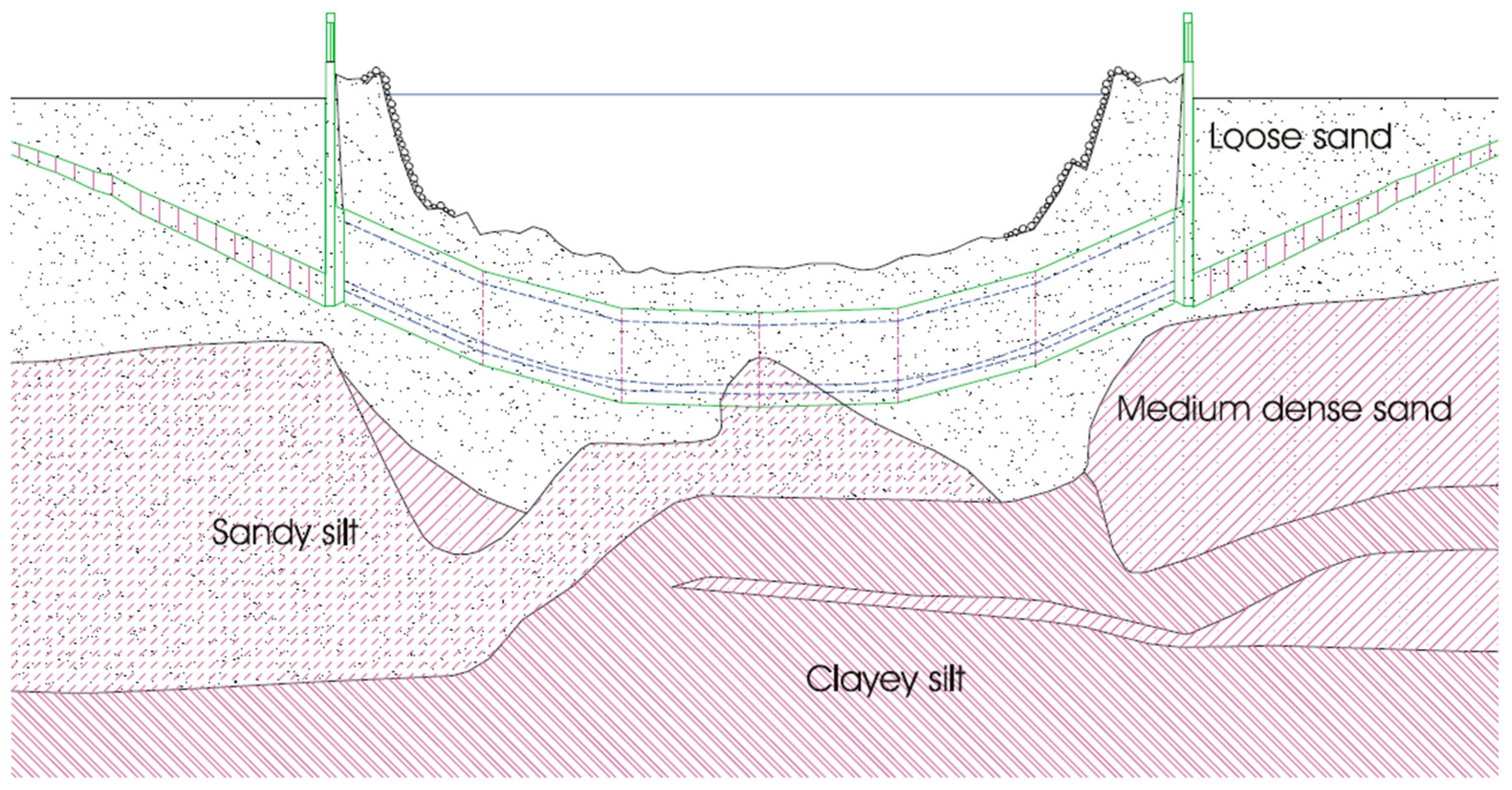

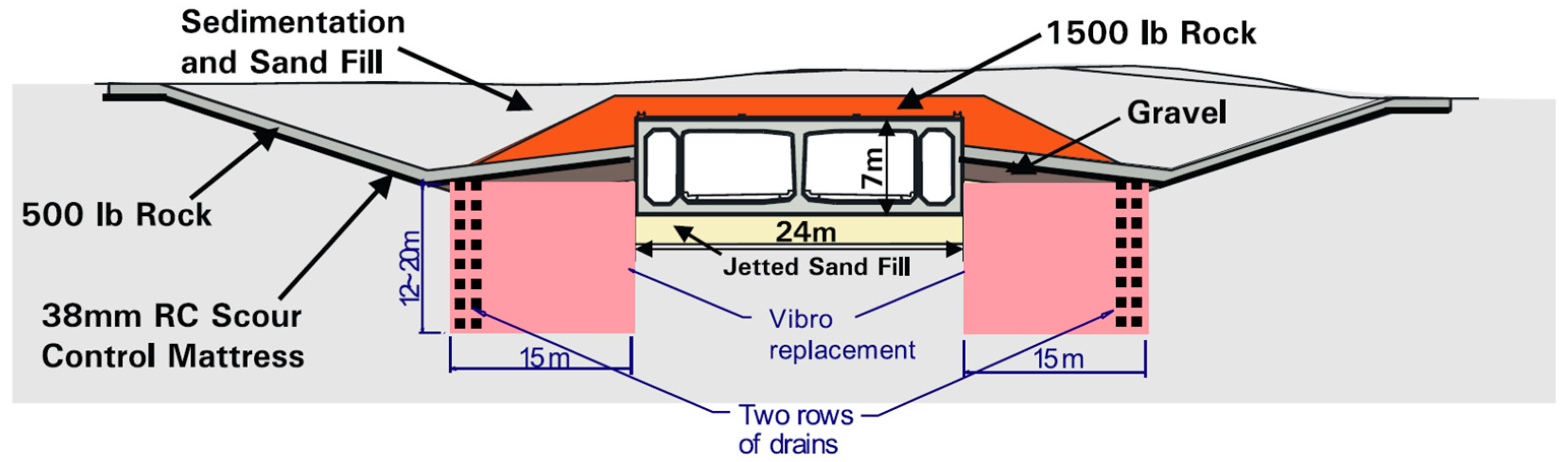

45].

The geological profile, derived from borehole data, is shown in

Figure 25 (approximately 50 m deep and 1000 m wide). The upper 15 m of subsoil consists of loose sand and interbedded sandy silt, underlain by clayey silt [

46].

Figure 23.

The George Massey Tunnel location (Google Earth).

Figure 23.

The George Massey Tunnel location (Google Earth).

Figure 24.

The George Massey Tunnel cross-section (reproduced with permission from COWI [

47]. John Wiley and Sons, 2005).

Figure 24.

The George Massey Tunnel cross-section (reproduced with permission from COWI [

47]. John Wiley and Sons, 2005).

Figure 25.

Geological profile along the George Massey Tunnel (reproduced with permission from COWI [

47]. John Wiley and Sons, 2005).

Figure 25.

Geological profile along the George Massey Tunnel (reproduced with permission from COWI [

47]. John Wiley and Sons, 2005).

In 2003, the tunnel underwent seismic retrofitting to resist two design earthquake scenarios: (1) a local non-subduction event with PGA of 0.25 g, moment magnitude (Mw) 7.0, with a 10% probability of exceedance in 50 years (475 year return period), and (2) a 120 km distant subduction earthquake with PGA of 0.15 g and Mw 8.2. The design scenarios were defined by the British Columbia Ministry of Transportation, which provided time history records for both cases. These records, with an 80 s duration, have been fitted to the design earthquake characteristics. The retrofit aimed to prevent collapse and loss of life while limiting damage to repairable levels, including controllable water ingress [

45,

46]. The primary challenge was addressing potential soil liquefaction in both the native loose deposits and the jetted backfill sand and its consequences.

Design earthquake motions were specified at the bedrock, approximately 300 m below the tunnel site. To avoid extending the 2D numerical models to this depth, which would have made them prohibitively large and computationally expensive, ground response analyses using the equivalent-linear method [

48] was carried out to provide input motion time histories at 50 m depth and cyclic stress ratios for preliminary liquefaction triggering assessments.

The primary geotechnical design tool was two-dimensional nonlinear dynamic analysis using FLAC. Constitutive models included UBCTOT and UBCSAND, developed at the University of British Columbia [

39,

49,

50], addressing dynamic loading, liquefaction initiation, post-liquefaction behavior, and soil–structure interaction. Model parameters were calibrated using laboratory and empirical data. During shaking, pore pressures were generated via shear-induced plastic volumetric strain, reducing mean effective stress and initiating water flow gradients.

Both transverse and longitudinal sections were modeled. Transverse models assessed liquefaction effects around the tunnel, riverbed morphology influence, and pore pressure redistribution, helping to optimize mitigation strategies. The longitudinal model evaluated “migration effects,” wherein liquefied soils beneath the tunnel and riverbanks could flow toward the mid-river, driven by stress gradients (higher stresses at the riverbanks). This would induce settlement beneath the banks and uplift of the tunnel in the channel. Due to consolidation of the liquefied soils during the post-liquefaction phase, tensile forces could develop at the tunnel ends and compression forces in mid-sections, with potential for excessive bending moments in the tunnel [

46].

Analyses included various earthquake records, riverbed slopes, and soil profiles [

45]. Key tunnel vulnerabilities identified were:

Wave passage effects: The tunnel’s length leads to varying seismic motion along its alignment. Propagating waves in the ground will induce stresses in the tunnel as they travel along its length. Moreover, spatial variability of the ground properties along the tunnel’s length will result in additional variation of the ground motion.

Liquefaction (up to 20 m depth): A critical factor, more influential than wave passage effects. Liquefaction reduces soil stiffness and strength, leading to ground failure and differential movement. Consequences include tunnel uplift, lateral displacement due to riverbed slope, movement of soil from the river banks toward the center channel, upward heave of the approach structures, and differential consolidation settlement after shaking due to post-liquefaction dissipation of excess pore water pressures.

Groundwater migration: Elevated pore pressures during shaking can cause vertical water flow or lateral flow under the tunnel or approach structures, inducing uplift. Low-permeability interlayers may direct excess pore pressure to dissipate toward the tunnel post-earthquake and induce uplift [

46].

Stiff joints between the tunnel and ventilation structures: These may attract significant tensile/compressive forces, risking joint failure.

Wave passage effects, assuming a wave travelling in the underlying bedrock (velocity = 2000 m/s), induced displacements of <0.05 m over 650 m. Soil column variations in the upper 50 m added ~0.02 m differential settlement. However, liquefaction-induced movements were an order of magnitude greater and dominated the design. With a flat riverbed and no ground improvement, the tunnel could heave 0.5–1.5 m during shaking. A sloped riverbed reduced vertical heave to 0.2–0.3 m but led to lateral displacements of 1–2 m [

45].

These effects could result in cracking, especially in under-reinforced areas and joints, potentially causing water leakage. Thus, the retrofit objective was to avoid structural failure and restrict damage to ensure reparability after a major earthquake [

47]. As significant uplift and lateral tunnel displacements were expected, various deformation mitigation strategies were evaluated, including ground densification, gravel drains, sheet piles to stop liquefied soil and water from moving in under the tunnel, jet grouting to support the tunnel and prevent soil movement under the tunnel, and compaction grouting and micropiles to control post-liquefaction settlement. The widths and configurations of the densification zones were optimized through modeling.

A final structural retrofit was developed using a 3D ABAQUS finite element model of the tunnel and ventilation buildings, incorporating soil–structure interaction. Equivalent springs represented surrounding soil stiffness. Two critical loading scenarios were considered: (a) seismic loading from wave passage and (b) post-liquefaction differential settlement based on 2D longitudinal analyses. UBCSAND was found to underestimate post-liquefaction consolidation, necessitating a bulk modulus adjustment to achieve realistic settlements.

Sheet piles effectively reduced uplift but were less efficient for lateral restraint on sloped beds and were costlier than alternative solutions. Similarly, jet grouting cut-off walls were more expensive than stone column densification.

Therefore, the selected measures included ground densification through vibro-replacement stone columns and vertical seismic drains on both sides of the tunnel (

Figure 26). The former controlled uplift and lateral spread; the latter dissipated excess pore pressure and prevented groundwater-induced uplift. Gravel drains also reduced pore pressure buildup in the densified zones, maintaining soil strength during shaking.

Numerical analysis predicted that, with these measures, lateral tunnel displacement would be limited to 0.1–0.4 m, vertical heave to <0.2 m, and differential settlement due to post-liquefaction consolidation to <0.6 m over 250 m [

45].

Finally, centrifuge testing [

28] was conducted to validate numerical predictions. Three tests were performed: (1) no ground improvement, (2) 10 m densification zones, and (3) 10 m gravel drainage zones on either side of the tunnel. The results confirmed liquefaction under design earthquakes and associated upward and lateral tunnel movements. Both improvement strategies reduced displacements, with gravel drains showing greater effectiveness per unit area treated. Overall, good agreement between centrifuge test and numerical model results supported the final retrofit decision [

51].

5.5. The Hong Kong–Zhuhai–Macau Immersed Tunnel

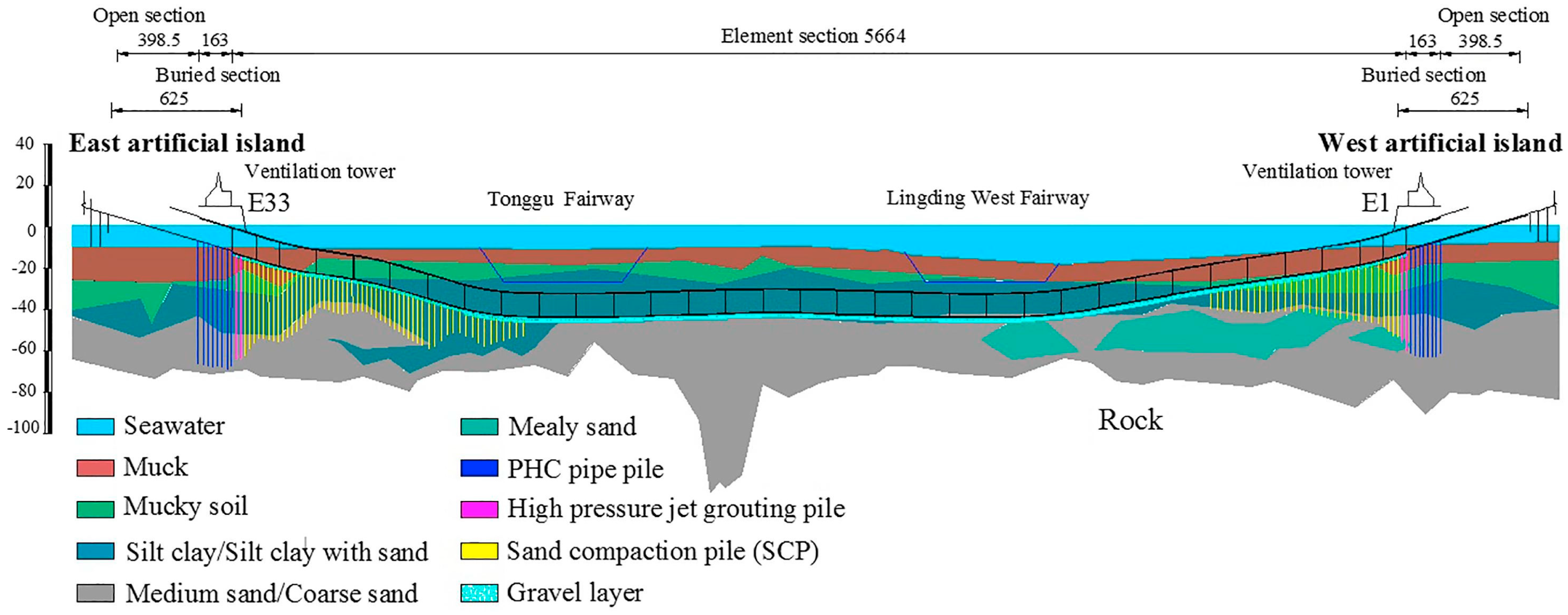

The Hong Kong–Zhuhai–Macau (HZM) Bridge spans approximately 35.6 km across the Pearl River Estuary, connecting the cities of Hong Kong, Zhuhai, and Macau. The primary crossing comprises two artificial islands and a 5.7 km long immersed tunnel (

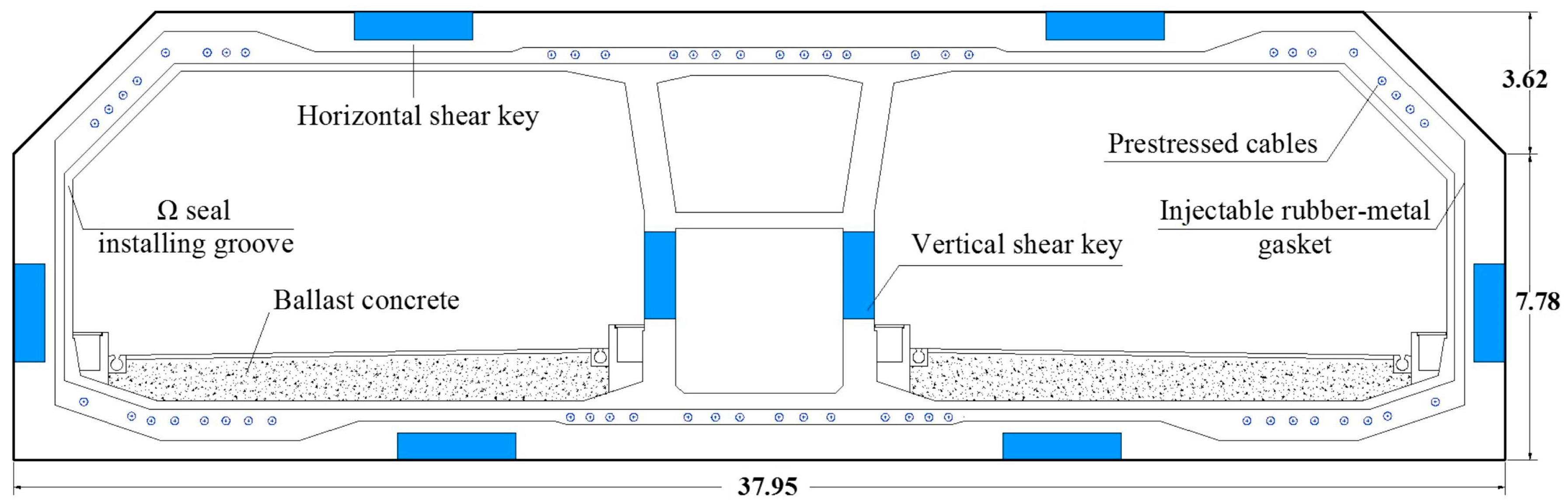

Figure 27), reaching a maximum depth of 45 m. The tunnel consists of thirty-three prefabricated reinforced concrete elements, each 180 m long and composed of eight 22.5 m segments. The tunnel cross-section is nearly rectangular, with a width of 37.95 m and a height of 11.4 m, containing three separate cells: two for vehicular traffic and one for pipelines and ventilation.

Most elements rest on approximately 60 m thick soft soil layers composed of muck, mucky soil, silty clay, mealy sand, medium sand, and coarse sand, with significant variability across layers (

Figure 28). The segment joints incorporate omega seals, injectable rubber–metal gaskets, reinforced concrete shear keys, and prestressed cables (

Figure 29). These joints lack continuous reinforcement, allowing for articulation during settlement, while shear keys constrain vertical and horizontal displacements. Due to the site-specific ground conditions, the temporary prestressed cables are retained in the HZM Tunnel.

Li et al. [

53] developed a simplified numerical model to analyze the seismic response of the tunnel under longitudinally non-uniform earthquake excitation, accounting for wave passage effects and local site conditions. An acceleration time history with 3% probability of exceedance in 120 years was artificially generated and applied at the bedrock, with a corresponding PGA of 0.23 g. A 1D linear analysis was used to determine the free-field motion, and a mass–spring–dashpot model was adopted for the tunnel–ground system. The surrounding ground was discretized into slices perpendicular to the tunnel axis, each modeled as a mass connected to the bedrock and adjacent masses via springs and dashpots. Tunnel–ground interaction was also represented by springs and dashpots connecting each ground mass to the tunnel, which was modeled as a beam system (

Figure 30). Immersion joints were represented by five nonlinear springs capturing longitudinal displacement, transverse and vertical bending (Gina gaskets), and transverse and vertical shear (steel shear keys). The results showed that non-uniform excitation significantly increased joint deformation, especially at lower wave velocities due to larger time lags and intensified non-uniformity.

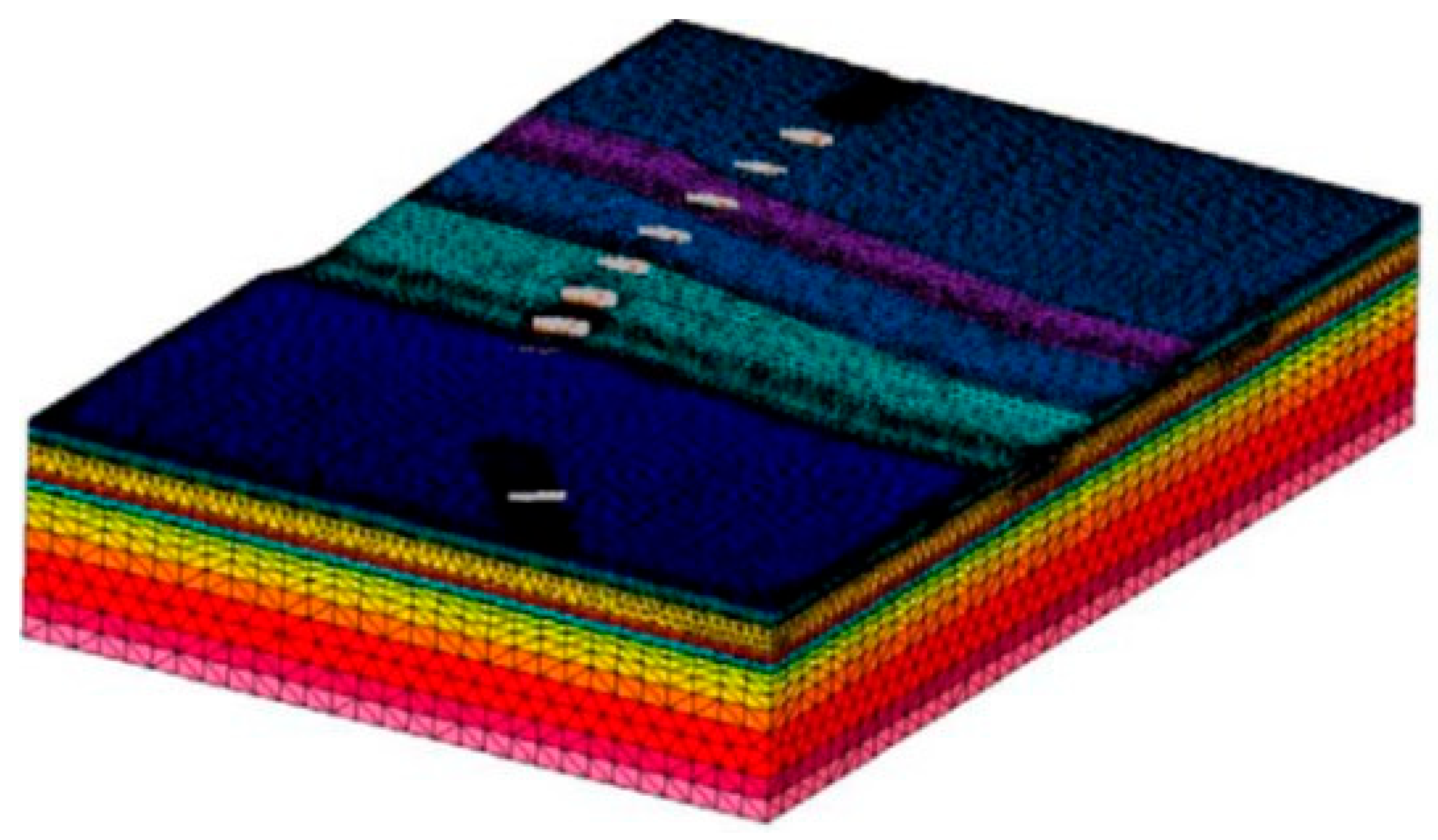

Chen et al. [

54] conducted dynamic finite element analyses to further investigate the effects of ground spatial variability and wave passage. First, a 2D free-field model (without the tunnel) was used to obtain ground acceleration time histories beneath the tunnel. The ground motion recorded in the Kobe earthquake (17 January 1995) was adopted as the input motion in the free field analysis, with a PGA of 0.25 g. The wave passage effect was found to reduce peak ground acceleration (PGA), whereas ground variability increased it. Low-frequency amplification was observed, notably when ground properties varied spatially. Subsequently, a 3D beam–spring–dashpot model of the tunnel was developed, where each tunnel segment was divided into four beam elements and joints were modeled using nonlinear springs with five degrees of freedom (axial compression, horizontal and vertical shear, horizontal and vertical bending). Prestressed cables in the segment joints were simulated using tension-only truss elements. The results revealed that both wave passage and ground spatial variability substantially increased axial forces and Gina gasket deformations, while the latter also caused elevated bending moments. When both effects were combined, gasket deformations exceeded design compression limits, indicating a risk of joint failure and leakage.

Yan et al. [

55] and Yuan et al. [

56] designed a linear multi-point shaking table system and a 40 m long segmented model container to simulate the tunnel’s seismic response under non-uniform excitation. A 1:60 scale tunnel model rested on four shaking tables capable of motion in multiple directions and rotation in the horizontal plane. Time lags between tables simulated wave passage effects. The in situ soil, mainly fine silty sand, was represented by a synthetic mixture of sawdust and sand (mass ratio 1:2.5), achieving similar dynamic properties. Gina gaskets were represented by silicone strips, and steel cables were used to simulate prestressed connections between segments.

Yu et al. [

57] tested the scaled model under various seismic amplitudes. Three types of earthquakes were considered, the ODE, Operational Design Earthquake, with a PGA of 0.05 g (63%probability of exceedance in 120 years), the MDE, Maximum Design Earthquake), with a PGA of 0.15 g (10% probability of exceedance in 120 years), and the RDE, Rare Design Earthquake, with a PGA of 0.23 g (3%probability of exceedance in 120 years). The results showed that non-uniform excitation caused greater joint deformation than uniform excitation. The tunnel exhibited a stronger dynamic response than the surrounding soil, and significant variability was observed across different ground conditions.

Binder et al. [

58] performed 44 earthquake tests on 13 model tunnel elements, simulating three epicenter locations (east, west, or south of the tunnel) and subjecting the structure to longitudinal waves (P-waves), transversal waves (S-waves), and a combination of both. The considered PGAs were similar to the ones defined by Yu et al. [

57]. Two embedment scenarios were studied: a thin sediment layer (immediately post-construction) and a thick layer (several years post-construction) covering the tunnel. Frequency analysis yielded the following key insights (amplification/attenuation was defined as the difference between the Fourier amplitude of the excitation measured at the tunnel and the corresponding Fourier amplitude of the excitation applied at the shaking tables):

The tunnel’s first eigenfrequency was approximately 20 Hz in the model, corresponding to 1.15 Hz at full scale.

Frequencies between 10 and 20 Hz (0.58–1.15 Hz full scale) were amplified, while those from 30 to 100 Hz (1.73–5.77 Hz) were attenuated.

Amplification was greater with a thin overburden, indicating that increased sediment coverage reduces amplification.

Attenuation was more significant for longitudinal (P-wave) excitation than for transverse (S-wave), suggesting greater tunnel sensitivity to S-waves.

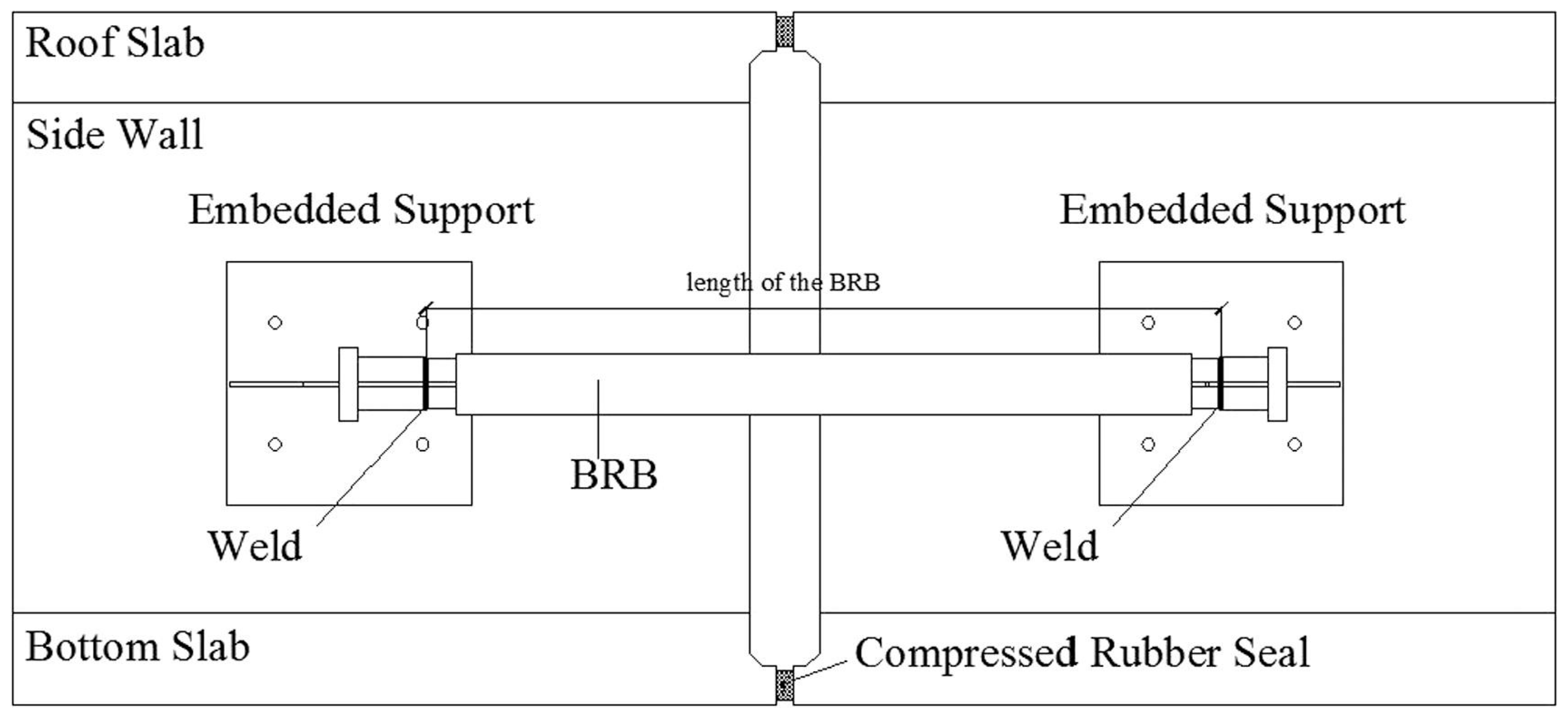

To improve seismic performance of the tunnel joints, Yu et al. [

59] proposed the use of Buckling Restrained Braces (BRBs) installed axially between adjacent tunnel elements (

Figure 31). The elastic stiffness and yielding force of the device were optimized to maximize energy dissipation. A 1:10 scale model of an immersion joint and two adjacent tunnel elements was tested under compression and cyclic bending. The joint with BRBs dissipated 69% more energy, supported 37% greater bending moments, and exhibited 45% higher flexural stiffness than the unreinforced joint. However, the stiff rubber seal bore a large portion of the bending moment, limiting BRB performance. A softer seal and hinged end connections were recommended to enhance joint rotation and BRB efficiency by elongating its yielding stage and reducing the bending moment in the device.

Lin et al. [

60] developed special vertical shear key bearings designed to “remember” the allowable shear force. Just before exceeding this threshold, the bearings compress to prevent damage in the shear keys by inducing a vertical offset in the joint, protecting the structure of the immersed tunnel from differential settlement.

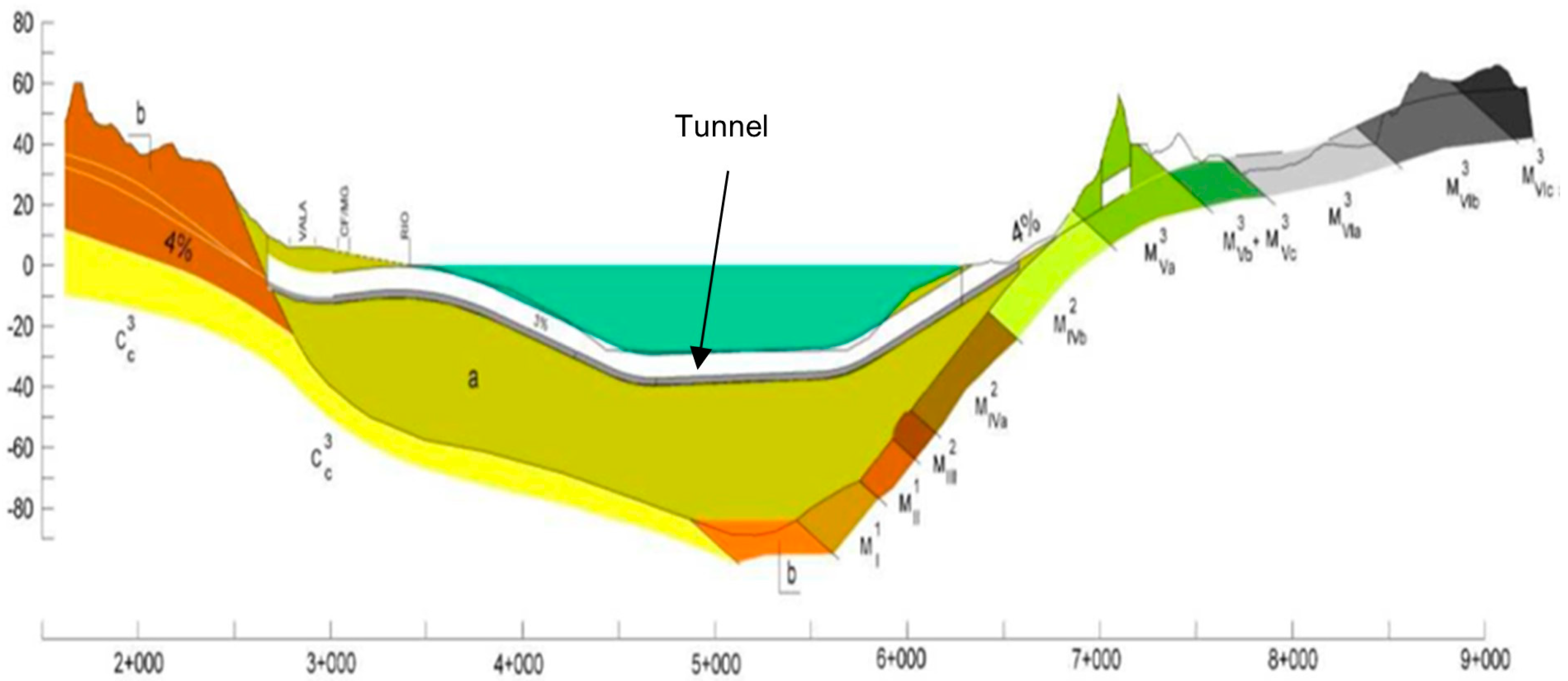

Hu et al. [