1. Introduction

Oil sands mining has become a vital aspect of global energy production, particularly in regions like Alberta, Canada. However, along with its significant contributions to the energy supply, the extraction process generates substantial amounts of waste, primarily in the form of tailings, which pose significant environmental challenges. These tailings consist of water, mineral solids, including sand, silt, and clay, residual bitumen, and other chemical contaminants. Fluid fine tailings (FFT) with a high water content are generally observed to consolidate at a very slow rate. This slow consolidation is primarily due to the dispersion of clay caused by chemical interactions between clay, water, and residual bitumen during the extraction process, which significantly reduces the hydraulic conductivity of the FFT. Their management is crucial due to their potential impacts on surrounding ecosystems and communities [

1]. One of the primary issues associated with oil sands mine waste is its sheer volume and composition. Tailings storage facilities can cover vast areas and contain billions of gallons of waste material, presenting risks of contamination to water sources, soil, and air [

2]. For instance, in the Athabasca oil sands region, the cumulative volume of fluid tailings stored at the mine sites reached 1392 million cubic meters in the year 2020 [

1]. Consolidation and dewatering issues exacerbate the challenges of managing oil sands mine waste [

3,

4]. As tailings settle and consolidate over time, they undergo substantial volume reductions, resulting in surface subsidence. If the closure objective for the FFT deposit is to create a terrestrial landform, this level of settlement can lead to extensive flooded areas, increasing the risk of dam breaches and altering the landform’s water balance [

5,

6].

Dewatering, on the other hand, involves the removal of excess water from the tailings, which is essential for minimizing the volume of waste and facilitating subsequent reclamation efforts. However, both consolidation and dewatering processes require careful monitoring and management to prevent environmental contamination and ensure the stability of waste management infrastructure [

7]. The benefits of quantifying consolidation behavior quickly are manifold. Rapid assessment allows for timely decision making regarding tailings treatment options and management, facilitating the implementation of appropriate containment and reclamation measures [

1]. Understanding consolidation behavior also enables engineers to optimize the design of tailings storage facilities and other waste management infrastructure, potentially reducing construction costs and environmental impacts. Additionally, the swift quantification of consolidation behavior with many more samples can aid in predicting long-term settlement patterns, allowing for proactive measures to mitigate potential risks that can be validated vis field data as opposed to relying solely on smaller datasets from more time-consuming, conventional lab tests.

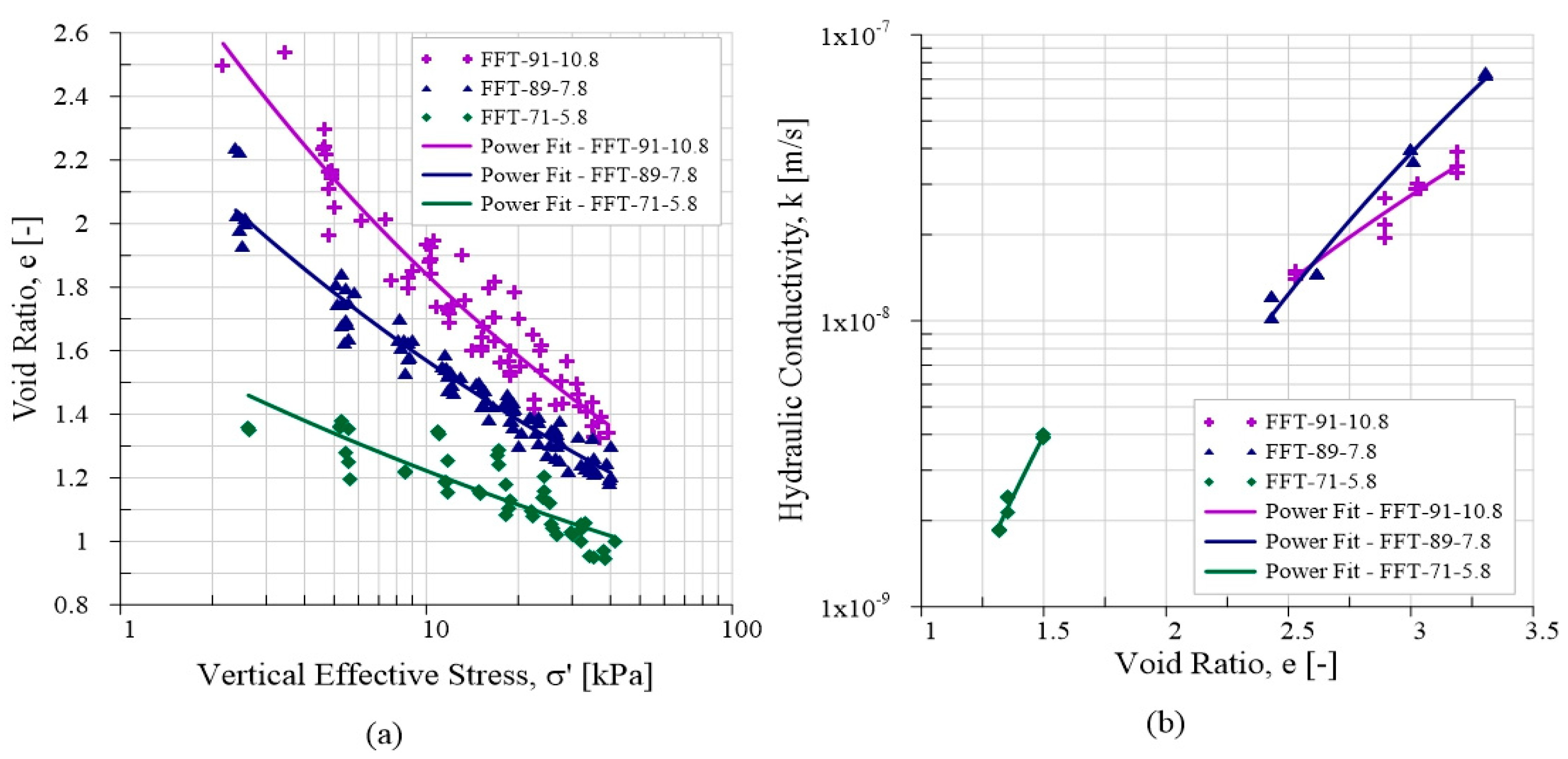

Various testing techniques may be employed to evaluate the large strain consolidation behavior of oil sands mine waste. Large strain geotechnical testing methods, such as the multi-step large strain consolidation (MLSC) test [

8,

9,

10,

11,

12,

13] and seepage-induced consolidation test (SICT) [

14,

15], provide valuable data on the consolidation behavior of the tailings under loading, known as compressibility (

e-σ′), and the void ratio–hydraulic conductivity (

k-

e), where

e is the void ratio, σ′ is the vertical effective stress, and

k is the hydraulic conductivity. Advanced modeling techniques, including finite element analysis, utilize these constitutive relationships to simulate the complex consolidation processes and predict long-term settlement behavior. Furthermore, centrifuge testing techniques offer an alternative approach to studying consolidation behavior by subjecting tailings samples to an increased gravitational force, allowing oil sands operators to observe and analyze consolidation processes under controlled conditions [

16,

17,

18,

19]. Furthermore, several researchers have examined the consolidation of mine tailings and dredged deposits under the influence of self-weight using geotechnical beam centrifuges [

20,

21,

22]. Beam centrifuges, commonly utilized in research environments, are sizable apparatuses that occupy entire rooms and entail significant operating costs. They are specifically designed to create a configuration that better aligns with theoretical ideals for geotechnical experiments and monitoring purposes. These centrifuges possess a larger spin radius, usually ranging between 2 and 8 m, which enables the generation of a more uniform acceleration field and facilitates the accommodation of substantial sample volumes [

12]. Suncor has implemented a commercial technology known as a Permanent Aquatic Storage Structure (PASS) within its Accelerate Dewatering (ADW) process. This technology aims to convert mature fine tailings (MFT) or FFT into a substrate suitable for reclamation into freshwater lakes. The PASS centrifuge, developed in collaboration with Coanda, is a benchtop centrifuge patented by Suncor as a part of this initiative [

23]. It allows for the rapid evaluation of the settling performance of treated tailings over short periods, typically a few hours, providing immediate insights into the long-term behavior of processed tailings upon production [

23].

Benchtop centrifuges are ideal for both fieldwork and laboratory settings, yet they are often lacking in in-flight monitoring devices to track consolidation progress, unlike the geotechnical beam centrifuge [

12] and PASS centrifuge [

23]. Typically, sample analysis occurs at the conclusion of the spinning process. Although benchtop centrifuges have certain limitations, particularly related to their small size, they have still been utilized to simulate the self-weight consolidation of soft soils and slurry-like materials. Several researchers have examined the consolidation of very soft soils with high water contents under the influence of self-weight using benchtop centrifuges [

24,

25,

26].

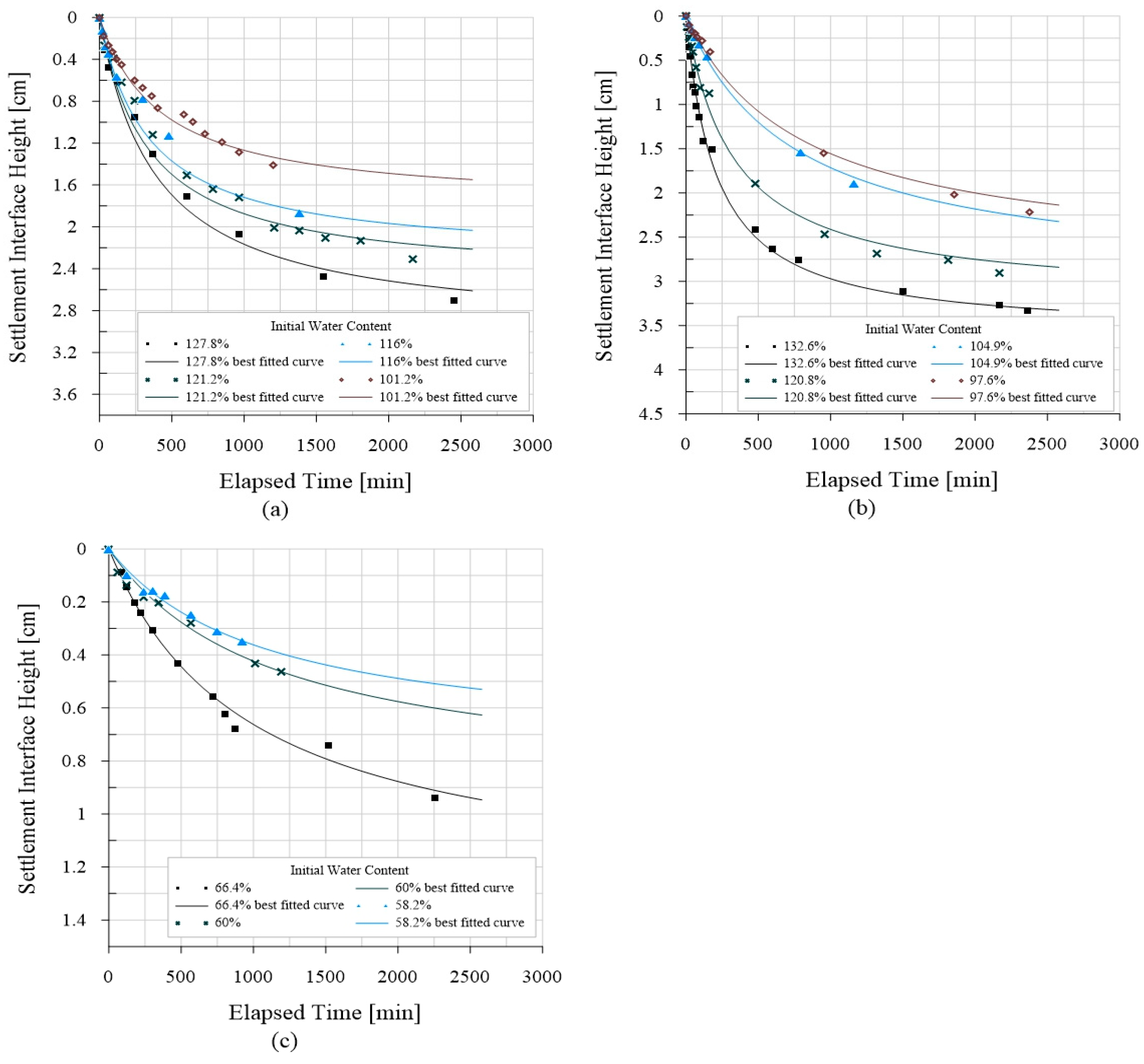

McDermott and King [

24] conducted accelerated consolidation testing on Speswhite kaolin clay using a benchtop centrifuge. Their aim was to assess the consolidation behavior of kaolin slurries at varying initial moisture levels. They adopted a method for estimating hydraulic conductivity based on a methodology developed by Takada and Mikasa [

21]. According to Takada and Mikasa’s method, the initial settling rate follows a near-linear pattern, indicating the permeability at the outset of the process. The relationship between the void ratio and effective stress was determined by analyzing the final void ratio distribution across the depth of the samples, following a methodology proposed by Takada and Mikasa [

21]. A limitation of the study is the absence of data on whether the samples experienced segregation, particularly under a nominal acceleration of 753 g.

Reid et al. [

26] utilized a modified benchtop centrifuge to investigate the consolidation behavior of slurry-like soil, specifically kaolin clay sourced from Unimin Australia [

27]. They established the compressibility profile by directly measuring the moisture content at one- or two-millimeter intervals across the cored specimen post-consolidation, assuming the full saturation of the samples. Furthermore, they utilized the FLAC v7.0 finite difference code to develop an iterative numerical model. This model aimed to estimate the profile of the effective stress–hydraulic conductivity for the tested samples, aligning it with the observed dissipation of pore water pressure data. A drawback of the study is the lack of precise control and measurement of water loss through evaporation during spinning, which could complicate the numerical modeling and potentially destabilize the centrifuge due to uneven evaporation rates.

A benchtop centrifuge (BTC) enables faster data collection and analysis, providing insights into long-term settlement behavior in a fraction of the time required by conventional methods. A decreased turnaround time would offer numerous advantages to the oil sands sector, such as reducing the time to evaluate alternative tailings treatment technologies, enhanced tailings quality assurance and control, and expedited analysis and planning. This abbreviated testing period enables the assessment of a larger quantity of samples, thereby contributing to the development of an extensive properties database. As a result, engineers and researchers can make informed decisions more quickly, leading to more efficient tailings management strategies. The BTC enables operators to make well-informed decisions about the effectiveness of additives without the lengthy wait required for testing in the MLSC. Abdulnabi et al. [

28] investigated the performance of various polymer and coagulant combinations used to enhance tailings dewatering and strength properties. Traditionally, MLSC testing for these additives takes between 4 and 10 months. However, the BTC can significantly reduce this timeframe, providing performance insights within just a few days.

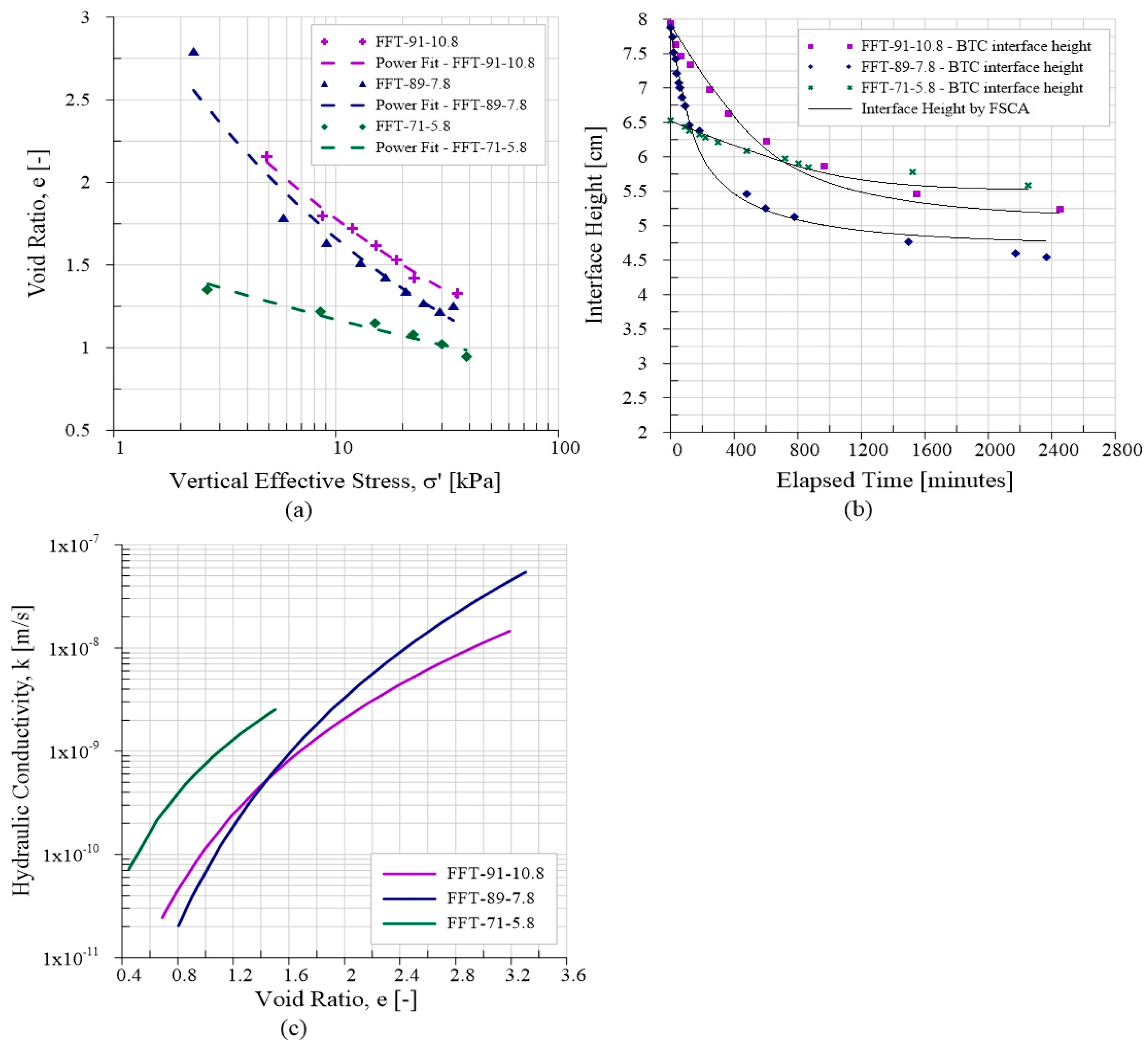

The application of benchtop centrifuges for the assessment of the consolidation behavior of clay-rich high-water-content slurries like oil sands tailings is limited. Hence, this study aimed to examine the application of a benchtop centrifuge for swiftly acquiring consolidation parameters pertaining to oil sands tailings materials. The evaluation of these parameters was conducted by comparing them with data obtained from conventional large strain consolidation testing using the MLSC test. Furthermore, a series of tests were performed to verify the consistency, scaling law accuracy, and the impact of the benchtop centrifuge’s small radius.

2. Principles Behind Centrifuge Modeling

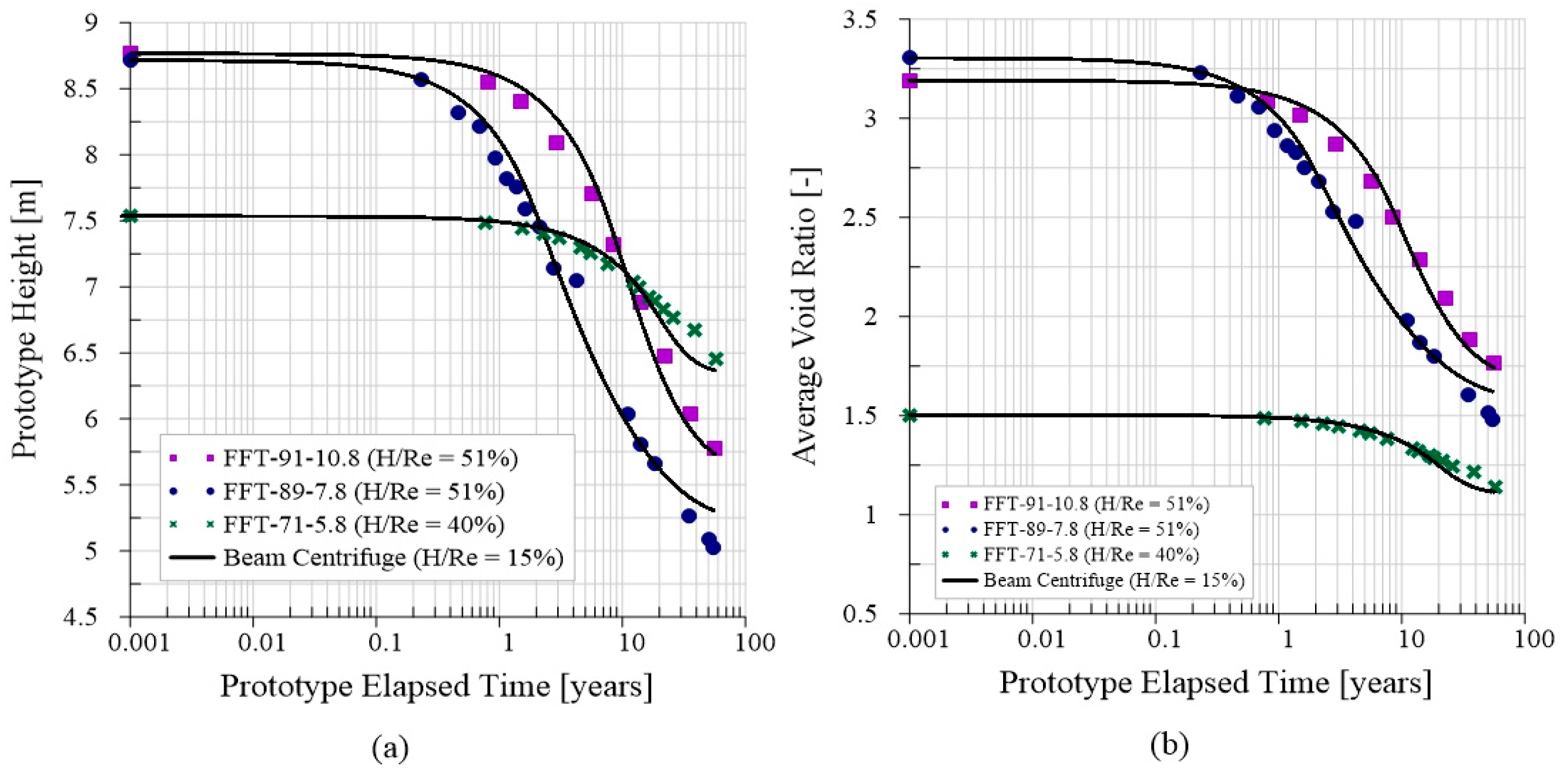

Centrifuge modeling aims to replicate the stress experienced by a prototype in a scaled-down model. This is particularly true in the case of centrifuge modeling, where the model is a smaller replica of the prototype. To accurately recreate the prototype’s response or interpret model findings in relation to prototype behavior, it is necessary to establish an appropriate scaling law that relates the prototype to the model [

29]. For instance, when simulating the consolidation of tailings under significant strain, the geotechnical centrifuge model utilizes Equations (1) and (2) to describe the scaling laws for height and time, respectively, as follows:

where

hp represents the height of the prototype,

hm represents the height of the specimen in the centrifuged model,

N is the gravity scale factor which represents the ratio of the centrifuge acceleration (

am) to the gravitational acceleration of the Earth (

g),

tp represents the elapsed time in the prototype, and

tm represents the elapsed time in the centrifuged model.

When utilizing centrifuge testing for investigating the self-weight consolidation behavior of slurry-like materials, it is typically bound by several fundamental assumptions and inherent constraints. These include acknowledging the non-uniform distribution of vertical stress, recognizing the deviation from uniformity in horizontal stress distribution, and disregarding segregation effects, which will be described below.

The Earth’s gravitational acceleration remains uniform within the practical prototype height in many civil engineering applications, resulting in a linear vertical stress distribution across the prototype height. However, when employing a centrifuge to create the high acceleration necessary for physical modeling, there exists a slight variation in acceleration across the model. This discrepancy arises from the inertial acceleration field, calculated as Ng = rω2, where r is the radius to any element within the soil model and ω is the centrifuge’s angular velocity. This indicates that the centrifugal acceleration level (g-level) increases linearly with the radius, leading to an uneven acceleration field and consequently causing an inherent variation in the vertical stress distribution across the centrifuge model, rendering it non-uniform.

An effective centrifuge radius (

Re) is selected in a model to minimize the vertical stress distribution error. The effective centrifuge radius is defined by Schofield [

30] and Taylor [

31] as the distance from the center of rotation to one-third the specimen height. However, the one-third depth guideline is for samples that experience small strain and have a uniform material density. Therefore, Fox et al. [

32] reported that, as the specimen undergoes larger deformations, the effective centrifuge radius increases with an increasing centrifugal acceleration ratio (

N), specimen height, and initial void ratio. The error in the time–settlement curves was less than 1.6% for all simulations when the effective radius was taken at the specimen’s initial mid-height. Taylor [

31] reports that, provided the specimen height in the centrifuged model is less than about 20% of the effective centrifuge radius, the maximum error in the vertical stress distribution is often deemed negligible, and generally less than 3% of the actual prototype stress. The larger the effective centrifuge radius, the smaller the maximum error in the vertical stress distribution.

Furthermore, since a specimen in centrifuge modeling rotates in a circular path, the equipotential lines across the model are curved. Therefore, in the center of the specimen, the material is subjected only to vertical stresses, whereas, elsewhere, it is subjected to both vertical and horizontal stresses. A field deposit primarily experiences self-weight stress in the vertical direction, but it is not exclusively controlled by this force, whereas a centrifuge model experiences stress in the horizontal direction as well. This horizontal stress component in the centrifugal model will result in an inherent horizontal stress modeling error. Hird [

33] reports that, provided the specimen width in the centrifuge model is less than about 20% of the centrifuge effective radius, the error introduced due to the curvilinear stress distribution across the specimen is often deemed negligible.

In centrifuge modeling, high gravitational acceleration will enhance the particle segregation [

21,

34,

35,

36]. This would cause specimen behavior in the centrifuge model to differ from what was observed in the prototype due to segregation. When segregation occurs, neither the test findings nor a segregated soil is representative of the prototype material. Reducing the potential of segregation during centrifuge tests may require the following: (1) utilizing a reduced g-force, (2) testing the slurry-like materials using a multi-staged centrifuge testing, (3) waiting some time to allow the specimen to consolidate and gain some strengths before spinning, and (4) increasing the initial solids content of the tested material. Takada and Mikasa [

21] and McDermott and King [

24] recommend that, to prevent particle segregation, but without practical basis, the slurry-like materials should be prepared at initial water content equal to or less than twice its liquid limit.

5. Practical Implications of Proposed Technique

Wall friction introduces experimental errors in geotechnical tests like MLSC and BTC tests, but its impact in centrifuge tests is scarcely addressed in the literature. Wong et al. [

19] utilized specimens with a diameter-to-height ratio of 0.3 in bench-scale centrifuge tests. They observed that the influence of friction along the centrifuge tube wall on the density distribution was evident under both 1-g and N-g loading conditions, especially at elevations close to the specimen’s top surface. However, the density distribution across each elevation profile exhibits irregularities, yet the variation in density values throughout the profile remains minimal, typically less than 3%. Sorta et al. [

23] utilized PASS centrifuge tests to examine how jar wall effects impact the settlement behavior, employing both standard and modified jars. The findings revealed comparable settlement behavior between the two jar types, with the modified jars displaying slightly lower average void ratios (1–6%) compared to the regular jars, indicating the negligible influence from wall effects. Typical guidelines for minimizing the impact in consolidation tests encompass maintaining a diameter-to-height ratio of 2:1, ensuring a diameter exceeding 10 cm, applying lubrication to the side walls, and adjusting for vertical effective stress to account for wall friction. The initial height of the sample in all of the MLSC tests in this study was selected to ensure that the diameter-to-height ratio exceeded 2.5:1 [

52]. This was performed to minimize the wall friction, particularly when vertical effective stresses reached significant levels above 10 kPa.

While BTC can be a valuable tool for technology screening and initial assessments, its scale and experimental conditions may not fully capture the real-world, long-term consolidation behavior of tailings. As a result, relying solely on BTC findings for critical engineering decisions may lead to inaccuracies or misinterpretations. When comparing laboratory predictions to field data, challenges such as sample heterogeneity, boundary effects, and differences in stress paths between lab and field conditions must be considered. These factors can influence the accuracy of predictions, underscoring the importance of integrating both laboratory and field validations with BTC findings. This approach ensures a more comprehensive and reliable foundation for engineering design decisions.