Abstract

Innovations in nanogenerator technology foster pervading self-power devices for human use, environmental surveillance, energy transfiguration, intelligent energy storage systems, and wireless networks. Energy harvesting from ubiquitous ambient mechanical, thermal, and solar energies by nanogenerators is the hotspot of the modern electronics research era. Ferroelectric materials, which show spontaneous polarization, are reversible when exposed to the external electric field, and are responsive to external stimuli of strain, heat, and light are promising for modeling nanogenerators. This review demonstrates ferroelectric material-based nanogenerators, practicing the discrete and coupled pyroelectric, piezoelectric, triboelectric, and ferroelectric photovoltaic effects. Their working mechanisms and way of optimizing their performances, exercising the conjunction of effects in a standalone device, and multi-effects coupled nanogenerators are greatly versatile and reliable and encourage resolution in the energy crisis. Additionally, the expectancy of productive lines of future ensuing and propitious application domains are listed.

1. Introduction

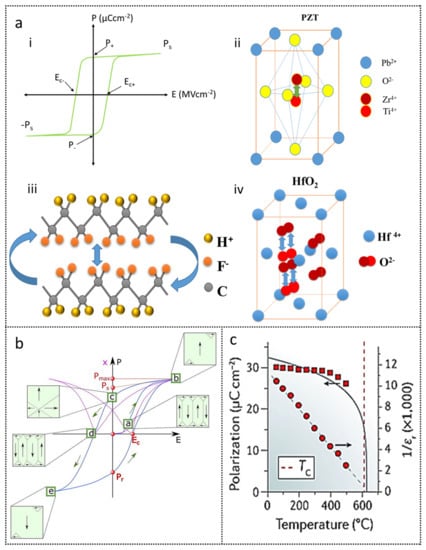

With the advancement in modern mobile electronics, wireless communication systems, and the internet of things (IoT), researchers became more concerned with the miniaturization and multi-functionality of devices, e.g., low power, flexibility, etc. Mobile devices are handy and carry information that is immediately accessible and transmittable wirelessly. The devices are small enough to be worn or fastened with objects of everyday use, such as goggles, clothes, wristwatches, and many others. These minuscule devices need small operational powers, usually in micro-watt or milli-watt, for which the use of the traditional chemical batteries is a miser and are the cause of environmental threaten, too; hence, small-scale sustainable power solutions are in need. The make-up to this innovates the maturing of energy harvesting units, which can efficiently harvest energy, such as mechanical, heat, and light energy, to electrical energy and reuse sources of energies from the ambient atmosphere [1,2,3,4]. In 2006, Z. L. Wang and J. Song developed nanogenerators (NGs) by transforming nanoscale mechanical energy into electricity using arrays of piezoelectric ZnO nanowire and marked energy harvesters to jump into a new span [5]. The basic theory of nanogenerators was established based on the concept of the use of the Maxwell displacement current as a driving force to convert environmental energies into electrical energy signals. Therefore, NGs work by current generations and employ the concept of internal polarization of the material [6]. Out of thirty-two crystal structures, twenty-one crystal classes do not possess central symmetry and are non-centrosymmetric, twenty of which show polarization as the reaction of mechanical stress forces are piezoelectric and, among these, twenty (1, 2, m, 222, mm2, 4, −4, 422, 4 mm, −42 m, 3, 32, 3 m, 6, −6, 622 m 6 mm, −62 m, 23, −43 m). Among these twenty piezoelectrics, ten show spontaneous polarization variations, induced by temperature changes are pyroelectric (1, 2, m, mm2, 3, 3 m, 4, 4 mm, 6, 6 mm). Their polarization turned out to be reversed with the implementation of the electric field; additionally, the particular materials are ferroelectrics [7,8]. Ferroelectrics are functional dielectric materials that have shown spectacular properties of spontaneous polarization at zero electric fields. The spontaneous polarization (Ps) can be switched to reversed direction when a large poling electric field (in units of kV/cm to MV/cm) is applied. Figure 1a(i) demonstrates the typical ferroelectric P-E curve [9], showing both the states are steady and thermodynamically stable. Thus, ferroelectric materials have been of great research interest for almost over a century [10,11]. In conventional ferroelectric (FE) materials, also known as proper ferroelectrics, the spontaneous polarization (Ps) is responsible for the change in structure (i.e., structural phase transition) breaking the crystal symmetry at curie temperature (Tc). So, the order parameter of phase transition in proper ferroelectrics is spontaneous polarization. Ferroelectrics have posted a wide range of applications contributing to frequency filters, pressure and temperature sensors, actuators, hydrophones, oscillators, and many others [12,13,14,15,16,17,18]. Since all the ferroelectrics are piezoelectric and pyroelectric, they speculate the phenomenon of piezoelectricity, pyroelectricity, and photovoltaic ferroelectric effects. These effects are the result of responses from external stimuli, such as mechanical, thermal, and solar energies, respectively [19,20,21,22]. The piezoelectric coefficient of semiconductor piezoelectric ZnO is ~12 pC/N, which is quite low, in contrast to the ferroelectric materials with perovskite structure, e.g., BaTiO3 and Pb(Zr, Ti)O3, which exhibit high piezoelectric coefficients of 100 pC/N and 200 pC/N, respectively [23]. These properties of ferroelectrics promote their use in the fabrication of nanogenerators for energy scavenging and harvesting from low frequency natural and artificial energy sources from the environment [24,25]. Along with energy storage units, self-powered systems can also be integrated by nanogenerators for powering functional devices. Many nanogenerators have been fashioned after, including piezoelectric NGs (PENG), pyroelectric NGs (PyENG), triboelectric NGs (TENG), and photovoltaics (PVC) [26,27,28,29]. Piezoelectric and triboelectric NGs transform mechanical stress forces and/or energies from wind/airflow, water waves, human motions, biomechanical energies, etc., to electrical energy, accompanied by changing polarization degrees in ferroelectrics [30,31,32,33,34,35]. Pyroelectric NGs works by temperature variations from industrial heat wastes, radiations from the sun, etc. [36,37,38,39,40,41]. The photovoltaic effect in ferroelectrics demonstrated that the photocurrent is not limited by the bandgap of material; rather, it is associated with material polarity and separation of light-induced photo carriers [42,43,44,45]. At present, hybrid nanogenerators and multi-effect coupled NGs are of practical interest, developed by integrating the above mentioned effects into a single structure and, hence, contributing to the maximization of energies for high electrical power outputs, depending on the strength of external stimuli [6,46,47,48,49,50]. The ever first one-structured coupled nanogenerator, based on piezo–tribo–pyro–photovoltaic effects, was proposed by professor Ya Yang and his co-workers in 2015 [51]. Ferroelectric materials possess permanent dipole moments in the electric field, which increases their polarization density and facilitates their use in wearable, flexible electronics. The conventional semiconductor materials do not own this property and so ferroelectrics gather more attention [52]. The most active ferroelectric materials encapsulated in nanogenerator application are inorganic ferroelectric ceramics and organic polymers; the best of them include BaTiO3 (BTO) [53], PbZr1-xTixO3 (PZT) [54], Na0.5Bi0.5TiO3 (NBT) [55], KNaNbO3 (KNN) [56], BiFeO3 (BFO) [57], Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-PT) [58], PVDF [59,60,61], and P(VDF-TrFE) [62]. In comparison with inorganic ferroelectrics, very few organic ferroelectrics exist. For example, single-component polar organic molecules, such as CDA, DNP, CT complexes, and polymers, such as PVDF, nylon-11, and organic-inorganic composites, such as HdabecoReO4, TGS, TSCC, are excellent for applications in piezoelectric and triboelectric nanogenerators [63]. Other reports on semiconductor ferroelectric have also been found. Ferroelectric polymers are highly flexible and have found applications in wearable and foldable devices. Ferroelectric ceramics are hard and are often complexed with other ferroelectric/non-ferroelectric material and stacked to multilayered architecture, in order to improve their output features with various structural morphologies and, e.g., (Ba0.85Ca0.15)(Ti0.90Zr0.10)O3-x BiHoO3/PDMS [64], PDMS/PZT [65], and CNTs-PMNT/PDMS [66]. In this peer review paper, we briefly talk about the basic properties of ferroelectric materials, together with related phenomena for energy conversion, i.e., piezoelectricity, pyroelectricity, triboelectricity, and ferroelectric photovoltaic effects, as well as operating conditions of various types of ferroelectric material-based NGs. Mechanism of ferroelectrics-based hybrid and multi-effect coupled NGs, with their structure-related performances and power conversion efficiencies, are also discussed. Some recent applications, including self-powered micro/nano-systems, multifunctional sensors, and wearable flexible devices, are discussed. Furthermore, the advantages of ferroelectric-based NGs and future prospects are devised.

Figure 1.

Hysteresis curve and typical ferroelectric crystals structures. (a) Hysteresis curve for ferroelectric materials with important factors of coercive field (Ec), remanent (PR), and spontaneous polarization (Ps); (i) PZT crystal, representing the two stable positions of Zr4+ or Ti4+ ions; (ii) PVDF polymer chain with the two orientations for polarization; (iii) hafnium oxide with switching O2- oxygen ions; (iv) O2- ion switching in fluoride structure of orthorhombic hafnium oxide (HfO2). (b) Domain wall movement. Reprinted with permission from reference [67], Copyright 2017, AIP Publishing. (c) Transition temperature dependence of ferroelectrics. Reprinted with permission from reference [68], Copyright 2016, Springer Nature.

2. Ferroelectric Materials

2.1. Fortunes of Ferroelectric Materials

Ferroelectric materials in their ferroelectric phase exhibit net dipole moment, i.e., the centers of charges (positive and negative) do not coincide, resulting in robust polarization lasting permanently below a particular temperature, called the curie temperature (Tc), in the non-poled state. Before the time of the second world war, from 1920–1943, ferroelectric materials remained of academic and theoretical interest for small applications zones. In the 1950s, BaTiO3 (BTO) discovered that strong ferroelectric behavior evoked the electronic ceramic industry and became an interesting candidate for piezoelectric transducers. By the 1960s, researchers undertook ferroelectric thin films and realized practicing non-volatile memories, but quality maintenance, restricted their practical applications, up until the 1980s; later in the 1990s, ferroelectrics, alongside microsensors, found widespread applications in radio frequency and microwave devices. In 1994, the bypass ferroelectric capacitors installed in digital mobile phones provided a breakthrough in the leading micro-digital industry [69,70,71]. For the past two decades, ferroelectric materials subsisted a great application tempt in energy harvesting.

2.2. Crystal Structures

Joesph Valasek has discovered the phenomenon of ferroelectricity in Rochelle salt (NaKC4H4O6.4H2O) orthorhombic crystal structure first. Up until now, more than seven hundred ferroelectric materials have been demonstrated, inclusive of oxides, polymers, ceramics, and liquid crystals, as well. Typical ferroelectric materials have either ABO3 perovskite or hydrogen-bonded potassium dihydrate phosphate KH2PO4 (KDP) structures, but others also exist, such as GeTe, SrAlF5, SbSI, SbSeI, etc. [72,73]. Perovskite ferroelectric materials are with crystal structure isomorphous to the mineral perovskite calcium titanium oxide CaTiO3, general formula ABO3, whereupon A and B stand as cation, and O is the oxygen ion. The ionic radius of cation A and B is particularly around 1.2 Å to 1.6 Å and 0.6 Å to 0.7 Å, respectively. Oxygen atoms/ions are positioned at the face center and A ion at the cube corner, forming octahedral surrounding B ions and staying at the body center. Structure stability requires that the valencies of ions be balanced. Moreover, the structural distortions, such as octahedral distortion or tilting, associated with low space group symmetries, cause relief of B-site electronic instabilities, leading to high values of ferroelectric polarization, piezoelectric coefficients, unusual photovoltaic behaviors, and dielectric constants [7]. Figure 1a(ii) represent perovskite structure-based inorganic ferroelectric materials, such as lead zirconate titanate PZT (Pb(TixZr1−x)O3), barium titanate BTO (BaTiO3), and layered strontium bismuth tantalite SBT (SrBi2Ta2O9); in all of them, the central cation switches its position between the stable states [9]. The literature revealed the existence of morphotropic phase boundary (MBP) in PZT, with compositional variations that benefited piezo ceramics a lot [74,75,76,77]. Furthermore, the nature of lead (Pb) is weighty and detrimental to humans and the environment. Therefore, lead-free materials (e.g., BiFeO3 (BFO), KNaNbO3 (KNN), etc.) which are non-toxic, environmentally friendly, and biocompatible, are of more research interest [78,79]. Some ferroelectrics, with more complex perovskite structures, have also been observed with cations of different valencies but fixed molar concentrations. For example, PbMg1/3Nb2O3 (PMN), PbSc1/2Ta1/2O3 (PST), and Bi1/2Na1/2TiO3 (BNT) [80,81]. Ferroelectric hafnium oxide (HfO2) is also of great interest and becoming a spotlight for the memories industry [9].

Ferroelectrics with ilmenite structure are similar to perovskites, with distinction in the A cation, which is small enough to fill ABO3 structure coordinated site. Oxygen ions are packed closely in a hexagonal layer, with cations A and B located between the layers at octahedral sites LiNbO3 and LiTaO3, which are two important uniaxial ferroelectric materials of this class [82,83,84].

Polyvinylidene fluoride (PVDF) with CH2CF2 monomer was observed to be the first ferroelectric polymer, without any particular curie temperature, as melting occurs first. PVDF exists in four different polymorphs (i.e., the phases), depending on the configuration of carbon–carbon links. Fluorine atoms are electronegative and make the C–F bond polar, resulting in the molecule having a net dipole moment orthogonal to molecular length carbon backbone chain. Though the molecules of polymer arrange in the unit cell and, hence, the dipoles balance each other in the -phase; so, the PVDF in -phase is not ferroelectric, but its field application produces a net dipole moment on unit cell and put it in -phase. Annealing of these systems at high temperatures crystalizes them in the -phase, which also has a net dipole moment perpendicular to the carbon backbone and is polar. Orthorhombic -phase can be achieved by stretch or draw in previously derived phases and is an all-trans configuration with high spontaneous polarization and a dielectric constant [85]. So, electric poling makes -PVDF-phase a strong piezoelectric and pyroelectric phase, when compared with other polymorphs. -PVDF-phase can be directly obtained by the copolymerization of vinylidene fluoride with trifluroethylene TrFE (~10 to 46% by wt.); the resultant P(VDF-TrFE) material has the same activity rate as pure PVDF but exhibits high remnant polarization [82,86,87]. Figure 1a(iii,iv) show the switching behavior of polar polymer chains in organic ferroelectric polyvinylidene fluoride (PVDF) polymerized, with tetrafluoroethylene (TrFE) and O−2 ion switching in fluoride structure of orthorhombic hafnium oxide (HfO2), respectively [9]. Hexafluoropropylene HFP is another important copolymer material for the PVDF matrix. Other polymers that exhibit ferroelectric behavior include odd-numbered nylons, but these are only weakly piezoelectric. These polymeric ferroelectrics are useful in flexible electronics, especially in wearable devices.

Another class of ferroelectrics comprises of improper ferroelectrics, for those in which the order parameter is not the polarization; rather, the spontaneous polarization arises as to the by-product of phase transition, as a secondary effect. The temperature dependence of the permittivity does not follow Curie–Wiess law; additionally, the phase transition is not suppressed by the electric fields in improper ferroelectrics [88]. The dielectric constant of improper ferroelectric remains low, usually near the phase transition temperature, and is conducive to the large pyroelectric figure of merits. Examples of improper ferroelectric involve iron-iodine-boracite [FeB7O13I (TMO)], dicalcium-lead-propionate [Ca2Pb(CH3CH2COO)6 (DLP)], [Hdabeco]ClO4, etc., [89]. A subset of ferroelectric materials forms ferroelastic materials, which may show spontaneous strain and possibly exhibit two or more stable orientation states under zero electric field or mechanical stress. Pb3(PO)4 is a particular example of ferroelastic materials [68].

Anti-ferroelectric (AFE) structures are mainly characterized by the phase transition from the low symmetry state, usually from the low-temperature phase to the high symmetry state (usually high-temperature phase). Contrary to ferroelectrics, the anti-ferroelectrics do not have permanent electric polarization. Therefore, an anti-ferroelectric crystal lattice can be considered to be made up of two interpenetrating sublattices with equal but opposite polarizations. However, high spontaneous polarization (Ps) appears as the transition from the anti-ferroelectric phase to the ferroelectric phase. They exhibit low dielectrics losses and coercive fields. A typical anti-ferroelectric material with a perovskite structure is PbZrO3, with Sr doping energy density of 14.5 J/cm3, which had been observed at 900 kV/cm by Hao et al. [90]. Anti-ferroelectric Zr doped HfO2 had shown the largest energy density of 46 J/cm3 at 4.5 MV/cm [91]. Ferroelectric relaxors have also been demonstrated in the past few years; relaxors belong to disordered crystals when nonequilibrium ions are added into normal ferroelectric materials or heated above transition temperatures and de-poled under critical electric fields. They exhibit broad and suppressed dielectric peaks but higher susceptibilities. The ferroelectric (SrxBa1−x)Nb2O6 (SBN) contains five Sr or Ba ions; so, one of the A-site remains unfilled, therefore, varying the Sr/Ba concentration to an increased ratio, they transform from normal ferroelectrics to relaxor ferroelectric, as reported for x = 0.75 in reference [92]. The 0.67 Pb(Mg1/3Nb2/3)O3-0.33PbTiO3 composite ferroelectric relaxor shows two phase transitions at 34 °C (from rhombohedral to tetragonal) and at 144 °C (from tetragonal to cubic) [93]. PVDF shows the relaxor behavior with improved dielectric properties and piezoelectric responses by carrying temperature treatment and further copolymerization to TrFE-CFE [94,95].

2.3. Ferroelectricity and Hysteresis

Ferroelectricity is the material property of exhibiting spontaneous polarization (Ps). Ferroelectric materials have high dielectric constants, and field removal does not bring polarization back to its original direction spontaneously, which signifies that the polarization is persistent. This characteristic behavior of ferroelectric materials is defined by a schematic, non-linear curve observed between the electric field (E) and polarization (P), known typically as hysteresis, displayed in Figure 1a(i) [9]. Field escalations align polarizations in distinct dipolar regions of a ferroelectric crystal, reaching a saturation value of spontaneous polarization (Ps) and setting off the field to zero gives remanent polarization (P+), which is slightly smaller than Ps and the result of charge displacement. Negative field value reduces the polarization to zero at the coercive field (Ec−), and further increases cause reverse saturation polarization (−Ps) and remanent polarization (P−) on returning to zero field value. Polarization, again, reaches zero at Ec+, towards a positive applied field and back to Ps. An important feature of ferroelectrics is that remanent polarization (2PR = |P+| + |P−|) persists, even after externally applied E is abolished; this makes them suitable for application in non-volatile random-access memories. BaTiO3 shows a remanent polarization and coercive field of 2.55 μC/cm2 and 3.14 kV/cm, respectively [96]. NBT (Na0.5Bi0.5TiO3) has a remanent polarization of 38 μC/cm2 and coercive field of 70 kV/cm only [97]. However, doping of ST (SrTiO3) to NBT reduces the value of remanent polarization and coercive field to 0.007 μC/cm2 and 0.15 kV/mm [98]. During the process of poling for polarization reorientations in the same direction, the bound charges restrain at the opposite faces of polarization moment, i.e., positive at the negative end and vice versa. The bound charges establish a depolarization field and side of the material, in order to maintain charge neutrality, while the screening for free charge accumulates on the surface, compensating the bound charge keeping the surface neutral [97,98].

2.4. Ferroelectric Domains and Phase Transition

In the ferroelectric materials, certain regions, called domains, exist and are separated by interfaces known as domain walls. Each region containing polarization mixtures has a different polarization direction for other regions, inferring that the virgin ferroelectric material does not show a particular net polarization direction. When ferroelectric materials are poled, their domains begin to set in the field direction and show a net polarization. This signifies that polarization switching is quantum-mechanically functionalized by domain wall motion. Figure 1b shows the domain wall motions and corresponding polarization switching in BTO ceramics [67]. Two unique domains are labeled as 180° domains, with polarizations aligned antiparallel to each other and 90° domains with polarizations aligned perpendicular to each other. The motion of the 180° domain walls gives rise to dielectric and piezoelectric response, whilst for 90° to the only dielectric response. The fact is important for ferroelectric material’s use as energy harvesters and has been observed in many perovskite structure ferroelectrics. The symmetry of the crystal determines the favorable domain formation; hence, ferroelectric materials need to be non-centrosymmetric. The polar ferroelectric behavior exists below a particular temperature, called the critical temperature or curie point (Tc), above which nonpolar highly symmetric para-electric phase transition occurs, reflecting the optical mode softening at the BZ center [99]. BaTiO3 is cubic in its para-electric phase and tetragonal in its ferroelectric phase at Tc 120 °C. At 5 °C, a second-order phase transition from tetragonal to orthorhombic occurs for BTO [7], the transition/curie temperature for KDP (~−150 °C) and Rochelle salt (~24 °C) for PVDF ~150 °C [100,101,102]. In PbTiO3 tetragonal ferroelectric phase occurs below 490 °C, assisted by cation displacement in <100>. LiNbO3 and LiTaO3 are two important uniaxial ferroelectric materials, comprising of high curie temperatures at 1200 °C and 620 °C, respectively, and containing only 180° domains [7]. Studies show that for PZT ferroelectric, the piezoelectric response is related to the volume snippet of 180° domain walls. Pyroelectric coefficients can be tuned at phase transitions ascribed with temperature-controlled domain wall motions, as observed in PZT films subjected to tensile strains [103,104,105,106]. Huan et al. reported the grain size effect of BTO and found that by reducing grain size, the width of the 90° domain diminished, leading to enhanced piezoelectric properties of BTO [107]. However, the materials with complexed domain wall structures show different properties from single domain wall ferroelectrics. Multiferroic BiFeO3 (BFO) is ferroelectric at Tc = 1103 K with a rhombohedral structure and possesses 71°, 109°, and 180° domain walls. Seidel et al. reported the observation of room-temperature electronic conductivity at 109° and 180° ferroelectric domain walls in insulating BeFiO3, proving domain walls as discrete functional entities with potential in nanoelectronic applications [108]. Ghara et al. demonstrated the formation of highly conductive domain walls in multiferroic GaV4S8, which can be annihilated magnetically by driving the system to a single domain state [109]. Werner et al. reported the stable, metal-like conductivity of charged domain walls in lithium niobate crystals, with orders 13 higher than the bulk, high stability for the temperatures ≤70 °C, and promoted advanced LN-semiconductor optoelectronic devices [110].

Lattice defects can also pin the motion of domain walls, as observed oxygen vacancies and dipole defects lower the polarization values in KBNNO pyro and piezo response. The defects can couple with polarization and beget anisotropic lattice deformations, complementing the curie point, as shown in Figure 1c. Hence, ferroelectric material properties can be tailored by controlled poling, defects, and engineering at a small scale, with non-ferroelectric materials producing composite multilayer structures [68].

3. Energy Harvesting Ferroelectric Materials for Nanogenerators (NGs)

Ferroelectric materials can efficiently harvest energy, with variations of the internal dipole moments or potentials, induced by surrounding ambient energies. These available ambient energies are being utilized individually and by coupling with physical phenomena related to mechanical, thermal, and solar energy to generate electricity. In this section, we will discuss the basic energy conversion phenomenon related to ferroelectric materials and the corresponding energy harvesting nanogenerators (NGs).

3.1. Piezoelectric Effect and Piezoelectric Nanogenerators

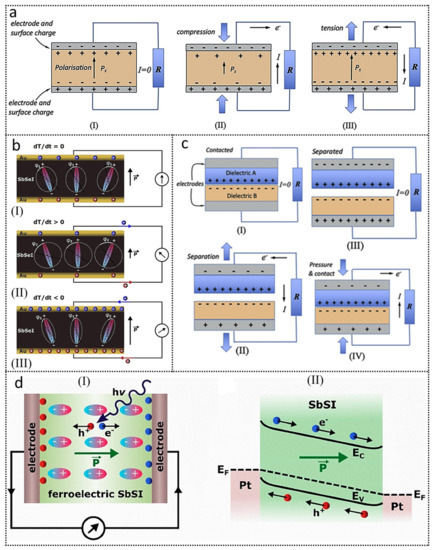

The piezoelectric effect is interwined to the causation of electric charges in a material; when subjected to mechanical stress or strain forces, the center of cations and anions move apart in an asymmetric manner, the material becomes electrically polarized and builds piezoelectric potential. The polarity of the developed charge depends on the stress direction, i.e., either the stress is compressive or tensile. Whilst in converse piezoelectric effect, the applied electric field develops mechanical strain in the material, and field direction determines either the material expands or contracts. P. Cure and J. Curie were the first to observe the phenomenon of piezoelectricity (in 1880) in quartz and Rochelle salt [111]. The dielectric polarization (P) is defined by a linear relation for direct piezoelectric effect:

where in d and X represent the piezoelectric coefficient or constant and the applied stress, respectively. The piezoelectric coefficient d evinces piezoelectric material performance and is anisotropic. The subscripts i and j indicate the directions of dielectric displacement and applied stress, respectively [112]. Ferroelectric materials (such as PZT, KNN, and PMN) with morphotropic (MPB) or polymorphic phase boundary (PPB) relate to the rotation of polarization and indicate the presence of multiple phases within the material, show exceptional piezoelectric response, and piezoelectric coefficient [113,114] BTO; PVDF has also been studied widely in piezoelectric harvesters of mechanical energies, known as piezoelectric nanogenerators (PENG). The operational mechanism of ferroelectric PENG is based on the volume density model; that is, compressing the ferroelectric dipole density increases over the reduced material thickness and stretching material dipole density declines over increased material thickness [85,115]. Consequently, ferroelectric material polarization changes as dipole density vary and results in the generation of the piezoelectric signal. Figure 2a(I) portrays a poled piezoelectric generator (PENG) in a stress-free situation; polarized to value Ps, the charge will sit on the surface to establish charge balance. Subjecting the material to compressive stress, as in Figure 2a(II), the polarization level decreases, and the surface charge becomes free to flow generating electric current signal across the load R. Figure 2a(III) depicts that, when removing stress or applying tensile stress, the material polarization level increases, generating current in the opposite direction to keep charge balance. Typically, the current signal, generated by PENGs, is AC; therefore, the rectification of the output signal is needed. For energy harvesting by PENGs, the selection of load resistance R must lead to an optimum value of piezo potential and current for power generation, which is possible by impedance matching of R and energy material. Furthermore, the infinite value of R leads to an open-circuit device condition, which is suitable to develop sensitive voltage sensors, and the zero value of R leads to a short-circuiting device [116]. Perovskite ceramic ferroelectrics, e.g., BTO and KNN, have usually high piezoelectric coefficients; hence, ferroelectric ceramics-based PENGs show high-output power performances. Guo et al. estimated the piezoelectric coefficient (d33) of ~30 pC/V and dielectric constant of (ε) ~340 for 140 nm thick BTO film, deposited on Pt/TiOx/SiO2/Si, with the LiNbO3 buffer layer [117]. Huan et al. accounted for the grain size effects on the piezoelectric coefficient of BTO, they found that reducing the grain size to 1 μm gives a maximum d33 of 519 pC/V, the dielectric constant of (ε) ~6079, and electromechanical coupling factor (Kp) of 39.5% [107]. Du et al. derived the piezoelectric features of (K0.5Na0.5)NbO3 (KNN) with the perfect perovskite phase, orthorhombic symmetry, piezoelectric coefficient (d33) of 120 pC/N, electromechanical coupling factor (Kp) of 0.40, and curie temperature of 400 °C [118]. Matsubara et al. showed that, for KNN, there was an estimated ~180 pC/N piezoelectric coefficient (d33), with an electromechanical coupling factor (Kp) ~0.39 and curie temperature of 420 °C [119]. As the ceramic materials make it difficult to achieve flexibility, they should be deposited with smaller dimensions, i.e., as thin films or nanoparticles. Chen et al. studied lead-free Ba0.9Ca0.1Ti0.90Sn0.10O3-xLa2O3 for x = 0.03 mol%, and they got an optimized d33 = 496 pC/N and Kp = 41.7, with coexisting orthorhombic and tetragonal phase [120]. Ferroelectric polymer composites (e.g., ZnSnO3:PDMS) can easily be employed in PENGs and has the advantage of low-cost, large-area manufacturing and large mechanical durability, even under high-stress conditions. Ferroelectric polymers, such as PVDF and P(VDF-TrFE), with piezoelectric coefficients 18 pC/N and −21 pC/N with dielectric constants of 8.4 and 10 are promising for total flexible PENGs, they are even foldable, stretchable, and twistable [94,121].

Pi = dij Xj

Figure 2.

Various effects in ferroelectrics. (a) Piezoelectric ferroelectric nanogenerators. Reprinted with permission from reference [116], Copyright 2020, IScience. (b) The pyroelectric effect in SbSeI nanowires 1, 2, and 3 represent the degrees of dipole oscillations. Reprinted with permission from reference [122], Copyright 2019, Elsevier. (c) Triboelectric effect in contact-separation mode. Reprinted with permission from reference [116], Copyright 2020, Elsevier. (d) Ferroelectric photovoltaic effect in SbSI. Reprinted with permission from reference [29], Copyright 2019, MDPI.

3.2. Pyroelectric Effect and Pyroelectric Nanogenerators

The pyroelectric effect is associated with the variations in spontaneous polarization with temporal temperature changes and, hence, the generation of electric current. Thermal energy, generated by nature, mechanical frictions, and machines, can efficiently be altered into electric energy, owing to the pyroelectric effect. Pyroelectric coefficient p is defined as:

where p represents the efficiency of pyroelectric material, and pyroelectrics have high pyroelectric coefficients. Ps is the spontaneous polarization of pyroelectric, and T is the temperature [123]. Pyroelectric nanogenerators include three main layers: the metallic top layer, acting as the top electrode, is designed to collect heat efficiently; the middle layer is the pyroelectric material layer, facilitating heat conversion into electricity by variations in internal polarization; and the third metal layer is the bottom electrode [124,125]. The pyroelectric materials have a unique polar axis. Figure 2b shows SbSeI ferroelectric-based PyENG [122]; when the material temperature is fixed, the electric dipole oscillates randomly around aligning axes, , reaching their equilibrium, as shown in Figure 2b(I). No current was observed since Ps remained the same. Thermal fluctuations produce polarization change, which heads to the separation of bound charges and their accretion at the electrodes. Increasing temperature creates net dipole moments, by enhanced dipole oscillation and spontaneous polarization, decreases by increased thermal agitations. This leads to the depletion of bound charge, so free charge redistributes itself to compensate for the bound charge and, consequently, pyroelectric current flows (Figure 2b(II)). Cooling the sample reverts the current direction and increases spontaneous polarization as the dipole oscillation reduces (Figure 2b(III)). The pyroelectric effect lasts only until temperature fluctuation remains. The output power of PyENGs can be significantly improved by enhancing the absorption of thermal energy with structural modifications, increasing the pyroelectric coefficient by material alteration, and strengthening spontaneous polarization carried out by thermal expansion [122]. Pyroelectric materials exhibit piezoelectricity, too; so, accordingly, the temperature variations encourage stress production and piezo polarization, i.e., secondary pyroelectric effect. Therefore, the bulk pyroelectric coefficient is the additive of both the primary and secondary coefficients [126]. However, in the hybrid systems, with polar inclusions embedded into polar matrixes, it is possible to control the individual component polarization, so the pyroelectric and piezoelectric responses can be compensated. For example, Ploss et al. reported that 27% volume of lead titanate (PT) embedded in PVDF-TrFE matrix, followed by parallel or antiparallel poling inclusions, can cause piezoelectric-compensated pyroelectric material or pyroelectric-compensated piezoelectric material to be constructed, respectively [127]. Similar trends were observed by Meirzadeh et al. for α-glycine crystals doped with minute amounts of different L-amino acids [128].

Inorganic ferroelectric PyNGs, e.g., PZT, show low-output power, due to a small pyroelectric constant, ~−80 nC/cm2K; polymer PVDF ferroelectric is found to be most favorable and shows a high coefficient, ~200 μC/cm2K [126,129]. For BTO, Song et al. found the pyroelectric coefficient to be dependent on temperature, from 16 nC/cm2K to 57 nC/cm2K for 299–310 K and 45.2 nC/cm2K for 310–324 K for light-induced pyroelectric effect [130].

3.3. Triboelectric Effect and Triboelectric Nanogenerators

The triboelectric effect is delineated as the exchange of charge among two different materials in contact with each other. Triboelectric nanogenerators TENGs work by coupling triboelectrification (static polarized charge production on the material surface) and electrostatic induction [131,132,133]. Electrostatic induction drives the harvesting of ambient mechanical energy to electrical energy by variations in potential, which are incited by impulsively agitated material layer separation (particularly by displacement). Periodic mechanical triggering of the triboelectric layer generates AC output. TENGs works by four different mechanisms, taking account of the change in the polarization direction of two triboelectric material surfaces/layers and the configuration of electrodes, which are insulated carefully from each other. The four distinct modes are (i) vertical contact-separation (CS) mode, prompted by series of contacting and separating the triboelectric layers attached to the electrodes. The mode shows high-output peak current and figure of merit (FOM), which can further be enhanced by a stacked multilayer structure [134]. Figure 2c is a schematic of CS-mode TENG [116]. In Figure 2c(I), two layers are pressed by external force, in order to create contact and generation of charges at the interface of dielectric triboelectric layers A and B. Releasing outside force (Figure 2c(II)) leads to charge separation among the layers, establishing the potential difference that drives free charges in the electrode for potential balance setting current across the load R. When the charge is balanced, the current disappears, see Figure 2c(III). Again, pressing layers to make contact results in the flow of free charge, accumulated on the surface of the electrode, back into the circuit, resulting in current, but reversed, direction. The electric potential (V) of TENG is defined as:

In the above equation, is the triboelectric charge density, d is the gap distance betwixt two triboelectric material layers, is the permittivity of free space, and is the relative permittivity of triboelectric material. Clearly, the potential produced is a function of layer gap and depends on layer movement, so, the current. (ii) Lateral-sliding (LS) mode [116] is triggered by sliding the tribo-layers, studies revealed that longer sliding distances lead to lower FOM, but charge densities are high. The output performance of LS mode TENGs can be improved by structure grating, which can also be altered to either rotational or cylindrical gratings [135]. (iii) In the single-electrode (SL) mode, the back electrode is removed, which offers a very small amount of charge transfer and voltage [136]. (iv) In the freestanding triboelectric layer (FL) mode, the triboelectric layers are free from electrodes and can locomote with or without contacting with static electrodes, resulting in high-output power and energy conversion efficiency records [137]. Introducing the ferroelectric material layer to TENG speculates the increased surface charge density, e.g., the barium titanate ferroelectric ceramic layer, on polytetrafluoroethylene (PTFE) TENG [138]. Liu et al. obtained a high piezoelectric and pyroelectric coefficient of 150 pC/N and 29.7 nC/cm2K for BTO polarized disc by wind-driven TENG at speeds of 14 m/s, which resulted in the high-output voltage of 1000 V in <10 ms [40]. The literature revealed the improved output performance of PVDF-TrFE, based TENG, due to well-oriented polarization. TENGs offer broad material availability and high efficiency, yet low operation frequency [139].

3.4. Ferroelectric Photovoltaic Effect and Photovoltaic Cells

The ferroelectric photovoltaic effect refers to the photovoltaic response, i.e., photovoltage and/or photocurrent, observed in ferroelectric materials when exposed to light. The photovoltaic phenomenon in ferroelectrics is significantly dissimilar to the conventional photovoltaic effect (PVE) observed in semiconductor pn-junction. The built-in electric field, across the depletion region of the pn-junction, separates the generated photo-carriers, thereby defining that the open-circuit voltage for particular photovoltaic effects in semiconductors has a bandgap constraint. However, in the ferroelectric photovoltaic effect, the built-in field is because of remnant polarization (PR) and goes throughout the ferroelectric material, and there is no bandgap restriction for charge separation. Therefore, the photo-potential generated in ferroelectrics is much greater to abnormal value than their band gaps. This phenomenon is the so-called abnormal photovoltaic effect or bulk photovoltaic effect (BPVE) and had been known in barium titanate and lithium niobate for decades. However, its clear explanation is still a mystery and the photovoltage integrated can be visualized as the photovoltage of domains [140,141]. The bulk ferroelectric photovoltaic effect has been observed in bulk ferroelectric materials, such as BFO (BiFeO3), with large photovoltage stipulating the internal bias field presence. The thin films of BTO (BaTiO3) evidenced that the direction of photocurrent and photovoltage can be rolled over by reverting polarization, proving the polarization as a dominant feature in the bulk photovoltaic effect [140,142,143]. Figure 2d(I) represents the ferroelectric photovoltaic effect mechanism in poled SbSI nanowires with Pt metal contacts [29]. The SbSI nanowires proposed the bulk photovoltaic ferroelectric (BPVE) mechanism, shining light with energy greater than the bandgap of SbSI ferroelectric, resulting in the absorption of light photons, and promoting the photo-generation of electron and holes as excess carriers. Poling the SbSI ferroelectric caused band bending and, thus, the internal electric field, due to the spontaneous polarization of nanowires (Figure 2d(II)). The internal field determines spatial separation charge carriers in ferroelectric photovoltaic devices and these excess carriers contribute to the photovoltaic output current [29].

3.5. Coupled Effects NGs

Recently, hybridized nanogenerators NGs have also been reported by integrating individual piezoelectric, pyroelectric, triboelectric, and PVC harvesters, in series or parallel, for the realization of self-powering of devices with higher consumption powers by utilizing multi-energies. The hybrid stacked structures enhance the overall output power but restrict the interaction among various effects in the device, as different electrodes export electrical energy. Furthermore, it is discouraging for reducing device size and heavy productions [6,46,56,144]. Therefore, it is greatly aspired to deploy multifunctional energy harvesting materials for establishing the coupled nanogenerators, based on a single structure. Ferroelectric materials are multifunctional, thereby defining that the piezoelectric, pyroelectric, and photoelectric properties concur, also a common feature among piezoelectricity, pyroelectricity, triboelectricity, and the ferroelectric photovoltaic effect is that they all work by having an influence on the polarization of ferroelectric materials. This similarity indicates the potential to couple these effects, in order to magnify the charge quantity and electric power from various energy resources simultaneously and promote their use in multi-effect coupled NGs, whenever all the mechanical, thermal, and solar energies are either available individually or simultaneously. The multi-effect coupled NGs are composed of multilayers, with only one electrode pair that is highly versatile, reliable, simply smaller, and low cost. The multi-effects coexist and interact to produce electrical output; their performance hangs on the strength and type of external stimuli. Device design determines the performance of multi-effect coupled nanogenerators. By now, a sandwich layer layout with a function material embedded in two electrodes, planer structure consisting of two parts, functional material layer, coplanar electrodes realized by laser etching or masking, and heterojunction design (which commonly intervene in PVCs) have been contrived [6,47,145].

4. Device Structure and Performances of Ferroelectric NGs

Exceptional output device performances are always in search of better design and tailoring material properties.

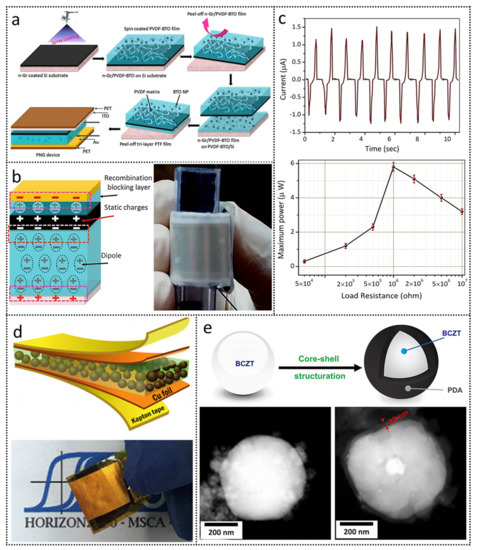

4.1. Device Design and Output Power Optimization in Piezoelectric PENGs

The piezoelectric ceramic perovskites show high piezoelectric constants and electromechanical response because of polarization rotations. The ferroelectric, ceramic-based PENGs with active layers of lead zirconate titanate (PZT) [146,147], barium titanate (BTO) [148,149,150], lead magnesium niobate titanate (PMN-PT) [151,152,153,154], sodium bismuth titanate (NBT) [155,156,157,158,159], and sodium potassium niobate (KNN) [160,161] have been reported with high-output performances. Ferroelectric thin film PENGs have also been reported on flexible plastic substrates with metal electrodes and by transferring techniques [146,154]. However, ceramic PENGs have limitations of large-area devices fabrication; additionally, ceramics are frangible in nature and cannot withstand very strong strain-producing forces. To get out of these problems, reports on a polymer matrix supported by ferroelectric powder composites have been found, which fortified a large area of manufacturing devices, reduced cost, sustain high-stress forces, and enhanced mechanical resilience, but are not admissible in low magnitude and frequency input forces [146,153]. This time, highly durable and elastic polymer ferroelectric-based PENGs were proposed, with high mechanical permanence and optimistic output performances [62,162,163,164]. Semi-metallic/conductive layers or electrodes are deposited over the ferroelectric active layers to get charge separation without poling; graphene is a potential conductive layer, due to high thermal and electrical properties over the large surface area. Additionally, surface treatments or doping can make graphene either p-type or n-type, which can further align the polarized charges efficiently. Polyvinylidene fluoride (PVDF) and its copolymers are rosy for polymeric ferroelectric-based PENGs. PVDF exhibit a smaller dielectric constant but have extremely high parameters of voltage (g33 = 28.26) and piezoelectric constants (d33 = 16.2 pC/N) [63,163]. The d33 value can be further enhanced by introducing ceramic fillers with relatively larger permittivity, e.g., PZT, PLZT (PZT:La), PTO, BTO, and PMN-PT into the PVDF matrix. The quantity of ceramic powder fillers is most important, and it controls the harvesting properties of PENGs; the positive and negative piezocoefficients of ceramic and polymeric ferroelectrics may rule out each other’s effects, thereby reducing the output performances, so tedious measurements must be taken into account [165,166]. Yaqoob et al. [167] fabricated a novel tri-layer PVDF-BTO/n-Gr/PVDF-BTO piezoelectric NG, with 60 µm thickness. The PVDF/BTO layers stacked on both sides of the N-graphene layer deposited over Si substrate. Figure 3a demonstrates the making process of tri-layer PENG. The working mechanism of tri-layer PENG is illustrated in Figure 3b, escribing that between n-Gr and PVDF-BTO, the layer charge barriers are created, due to the accumulation of opposite charges near the interfaces. The lower n-Gr/PVDF-BTO layer acts as a blocker and restricts recombination and sustains the charge on the upper layer, and dipole alignment happens on both sides. Extreme bending of PENG shows high flexibility. FESEM studies confirmed that BTO nanoparticles were dispersed uniformly in the PVDF matrix and graphene over PVD-BTO film in the -tetragonal phase. The high peak-to-peak open-circuit voltage of 1.5 V and 10 V was observed in un-poled and poled PENG under the force of 2 N by human finger tapping. Figure 3c shows the maximum short-circuit current output of 2.5 µA and instantaneous powers of tri-layer PENG was found saturated at 10 MΩ load resistance, with a maximum value of 5.8 µW at 1 MΩ. PENG was found to be highly stable, even under continuous pressing and releasing at 2 N for 1000 s, and is attributed with N-graphene, suggesting graphene-enhanced PENG performance and realizing that the tri-layer structure is efficient for mechanical energy harvesting and perspective to use as a pressure sensor and power source of self-powered devices. Hanani et al. [33] investigated a bio-flexible PENG with potential in self-powered biomedical devices, as well as lead-free, bio-ceramic Ba0.85Ca0.15Zr0.10Ti0.90O3 (BCZT), functionalized with polydopamine that is embedded with polylactic acid. BCZT@PDA/PLA is sandwiched between two Cu-foils and encapsulated with Kapton tape to keep it water- and dust-proof and secure, as of repeated mechanical excitations, see Figure 3d. PLA has a high piezoelectric coefficient d13 of 10 pC/N, without poling or being self-poled. The BCZT nanoparticle’s surface was functionalized via core-shell saturation (Figure 3e), with a PDA layer to promote interaction among the two. Under gentle finger tapping, the mechanical performances, open-circuit voltage, and short-circuit current were quantified to be 14.40 V and 0.55 µA, respectively; however, the increased imparting pressures caused Voc to rise. Young modulus of 2.1 GPa endures mechanical robustness, and the high-output power density of 7.54 mW/cm3 is capable of driving the 1 µF capacitor, with an energy storage of 3.92 µJ, only in 115 s, under gentle finger tapping and longer stability at 23 Hz for 14,000 cycles by sewing machine, which showed no performance degradation for 4800 cycles, even after one year.

Figure 3.

Device structure and performances of piezoelectric ferroelectric nanogenerators (PENGs). (a) Fabrication steps for tri-layer n-Gr/BTO-PVDF on BTO-PVDF/Si PENG. (b) The working mechanism of tri-layer PENG, along with an optical image of the extreme bending situation. (c) Short-circuit current and instantaneous power output of tri-layer PENG. (a–c) Reprinted with permission from reference [167], Copyrights 2017, Elsevier. (d) Schematic of Bio-flexible BCZT-based nanogenerator. (e) Illustration of the core-shell structuration of BCZT nanoparticles, by PDA, along with microimages of BCZT and BCZT@PDA. (d,e) Reprinted with permission from reference [33], Copyrights 2021, Elsevier.

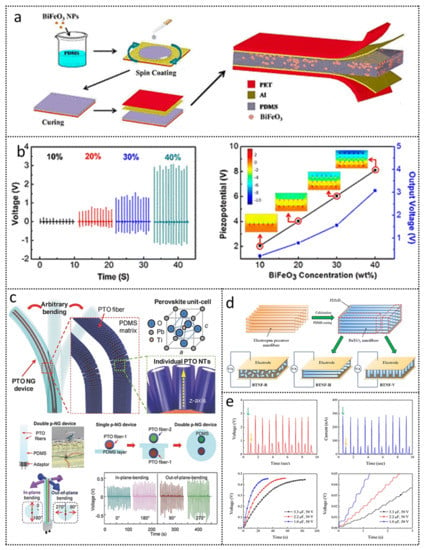

Xiaohu et al. [168] exposited BiFeO3-PDMS composite (~100 nm)-based flexible PENG on polyethylene terephthalate (PET) substrate and Al-foil electrodes (PET/Al/BFO-PDMS/Al/PET), see Figure 4a. BiFeO3 nanoparticles (NPs) had a rhombohedral structure, with 180° domain switching of permanent polarization. The PENGs showed the maximum output, open-circuit voltage of 3 V for 40% BFO NPs in PVDS matrix and a short-circuit current of 250 nA, under hand pressing, can be seen in Figure 4b. Simulated piezo potential distribution is indicated on the right side of the voltage-time graph, as a response to the compressive stress of 10 KPa. The fabricated BFO PENG can light commercial LEDs. Lee et al. [169] reported a novel fiber-type piezoelectric NG, based on PTO (PbTiO3) nanotubes, grown radially on Ti metal fiber; the PTO/Ti core-shell fiber was embedded in the PDMS cylindrical templates, with inter-wire spacing formed and thin, insulating PDMS. Poling (via convex and concave bending of the PENG) the output voltage and current of 623 mV and 1.0 nA/cm2 was estimated. When a second core-shell was added in the back of the first (Figure 4c), poled in radial direction because of radial alignment of PTO domains, the output voltage estimated in- and out-of-plane bending were ±320 and ±390 mV (for 0° and 180°) and ±370 and ±450 mV (for 90° and 270°), respectively. Under natural wind, blowing the output voltage of 69.74 ± 10.97 mV with 0–360°, bending was observed. The idea captivates applications in portable and flexible devices. Yan et al. [170] reported a PDMS-based, flexible PENG, with BTO nanofibers in three different alignment modes (random, horizontal, and vertical) and tetragonal structure, as shown in Figure 4d, poled for 12 h at 120 °C and an electric field of 5 kV/mm. Random (BTNF-R), horizontal (BTNF-H), and vertical (BTNF-V) alignment of BTO nanofiber PENGs showed output voltages of 0.56 V, 1.48 V, and 2.67 V and currents 57.78 nA, 103.33 nA, and 261, 40 nA, respectively, under a poled situation and periodic mechanical compressive pressure of 0.002 MPa, with a harvesting power of ~0.1841 µW in vertical mode (BTNF-V). This pointed out that the vertically lined BTO nanofibers were finest in dielectric and piezoelectric response and used to light commercial LED and charge a 1 μF capacitor to 0.46 V in just 34 s (shown in Figure 4e), stating wonderful alignment for use as harvester units or storage entities for wireless networks. Jung et al. [171] presented a PENG based on NaNbO3 nanowires, composited with the PDMS matrix and Au/Cr coated films (PS/Au-Cr-coated kapton/NaNbO3-PDMS/Au/Cr-coated Kapton; PS is the supporting polyester film, the strain neutral line lies near the vicinity of PS film). Estimated output voltage Voc of 3.2 V, short-circuit current Isc of 72 nA, and power density of 0.6 mW/cm3, under the compressive strain produced by vibrations of 0.33 Hz. Production of NaNbO3, at relatively low temperature and domain control (by poling) make them perfect nanogenerator members. Park et al. [150] devised MIM structure-based Au/BTO/Pt PENG with a ribbon structure over a plastic substrate, using PDMS stamp, the Kapton film, and poled for 15 h at 140 °C, with a field application of 100 kV/cm. Poling caused d33 to increase from 40 pm/V to 105 pm/V; periodic bending (by finger) resulted in an output voltage and current values of ~1.0 V and ~26 nA and the power density of 7 mW/cm3. In comparison to inorganic ferroelectrics, very few organic ferroelectrics exist. For example, single-component polar organic molecules, such as CDA, DNP, CT complexes, polymers (such as PVDF and nylon-11), and organic-inorganic composites (such as HdabecoReO4, TGS, and TSCC), are excellent for applications in piezoelectric and triboelectric nanogenerators. Isakov et al. [172] reported a piezoelectric nanogenerator, based on organic ferroelectric nanofibers of hybrid 1,4-diazabicyclo[2.2.2]octance perrhenate (dabacoHReO4), with an output voltage of 100 mV under moderate strain values. Ferroelectric diphenylalanine peptides are also becoming promising for piezoelectric energy harvesting and are biocompatible. Zelenovskii et al. [173] reported the fabrication of the 2D layered biomolecular crystals of diphenylalanine, with a piezoelectric constant d33 of 20 pm/V and voltage coefficient g33 of 0.75 Vm/N, which is suitable for microfluidic device applications. Nguyen et al. [174] estimated strong piezoelectricity in diphenylalanine (FF) peptide nanotubes, with a piezoelectric constant d33 of 17.9 pm/V, open-circuit output voltage of 1.4 V, and power density of 3.3 nW/cm2. In a report by Lee et al. [175], peptide-based piezoelectric energy harvesters, at a force of 42 N, can produce an output voltage of 2.8 V, current of 27.4 nA, and power of 8.2 nW, which is sufficient to power multiple liquid-crystal display panels. Table 1 gives a quick insight into various piezoelectric nanogenerators (PENG), along with their output characteristics and working conditions, made with various structural variations and morphologies, indicating the high-output characteristics.

Figure 4.

Device structure and performances of piezoelectric ferroelectric nanogenerators (PENGs). (a) Lead-free flexible BFO-PDMS PENG. (b) Time-dependent voltage and COSMOL simulated piezo potential for 0–40% BFO nanoparticle concentration PENGs. (a,b) Reprinted with permission from reference [168], Copyrights 2016, ACS Publications. (c) PTO/Ti fiber PENG in arbitrary bending direction with PDMS polymer matrix. The bottom line shows the double PTO fiber PENGs, along with two possible bending directions (in- and out-plane) and corresponding output voltages. Reprinted with permission from reference [169], Copyrights 2017, John Wiley and Sons. (d) Schematic of BTO-based PENG nanogenerator in three different alignment modes. (e) Rectified voltage-current signals and voltage-time graphs for different capacitors. (d,e) Reprinted with permission from reference [170], Copyrights 2016, ACS Publications.

Table 1.

Piezoelectric nanogenerators, based on ferroelectric materials, for energy harvesting.

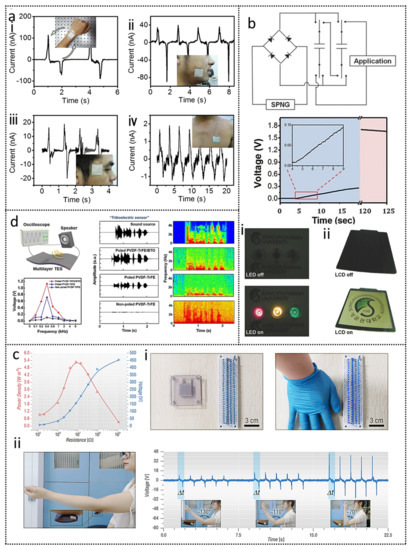

4.2. Device Design and Output Power Optimization in Pyroelectric PyENGs

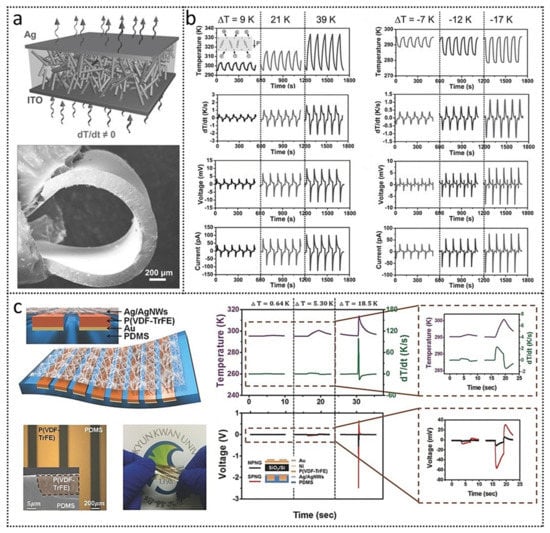

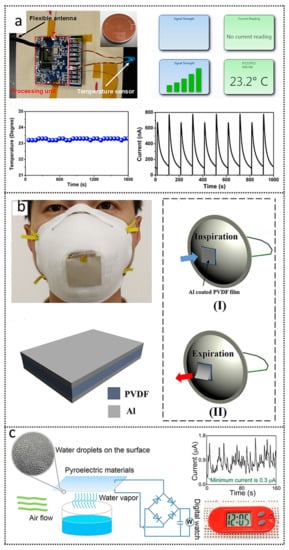

Low-grade heat wastes coming from the industry of which maximum portion is hard to recuperate, a way to rescue these heat wastes is harvesting them into electric energy by temperature fluctuations either by Seebeck effect or by pyroelectricity. Thermoelectric nanogenerators require a steady gradient temperature that is infrequent in nature, otherwise, by pyroelectric nanogenerators, PyENG, lined with temporal temperature sways. The material and structure designs are crucial for the improvement in the output of PyENGs because the pyroelectric coefficients have small values. Improving these various approaches has already been reported, including the control over crystallinity for im-proving pyroelectric coefficient [185], introducing strain coupling effects [186], or polymer modifications [187]. Kim et al. [185] used high dipole moment solvents for improving the crystallinity and pyroelectric coefficient of P(VDF-TrFE); the solvents they used were THF (tetahydrofuran), MEK (methylethylketone), DFM (dimethylformamide), and DMSO (dimethylsulfoxide). High crystallinity and improved pyroelectric constant were observed and figured to be associated with the long-chain lengths of P(VDF-TrFE); they exhibited high molecular weight and 1.4 times higher output voltage and current. Hence, pyroelectric coefficient enhancement, by utilizing high dipole moment solvents, is a promising way to improve output PENG performance. Ghosh et al. [187] presented improved pyroelectricity of PVDF PyENG by introducing the Er+3 via formation of self-polarized β-phase and porous flower-like structures, as well as enhanced thermal sensitivity, triggered by IR irradiations. Under a temperature change rate of 1 K/s, the estimated output current was 13 nA. The 4.7 μF capacitor was easily charged by Er-PVDF PyENG, which operates low-power electronic devices with great ease. Mistewicz et al. [122] demonstrated low-temperature heat waste by SbSeI-based PyENG, with a pyroelectric coefficient of 44(5) nCK−1/cm2 at 327 K. The output voltage, current, and power of 12 mV, 11 nA, and 0.59(4) μW/m2 were generated by PyENG for temperature fluctuations of 324 K to 334 K. Yang et al. [188] reported KNbO3 single-crystal nanowire (~150 nm), along a [011] direction composite with PDMS (KNbO3-PDMS in 3:7 and pyroelectric constant 0.8 nC/cm2K) PyENG, embedded with Ag and ITO electrodes, Figure 5a. Positive poling caused the dipoles in the KNbO3 nanowires to align from top to bottom and reverse, i.e., bottom to top, for negative poling. Increased temperature from RT resulted in output voltage and current peaks to be positive, which go opposite for lowing the temperature (see Figure 5b). At a temperature change of about 40 K, the observed output voltage and current peaks were 10 mV and 120 pA, and the output current is directly related to temperature variations (dT/dt > 0). They also deployed the generator for harvesting the solar energy, as heat is induced by the sun, showing potential for self-powered widgets. Lee et al. [186] designed an innovatively stretchable pyroelectric nanogenerator (SPNG), by coupling thermally induced piezoelectric and pyroelectric effects, using P(VDF-TrFE) and PDMS; the piezoelectric effect was generated by thermal energy, only by accomplishing the different thermal expansions (122 × 10−6/K for P(VDF-TrFE) and 310 × 10−6/K for PDMS) and generating a compressive strain in P(VDF-TrFE) by PDMS. Figure 5c shows a schematic of stretchable PyENG, Ag/AgNWs/P(VDF-TrFE)/Au/PDMS, along with an optical micrograph of 500 µm × 700 µm P(VDF-TrFE) in β-phase and 200 µm × 200 µm PDMS. The temperature sensitivity of stretched nanogenerator was analyzed by comparing it with a normal P(VDF-TrFE)/Ni/SiO2/Si nanogenerator, and negative peak signals were reported for temperature elevation from RT (right part of Figure 5c). The sensitive, stretchable pyroelectric NG, under extremely low temperature variations (ΔT) of 0.64 K, to higher variations 18.5 K, showcased highly stable output voltage performance of 8 mV to 2.48 V under extreme stretch circumstances over a normal nanogenerator 2 mV to 0.54 V. Almost 15% stretching, caused only the PDMS layer to expand by 30 µm, and temperature variation of 22 K from RT caused an output voltage and current density of 2.5 V and 570 nA/cm2, respectively. Yang et al. [37] reported a PZT film-based pyroelectric nanogenerator (PyENG) with Ni, a top and bottom electrode connected, and Cu-wires (fixed with Ag paste) for electrical measurements and encased with Kapton tape. For temperature changes of 45 K, at the rate of 0.2 K/s, the output open-circuit voltage, short-circuit current, and short-circuit current density of PENG reached 22 V, 430 nA, and 171 nA/cm2, respectively; the corresponding maximum power density of 0.215 mW/cm3 was estimated, and a single electrical pulse can power a liquid crystal display (LCD) for more than the 60 s. The proposed PyENG showed potential applications as wireless sensors, drivable by a rechargeable Li-ion battery with a voltage of 2.8 V, see Figure 6a. The pyropotential calculation of PZT film showed distributions from −200 V to 200 V for temperature variations from 295 K to 340 K. With the measured electric potential of 22 V, much smaller than the theoretical value, they showed increased output current, as the surface area of PyENG was doubled than original. Xue et al. [27] proposed the self-powered wearable pyroelectric nanogenerator, based on Al-coated PVDF film, exercised in an N95 respirator for the sustainable harvesting and monitoring of human breathing energy, see Figure 6b. They observed that the open-circuit output voltage Voc of ~42 V is generated by the temperature oscillations rate, 13 °C/s, encouraged by humans breathing exhausted gas, at an ambient temperature of 5 °C with short-circuit current of 2.5 μA and the maximum power output of 8.31 μW. The power produced can drive a liquid crystal display (LCD) and/or LED directly. They employ the fabricated PyENG as self-power sensors for human health monitoring and temperature. Gao et al. [189] proposed a P(VDF-TrFE)-based pyroelectric nanogenerator, driven by temperature fluctuations, induced up to 23 °C/s by water vapors during the process of evaporation and condensation. As can be seen in Figure 6c, the oscillation airflow environment was created by a fan with an air speed of 1–2 m/s. The PyENG was capable of generating a high-output voltage and current density of 145 V and 0.12 μA, with a power density of 1.47 mW/cm3 and 4.12 μW/cm3 by volume and area. The water-operated PyENG could run a low-power digital watch, blue LED light, and charge a capacitor of 2.2 μF, giving a new map to harvest energy from the wastewater of industries. Yang et al. [36] prepared a self-powered temperature sensor, based on a pyroelectric nanogenerator, using a single micro/nanowire of PZT on a thin glass substrate, packaged by PDMS. Employing this device to touch the heat source the voltage was found to vary linearly with temperature increments, as well as the response and reset time of 0.9 s and 3 s. The minimum constraint on detecting temperature variations at RT was 4 K, and the device was as sensitive to detecting the temperature of the fingertip; large temperature fluctuations could light up the LCD. Some other pyroelectric nanogenerators, PyENG, have been listed in Table 2.

Figure 5.

Device structure and performances of pyroelectric ferroelectric nanogenerators (PyENGs). (a) Schematic of KNbO3-PDMS composite pyroelectric nanogenerator, with Ag ad ITO electrodes; the bottom line is the SEM image of KNbO3 in the bent state. (b) Cyclic changes in temperature, with corresponding differential curves of open-circuit voltage Voc and short-circuit current Isc. (a,b) Reprinted with permission from reference [188], Copyrights 2012, John Wiley and Sons. (c) Schematic of highly stretchable P(VDF-TrFE) pyroelectric nanogenerator (SPNG); the bottom line left image indicates the top view of SPNG, along with photo image. The right hand image indicates the measured output characteristics for both stretchable and normal pyroelectric nanogenerators. Reprinted with permission from reference [186], Copyrights 2015, John Wiley and Sons.

Figure 6.

Device structure and performances of pyroelectric ferroelectric nanogenerators (PyENGs). (a) Photograph of wireless temperature sensor, based on PZT PyENG, along with temperature signals from a wireless sensor in off- and on-state, temperature signal data, as a function of time, was recorded for half an hour (for every one minute) and enhanced the output current profile of as-deposited PyENG for doubled surface area. Reprinted with reference from [37], Copyrights 2012, ACS Publishers. (b) Physical schematic image of the wearable PyENG with PVDF film, driven by human respiration, along with states of (I) inspiration and (II) expiration. Reprinted with permission from reference [27], Copyrights 2017, Elsevier. (c) Powering digital watch from P(VDF-TrFE)-based PyENG, powered by hot water vapors. Reprinted with permission from reference [189], Copyrights 2016, Elsevier.

Table 2.

Pyroelectric nanogenerators, based on various ferroelectric materials.

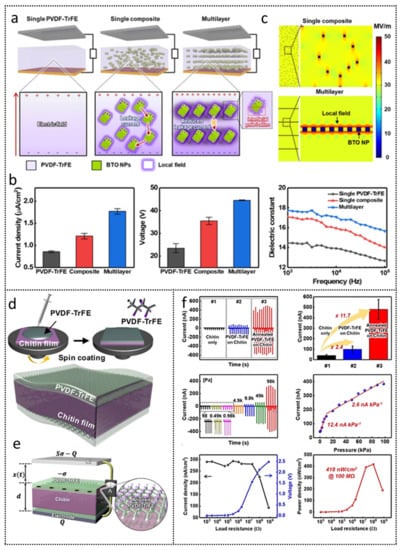

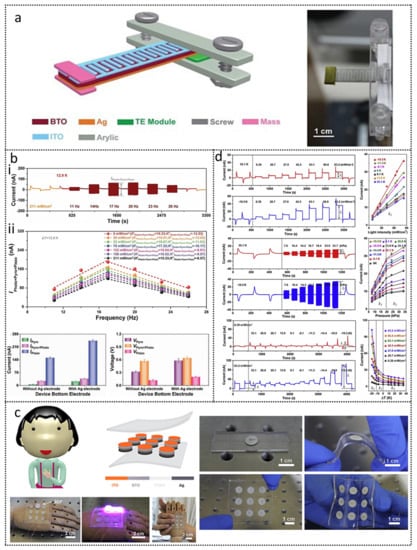

4.3. Device Design and Output Power Optimization in Triboelectric Nanogenerators TENG

The electrical outputs generated from TENG are proportional to the intensity of the mechanical input strengths. Triboelectric nanogenerators can be supported by ferroelectrics because of their switchable intrinsic polarization. It increases the triboelectric charging behavior to enhance their output characteristics by coupling residual dielectric and surface polarization. Organic ferroelectrics, such as P(VDF-TrFE), show controllable ferroelectric polarization, leading to elevated surface charge density and improved TENG performance. High dielectric, inorganic ferroelectric ceramics and polymer composites of TENG need precise control of the nanoparticles’ dispersion into the dispersive media. The precision control avoids the agglomeration that leads to the degradation of device performances. Park et al. [196] reported TENG with multilayer nanocomposites, comprised of alternate layers of organic and inorganic ferroelectric materials P(VDF-TrFE) and BTO nanoparticles with Al and Cu electrodes (Figure 7a). The organic soft layer P(VDF-TrFE) significantly transfers the vertically applied stress to the BTO inorganic layer. It exhibits a dielectric constant of 17.06 at 10 kHz in a multilayer structure, which yields superior interfacial polarization. The multilayer structure facilitates less leakage current, instigated by the P(VDF-TrFE) barrier between BTO layers. Poling at 30 MV/m further induced the surface potential of −2.85 V. As a result, more increased output characteristics of current, voltage, and dielectric constants, compared to only P(VDF-TrFE) and a single layer of BTO dispersed in P(VDF-TrFE) (Figure 7b,c). Multilayered TENG had a pressure sensitivity of 0.94 V/kPa with an output power density of 29.4 µW/cm2 and an output current density of 1.77 μAcm−2 and voltage of 44.5 V, with active application in healthcare monitoring devices. Fang et al. [197] reported TENG with self-assembled nanospheres of polystyrene with PVDF porous film. Its unique structure showed an outstanding high-output voltage of 220 V being able to directly pole single crystal of 0.65Pb(Mg1/3Nb2/3)O3-0.35PbTiO3 (PMN-PT). They realized the application of TENG in ferroelectric FET, with PMN-PT as a gate material, posting the potential of TENG in a self-powered memory system. Ferroelectric ceramics, polymerized with non-ferroelectric materials, have a great impact on the output performance enhancement of TENGs. Sahu et al. [64] demonstrated the increase in output performance of TENG by introducing a ferroelectric material layer of (Ba0.85Ca0.15)(Ti0.90Zr0.10)O3x BiHoO3 nanoparticles (BCZTBH for x = 0.02 to 0.1) into non-ferroelectric PDMS negative triboelectric layer. They correlated the piezoelectric properties of BCZTBH and integrated a multistacked piezo/tribo hybrid nanogenerator. They also concluded that mechanical excitation gives a higher output voltage of 300 V, a current of 6.6 μA, and a power density of 157 mW/m2. Further, they integrated the multi-stacked device to charge a capacitor, in order to monitor the biomedical energy released from the body in various yoga poses. The module, as IR receivers and transmitters, were installed into a self-powered, wireless IR sensor communication system for high reliability and efficiency checks. The literature revealed that the annealing of poly(vinylidene fluoride-co-trifluroethylene) leads to crystal orientation instability and improper polarization axis match with the substrate. It prohibits its merits and obstructs its applications to TENGs. So, crystal orientation tailoring is in need. To treat the problem, researchers have worked to introduce a graphene layer [198], employed self-assembled monolayer-modified Au-substrates [198,199], and organo-silicate lamella [200], lattice matching with molecularly ordered PTFE substrates via epitaxy [201]. All these epitaxial fabrication and graphene layer insertions yielded fabulous results by controlling the orientation of the crystal polarization axis by recrystallization after melting. However, during TENG operation, insurance of adequate charge density on the surface is a big problem that leads to inferior performance of TENG. To get out of this problem, the right angle alignment of the b-axis of PVDF-TrFE with the substrate is proposed. Eom et al. [139] reported on the TENG that was based on epitaxially grown PVDF-TrFE over chitin film (Figure 7d), the crystallographic overlap between two enabled tailoring the PVDF-TrFE crystal orientation with polarization axis (b-axis) orthogonal to chitin (c-axis) substrate. The observed remanent polarization (~4.2 µC/cm2) was quite high, corresponding to a sweep voltage of ±80 V and coercive field ~60 MV/m higher than its theoretical value of 50 Mv/m, attributed with the series connection of PVDF-TrFE and chitin film. Chitin film showed severe distortions in humid circumstances, which can cause the short-circuiting of TENG. To avoid penetration of water molecules into chitin they deposited PVDF-TrFE film on two sides of chitin substrate by spin coating. Figure 7e depicts PVDF-TrFE/chitin hybrid layer TENG in vertical contact separation mode with an Al electrode. The 200 °C annealed hybrid film structure showed 11.7 and 4.9 times higher output current when compared with freestanding chitin film and non-epitaxial PVDF-TrFE/chitin hybrid film with a maximum power density of ~418 nW/cm2 at 100 MΩ (Figure 7f). They fabricated triboelectric sensors of epitaxial PVDF-TrFE/chitin films. The allowed monitoring of subtle pressures suggested that tailoring the crystal orientation of PVDF-TrFE is encouraging for developing high-performance TENGs.

Figure 7.

Device structure and performances of triboelectric ferroelectric nanogenerators (TENGs). (a) Schematic illustration of PVDF-TrFE/BTO composite TENG with single PVDF-TrFE, single PVDF-TrFE/BTO, and multilayer PVDF-TrFE/BTO layers. (b) Plots for output current density, voltage, and dielectric constant of three TENGs at vertical pressure of 98 kPa and 2 Hz. (c) Simulated potential in single and multilayered PVD F-TrFE/BTO composites. (a–c) Reprinted with permission from reference [196], Copyrights 2020, ACS Publisher. (d,e) Schematics of chitin-based PVDF-TrFE TENG. (f) Current and power plots of chitin /PVDF-TrFE hybrid film TENG. (d–f) Reprinted with permission from reference [139], Copyrights 2020, ACS Publications.

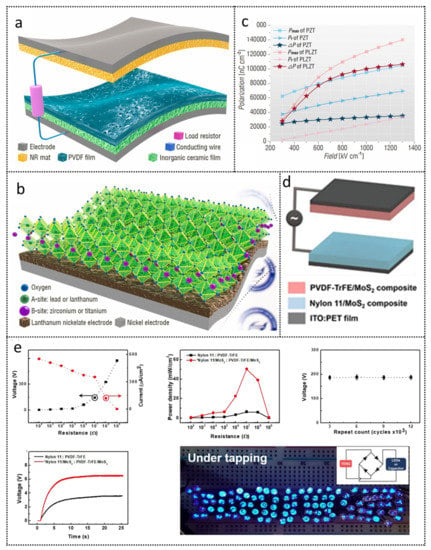

Since ferroelectrics have large remanent polarization. They can trap the spatial charge on electrodes for longer times and limit the TENG application in energy harvesting and sensing. To avoid this, exploitation of PLZT, a flexible anti-ferroelectric ceramic with large polarization differences (ΔP = Pr − Pmax), was carried out by Zhang et al. [202]. They proposed that Pb0.94La0.04Zr0.98Ti0.02O3, with zero remanent polarization (Pr) and large maximum polarization (Pmax), can enable all the dielectric polarization-induced charges, when used as an inner layer in TENG. A conducting fabric was attached with a natural rubber mat and PVDF/PZLT on LNO/Ni, as electrodes behave as a tribo-positive and -negative layer, as shown in Figure 8a. PLZT–TENG showed a record high ΔP = 1.065 × 105 nC/cm2 at 1300 kV/cm, much higher than PZT-TENG (PbZr0.52Ti0.48O3), shown in Figure 8b,c. PLZT–TENG delivered a high-output voltage of 456 V, with a high current density of 11.6 µA/cm2 and charge transfer density of 13.5 nC/cm2 at the impulse force of 5 N. Their study revealed that PLZT-based TENG exhibits excellent mechanical and polarization stability and can serve as self-powered sensors for joint motion detection, along with biomedical energy harvesting. Their study has paved a path to upgraded and optimized TENGs. Singh et al. [203] determined improved triboelectrification, by incorporating ZnO nanorods to PVDF polymer and PTFE and fastening to a moveable wooden frame with double-sided foam tape. They reported that the fabricated ZnO/PDMS TENG showed 21% and 60% increased voltage (~119 V) and current (1.6 mA), as compared to PVDF/PTMS TENG, with output voltage and current 98 V and 1mA, as well as power output 10.6 mW/cm2 and 6.4 mW/cm2 at 150 MΩ. They proposed that the increase in triboelectric energy, observed by them in ferroelectric polymer TENGs, is because of -phase of PVDF enhancement. The surface roughness of films, hydrophobicity, and decreased work function is due to ZnO nanorod incorporations.

Figure 8.

Device structure and performances of triboelectric ferroelectric nanogenerators (TENGs). (a,b) Schematic illustration of TENG with PLZT inner dielectric layer on flexible electrodes. (c) Maximum polarization, remanent polarization, and polarization difference for PLZT TENG and PZT TENG. (a–c) Reprinted with permission from reference [202], Copyrights 2021, Elsevier. (d) Structure of MoS2, composited with PVDF-TrFE and nylon-11; right is an optical image of single PVDF-TrFE; PVDF-TrFE composited with MoS2 and with nylon-11 and nylon-11. MoS2, bottom line. (e); Voltage, current, and power conversion dependence, as for various load resistances and LED lighting. (d,e) Reprinted with permission from reference [204], Copyrights 2019, ACS Publications.

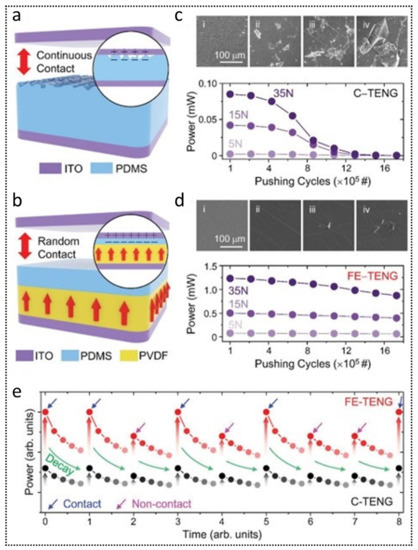

The continuous reiteration of TENG contact and separation is inevitable and leads to the life-shortening of the device. To overcome this wearing problem in TENGs, serval attempts had already been made, inclusive of which are the use of shape memory polymer as a contact material to heal damaged surfaces by heat application, proposed by Lee et al. [205]. The atomic layer deposition (ALD) technique for the in-filtering of inorganic materials from polymers was reported by Yu et al. [206]. Application of permanent magnet isolating outside vibrations was introduced by Huang et al. [207]. All the ways are innovative, but a much more facile way to avoid wearing issues, compatible with TENGs, is in need. Kim et al. [204] reported Nylon-11- and PVDF-TrFE-based TENGs, composited with bulk MoS2, as shown in Figure 8d. Both composite ferroelectric layers, along with increased polarization, led to an increased surface charge density and produced high-output voltage, current, and power density of 145 V, 350 µA/cm2, and 50 nW/cm2. The highest power density was reported at 10 MΩ, and the repeated output voltage measures for 12,000 cycles at 6.5 Hz operating frequency gave same voltage results. Additionally, can light LEDs without charge storage (see Figure 8e). Kim et al. [208] have reported a much simpler way to enhance TENG durability, by employing the concept of reduced contact number cycles in ferroelectric, PVD-based TENG, with ITO as the electrode and PDMS as an elastomer. They showed that the up-sided polarization (58 pm/V) of PVDF led to extremely fast charge accumulation and larger TE-outputs, when compared with a downside (36 pm/V) and non-polarized (1.1 pm/V) PVDF under contact state. Up-side polarized TENG showed as Li-ion battery chargeable, even by 40% reduced contact cycles. Figure 9a,c depicts convention TENG vs. PVDF ferroelectric TENG; SEM and power curves are depicted in Figure 9b,d. Continuous contact caused surface deterioration at a pushing cycle of 1.7 × 106 for vibration of 1 Hz. The power is reduced to 0.18 µW from 85 µW at a load resistance of 10 MΩ and mechanical force of 35 N for conventional TENG. In PVDF-based TENG, random contacts were performed, which significantly lowered surface wear and mitigated power after longer usage. The surface of PVDF remained clean and flat, even after the pushing cycle of 1.7 × 106, with the power loss from 1.23 mW to 0.87 mW, only a bit smaller. The results lasted for many load resistances and forces, even in non-contact mode (Figure 9e), realizing that stable power can be generated from random contacts, with output peak-to-peak values of voltage, current, and charge (410 V, 25 µA, and 60 nC, respectively). The deposited TENG show potential in wireless temperature sensor from water waves. Park et al. [209] developed the triboelectric nanogenerator, which relied on a cyclo-diphenylaladine (cyclo-FF) nanowire array with high-output performance voltage and a current of 350 V and 10 µA, respectively, which is sufficient to light up 100 LEDs.

Figure 9.

(a,c) Schematic of conventional (ITO/PDMS) and ferroelectric TENG (ITO/PDMS/PVDF) with magnified ITO, PDMS, and PVDF surfaces in contact (b,d). Pushing morphology-dependent power generation of conventional and ferroelectric TENG. (e) Power generation and decay for both types, with contact and noncontact conditions. (a–e) Reprinted with permission from reference [208], Copyrights 2019, John Wiley and Sons.

Some more triboelectric nanogenerators have been listed in Table 3.

Table 3.

Triboelectric nanogenerators, based on various ferroelectric materials.

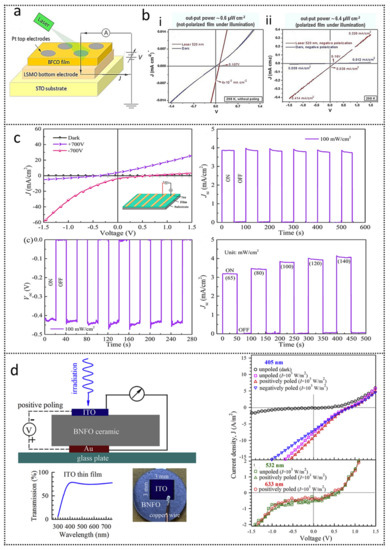

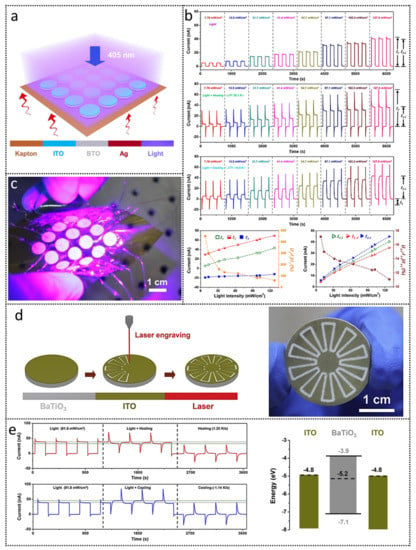

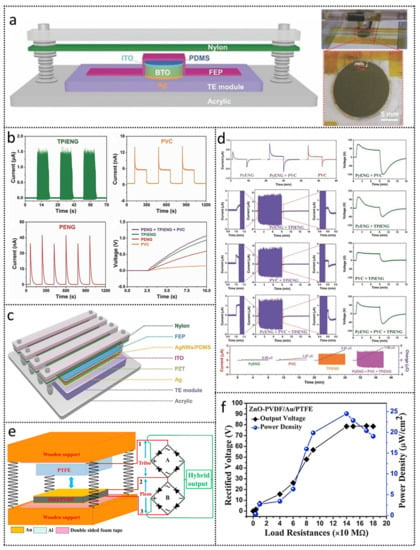

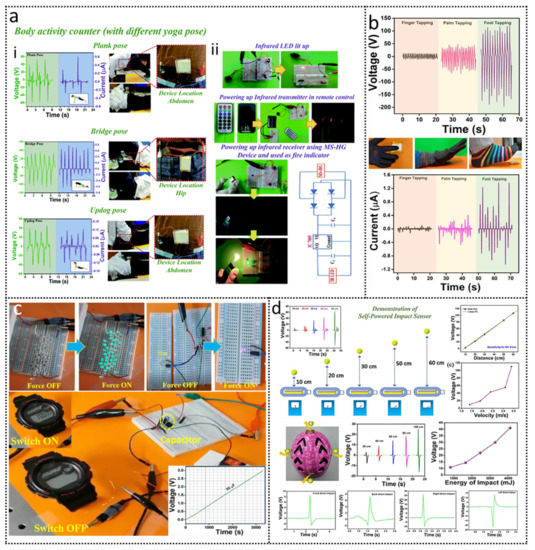

4.4. Device Design and Output Power Optimization in Ferroelectric Photovoltaics (PVC)