Time-Dependent Hydrothermal Synthesis of TiO2 in the Presence of Zn2+: Effects on Photoconductivity

Abstract

1. Introduction

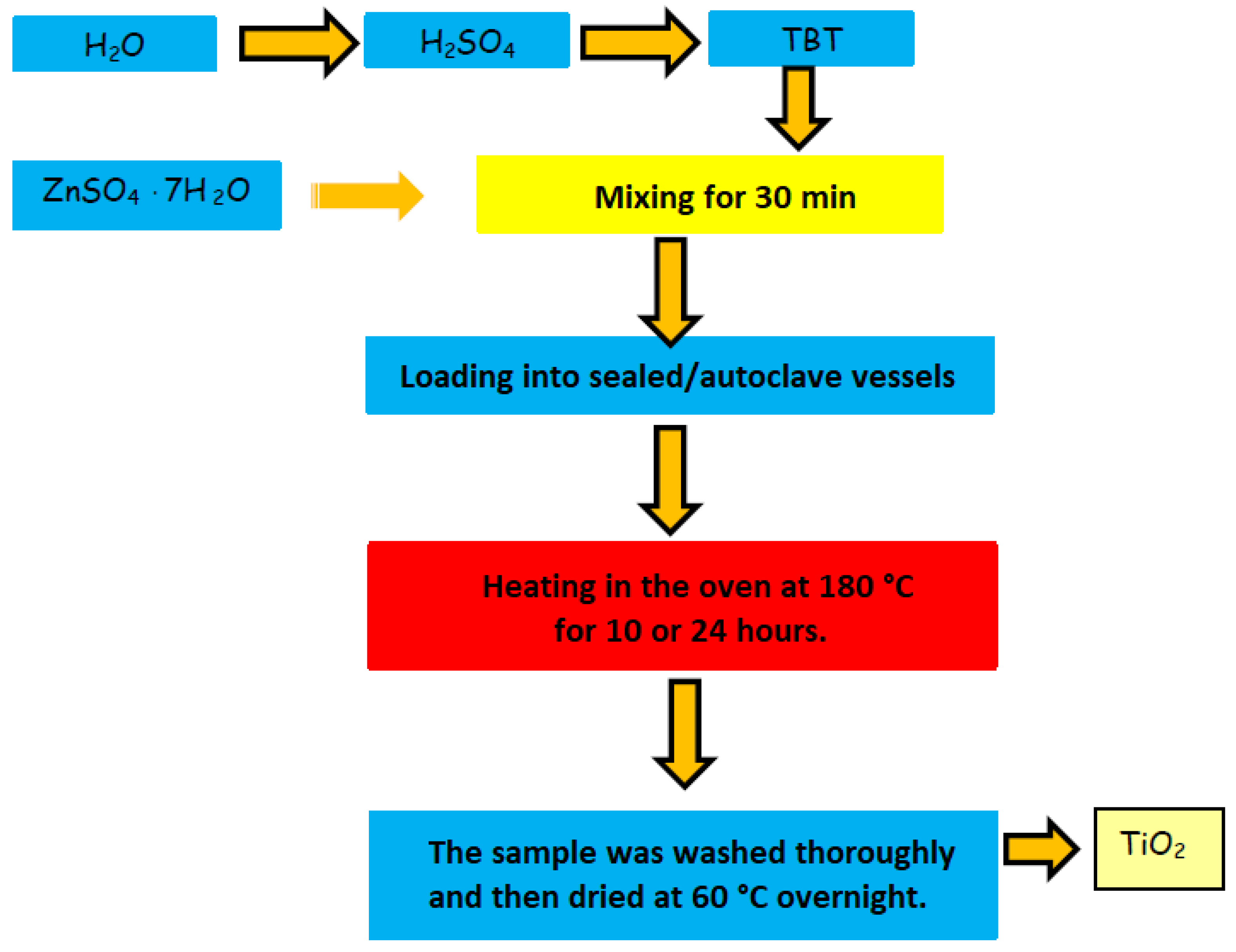

2. Materials and Methods

3. Results and Discussion

3.1. Crystalline Structures

3.2. Morphology and Band Gap Analysis

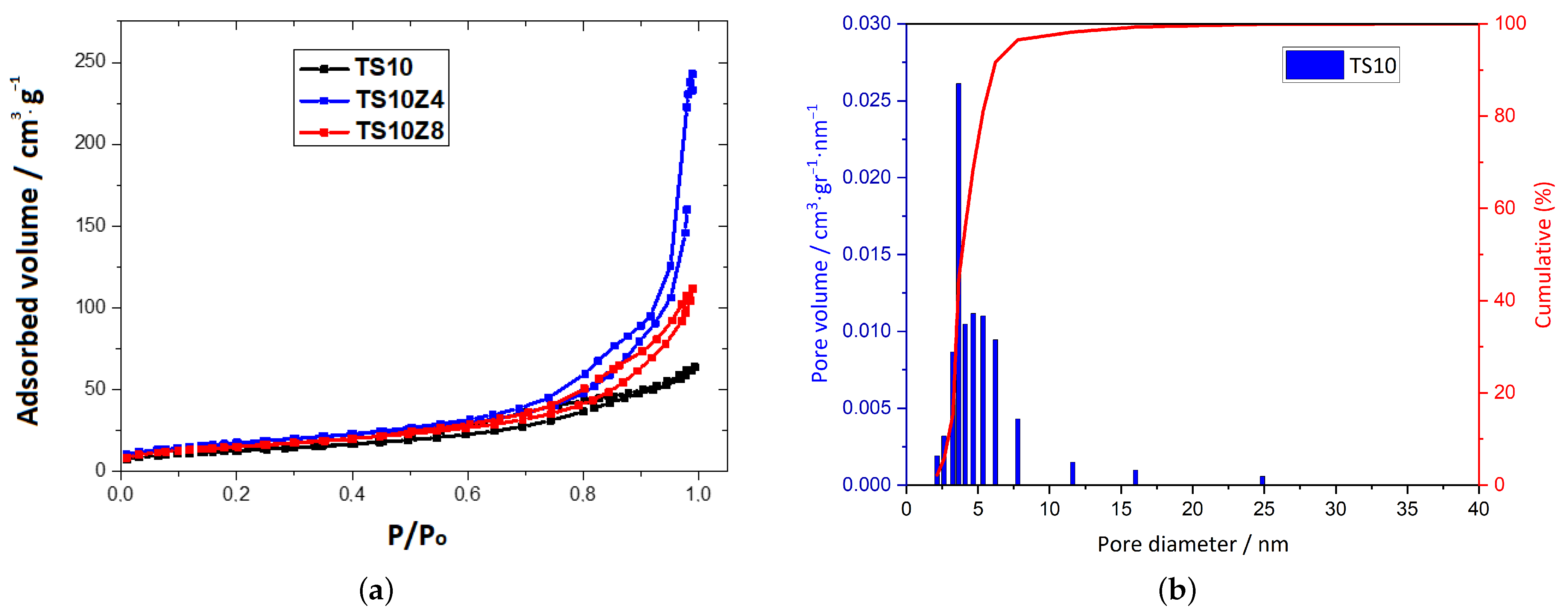

3.3. Specific Surface Area

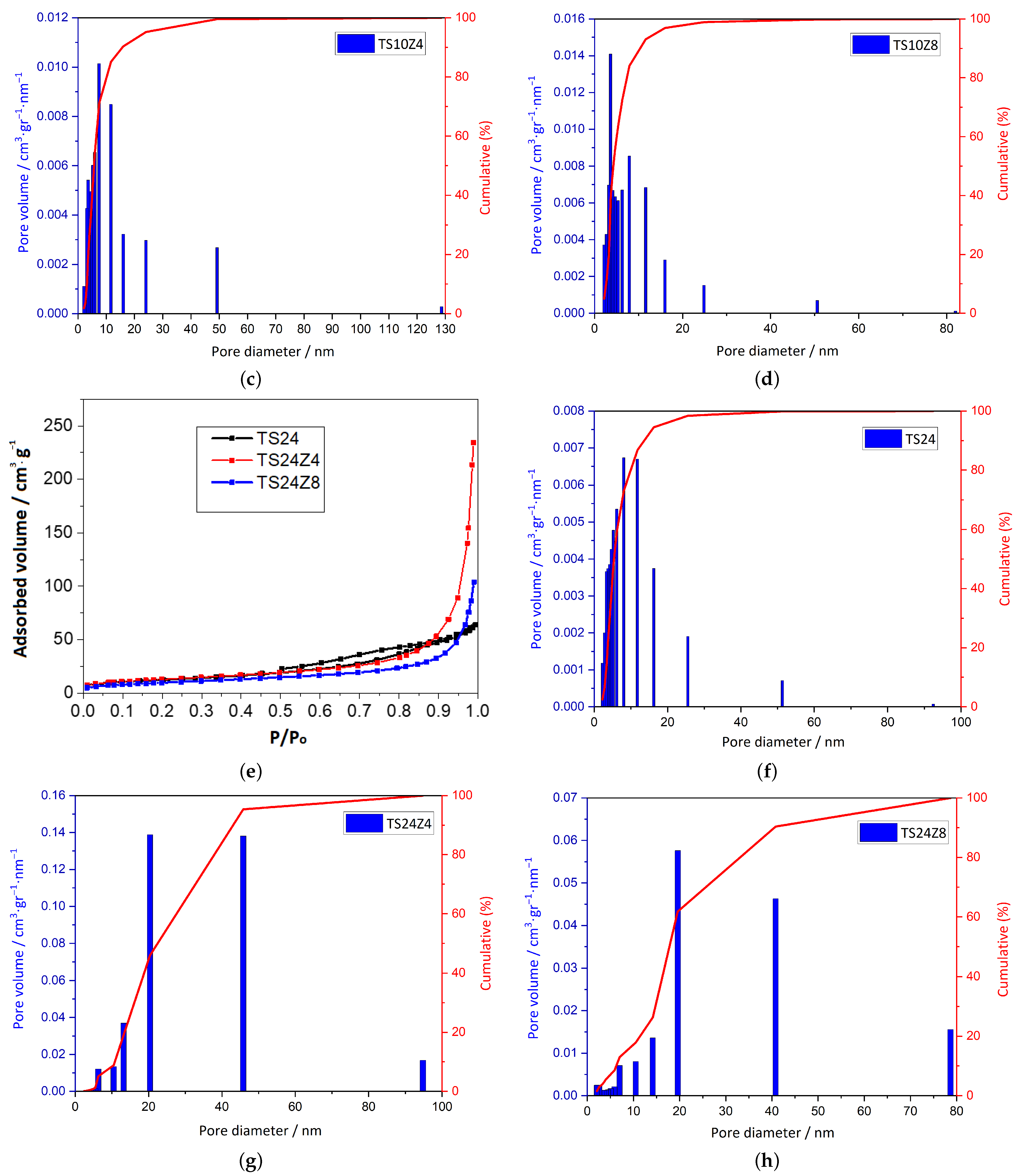

3.4. Photoconductivity

3.4.1. Vacuum

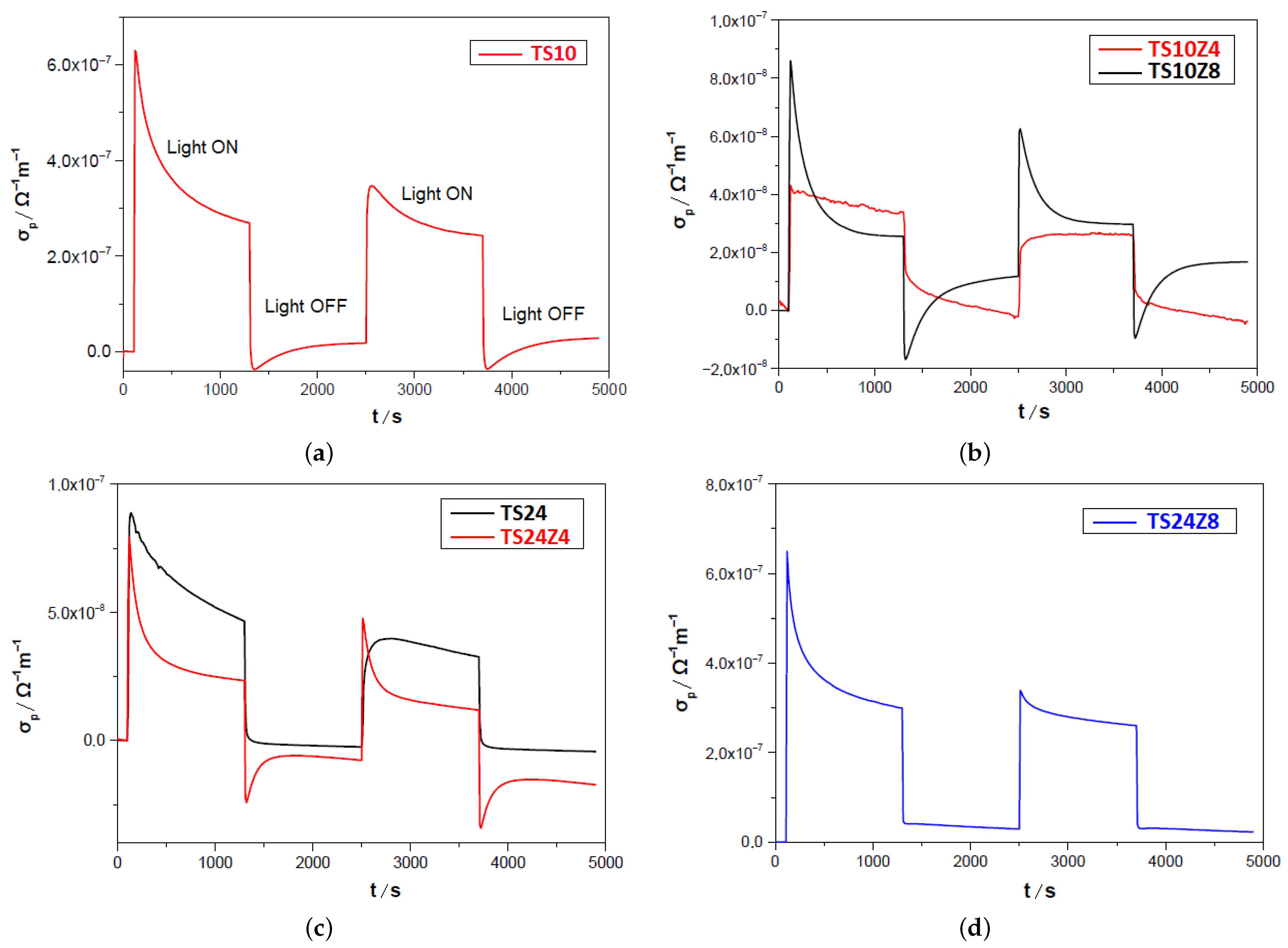

3.4.2. Air

3.5. Comparison Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kang, X.; Liu, S.; Dai, Z.; He, Y.; Song, X.; Tan, Z. Titanium dioxide: From engineering to applications. Catalysts 2019, 9, 191. [Google Scholar] [CrossRef]

- Ijaz, M.; Zafar, M. Titanium dioxide nanostructures as efficient photocatalyst: Progress, challenges and perspective. Int. J. Energy Res. 2021, 45, 3569–3589. [Google Scholar] [CrossRef]

- Pelaez, M.; Nolan, N.T.; Pillai, S.C.; Seery, M.K.; Falaras, P.; Kontos, A.G.; Dunlop, P.S.; Hamilton, J.W.; Byrne, J.A.; O’shea, K.; et al. A review on the visible light active titanium dioxide photocatalysts for environmental applications. Appl. Catal. B Environ. 2012, 125, 331–349. [Google Scholar] [CrossRef]

- Agócs, T.Z.; Puskás, I.; Varga, E.; Molnár, M.; Fenyvesi, É. Stabilization of nanosized titanium dioxide by cyclodextrin polymers and its photocatalytic effect on the degradation of wastewater pollutants. Beilstein J. Org. Chem. 2016, 12, 2873–2882. [Google Scholar] [CrossRef]

- Areerachakul, N.; Sakulkhaemaruethai, S.; Johir, M.; Kandasamy, J.; Vigneswaran, S. Photocatalytic degradation of organic pollutants from wastewater using aluminium doped titanium dioxide. J. Water Process Eng. 2019, 27, 177–184. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, D.; Shen, T.; Hou, X.; Zhu, M.; Liu, S.; Hu, Q. Titanium dioxide/magnetic metal-organic framework preparation for organic pollutants removal from water under visible light. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 589, 124484. [Google Scholar] [CrossRef]

- O’Keeffe, C.; Gannon, P.; Gilson, P.; Kafizas, A.; Parkin, I.P.; Binions, R. Air purification by heterogeneous photocatalytic oxidation with multi-doped thin film titanium dioxide. Thin Solid Film. 2013, 537, 131–136. [Google Scholar] [CrossRef]

- Leng, Z.; Yu, H. Novel method of coating titanium dioxide on to asphalt mixture based on the breath figure process for air-purifying purpose. J. Mater. Civ. Eng. 2016, 28, 04015188. [Google Scholar] [CrossRef]

- Verma, S.; Kumar, N.; Kim, K.H.; Park, J. Photocatalytic efficacy of air purifiers equipped with self-cleaning titanium dioxide xerogel coatings against gaseous formaldehyde: A study using DRIFTS and DFT analysis. Chem. Eng. J. 2024, 486, 150269. [Google Scholar] [CrossRef]

- Wang, Q.; Zhan, X.; Fan, C.; Yang, X.; Li, B.; Liu, H.; Wu, Y.; Zhang, K.; Tang, P. Rational design of versatile 1D Ti–O-based core–shell nanostructures for efficient pollutant removal and solar fuel production. J. Mater. Chem. A 2024, 12, 33290–33300. [Google Scholar] [CrossRef]

- Kasanen, J.; Suvanto, M.; Pakkanen, T.T. Self-cleaning, titanium dioxide based, multilayer coating fabricated on polymer and glass surfaces. J. Appl. Polym. Sci. 2009, 111, 2597–2606. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Saleem, Z.; Riaz, S.; Naseem, S.; Saleemi, F. Deposition of porous titanium oxide thin films as anti-fogging and anti-reflecting medium. Optik 2016, 127, 5124–5127. [Google Scholar] [CrossRef]

- Syafiq, A.; Balakrishnan, V.; Rahim, N.A. Durable self-cleaning nano-titanium dioxide superhydrophilic coating with anti-fog property. Pigment Resin Technol. 2024, 53, 261–270. [Google Scholar] [CrossRef]

- Chao, S.; Petrovsky, V.; Dogan, F. Effects of sintering temperature on the microstructure and dielectric properties of titanium dioxide ceramics. J. Mater. Sci. 2010, 45, 6685–6693. [Google Scholar] [CrossRef]

- Taiwo, L.A.; Obianyo, I.I.; Amu, O.O.; Omoniyi, A.O.; Onwualu, A.P.; Soboyejo, A.B. Effects of titanium dioxide coatings on building composites for sustainable construction applications. Cogent Eng. 2022, 9, 2151168. [Google Scholar] [CrossRef]

- Felice, B.; Seitz, V.; Bach, M.; Rapp, C.; Wintermantel, E. Antimicrobial polymers: Antibacterial efficacy of silicone rubber–titanium dioxide composites. J. Compos. Mater. 2017, 51, 2253–2262. [Google Scholar] [CrossRef]

- Abdulazeem, L.; Al-Amiedi, B.; Alrubaei, H.A.; AL-Mawlah, Y.H. Titanium dioxide nanoparticles as antibacterial agents against some pathogenic bacteria. Drug Invent. Today 2019, 12, 963–967. [Google Scholar]

- Yao, Y.; Lin, P.; Ye, D.; Miao, H.; Cao, L.; Zhang, P.; Xu, J.; Dai, L. Enhanced Long-Term Antibacterial and Osteogenic Properties of Silver-Loaded Titanium Dioxide Nanotube Arrays for Implant Applications. Int. J. Nanomed. 2025, 20, 3749–3764. [Google Scholar] [CrossRef]

- Li, J.; Zhang, D.; Hou, C. Application of nano-titanium dioxide in food antibacterial packaging materials. Bioengineering 2024, 12, 19. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.; Sahu, K.; Singh, R.; Som, T.; Kotnala, R.; Mohapatra, S. Thermal annealing induced strong photoluminescence enhancement in Ag-TiO2 plasmonic nanocomposite thin films. J. Alloy. Compd. 2019, 786, 750–757. [Google Scholar] [CrossRef]

- Shen, P.S.; Tseng, C.M.; Kuo, T.C.; Shih, C.K.; Li, M.H.; Chen, P. Microwave-assisted synthesis of titanium dioxide nanocrystalline for efficient dye-sensitized and perovskite solar cells. Sol. Energy 2015, 120, 345–356. [Google Scholar] [CrossRef]

- Balis, N.; Zaky, A.A.; Perganti, D.; Kaltzoglou, A.; Sygellou, L.; Katsaros, F.; Stergiopoulos, T.; Kontos, A.G.; Falaras, P. Dye sensitization of titania compact layer for efficient and stable perovskite solar cells. ACS Appl. Energy Mater. 2018, 1, 6161–6171. [Google Scholar] [CrossRef]

- Hsu, C.Y.; Al-Salman, H.; Hussein, H.H.; Juraev, N.; Mahmoud, Z.H.; Al-Shuwaili, S.J.; Ahmed, H.H.; Ami, A.A.; Ahmed, N.M.; Azat, S.; et al. Experimental and theoretical study of improved mesoporous titanium dioxide perovskite solar cell: The impact of modification with graphene oxide. Heliyon 2024, 10, e26633. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, L.; Tan, J.; Zhou, Q.; Huang, Z.; Xia, D.; Shu, H.; Yang, X.; Wang, X. One-pot synthesis of bicrystalline titanium dioxide spheres with a core–shell structure as anode materials for lithium and sodium ion batteries. J. Power Sources 2014, 269, 37–45. [Google Scholar] [CrossRef]

- Lou, S.; Zhao, Y.; Wang, J.; Yin, G.; Du, C.; Sun, X. Ti-based oxide anode materials for advanced electrochemical energy storage: Lithium/sodium ion batteries and hybrid pseudocapacitors. Small 2019, 15, 1904740. [Google Scholar] [CrossRef]

- Li, X.; Zhang, K.; Ao, H.; Gong, Y.; Yu, K.; Liang, C. Template-free synthesis of hollow titanium dioxide microspheres and amorphous titanium dioxide microspheres with superior lithium and sodium storage performance. J. Energy Storage 2025, 105, 114759. [Google Scholar] [CrossRef]

- Li, R.; Weng, Y.; Zhou, X.; Wang, X.; Mi, Y.; Chong, R.; Han, H.; Li, C. Achieving overall water splitting using titanium dioxide-based photocatalysts of different phases. Energy Environ. Sci. 2015, 8, 2377–2382. [Google Scholar] [CrossRef]

- Miyoshi, A.; Nishioka, S.; Maeda, K. Water splitting on rutile TiO2-based photocatalysts. Chem.-Eur. J. 2018, 24, 18204–18219. [Google Scholar] [CrossRef]

- Kumar, V.; Prasad Singh, G.; Kumar, M.; Kumar, A.; Singh, P.; Ansu, A.K.; Sharma, A.; Alam, T.; Yadav, A.S.; Dobrota, D. Nanocomposite marvels: Unveiling breakthroughs in photocatalytic water splitting for enhanced hydrogen evolution. ACS Omega 2024, 9, 6147–6164. [Google Scholar] [CrossRef]

- Ramanavicius, S.; Jagminas, A.; Ramanavicius, A. Gas sensors based on titanium oxides. Coatings 2022, 12, 699. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, Y.; Husain, S. Fabrication of symmetric polyaniline/nano-titanium dioxide/activated carbon supercapacitor device in different electrolytic mediums: Role of high surface area of carbon and facile interactions with nano-titanium dioxide for high-performance supercapacitor. Energy Technol. 2023, 11, 2200931. [Google Scholar] [CrossRef]

- Zuo, F.; Zhu, Y.; Wu, T.; Li, C.; Liu, Y.; Wu, X.; Ma, J.; Zhang, K.; Ouyang, H.; Qiu, X.; et al. Titanium dioxide nanomaterials: Progress in synthesis and application in drug delivery. Pharmaceutics 2024, 16, 1214. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, M.; Saini, M.; Satpati, B.; Som, T. White light-driven photo response of TiO2 thin films: Influence of substrate texturing. Sol. Energy 2018, 174, 231–239. [Google Scholar] [CrossRef]

- Chandoliya, R.; Sharma, S.; Sharma, V.; Joshi, R.; Sivanesan, I. Titanium dioxide nanoparticle: A comprehensive review on synthesis, applications and toxicity. Plants 2024, 13, 2964. [Google Scholar] [CrossRef]

- Rajkumar, C.; Arulraj, A. One-step synthesis of needle-like lanthanum-doped TiO2 nanomaterials and their photoconductivity activity in air medium. Mater. Lett. 2025, 380, 137733. [Google Scholar]

- Georgakopoulos, T.; Todorova, N.; Pomoni, K.; Trapalis, C. On the transient photoconductivity behavior of sol–gel TiO2/ZnO composite thin films. J. Non-Cryst. Solids 2015, 410, 135–141. [Google Scholar] [CrossRef]

- Fukuhara, Y.; Yamakawa, T.; Sakai, Y.; YAMASAKI, A.; SATOKAWA, S.; KOJIMA, T. Synthesis of TiO2 by CVD using Titanium Tetraisopropoxide and their Photocatalytic Activity. J. Ecotechnol. Res. 2010, 15, 85–89. [Google Scholar]

- Georgakopoulos, T.; Todorova, N.; Boukos, N.; Pomoni, K.; Trapalis, C. Evaluation of the photoconductive and photocatalytic properties of nanocrystalline TiO2/ZnO powder systems prepared by one-step hydro-solvothermal method. Mater. Sci. Eng. B 2025, 322, 118637. [Google Scholar] [CrossRef]

- Sasinska, A.; Singh, T.; Wang, S.; Mathur, S.; Kraehnert, R. Enhanced photocatalytic performance in atomic layer deposition grown TiO2 thin films via hydrogen plasma treatment. J. Vac. Sci. Technol. A 2015, 33, 01A152. [Google Scholar] [CrossRef]

- Kamble, A.A.; Ubale, P.A.; Jadhav, A.L.; Jadhav, S.L.; Kadam, A.V.; Kanamadi, C.M.; Bhuse, V.M. Studies on optical, structure, and photoconductivity of titanium dioxide thin films prepared by chemical bath deposition via aqueous route. In Macromolecular Symposia; Wiley Online Library: Hoboken, NJ, USA, 2021; Volume 400, p. 2100020. [Google Scholar]

- Chen, X.; Mao, S.S. Titanium dioxide nanomaterials: Synthesis, properties, modifications, and applications. Chem. Rev. 2007, 107, 2891–2959. [Google Scholar] [CrossRef]

- Zheng, Z.; Huang, B.; Meng, X.; Wang, J.; Wang, S.; Lou, Z.; Wang, Z.; Qin, X.; Zhang, X.; Dai, Y. Metallic zinc-assisted synthesis of Ti3+ self-doped TiO2 with tunable phase composition and visible-light photocatalytic activity. Chem. Commun. 2013, 49, 868–870. [Google Scholar] [CrossRef]

- Zhao, Z.; Sun, Z.; Zhao, H.; Zheng, M.; Du, P.; Zhao, J.; Fan, H. Phase control of hierarchically structured mesoporous anatase TiO2 microspheres covered with {001} facets. J. Mater. Chem. 2012, 22, 21965–21971. [Google Scholar] [CrossRef]

- Zlobin, V.; Nevedomskiy, V.; Almjasheva, O. Formation and growth of anatase TiO2 nanocrystals under hydrothermal conditions. Mater. Today Commun. 2023, 36, 106436. [Google Scholar] [CrossRef]

- Kojima, T.; Baba, T.; Inamoto, K.; Isowaki, R.; Yukita, C.; Ujiie, K.; Takeda, A.; Shiba, F.; Uekawa, N. Preparation of porous titania particles by partial dissolution and hot-water or hydrothermal treatment of hydrous titania. Adv. Appl. Ceram. 2023, 122, 10–16. [Google Scholar] [CrossRef]

- Li, H.; Li, T.; Liu, H.; Huang, B.; Zhang, Q. Hierarchical flower-like nanostructures of anatase TiO2 nanosheets dominated by {001} facets. J. Alloy. Compd. 2016, 657, 1–7. [Google Scholar]

- Ong, W.J.; Tan, L.L.; Chai, S.P.; Yong, S.T.; Mohamed, A.R. Highly reactive {001} facets of TiO2-based composites: Synthesis, formation mechanism and characterization. Nanoscale 2014, 6, 1946–2008. [Google Scholar] [CrossRef]

- Pantaleone, S.; Pellegrino, F.; Maurino, V.; Corno, M.; Ugliengo, P.; Mino, L. Disclosing the true atomic structure of {001} facets in shape-engineered TiO2 anatase nanoparticles. J. Mater. Chem. A 2024, 12, 4325–4332. [Google Scholar] [CrossRef]

- Zhao, C.; Ren, L.; Shi, Y.; Wang, X.; Huang, W.; Xie, H. Advances and recent applications in high-energy {001} facets of anatase TiO2: A review. J. Environ. Chem. Eng. 2025, 13, 115764. [Google Scholar] [CrossRef]

- Murphy, A. Modified Kubelka–Munk model for calculation of the reflectance of coatings with optically-rough surfaces. J. Phys. D Appl. Phys. 2006, 39, 3571. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P. The use of van der waals adsorption isotherms in determining the surface area of iron synthetic ammonia catalysts. J. Am. Chem. Soc. 1935, 57, 1754–1755. [Google Scholar] [CrossRef]

- Emmett, P.H.; Brunauer, S. The use of low temperature van der Waals adsorption isotherms in determining the surface area of iron synthetic ammonia catalysts. J. Am. Chem. Soc. 1937, 59, 1553–1564. [Google Scholar] [CrossRef]

- Sing, K.S. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Everett, D.; Fairbridge, C.; Haynes, M.; Pernicone, N.; Ramsay, J.; Sing, K.; Unger, K. Guidelines for the characterization of porous solids. In Studies in Surface Science and Catalysis; Elsevier: Amsterdam, The Netherlands, 1994; Volume 87, pp. 1–9. [Google Scholar]

- Jiang, X.; Zhang, Y.; Jiang, J.; Rong, Y.; Wang, Y.; Wu, Y.; Pan, C. Characterization of oxygen vacancy associates within hydrogenated TiO2: A positron annihilation study. J. Phys. Chem. C 2012, 116, 22619–22624. [Google Scholar] [CrossRef]

- Xiao-Quan, C.; Huan-Bin, L.; Guo-Bang, G. Preparation of nanometer crystalline TiO2 with high photo-catalytic activity by pyrolysis of titanyl organic compounds and photo-catalytic mechanism. Mater. Chem. Phys. 2005, 91, 317–324. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Liu, X.; Gao, S.; Huang, B.; Dai, Y. Preparation of Ti3+ self-doped TiO2 nanoparticles and their visible light photocatalytic activity. Chin. J. Catal. 2015, 36, 389–399. [Google Scholar] [CrossRef]

- Qiu, B.; Zhou, Y.; Ma, Y.; Yang, X.; Sheng, W.; Xing, M.; Zhang, J. Facile synthesis of the Ti3+ self-doped TiO2-graphene nanosheet composites with enhanced photocatalysis. Sci. Rep. 2015, 5, 8591. [Google Scholar] [CrossRef] [PubMed]

- Sirisuk, A.; Klansorn, E.; Praserthdam, P. Effects of reaction medium and crystallite size on Ti3+ surface defects in titanium dioxide nanoparticles prepared by solvothermal method. Catal. Commun. 2008, 9, 1810–1814. [Google Scholar] [CrossRef]

- Xin, X.; Xu, T.; Yin, J.; Wang, L.; Wang, C. Management on the location and concentration of Ti3+ in anatase TiO2 for defects-induced visible-light photocatalysis. Appl. Catal. B Environ. 2015, 176, 354–362. [Google Scholar] [CrossRef]

- Satuf, M.L.; Brandi, R.J.; Cassano, A.E.; Alfano, O.M. Photocatalytic degradation of 4-chlorophenol: A kinetic study. Appl. Catal. B Environ. 2008, 82, 37–49. [Google Scholar] [CrossRef]

- Si, L.; Huang, Z.; Lv, K.; Tang, D.; Yang, C. Facile preparation of Ti3+ self-doped TiO2 nanosheets with dominant {0 0 1} facets using zinc powder as reductant. J. Alloy. Compd. 2014, 601, 88–93. [Google Scholar] [CrossRef]

- Georgakopoulos, T.; Apostolopoulou, A.; Todorova, N.; Pomoni, K.; Trapalis, C.; Stathatos, E. Evaluation of photoconductive and photoelectrochemical properties of mesoporous nanocrystalline TiO2 powders and films prepared in acidic and alkaline media. J. Alloy. Compd. 2017, 692, 313–321. [Google Scholar] [CrossRef]

- Mahesh, A.; Jawahar, I.; Biju, V. Photogenerated charge carrier processes in carbonate derived nanocrystalline ZnO: Photoluminescence, photocurrent response and photocatalytic activity. Appl. Phys. A 2024, 130, 360. [Google Scholar] [CrossRef]

- Ruda, H.E. Photoconductivity of Nanowire Systems. Photocond. Photocond. Mater. Fundam. Tech. Appl. 2022, 2, 493–522. [Google Scholar]

- Randall, J.T.; Wilkins, M.H.F. Phosphorescence and electron traps-I. The study of trap distributions. Proc. R. Soc. Lond. Ser. A. Math. Phys. Sci. 1945, 184, 365–389. [Google Scholar]

- Georgakopoulos, T.; Sofianou, M.; Pomoni, K.; Todorova, N.; Giannakopoulou, T.; Trapalis, C. The environment effect on the electrical conductivity and photoconductivity of anatase TiO2 nanoplates with silver nanoparticles photodeposited on {101} crystal facets. Mater. Sci. Semicond. Process. 2016, 56, 386–393. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, S.; Zhang, S.; Liu, Z.; Huang, B.; Wang, N.; Zhang, J.; Li, X. UV-activated hollow ZnO@ TiO2 heterostructured nanaospheres for detecting formaldehyde at room temperature. Sens. Actuators B Chem. 2023, 394, 134306. [Google Scholar] [CrossRef]

- Dittrich, T.; Sydorenko, J.; Spalatu, N.; Nickel, N.H.; Mere, A.; Krunks, M.; Oja Acik, I. Synthesis control of charge separation at anatase TiO2 thin films studied by transient surface photovoltage spectroscopy. ACS Appl. Mater. Interfaces 2022, 14, 43163–43170. [Google Scholar] [CrossRef]

- Pan, X.; Yang, M.Q.; Fu, X.; Zhang, N.; Xu, Y.J. Defective TiO2 with oxygen vacancies: Synthesis, properties and photocatalytic applications. Nanoscale 2013, 5, 3601–3614. [Google Scholar] [CrossRef] [PubMed]

| Reagent/Material | Abbreviation | Source | Purity |

|---|---|---|---|

| Titanium butoxide (Ti) | TBT | Merck (Darmstadt, Germany) | 97% |

| Sulfuric acid () | SA | Fluka (Buchs, Switzerland) | 95% |

| Zinc sulfate heptahydrate (7O) | ZS | Sigma-Aldrich (Darmstadt, Germany) | 99% |

| Samples | ZS (g) | Abbreviation | Reaction Time (h) |

|---|---|---|---|

| 10 h | 0 | TS10 | 10 |

| 10 h 4% ZS | 0.120 | TS10Z4 | 10 |

| 10 h 8% ZS | 0.183 | TS10Z8 | 10 |

| 24 h | 0 | TS24 | 24 |

| 24 h 4% ZS | 0.120 | TS24Z4 | 24 |

| 24 h 8% ZS | 0.183 | TS24Z8 | 24 |

| Samples | d(101) nm | d(004) nm | d(200) nm |

|---|---|---|---|

| TS10 | 15.8 ± 0.3 | 17.9 ± 0.4 | 15.0 ± 0.5 |

| TS10Z4 | 16.1 ± 0.3 | 15.3 ± 0.5 | 16.1 ± 0.6 |

| TS10Z8 | 16.6 ± 0.3 | 18.1 ± 0.4 | 16.5 ± 0.6 |

| TS24 | 17.5 ± 0.4 | 21.7 ± 0.5 | 17.8 ± 0.3 |

| TS24Z4 | 19.7 ± 0.5 | 18.6 ± 0.4 | 19.3 ± 0.8 |

| TS24Z8 | 22.2 ± 0.3 | 24.3 ± 0.7 | 22.6 ± 0.6 |

| Samples | Eg (eV) |

|---|---|

| TS10 | 3.13 |

| TS10Z4 | 3.20 |

| TS10Z8 | 3.19 |

| TS24 | 3.20 |

| TS24Z4 | 3.15 |

| TS24Z8 | 3.21 |

| Samples | S (m2/g) | Vp (cm3/g) | Dpor (nm) | ϕ (%) |

|---|---|---|---|---|

| TS10 | 45.33 | 0.099 | 7.28 | 27.26 |

| TS10Z4 | 62.48 | 0.376 | 19.64 | 58.82 |

| TS10Z8 | 54.85 | 0.173 | 10.65 | 39.64 |

| TS24 | 47.63 | 0.173 | 13.41 | 39.68 |

| TS24Z4 | 46.20 | 0.362 | 24.54 | 57.92 |

| TS24Z8 | 36.15 | 0.161 | 16.17 | 37.91 |

| Samples | E1 (eV) | E2 (eV) | (s) | (s) | |||

|---|---|---|---|---|---|---|---|

| P25 | 1.53 × | 2.24 × | 3.52 × | 0.671 | 0.671 | 43 | 1646 |

| TS10 | 1.46 × | 3.55 × | 5.96 × | 0.682 | 0.614 | 64 | 1043 |

| TS10Z4 | 4.66 × | 4.66 × | 8.43 × | 0.689 | 0.620 | 83 | 1336 |

| TS10Z8 | 6.22 × | 1.44 × | 2.20 × | 0.688 | 0.602 | 41 | 1285 |

| TS24 | 1.44 × | 7.78 × | 1.20 × | 0.690 | 0.604 | 44 | 1377 |

| TS24Z4 | 6.04 × | 3.14 × | 4.71 × | 0.688 | 0.602 | 41 | 1324 |

| TS24Z8 | 9.98 × | 6.70 × | 9.00 × | 0.692 | 0.613 | 41 | 1012 |

| Samples | ||

|---|---|---|

| TS10 | 1.46 × | 2.65 × |

| TS10Z4 | 2.78 × | 3.40 × |

| TS10Z8 | 2.26 × | 2.55 × |

| TS24 | 3.50 × | 4.46 × |

| TS24Z4 | 3.49 × | 2.34 × |

| TS24Z8 | 2.76 × | 4.89 × |

| Ref. | Synthesis Method | Material | Property | Change |

|---|---|---|---|---|

| [36] | Sol-gel | /ZnO film | Photoconductivity | Performance reduced |

| [37] | Chemical vapor deposition (CVD) | powder | Surface area | Increased activity |

| [38] | Hydrothermal/solvothermal | /ZnO powder | Photoconductivity | 65% increase in vacuum |

| [39] | Atomic layer deposition (ALD) | film | Photocurrent density | ×8 increase |

| [40] | Electrochemical | film | Conversion efficiency | Improved |

| CW | Hydrothermal | powder | Photoconductivity | ×30 increase in vacuum |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Georgakopoulos, T.; Samourgkanidis, G.; Todorova, N.; Trapalis, C.; Pomoni, K. Time-Dependent Hydrothermal Synthesis of TiO2 in the Presence of Zn2+: Effects on Photoconductivity. Nanomanufacturing 2025, 5, 17. https://doi.org/10.3390/nanomanufacturing5040017

Georgakopoulos T, Samourgkanidis G, Todorova N, Trapalis C, Pomoni K. Time-Dependent Hydrothermal Synthesis of TiO2 in the Presence of Zn2+: Effects on Photoconductivity. Nanomanufacturing. 2025; 5(4):17. https://doi.org/10.3390/nanomanufacturing5040017

Chicago/Turabian StyleGeorgakopoulos, Tilemachos, Georgios Samourgkanidis, Nadia Todorova, Christos Trapalis, and Katerina Pomoni. 2025. "Time-Dependent Hydrothermal Synthesis of TiO2 in the Presence of Zn2+: Effects on Photoconductivity" Nanomanufacturing 5, no. 4: 17. https://doi.org/10.3390/nanomanufacturing5040017

APA StyleGeorgakopoulos, T., Samourgkanidis, G., Todorova, N., Trapalis, C., & Pomoni, K. (2025). Time-Dependent Hydrothermal Synthesis of TiO2 in the Presence of Zn2+: Effects on Photoconductivity. Nanomanufacturing, 5(4), 17. https://doi.org/10.3390/nanomanufacturing5040017