Nanoimprinting of Biomimetic Nanostructures

Abstract

1. Introduction

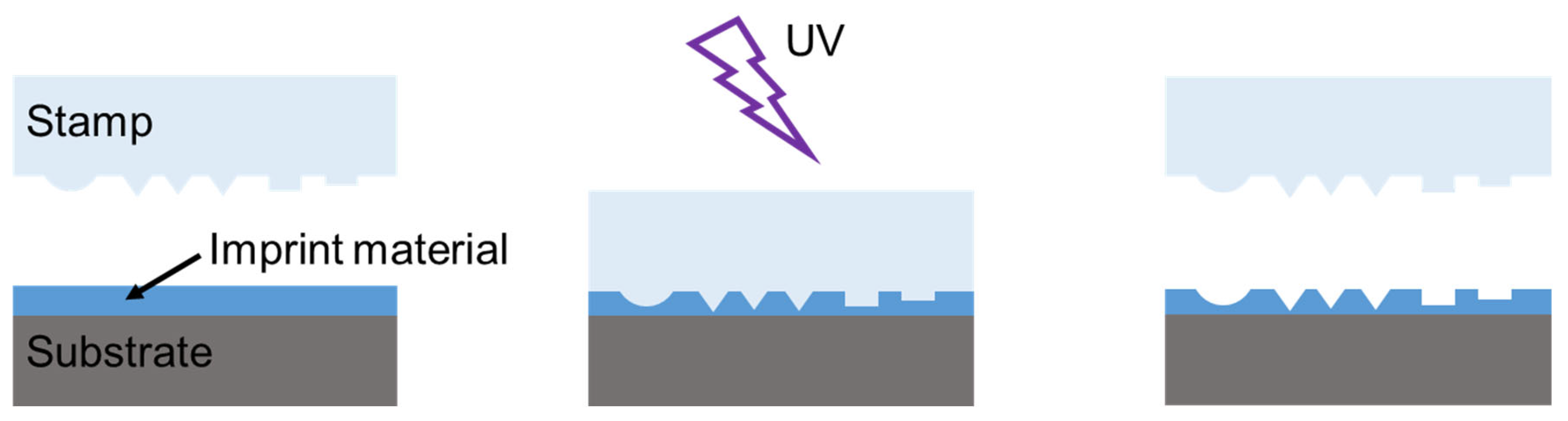

1.1. Nanoimprinting

1.1.1. High Resolution

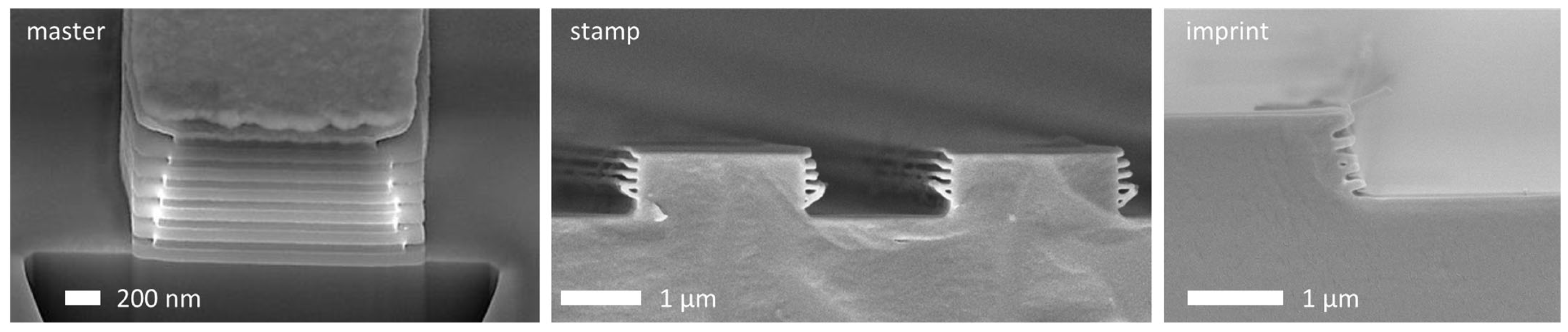

1.1.2. Direct Patterning of Complex and Hierarchical Structures

1.1.3. Direct Patterning of Functional Materials

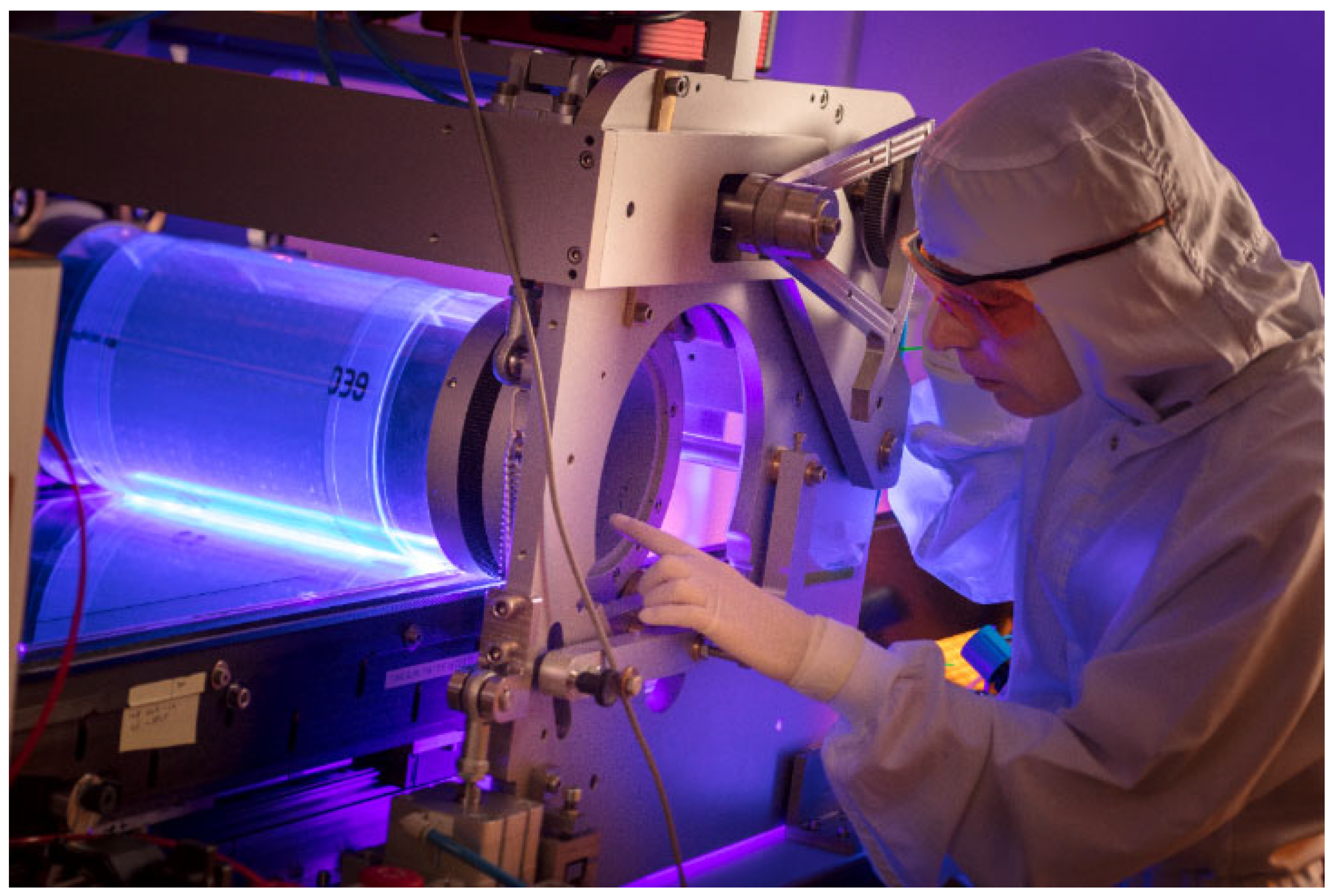

1.1.4. Cost-Effective Large-Area Patterning

1.1.5. Different Types of Nanoimprinting

1.2. Biomimetics

2. Nanoimprinting and Biomimetics

Suitability of Nanoimprinting

3. Functionalities

3.1. Optics

3.1.1. Structural Colors

3.1.2. Antireflection Structures

3.2. Surface Interactions with Solids

3.2.1. Friction

3.2.2. Adhesion

3.3. Surface Interaction with Liquids

3.3.1. Repelling of Liquids

3.3.2. Liquid Transport

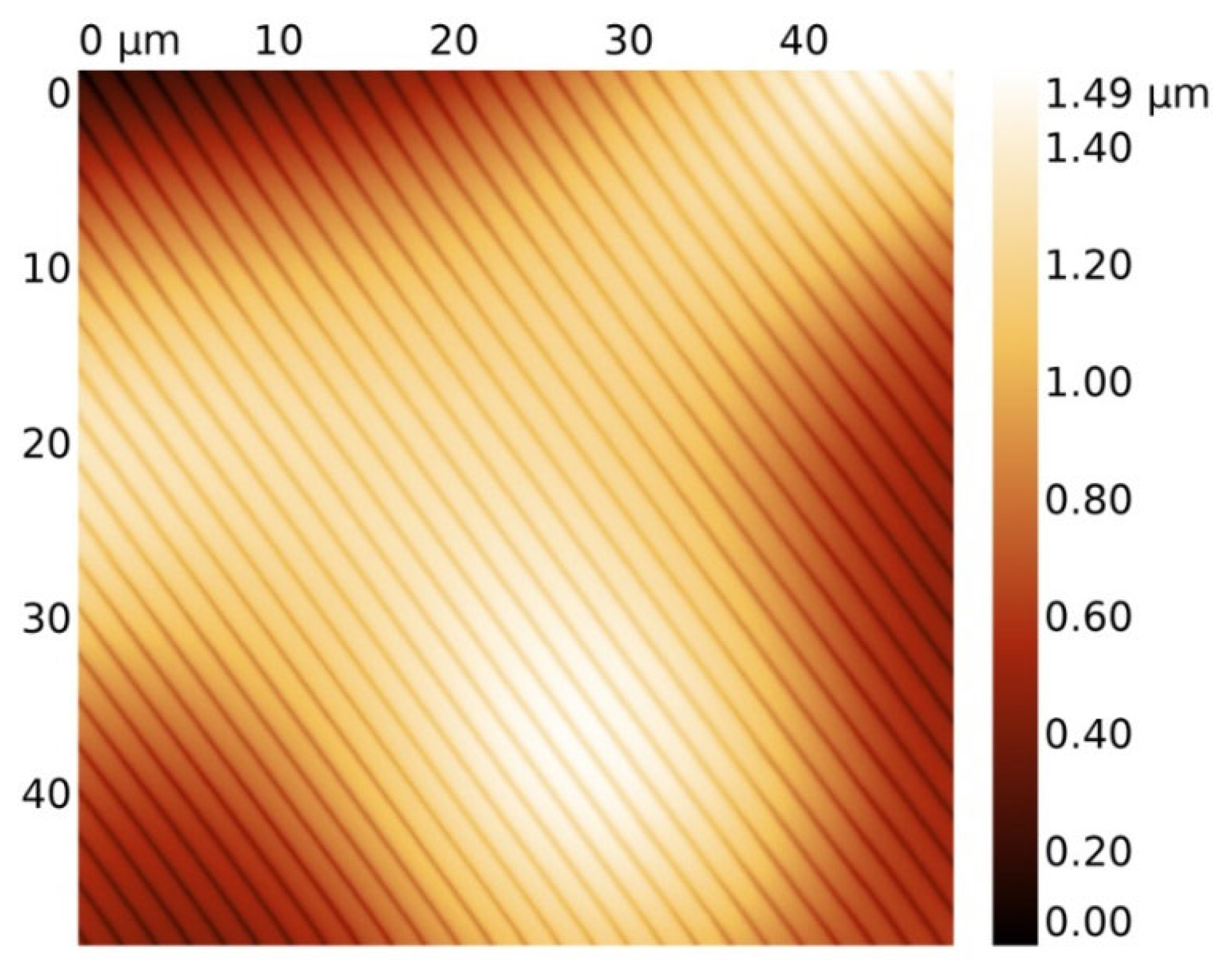

3.3.3. Drag Reduction

3.4. Life Sciences

3.4.1. Cell Growth

3.4.2. Antimicrobial and Anti-Biofouling Surfaces

3.5. Energy Applications

3.6. Mastering of Biomimetic Structures

4. Discussion

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schift, H. Nanoimprint Lithography: An Old Story in Modern Times? A Review. J. Vac. Sci. Technol. B Microelectron. Nanometer. Struct. 2008, 26, 458. [Google Scholar] [CrossRef]

- Zhou, W. Nanoimprint Lithography: An Enabling Process for Nanofabrication; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; ISBN 978-3-642-34428-2. [Google Scholar]

- Miyauchi, A. (Ed.) Nanoimprinting and Its Applications; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-62851-1. [Google Scholar]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of Sub-25 Nm Vias and Trenches in Polymers. Appl. Phys. Lett. 1995, 67, 3114. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint Lithography. J. Vac. Sci. Technol. B 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Haisma, J.; Verheijen, M.; van den Heuvel, K.; van den Berg, J. Mold-assisted Nanolithography: A Process for Reliable Pattern Replication. J. Vac. Sci. Technol. B 1996, 14, 4124–4128. [Google Scholar] [CrossRef]

- Haslinger, M.J.; Verschuuren, M.A.; van Brakel, R.; Danzberger, J.; Bergmair, I.; Mühlberger, M. Stamp Degradation for High Volume UV Enhanced Substrate Conformal Imprint Lithography (UV-SCIL). Microelectron. Eng. 2016, 153, 66–70. [Google Scholar] [CrossRef]

- Haslinger, M.J.; Mitteramskogler, T.; Kopp, S.; Leichtfried, H.; Messerschmidt, M.; Thesen, M.W.; Mühlberger, M. Development of a Soft UV-NIL Step&repeat and Lift-off Process Chain for High Speed Metal Nanomesh Fabrication. Nanotechnology 2020, 31, 345301. [Google Scholar] [CrossRef]

- Muehlberger, M.; Boehm, M.; Bergmair, I.; Chouiki, M.; Schoeftner, R.; Kreindl, G.; Kast, M.; Treiblmayr, D.; Glinsner, T.; Miller, R.; et al. Nanoimprint Lithography from CHARPAN Tool Exposed Master Stamps with 12.5 nm hp. Microelectron. Eng. 2011, 88, 2070–2073. [Google Scholar] [CrossRef]

- Hua, F.; Sun, Y.; Gaur, A.; Meitl, M.A.; Bilhaut, L.; Rotkina, L.; Wang, J.; Geil, P.; Shim, M.; Rogers, J.A.; et al. Polymer Imprint Lithography with Molecular-Scale Resolution. Nano Lett. 2004, 4, 2467–2471. [Google Scholar] [CrossRef]

- Austin, M.D.; Ge, H.; Wu, W.; Li, M.; Yu, Z.; Wasserman, D.; Lyon, S.A.; Chou, S.Y. Fabrication of 5 Nm Linewidth and 14 Nm Pitch Features by Nanoimprint Lithography. Appl. Phys. Lett. 2004, 84, 5299–5301. [Google Scholar] [CrossRef]

- Verschuuren, M.A.; Knight, M.W.; Megens, M.; Polman, A. Nanoscale Spatial Limitations of Large-Area Substrate Conformal Imprint Lithography. Nanotechnology 2019, 30, 345301. [Google Scholar] [CrossRef]

- Resnick, D.J.; Dauksher, W.J.; Mancini, D.; Nordquist, K.J.; Ainley, E.; Gehoski, K.; Baker, J.H.; Bailey, T.C.; Choi, B.J.; Johnson, S.; et al. High Resolution Templates for Step and Flash Imprint Lithography. J. Micro/Nanolithography MEMS MOEMS 2002, 1, 284–289. [Google Scholar] [CrossRef]

- Moharana, A.R.; Außerhuber, H.M.; Mitteramskogler, T.; Haslinger, M.J.; Mühlberger, M.M. Multilayer Nanoimprinting to Create Hierarchical Stamp Masters for Nanoimprinting of Optical Micro- and Nanostructures. Coatings 2020, 10, 301. [Google Scholar] [CrossRef]

- Okuda, K.; Niimi, N.; Kawata, H.; Hirai, Y. Micro-Nano Mixture Patterning by Thermal-UV Novel Nanoimprint. J. Vac. Sci. Technol. B 2007, 25, 2370. [Google Scholar] [CrossRef]

- Landis, S.; Reboud, V.; Enot, T.; Vizioz, C. Three Dimensional on 300mm Wafer Scale Nano Imprint Lithography Processes. Microelectron. Eng. 2013, 110, 198–203. [Google Scholar] [CrossRef]

- Waid, S.; Wanzenboeck, H.D.; Gavagnin, M.; Langegger, R.; Muehlberger, M.; Bertagnolli, E. Focused Ion Beam Induced Ga-Contamination—An Obstacle for UV-Nanoimprint Stamp Repair? J. Vac. Sci. Technol. B 2013, 31, 041602. [Google Scholar] [CrossRef]

- Wanzenboeck, H.D.; Waid, S.; Bertagnolli, E.; Muehlberger, M.; Bergmair, I.; Schoeftner, R. Nanoimprint Lithography Stamp Modification Utilizing Focused Ion Beams. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2009, 27, 2679. [Google Scholar] [CrossRef]

- Koshelev, A.; Calafiore, G.; Piña-Hernandez, C.; Allen, F.I.; Dhuey, S.; Sassolini, S.; Wong, E.; Lum, P.; Munechika, K.; Cabrini, S. High Refractive Index Fresnel Lens on a Fiber Fabricated by Nanoimprint Lithography for Immersion Applications. Opt. Lett. 2016, 41, 3423. [Google Scholar] [CrossRef]

- Zhang, F.; Low, H.Y. Ordered Three-Dimensional Hierarchical Nanostructures by Nanoimprint Lithography. Nanotechnology 2006, 17, 1884–1890. [Google Scholar] [CrossRef]

- Jeong, H.E.; Kwak, R.; Khademhosseini, A.; Suh, K.Y. UV-Assisted Capillary Force Lithography for Engineering Biomimetic Multiscale Hierarchical Structures: From Lotus Leaf to Gecko Foot Hairs. Nanoscale 2009, 1, 331. [Google Scholar] [CrossRef]

- Choi, H.-J.; Choo, S.; Shin, J.-H.; Kim, K.-I.; Lee, H. Fabrication of Superhydrophobic and Oleophobic Surfaces with Overhang Structure by Reverse Nanoimprint Lithography. J. Phys. Chem. C 2013, 117, 24354–24359. [Google Scholar] [CrossRef]

- Haslinger, M.J.; Moharana, A.R.; Mühlberger, M. Antireflective moth-eye structures on curved surfaces fabricated by nanoimprint lithography. In Proceedings of the 35th European Mask and Lithography Conference, Dresden, Germany, 29 August 2019. [Google Scholar] [CrossRef]

- Moharana, A.R.; Kulha, P.; Haslinger, M.J.; Mühlberger, M.; Fechtig, D. 3D Printed Freeform Lenses with Nanoimprinted Moth-Eye Antireflective Structures; Presented at the NNT2019, Boston [Mass.]; PROFACTOR GmbH: Steyr, Austria, 2019; Available online: https://nnt2019.org/documents/uploads/Amiya_R._Moharana_Pavel_Kulha_Michael_J._Haslinger_Michael_Muehlberger_and_Daniel_Fechtig~NNT2019_Abstract_amohar_final.pdf (accessed on 30 November 2021).

- Farshchian, B.; Amirsadeghi, A.; Hurst, S.M.; Wu, J.; Lee, J.; Park, S. Soft UV-Nanoimprint Lithography on Non-Planar Surfaces. Microelectron. Eng. 2011, 88, 3287–3292. [Google Scholar] [CrossRef]

- Köpplmayr, T.; Häusler, L.; Bergmair, I.; Mühlberger, M. Nanoimprint Lithography on Curved Surfaces Prepared by Fused Deposition Modelling. Surf. Topogr. Metrol. Prop. 2015, 3, 024003. [Google Scholar] [CrossRef]

- Chang, C.-Y.; Yang, S.-Y.; Chu, M.-H. Rapid Fabrication of Ultraviolet-Cured Polymer Microlens Arrays by Soft Roller Stamping Process. Microelectron. Eng. 2007, 84, 355–361. [Google Scholar] [CrossRef]

- Chang, C.Y.; Yang, S.Y.; Sheh, J.L. A Roller Embossing Process for Rapid Fabrication of Microlens Arrays on Glass Substrates. Microsyst. Technol. 2006, 12, 754–759. [Google Scholar] [CrossRef]

- Yang, Y.; Lee, K.; Mielczarek, K.; Hu, W.; Zakhidov, A. Nanoimprint of Dehydrated PEDOT:PSS for Organic Photovoltaics. Nanotechnology 2011, 22, 485301. [Google Scholar] [CrossRef]

- Osipov, V.; Doskolovich, L.L.; Bezus, E.A.; Drew, T.; Zhou, K.; Sawalha, K.; Swadener, G.; Wolffsohn, J.S.W. Application of Nanoimprinting Technique for Fabrication of Trifocal Diffractive Lens with Sine-like Radial Profile. J. Biomed. Opt. 2015, 20, 025008. [Google Scholar] [CrossRef]

- Mattelin, M.-A.; Radosavljevic, A.; Missinne, J.; Cuypers, D.; Kommeren, S.; Vandael, J.; ter Meulen, J.M.; Verduyckt, L.; Van Steenberge, G. Fabrication and replication of high efficiency blazed gratings with grayscale electron beam lithography and UV nanoimprint lithography. In Proceedings of the Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XIII; von Freymann, G., Blasco, E., Chanda, D., Eds.; SPIE: San Francisco, CA, USA, 2020; p. 3. [Google Scholar]

- Gale, M. Replication Techniques for Diffractive Optical Elements. Microelectron. Eng. 1997, 34, 321–339. [Google Scholar] [CrossRef]

- Xie, S.; Wan, X.; Yang, B.; Zhang, W.; Wei, X.; Zhuang, S. Design and Fabrication of Wafer-Level Microlens Array with Moth-Eye Antireflective Nanostructures. Nanomaterials 2019, 9, 747. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.; Liang, X.; Fu, Z.; Chou, S.Y. High Fidelity Fabrication of Microlens Arrays by Nanoimprint Using Conformal Mold Duplication and Low-Pressure Liquid Material Curing. J. Vac. Sci. Technol. B 2007, 25, 410–414. [Google Scholar] [CrossRef][Green Version]

- Chen, J.; Zhou, Y.; Wang, D.; He, F.; Rotello, V.M.; Carter, K.R.; Watkins, J.J.; Nugen, S.R. UV-Nanoimprint Lithography as a Tool to Develop Flexible Microfluidic Devices for Electrochemical Detection. Lab Chip 2015, 15, 3086–3094. [Google Scholar] [CrossRef]

- Gale, B.K.; Jafek, A.R.; Lambert, C.J.; Goenner, B.L.; Moghimifam, H.; Nze, U.C.; Kamarapu, S.K. A Review of Current Methods in Microfluidic Device Fabrication and Future Commercialization Prospects. Inventions 2018, 3, 60. [Google Scholar] [CrossRef]

- Talin, A. Micromechanical and Microfluidic Devices Incorporating Resonant Metallic Gratings Fabricated Using Nanoimprint Lithography. J. Nanophotonics 2008, 2, 021785. [Google Scholar] [CrossRef][Green Version]

- Islam, R.; Glinsner, T. Microfluidic technology and polymer nanoimprinting. In Proceedings of the Microfluidics and BioMEMS, San Francisco, CA, USA, 21–25 October 2001; SPIE: Bellingham, WA, USA, 2001; Volume 4560, pp. 250–255. [Google Scholar]

- Pépin, A.; Youinou, P.; Studer, V.; Lebib, A.; Chen, Y. Nanoimprint Lithography for the Fabrication of DNA Electrophoresis Chips. Microelectron. Eng. 2002, 61–62, 927–932. [Google Scholar] [CrossRef]

- Haslinger, M.J.; Sivun, D.; Pöhl, H.; Munkhbat, B.; Mühlberger, M.; Klar, T.A.; Scharber, M.C.; Hrelescu, C. Plasmon-Assisted Direction- and Polarization-Sensitive Organic Thin-Film Detector. Nanomaterials 2020, 10, 1866. [Google Scholar] [CrossRef]

- Deng, K.; Liu, Z.; Wang, M.; Li, L. Nanoimprinted Grating-Embedded Perovskite Solar Cells with Improved Light Management. Adv. Funct. Mater. 2019, 29, 1900830. [Google Scholar] [CrossRef]

- Kim, M.-S.; Kim, J.-S.; Cho, J.C.; Shtein, M.; Kim, J.; Guo, L.J.; Kim, J. Flexible Conjugated Polymer Photovoltaic Cells with Controlled Heterojunctions Fabricated Using Nanoimprint Lithography. Appl. Phys. Lett. 2007, 90, 123113. [Google Scholar] [CrossRef]

- Saison, T.; Peroz, C.; Chauveau, V.; Berthier, S.; Sondergard, E.; Arribart, H. Replication of Butterfly Wing and Natural Lotus Leaf Nanostructures by Nanoimprint on Silica Sol-Gel Films. Bioinspiration Biomim. 2008, 3, 046004. [Google Scholar] [CrossRef]

- Chou, S.Y.; Keimel, C.; Gu, J. Ultrafast and Direct Imprint of Nanostructures in Silicon. Nature 2002, 417, 835–837. [Google Scholar] [CrossRef]

- Yu, C.-C.; Chen, H.-L. Nanoimprint Technology for Patterning Functional Materials and Its Applications. Microelectron. Eng. 2015, 132, 98–119. [Google Scholar] [CrossRef]

- Nanoimprint Lithography (NIL)-SmartNIL®. Available online: https://www.evgroup.com/technologies/nanoimprint-lithography-smartnil/ (accessed on 3 November 2021).

- Applications. Morphotonics. Available online: https://www.morphotonics.com/applications-2/ (accessed on 30 November 2021).

- Meulen, J.M.T.; Veldhuizen, L.W.; Kommeren, A.S.; Willems, A.A.G.; Dielen, M.; Driessen, E.; Neelen, R.A.W.; Ercan, E.; Tam, K.K.G.; Titulaer, B.J.F. 33-6: Roll-To-Plate Nano-Imprint Lithography for High-Volume Production of AR Glasses: Equipment, Materials, and Processes. SID Symp. Dig. Tech. Pap. 2021, 52, 447–449. [Google Scholar] [CrossRef]

- Ter Meulen, J.M.; Veldhuizen, P.; Kommeren, S.; Ercan, E.; Tam, G.; Titulaer, B. Roll-to-plate nanoimprint lithography for high volume production: Equipment, materials, and processes. In Proceedings of the Advanced Fabrication Technologies for Micro/Nano Optics and Photonics XIV, Online, 6–12 March 2021; SPIE: Bellingham, WA, USA, 2021; Volume 11696, p. 116960R. [Google Scholar]

- Tan, H.; Gilbertson, A.; Chou, S.Y. Roller Nanoimprint Lithography. J. Vac. Sci. Technol. B 1998, 16, 3926–3928. [Google Scholar] [CrossRef]

- Guo, C.; Tian, Q.; Wang, H.; Sun, J.; Du, L.; Wang, M.; Zhao, D. Roller Embossing Process for the Replication of Shark-Skin-Inspired Micro-Riblets. Micro Nano Lett. 2017, 12, 439–444. [Google Scholar] [CrossRef]

- John, J.; Tang, Y.; Rothstein, J.P.; Watkins, J.J.; Carter, K.R. Large-Area, Continuous Roll-to-Roll Nanoimprinting with PFPE Composite Molds. Nanotechnology 2013, 24, 505307. [Google Scholar] [CrossRef]

- Mäkelä, T.; Haatainen, T. Roll-to-Roll Pilot Nanoimprinting Process for Backlight Devices. Microelectron. Eng. 2012, 97, 89–91. [Google Scholar] [CrossRef]

- Leitgeb, M.; Nees, D.; Ruttloff, S.; Palfinger, U.; Götz, J.; Liska, R.; Belegratis, M.R.; Stadlober, B. Multilength Scale Patterning of Functional Layers by Roll-to-Roll Ultraviolet-Light-Assisted Nanoimprint Lithography. ACS Nano 2016, 10, 4926–4941. [Google Scholar] [CrossRef]

- Yde, L.; Lindvold, L.; Stensborg, J.; Voglhuber, T.; Außerhuber, H.; Wögerer, S.; Fischinger, T.; Mühlberger, M.; Hackl, W. Roll-to-Plate UV-Nanoimprinting for Micro and Nano-Optics. Available online: http://www.nntconf.org/submissions/rollerNIL%20NNT%20R2P%20v1.pdf (accessed on 28 August 2020).

- Lee, J.; Park, S.; Choi, K.; Kim, G. Nano-Scale Patterning Using the Roll Typed UV-Nanoimprint Lithography Tool. Microelectron. Eng. 2008, 85, 861–865. [Google Scholar] [CrossRef]

- Ge, J.; Ding, B.; Hou, S.; Luo, M.; Nam, D.; Duan, H.; Gao, H.; Lam, Y.C.; Li, H. Rapid Fabrication of Complex Nanostructures Using Room-Temperature Ultrasonic Nanoimprinting. Nat. Commun. 2021, 12, 3146. [Google Scholar] [CrossRef]

- Ahn, S.-W.; Lee, K.-D.; Kim, J.-S.; Kim, S.H.; Park, J.-D.; Lee, S.-H.; Yoon, P.-W. Fabrication of a 50 Nm Half-Pitch Wire Grid Polarizer Using Nanoimprint Lithography. Nanotechnology 2005, 16, 1874–1877. [Google Scholar] [CrossRef]

- Viheriälä, J.; Niemi, T.; Kontio, J.; Pessa, M. Nanoimprint lithography—Next generation nanopatterning methods for nanophotonics fabrication. In Recent Optical and Photonic Technologies; IntechOpen: London, UK, 2010; ISBN 978-953-7619-71-8. [Google Scholar]

- Malloy, M. Technology Review and Assessment of Nanoimprint Lithography for Semiconductor and Patterned Media Manufacturing. J. Micro/Nanolithog. MEMS MOEMS 2011, 10, 032001. [Google Scholar] [CrossRef]

- Resnick, D.J.; Choi, J. A Review of Nanoimprint Lithography for High-Volume Semiconductor Device Manufacturing. Adv. Opt. Technol. 2017, 6, 229–241. [Google Scholar] [CrossRef]

- J-FIL Overview–Canon Nanotechnologies. Available online: http://cnt.canon.com/technology/j-fil-overview/ (accessed on 3 November 2021).

- Technology-How It Works. SCIL Nanoimprint Solutions. Available online: https://www.scil-nano.com/technology-how-it-works/ (accessed on 3 November 2021).

- Obducat. Mashen-Admin STU®—Simultaneous Thermal and UV. Available online: https://www.obducat.com/technologies-markets/our-technologies/stu-simultaneous-thermal-and-uv/ (accessed on 3 November 2021).

- Huang, X.D.; Bao, L.-R.; Cheng, X.; Guo, L.J.; Pang, S.W.; Yee, A.F. Reversal Imprinting by Transferring Polymer from Mold to Substrate. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2002, 20, 2872. [Google Scholar] [CrossRef]

- Michel, B.; Bernard, A.; Bietsch, A.; Delamarche, E.; Geissler, M.; Juncker, D.; Kind, H.; Renault, J.-P.; Rothuizen, H.; Schmid, H.; et al. Printing Meets Lithography: Soft Approaches to High-Resolution Patterning. IBM J. Res. Dev. 2001, 45, 697–719. [Google Scholar] [CrossRef]

- Kaufmann, T.; Jan Ravoo, B. Stamps, Inks and Substrates: Polymers in Microcontact Printing. Polym. Chem. 2010, 1, 371–387. [Google Scholar] [CrossRef]

- Kumar, A.; Whitesides, G.M. Features of Gold Having Micrometer to Centimeter Dimensions Can Be Formed through a Combination of Stamping with an Elastomeric Stamp and an Alkanethiol “Ink” Followed by Chemical Etching. Appl. Phys. Lett. 1993, 63, 2002–2004. [Google Scholar] [CrossRef]

- Bhushan, B. Biomimetics: Lessons from Nature—An Overview. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2009, 367, 1445–1486. [Google Scholar] [CrossRef]

- Stachelberger, H.; Gruber, P.; Gebeshuber, I.C. Biomimetics: Its technological and societal potential. In Biomimetics—Materials, Structures and Processes: Examples, Ideas and Case Studies; Gruber, P., Bruckner, D., Hellmich, C., Schmiedmayer, H.-B., Stachelberger, H., Gebeshuber, I.C., Eds.; Biological and Medical Physics, Biomedical Engineering; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1–6. ISBN 978-3-642-11934-7. [Google Scholar]

- Bar-Cohen, Y. Biomimetics—Using Nature to Inspire Human Innovation. Bioinspir. Biomim. 2006, 1, P1–P12. [Google Scholar] [CrossRef]

- Miyauchi, A.; Shimomura, M. Industrial Biomimetics; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0-429-60275-7. [Google Scholar]

- Lenau, T.; Cheong, H.; Shu, L. Sensing in Nature: Using Biomimetics for Design of Sensors. Sens. Rev. 2008, 28, 311–316. [Google Scholar] [CrossRef]

- Boaretto, J.; Fotouhi, M.; Tende, E.; Aver, G.F.; Marcon, V.R.R.; Cordeiro, G.L.; Bergmann, C.P.; de Camargo, F.V. Biomimetics and Composite Materials toward Efficient Mobility: A Review. J. Compos. Sci. 2021, 5, 22. [Google Scholar] [CrossRef]

- Sullivan, T.; O’Callaghan, I. Recent Developments in Biomimetic Antifouling Materials: A Review. Biomimetics 2020, 5, 58. [Google Scholar] [CrossRef]

- Du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Google Scholar. Available online: https://scholar.google.com/ (accessed on 7 December 2021).

- Malshe, A.P.; Bapat, S.; Rajurkar, K.P.; Haitjema, H. Bio-Inspired Textures for Functional Applications. CIRP Ann. 2018, 67, 627–650. [Google Scholar] [CrossRef]

- Kinoshita, S.Y.S.; Yoshioka, S.; Miyazaki, J. Physics of Structural Colors. Rep. Prog. Phys. 2008, 71, 076401. [Google Scholar] [CrossRef]

- Anderson, T.F. An Electron Microscope Study of Some Structural Colors of Insects. J. Appl. Phys. 1942, 13, 748. [Google Scholar] [CrossRef]

- Xu, J. Biomimetic Photonic Materials with Tunable Structural Colors. J. Colloid Interface Sci. 2013, 17, 1–17. [Google Scholar] [CrossRef]

- Saito, A. Material Design and Structural Color Inspired by Biomimetic Approach. Sci. Technol. Adv. Mater. 2011, 12, 064709. [Google Scholar] [CrossRef]

- Mason, C.W. Structural Colors in Insects. I. J. Phys. Chem. 1926, 30, 383–395. [Google Scholar] [CrossRef]

- Mason, C.W. Structural Colors in Insects. II. J. Phys. Chem. 1927, 31, 321–354. [Google Scholar] [CrossRef]

- Butt, H.; Yetisen, A.K.; Mistry, D.; Khan, S.A.; Hassan, M.U.; Yun, S.H. Morpho Butterfly-Inspired Nanostructures. Adv. Opt. Mater. 2016, 4, 497–504. [Google Scholar] [CrossRef]

- Stavenga, D.G. Thin Film and Multilayer Optics Cause Structural Colors of Many Insects and Birds. Mater. Today Proc. 2014, 1, 109–121. [Google Scholar] [CrossRef]

- Zobl, S.; Wilts, B.D.; Salvenmoser, W.; Pölt, P.; Gebeshuber, I.C.; Schwerte, T. Orientation-Dependent Reflection of Structurally Coloured Butterflies. Biomimetics 2020, 5, 5. [Google Scholar] [CrossRef]

- McCoy, D.E.; McCoy, V.E.; Mandsberg, N.K.; Shneidman, A.V.; Aizenberg, J.; Prum, R.O.; Haig, D. Structurally Assisted Super Black in Colourful Peacock Spiders. Proc. R. Soc. B 2019, 286, 20190589. [Google Scholar] [CrossRef] [PubMed]

- Wilts, B.D.; Otto, J.; Stavenga, D.G. Ultra-Dense, Curved, Grating Optics Determines Peacock Spider Coloration. Nanoscale Adv. 2020, 2, 1122–1127. [Google Scholar] [CrossRef]

- Mason, C.W. Structural Colors in Feathers. I. J. Phys. Chem. 1923, 27, 201–251. [Google Scholar] [CrossRef]

- Mason, C.W. Structural Colors in Feathers. II. J. Phys. Chem. 1923, 27, 401–448. [Google Scholar] [CrossRef]

- Fu, Y.; Tippets, C.A.; Donev, E.U.; Lopez, R. Structural Colors: From Natural to Artificial Systems: Structural Colors. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnology 2016, 8, 758–775. [Google Scholar] [CrossRef]

- Saito, A.; Ishikawa, Y.; Miyamura, Y.; Akai-Kasaya, M.; Kuwahara, Y. Optimization of reproduced morpho-blue coloration. In Proceedings of the Volume 6767, Photonic Crystals and Photonic Crystal Fibers for Sensing Applications III, Boston, MA, USA, 9–12 September 2007; Du, H.H., Fudouzi, H., Eds.; SPIE: Bellingham, WA, USA, 2007; p. 676706. [Google Scholar] [CrossRef]

- Saito, A.; Miyamura, Y.; Ishikawa, Y.; Murase, J.; Akai-Kasaya, M.; Kuwahara, Y. Reproduction, Mass-Production, and Control of the Morpho-Butterfly’s Blue. Adv. Fabr. Technol. Micro/Nano Opt. Photonics II 2009, 7205, 720506. [Google Scholar] [CrossRef]

- Saito, A.; Ishibashi, K.; Ohga, J.; Hirai, Y.; Kuwahara, Y. Fabrication Process of Large-Area Morpho-Color Flexible Film via Flexible Nano-Imprint Mold. J. Photopol. Sci. Technol. 2018, 31, 113–119. [Google Scholar] [CrossRef]

- Toyota’s New Structural Blue Paint Shimmers on Lexus LC500. Available online: https://www.sae.org/site/news/2017/11/toyotas-new-structural-blue-paint-shimmers-on-lexus-lc500 (accessed on 9 December 2021).

- Muehlberger, M.; Ruttloff, S.; Nees, D.; Moharana, A.; Belegratis, M.R.; Taus, P.; Kopp, S.; Wanzenboeck, H.D.; Prinz, A.; Fechtig, D. Nanoimprint Replication of Biomimetic, Multilevel Undercut Nanostructures. Nanomaterials 2021, 11, 1051. [Google Scholar] [CrossRef]

- Taus, P.; Prinz, A.; Wanzenboeck, H.D.; Schuller, P.; Tsenov, A.; Schinnerl, M.; Shawrav, M.M.; Haslinger, M.; Muehlberger, M. Mastering of NIL Stamps with Undercut T-Shaped Features from Single Layer to Multilayer Stamps. Nanomaterials 2021, 11, 956. [Google Scholar] [CrossRef]

- Zobl, S.; Salvenmoser, W.; Schwerte, T.; Gebeshuber, I.C.; Schreiner, M. Morpho Peleides Butterfly Wing Imprints as Structural Colour Stamp. Bioinspir. Biomim. 2016, 11, 016006. [Google Scholar] [CrossRef]

- Huang, J.; Wang, X.; Wang, Z.L. Controlled Replication of Butterfly Wings for Achieving Tunable Photonic Properties. Nano Lett. 2006, 6, 2325–2331. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Zhang, Y.; Li, M.; Zheng, Y.; Shen, W.; Jiang, L. The Structural Color of Red Rose Petals and Their Duplicates. Langmuir 2010, 26, 14885–14888. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Zhang, Y.; Xi, J.; Zhu, Y.; Wang, N.; Xia, F.; Jiang, L. Petal Effect: A Superhydrophobic State with High Adhesive Force. Langmuir 2008, 24, 4114–4119. [Google Scholar] [CrossRef]

- Bernhard, C.G.; Miller, W.H. A Corneal Nipple Pattern in Insect Compound Eyes. Acta Physiol. Scand. 1962, 56, 385–386. [Google Scholar] [CrossRef]

- Bernhard, C.G. Structural and Functional Adaptation in a Visual System-Strukturelle Und Funktionelle Adaptation in Einem Visuellen System. Endeavour 1967, 26, 79–84. [Google Scholar]

- Wilson, S.J.; Hutley, M.C. The Optical Properties of “Moth Eye” Antireflection Surfaces. Opt. Acta Int. J. Opt. 1982, 29, 993–1009. [Google Scholar] [CrossRef]

- Ultra Black Technology for Those of Us Who Don’t Turn off the Lights to Watch TV. Available online: https://news.samsung.com/global/ultra-black-technology-for-those-of-us-who-dont-turn-off-the-lights-to-watch-tv (accessed on 18 January 2022).

- Buy the Philips 9000 Series Smart LED TV 46PFL9706T/12 Smart LED TV. Available online: https://www.philips.co.uk/c-p/46PFL9706T_12/9000-series-smart-led-tv-with-ambilight-spectra-xl-and-perfect-pixel-hd (accessed on 18 January 2022).

- G.MothTM|Anti-Reflection & Anti-Glare|Optical Control|Products & Solutions|GEOMATEC. Available online: https://www.geomatec.com/products-and-solutions/optical-control/anti-reflection-and-anti-glare/gmoth/ (accessed on 18 January 2022).

- Moth Eye-Type Antireflective Film MOSMITETM Online Exhibition|Products. Available online: https://www.m-chemical.co.jp/en/products/departments/mcc/ams/tech/1209994_7578.html (accessed on 18 January 2022).

- Stavenga, D.G.; Foletti, S.; Palasantzas, G.; Arikawa, K. Light on the Moth-Eye Corneal Nipple Array of Butterflies. Proc. R. Soc. B Biol. Sci. 2006, 273, 661–667. [Google Scholar] [CrossRef]

- Chen, Q.; Hubbard, G.; Shields, P.A.; Liu, C.; Allsopp, D.W.E.; Wang, W.N.; Abbott, S. Broadband Moth-Eye Antireflection Coatings Fabricated by Low-Cost Nanoimprinting. Appl. Phys. Lett. 2009, 94, 263118. [Google Scholar] [CrossRef]

- Sun, J.; Wang, X.; Wu, J.; Jiang, C.; Shen, J.; Cooper, M.A.; Zheng, X.; Liu, Y.; Yang, Z.; Wu, D. Biomimetic Moth-Eye Nanofabrication: Enhanced Antireflection with Superior Self-Cleaning Characteristic. Sci. Rep. 2018, 8, 5438. [Google Scholar] [CrossRef]

- Tan, G.; Lee, J.-H.; Lan, Y.-H.; Wei, M.-K.; Peng, L.-H.; Cheng, I.-C.; Wu, S.-T. Broadband Antireflection Film with Moth-Eye-like Structure for Flexible Display Applications. Optica 2017, 4, 678. [Google Scholar] [CrossRef]

- Bae, B.-J.; Hong, S.-H.; Hong, E.-J.; Lee, H.; Jung, G. Fabrication of Moth-Eye Structure on Glass by Ultraviolet Imprinting Process with Polymer Template. Jpn. J. Appl. Phys. 2009, 48, 010207. [Google Scholar] [CrossRef]

- Burghoorn, M.; Roosen-Melsen, D.; de Riet, J.; Sabik, S.; Vroon, Z.; Yakimets, I.; Buskens, P. Single Layer Broadband Anti-Reflective Coatings for Plastic Substrates Produced by Full Wafer and Roll-to-Roll Step-and-Flash Nano-Imprint Lithography. Materials 2013, 6, 3710–3726. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Gong, L.; Zhang, S.; Ma, R.; Pan, L.; Zhao, J.; Li, Y. Biomimetic Moth-Eye Anti-Reflective Poly-(Methyl Methacrylate) Nanostructural Coating. J. Bionic Eng. 2019, 16, 1030–1038. [Google Scholar] [CrossRef]

- Boden, S.A.; Bagnall, D.M. Nanostructured biomimetic moth-eye arrays in silicon by nanoimprint lithography. In Proceedings of the Biomimetics and Bioinspiration, San Diego, CA, USA, 2–6 August 2009; International Society for Optics and Photonics: Bellingham, WA, USA, 2009; Volume 7401, p. 74010J. [Google Scholar] [CrossRef]

- Deniz, H.; Khudiyev, T.; Buyukserin, F.; Bayindir, M. Room Temperature Large-Area Nanoimprinting for Broadband Biomimetic Antireflection Surfaces. Appl. Phys. Lett. 2011, 99, 183107. [Google Scholar] [CrossRef]

- Zhang, C.; Peng, L.; Lai, X.; Ni, J. Fabrication of Moth-Eye Nanostructure Arrays Using Roll-to-Roll UV-Nanoimprint Lithography with an Anodic Aluminum Oxide Mold. IEEE Trans. Nanotechnol. 2015, 14, 1127–1137. [Google Scholar] [CrossRef]

- Yano, T.; Sugawara, H.; Taniguchi, J. Moth-Eye Structured Mold Using Sputtered Glassy Carbon Layer for Large-Scale Applications. Micro Nano Eng. 2020, 9, 100077. [Google Scholar] [CrossRef]

- Raut, H.K.; Dinachali, S.S.; Loke, Y.C.; Ganesan, R.; Ansah-Antwi, K.K.; Góra, A.; Khoo, E.H.; Ganesh, V.A.; Saifullah, M.S.M.; Ramakrishna, S. Multiscale Ommatidial Arrays with Broadband and Omnidirectional Antireflection and Antifogging Properties by Sacrificial Layer Mediated Nanoimprinting. ACS Nano 2015, 9, 1305–1314. [Google Scholar] [CrossRef]

- Schulte, A.J.; Koch, K.; Spaeth, M.; Barthlott, W. Biomimetic Replicas: Transfer of Complex Architectures with Different Optical Properties from Plant Surfaces onto Technical Materials. Acta Biomater. 2009, 5, 1848–1854. [Google Scholar] [CrossRef]

- Koch, K.; Schulte, A.J.; Fischer, A.; Gorb, S.N.; Barthlott, W. A Fast, Precise and Low-Cost Replication Technique for Nano- and High-Aspect-Ratio Structures of Biological and Artificial Surfaces. Bioinspir. Biomim. 2008, 3, 046002. [Google Scholar] [CrossRef]

- Baum, M.J.; Heepe, L.; Fadeeva, E.; Gorb, S.N. Dry Friction of Microstructured Polymer Surfaces Inspired by Snake Skin. Beilstein J. Nanotechnol. 2014, 5, 1091–1103. [Google Scholar] [CrossRef]

- Baum, M.J.; Kovalev, A.E.; Michels, J.; Gorb, S.N. Anisotropic Friction of the Ventral Scales in the Snake Lampropeltis Getula Californiae. Tribol. Lett. 2014, 54, 139–150. [Google Scholar] [CrossRef]

- Mühlberger, M.; Rohn, M.; Danzberger, J.; Sonntag, E.; Rank, A.; Schumm, L.; Kirchner, R.; Forsich, C.; Gorb, S.; Einwögerer, B.; et al. UV-NIL Fabricated Bio-Inspired Inlays for Injection Molding to Influence the Friction Behavior of Ceramic Surfaces. Microelectron. Eng. 2015, 141, 140–144. [Google Scholar] [CrossRef]

- Kirchner, R.; Guzenko, V.A.; Rohn, M.; Sonntag, E.; Mühlberger, M.; Bergmair, I.; Schift, H. Bio-Inspired 3D Funnel Structures Made by Grayscale Electron-Beam Patterning and Selective Topography Equilibration. Microelectron. Eng. 2015, 141, 107–111. [Google Scholar] [CrossRef]

- Gorb, S.N. Visualisation of Native Surfaces by Two-Step Molding. Micros. Today 2007, 15, 44–47. [Google Scholar] [CrossRef]

- Baum, M.J.; Heepe, L.; Gorb, S.N. Friction Behavior of a Microstructured Polymer Surface Inspired by Snake Skin. Beilstein J. Nanotechnol. 2014, 5, 83–97. [Google Scholar] [CrossRef]

- Yoon, E.; Singh, A.; Kong, H.; Kim, B.; Kim, D.-H.; Jeong, H.; Suh, K.Y. Tribological Properties of Bio-Mimetic Nano-Patterned Polymeric Surfaces on Silicon Wafer. Tribol. Lett. 2006, 21, 31–37. [Google Scholar] [CrossRef]

- Burton, Z.; Bhushan, B. Hydrophobicity, Adhesion, and Friction Properties of Nanopatterned Polymers and Scale Dependence for Micro- and Nanoelectromechanical Systems. Nano Lett. 2005, 5, 1607–1613. [Google Scholar] [CrossRef]

- Singh, R.A.; Siyuan, L.; Satyanarayana, N.; Kustandi, T.S.; Sinha, S.K. Bio-Inspired Polymeric Patterns with Enhanced Wear Durability for Microsystem Applications. Mater. Sci. Eng. C 2011, 31, 1577–1583. [Google Scholar] [CrossRef]

- Arvind Singh, R.; Yoon, E.-S.; Suh, K.-Y.; Kim, D.-H. Biomimetic surfaces for tribological applications in micro/nano-devices. In Nano-Tribology and Materials in MEMS; Sinha, S.K., Satyanarayana, N., Lim, S.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 147–162. ISBN 978-3-642-36934-6. [Google Scholar]

- Singh, R.A.; Yoon, E.-S.; Kim, H.J.; Kong, H.; Park, S.; Jeong, H.E.; Suh, K.Y. Enhanced Tribological Properties of Lotus Leaf-like Surfaces Fabricated by Capillary Force Lithography. Surf. Eng. 2007, 23, 161–164. [Google Scholar] [CrossRef]

- Singh, R.A.; Yoon, E.-S.; Kim, H.J.; Kim, J.; Jeong, H.E.; Suh, K.Y. Replication of Surfaces of Natural Leaves for Enhanced Micro-Scale Tribological Property. Mater. Sci. Eng. C 2007, 27, 875–879. [Google Scholar] [CrossRef]

- Kroner, E.; Davis, C.S. A Study of the Adhesive Foot of the Gecko: Translation of a Publication by Franz Weitlaner. J. Adhes. 2015, 91, 481–487. [Google Scholar] [CrossRef]

- Weitlaner, F. Eine Untersuchung über den Haftfuss des Gecko. Verh. Der Zool. Bot. Ges. Wien 1902, 52, 328–332. [Google Scholar]

- Autumn, K.; Puthoff, J. Properties, principles, and parameters of the gecko adhesive system. In Biological Adhesives; Smith, A.M., Ed.; Springer International Publishing: Cham, Switzerland, 2016; pp. 245–280. ISBN 978-3-319-46081-9. [Google Scholar]

- Autumn, K.; Gravish, N. Gecko Adhesion: Evolutionary Nanotechnology. Phil. Trans. R. Soc. A 2008, 366, 1575–1590. [Google Scholar] [CrossRef]

- Brodoceanu, D.; Bauer, C.T.; Kroner, E.; Arzt, E.; Kraus, T. Hierarchical Bioinspired Adhesive Surfaces—A Review. Bioinspir. Biomim. 2016, 11, 051001. [Google Scholar] [CrossRef]

- Davies, J.; Haq, S.; Hawke, T.; Sargent, J.P. A Practical Approach to the Development of a Synthetic Gecko Tape. Int. J. Adhes. Adhes. 2009, 29, 380–390. [Google Scholar] [CrossRef]

- Kim, S.; Sitti, M. Biologically Inspired Polymer Microfibers with Spatulate Tips as Repeatable Fibrillar Adhesives. Appl. Phys. Lett. 2006, 89, 261911. [Google Scholar] [CrossRef]

- Kwak, M.K.; Jeong, H.E.; Bae, W.G.; Jung, H.-S.; Suh, K.Y. Anisotropic Adhesion Properties of Triangular-Tip-Shaped Micropillars. Small 2011, 7, 2296–2300. [Google Scholar] [CrossRef]

- Hu, H.; Tian, H.; Li, X.; Shao, J.; Ding, Y.; Liu, H.; An, N. Biomimetic Mushroom-Shaped Microfibers for Dry Adhesives by Electrically Induced Polymer Deformation. ACS Appl. Mater. Interfaces 2014, 6, 14167–14173. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, H.; Shao, J.; Ding, Y. Fabrication of Well-Defined Mushroom-Shaped Structures for Biomimetic Dry Adhesive by Conventional Photolithography and Molding. ACS Appl. Mater. Interfaces 2014, 6, 2213–2218. [Google Scholar] [CrossRef]

- Raut, H.K.; Baji, A.; Hariri, H.H.; Parveen, H.; Soh, G.S.; Low, H.Y.; Wood, K.L. Gecko-Inspired Dry Adhesive Based on Micro–Nanoscale Hierarchical Arrays for Application in Climbing Devices. ACS Appl. Mater. Interfaces 2018, 10, 1288–1296. [Google Scholar] [CrossRef]

- Terashima, S.; Ochi, A.; Sato, J.; Suzuki, M.; Takahashi, T.; Aoyagi, S. Proposal of a Three-Stage Hair Structure Imitating the Sole of Gecko Foot and Its Fabrication by UV Nanoimprinting. Precis. Eng. 2021, 67, 359–369. [Google Scholar] [CrossRef]

- Ho, A.Y.Y.; Yeo, L.P.; Lam, Y.C.; Rodríguez, I. Fabrication and Analysis of Gecko-Inspired Hierarchical Polymer Nanosetae. ACS Nano 2011, 5, 1897–1906. [Google Scholar] [CrossRef]

- Suh, K.Y.; Kim, Y.S.; Lee, H.H. Capillary Force Lithography. Adv. Mater. 2001, 1386–1389. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the Sacred Lotus, or Escape from Contamination in Biological Surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Webb, H.K.; Crawford, R.J.; Ivanova, E.P. Wettability of Natural Superhydrophobic Surfaces. Adv. Colloid Interface Sci. 2014, 210, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Jiaqiang, E.; Jin, Y.; Deng, Y.; Wei, Z.; Zhao, X.; Han, D.; Peng, Q.; Zhiqing, Z. Wetting Models and Working Mechanisms of Typical Surfaces Existing in Nature and Their Application on Superhydrophobic Surfaces: A Review. Adv. Mater. Interfaces 2018, 5, 1701052. [Google Scholar] [CrossRef]

- Celia, E.; Darmanin, T.; de Givenchy, E.T.; Amigoni, S.; Guittard, F. Recent Advances in Designing Superhydrophobic Surfaces. J. Colloid Interface Sci. 2013, 402, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Subhash Latthe, S.; Basavraj Gurav, A.; Shridhar Maruti, C.; Shrikant Vhatkar, R. Recent Progress in Preparation of Superhydrophobic Surfaces: A Review. JSEMAT 2012, 2, 76–94. [Google Scholar] [CrossRef]

- Nishimoto, S.; Bhushan, B. Bioinspired Self-Cleaning Surfaces with Superhydrophobicity, Superoleophobicity, and Superhydrophilicity. RSC Adv. 2013, 3, 671–690. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Xia, H.; Kim, E.; Sun, H.-B. Recent Developments in Superhydrophobic Surfaces with Unique Structural and Functional Properties. Soft Matter 2012, 8, 11217–11231. [Google Scholar] [CrossRef]

- Quan, Y.-Y.; Chen, Z.; Lai, Y.; Huang, Z.-S.; Li, H. Recent Advances in Fabricating Durable Superhydrophobic Surfaces: A Review in the Aspects of Structures and Materials. Mater. Chem. Front. 2020, 5, 1655–1682. [Google Scholar] [CrossRef]

- Liravi, M.; Pakzad, H.; Moosavi, A.; Nouri-Borujerdi, A. A Comprehensive Review on Recent Advances in Superhydrophobic Surfaces and Their Applications for Drag Reduction. Prog. Org. Coat. 2020, 140, 105537. [Google Scholar] [CrossRef]

- Kong, T.; Luo, G.; Zhao, Y.; Liu, Z. Bioinspired Superwettability Micro/Nanoarchitectures: Fabrications and Applications. Adv. Funct. Mater. 2019, 29, 1808012. [Google Scholar] [CrossRef]

- Hwang, J.; Hong, S.-H.; Lee, H. Mimicking the Nanostructure of Bamboo Leaves (Backside) for Hydrophobicity Using Polydimethylsiloxane Moulding and Nano-Imprint Lithography. J. Nanosci. Nanotech. 2009, 9, 3644–3647. [Google Scholar] [CrossRef]

- Choo, S.; Choi, H.-J.; Lee, H. Replication of Rose-Petal Surface Structure Using UV-Nanoimprint Lithography. Mater. Lett. 2014, 121, 170–173. [Google Scholar] [CrossRef]

- Yang, Y.; He, H.; Li, Y.; Qiu, J. Using Nanoimprint Lithography to Create Robust, Buoyant, Superhydrophobic PVB/SiO2 Coatings on Wood Surfaces Inspired by Red Roses Petal. Sci. Rep. 2019, 9, 9961. [Google Scholar] [CrossRef]

- Dai, S.; Ding, W.; Wang, Y.; Zhang, D.; Du, Z. Fabrication of Hydrophobic Inorganic Coatings on Natural Lotus Leaves for Nanoimprint Stamps. Thin Solid Films 2011, 519, 5523–5527. [Google Scholar] [CrossRef]

- Sun, J.; Li, H.; Huang, Y.; Zheng, X.; Liu, Y.; Zhuang, J.; Wu, D. Simple and Affordable Way to Achieve Polymeric Superhydrophobic Surfaces with Biomimetic Hierarchical Roughness. ACS Omega 2019, 4, 2750–2757. [Google Scholar] [CrossRef]

- Li, Y.; John, J.; Kolewe, K.W.; Schiffman, J.D.; Carter, K.R. Scaling up Nature: Large Area Flexible Biomimetic Surfaces. ACS Appl. Mater. Interfaces 2015, 7, 23439–23444. [Google Scholar] [CrossRef]

- Kim, S.; Jung, U.T.; Kim, S.-K.; Lee, J.-H.; Choi, H.S.; Kim, C.-S.; Jeong, M.Y. Nanostructured Multifunctional Surface with Antireflective and Antimicrobial Characteristics. ACS Appl. Mater. Interfaces 2015, 7, 326–331. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Yu, W.; Hao, D.; Li, L.; Liu, H.; Lu, Z. Functional Nanostructured Surfaces in Hybrid Sol–Gel Glass in Large Area for Antireflective and Super-Hydrophobic Purposes. J. Mater. Chem. 2012, 22, 17328. [Google Scholar] [CrossRef]

- Li, Y.; Dai, S.; John, J.; Carter, K.R. Superhydrophobic Surfaces from Hierarchically Structured Wrinkled Polymers. ACS Appl. Mater. Interfaces 2013, 5, 11066–11073. [Google Scholar] [CrossRef] [PubMed]

- McHale, G.; Orme, B.V.; Wells, G.G.; Ledesma-Aguilar, R. Apparent Contact Angles on Lubricant-Impregnated Surfaces/SLIPS: From Superhydrophobicity to Electrowetting. Langmuir 2019, 35, 4197–4204. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Lin, G.; Li, J.; Xue, H.; Luo, Y.; Gao, X. Fabrication of Biomimetic Polymer Nanocone Films with Condensate Microdrop Self-Removal Function. Adv. Mater. Interfaces 2015, 2, 1500238. [Google Scholar] [CrossRef]

- Li, J.; Zhu, J.; Gao, X. Bio-Inspired High-Performance Antireflection and Antifogging Polymer Films. Small 2014, 10, 2578–2582. [Google Scholar] [CrossRef]

- Durret, J.; Frolet, N.; Gourgon, C. Hydrophobicity and Anti-Icing Performances of Nanoimprinted and Roughened Fluoropolymers Films under Overcooled Temperature. Microelectron. Eng. 2016, 155, 1–6. [Google Scholar] [CrossRef]

- Han, Z.; Feng, X.; Guo, Z.; Niu, S.; Ren, L. Flourishing Bioinspired Antifogging Materials with Superwettability: Progresses and Challenges. Adv. Mater. 2018, 30, 1704652. [Google Scholar] [CrossRef]

- Hensel, R.; Finn, A.; Helbig, R.; Braun, H.-G.; Neinhuis, C.; Fischer, W.-J.; Werner, C. Biologically Inspired Omniphobic Surfaces by Reverse Imprint Lithography. Adv. Mater. 2014, 26, 2029–2033. [Google Scholar] [CrossRef]

- Helbig, R.; Nickerl, J.; Neinhuis, C.; Werner, C. Smart Skin Patterns Protect Springtails. PLoS ONE 2011, 6, e25105. [Google Scholar] [CrossRef]

- Noble-nesbitt, J. Transpiration in Podura Aquatica L.(Collembola, Isotomidae) and the Wetting Properties of Its Cuticle. J. Exp. Biol. 1963, 40, 681–700. [Google Scholar] [CrossRef]

- Lifka, S.; Hischen, F.; Heitz, J.; Baumgartner, W. An Optimised Surface Structure for Passive, Unidirectional Fluid Transport Bioinspired by True Bugs. J. Bionic Eng. 2021, 18, 375–386. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, G.; Chen, H.; Liu, X.; Ran, T.; Zhang, Y.; Gan, Y.; Zhang, D. Bioinspired Unidirectional Liquid Transport Micro-Nano Structures: A Review. J. Bionic Eng 2021, 18, 1–29. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, P.; Zhang, L.; Liu, H.; Jiang, Y.; Zhang, D.; Han, Z.; Jiang, L. Continuous Directional Water Transport on the Peristome Surface of Nepenthes Alata. Nature 2016, 532, 85–89. [Google Scholar] [CrossRef]

- Peng, Z.; Wu, T. High-Throughput Droplet Array Generated by Roller Nanoimprint Lithography with Biomimetic Surfaces. In Proceedings of the 2019 41st Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Berlin, Germany, 23–27 July 2019; IEEE: Berlin, Germany, 2019; pp. 1074–1077. [Google Scholar]

- Bhushan, B. Biomimetics Inspired Surfaces for Drag Reduction and Oleophobicity/Philicity. Beilstein J. Nanotechnol. 2011, 2, 66–84. [Google Scholar] [CrossRef]

- Jung, Y.C.; Bhushan, B. Biomimetic Structures for Fluid Drag Reduction in Laminar and Turbulent Flows. J. Phys. Condens. Matter 2010, 22, 035104. [Google Scholar] [CrossRef]

- Pu, X.; Li, G.; Huang, H. Preparation, Anti-Biofouling and Drag-Reduction Properties of a Biomimetic Shark Skin Surface. Biol. Open 2016, 5, 389–396. [Google Scholar] [CrossRef]

- Han, X.; Zhang, D.; Li, X.; Li, Y. Bio-Replicated Forming of the Biomimetic Drag-Reducing Surfaces in Large Area Based on Shark Skin. Sci. Bull. 2008, 53, 1587–1592. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, X.; Ma, L.; Che, D.; Zhang, D.; Sudarshan, T.S. Investigation on Large-Area Fabrication of Vivid Shark Skin with Superior Surface Functions. Appl. Surf. Sci. 2014, 316, 124–131. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Y.; Chen, H.; Zhang, D. Bio-inspired Drag Reduction Surface from Sharkskin. Biosurface Biotribology 2018, 4, 39–45. [Google Scholar] [CrossRef]

- Lohse, M.; Heinrich, M.; Grützner, S.; Haase, A.; Ramos, I.; Salado, C.; Thesen, M.W.; Grützner, G. Versatile Fabrication Method for Multiscale Hierarchical Structured Polymer Masters Using a Combination of Photo- and Nanoimprint Lithography. Micro Nano Eng. 2021, 10, 100079. [Google Scholar] [CrossRef]

- Bilenberg, B.; Hansen, M.; Johansen, D.; Özkapici, V.; Jeppesen, C.; Szabo, P.; Obieta, I.M.; Arroyo, O.; Tegenfeldt, J.O.; Kristensen, A. Topas-Based Lab-on-a-Chip Microsystems Fabricated by Thermal Nanoimprint Lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2005, 23, 2944. [Google Scholar] [CrossRef]

- Bianconi, E.; Piovesan, A.; Facchin, F.; Beraudi, A.; Casadei, R.; Frabetti, F.; Vitale, L.; Pelleri, M.C.; Tassani, S.; Piva, F.; et al. An Estimation of the Number of Cells in the Human Body. Ann. Hum. Biol. 2013, 40, 463–471. [Google Scholar] [CrossRef] [PubMed]

- HuBMAP Consortium. The Human Body at Cellular Resolution: The NIH Human Biomolecular Atlas Program. Nature 2019, 574, 187–192. [Google Scholar] [CrossRef] [PubMed]

- Andalib, M.N.; Dzenis, Y.; Donahue, H.J.; Lim, J.Y. Biomimetic Substrate Control of Cellular Mechanotransduction. Biomater. Res. 2016, 20, 11. [Google Scholar] [CrossRef]

- McMurray, R.; Dalby, J.M.; Gadegaar, N. Nanopatterned surfaces for biomedical applications. In Biomedical Engineering, Trends in Materials Science; Laskovski, A., Ed.; IntechOpen: London, UK, 2011; ISBN 978-953-307-513-6. [Google Scholar]

- Quist, A.P.; Pavlovic, E.; Oscarsson, S. Recent Advances in Microcontact Printing. Anal. Bioanal. Chem. 2005, 381, 591–600. [Google Scholar] [CrossRef]

- Kim, D.-H.; Lee, H.; Lee, Y.K.; Nam, J.-M.; Levchenko, A. Biomimetic Nanopatterns as Enabling Tools for Analysis and Control of Live Cells. Adv. Mater. 2010, 22, 4551–4566. [Google Scholar] [CrossRef]

- Hu, W.; Yim, E.K.F.; Reano, R.M.; Leong, K.W.; Pang, S.W. Effects of Nanoimprinted Patterns in Tissue-Culture Polystyrene on Cell Behavior. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2005, 23, 2984. [Google Scholar] [CrossRef]

- Viela, F.; Granados, D.; Ayuso-Sacido, A.; Rodríguez, I. Biomechanical Cell Regulation by High Aspect Ratio Nanoimprinted Pillars. Adv. Funct. Mater. 2016, 26, 5599–5609. [Google Scholar] [CrossRef]

- Wu, Y.-N.; Law, J.B.K.; He, A.Y.; Low, H.Y.; Hui, J.H.P.; Lim, C.T.; Yang, Z.; Lee, E.H. Substrate Topography Determines the Fate of Chondrogenesis from Human Mesenchymal Stem Cells Resulting in Specific Cartilage Phenotype Formation. Nanomed. Nanotechnol. Biol. Med. 2014, 10, 1507–1516. [Google Scholar] [CrossRef]

- Seunarine, K.; Gadegaard, N.; Tormen, M.; Meredith, D.; Riehle, M.; Wilkinson, C. 3D Polymer Scaffolds for Tissue Engineering. Nanomedicine 2006, 1, 281–296. [Google Scholar] [CrossRef]

- Nowduri, B.; Schulte, S.; Decker, D.; Schäfer, K.-H.; Saumer, M. Biomimetic Nanostructures Fabricated by Nanoimprint Lithography for Improved Cell-Coupling. Adv. Funct. Mater. 2020, 30, 2004227. [Google Scholar] [CrossRef]

- Monteiro, N.O.; Fangueiro, J.F.; Neves, N.M. Fabrication of Biomimetic Patterned PCL Membranes Mimicking the Complexity of Rubus Fruticosus Leaves Surface. Colloids Surf. B Biointerfaces 2021, 206, 111910. [Google Scholar] [CrossRef]

- López-Valverde, N.; Flores-Fraile, J.; Ramírez, J.M.; de Sousa, B.M.; Herrero-Hernández, S.; López-Valverde, A. Bioactive Surfaces vs. Conventional Surfaces in Titanium Dental Implants: A Comparative Systematic Review. J. Clin. Med. 2020, 9, 2047. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, P.; Liu, S.; Attarilar, S.; Ma, R.L.-W.; Zhong, Y.; Wang, L. Multi-Scale Surface Treatments of Titanium Implants for Rapid Osseointegration: A Review. Nanomaterials 2020, 10, 1244. [Google Scholar] [CrossRef]

- Domanski, M.; Luttge, R.; Lamers, E.; Walboomers, X.F.; Winnubst, L.; Jansen, J.A.; Gardeniers, J.G.E. Submicron-Patterning of Bulk Titanium by Nanoimprint Lithography and Reactive Ion Etching. Nanotechnology 2012, 23, 065306. [Google Scholar] [CrossRef]

- Greer, A.I.M.; Seunarine, K.; Khokhar, A.Z.; MacLaren, I.; Brydone, A.S.; Moran, D.A.J.; Gadegaard, N. Increased Efficiency of Direct Nanoimprinting on Planar and Curved Bulk Titanium through Surface Modification. Microelectron. Eng. 2013, 112, 67–73. [Google Scholar] [CrossRef]

- Alalwan, H.; Nile, C.J.; Rajendran, R.; McKerlie, R.; Reynolds, P.; Gadegaard, N.; Ramage, G. Nanoimprinting of Biomedical Polymers Reduces Candidal Physical Adhesion. Nanomed. Nanotechnol. Biol. Med. 2018, 14, 1045–1049. [Google Scholar] [CrossRef]

- Jaggessar, A.; Shahali, H.; Mathew, A.; Yarlagadda, P.K.D.V. Bio-Mimicking Nano and Micro-Structured Surface Fabrication for Antibacterial Properties in Medical Implants. J. Nanobiotechnol. 2017, 15, 64. [Google Scholar] [CrossRef]

- Larrañaga-Altuna, M.; Zabala, A.; Llavori, I.; Pearce, O.; Nguyen, D.T.; Caro, J.; Mescheder, H.; Endrino, J.L.; Goel, G.; Ayre, W.N.; et al. Bactericidal Surfaces: An Emerging 21st-Century Ultra-Precision Manufacturing and Materials Puzzle. Appl. Phys. Rev. 2021, 8, 021303. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, J.; Xie, G.; Liu, Z.; Shao, H. Cicada Wings: A Stamp from Nature for Nanoimprint Lithography. Small 2006, 2, 1440–1443. [Google Scholar] [CrossRef]

- Reid, G.; McCormack, J.C.; Habimana, O.; Bayer, F.; Goromonzi, C.; Casey, E.; Cowley, A.; Kelleher, S.M. Biomimetic Polymer Surfaces by High Resolution Molding of the Wings of Different Cicadas. Materials 2021, 14, 1910. [Google Scholar] [CrossRef] [PubMed]

- Minoura, K.; Yamada, M.; Mizoguchi, T.; Kaneko, T.; Nishiyama, K.; Ozminskyj, M.; Koshizuka, T.; Wada, I.; Suzutani, T. Antibacterial Effects of the Artificial Surface of Nanoimprinted Moth-Eye Film. PLoS ONE 2017, 12, e0185366. [Google Scholar] [CrossRef] [PubMed]

- Yamada, M.; Minoura, K.; Mizoguchi, T.; Nakamatsu, K.; Taguchi, T.; Kameda, T.; Sekiguchi, M.; Suzutani, T.; Konno, S. Antibacterial Effects of Nano-Imprinted Moth-Eye Film in Practical Settings. PLoS ONE 2018, 13, e0198300. [Google Scholar] [CrossRef] [PubMed]

- Dundar Arisoy, F.; Kolewe, K.W.; Homyak, B.; Kurtz, I.S.; Schiffman, J.D.; Watkins, J.J. Bioinspired Photocatalytic Shark-Skin Surfaces with Antibacterial and Antifouling Activity via Nanoimprint Lithography. ACS Appl. Mater. Interfaces 2018, 10, 20055–20063. [Google Scholar] [CrossRef]

- Chung, K.K.; Schumacher, J.F.; Sampson, E.M.; Burne, R.A.; Antonelli, P.J.; Brennan, A.B. Impact of Engineered Surface Microtopography on Biofilm Formation of Staphylococcus Aureus. Biointerphases 2007, 2, 89–94. [Google Scholar] [CrossRef]

- May, R.M.; Hoffman, M.G.; Sogo, M.J.; Parker, A.E.; O’Toole, G.A.; Brennan, A.B.; Reddy, S.T. Micro-Patterned Surfaces Reduce Bacterial Colonization and Biofilm Formation in Vitro: Potential for Enhancing Endotracheal Tube Designs. Clin. Transl. Med. 2014, 3, 8. [Google Scholar] [CrossRef]

- IPCC. Summary for Policymakers. In IPCC Special Report on Renewable Energy Sources and Climate Change Mitigation; Edenhofer, O., Pichs-Madruga, R., Sokona, Y., Seyboth, K., Matschoss, P., Kadner, S., Zwickel, T., Eickemeier, P., Hansen, G., Schlömer, S., von Stechow, C., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2011; Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/Summary-for-Policymakers-1.pdf (accessed on 22 December 2021).

- Sims, R.E.H. Renewable Energy: A Response to Climate Change. Sol. Energy 2004, 76, 9–17. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Nosonovsky, M.; Bhushan, B. Multiscale Effects and Capillary Interactions in Functional Biomimetic Surfaces for Energy Conversion and Green Engineering. Philos. Trans. R. Soc. A 2009, 367, 1511–1539. [Google Scholar] [CrossRef]

- Fritz, B.; Hünig, R.; Guttmann, M.; Schneider, M.; Reza, K.M.S.; Salomon, O.; Jackson, P.; Powalla, M.; Lemmer, U.; Gomard, G. Upscaling the Fabrication Routine of Bioreplicated Rose Petal Light Harvesting Layers for Photovoltaic Modules. Sol. Energy 2020, 201, 666–673. [Google Scholar] [CrossRef]

- Chen, J.Y.; Chang, W.-L.; Huang, C.K.; Sun, K.W. Biomimetic Nanostructured Antireflection Coating and Its Application on Crystalline Silicon Solar Cells. Opt. Express 2011, 19, 14411. [Google Scholar] [CrossRef]

- Chen, J.-D.; Zhou, L.; Ou, Q.-D.; Li, Y.-Q.; Shen, S.; Lee, S.-T.; Tang, J.-X. Enhanced Light Harvesting in Organic Solar Cells Featuring a Biomimetic Active Layer and a Self-Cleaning Antireflective Coating. Adv. Energy Mater. 2014, 4, 1301777. [Google Scholar] [CrossRef]

- Choi, D.; Kim, D.W.; Yoo, D.; Cha, K.J.; La, M.; Kim, D.S. Spontaneous Occurrence of Liquid-Solid Contact Electrification in Nature: Toward a Robust Triboelectric Nanogenerator Inspired by the Natural Lotus Leaf. Nano Energy 2017, 36, 250–259. [Google Scholar] [CrossRef]

- Back, F.; Bockmeyer, M.; Rudigier-Voigt, E.; Löbmann, P. Periodic Nanostructures Imprinted on High-Temperature Stable Sol–Gel Films by Ultraviolet-Based Nanoimprint Lithography for Photovoltaic and Photonic Applications. Thin Solid Film. 2014, 562, 274–281. [Google Scholar] [CrossRef]

- Goto, K.; Taniguchi, J. Fabrication of Bio-Inspired 3D Nanoimprint Mold Using Acceleration-Voltage-Modulation Electron-Beam Lithography. Adv. Opt. Technol. 2019, 8, 289–297. [Google Scholar] [CrossRef]

- Ho, A.Y.Y.; Gao, H.; Lam, Y.C.; Rodríguez, I. Controlled Fabrication of Multitiered Three-Dimensional Nanostructures in Porous Alumina: Three-Dimensional Nanostructures in Porous Alumina. Adv. Funct. Mater. 2008, 18, 2057–2063. [Google Scholar] [CrossRef]

| Functionality | Inspiration | Features | Replication Process | References |

|---|---|---|---|---|

| Structural colors | Morpho butterfly | artificial | UV-NIL | [94,95] |

| artificial | UV-NIL | [97] | ||

| natural | epoxy casting | [99] | ||

| rose | natural | solvent assisted casting | [101,102] | |

| Antireflection structures | moth-eye | artificial | UV soft roller nanoimprint | [111] |

| R2P UV-NIL | [112,115] | |||

| R2R UV-NIL | [119] | |||

| UV-NIL | [33,120] | |||

| hot embossing | [116,117] | |||

| plants | natural | epoxy casting | [122] |

| Functionality | Inspiration | Features | NIL Process | References |

|---|---|---|---|---|

| Friction modification | snake skin | artificial | UV-NIL | [126] |

| epoxy casting | [124,129] | |||

| lotus leave | artificial | hot embossing | [130,131,132] | |

| natural | hot embossing | [134,135] | ||

| Adhesion | gecko foot | artificial | silicone casting | [141,143,145] |

| hot embossing | [144,146,148] | |||

| UV-NIL | [147] |

| Functionality | Inspiration | Features | NIL Process | Ref |

|---|---|---|---|---|

| Repelling of liquids | lotus | natural | thermal NIL | [43] |

| hot embossing | [163] | |||

| bamboo | natural | UV-NIL | [160] | |

| rose | natural | UV-NIL | [161] | |

| hot embossing | [162,164] | |||

| artificial | R2R UV-NIL | [165] | ||

| hot embossing | [164] | |||

| pitcher plants | artificial | R2R UV-NIL | [165] | |

| butterfly | natural | thermal NIL | [43] | |

| moth-eye | artificial | R2R UV-NIL | [112] | |

| hot embossing | [166,172] | |||

| UV+ thermal | [167] | |||

| springtail | artificial | reversal | [174] | |

| liquid guidance | pitcher plant | artificial | R2R | [180] |

| drag reduction | shark skin | natural | hot embossing | [184] |

| epoxy/PU casting | [182] | |||

| UV-NIL | [185] |

| Functionality | Inspiration | Features | NIL Process | References |

|---|---|---|---|---|

| cell growth | collagen fibers | natural | hot embossing | [199] |

| tissue engineering | Rubus fruticosus leaves | natural | hot embossing | [200] |

| antibacterial | moth-eye | UV-NIL | [210,211] | |

| cicada wing | natural | UV-NIL | [209] | |

| shark skin | natural | PDMS and PU casting | [183] | |

| UV-NIL | [185] | |||

| artificial | UV-NIL | [212] | ||

| PDMS casting | [213] |

| Functionality | Inspiration | Features | NIL Process | Reference |

|---|---|---|---|---|

| antireflection and light management for photovoltaics | moth-eye | artificial | reversal NIL | [220] |

| artificial | room temperature embossing | [118] | ||

| thermal NIL | [221] | |||

| rose petal | natural | hot embossing | [219] | |

| artificial | UV-NIL | [223] | ||

| current generation | lotus leave | natural | hot embossing | [222] |

| Mastering Technology | Inspiration | References |

|---|---|---|

| electron beam lithography | snake skin | [127] |

| rose petal | [224] | |

| optical lithography | shark skin | [214] |

| laser interference lithography | moth-eye | [111,203] |

| self-organized etching | moth-eye | [118] |

| gecko | [148,225] | |

| nanoparticle self-assembly + etching | moth-eye | [113,220] |

| additive manufacturing | gecko | [147] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muehlberger, M. Nanoimprinting of Biomimetic Nanostructures. Nanomanufacturing 2022, 2, 17-40. https://doi.org/10.3390/nanomanufacturing2010002

Muehlberger M. Nanoimprinting of Biomimetic Nanostructures. Nanomanufacturing. 2022; 2(1):17-40. https://doi.org/10.3390/nanomanufacturing2010002

Chicago/Turabian StyleMuehlberger, Michael. 2022. "Nanoimprinting of Biomimetic Nanostructures" Nanomanufacturing 2, no. 1: 17-40. https://doi.org/10.3390/nanomanufacturing2010002

APA StyleMuehlberger, M. (2022). Nanoimprinting of Biomimetic Nanostructures. Nanomanufacturing, 2(1), 17-40. https://doi.org/10.3390/nanomanufacturing2010002