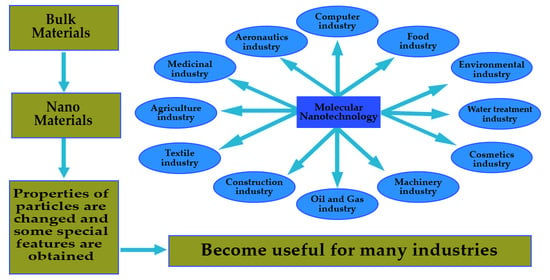

Advances with Molecular Nanomaterials in Industrial Manufacturing Applications

Abstract

1. Introduction

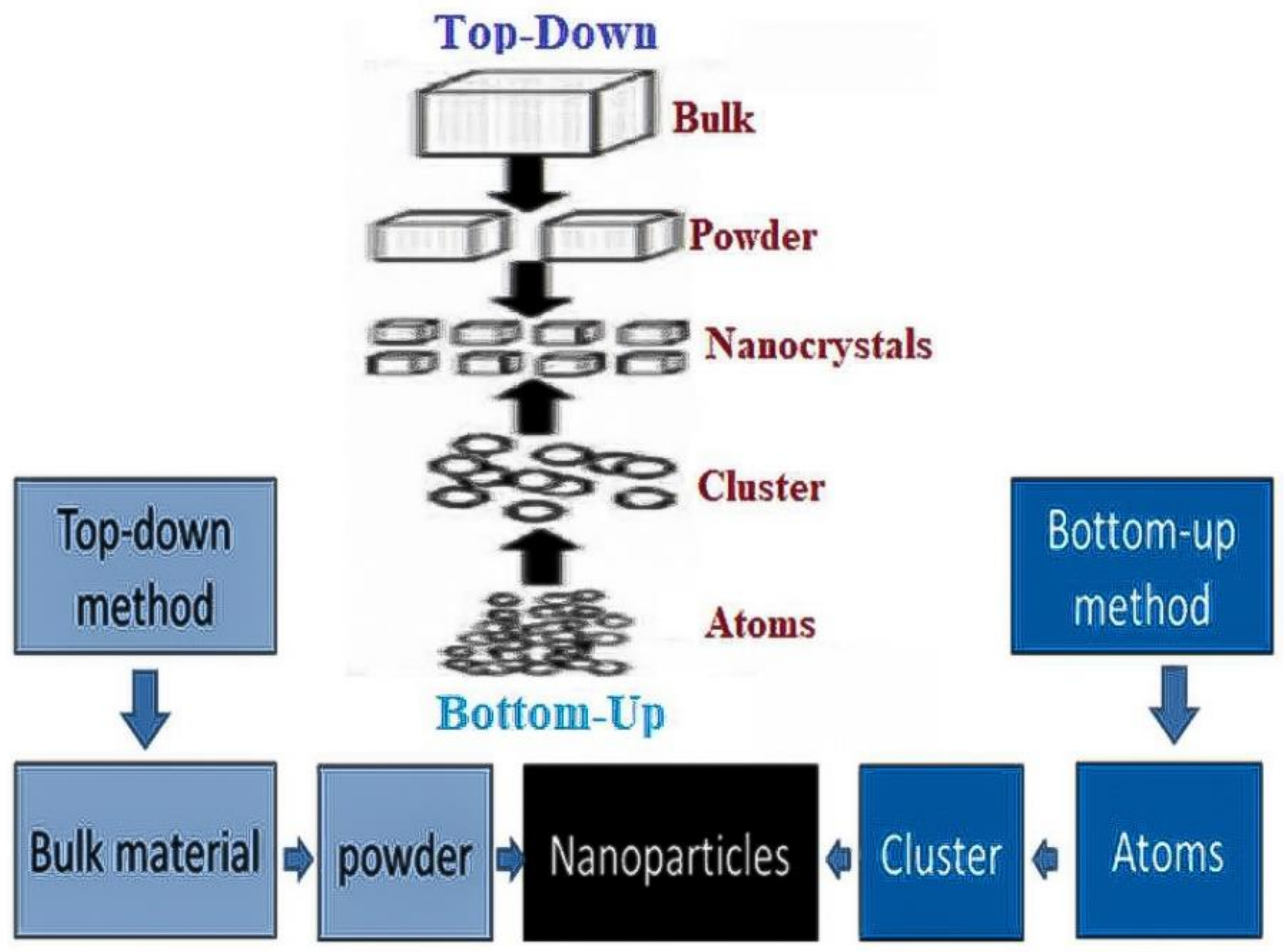

2. Fabrication and Characterization of Molecular Nanomaterials

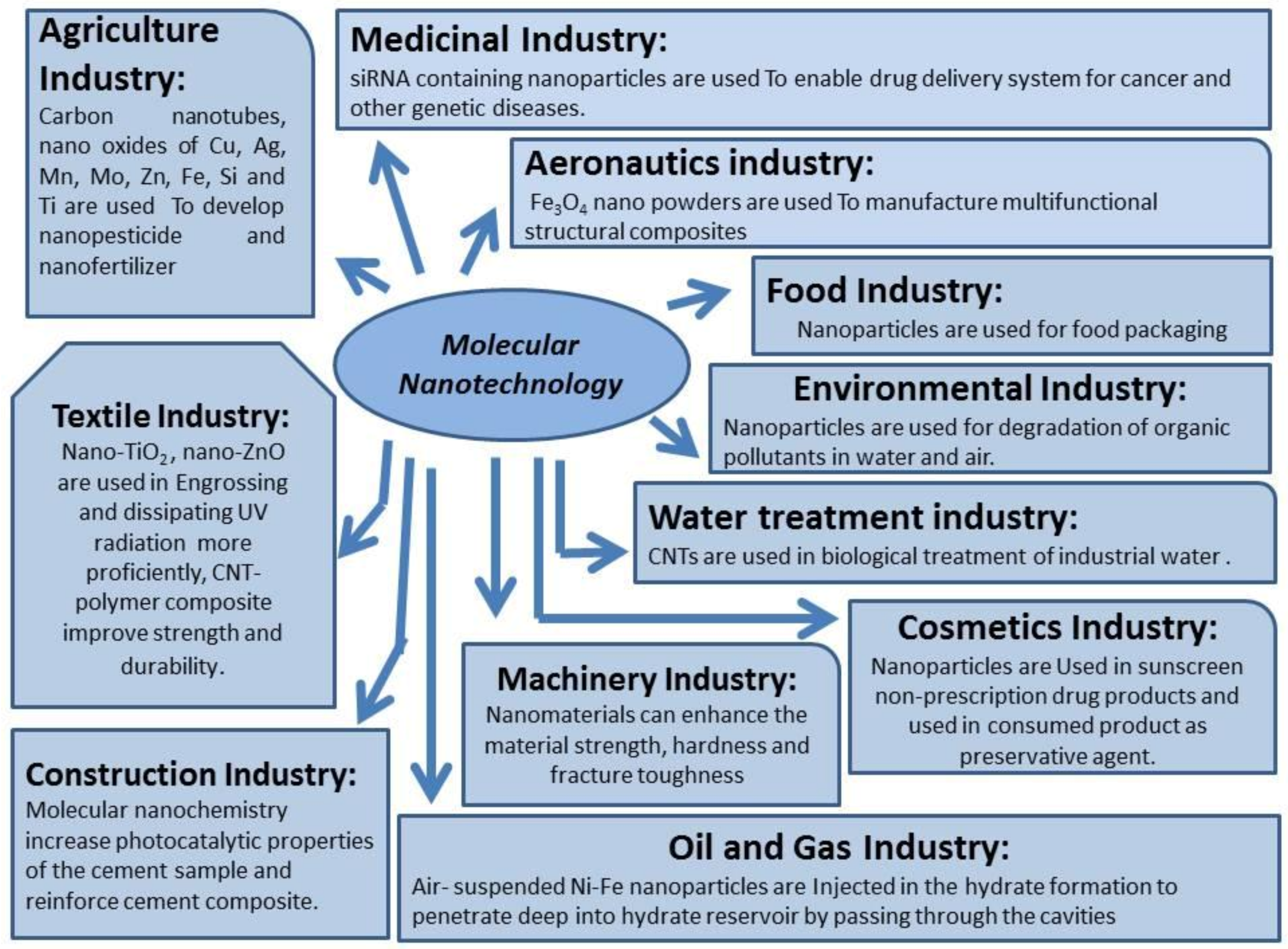

3. Industrial Applications

3.1. Construction Industry

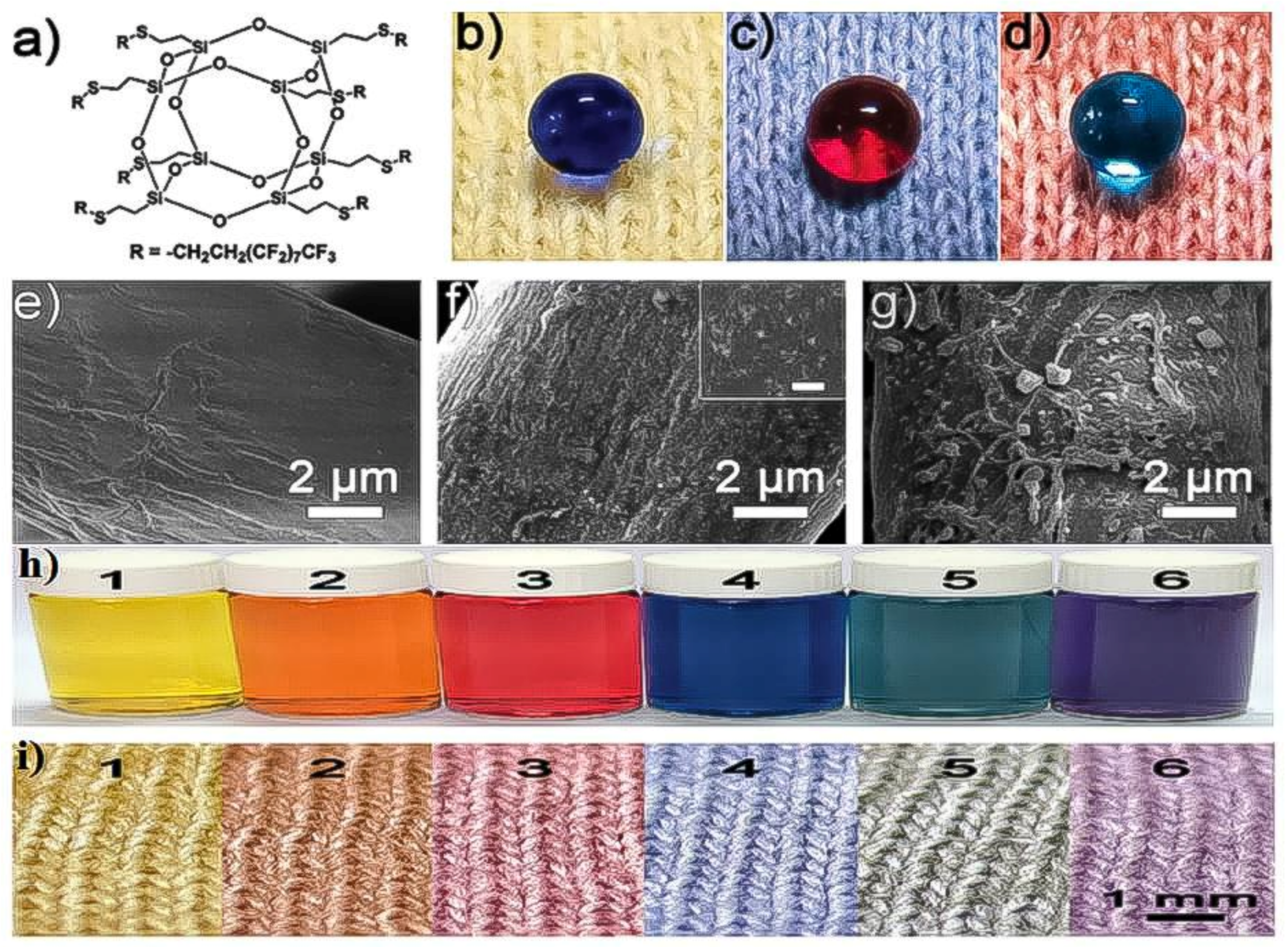

3.2. Textile Industry

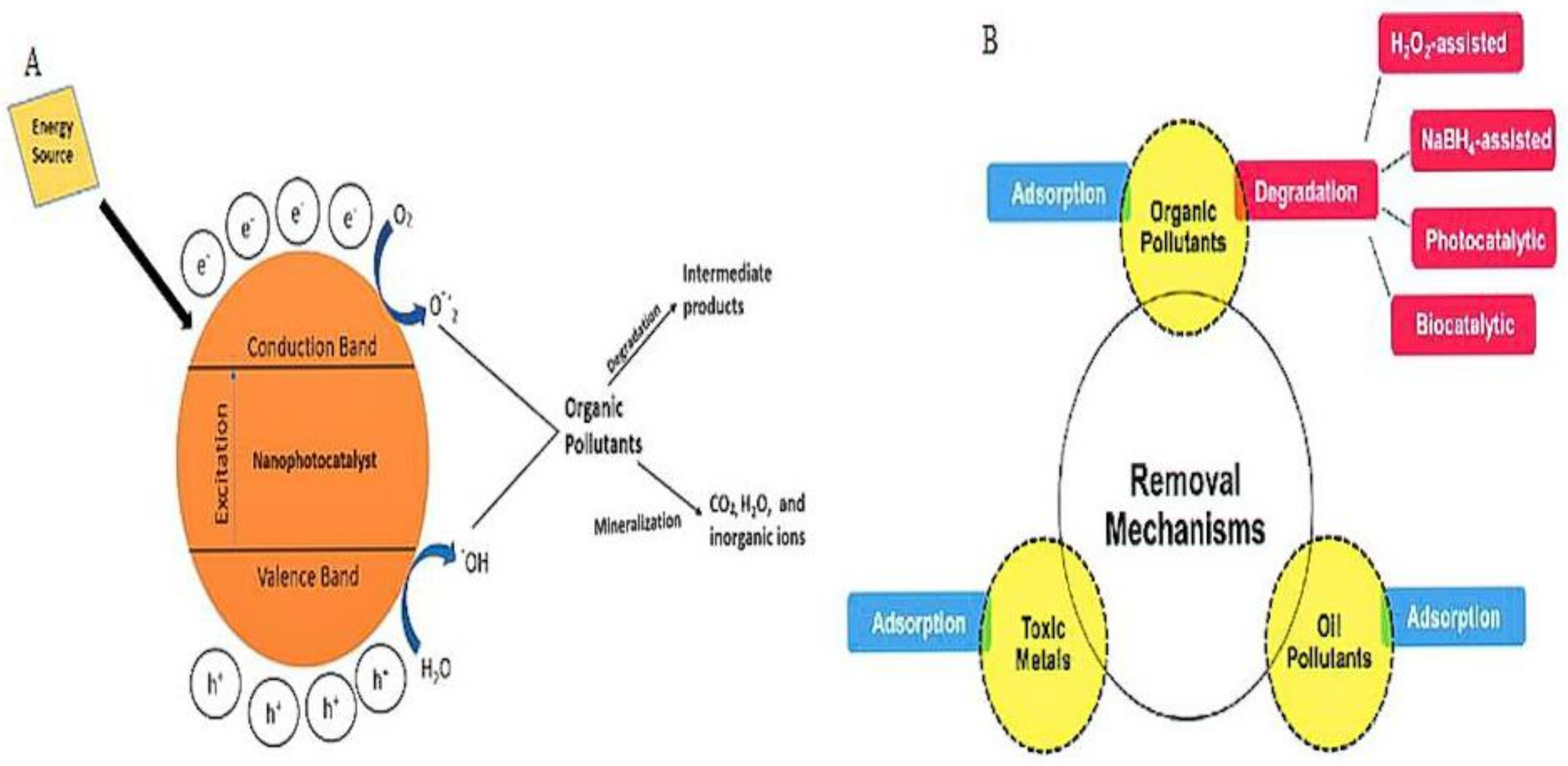

3.3. Water Treatment Industry

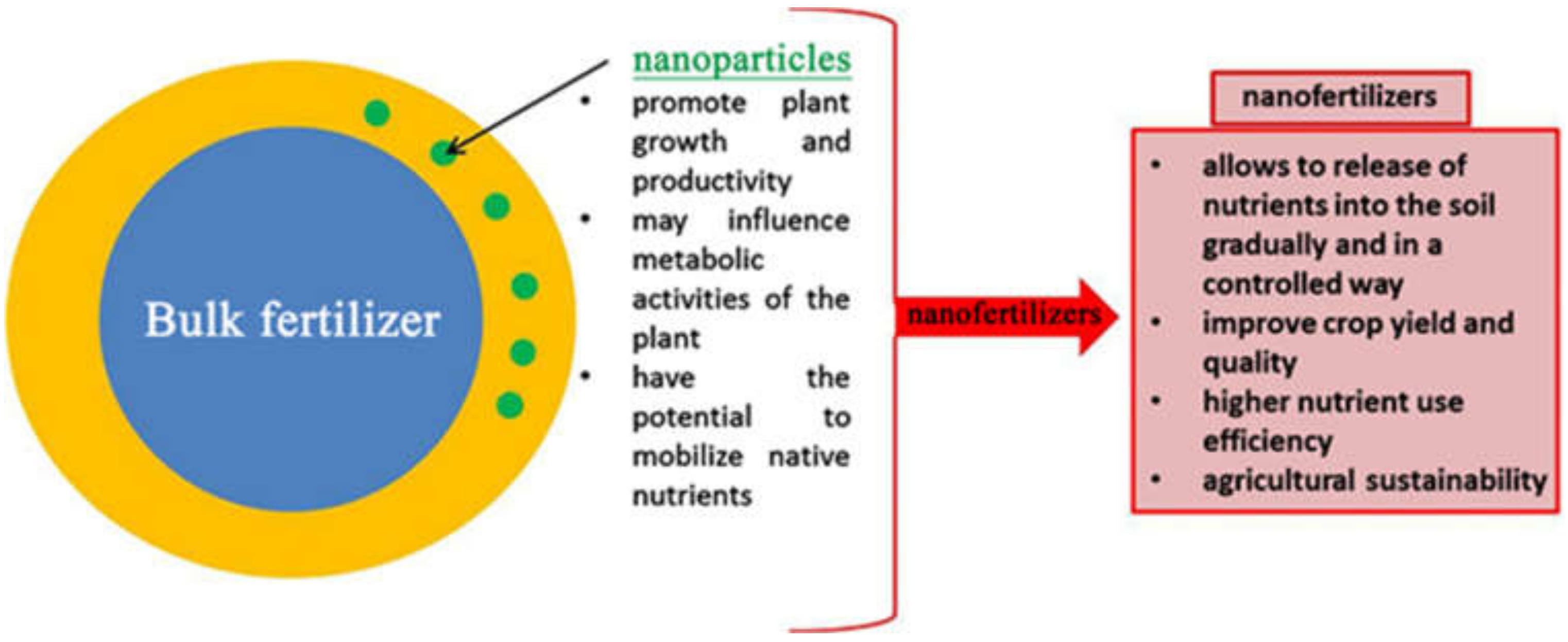

3.4. Agriculture Industry

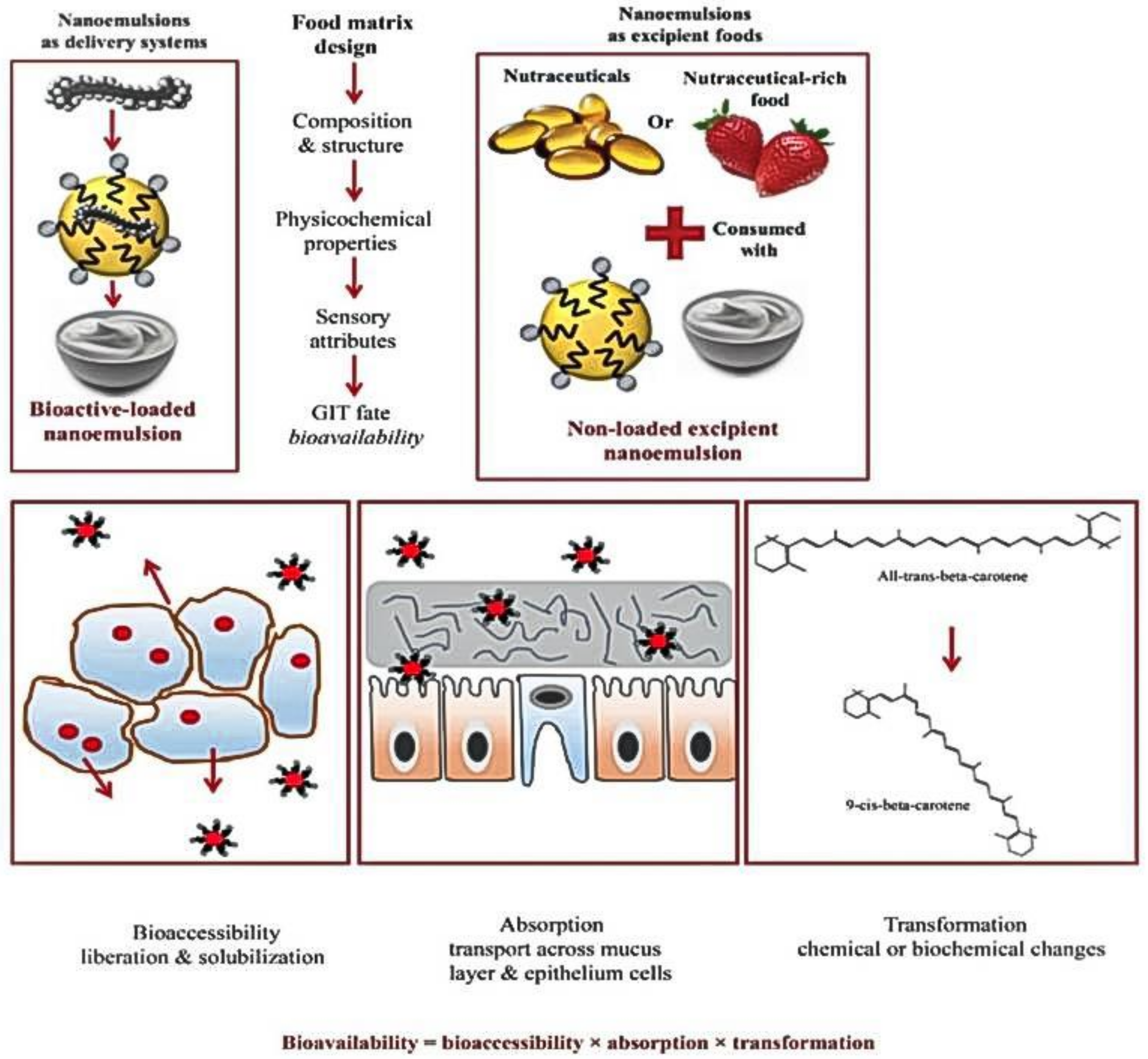

3.5. Food Industry

3.6. Aeronautics Industry

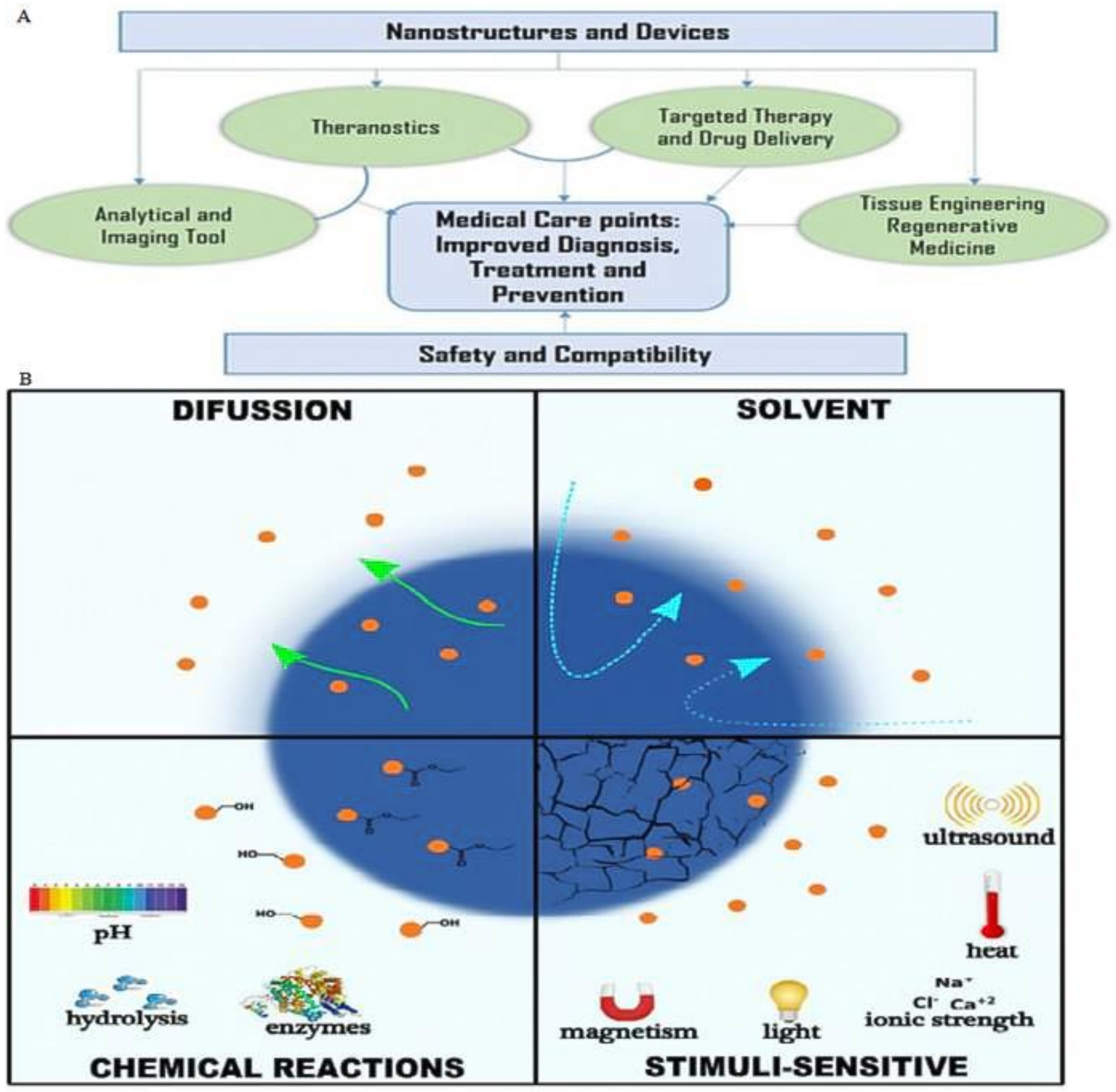

3.7. Medicinal Industry

3.8. Environmental Industry

3.9. Cosmetics Industry

3.10. Machinery Industry

3.11. Oil and Gas Industry

3.12. Computer Industry

3.13. Miscellaneous Applications of Molecular Nanomaterials

4. Toxicity of Nanomaterials

5. Future Research Perspectives and Challenges

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tamirat, Y. The Role of Nanotechnology in Semiconductor Industry: Review Article. J. Mater. Sci. Nanotechnol. 2017, 5, 202. [Google Scholar]

- Sobolev, K.; Gutierrez, M.F. How Nanotechnology Can Change the Concrete World Successfully mimicking nature’s bottom-up construction processes is one of the most promising directions. Am. Ceram. Soc. Bull. 2021, 84, 15–17. [Google Scholar]

- Zhu, W.; Bartos, P.; Porro, A. Application of nanotechnology in construction. Mater. Struct. 2004, 37, 649–658. [Google Scholar] [CrossRef]

- Havancsák, K. Nanotechnology at Present and its Promise for the Future. Mater. Sci. Forum 2003, 414, 85–94. [Google Scholar] [CrossRef]

- Silva, G. Neuroscience nanotechnology: Progress, opportunities and challenges. Nat. Rev. Neurosci. 2006, 7, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Asif, A.K.M.A.H.; Hasan, M.Z. Application of Nanotechnology in Modern Textiles: A Review. Int. J. Curr. Eng. Technol. 2018, 8, 227–231. [Google Scholar]

- Muñoz-Écija, T.; Vargas-Quesada, B.; Chinchilla Rodríguez, Z. Coping with methods for delineating emerging fields: Nanoscience and nanotechnology as a case study. J. Inf. 2019, 13, 100976. [Google Scholar] [CrossRef]

- Satalkar, P.; Elger, B.; Shaw, D. Defining Nano, Nanotechnology and Nanomedicine: Why Should It Matter? Sci. Eng. Ethics 2015, 22, 1255–1276. [Google Scholar] [CrossRef] [PubMed]

- Bale, A.S.; Aditya Khatokar, J.A.; Singh, S.; Bharath, G.; Kiran Mohan, M.K.; Reddy, S.V.; Satheesha, T.; Huddar, S.A. Nanosciences fostering cross domain engineering applications. Mater. Today Proc. 2021, 43, 3428–3431. [Google Scholar] [CrossRef]

- Sawhney, A.P.S.; Condon, B.; Singh, K.V.; Pang, S.S.; Li, G.; Hui, D. Modern Applications of Nanotechnology in Textiles. Text. Res. J. 2008, 78, 731–739. [Google Scholar] [CrossRef]

- Nigam Joshi, P. Green Chemistry for Nanotechnology: Opportunities and Future Challenges. Res. Rev. J. Chem. 2016, 5, 3–4. [Google Scholar]

- Grieneisen, M.; Zhang, M. Nanoscience and Nanotechnology: Evolving Definitions and Growing Footprint on the Scientific Landscape. Small 2011, 7, 2836–2839. [Google Scholar] [CrossRef] [PubMed]

- Mulvaney, P.; Weiss, P. Have Nanoscience and Nanotechnology Delivered? ACS Nano 2016, 10, 7225–7226. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Deng, L.; Hu, W.; Deng, H.; Xiao, S. Surface Segregation and Structural Features of Bimetallic Au−Pt Nanoparticles. J. Phys. Chem. C 2010, 114, 11026–11032. [Google Scholar] [CrossRef]

- Wang, J.; Fan, Y. Lung Injury Induced by TiO2 Nanoparticles Depends on Their Structural Features: Size, Shape, Crystal Phases, and Surface Coating. Int. J. Mol. Sci. 2014, 15, 22258–22278. [Google Scholar] [CrossRef]

- Kolahalam, L.A.; Kasi Viswanath, I.V.; Diwakar, B.S.; Govindh, B.; Reddy, V.; Murthy, Y.L.N. Review on nanomaterials: Synthesis and applications. Mater. Today Proc. 2019, 18, 2182–2190. [Google Scholar] [CrossRef]

- Santos, C.; Gabriel, B.; Blanchy, M.; Neto, V.; Santos, C.S.C.; Menes, O.; Arconada, N. Industrial Applications of Nanoparticles—A Prospective Overview. Mater. Today Proc. 2014, 2, 456–465. [Google Scholar] [CrossRef]

- Lin, G.M.; Shang, M.; Zhang, W.G. Research on nanomaterials and its latest application. Adv. Mater. Res. 2014, 912–914, 305–308. [Google Scholar] [CrossRef]

- Ríos, Á.; Zougagh, M. Recent advances in magnetic nanomaterials for improving analytical processes. TrAC Trends Anal. Chem. 2016, 84, 72–83. [Google Scholar] [CrossRef]

- Teo, B.K.; Sun, X.H. Classification and representations of low-dimensional nanomaterials: Terms and symbols. J. Clust. Sci. 2007, 18, 346–357. [Google Scholar] [CrossRef]

- Saratale, R.G.; Shin, H.S.; Kumar, G.; Benelli, G.; Ghodake, G.S.; Jiang, Y.Y.; Kim, D.S.; Saratale, G.D. Exploiting fruit byproducts for eco-friendly nanosynthesis: Citrus × clementina peel extract mediated fabrication of silver nanoparticles with high efficacy against microbial pathogens and rat glial tumor C6 cells. Environ. Sci. Pollut. Res. 2018, 25, 10250–10263. [Google Scholar] [CrossRef]

- Ealias, A.M.; Saravanakumar, M.P. A review on the classification, characterisation, synthesis of nanoparticles and their application. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 032019. [Google Scholar]

- Kruis, F.; Fissan, H.; Peled, A. Synthesis of nanoparticles in the gas phase for electronic, optical and magnetic applications—A review. J. Aerosol. Sci. 1998, 29, 511–535. [Google Scholar] [CrossRef]

- Daruich De Souza, C.; Ribeiro Nogueira, B.; Rostelato, M.E.C.M. Review of the methodologies used in the synthesis gold nanoparticles by chemical reduction. J. Alloys Compd. 2019, 798, 714–740. [Google Scholar] [CrossRef]

- Dąbrowska, S.; Chudoba, T.; Wojnarowicz, J.; Łojkowski, W. Current trends in the development of microwave reactors for the synthesis of nanomaterials in laboratories and industries: A Review. Crystals 2018, 8, 379. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, C.K. Methods for characterization of nanoparticles. In Advances in Nanomedicine for the Delivery of Therapeutic Nucleic Acids, 1st ed.; Nimesh, S., Chandra, R., Gupta, N., Eds.; Woodhead Publishing: Delhi, India, 2017; pp. 44–58. [Google Scholar]

- Chu, B.; Liu, T. Characterization of nanoparticles by scattering techniques. J. Nanopart. Res. 2000, 2, 29–41. [Google Scholar] [CrossRef]

- Kim, H.Y.; Lee, J.H.; Kim, J.Y.; Lim, W.J.; Lim, S.T. Characterization of nanoparticles prepared by acid hydrolysis of various starches. Starch 2012, 64, 367–373. [Google Scholar] [CrossRef]

- Baer, D.R.; Gaspar, D.J.; Nachimuthu, P.; Techane, S.D.; Castner, D.G. Application of surface chemical analysis tools for characterization of nanoparticles. Anal. Bioanal. Chem. 2010, 396, 983–1002. [Google Scholar] [CrossRef]

- Qian, Q.Z.; Boxman, A.; Chowdhry, U. Nanotechnology in the chemical industry—Opportunities and challenges. J. Nanoparticle Res. 2003, 5, 567–572. [Google Scholar]

- Kashef, M.; Sabouni, A.R. Nanotechnology and the building industry. In Proceedings of the International Conference on Nanotechnology: Fundamentals and Applications, Ottawa, ON, Canada, 4–6 August 2010; pp. 550–558. [Google Scholar]

- Du, S.; Wu, J.; Alshareedah, O.; Shi, X. Nanotechnology in cement-based materials: A review of durability, modeling, and advanced characterization. Nanomaterials 2019, 9, 1213. [Google Scholar] [CrossRef]

- Eftekhari, M.; Mohammadi, S.; Khanmohammadi, M. A hierarchical nano to macro multiscale analysis of monotonic behavior of concrete columns made of CNT-reinforced cement composite. Constr. Build. Mater. 2018, 175, 134–143. [Google Scholar] [CrossRef]

- Choi, Y.C. Cyclic heating and mechanical properties of CNT reinforced cement composite. Compos. Struct. 2021, 256, 113104. [Google Scholar] [CrossRef]

- Jayapalan, A.R.; Lee, B.Y.; Kurtis, K.E. Effect of Nano-sized Titanium Dioxide on Early Age Hydration of Portland Cement. In Nanotechnology in Construction 3; Springer: Berlin/Heidelberg, Germany, 2009; pp. 267–273. [Google Scholar]

- Meng, T.; Yu, Y.; Qian, X.; Zhan, S.; Qian, K. Effect of nano-TiO2 on the mechanical properties of cement mortar. Constr. Build. Mater. 2012, 29, 241–245. [Google Scholar] [CrossRef]

- Wu, M.; Ma, B.; Pan, T.; Chen, S.; Sun, J. Silver-Nanoparticle-Colored Cotton Fabrics with Tunable Colors and Durable Antibacterial and Self-Healing Superhydrophobic Properties. Adv. Funct. Mater. 2016, 26, 569–576. [Google Scholar] [CrossRef]

- Yetisen, A.K.; Qu, H.; Manbachi, A.; Butt, H.; Dokmeci, M.R.; Hinestroza, J.P.; Skorobogatiy, M.; Khademhosseini, A.; Yun, S.H. Nanotechnology in Textiles. ACS Nano 2016, 10, 3042–3068. [Google Scholar] [CrossRef] [PubMed]

- Prieto, O.; Fermoso, J.; Nuñez, Y.; Del Valle, J.L.; Irusta, R. Decolouration of textile dyes in wastewaters by photocatalysis with TiO2. Sol. Energy 2005, 79, 376–383. [Google Scholar] [CrossRef]

- Saravanan, R.; Gracia, F.; Khan, M.M.; Poornima, V.; Gupta, V.K.; Narayanan, V.; Stephen, A. ZnO/CdO nanocomposites for textile effluent degradation and electrochemical detection. J. Mol. Liq. 2015, 209, 374–380. [Google Scholar] [CrossRef]

- Saravanan, R.; Karthikeyan, N.; Gupta, V.K.; Thirumal, E.; Thangadurai, P.; Narayanan, V.; Stephen, A. ZnO/Ag nanocomposite: An efficient catalyst for degradation studies of textile effluents under visible light. Mater. Sci. Eng. C 2013, 33, 2235–2244. [Google Scholar] [CrossRef] [PubMed]

- Sathishkumar, P.; Sweena, R.; Wu, J.J.; Anandan, S. Synthesis of CuO-ZnO nanophotocatalyst for visible light assisted degradation of a textile dye in aqueous solution. Chem. Eng. J. 2011, 171, 136–140. [Google Scholar] [CrossRef]

- Xie, H.; Ye, X.; Duan, K.; Xue, M.; Du, Y.; Ye, W.; Wang, C. CuAu–ZnO–grapheme nanocomposite: A novel graphene-based bimetallic alloy-semiconductor catalyst with its enhanced photocatalytic degradation performance. J. Alloys Compd. 2015, 636, 40–47. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Parveen, T.; Umar, K.; Mohamad Ibrahim, M.N. Role of Nanomaterials in the Treatment of Wastewater: A Review. Water 2020, 12, 495. [Google Scholar] [CrossRef]

- Alvarez, P.J.J.; Chan, C.K.; Elimelech, M.; Halas, N.J.; Villagrán, D. Emerging opportunities for nanotechnology to enhance water security. Nat. Nanotechnol. 2018, 13, 634–641. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, Z.; Lin, S.; Jin, H.; Gao, S.; Zhu, Y.; Jin, J. Nanoparticle-templated nanofiltration membranes for ultrahigh performance desalination. Nat. Commun. 2018, 9, 2004. [Google Scholar] [CrossRef] [PubMed]

- Jassby, D.; Cath, T.Y.; Buisson, H. The role of nanotechnology in industrial water treatment. Nat. Nanotechnol. 2018, 13, 670–672. [Google Scholar] [CrossRef] [PubMed]

- Danwittayakula, S.; Jaisaib, M.; Duttab, J. Efficient solar photocatalytic degradation of textile wastewater usingZnO/ZTO composites. Appl. Catal. B Environ. 2015, 163, 1–8. [Google Scholar] [CrossRef]

- Qian, C.; Yin, J.; Zhao, J.; Li, X.; Wang, S.; Bai, Z.; Jiao, T. Facile preparation and highly efficient photodegradation performances of self-assembled Artemia eggshell-ZnO nanocomposites for wastewater treatment. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125752. [Google Scholar] [CrossRef]

- Botsa, S.M.; Basavaiah, K. Removal of Nitrophenols from wastewater by monoclinic CuO/RGO nanocomposite. Nanotechnol. Environ. Eng. 2019, 4, 1–7. [Google Scholar] [CrossRef]

- Gao, S.J.; Shi, Z.; Zhang, W.B.; Zhang, F.; Jin, J. Photoinduced superwetting single-walled carbon nanotube/TiO2 ultrathin network films for ultrafast separation of oil-in-water emulsions. ACS Nano 2014, 8, 6344–6352. [Google Scholar] [CrossRef]

- Campagnolo, L.; Lauciello, S.; Athanassiou, A.; Fragouli, D. Au/ZnO hybrid nanostructures on electrospun polymeric matsfor improved photocatalytic degradation of organic pollutants. Water 2019, 11, 1787. [Google Scholar] [CrossRef]

- Handford, C.E.; Dean, M.; Henchion, M.; Spence, M.; Elliott, C.T.; Campbell, K. Implications of nanotechnology for the agri-food industry: Opportunities, benefits and risks. Trends Food Sci. Technol. 2014, 40, 226–241. [Google Scholar] [CrossRef]

- Ndlovu, N.; Mayaya, T.; Muitire, C.; Munyengwa, N. Nanotechnology Applications in Crop Production and Food Systems. Int. J. Plant Breed. 2020, 7, 624–634. [Google Scholar]

- Bratovcic, A.; Hikal, W.; Said-Al Ahl, H.; Tkachenko, K.; Baeshen, R.; Sabra, A.; Sany, H. Nanopesticides and Nanofertilizers and Agricultural Development: Scopes, Advances and Applications. Open J. Ecol. 2021, 11, 301–316. [Google Scholar] [CrossRef]

- Raliya, R.; Saharan, V.; Dimkpa, C.; Biswas, P. Nanofertilizer for Precision and Sustainable Agriculture: Current State and Future Perspectives. J. Agric. Food Chem. 2018, 66, 6487–6503. [Google Scholar] [CrossRef]

- Chhipa, H. Nanofertilizers and nanopesticides for agriculture. Environ. Chem. Lett. 2017, 15, 15–22. [Google Scholar] [CrossRef]

- Dimkpa, C.O.; Bindraban, P.S. Nanofertilizers: New Products for the Industry? J. Agric. Food Chem. 2018, 66, 6462–6473. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.A. Nanotechnology innovations, industrial applications and patents. Environ. Chem. Lett. 2017, 15, 185–191. [Google Scholar] [CrossRef]

- Tarafdar, J.C.; Raliya, R.; Mahawar, H.; Rathore, I. Development of Zinc Nanofertilizer to Enhance Crop Production in Pearl Millet. Agric. Res. 2014, 3, 257–262. [Google Scholar] [CrossRef]

- Wang, H.; Kou, X.; Pei, Z.; Xiao, J.Q.; Shan, X.; Xing, B. Physiological effects of magnetite (Fe3O4) nanoparticles on perennial ryegrass (Lolium perenne L.) and pumpkin (Cucurbita mixta) plants. Nanotoxicology 2021, 5, 30–42. [Google Scholar] [CrossRef]

- Dimkpa, C.O.; McLean, J.E.; Britt, D.W.; Anderson, A.J. Bioactivity and biomodification of Ag, ZnO, and CuO nanoparticles with relevance to plant performance in agriculture. Ind. Biotechnol. 2012, 8, 344–357. [Google Scholar] [CrossRef]

- He, X.; Hwang, H.M. Nanotechnology in food science: Functionality, applicability, and safety assessment. J. Food Drug Anal. 2016, 24, 671–681. [Google Scholar] [CrossRef]

- Li, W.L.; Li, X.H.; Zhang, P.P.; Xing, Y.G. Development of nano-ZnO coated food packaging film and its inhibitory effect on Escherichia coli in vitro and in actual tests. Adv. Mater. Res. 2010, 152, 489–492. [Google Scholar] [CrossRef]

- Eljeeva Emerald, F.M.; Pushpadass, H.A.; Joseph, D.; Jaya, S.V. Impact of Nanotechnology in Beverage Processing. In Innovative Food Processing Technologies, 1st ed.; Muthukumarappan, K., Knoerzer, K., Eds.; Elsevier E-book: Amsterdam, The Netherlands, 2021; pp. 688–700. [Google Scholar]

- Othman, S.H.; Abd Salam, N.R.; Zainal, N.; Kadir Basha, R.; Talib, R.A. Antimicrobial activity of TiO2 nanoparticle-coated film for potential food packaging applications. Int. J. Photoenergy 2014, 2014, 1–6. [Google Scholar] [CrossRef]

- Ferreira, L.M.P.; Bayraktar, E.; Miskioglu, I.; Robert, M.H. Design and physical properties of multifunctional structural composites reinforced with nanoparticles for aeronautical applications. Adv. Mater. Process. Technol. 2017, 3, 33–44. [Google Scholar] [CrossRef]

- Luna-Ochoa, S.; Robles-Belmont, E.; Suaste-Gomez, E. A profile of Mexico’s technological agglomerations: The case of the aerospace and nanotechnology industry in Querétaro and Monterrey. Technol. Soc. 2016, 46, 120–125. [Google Scholar] [CrossRef]

- Viscardi, M.; Arena, M.; Guadagno, L.; Vertuccio, L.; Barra, G. Multi-functional nanotechnology integration for aeronautical structures performance enhancement. Int. J. Struct. Integr. 2018, 9, 737–752. [Google Scholar] [CrossRef]

- Iqbal, A.; Saeed, A.; Ul-Hamid, A. A review featuring the fundamentals and advancements of polymer/CNT nanocomposite application in aerospace industry. Polym. Bull. 2021, 78, 539–557. [Google Scholar] [CrossRef]

- De Vivo, B.; Lamberti, P.; Tucci, V.; Guadagno, L.; Vertuccio, L.; Vittoria, V.; Sorrentino, A. Comparison of the physical properties of epoxy-based composites filled with different types of carbon nanotubes for aeronautic applications. Adv. Polym. Technol. 2012, 31, 205–218. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Muhammad, B. Review of Applications of Polymer/Carbon Nanotubes and Epoxy/CNT Composites. Polym. Plast. Technol. Eng. 2016, 55, 1167–1191. [Google Scholar] [CrossRef]

- Bazile, D.V. Nanotechnologies in drug delivery—An industrial perspective. J. Drug Deli. Sci. Technol. 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Namita Ashish, S. Nanotechnology definitions, research, industry and property rights. In Nanoscience in Food and Agriculture 1, Sustainable Agriculture Reviews 20; Ranjan, S., Dasgupta, N., Lichtfouse, E., Eds.; Springer International Publishing: Basel, Switzerland, 2016; pp. 43–64. [Google Scholar]

- Palit, S.; Hussain, C.M. Nanodevices applications and recent advancements in nanotechnology and the global pharmaceutical industry. In Nanomaterials in Diagnostic Tools and Devices; Kanchi, S., Sharma, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 395–415. [Google Scholar]

- Patra, J.K.; Das, G.; Fraceto, L.F.; Campos, E.V.R.; del Pilar Rodriguez-Torres, M.; Acosta-Torres, L.S.; Diaz-Torres, L.A.; Grillo, R.; Swamy, M.K.; Sharma, S.; et al. Nano based drug delivery systems: Recent developments and future prospects. J. Nanobiotechnol. 2018, 16, 71. [Google Scholar] [CrossRef]

- Kunrath, M.F.; Hubler, R.; Shinkai, R.S.A.; Teixeira, E.R. Application of TiO2 Nanotubes as a Drug Delivery System for Biomedical Implants: A Critical Overview. ChemistrySelect 2018, 3, 11180–11189. [Google Scholar] [CrossRef]

- Grigore, M.E.; Biscu, E.R.; Holban, A.M.; Gestal, M.C.; Grumezescu, A.M. Methods of synthesis, properties and biomedical applications of CuO nanoparticles. Pharmaceuticals 2016, 9, 75. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Jiang, H.; Wan, L.; Zhao, Q.; Jiang, T.; Wang, B.; Wang, S. Potential application of functional porous TiO2 nanoparticles in light-controlled drug release and targeted drug delivery. Acta Biomater. 2015, 13, 354–363. [Google Scholar] [CrossRef]

- Sathishkumar, P.; Li, Z.; Govindan, R.; Jayakumar, R.; Wang, C.; Long Gu, F. Zinc oxide-quercetin nanocomposite as a smart nano-drug delivery system: Molecular-level interaction studies. Appl. Surf. Sci. 2021, 536, 147741. [Google Scholar] [CrossRef]

- Gholamali, I.; Hosseini, S.N.; Alipour, E.; Yadollahi, M. Preparation and Characterization of Oxidized Starch/CuO Nanocomposite Hydrogels Applicable in a Drug Delivery System. Starch/Staerke 2019, 71, 1800118. [Google Scholar] [CrossRef]

- Ahmadian, Y.; Bakravi, A.; Hashemi, H.; Namazi, H. Synthesis of polyvinyl alcohol/CuO nanocomposite hydrogel and its application as drug delivery agent. Polym. Bull. 2019, 76, 1967–1983. [Google Scholar] [CrossRef]

- Pandit, S.; Dasgupta, D.; Dewan, N.; Ahmed, P. Nanotechnology based biosensors and its application. Pharm. Innov. J. 2016, 5, 18–25. [Google Scholar]

- George, J.M.; Antony, A.; Mathew, B. Metal oxide nanoparticles in electrochemical sensing and biosensing: A review. Microchim. Acta 2018, 185, 358. [Google Scholar] [CrossRef]

- Arya, S.K.; Saha, S.; Ramirez-Vick, J.E.; Gupta, V.; Bhansali, S.; Singh, S.P. Recent advances in ZnO nanostructures and thin films for biosensor applications: Review. Anal. Chim. Acta 2012, 737, 1–21. [Google Scholar] [CrossRef]

- Ghodake, G.; Shinde, S.; Kadam, A.; Saratale, R.G.; Saratale, G.D.; Syed, A.; Shair, O.; Alsaedi, M.; Kim, D.Y. Gallic acid-functionalized silver nanoparticles as colorimetric and spectrophotometric probe for detection of Al3+ in aqueous medium. J. Ind. Eng. Chem. 2020, 82, 243–253. [Google Scholar] [CrossRef]

- Exley, C.; Clarkson, E. Aluminium in human brain tissue from donors without neurodegenerative disease: A comparison with Alzheimer’s disease, multiple sclerosis and autism. Sci. Rep. 2020, 10, 7770. [Google Scholar] [CrossRef] [PubMed]

- Pathakoti, K.; Manubolu, M.; Hwang, H.M. Nanotechnology applications for environmental industry. In Handbook of Nanomaterials for Industrial Applications; Chaudhery, M.H., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 894–907. [Google Scholar]

- Desai, M.A.; Vyas, A.N.; Saratale, G.D.; Sartale, S.D. Zinc oxide superstructures: Recent synthesis approaches and application for hydrogen production via photoelectrochemical water splitting. Int. J. Hydrogen Energy 2019, 44, 2091–2127. [Google Scholar] [CrossRef]

- Katz, L.; Dewan, K.; Bronaugh, R. Nanotechnology in cosmetics. Food Chem. Toxicol. 2015, 85, 127–137. [Google Scholar] [CrossRef] [PubMed]

- Jaroenworaluck, A.; Sunsaneeyametha, W.; Kosachan, N.; Stevens, R. Characteristics of silica-coated TiO2 and its UV absorption for sunscreen cosmetic applications. Surf. Interface Anal. 2006, 38, 473–477. [Google Scholar] [CrossRef]

- Leong, H.J.; Jang, I.; Hyun, K.S.; Jung, S.K.; Hong, G.H.; Jeong, H.A.; Oh, S.G. Preparation of alpha-bisabolol and phenylethyl resorcinol/TiO2 hybrid composites for potential applications in cosmetics. Int. J. Cosmet. Sci. 2016, 38, 524–534. [Google Scholar] [CrossRef]

- García-Mesa, J.C.; Montoro-Leal, P.; Rodríguez-Moreno, A.; López Guerrero, M.M.; Vereda Alonso, E.I. Direct solid sampling for speciation of Zn2+ and ZnO nanoparticles in cosmetics by graphite furnace atomic absorption spectrometry. Talanta 2021, 223, 121795. [Google Scholar] [CrossRef]

- Nia, S.; Hanb, F.; Wanga, W.; Hana, D.; Baoa, Y.; Hana, D.; Wanga, H.; Niua, L. Innovations upon antioxidant capacityevaluation for cosmetics: Aphotoelectrochemical sensor exploitation based on N-dopedgraphene/TiO2 nanocomposite. Sens. Actuators B 2018, 259, 963–971. [Google Scholar] [CrossRef]

- Feng, X.; Liu, A.; Cheng, J. Applications and development of nanotechnology in machinery industry. Adv. Mater. Res. 2010, 121, 5–10. [Google Scholar] [CrossRef]

- Hernández Battez, A.; Viesca, J.L.; González, R.; Blanco, D.; Asedegbega, E.; Osorio, A. Friction reduction properties of a CuO nanolubricant used as lubricant for a NiCrBSi coating. Wear 2010, 268, 325–328. [Google Scholar] [CrossRef]

- Meindl, J.D. Beyond Moore’s Law: The Interconnect Era. Comput. Sci. Eng. 2003, 5, 20–24. [Google Scholar] [CrossRef]

- Kish, L.B. End of Moore’s law: Thermal (noise) death of integration in micro and nano electronics. Phys. Lett. A 2002, 305, 144–149. [Google Scholar] [CrossRef]

- Esmaeili, A. Applications of Nanotechnology in Oil and Gas Industry. In Proceedings of the Petrotech Conference, PETROTECH–2009, P09–076, New Delhi, India, 11–15 January 2009. [Google Scholar]

- Nabhani, N.; Emami, M.; Moghadam, A.B.T. Application of nanotechnology and nanomaterials in oil and gas industry. AIP Conf. Proc. 2011, 1415, 128–131. [Google Scholar]

- Ponmani, S.; Nagarajan, R.; Sangwai, J. Applications of nanotechnology for upstream oil and gas industry. J. Nano Res. 2013, 24, 7–15. [Google Scholar] [CrossRef]

- Saththasivam, J.; Yiming, W.; Wang, K.; Jin, J.; Liu, Z. A Novel Architecture for Carbon Nanotube Membranes towards Fast and Efficient Oil/water Separation. Sci. Rep. 2018, 8, 7418. [Google Scholar] [CrossRef] [PubMed]

- Mamalis, A.G. Recent advances in nanotechnology. J. Mater. Process. Technol. 2007, 181, 52–58. [Google Scholar] [CrossRef]

- Jadhav, S.S.; Jadhav, S.V. Application of Nanotechnology in Modern Computers. In Proceedings of the 2018 International Conference on Circuits and Systems in Digital Enterprise Technology (ICCSDET), Kottayam, India, 21–22 December 2018. [Google Scholar]

- Mitchell, S.; Qin, R.; Zheng, N.; Pérez-Ramírez, J. Nanoscale engineering of catalytic materials for sustainable technologies. Nat. Nanotechnol. 2021, 16, 129–139. [Google Scholar] [CrossRef]

- Malani, A.S.; Chudhari, A.D.; Sambje, R.U. A Review on Applications of Nanotechnology in Automotive Industry. Int. J. Mech. Mechatron. Eng. 2016, 10, 36–40. [Google Scholar]

- Paradise, M.; Goswami, T. Carbon nanotubes—Production and industrial applications. Mater. Des. 2007, 28, 1477–1489. [Google Scholar] [CrossRef]

- Hazrati, M.K.; Javanshir, Z.; Bagheri, Z. B24N24 fullerene as a carrier for 5-fluorouracil anti-cancer drug delivery: DFT studies. J. Mol. Graph. Model. 2017, 77, 17–24. [Google Scholar] [CrossRef] [PubMed]

- Shi, J.; Zhang, H.; Wang, L.; Li, L.; Wang, H.; Wang, Z.; Li, Z.; Chen, C.; Hou, L.; Zhang, C.; et al. PEI-derivatized fullerene drug delivery using folate as a homing device targeting to tumor. Biomaterials 2013, 34, 251–261. [Google Scholar] [CrossRef]

- Schroeder, B.C.; Li, Z.; Brady, M.A.; Faria, G.C.; Ashraf, R.S.; Takacs, C.J.; Cowart, J.S.; Duong, D.T.; Chiu, K.H.; Tan, C.H.; et al. Enhancing Fullerene-Based Solar Cell Lifetimes by Addition of a Fullerene Dumbbell. Angew. Chem. 2014, 53, 12870–12875. [Google Scholar] [CrossRef]

- Mohajeri, A.; Omidvar, A. Fullerene-based materials for solar cell applications: Design of novel acceptors for efficient polymer solar cells—A DFT study. Phys. Chem. Chem. Phys. 2015, 17, 22367–22376. [Google Scholar] [CrossRef]

- Jaros, A.; Bonab, E.F.; Straka, M.; Foroutan-Nejad, C. Fullerene-based switching molecular diodes controlled by oriented external electric fields. J. Am. Chem. Soc. 2019, 141, 19644–19654. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Hung, Y.; Liau, I.; Huang, G.S. Assessment of the In Vivo Toxicity of Gold Nanoparticles. Nanoscale Res. Lett. 2009, 4, 858–864. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.M.; Hess, K.L.; Gearhart, J.M.; Geiss, K.T.; Schlager, J.J. In Vitro Toxicity of Nanoparticles in BRL 3A Rat Liver Cells. Toxicol. Vitr. 2005, 19, 975–983. [Google Scholar] [CrossRef] [PubMed]

- Buzea, C.; Pacheco, I.I.; Robbiec, K. Nanomaterials and nanoparticles: Sources and toxicity. Biointerphases 2007, 2, 17–71. [Google Scholar] [CrossRef]

- Burello, E.; Worth, A. Predicting toxicity of nanoparticles. Nat. Nanotechnol. 2011, 6, 138–139. [Google Scholar] [CrossRef]

- Shea, C.M. Future management research directions in nanotechnology: A case study. J. Eng. Technol. Manag. 2005, 22, 185–200. [Google Scholar] [CrossRef]

| Dimension | Ranges | Example |

|---|---|---|

| Zero-D | No dimensions are in the nanoscale range | Nanoporous material |

| One-D | One dimension is in the nanoscale range | Graphene sheets |

| Two-D | Two dimensions are in the nanoscale range | Nanowires, Biopolymers |

| Three-D | Three dimensions are in the nanoscale range | Quantum dots (QDs), Dendrimers |

| Industry | Molecular Nanomaterials Used | Applications | References |

|---|---|---|---|

| Construction Industry | Nano-TiO2 | To increase photocatalytic properties of the cement sample. | [32] |

| CNT, nano-MgO, nano-smectite-based clay | To reinforce cement composite. | [32,33] | |

| Textile Industry | Nano-TiO2, nano-ZnO | Engrossing and dissipating UV radiation more proficiently | [6] |

| CNT-reinforced polymer composite fibers | To improve strength and durability and to reduce weight. | [38] | |

| Water Treatment Industry | CNTs | In biological treatment of industrial wastewater. | [47] |

| Agriculture Industry | Carbon nanotubes, nano oxides of Cu, Ag, Mn, Mo, Zn, Fe, Si and Ti | To develop nanopesticide and nanofertilizer | [57] |

| Food Industry | ZnO nanoparticle with polystyrene film | Used for food packaging | [53,63] |

| Silver nanoparticles and nanocomposites | Antibacterial agents for improving food safety | [53,63] | |

| Aeronautics Industry | Fe3O4 nano powders | To manufacture multifunctional structural composites | [67] |

| Medicinal Industry | siRNA containing nanoparticles | To enable drug delivery system for cancer and other genetic diseases | [73] |

| Environmental Industry | TiO2 and ZnO nanoparticles | Used for degradation of organic pollutants in water and air. | [88] |

| Cosmetics Industry | TiO2 and ZnO nanoparticles | Used in sunscreen non-prescription drug products | [90] |

| Polycaprolactone (PCL) nanocapsules | To encapsulate elements for use in cosmetic items | [90] | |

| Silver nanomaterials | Used in consumer product as preservative agent | [90] | |

| Machinery Industry | Nano-titanium nitride | To enhance the material strength, hardness and fracture toughness. | [95] |

| Oil and Gas Industry | Air-suspended Ni-Fe nanoparticles | Injected in the hydrate formatin to penetrate deep into hydrate reservoir by passing through the cavities | [74] |

| Computer Industry | Nanotube/carbon nanotube | Nanotubes are applied to manufacture smaller transistors or electronic devices | [107] |

| Medicine and Computer Industries | Flullerene | One of the most important medical application of fullerene is the controlled release of drugs for cancer and other diseases. In the electronic industry, it has useful applications in solar cells, diode, and semiconductors. Fullerene has potential applications in the pharmaceuticals as well as in nanomedicine. | [108,109,110,111,112] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subhan, M.A.; Choudhury, K.P.; Neogi, N. Advances with Molecular Nanomaterials in Industrial Manufacturing Applications. Nanomanufacturing 2021, 1, 75-97. https://doi.org/10.3390/nanomanufacturing1020008

Subhan MA, Choudhury KP, Neogi N. Advances with Molecular Nanomaterials in Industrial Manufacturing Applications. Nanomanufacturing. 2021; 1(2):75-97. https://doi.org/10.3390/nanomanufacturing1020008

Chicago/Turabian StyleSubhan, Md Abdus, Kristi Priya Choudhury, and Newton Neogi. 2021. "Advances with Molecular Nanomaterials in Industrial Manufacturing Applications" Nanomanufacturing 1, no. 2: 75-97. https://doi.org/10.3390/nanomanufacturing1020008

APA StyleSubhan, M. A., Choudhury, K. P., & Neogi, N. (2021). Advances with Molecular Nanomaterials in Industrial Manufacturing Applications. Nanomanufacturing, 1(2), 75-97. https://doi.org/10.3390/nanomanufacturing1020008