Comparative Efficacy of Latent Fingerprint Development Techniques in Varying Aquatic Environments of Rajasthan’s Shekhawati Region: Analyzing the Impact of Water Composition and Surface Interactions

Abstract

1. Introduction

1.1. Hard Water from Rajasthan’s Shekhawati Region

1.2. Commercial Mineral Water

1.3. Rainwater

- i.

- Evaluate the influence of different water compositions on the quality and recoverability of latent fingerprints on non-porous surfaces.

- ii.

- Three development techniques (powder dusting, activated charcoal-based SPR, and cyanoacrylate fuming) are assessed for their effectiveness under varying submersion conditions.

- iii.

- Identify optimal recovery protocols for each substrate type, water composition, and duration of submersion.

2. Methodology

2.1. Materials and Equipment

2.1.1. Substrates

2.1.2. Development Materials

- Powder Method

- Small Particle Reagent (SPR) Method

- Cyanoacrylate Fuming Method

2.1.3. Additional Equipment

2.1.4. Water Samples

- Hard Water

- Mineral Water

- Rainwater

2.1.5. Environmental Conditions

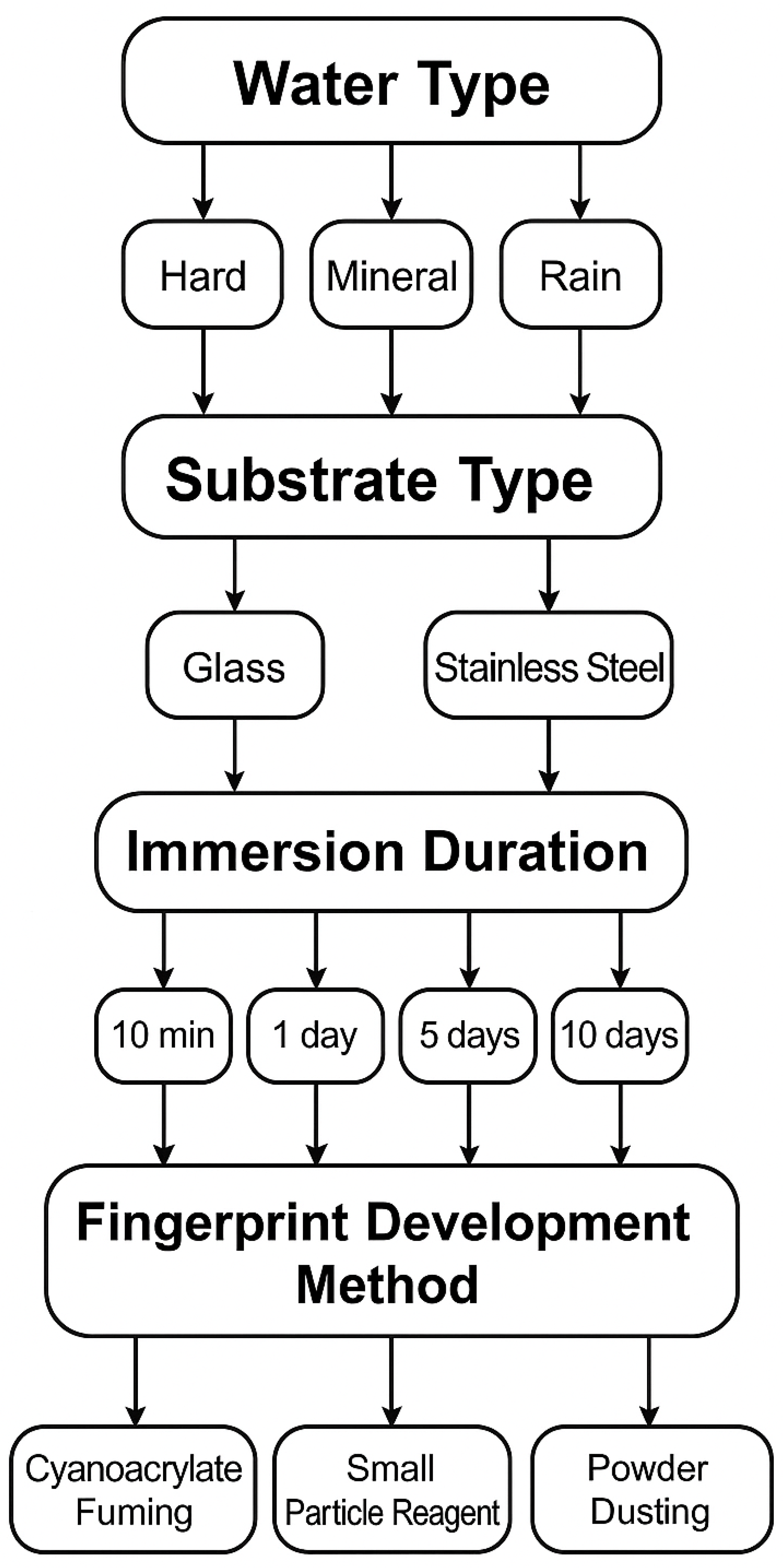

2.2. Experimental Design

2.2.1. Fingerprint Deposition

2.2.2. Submersion Protocol

2.2.3. Development Techniques

- Powder Method

- Small Particle Reagent (SPR) Method

- Cyanoacrylate Fuming Method

2.2.4. Fingerprints Examination

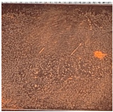

- Initial Capture: All the images were scanned at a resolution of 600 dpi with a calibrated flatbed scanner with a constant lighting on (ambient temperature: 35 °C, relative humidity: 88%).

- Basic Normalization: The brightness and contrast were uniformly applied in all images using the standardized parameters (brightness + 10% contrast + 15%).

- Background Optimization: Future research will use high-quality image processing software (e.g., Adobe Photoshop with forensic plug-ins, ImageJ, or special fingerprint processing software, e.g., NIST Biometric Image Software) to reduce the effect of the background whilst maintaining genuine ridge features. In the current study, the background suppressions were intentionally restricted to prevent the artifacts that might cause distortion of the ridge morphology.

- No Artificial Enhancement: Other methods of digital enhancement (edge sharpening, sophisticated contrast control or ridges reconstruction algorithms) were tested, but these did not leave the ridge structure intact and produced artifacts and distortions. Since the maintenance of real ridges traits is a key factor in forensic interpretation, no artificial improvement other than equalization of brightness and contrast was used.

- Assessment Protocol:

- Scoring System and Forensic Utility:

- Scores 4–5 (Good to Excellent): Prints that can be compared and possibly identified, and have enough amount of ridge detail to elicit minutiae.

- Score 3 (Fair): Prints that have poor forensic value, and need to be improved or developed further.

- Scores 1–2 (Poor to Very Poor): Prints unsuitable for identification purposes

- Limitations and Future Improvements:

- Minutiae-Based Analysis: both Manual and Automated Counting of Type I (ridge endings) and Type II (bifurcations) minutiae by a group of independent examiners.

- Automated Quality Metrics: use of specialized software (e.g., NIST Biometric Image Software, VeriFinger SDK) for objective quality scores.

- Threshold Standards: usage of minimum number of minutiae to be used in positive identification in accordance with the Indian forensic guidelines and international guidelines (usually 12-point standard).

- Advanced Imaging: adoption of forensic light sources, fluorescent dyes after development, and special photography guidelines.

- Inter-Laboratory Validation: cooperation with forensic laboratories that have Automated Fingerprint Identification System (AFIS) to measure quality on the same basis.

3. Results and Discussion

3.1. Fingerprint Recovery on Glass Slides

3.2. Analysis of Fingerprint Recovery on Stainless Steel Blades

3.3. Statistical Analysis

4. Discussion

4.1. Glass Slides Fingerprint Recovery

4.2. Fingerprint Recovery on Stainless Steel Blades

4.3. Statistical Analysis Using Chi-Square

4.4. Methodological Considerations and Quality Assessment

- Image Quality and Visual Documentation Limitations:

- State of the Imaging: forensic light sources (alternate light sources, UV light) and high-resolution digital microscopy.

- Fluorescent Enhancement: fluorescent dyes (e.g., Rhodamine 6G, Basic Yellow 40) should be applied after cyanoacrylate treatment in order to increase contrast to facilitate photography.

- Specialized Software: it is necessary to implement a background suppressing software (Adobe Photoshop with forensics plug-ins, ImageJ with Ridge detection algorithms, or commercial fingerprint analysis packages) that will be able to suppress backgrounds without removing ridges.

- Standardized Procedures: implementation of SWGFAST (Scientific Working Group on Friction Ridge Analysis, Study and Technology) principles of fingerprint photography and documentation.

- Multi-Modality: white light, oblique lighting, and reflected ultraviolet imaging (RUVIS) are used to produce a comprehensive documentation.

- Objective Quality Metrics and Quantitative Analysis:

- Proposed Quantitative Metrics for Future Studies:

- 1.

- Minutiae Count Analysis:

- ○

- Counting of Type I (ridge endings) and Type II (ridge bifurcations) minutiae manually by various independent examiners.

- ○

- Setting of a threshold value according to the minimum requirements of identification (12 points standard in most jurisdictions, although, again, this differs across countries).

- ○

- Comparison with other jurisdictional standards like the ones prescribed by the National Crime Records Bureau (NCRB) of India.

- 2.

- Ridge Flow Continuity Index:

- ○

- Measures of ridge flow interruptions per unit area quantitatively.

- ○

- Ridge width and clarity measurement.

- 3.

- Automated Quality Scores:

- ○

- Application of NIST Fingerprint Image Quality (NFIQ) algorithm.

- ○

- Commercial AFIS quality metrics (e.g., match scores, quality flags) are used.

- ○

- The use of ISO/IEC 29794-1 standards of biometric sample quality [38].

- 4.

- Inter-Examiner Reliability:

- ○

- Statistical confirmation based on the kappa coefficient of Cohen when it comes to categorical measurements.

- ○

- Coefficients of intraclass correlation coefficient (ICC) on continuous measures.

- ○

- Random duplicate analysis of test–retest reliability.

- Justification for Current Methodology:

- Equipment Availability: AFIS or software to detect minutiae are not available to many forensic laboratories in rural and semi-urban locations.

- Extreme Degradation: a significant number of samples in this experiment (especially at 5- and 10-day immersion times) showed such intense degradation that they could not be reliably counted using the manual method even at a minutiae level.

- Practical Relevance: the scoring system is also directly proportional to the decision-making of field investigators: is this print useful to be analyzed further or not?

- Establishment of Threshold Standards:

- Minimum Minutiae Count: prints must contain ≥12 clearly identifiable minutiae points for potential identification (adjustable based on jurisdictional requirements).

- Ridge Clarity Index: development of a quantitative metric assessing ridge edge sharpness and contrast using image analysis software.

- Comparison Standards: review of qualitative scores with quantitative measures in order to authenticate the scoring system employed in the study.

4.5. Environmental and Chemical Factors

- Temperature and pH Considerations:

- Ion–Residue Interactions:

- Mechanisms of Degradation:

- Practical Forensic Implications:

- Rapid Evidence Collection: evidence that is submerged in hard water must be given priority to recover and process it immediately.

- Water Sampling: sampling of water at crime scenes can be used to analyze the water samples chemically and can assist in predicting the probability of fingerprint preservation.

- Method Selection: cyanoacrylate fuming should be the initial technique of development in situations where submersion is of hard water.

- Chain of Custody: detailed documentation of water exposure conditions should be included in evidence documentation

4.6. Study Limitations and Methodological Constraints

- Experimental Design Limitations:

- 1.

- Controlled Laboratory Conditions: the experiments were conducted under controlled laboratory conditions (constant temperature: 35 °C, relative humidity: 88%), which may not fully replicate the complexity of natural aquatic environments. Real-world crime scenes involve additional variables such as the following:

- ○

- Water current and turbulence

- ○

- Sediment and particulate contamination

- ○

- Sunlight exposure and UV degradation

- ○

- Diurnal temperature fluctuations

- ○

- Presence of aquatic vegetation

- 2.

- Biological and Microbiological Factors: There was no independent analysis of factors like biofilm formation, colonization, and microbial activity that might also have a further effect on residue degradation. Fingerprint residues contain organic constituents that microorganisms can process in order to degrade them faster than in the case with chemical factors only.

- 3.

- Single Donor Limitation: The fingerprints were taken on one volunteer to minimize inter-individual differences in the composition of the residues. Although this method provides consistency to compare with the previous analysis, it restricts the extrapolation to a spectrum of fingerprint patterns. Future research is required to include the following:

- ○

- Various donors of different sebaceous glands activity.

- ○

- Various ages (juvenile and adult prints).

- ○

- Male and female donors to determine the hormonal effects on the residue composition.

- ○

- Plastic materials (polyethylene, polypropylene, PVC).

- ○

- Surfaces made of ceramics and porcelain.

- ○

- Painted or coated metals.

- ○

- Laminated surfaces.

- 4.

- Fixed Time Intervals: the time intervals that were chosen (10 min, 1 day, 5 days, 10 days) might not fully show the degradation kinetics. Sampling more often (e.g., every hour during the first 24 h) may indicate some critical transition points.

- Assessment and Documentation Limitations:

- Subjective Scoring System: The five-point qualitative scoring system is practical and representative of forensic utility, although it is not as quantitative as minutiae-based analysis or automated quality measures. This restriction has been discussed in detail in Section 4.4.

- Image Quality Constraints: As it has been admitted, the process of visual recording of poor fingerprints is quite difficult by nature. The clarity and resolution of the images provided indicate real-life circumstances of forensic conditions, as opposed to a lack of photons; however, it can be observed that further research would be improved by the use of more sophisticated imaging modalities.

- Limited Development Technique Variations: There are many variations in each technique (cyanoacrylate, SPR, powder) (e.g., different powder compositions, SPR surfactant concentration, cyanoacrylate exposure time). This experiment used conventional procedures without a systematic investigation of the optimization of individual method.

- Environmental Control Limitations:

- Temperature and pH: These factors were not manipulated separately to determine their respective effect on degradation as they were monitored.

- Water Chemistry Complexity: There are hundreds of dissolved compounds in the natural water sources. Major ions, which were the subject of the study, were Ca2+, Mg2+, and F−, but the remaining were not analyzed:

- ○

- Trace metals

- ○

- Organic pollutants

- ○

- Dissolved oxygen levels

- ○

- Potential of oxidation–reduction

- ○

- Total dissolved solids (TDS)

- Statistical and Analytical Limitations:

- Sample Size: Although all conditions were repeated thrice, the sample sizes could be larger, which would enhance the statistical power and allow identification of the nuanced effects.

- Statistical Tests: Chi-Square tests suit categorical data but fail to give the scale of effects. Future research is required to include the following:

- ○

- Continuous variables analysis of variance (ANOVA).

- ○

- Multiple variables regression to predict quality scores.

- ○

- Survival analysis in order to model the kinetics of degradation.

- Generalizability Considerations:

- Reproducibility and Validation:

5. Conclusions

- Methodological Contributions and Future Directions:

- Specific Recommendations for Future Research:

- Objective Minutiae-Based Quality Metrics:

- i.

- Counting of Type II and Type I minutiae Manual and automated (Type I and Type II) Minutiae counting.

- ii.

- Setting of threshold values that corresponded to the forensic identification standards (e.g., 12-point minimum required to be identified as positive).

- iii.

- Measures of continuity of ridge flows and quantitative clarity.

- iv.

- Use of universal measure of biometric quality (ISO/IEC 29794-1, NIST NFIQ) [38].

- Advanced Imaging and Documentation Techniques:

- i.

- Application of forensic light sources (alter light sources, UV light, RUVIS).

- ii.

- Introduction of fluorescent dyes after development of increased contrast.

- iii.

- Background suppressing image processing software with background preserving ridges.

- iv.

- Multi-imaging (white light and oblique lighting and reflected UV) of complete documentation.

- v.

- Implementation of SWGFAST guidelines of standardized fingerprint photography.

- Expanded Experimental Design:

- i.

- Several fingerprint donors to determine inter-individual compositional variability.

- ii.

- A wide range of ages and both sexes in order to measure the influence of hormones and age.

- iii.

- Other types of substrates (plastics, ceramics, coated metals, painted surfaces, etc.).

- iv.

- Long time series with increased sampling rate to obtain degradation kinetics.

- Independent Environmental Variable Analysis:

- i.

- Controlled independent variable systematic variation in temperature (10–40degC range).

- ii.

- pH change (4–9 range) to measure the acidity/alkalinity effects.

- iii.

- Evaluation of water flow dynamics (static and flowing water).

- iv.

- Assessing the effects of UV radiation and sunlight degradation.

- v.

- Microbiological tests such as biofilm formation and colonization of bacteria.

- Advanced Chemical and Physical Analysis:

- i.

- Extensive water chemistry (trace metals, organic pollutants, TDS, oxidation–reduction potential).

- ii.

- Interaction analysis spectroscopic (FTIR, Raman spectroscopy) of residue-water.

- iii.

- Pre- and post-submersion surface analysis of substrates (SEM, AFM, contact angle measurements).

- iv.

- Degradation processes Kinetic modeling.

- Enhanced Statistical and Validation Approaches:

- i.

- Extensive water chemistry (trace metals, organic pollutants, TDS, oxidation–reduction potential).

- ii.

- Interaction analysis spectroscopic (FTIR, Raman spectroscopy) of residue-water.

- iii.

- Pre- and post-submersion surface analysis of substrates (SEM, AFM, contact angle measurements).

- iv.

- Degradation processes Kinetic modeling.

- Practical Forensic Protocol Development:

- i.

- User-friendly field testing kits of water chemistry.

- ii.

- Decision matrices that are used to match water parameters with the best development techniques.

- iii.

- Aquatic evidence recovery standard operating procedures (SOPs).

- iv.

- Forensic Personnel Training Modules on the basis of study findings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

List of Abbreviations

| ABFO | American Board of Forensic Odontology |

| Ca | Calcium |

| CGWB | Central Ground Water Board |

| Cl− | Chloride Ion |

| DMSO | Dimethyl Sulfoxide |

| GRM | General Reagent Grade |

| K | Potassium |

| Mg | Magnesium |

| MoS2 | Molybdenum Disulfide |

| Na | Sodium |

| pH | Potential of Hydrogen (acidity/alkalinity scale) |

| SDS | Sodium Dodecyl Sulfate |

| SO42− | Sulfate Ion |

| SPR | Small Particle Reagent |

| UV | Ultraviolet |

References

- Abedi, M.; Afoakwah, C.; Bonsu, D.N.O.M. Lip print enhancement. Forensic Sci. Res. 2022, 7, 24–28. [Google Scholar] [CrossRef] [PubMed]

- Arshad, A.; Farrukh, M.A.; Ali, S.; Khaleeq-ur-Rahman, M.; Tahir, M.A. Development of latent fingermarks on various surfaces using ZnO-SiO2 nanopowder. J. Forensic Sci. 2015, 60, 1182–1187. [Google Scholar] [CrossRef] [PubMed]

- Kapoor, S.; Sodhi, G.S.; Sanjiv, K. Visualization of Latent Fingermarks using Rhodamine B: A new method. Int. J. Forensic Sci Pathol. 2015, 3, 199–201. [Google Scholar] [CrossRef]

- Houck, M.M. Forensic Fingerprints; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Saharan, S.; Yadav, A.; Yadav, B. Novel C stain-based chemical method for differentiating real and forged fingerprints. Egypt. J. Forensic Sci. 2020, 10, 16. [Google Scholar] [CrossRef]

- Saharan, S.; Yadav, A.; Yadav, B. Forge fingerprints: Fabrication, development, and detection techniques. Int. J. Med. Toxicol. Leg. Med. 2021, 24, 189–194. [Google Scholar] [CrossRef]

- Saharan, S.; Yadav, A.; Yadav, B. Application of Hertzberg stain in the identification and differentiation of polyvinyl acetate-based forged fingerprints. Curr. Sci. 2022, 123, 160–169. [Google Scholar] [CrossRef]

- Saharan, S.; Yadav, A.; Yadav, B. Iodine Potassium Iodide as a Potential Stain for Detection of Polyvinyl Acetate Based Forged Fingerprints. J. Punjab-Acad. Forensic Med. Toxicol. 2022, 22, 102–105. [Google Scholar] [CrossRef]

- Lim, I.Y. Effects of Aquatic Environments on the Detection of Latent Fingermarks on Paper. Master’s Thesis, Murdoch University, Murdoch, Australia, 2023. [Google Scholar]

- Bleay, S.M.; Bailey, M.J.; Croxton, R.S.; Francese, S. The forensic exploitation of fingermark chemistry: A review. Wiley Interdiscip. Rev. Forensic Sci. 2021, 3, e1403. [Google Scholar] [CrossRef]

- Brčeski, I.; Vaseashta, A. Environmental forensic tools for water resources. In Water Safety, Security and Sustainability: Threat Detection and Mitigation; Springer: Berlin/Heidelberg, Germany, 2021; pp. 333–370. [Google Scholar] [CrossRef]

- Thandauthapani, T.D. The Role of Wetting Effects on the Development of Latent Fingermarks. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2019. [Google Scholar]

- Banerjee, C. Recovery of latent fingerprints on different substrates submerged under fresh water: A review. IP Int. J. Forensic Med. Toxicol. Sci. 2023, 8, 23–26. [Google Scholar] [CrossRef]

- Datta, A.K.; Lee, H.C.; Ramotowski, R.; Gaensslen, R. Advances in Fingerprint Technology; CRC Press: Boca Raton, FL, USA, 2001. [Google Scholar]

- Dhall, J.K.; Kapoor, A. Development of latent prints exposed to destructive crime scene conditions using wet powder suspensions. Egypt. J. Forensic Sci. 2016, 6, 396–404. [Google Scholar] [CrossRef]

- Madkour, S.; El Dine, F.B.; Elwakeel, Y.; AbdAllah, N. Development of latent fingerprints on non-porous surfaces recovered from fresh and sea water. Egypt. J. Forensic Sci. 2017, 7, 3. [Google Scholar] [CrossRef]

- Ground Water Year Book: Rajasthan 2021–2022; Central Ground Water Board, Ministry of Jal Shakti, Government of India: Jaipur, India, 2022. Available online: https://share.google/8xCBq9GfQ4nl8sSYi (accessed on 28 June 2025).

- Kumar, S.; Kumar, A.; Kumar, P. The Quality Analysis of Ground Water of Fatehpur Shekhawati Block of Sikar District in Rajasthan: Assessing the Impact of High Fluoride Concentration in Groundwater on Public Health. J. Adv. Sch. Res. Allied Educ. 2019, 16, 106–109. [Google Scholar]

- Parag, Y.; Elimelech, E.; Opher, T. Bottled water: An evidence-based overview of economic viability, environmental impact, and social equity. Sustainability 2023, 15, 9760. [Google Scholar] [CrossRef]

- Abedi, M.; Afoakwah, R.; Appiah, R.; Asante, E.; Arthur, F.; Khariyal, S. Optimization of the superglue fuming and powder technique for the enhancement of latent fingerprints from objects submerged in water: An experimental study in Ghana. J. Forensic Sci. Med. 2023, 9, 200–206. [Google Scholar] [CrossRef]

- Onstwedder, J., III; Gamboe, T., Jr. Small particle reagent: Developing latent prints on water-soaked firearms and effect on firearms analysis. J. Forensic Sci. 1989, 34, 321–327. [Google Scholar] [CrossRef]

- Ferreira, G.; Paula, R.B.A.; Okuma, A.; Costa, L.M. Fingerprint Development Techniques: A Review. Rev. Virtual Química 2021, 13, 1278–1302. [Google Scholar] [CrossRef]

- Trapecar, M. Finger marks on glass and metal surfaces recovered from stagnant water. Egypt. J. Forensic Sci. 2012, 2, 48–53. [Google Scholar] [CrossRef][Green Version]

- Yamashita, B.; French, M. Fingerprint Sourcebook-Chapter 7: Latent Print Development; US Department Justice Office Justice Programs, National Institute of Justice: Washington, DC, USA, 2010. [Google Scholar][Green Version]

- Mouli, P.C.; Mohan, S.V.; Reddy, S.J. Rainwater chemistry at a regional representative urban site: Influence of terrestrial sources on ionic composition. Atmos. Environ. 2005, 39, 999–1008. [Google Scholar] [CrossRef]

- Castelló, A.; Francés, F.; Verdú, F. Solving underwater crimes: Development of latent prints made on submerged objects. Sci. Justice 2013, 53, 328–331. [Google Scholar] [CrossRef]

- Bumbrah, G.S. Cyanoacrylate fuming method for detection of latent fingermarks: A review. Egypt. J. Forensic Sci. 2017, 7, 4. [Google Scholar] [CrossRef]

- Hassan, F. Recovery of latent fingermarks on metal part of motorcycle submerged in different aquatic environments. Sains Malays. 2021, 50, 2343–2354. [Google Scholar] [CrossRef]

- da Silva, M.E.Z.; Santana, R.G.; Guilhermetti, M.; Camargo Filho, I.; Endo, E.H.; Ueda-Nakamura, T.; Nakamura, C.V.; Dias Filho, B.P. Comparison of the bacteriological quality of tap water and bottled mineral water. Int. J. Hyg. Environ. Health 2008, 211, 504–509. [Google Scholar] [CrossRef] [PubMed]

- Ram, H.; P Lamba, N.; Kumar, P. Physico-Chemical Analysis of Groundwater of Shekhawati Vicinity of Rajasthan (Pre-Monsoon). Int. J. Environ. Clim. Change 2022, 12, 991–996. [Google Scholar] [CrossRef]

- Cadd, S.; Islam, M.; Manson, P.; Bleay, S. Fingerprint composition and aging: A literature review. Sci. Justice 2015, 55, 219–238. [Google Scholar] [CrossRef]

- Girod, A.; Ramotowski, R.; Weyermann, C. Composition of fingermark residue: A qualitative and quantitative review. Forensic Sci. Int. 2012, 223, 10–24. [Google Scholar] [CrossRef]

- De Alcaraz-Fossoul, J.; Mestres Patris, C.; Balaciart Muntaner, A.; Barrot Feixat, C.; Gené Badia, M. Determination of latent fingerprint degradation patterns—A real fieldwork study. Int. J. Leg. Med. 2013, 127, 857–870. [Google Scholar] [CrossRef]

- Jones, B.J.; Downham, R.; Sears, V. Effect of substrate surface topography on forensic development of latent fingerprints with iron oxide powder suspension. Surf. Interface Anal. 2010, 42, 438–442. [Google Scholar] [CrossRef]

- Kadry, S. Corrosion analysis of stainless steel. Eur. J. Sci. Res 2008, 22, 508–516. [Google Scholar]

- Kumaran, S.T.; Baranidharan, K.; Uthayakumar, M.; Parameswaran, P. Corrosion studies on stainless steel 316 and their prevention-a review. Incas Bull. 2021, 13, 245–251. [Google Scholar] [CrossRef]

- Pietrucha-Urbanik, K.; Skowrońska, D.; Papciak, D. Assessment of corrosion properties of selected mineral waters. Coatings 2020, 10, 571. [Google Scholar] [CrossRef]

- ISO/IEC 29794-1:2024; Information Technology—Biometric Sample Quality—Part 1: Framework. ISO/IEC: Geneva, Switzerland, 2024.

| Scores | Criteria | Description |

| 1 | Very poor |

|

| 2 | Poor |

|

| 3 | Fair |

|

| 4 | Good |

|

| 5 | Excellent |

|

| Time Interval | Technique Used | Quality of Print | Score | Mean Score |

|---|---|---|---|---|

| 10 min | Cyanoacrylate Fuming Method | Excellent | 5 | 4.66 |

| SPR method | Excellent | 5 | ||

| Powder Method | Good | 4 | ||

| 1 day | Cyanoacrylate Fuming Method | Good | 4 | 3 |

| SPR Method | Fair | 3 | ||

| Powder Method | Poor | 2 | ||

| 5 days | Cyanoacrylate Fuming Method | Fair | 2 | 2 |

| SPR Method | Fair | 3 | ||

| Powder Method | Very poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1.66 |

| SPR Method | Poor | 2 | ||

| Powder Method | Poor | 2 |

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Fuming Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Time Interval | Mean Score | SD | ||

|---|---|---|---|---|

| 10 min | 4.00 | 0.00 | ||

| 1 day | 3.66 | 0.47 | ||

| 5 days | 1.66 | 0.94 | ||

| 10 days | 1.33 | 0.47 | ||

| Time interval | Technique | Quality of print | Score | Mean score |

| 10 min | Cyanoacrylate Fuming Method | Good | 4 | 4 |

| SPR method | Good | 4 | ||

| Powder Method | Good | 4 | ||

| 1 day | Cyanoacrylate Fuming Method | Good | 4 | 3.66 |

| SPR Method | Good | 4 | ||

| Powder Method | Fair | 3 | ||

| 5 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1.66 |

| SPR Method | Fair | 3 | ||

| Powder Method | Poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1.33 |

| SPR Method | Poor | 2 | ||

| Powder Method | Very poor | 1 | ||

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Fuming Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Time Interval | Mean Score | SD | ||

|---|---|---|---|---|

| 10 min | 3.66 | 0.47 | ||

| 1 day | 1.66 | 0.94 | ||

| 5 days | 1 | 0 | ||

| 10 days | 1 | 0 | ||

| Time interval | Technique used | Quality of print | Score | Mean score |

| 10 min | Cyanoacrylate Fuming Method | Good | 4 | 3.66 |

| SPR method | Good | 4 | ||

| Powder Method | Fair | 3 | ||

| 1 day | Cyanoacrylate Fuming Method | Fair | 3 | 1.66 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| 5 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Fuming Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Time Interval | Mean Score | SD | ||

|---|---|---|---|---|

| 10 min | 4.00 | 0.00 | ||

| 1 day | 2.33 | 0.47 | ||

| 5 days | 1.33 | 0.47 | ||

| 10 days | 1.00 | 0.00 | ||

| Time interval | Technique used | Quality of print | Score | Mean score |

| 10 min | Cyanoacrylate Fuming Method | Good | 4 | 4 |

| SPR method | Good | 4 | ||

| Powder Method | Good | 4 | ||

| 1 day | Cyanoacrylate Fuming Method | Fair | 3 | 2.33 |

| SPR Method | Poor | 2 | ||

| Powder Method | Poor | 2 | ||

| 5 days | Cyanoacrylate Fuming Method | Poor | 2 | 1.33 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Fuming Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Time Interval | Mean Score | SD | ||

|---|---|---|---|---|

| 10 min | 3.66 | 0.47 | ||

| 1 day | 1.66 | 0.94 | ||

| 5 days | 1.00 | 0.00 | ||

| 10 days | 1.00 | 0.00 | ||

| Time interval | Technique used | Quality of print | Score | Mean score |

| 10 min | Cyanoacrylate Fuming Method | Good | 4 | 3.66 |

| SPR method | Good | 4 | ||

| Powder Method | Fair | 3 | ||

| 1 day | Cyanoacrylate Fuming Method | Fair | 3 | 1.66 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| 5 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Very poor | 1 | 1 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Time Interval | Mean Score | SD | ||

|---|---|---|---|---|

| 10 min | 3.00 | 0.00 | ||

| 1 day | 2.66 | 0.47 | ||

| 5 days | 1.66 | 0.47 | ||

| 10 days | 1.33 | 0.47 | ||

| Time interval | Technique used | Quality of print | Score | Mean score |

| 10 min | Cyanoacrylate Fuming Method | Fair | 3 | 3 |

| SPR method | Fair | 3 | ||

| Powder Method | Fair | 3 | ||

| 1 day | Cyanoacrylate Fuming Method | Fair | 3 | 2.66 |

| SPR Method | Poor | 2 | ||

| Powder Method | Fair | 3 | ||

| 5 days | Cyanoacrylate Fuming Method | Poor | 2 | 1.66 |

| SPR Method | Poor | 2 | ||

| Powder Method | Very poor | 1 | ||

| 10 days | Cyanoacrylate Fuming Method | Poor | 2 | 1.33 |

| SPR Method | Very poor | 1 | ||

| Powder Method | Very poor | 1 | ||

| Timeline | |||||

|---|---|---|---|---|---|

| Techniques | Control Group | After 10 min | After 1 Day | After 5 Days | After 10 Days |

| Cyanoacrylate Method |  |  |  |  |  |

| SPR Method |  |  |  |  |  |

| Powder Method |  |  |  |  |  |

| Cases | ||||||

|---|---|---|---|---|---|---|

| Valid | Missing | Total | ||||

| N | Percent | N | Percent | N | Percent | |

| Time duration × Quality of print | 75 | 100.0% | 0 | 0.0% | 75 | 100.0% |

| Cases | ||||||

|---|---|---|---|---|---|---|

| Valid | Missing | Total | ||||

| N | Percent | N | Percent | N | Percent | |

| Time Duration × Quality of prints × Water type | 73 | 100.0% | 0 | 0.0% | 73 | 100.0% |

| Cases | ||||||

|---|---|---|---|---|---|---|

| Valid | Missing | Total | ||||

| N | Percent | N | Percent | N | Percent | |

| Water type × mean × Techniques used | 22 | 100.0% | 0 | 0.0% | 20.378 | 100.0% |

| Quality of Print | |||||||

|---|---|---|---|---|---|---|---|

| Excellent | Fair | Good | Poor | Very Poor | |||

| Time duration | 10 min | Count | 2 | 4 | 12 | 0 | 0 |

| Expected Count | 0.5 | 4.1 | 3.6 | 2.9 | 7.0 | ||

| 1 day | Count | 0 | 7 | 3 | 4 | 4 | |

| Expected Count | 0.5 | 4.1 | 3.6 | 2.9 | 7.0 | ||

| 5 days | Count | 0 | 3 | 0 | 4 | 11 | |

| Expected Count | 0.5 | 4.1 | 3.6 | 2.9 | 7.0 | ||

| 10 days | Count | 0 | 3 | 0 | 4 | 14 | |

| Expected Count | 0.6 | 4.8 | 4.2 | 3.4 | 8.1 | ||

| Total | Count | 2 | 17 | 15 | 12 | 29 | |

| Expected Count | 2.0 | 17.0 | 15.0 | 12.0 | 29.0 | ||

| Total | |||

|---|---|---|---|

| Time duration | 10 min | Count | 18 |

| Expected Count | 18.0 | ||

| 1 day | Count | 18 | |

| Expected Count | 18.0 | ||

| 5 days | Count | 18 | |

| Expected Count | 18.0 | ||

| 10 days | Count | 21 | |

| Expected Count | 21.0 | ||

| Total | Count | 75 | |

| Expected Count | 75.0 | ||

| Water Type | Value | df | Asymptotic Significance (2-Sided) | |

|---|---|---|---|---|

| Hard water | Pearson Chi-Square | 29.333 b | 9 | 0.001 |

| Likelihood Ratio | 32.583 | 9 | 0.000 | |

| Linear-by-Linear Association | 16.696 | 1 | 0.000 | |

| N of Valid Cases | 24 | |||

| Mineral | Pearson Chi-Square | 22.267 c | 12 | 0.035 |

| Likelihood Ratio | 26.577 | 12 | 0.009 | |

| Linear-by-Linear Association | 12.708 | 1 | 0.000 | |

| N of Valid Cases | 24 | |||

| Rainwater | Pearson Chi-Square | 21.220 d | 9 | 0.012 |

| Likelihood Ratio | 27.104 | 9 | 0.001 | |

| Linear-by-Linear Association | 15.866 | 1 | 0.000 | |

| N of Valid Cases | 25 | |||

| Total | Pearson Chi-Square | 59.008 a | 12 | 0.000 |

| Likelihood Ratio | 71.112 | 12 | 0.000 | |

| Linear-by-Linear Association | 44.478 | 1 | 0.000 | |

| N of Valid Cases | 73 | |||

| Water Type | Quality of Prints | Total | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Very Poor | Poor | Fair | Good | Excellent | |||||

| Hard water | Time duration | 10 min | Count | 0 | 0 | 1 | 5 | 6 | |

| Expected Count | 3.3 | 0.8 | 0.8 | 1.3 | 6.0 | ||||

| 1 day | Count | 2 | 2 | 2 | 0 | 6 | |||

| Expected Count | 3.3 | 0.8 | 0.8 | 1.3 | 6.0 | ||||

| 5 days | Count | 5 | 1 | 0 | 0 | 6 | |||

| Expected Count | 3.3 | 0.8 | 0.8 | 1.3 | 6.0 | ||||

| 10 days | Count | 6 | 0 | 0 | 0 | 6 | |||

| Expected Count | 3.3 | 0.8 | 0.8 | 1.3 | 6.0 | ||||

| Total | Count | 13 | 3 | 3 | 5 | 24 | |||

| Expected Count | 13.0 | 3.0 | 3.0 | 5.0 | 24.0 | ||||

| Mineral | Time duration | 10 min | Count | 0 | 0 | 1 | 3 | 2 | 6 |

| Expected Count | 2.5 | 0.8 | 1.3 | 1.0 | 0.5 | 6.0 | |||

| 1 day | Count | 2 | 1 | 2 | 1 | 0 | 6 | ||

| Expected Count | 2.5 | 0.8 | 1.3 | 1.0 | 0.5 | 6.0 | |||

| 5 days | Count | 4 | 0 | 2 | 0 | 0 | 6 | ||

| Expected Count | 2.5 | 0.8 | 1.3 | 1.0 | 0.5 | 6.0 | |||

| 10 days | Count | 4 | 2 | 0 | 0 | 0 | 6 | ||

| Expected Count | 2.5 | 0.8 | 1.3 | 1.0 | 0.5 | 6.0 | |||

| Total | Count | 10 | 3 | 5 | 4 | 2 | 24 | ||

| Expected Count | 10.0 | 3.0 | 5.0 | 4.0 | 2.0 | 24.0 | |||

| Rainwater | Time duration | 10 min | Count | 0 | 0 | 3 | 3 | 6 | |

| Expected Count | 1.4 | 1.4 | 1.9 | 1.2 | 6.0 | ||||

| 1 day | Count | 0 | 1 | 4 | 2 | 7 | |||

| Expected Count | 1.7 | 1.7 | 2.2 | 1.4 | 7.0 | ||||

| 5 days | Count | 2 | 3 | 1 | 0 | 6 | |||

| Expected Count | 1.4 | 1.4 | 1.9 | 1.2 | 6.0 | ||||

| 10 days | Count | 4 | 2 | 0 | 0 | 6 | |||

| Expected Count | 1.4 | 1.4 | 1.9 | 1.2 | 6.0 | ||||

| Total | Count | 6 | 6 | 8 | 5 | 25 | |||

| Expected Count | 6.0 | 6.0 | 8.0 | 5.0 | 25.0 | ||||

| Total | Time duration | 10 min | Count | 0 | 0 | 5 | 11 | 2 | 18 |

| Expected Count | 7.2 | 3.0 | 3.9 | 3.5 | 0.5 | 18.0 | |||

| 1 day | Count | 4 | 4 | 8 | 3 | 0 | 19 | ||

| Expected Count | 7.5 | 3.1 | 4.2 | 3.6 | 0.5 | 19.0 | |||

| 5 days | Count | 11 | 4 | 3 | 0 | 0 | 18 | ||

| Expected Count | 7.2 | 3.0 | 3.9 | 3.5 | 0.5 | 18.0 | |||

| 10 days | Count | 14 | 4 | 0 | 0 | 0 | 18 | ||

| Expected Count | 7.2 | 3.0 | 3.9 | 3.5 | 0.5 | 18.0 | |||

| Total | Count | 29 | 12 | 16 | 14 | 2 | 73 | ||

| Expected Count | 29.0 | 12.0 | 16.0 | 14.0 | 2.0 | 73.0 | |||

| Techniques Used | Mean | Total | |||||

|---|---|---|---|---|---|---|---|

| High | Low | Medium | |||||

| Cyanoacrylate | Water type | Hard water | Count | 0 | 2 | 2 | |

| Expected Count | 1.5 | 0.5 | 2.0 | ||||

| Mineral water | Count | 3 | 0 | 3 | |||

| Expected Count | 2.3 | 0.8 | 3.0 | ||||

| Rainwater | Count | 3 | 0 | 3 | |||

| Expected Count | 2.3 | 0.8 | 3.0 | ||||

| Total | Count | 6 | 2 | 8 | |||

| Expected Count | 6.0 | 2.0 | 8.0 | ||||

| Powder | Water type | Hard water | Count | 2 | 0 | 2 | |

| Expected Count | 0.7 | 1.3 | 2.0 | ||||

| Mineral water | Count | 0 | 2 | 2 | |||

| Expected Count | 0.7 | 1.3 | 2.0 | ||||

| Rainwater | Count | 0 | 2 | 2 | |||

| Expected Count | 0.7 | 1.3 | 2.0 | ||||

| Total | Count | 2 | 4 | 6 | |||

| Expected Count | 2.0 | 4.0 | 6.0 | ||||

| SPR | Water type | Hard water | Count | 0 | 2 | 2 | |

| Expected Count | 1.5 | 0.5 | 2.0 | ||||

| Mineral water | Count | 3 | 0 | 3 | |||

| Expected Count | 2.3 | 0.8 | 3.0 | ||||

| Rainwater | Count | 3 | 0 | 3 | |||

| Expected Count | 2.3 | 0.8 | 3.0 | ||||

| Total | Count | 6 | 2 | 8 | |||

| Expected Count | 6.0 | 2.0 | 8.0 | ||||

| Total | Water type | Hard water | Count | 0 | 4 | 2 | 6 |

| Expected Count | 3.3 | 1.1 | 1.6 | 6.0 | |||

| Mineral water | Count | 6 | 0 | 2 | 8 | ||

| Expected Count | 4.4 | 1.5 | 2.2 | 8.0 | |||

| Rainwater | Count | 6 | 0 | 2 | 8 | ||

| Expected Count | 4.4 | 1.5 | 2.2 | 8.0 | |||

| Total | Count | 12 | 4 | 6 | 22 | ||

| Expected Count | 12.0 | 4.0 | 6.0 | 22.0 | |||

| Techniques Used | Value | Df | Asymptotic Significance (2-Sided) | |

|---|---|---|---|---|

| Cyanoacrylate | Pearson Chi-Square | 8.000 b | 2 | 0.018 |

| Likelihood Ratio | 8.997 | 2 | 0.011 | |

| N of Valid Cases | 8 | |||

| Powder | Pearson Chi-Square | 6.000 c | 2 | 0.050 |

| Likelihood Ratio | 7.638 | 2 | 0.022 | |

| N of Valid Cases | 6 | |||

| SPR | Pearson Chi-Square | 8.000 b | 2 | 0.018 |

| Likelihood Ratio | 8.997 | 2 | 0.011 | |

| N of Valid Cases | 8 | |||

| Total | Pearson Chi-Square | 15.278 a | 4 | 0.004 |

| Likelihood Ratio | 18.144 | 4 | 0.001 | |

| N of Valid Cases | 22 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, A.; Sharma, M.; Dabas, V.; Kumari, K.; Saharan, S. Comparative Efficacy of Latent Fingerprint Development Techniques in Varying Aquatic Environments of Rajasthan’s Shekhawati Region: Analyzing the Impact of Water Composition and Surface Interactions. Forensic Sci. 2025, 5, 79. https://doi.org/10.3390/forensicsci5040079

Gupta A, Sharma M, Dabas V, Kumari K, Saharan S. Comparative Efficacy of Latent Fingerprint Development Techniques in Varying Aquatic Environments of Rajasthan’s Shekhawati Region: Analyzing the Impact of Water Composition and Surface Interactions. Forensic Sciences. 2025; 5(4):79. https://doi.org/10.3390/forensicsci5040079

Chicago/Turabian StyleGupta, Abhaya, Mridu Sharma, Varsha Dabas, Kavita Kumari, and Sameer Saharan. 2025. "Comparative Efficacy of Latent Fingerprint Development Techniques in Varying Aquatic Environments of Rajasthan’s Shekhawati Region: Analyzing the Impact of Water Composition and Surface Interactions" Forensic Sciences 5, no. 4: 79. https://doi.org/10.3390/forensicsci5040079

APA StyleGupta, A., Sharma, M., Dabas, V., Kumari, K., & Saharan, S. (2025). Comparative Efficacy of Latent Fingerprint Development Techniques in Varying Aquatic Environments of Rajasthan’s Shekhawati Region: Analyzing the Impact of Water Composition and Surface Interactions. Forensic Sciences, 5(4), 79. https://doi.org/10.3390/forensicsci5040079