Investigation of In-Situ Low Copper Alloying of 316L Using the Powder Bed Fusion Process

Abstract

:1. Introduction

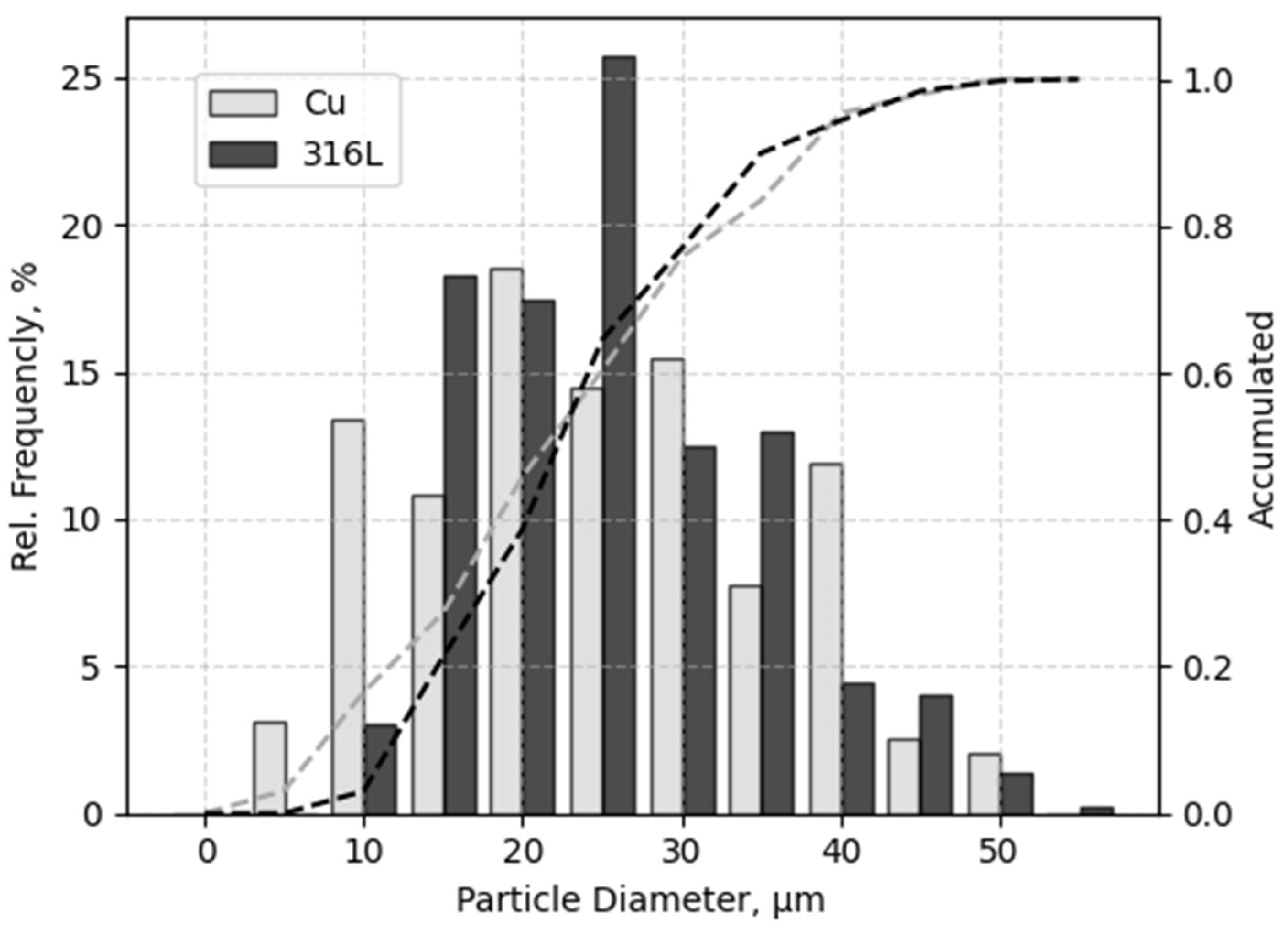

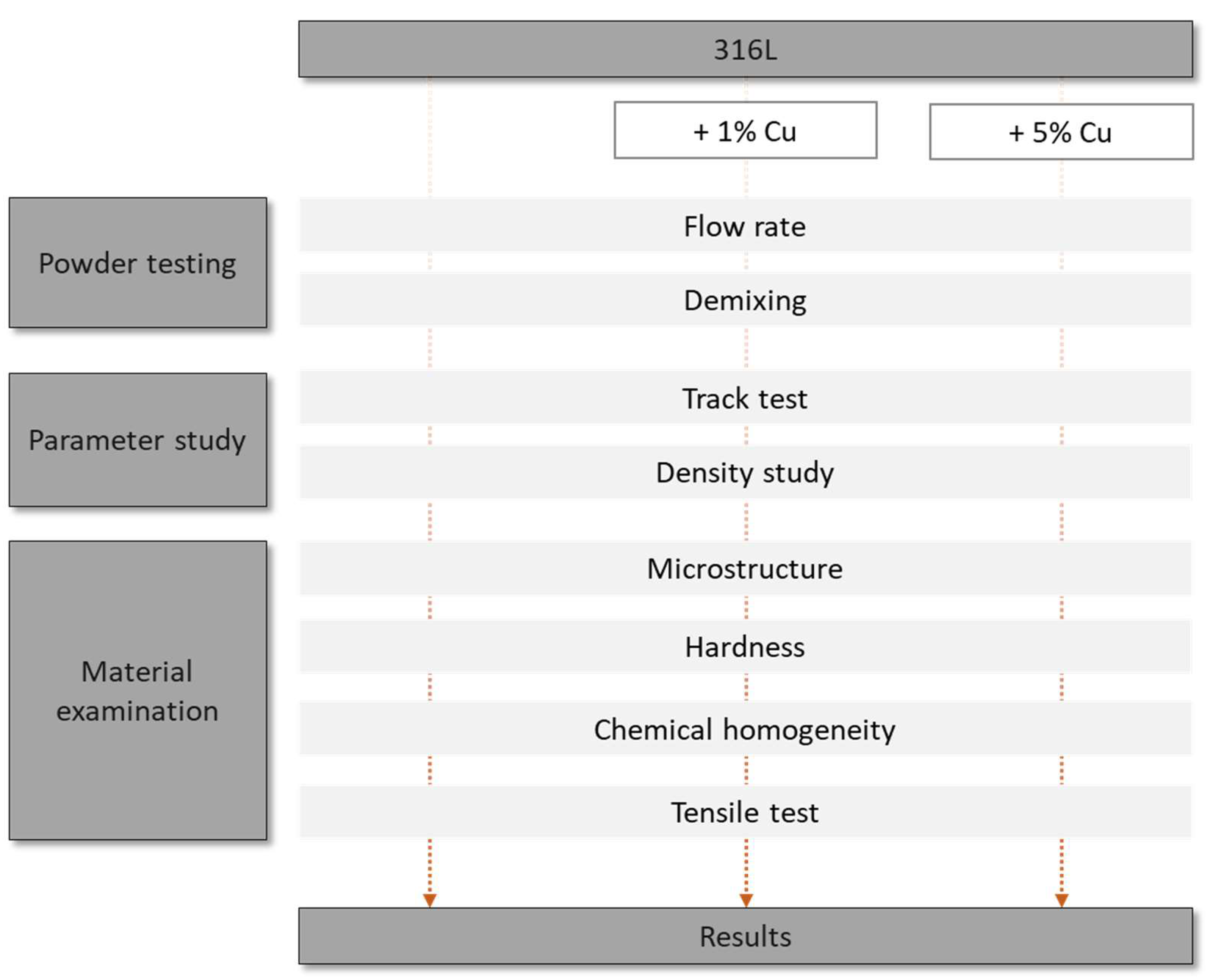

2. Materials and Methods

3. Results

3.1. Powder Testing

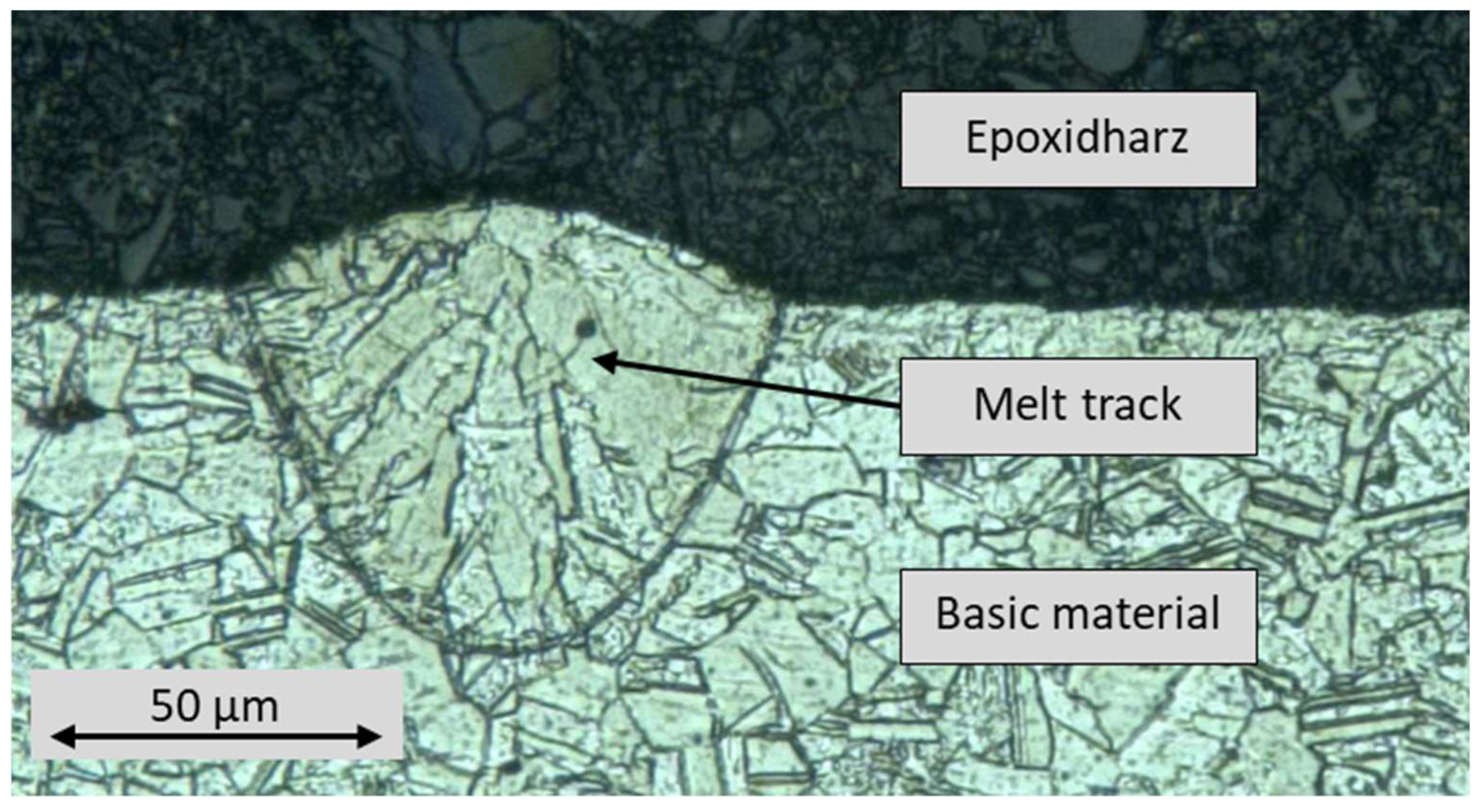

3.2. Parameter Study

3.3. Material Examination

4. Discussion

4.1. Powder

4.2. Parameter

4.3. Material

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kremer, R.; Khani, S.; Appel, T.; Palkowski, H.; Foadian, F. Selective Laser Melting of CuSn10: Simulation of Mechanical Properties, Microstructure, and Residual Stresses. Materials 2022, 15, 3902. [Google Scholar] [CrossRef] [PubMed]

- Lachmayer, R.; Lippert, R.B. Additive Manufacturing Quantifiziert; Spinger: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Lippert, R.B. Restriktionsgerechtes Gestalten Gewichtsoptimierter Strukturbauteile für das Selektive Laserstrahlschmelzen; TEWISS Verlag: Garbsen, Germany, 2018. [Google Scholar]

- Clayton, R. The Use of Elemental Powder Mixes in Laser-Based Additive Manufacturing. Master’s Theses, 2013. Available online: https://scholarsmine.mst.edu/masters_theses/7194 (accessed on 8 May 2023).

- Katz-Demyanetz, A.; Koptyug, A.; Popov, V.V. In-situ Alloying as a Novel Methodology in Additive Manufacturing. In Proceedings of the 2020 IEEE 10th International Conference Nanomaterials: Applications & Properties (NAP), Sumy, Ukraine, 9–13 November 2020. [Google Scholar]

- Foadian, F.; Kremer, R. In-Situ Alloy Formation During Selective Laser Melting with CuSn10 and Aluminum Powders. In TMS 2023 152nd Annual Meeting & Exhibition Supplemental Proceedings, 1st ed.; Springer Nature Switzerland: Cham, Switzerland, 2023. [Google Scholar]

- Huang, T.; Jiang, H.; Lu, Y.; Wang, T.; Li, T. Effect of Sc and Y addition on the microstructure and properties of HCP-structured high-entropy alloys. Appl. Phys. A 2019, 125, 180. [Google Scholar] [CrossRef]

- Bazhenov, V.; Li, A.; Komissarov, A.; Koltygin, A.; Tavolzhanskii, S.; Bautin, V.; Voropaeva, O.; Mukhametshina, A.; Tokar, A. Microstructure and mechanical and corrosion properties of hot-extruded Mg–Zn–Ca–(Mn) biodegradable alloys. J. Magnes. Alloys 2020, 9, 1428–1442. [Google Scholar] [CrossRef]

- Foadian, F.; Kremer, R.; Khani, S. Rapid alloying in additive manufacturing using integrated computational materials engineering. In Quality Analysis of Additively Manufactured Metals: Simulation Approaches, Processes, and Microstructure Properties; Kadkhodapour, J., Schmauder, S., Sajadi, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 583–624. [Google Scholar]

- Yin, X.; Zhai, Q.; Zhang, Q.; Wang, K.; Meng, L.; Ma, Z.; Chen, G.; Wang, S.; Wang, L. Effect of tungsten particles on microstructure and properties of 316 L stainless steel manufactured by selective laser melting. J. Manuf. Process. 2021, 68, 210–221. [Google Scholar] [CrossRef]

- Hu, Z.; Guan, K.; Qian, Z.; Dong, J.; Wu, J.; Ma, Z. Simultaneous enhancement of strength and ductility in selective laser melting manufactured 316L alloy by employing Y2O3 coated spherical powder as precursor. J. Alloys Compd. 2022, 899, 163262. [Google Scholar] [CrossRef]

- Zhou, Y.; Duan, L.; Li, F.; Chen, K.; Wen, S. Effect of heat treatment on the microstructure and mechanical property of W/316L multi-material fabricated by selective laser melting. J. Alloys Compd. 2021, 890, 161841. [Google Scholar] [CrossRef]

- Gao, C.; Li, S.; Liu, L.; Bin, S.; Yang, Y.; Peng, S.; Shuai, C. Dual alloying improves the corrosion resistance of biodegradable Mg alloys prepared by selective laser melting. J. Magnes. Alloys 2020, 9, 305–316. [Google Scholar] [CrossRef]

- Han, L.; Wang, C.; Li, Z. Mechanical, forming and biological properties of Ti-Fe-Zr-Y alloys prepared by 3D printing. J. Mater. Sci. Technol. 2019, 35, 1323–1333. [Google Scholar] [CrossRef]

- Zhuang, Y.; Zhang, S.; Yang, K.; Ren, L.; Dai, K. Antibacterial activity of copper-bearing 316L stainless steel for the prevention of implant-related infection. J. Biomed. Mater. Res. Part B Appl. Biomater. 2019, 108, 484–495. [Google Scholar] [CrossRef] [PubMed]

- Xi, T.; Shahzad, M.B.; Xu, D.; Sun, Z.; Zhao, J.; Yang, C.; Qi, M.; Yang, K. Effect of copper addition on mechanical properties, corrosion resistance and antibacterial property of 316L stainless steel. Mater. Sci. Eng. C 2017, 71, 1079–1085. [Google Scholar] [CrossRef] [PubMed]

- Fedrizzi, L.; Molinari, A.; DeFlorian, F.; Tiziani, A.; Bonora, P.L. Corrosion Study of Industrially Sintered Copper Alloyed 316L Austenitic Stainless Steel. Br. Corros. J. 1991, 26, 46–50. [Google Scholar] [CrossRef]

- Yamamoto, A.; Ashiura, T.; Kamisaka, E. Mechanism of Improvement on Corrosion Resistance by Copper Addition to Ferritic Stainless Steels. Corros. Eng. Dig. 1986, 35, 448–454. [Google Scholar] [CrossRef] [PubMed]

- Kremer, R.; Etzkorn, J.; Palkowski, H.; Foadian, F. Corrosion Resistance of 316L/CuSn10 Multi-Material Manufactured by Powder Bed Fusion. Materials 2022, 15, 8373. [Google Scholar] [CrossRef] [PubMed]

- VDI. VDI 3405 Blatt 2.3—Additive Fertigungsverfahren—Strahlschmelzen metallischer Bauteile—Charakterisierung von Pulverwerkstoffen. 2018. Available online: https://www.vdi.de/richtlinien/details/vdi-3405-blatt-23-additive-fertigungsverfahren-strahlschmelzen-metallischer-bauteile-charakterisierung-von-pulverwerkstoffen (accessed on 1 May 2023).

- VDI. VDI 3405 Blatt 2—Additive Fertigungsverfahren Strahlschmelzen metallischer Bauteile—Qualifizierung, Qualitätssicherung und Nachbearbeitung. 2013. Available online: https://www.vdi.de/richtlinien/details/vdi-3405-blatt-2-additive-fertigungsverfahren-strahlschmelzen-metallischer-bauteile-qualifizierung-qualitaetssicherung-und-nachbearbeitung (accessed on 1 May 2023).

| 316L | 316L + 1 wt.% Cu | 316L + 5 wt.% Cu | |

|---|---|---|---|

| Laser power [W] | 90 W | ||

| Scan speed [mm/s] | 800 mm/s | ||

| Layer thickness [µm] | 25 | ||

| Measured track width [µm] | 88 ± 3 | 83 ± 9 | 85 ± 8 |

| Hatching (chosen) [µm] | 62 | 58 | 59 |

| Density [g/cm3] | 7.996 | 7.98 | 7.68 |

| Relative density [%] | 99.95 | 99.63 | 95.38 |

| 316L | 316L + 1 wt.% Cu | 316L + 5 wt.% Cu | |

|---|---|---|---|

| Cu [wt.%] (n = 13) | 0.048 ± 0.001 | 1.002 ± 0.051 | 5.22 ± 0.19 |

| Hardness HV 30 | 221 ± 5 | 209 ± 2 | 197 ± 5 |

| Yield strength [MPa] | 504 ± 8 | 493 ± 9 | 476 ± 12 |

| Tensile strength [MPa] | 576 ± 5 | 547 ± 15 | 536 ± 13 |

| Elongation [%] | 22.0 ± 0.6 | 20.6 ± 0.4 | 12.8 ± 0.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foadian, F.; Kremer, R.; Post, M.; Taghizadeh Tabrizi, A.; Aghajani, H. Investigation of In-Situ Low Copper Alloying of 316L Using the Powder Bed Fusion Process. Solids 2023, 4, 156-165. https://doi.org/10.3390/solids4030010

Foadian F, Kremer R, Post M, Taghizadeh Tabrizi A, Aghajani H. Investigation of In-Situ Low Copper Alloying of 316L Using the Powder Bed Fusion Process. Solids. 2023; 4(3):156-165. https://doi.org/10.3390/solids4030010

Chicago/Turabian StyleFoadian, Farzad, Robert Kremer, Matthias Post, Arvin Taghizadeh Tabrizi, and Hossein Aghajani. 2023. "Investigation of In-Situ Low Copper Alloying of 316L Using the Powder Bed Fusion Process" Solids 4, no. 3: 156-165. https://doi.org/10.3390/solids4030010

APA StyleFoadian, F., Kremer, R., Post, M., Taghizadeh Tabrizi, A., & Aghajani, H. (2023). Investigation of In-Situ Low Copper Alloying of 316L Using the Powder Bed Fusion Process. Solids, 4(3), 156-165. https://doi.org/10.3390/solids4030010