Laboratory-Scale Drillstring Vibration Analysis

Abstract

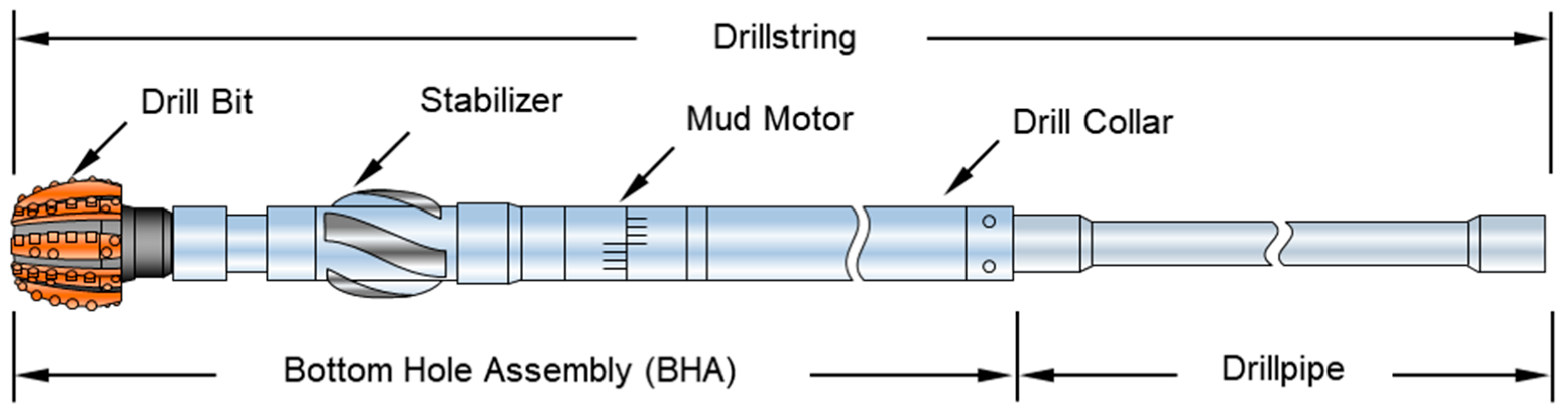

1. Introduction

2. Theoretical Background

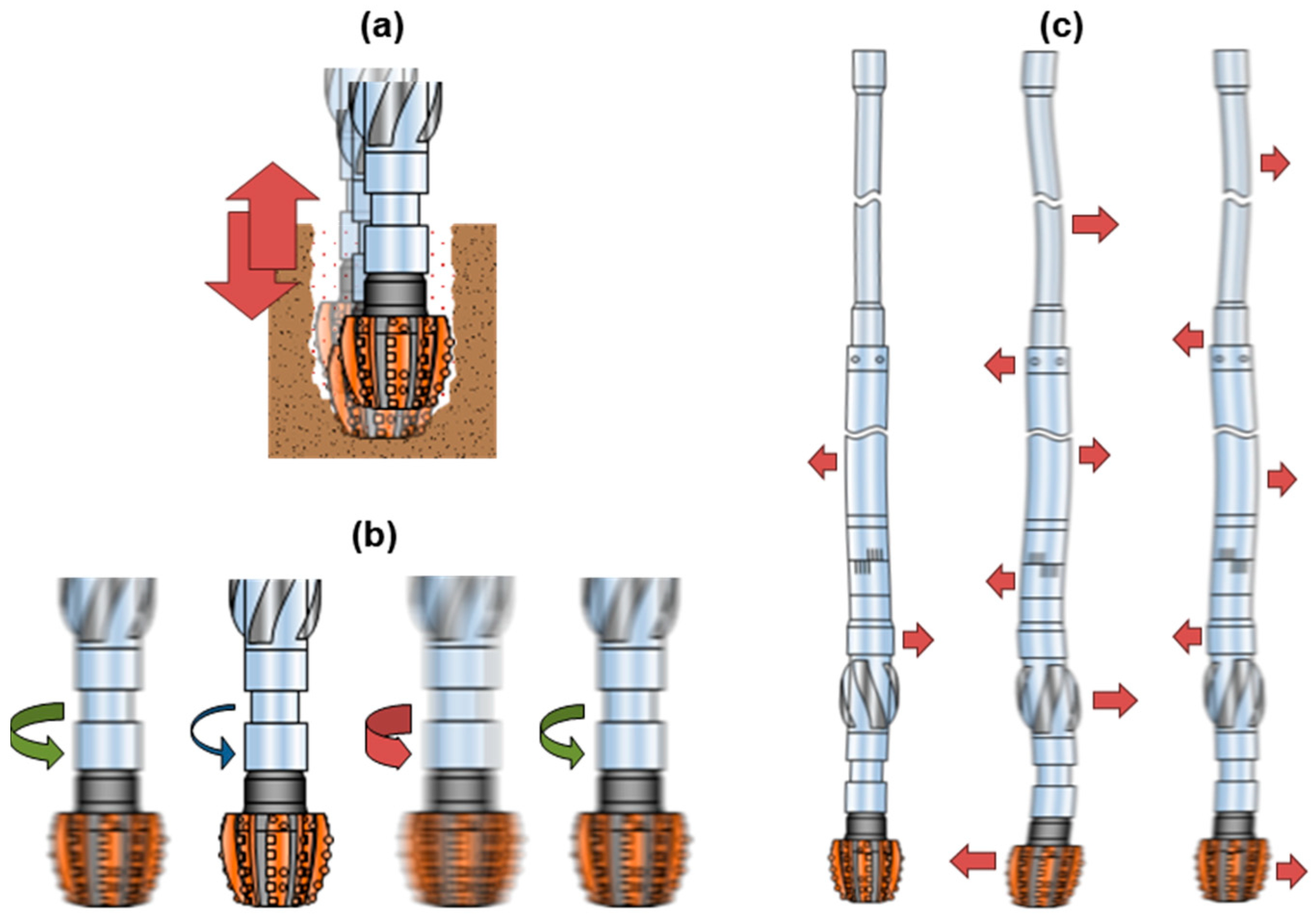

2.1. Drillstring Vibrations

2.2. Laboratory-Scale Experiments

2.3. Mechanical Scaling

2.4. Hydrodynamics Interactions

3. Drillstring Vibration Experiments

3.1. Flexible Disc-Rotor Models

3.2. Rigid Body Models

3.3. Hybrid Designs

3.4. Mechanically Scaled Models

3.5. Hydrodynamics Studies

3.6. Objective Modular Designs

4. Discussion

4.1. Comparative Summary

4.2. Parametric Details

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dareing, D.W. Drill collar length is a major factor in vibration control. J. Pet. Technol. 1984, 36, 637–644. [Google Scholar] [CrossRef]

- Chen, P.; Gao, D.; Wang, Z.; Huang, W. Study on aggressively working casing string in extended-reach well. J. Pet. Sci. Eng. 2017, 157, 604–616. [Google Scholar] [CrossRef]

- Li, W.; Huang, G.; Jing, Y.; Yu, F.; Ni, H. Modeling and mechanism analyzing of casing running with pick-up and release technique. J. Pet. Sci. Eng. 2019, 172, 538–546. [Google Scholar] [CrossRef]

- Shyu, R.J. Bending Vibration of Rotating Drill Strings. Ph.D. Thesis, MIT, Cambridge, MA, USA, 1989. [Google Scholar]

- Dykstra, M.W. Nonlinear Drill String Dynamics. Ph.D. Thesis, University of Tulsa, Tulsa, OK, USA, 1996. [Google Scholar]

- Dong, G.; Chen, P. A review of the evaluation, control, and application technologies for drill string vibrations and shocks in oil and gas well. Shock. Vib. 2016, 2016, 7418635. [Google Scholar] [CrossRef]

- Heisig, G.; Neubert, M. Lateral Drillstring Vibrations in Extended-Reach Wells. In Proceedings of the IADC/SPE Drilling Conference, New Orleans, LA, USA, 23–25 February 2000. [Google Scholar] [CrossRef]

- Cobern, M.; Perry, C.; Barbely, J.; Burgess, D.; Wassell, M. Drilling tests of an active vibration damper. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 20–22 February 2007; p. SPE-105400-MS. [Google Scholar] [CrossRef]

- Stonneger, J.C. Vibration Problems in Oil Wells; SPE 37-179; American Petroleum Institute: Washington, DC, USA, 1937. [Google Scholar]

- Spanos, P.D.; Payne, M.L. Advances in dynamic bottomhole assembly modeling and dynamic response determination. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, New Orleans, LA, USA, 18–21 February 1992; p. SPE-23905. [Google Scholar]

- Samuel, R.; Schottle, G.; Gupta, D.B. Vibration Analysis, Model Prediction, and avoidance: A case history. In Proceedings of the SPE/IADC Indian Drilling Technology Conference and Exhibition, Mumbai, India, 16–18 October 2006; p. SPE/IADC 102134. [Google Scholar] [CrossRef]

- Al Dushaishi, M.F.; Nygaard, R.; Stutts, D.S. Effect of drilling fluid hydraulics on drill stem vibrations. J. Nat. Gas Sci. Eng. 2016, 35, 1059–1069. [Google Scholar] [CrossRef]

- Bailey, J.R.; Biediger, E.A.O.; Gupta, V.; Ertas, D.; Elks, W.C.; Dupriest, F.E. Drilling vibrations modeling and field validation. In Proceedings of the IADC/SPE Drilling Conference, Orlando, FL, USA, 4–6 March 2008. [Google Scholar] [CrossRef]

- Finnie, I.; Bailey, J.J. An experimental study of drill-string vibration. ASME J. Eng. Ind. 1960, 82, 129–135. [Google Scholar] [CrossRef]

- Aarrestad, T.V.; Tønnesen, H.A.; Kyllingstad, Å. Drillstring vibrations: Comparison between theory and experiments on a full-scale research drilling rig. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Dallas, TX, USA, 9–12 February 1986. [Google Scholar] [CrossRef]

- Halsey, G.W.; Kyllingstad, A.; Aarrestad, T.V.; Lysne, D. Drillstring Torsional Vibrations: Comparison Between Theory and Experiment on a Full-Scale Research Drilling Rig. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 5–8 October 1986. [Google Scholar] [CrossRef]

- Mabile, C.; Desplans, J.P.; Pavone, D. A New Way of Using Surface Measurements to Detect Down Hole Vibrations. In Proceedings of the European Petroleum Conference, Milan, Italy, 22–24 October 1996. [Google Scholar] [CrossRef]

- Khulief, Y.A.; Al-Sulaiman, F.A. Laboratory investigation of drillstring vibrations. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 2249–2262. [Google Scholar] [CrossRef]

- Westermann, H.; Gorelik, I.; Rudat, J.; Moritz, C.; Neubauer, M.; Wallaschek, J.; Höhn, O. A new test rig for experimental studies of drillstring vibrations. SPE Drill. Complet. 2015, 30, 119–128. [Google Scholar] [CrossRef]

- Veeningen, D.; Hewlett, R.; Salazar, J.; Coit, A.; Furniss, E. Field Tests Quantify Processes Utilizing an Enhanced Downhole Dynamics Measurement Tool for Vibration Mitigation and Performance Optimization. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference & Exhibition, Dubai, United Arab Emirates, 7–9 October 2013. [Google Scholar] [CrossRef]

- Bowler, A.; Harmer, R.; Logesparan, L.; Sugiura, J.; Jeffryes, B.; Ignova, M. Continuous high-frequency measurements of the drilling process provide new insights into drilling-system response and transitions between vibration modes. SPE Drill. Complet. 2016, 31, 106–118. [Google Scholar] [CrossRef]

- Wiktorski, E.; Geekiyanage, S.; Løken, E.; Sui, D. Comparative Study of Surface and Downhole Drillstring Vibrations Measurements on a Laboratory-Scale Drilling Rig. In Proceedings of the SPE Norway One Day Seminar, Bergen, Norway, 14 May 2019. [Google Scholar] [CrossRef]

- Sugiura, J.; Jones, S. A drill bit and a drilling motor with embedded high-frequency (1600 Hz) drilling dynamics sensors provide new insights into challenging downhole drilling conditions. SPE Drill. Complet. 2019, 34, 223–247. [Google Scholar] [CrossRef]

- Maitra, E.K.; Al Dushaishi, M.F. Experimental visualization of the effect of flow rate on downhole drilling vibration. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 5–7 March 2024. [Google Scholar] [CrossRef]

- Zhang, J.; Cui, M.; Wang, Q.; Ren, H.; Ji, G.; Shao, F.; Zhuo, L.; Li, H.; Yu, J. Experimental study on rock drilling vibration of PDC bit in interbedded formations. Geoenergy Sci. Eng. 2025, 244, 213452. [Google Scholar] [CrossRef]

- Aldred, W.D.; Sheppard, M.C. Drillstring vibrations: A new generation mechanism and control strategies. In Proceedings of the SPE Annual Technical Conference and Exhibition, Washington, DC, USA, 4–7 October 1992. [Google Scholar] [CrossRef]

- Minett-Smith, D.J.; Stroud, D.R.; Pagett, J.M. Real-time whirl detector aids drilling optimization. In Proceedings of the SPE Annual Technical Conference and Exhibition, Florence, Italy, 19–22 September 2010. [Google Scholar] [CrossRef]

- Stroud, D.R.; Lines, L.A.; Minett-Smith, D.J. Analytical and experimental backward whirl simulations for rotary steerable bottom hole assemblies. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 1–3 March 2011. [Google Scholar] [CrossRef]

- Popp, T.; Stibbe, H.; Heinisch, D.; Reckmann, H.; Spanos, P. Backward whirl testing and modeling with realistic borehole contacts for enhanced drilling tool reliability. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, TX, USA, 6–8 March 2018. [Google Scholar] [CrossRef]

- Tang, L.; Guo, B.; Zhu, X.; Shi, C.; Zhou, Y. Stick–slip vibrations in oil well drillstring: A review. J. Low Freq. Noise Vib. Act. Control. 2019, 39, 885–907. [Google Scholar] [CrossRef]

- Forster, I.; Macfarlane, A.; Robert, D. Asymmetric Vibration Damping Tool—Small Scale Rig Testing and Full Scale Field Testing. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, New Orleans, LA, USA, 2–4 February 2010. [Google Scholar] [CrossRef]

- Ghasemloonia, A.; Rideout, D.G.; Butt, S.D. A review of drillstring vibration modeling and suppression methods. J. Pet. Sci. Eng. 2015, 131, 150–164. [Google Scholar] [CrossRef]

- Saldivar, B.; Mondié, S.; Niculescu, S.I.; Mounier, H.; Boussaada, I. A control oriented guided tour in oilwell drilling vibration modeling. Annu. Rev. Control. 2016, 42, 100–113. [Google Scholar] [CrossRef]

- Khulief, Y.A. Modeling of Rotary Drillstring Vibrations: An Overview. Int. J. Struct. Stab. Dyn. 2025, 2630002. [Google Scholar] [CrossRef]

- Zhu, X.; Tang, L.; Yang, Q. A literature review of approaches for stick-slip vibration suppression in oilwell drillstring. Adv. Mech. Eng. 2014, 6, 967952. [Google Scholar] [CrossRef]

- Zhong, R.; Salehi, C.; Johnson, R., Jr. Machine learning for drilling applications: A review. J. Nat. Gas Sci. Eng. 2022, 108, 104807. [Google Scholar] [CrossRef]

- Sharma, A.; Abid, K.; Srivastava, S.; Velasquez, A.F.B.; Teodoriu, C. A review of torsional vibration mitigation techniques using active control and machine learning strategies. Petroleum 2024, 10, 411–426. [Google Scholar] [CrossRef]

- Patil, P.A.; Teodoriu, C. Model development of torsional drillstring and investigating parametrically the stick-slips influencing factors. J. Energy Resour. Technol. 2013, 135, 013103. [Google Scholar] [CrossRef]

- Srivastava, S.; Teodoriu, C. An extensive review of laboratory scaled experimental setups for studying drill string vibrations and the way forward. J. Pet. Sci. Eng. 2019, 182, 106272. [Google Scholar] [CrossRef]

- Song, J.; Liu, S.; He, Y.; Gao, Y.; Jiang, S.; Zhu, H. The State-of-the-Art Review on the Drill Pipe Vibration. Geoenergy Sci. Eng. 2024, 243, 213337. [Google Scholar] [CrossRef]

- Pires, I.; Ayala, H.V.H.; Weber, H.I. Nonlinear ensemble gray and black-box system identification of friction induced vibrations in slender rotating structures. Mech. Syst. Signal Process. 2023, 186, 109815. [Google Scholar] [CrossRef]

- Henneuse, H. Surface Detection of Vibrations and Drilling Optimization: Field Experience. In Proceedings of the IADC/SPE Drilling Conference, New Orleans, LA, USA, 18–21 February 1992. [Google Scholar] [CrossRef]

- Spanos, P.D.; Chevallier, A.M.; Politis, N.P.; Payne, M.L. Oil and gas well drilling: A vibrations perspective. Shock. Vib. Dig. 2003, 35, 85–103. [Google Scholar] [CrossRef]

- Elsayed, M.A.; Raymond, D.W. Analysis of coupling between axial and torsional vibration in a compliant model of a drillstring equipped with a PDC bit. In Proceedings of the ASME Engineering Technology Conference on Energy, Houston, TX, USA, 4–5 February 2002; pp. 897–904. [Google Scholar] [CrossRef]

- Chi, A.; Zhang, J.; Ge, W.; Guo, B. Prediction of drillstring fatigue life under axial-torsional-combined vibration. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, AB, Canada, 15–17 May 2006. [Google Scholar] [CrossRef]

- Yigit, A.S.; Christoforou, A.P. Coupled torsional and bending vibrations of actively controlled drillstrings. J. Sound Vib. 2000, 234, 67–83. [Google Scholar] [CrossRef]

- Abdo, J.; Al-Sharji, H. Investigation of vibration effects on friction and axial force transfer of buckled rod constrained in a horizontal cylinder. Tribol. Int. 2015, 92, 317–327. [Google Scholar] [CrossRef]

- Liao, C.M.; Balachandran, B.; Karkoub, M.; Abdel-Magid, Y.L. Drill-string dynamics: Reduced-order models and experimental studies. J. Vib. Acoust. 2011, 133, 041008. [Google Scholar] [CrossRef]

- Gao, G.; Miska, S. Dynamic buckling and snaking motion of rotating drilling pipe in a horizontal well. SPE J. 2010, 15, 867–877. [Google Scholar] [CrossRef]

- Zhu, W.P.; Di, Q.F. Effect of prebent deflection on lateral vibration of stabilized drill collars. SPE J. 2011, 16, 200–216. [Google Scholar] [CrossRef]

- Warren, T.M.; Brett, J.F.; Sinor, L.A. Development of a Whirl-Resistant Bit. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–11 October 1990; p. SPE-19572-PA. [Google Scholar] [CrossRef]

- Ren, F.; Wang, B.; Zhao, L.; Zhu, A. Experimental investigation and analysis of dynamic buckling of drill string in horizontal well. Shock. Vib. 2017, 2017, 1658435. [Google Scholar] [CrossRef]

- Vandiver, K.J.; Nicholson, J.W.; Shyu, R.J. Case studies of the bending vibration and whirling motion of drill collars. SPE Drill. Eng. 1990, 5, 282–290. [Google Scholar] [CrossRef]

- Al Dushaishi, M.F. Numerical and Field Data Analysis of Drill Stem Vibration. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2015. Available online: https://www.proquest.com/docview/1761851213?pq-origsite=gscholar&fromopenview=true&sourcetype=Dissertations%20&%20Theses (accessed on 26 February 2024).

- Kapitaniak, M.; Vaziri, V.; Chávez, J.P.; Wiercigroch, M. Experimental studies of forward and backward whirls of drill-string. Mech. Syst. Signal Process. 2018, 100, 454–465. [Google Scholar] [CrossRef]

- Liu, W.; Ni, H.; Wang, Y.; Guo, Y.; Gao, Y.; He, P. Dynamic modeling and load transfer prediction of drill-string axial vibration in horizontal well drilling. Tribol. Int. 2023, 177, 107986. [Google Scholar] [CrossRef]

- Raymond, D.W.; Elsayed, M.A.; Polsky, Y.; Kuszmaul, S.S. Laboratory simulation of drill bit dynamics using a model-based servo hydraulic controller. In Proceedings of the ASME 2007 26th International Conference on Offshore Mechanics and Arctic Engineering, Volume 2: Structures, Safety and Reliability; Petroleum Technology Symposium, San Diego, CA, USA, 10–15 June 2008; pp. 905–914. [Google Scholar] [CrossRef]

- Mihajlovic, N. Torsional and Lateral Vibrations in Flexible Rotor Systems with Friction. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 2005. [Google Scholar] [CrossRef]

- Ambrus, A.; Skadsem, H.J.; Mihai, R.G. Similarity analysis for downscaling a full size drill string to a laboratory scale test drilling rig. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Madrid, Spain, 17–22 June 2018; p. V008T11A005. [Google Scholar] [CrossRef]

- Cayeux, E.; Sui, D.; Akisanmi, O.; Alani, O. Challenges in the Automation of a Laboratory-Scale Drilling Rig and Comparison with the Requirements for Full Scale Drilling Automation. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 5 April 2017. [Google Scholar] [CrossRef]

- Forster, I. Axial excitation as a means of stick slip mitigation-small scale rig testing and full scale field testing. In Proceedings of the SPE/IADC Drilling Conference and Exhibition, Amsterdam, The Netherlands, 1–3 March 2011. [Google Scholar] [CrossRef]

- Antunes, J.; Axisa, F.; Hareux, F. Flexural vibrations of rotors immersed in dense fluids Part II: Experiments. J. Fluids Struct. 1992, 6, 23–38. [Google Scholar] [CrossRef]

- Païdoussis, M.P.; Abdelbaki, A.R.; Butt, M.F.J.; Tavallaeinejad, M.; Moditis, K.; Misra, A.K.; Nahon, M.; Ratigan, J.L. Dynamics of a cantilevered pipe subjected to internal and reverse external axial flow: A review. J. Fluids Struct. 2021, 106, 103349. [Google Scholar] [CrossRef]

- Bavadiya, V.A.; Alsaihati, Z.; Ahmed, R.; Gustafson, K. Experimental investigation of the effects of rotational speed and weight on bit on drillstring vibrations, torque and rate of penetration. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017. [Google Scholar] [CrossRef]

- Berlioz, A.; Der Hagopian, J.; Dufour, R. Dynamic Behavior of a Drill-String: Experimental Investigation of Lateral Instabilities. J. Vib. Acoust. 1996, 118, 292–298. [Google Scholar] [CrossRef]

- Islam, M.R.; Hossain, M.E. State-of-the-art of drilling. In Drilling Engineering; Elsevier: Amsterdam, The Netherlands, 2021; pp. 17–178. [Google Scholar] [CrossRef]

- Abdul-Rani, A.M.; Ibrahim, K.; Ab Adzis, A.H.; Maulianda, B.T.; Mat Asri, M.N. Investigation on the effect of changing rotary speed and weight bit on PCD cutter wear. J. Pet. Explor. Prod. Technol. 2020, 10, 1063–1068. [Google Scholar] [CrossRef]

- Nelson, H.D. A Finite Rotating Shaft Element Using Timoshenko Beam Theory. ASME J. Mech. Des. 1980, 102, 793–803. [Google Scholar] [CrossRef]

- Wu, J.J.; Cartmell, M.P.; Whittaker, A.R. Prediction of the vibration characteristics of a full-size structure from those of a scale model. Comput. Struct. 2002, 80, 1461–1472. [Google Scholar] [CrossRef]

- Wu, J.J. Prediction of lateral vibration characteristics of a full-size rotor-bearing system by using those of its scale models. Finite Elem. Anal. Des. 2007, 43, 803–816. [Google Scholar] [CrossRef]

- Wu, J.J. Prediction of the torsional vibration characteristics of a rotor-shaft system using its scale model and scaling laws. World Acad. Sci. Eng. Technol. Int. J. Mech. Aerosp. Ind. Mechatron. Manuf. Eng. 2015, 9, 229–234. Available online: https://publications.waset.org/10000359/prediction-of-the-torsional-vibration-characteristics-of-a-rotor-shaft-system-using-its-scale-model-and-scaling-laws (accessed on 10 September 2021).

- Goicoechea, H.E.; Lima, R.; Sampaio, R. How to mathematically model a drill-string: Lumped or continuous models? Chaos Solitons Fractals 2024, 188, 115543. [Google Scholar] [CrossRef]

- Casaburo, A.; Petrone, G.; Franco, F.; De Rosa, S. A review of similitude methods for structural engineering. ASME Appl. Mech. Rev. 2019, 71, 030802. [Google Scholar] [CrossRef]

- Buckingham, E. On physically similar systems; illustrations of the use of dimensional equations. Phys. Rev. 1914, 4, 345–376. [Google Scholar] [CrossRef]

- Chen, S.S.; Wambsganss, M.T.; Jendrzejczyk, J.A. Added mass and damping of a vibrating rod in confined viscous fluids. Am. Soc. Mech. Eng. 1976, 43, 325–329. [Google Scholar] [CrossRef]

- Fritz, R.J. The Effects of an Annular Fluid on the Vibrations of a Long Rotor, Part 2—Test. ASME. J. Basic Eng. 1970, 92, 930–937. [Google Scholar] [CrossRef]

- Don, M.G.; Rideout, G. An experimentally-verified approach for enhancing fluid drag force simulation in vertical oilwell drill strings. Math. Comput. Model. Dyn. Syst. 2022, 28, 197–228. [Google Scholar] [CrossRef]

- Wang, B.; Wang, L.; Meng, X.; Ren, F. Effect of annular gas–liquid two-phase flow on lateral vibration of drill string in horizontal drilling for natural gas hydrate. Processes 2023, 11, 54. [Google Scholar] [CrossRef]

- Liang, F.; Yang, X.; Zhang, W.; Qian, Y. Vibrations in 3D space of a spinning supported pipe exposed to internal and external annular flows. J. Fluids Struct. 2019, 87, 247–262. [Google Scholar] [CrossRef]

- Abdollahi, R.; Firouz-abadi, R.D.; Rahmanian, M. On the stability of rotating pipes conveying fluid in annular liquid medium. J. Sound Vib. 2021, 494, 115891. [Google Scholar] [CrossRef]

- Modarres-Sadeghi, Y.; Semler, C.; Wadham-Gagnon, M.; Païdoussis, M.P. Dynamics of cantilevered pipes conveying fluid. Part 3: Three-dimensional dynamics in the presence of an end-mass. J. Fluids Struct. 2007, 23, 589–603. [Google Scholar] [CrossRef]

- Païdoussis, M.; Luu, T.; Prabhakar, S. Dynamics of a long tubular cantilever conveying fluid downwards, which then flows upwards around the cantilever as a confined annular flow. J. Fluids Struct. 2008, 24, 111–128. [Google Scholar] [CrossRef]

- Majeed, F.A.; Karki, H.; Karkoub, M.; Abdel-Magid, Y.L. Experimental Verification of Drill String Vibration Suppression Using an Adaptive Self-Tuning Controller. Int. J. Acoust. Vib. 2013, 18, 20–26. [Google Scholar] [CrossRef]

- Ullah, F.K.; Bohn, C. Dynamic surface control for the reduction of torsional vibrations in a scaled experimental drillstring setup. In Proceedings of the UKACC 12th International Conference on Control (CONTROL), Sheffield, UK, 5–7 September 2018; pp. 199–204. [Google Scholar] [CrossRef]

- Esmaeili, A.; Elahifar, B.; Fruhwirth, R.K.; Thonhauser, G. Laboratory scale control of drilling parameters to enhance rate of penetration and reduce drill string vibration. In Proceedings of the SPE Kingdom of Saudi Arabia Annual Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 8–11 April 2012; p. SPE-160872-MS. [Google Scholar] [CrossRef]

- Esmaeili, A.; Elahifar, B.; Fruhwirth, R.K.; Thonhauser, G. Formation prediction model based on drill string vibration measurements using laboratory scale rig. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Dubai, United Arab Emirates, 7–9 October 2013; p. SPE-166793-MS. [Google Scholar] [CrossRef]

- Elmgerbi, A.M.; Ettinger, C.P.; Tekum, P.M.; Thonhauser, G.; Nascimento, A. Application of machine learning techniques for real time rate of penetration optimization. In Proceedings of the SPE/IADC Middle East Drilling Technology Conference and Exhibition, Abu Dhabi, United Arab Emirates, 25–27 May 2021; p. SPE-202184-MS. [Google Scholar] [CrossRef]

- Bavadiya, V.A.; Aljubran, M.J.; Kibe, J.M.; Christy, S.M.; Le, H.N.; Ahmed, R.; Florence, F. Design, construction and operation of an automated drilling rig for the DSATS university competition. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 28–30 September 2015. [Google Scholar] [CrossRef]

- Al Shekaili, A.; Afebu, K.O.; Liu, Y.; Papatheou, E. Experimental analysis of drillstring vibrations using a small-scale drilling rig. Nonlinear Dyn. 2025, 113, 17491–17518. [Google Scholar] [CrossRef]

- Kapitaniak, M.; Hamaneh, V.V.; Chávez, J.P.; Nandakumar, K.; Wiercigroch, M. Unveiling complexity of drill–string vibrations: Experiments and modelling. Int. J. Mech. Sci. 2015, 101, 324–337. [Google Scholar] [CrossRef]

- Kapitaniak, M.; Hamaneh, V.V.; Wiercigroch, M. Torsional vibrations of helically buckled drill-strings: Experiments and FE modelling. J. Phys. Conf. Ser. 2016, 721, 012012. [Google Scholar] [CrossRef]

- Liu, Y.; Páez Chávez, J.; De Sa, R.; Walker, S. Numerical and experimental studies of stick–slip oscillations in drill-strings. Nonlinear Dyn. 2017, 90, 2959–2978. [Google Scholar] [CrossRef]

- Lian, Z.; Zhang, Q.; Lin, T.; Wang, F. Experimental and numerical study of drill string dynamics in gas drilling of horizontal wells. J. Nat. Gas Sci. Eng. 2015, 27, 1412–1420. [Google Scholar] [CrossRef]

- Lin, T.; Zhang, Q.; Lian, Z.; Xiao, Z.; Wang, T.; Li, G.; Ding, J. Experimental study on vibrational behaviors of horizontal drillstring. J. Pet. Sci. Eng. 2018, 164, 311–319. [Google Scholar] [CrossRef]

- Shao, D.D.; Guan, Z.C.; Wen, X. Experimental Device of Drilling String Dynamics in Horizontal Well and its Application. Adv. Mater. Res. 2013, 683, 690–693. [Google Scholar] [CrossRef]

- Wang, H.; Guan, Z.C.; Shi, Y.C.; Chen, W.Q.; Liu, Y.W.; Zhang, B.; Liang, D.Y.; Wang, X.H. Modeling and analyzing the motion state of bottom hole assembly in highly deviated wells. J. Pet. Sci. Eng. 2018, 170, 763–771. [Google Scholar] [CrossRef]

- Shao, D.D. Analysis of Drill String Dynamic Characteristics in Horizontal Well Hole; China University of Petroleum: Beijing, China, 2013. [Google Scholar]

- Sharma, A.; Srivastava, S.; Teodoriu, C. Experimental design, instrumentation, and testing of a laboratory-scale test rig for torsional vibrations—The next generation. Energies 2020, 13, 4750. [Google Scholar] [CrossRef]

- Li, W.; Huang, G.; Ni, H.; Yu, F.; Huang, B.; Jiang, W. Experimental study and mechanism analysis of the motion states of bottom hole assembly during rotary drilling. J. Pet. Sci. Eng. 2020, 195, 107859. [Google Scholar] [CrossRef]

- Butterfield, R. Dimensional analysis for geotechnical engineers. Geotechnique 1999, 49, 357–366. [Google Scholar] [CrossRef]

- Shi, Y.; Wan, Y.; Wu, C. Setting up A Simulate device on motion behavior of bottom-hole assembly according to similitude principles. J. Guangxi Univ. Nat. Sci. Ed. 2006, 31, 159–162. Available online: http://caod.oriprobe.com/articles/11827080/Setting_up_a_simulate_device_on_motion_behavior_of_bottom_hole_assembl.htm (accessed on 10 September 2021).

- Maitra, E.K. Fluid-Induced Drilling Dynamics—A Mechanically Scaled Experimental Investigation. Master’s Thesis, Oklahoma State University, Stillwater, OK, USA, 2023. Available online: https://hdl.handle.net/20.500.14446/338937 (accessed on 26 February 2024).

- Chehreghani, M.; Shaaban, A.; Misra, A.K.; Païdoussis, M.P. Dynamics of a hanging fluid-discharging pipe subjected to reverse external flow: An experimental investigation. J. Fluids Struct. 2023, 119, 103889. [Google Scholar] [CrossRef]

- Maitra, E.K.; Al Dushaishi, M.F. How does flow rate affect drillstring vibrations? Experimental investigation. In Proceedings of the AADE National Technical Conference, Midland, TX, USA, 4–5 April 2023; p. AADE-23-NTCE-061. Available online: https://www.aade.org/application/files/6417/2650/2196/AADE-23-NTCE-061_-_Maitra.pdf (accessed on 26 February 2024).

- Xu, Y.; Zhang, H.; Guan, Z. Dynamic characteristics of downhole bit load and analysis of conversion efficiency of drill string vibration energy. Energies 2021, 14, 229. [Google Scholar] [CrossRef]

- Zhang, H.; Guan, Z.; Wang, H. Experimental study of downhole shock absorber based on the similarity theory. Adv. Pet. Explor. Dev. 2015, 9, 98–102. [Google Scholar] [CrossRef]

- Maitra, E.K.; Al Dushaishi, M.F.; Sugiura, J.; Jones, S. Experimental Visualization of Downhole Drilling Vibration Using Industrial Drilling Dynamic Recorder. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 12 February 2024. [Google Scholar] [CrossRef]

| Article | Mode | Phenomena | Objective | Approach | Instrumentation |

|---|---|---|---|---|---|

| [58] | Torsional, Lateral | Stick–slip, Whirl | Validating a dynamic friction model that describes the effect of downhole contact friction on the downhole instability and characterizes friction-induced torsional and lateral vibrations, and their coupled nature | Characterizing the nature of both torsional and lateral vibrations in terms of imposed BHA-wellbore friction and damping | Rotation at the motor and lower disk with encoders, lateral displacement with two Linear Variable Differential Transformer (LVDT) sensors, and brake friction force using a force sensor |

| [48] | Torsional, Lateral | Bit-Bounce, Stick–slip, Whirl | Developing a mathematical model to determine frictional stick–slip interactions that lead to lateral instability | Analyzing the effects of WOB and friction with stick–slip interactions on the lateral displacement and motion pattern, and comparing the numerical and experimental results | Rotation at both disks with two encoders, and lateral motion photographed |

| [83] | Torsional, Lateral | Stick–slip, Whirl | Verifying the self-tuning closed-loop control algorithm | Testing bit-whirl and bit-rotation stability at different rotations | Rotation of both disks using two encoders |

| [84] | Torsional | Stick–slip | Developing a dynamic surface control system to reduce high-frequency torsional oscillation | Defining error equations to describe bit to wellbore friction as model uncertainty | Top-drive rotation with an incremental encoder, BHA torque, and speed using Magtrol® |

| [44,57] | Axial, Torsional | Bit-Bounce, Stick–slip | Investigating axial and torsional vibration coupling during hard rock drilling with a PDC coring bit with a torsionally compliant laboratory-scale drillstring, and developing control strategies to mitigate bit-bounce effects | Simulating torsional and axial vibration phenomena, analyzing axial and torsional vibration characteristics in relation to drilling rotation, WOB, and ROP, and evaluating the performance of a control system | WOB is measured using the input parameter of the hydraulic system, axial displacement using a transducer, torsional vibration using a torsional displacement transducer, and accelerometers for system vibrations |

| [85,86,87] | Axial, Lateral | N/A | Experimentally evaluating drillstring vibration management with optimum drilling parameters to maximize ROP and drilling performance using an automated test rig | Comparing vibration magnitudes to ROP deviation as the drilling performance indicator over a range of WOB and RPM, and developing formation prediction and ROP optimization models with vibration data using ANN and ML | Top-drive rotation and torque with motor input frequency and power, WOB using load cell, ROP with servo-motor’s interface and ultrasonic sensor, and drillstring vibrations using accelerometers |

| [64,88] | Axial, Torsional, Lateral | N/A | Examining drilling dynamics of PDC bit on soft and hard sandstone samples for various drilling parameters | Comparing vibration responses for ranges of WOB and RPM, and validating experimental data with an analytical model for the effect of drilling parameters and vibration on ROP in soft rock formation | Lateral vibration, ROP, and rotation using individual laser/optical sensors, and individual sensors for torque, axial vibration, WOB, pressure, and flow rate |

| [89] | Axial, Torsional, Lateral | Bit-Bounce, Stick–Slip, Whirl | Developing detection approaches of bit bounce, whirling, and stick–slip in laboratory scale, and identifying controlling parameters to mitigate their adverse effects | Conducting bivariate kernel estimation, spectrum analysis, and periodogram analysis to evaluate the drilling dynamics and the impact of drillstring vibrations on drilling performance | Rotation and torsional fluctuation at surface and downhole using torque sensors, ROP and bit-bounce using laser sensors, WOB and bit-bounce using three load cells, and lateral movement using eddy current sensors |

| [55,90,91] | Axial, Torsional, Lateral | Stick–Slip, Buckling, Whirl | Developing an experimental setup to simulate all vibration modes in the same instance, and studying the coupled effect of lateral vibration on torsional vibration | Analyzing multiple bit–rock interactions in relation to various WOB, RPM, and different vibration phenomena | Surface and downhole rotation with encoders, lateral displacement with eddy current sensors, ROP with an LVDT, TOB using a force transducer, and WOB with a load cell below the rock samples |

| [92] | Torsional | Stick–Slip | Identifying stick–slip control method using WOB, rotary speed, and drillstring geometric and mechanical properties | Comparing the effects of frictional torque due to WOB, applied rotary speed, and geometric and mechanical properties of the drillstring, i.e., stiffness, torsion, and damping constant, on stick–slip | Rotation with encoders at the surface and downhole, and rotary speed fluctuation by using the motor’s current |

| [4] | Axial, Lateral | Whirl | Investigating mechanisms of lateral vibration, whirling, and axial-lateral vibration coupling | Simulating forward and backward whirling, and conducting spectral analysis to identify the dominant vibration frequencies for model verification | Lateral vibrations using two single-axis strain gauges attached to the drillstring using a slip-ring |

| [19] | Lateral | Whirl | Determining the contact force between the drillstring and wellbore during whirl | Analyzing the vibration responses of the drillstring with contact force between the drillstring and the wellbore | Lateral displacement using eddy-current sensors and contact forces using force sensors |

| [93,94] | Axial, Torsional, Lateral | Buckling, Whirl | Studying the effects of WOB and rotary speed on the dynamics of horizontal drilling and drilling stability | Comparing WOB and rotary speed fluctuation, and the effect of rotary speed on vibration magnitudes and whirl frequency | Axial force, torque, and lateral displacement using designated sensors, and a high-speed camera for drillstring motion |

| [52] | Lateral | Buckling, Whirl | Investigating the dynamic buckling of drillstring in horizontal wells and developing a mathematical model to address the drillstring to wellbore friction | Observing WOB transfer efficiency due to drillstring-wellbore friction, and comparing critical buckling loads and lateral vibration amplitudes between the theoretical and experimental results | Rotation with tachometer generator, WOB using a strain-type pressure sensor below the bit, axial and lateral displacement using eddy-current sensors |

| [96] | Axial, Torsional, Lateral | Buckling, Whirl | Investigating the lateral stability and motion of a drillstring in inclined wells and model verification | Comparing the lateral vibration amplitudes and frequency for different conditions, and a wellbore inclination of 79° compared to a horizontal wellbore | Axial force using a downhole force sensor, and lateral displacement using laser displacement sensors at three locations |

| [39,98] | Torsional | Stick–slip | Surveying experiment design and developing an experimental facility to study torsional vibration | Identifying good material and equipment choices to study drillstring vibration, and measuring torsional vibration responses during stick–slip at the bit | Surface and bit rotation with encoders, torque sensor, hook load using a load cell, axial displacement using a linear-potentiometer |

| [99] | Axial, Torsional, Lateral | Buckling, Whirl | Studying the effects of well inclination, well friction, measurement position, rotation speed, and WOB on the lateral motion and whirl formation mechanism | Comparing lateral movement magnitude, changes in whirl directions, and patterns | Torque input using torque sensors, WOB using a force sensor, and lateral displacement using optical proximity sensors |

| [65] | Lateral | Stick–slip, Whirl | Evaluating the effect of external forces and fluid properties on lateral instabilities | Comparing the vibration amplitudes at the harmonic frequencies to determine the effect of dogleg angle, torque, axial forces, and drilling fluids properties of ten different liquids on individual and coupled modes of lateral vibrations | Torque from both ends using torque meters, axial force with a force transducer, lateral displacement with proximity sensors, and optical sensors |

| [18] | Torsional | Stick–slip | Tuning and validating an elastodynamic model to describe the interaction between fluid and drillstring vibration | Determining the damping factor and natural frequency of the drillstring in the presence of three different liquids through spectral analysis | Lateral displacement using three eddy current probes at three measurements along the length, and rotation with motor speed control |

| [103] | Lateral | N/A | Interpreting the fluid structure interactions between drilling fluid circulation and drillstring | Investigating the effects of drillstring slenderness, material properties, and eccentricity on the lateral instability for different internal and external fluid flow | Lateral displacement using high-speed cameras, inlet fluid flow using magnetic flow meters, and confinement pressure using a Bourdon tube pressure gauge |

| [24,102,104,107] | Axial, Lateral | Whirl | Investigating the effects of circulating fluid flow on drillstring vibrations and lateral instability | Comparing spectral analysis of vibration responses and downhole lateral movement of the drillstring subjected to various rotary speeds, bit interaction, fluid flow, and annulus flow regimes | Rotation using an optic proximity sensor, lateral displacement using inductive sensors at three measurements along the length, tri-axial bit vibration using accelerometers, and fluid flow with flow meter |

| [78] | Lateral | N/A | Investigating the mechanism of fluid-induced vibrations by annulus multiphase flow in horizontal well drilling | Observed the effect of annular drilling fluid velocity and gas content on the drillstring’s lateral stability | Annular gas content with a gas flow meter, lateral displacement at three sections using an eddy current sensor |

| [31] | Torsional, Lateral | Stick–Slip, Whirl | Evaluating vibration mitigation performance of AVDT with downscaled prototypes | Comparing AVDT vibration mitigation performance for torsional and lateral vibrations using different prototype designs, i.e., placement location, compression load, and inclination | Rotation at top-drive and BHA with tachometer, shocks with accelerometer, WOB, and torque using motor output voltage and current |

| [61] | Torsional | Stick–Slip | Developing a downhole axial agitator tool for stick–slip mitigation | Comparing the change in torsional vibration and stick–slip while inducing axial excitation | Input rotation and torque with motor current-flow, drillstring rotation with tachometer generator, and WOB by correlating with hanging load spring extension using displacement sensors |

| [105,106] | Axial | Bit-bounce | Studying the effectiveness of a downhole spring attachment as an axial shock absorber tool | Comparing the level WOB fluctuation and energy conversion efficiency of the system for ranges of WOB, rotary speed, spring stiffness, and position on the BHA | Downhole load using a pressure sensor, axial displacement and vibration using a laser displacement sensor and an accelerometer, and lateral bit forces with force sensors |

| Article | Configuration | Dimensions

| Applied Forces

| Interactions

|

|---|---|---|---|---|

| [58] | Vertical assembly of a two-disk rotor model with flexible steel |

|

|

|

| [48] | Vertical assembly of a two-disk rotor model of a drillstring section with flexible steel |

|

|

|

| [83] | Vertical assembly of a two-disk rotor model with a flexible carbon steel string |

|

|

|

| [84] | Vertical assembly of a two-disk rotor model with a flexible carbon steel string |

|

|

|

| [44,57] | Vertical assembly of a metal shaft with an inertia disk from the top-drive |

|

|

|

| [85,86,87] | Vertical assembly of a metal shaft |

|

|

|

| [64,88] | Vertical assembly of aluminum pipe |

|

|

|

| [89] | Vertical assembly of connected steel pipes and a heavier cylinder at the end |

|

|

|

| [55,90,91] | Vertical assembly of flexible string and rigid assembly model with weight disks as BHA |

|

|

|

| [92] | Vertical assembly of flexible string and rigid assembly model with weight disks as BHA |

|

|

|

| [4] | Vertical assembly of acrylic rod |

|

|

|

| [19] | Horizontal assembly of connected pipes |

|

|

|

| [93,94] | Horizontal assembly of connected steel pipes |

|

|

|

| [52] | Horizontal assembly |

|

|

|

| [96] | Horizontal and 79° inclined assembly, made of ABS engineering plastic pipe |

|

|

|

| [39,98] | Deviated assembly of a PVC string |

|

|

|

| [99] | Vertical to horizontal, several inclined assemblies of polymethyl methacrylate (PMMA) rods, an aluminum alloy near-bit stabilizer, and a bit |

|

|

|

| [65] | Vertical and a fixed curve deviated assembly with a 1° dogleg angle per 10 m |

|

|

|

| [18] | Vertical assembly of stainless-steel shaft |

|

|

|

| [103] | Vertically cantilevered three different models of flexible pipes made of silicone rubber and Santoprene |

|

|

|

| [24,102,104,107] | Horizontal assembly of a continuous PEX pipe with three stabilizer sections |

|

|

|

| [78] | Horizontal assembly of ABS engineering plastic pipe |

|

|

|

| [31] | Vertical and 30° upside-down assembly with multiple supported sections of steel strings |

|

|

|

| [61] | Vertical assembly of steel string |

|

|

|

| [105,106] | Vertical assembly of segmented ABS plastic pipes connected to a downhole axial shock absorber |

|

|

|

| Articles | Geometric | Rotary Speed | WOB |

|---|---|---|---|

| [4] | 18:1 | 1:5 | 27,248:1 |

| [19] | 4:1 | - | - |

| [93,94] | 8:1 | 1:8 | 64:1 |

| [52] | 10:1 | 1:3 | 9130:1 |

| [96] | 10:1 | 1:3 | 9130:1 |

| [39,98] | 30:1 | 1:1 | - |

| [99] | 43:1 | 1:4 | 130,000:1 |

| [24,102,104,107] | 17:1 | 1:2 | 3050:1 |

| [78] | 10:1 | - | - |

| [105,106] | 10:1 | 1:3 | 9130:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maitra, E.K.; Al Dushaishi, M.F. Laboratory-Scale Drillstring Vibration Analysis. Mining 2025, 5, 78. https://doi.org/10.3390/mining5040078

Maitra EK, Al Dushaishi MF. Laboratory-Scale Drillstring Vibration Analysis. Mining. 2025; 5(4):78. https://doi.org/10.3390/mining5040078

Chicago/Turabian StyleMaitra, Eshan K., and Mohammed F. Al Dushaishi. 2025. "Laboratory-Scale Drillstring Vibration Analysis" Mining 5, no. 4: 78. https://doi.org/10.3390/mining5040078

APA StyleMaitra, E. K., & Al Dushaishi, M. F. (2025). Laboratory-Scale Drillstring Vibration Analysis. Mining, 5(4), 78. https://doi.org/10.3390/mining5040078