Technogenic Waste in Backfill Composite Is a Paradigm of Circular Economy

Abstract

1. Introduction

- Replacement of natural pillars, thereby increasing recovery rates;

- More effective control of the stress–strain state of the rock mass;

- Prevention of roof collapses;

- Minimization of methane-conducting fracture formation;

- Reduction in the risk of subvertical faulting in the overlying strata, thus preventing surface subsidence;

- Elimination of voids, thereby reducing the likelihood of explosive accumulations of methane and coal dust.

2. Materials and Methods

2.1. Methodology

2.2. Equipment

2.3. Materials

2.3.1. Binder

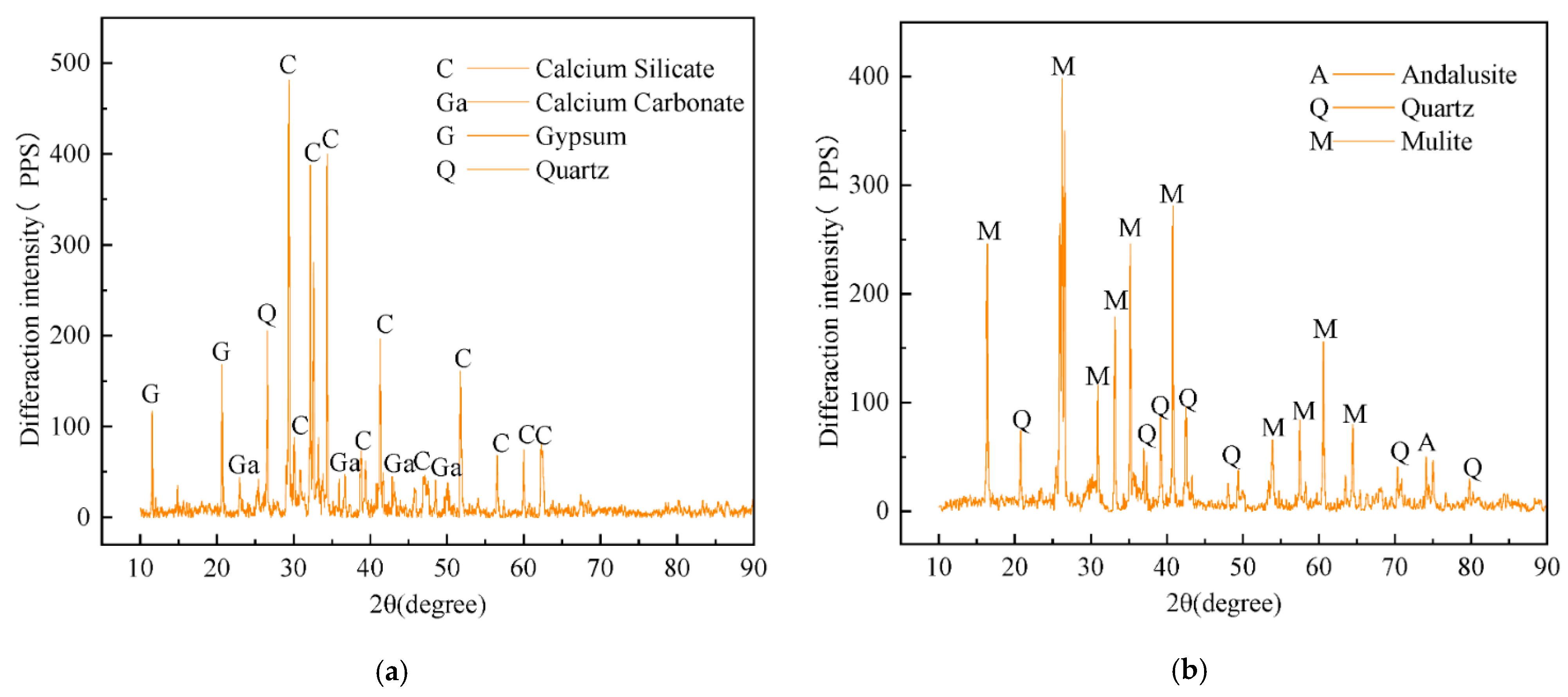

2.3.2. Aggregate

2.3.3. Additives

2.3.4. Hardener

3. Results and Discussions

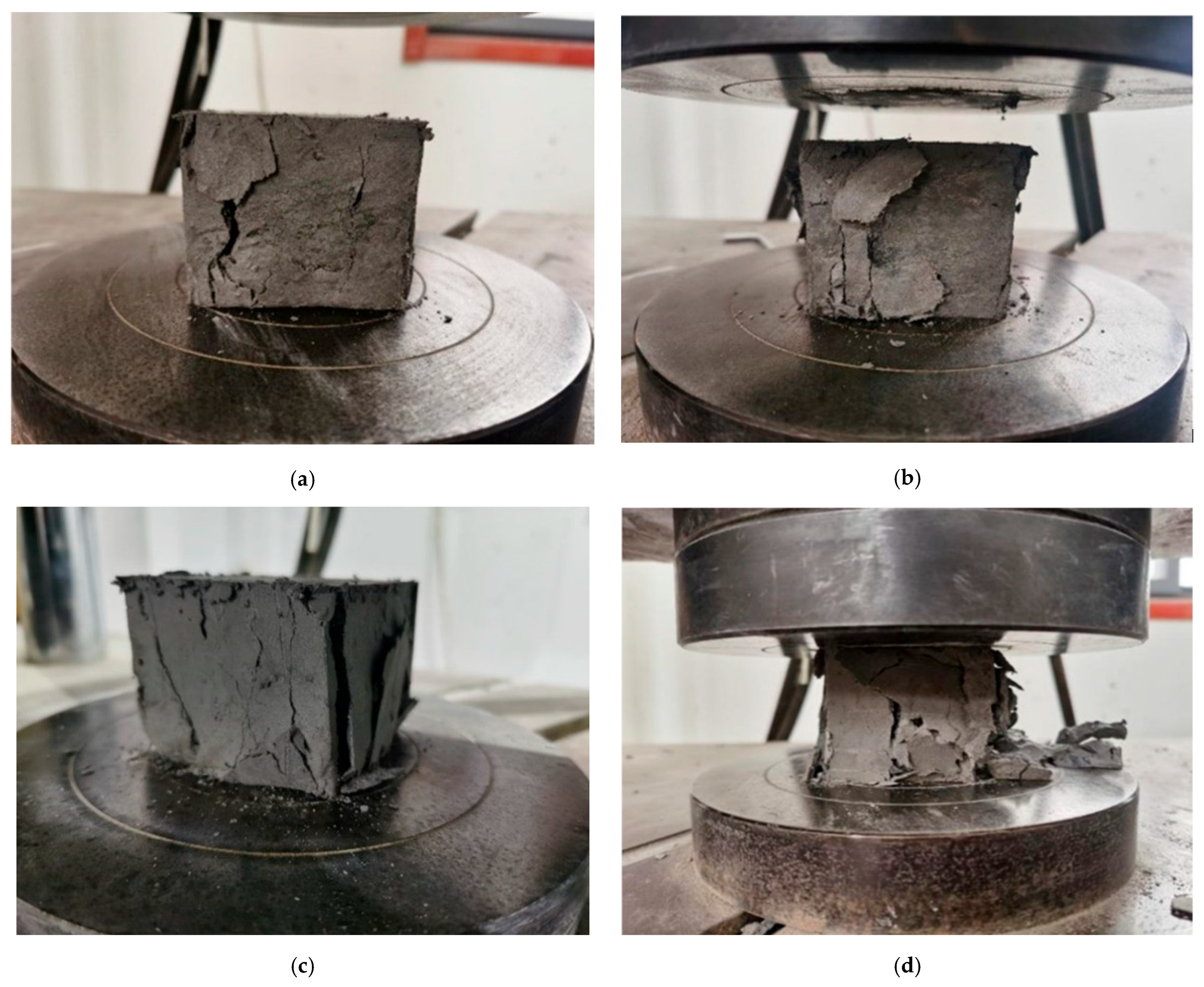

3.1. Uniaxial Compression Testing

3.2. Study in Splitting Mode

3.3. Microstructural Analysis

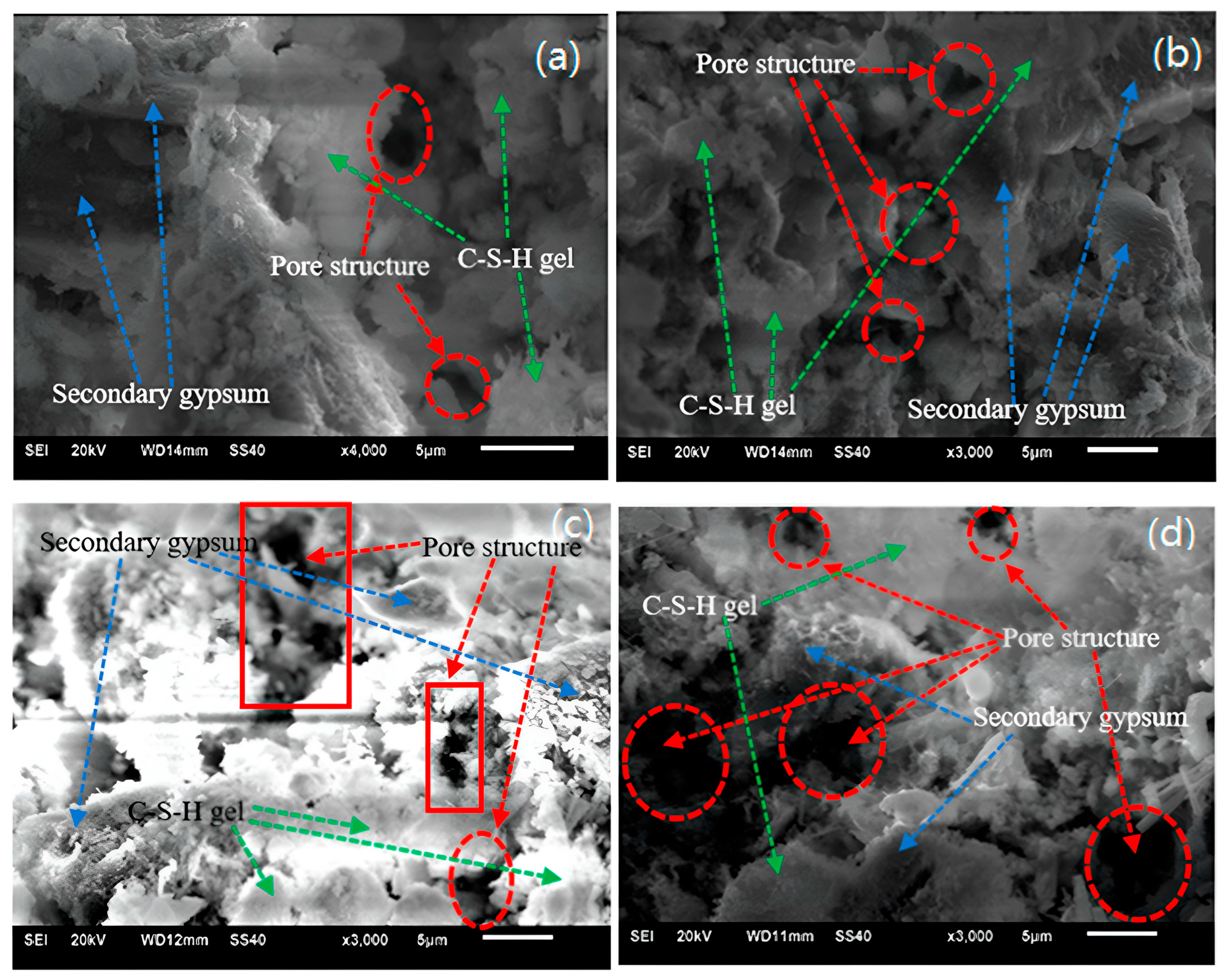

3.3.1. Influence of Nanomodified Silicon Dioxide

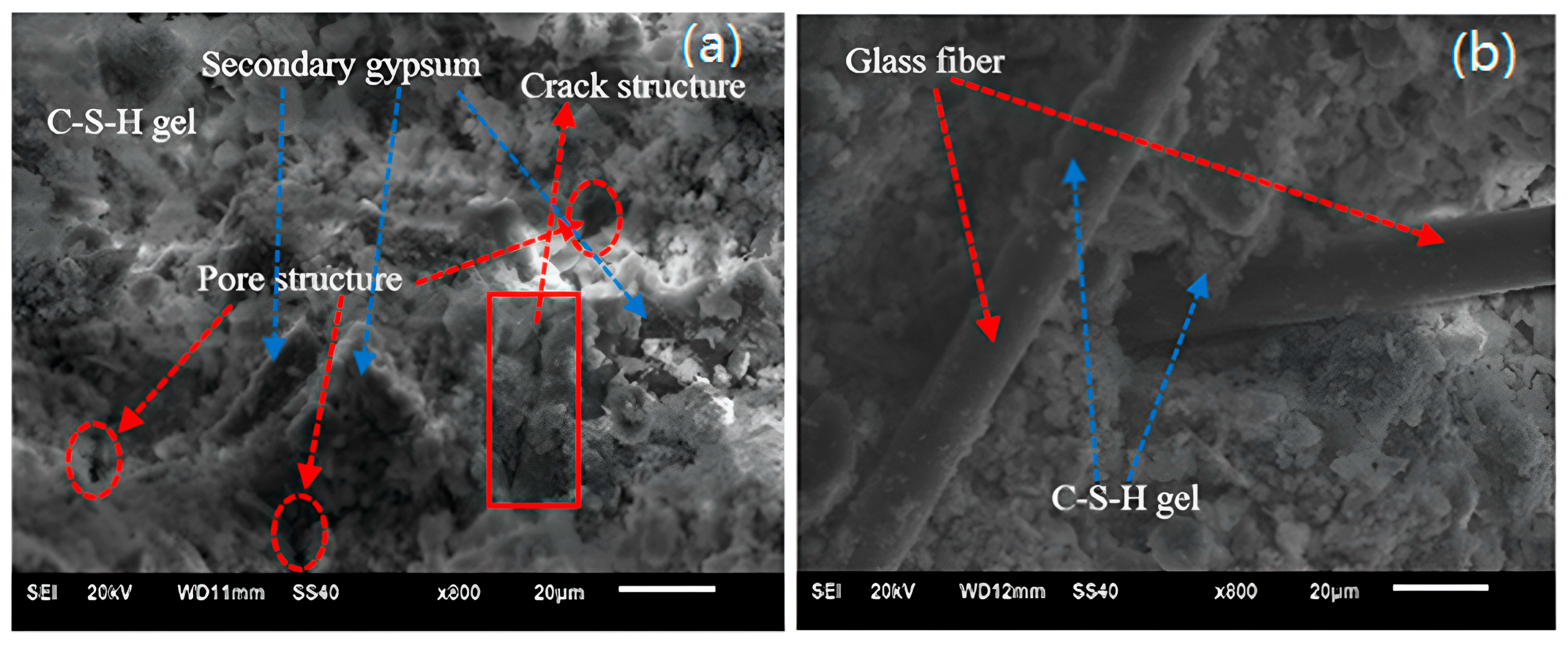

3.3.2. Influence of Glass Fiber

3.3.3. Environmental and System-Level Implications

4. Conclusions

- The circular (closed-loop) economy predetermines the use and recycling of technogenic (man-made, industrial) waste.

- The bench tests of the curing backfill composite, created from industrial waste from the coal industry, where crushed waste rock is used as an inert filler and traditional cement binder is replaced with fly ash, demonstrated the following results:

- 2.1.

- Nanomodified silicon dioxide at a dosage of 0.5% in the backfill composite formulation increases both its mechanical properties and the curing rate at the initial storage periods.

- 2.2.

- Increasing the curing time of the backfill composite with nanomodified silicon dioxide at a dosage of 0.5% leads to a gradual slowing of the growth of mechanical properties, followed by stabilization after 90 days.

- 2.3.

- Doubling the content of nanomodified silicon dioxide from 0.5% to 1.0% in the backfill composite formulation leads to a sharp increase in its strength properties during the initial curing periods, followed by a decrease in the rate of strength development at 60 days and transitioning to negative values after 90 days.

- 2.4.

- With increasing storage (curing) time, the nature of destruction and deformation changes from ductile to brittle.

- 2.5.

- Glass fiber in the backfill composite formulation enhances its mechanical properties but does not affect the rate of strength development, demonstrating a stable growth rate.

- 2.6.

- Simultaneous incorporation of glass fiber and nanomodified silicon dioxide into the backfill composite formulation results in a material with high strength characteristics, equalizes the rate of strength development throughout the storage period, and prevents the transition to negative values.

- The microstructural analysis of the curing backfill composite, created from industrial waste from the coal industry, where crushed waste rock is used as an inert filler and traditional cement binder is replaced with fly ash, demonstrated the following results:

- 3.1.

- With increasing curing time, nanomodified silicon dioxide in the backfill composite formulation leads to significant changes in the products of hydration, as well as in the quantity and structure of pores.

- 3.2.

- Doubling the nanomodified silicon dioxide in the backfill composite formulation (from 0.5% to 1.0%) during the initial stages of curing promotes accelerated hydration and advanced formation of secondary gypsum and C-S-H gel.

- 3.3.

- With increased curing time, the accelerated formation of secondary gypsum after 90 days leads to a weakening of mechanical properties due to the increase in the volumetric amount of secondary gypsum rather than its quantity.

- 3.4.

- Glass fiber in the backfill composite binds the matrix structure, and the hydration products dispersed on the surface of the glass fiber adhere to it, forming a strong bond, which makes the matrix more durable.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Babyr, N.V.; Gabov, V.V.; Nosov, A.A.; Nikiforov, A.V. Features of design and work method of mining module at coal deposits in the Russian Arctic. MIAB Min. Inf. Anal. Bull. 2024, 6, 5–16. (In Russian) [Google Scholar] [CrossRef]

- Petrenko, I.E. Russia’s coal industry performance for January–September, 2022. Ugol’ 2022, 12, 7–21. (In Russian) [Google Scholar] [CrossRef]

- Qiao, J.; Wang, Z.; Zhao, J. The evolution of thick coal seams mining methods in China. MIAB Min. Inf. Anal. Bull. 2020, 8, 105–117. [Google Scholar] [CrossRef]

- Babyr, N.V. Topical Themes and New Trends in Mining Industry: Scientometric Analysis and Research Visualization. Int. J. Eng. Trans. A Basics 2024, 37, 439–451. [Google Scholar] [CrossRef]

- Black, D.J. Review of coal and gas outburst in Australian underground coal mines. Int. J. Min. Sci. Technol. 2019, 29, 815–824. [Google Scholar] [CrossRef]

- Korshak, A.A.; Pshenin, V.V. Modeling of Water Slug Removal from Oil Pipelines by Methods of Computational Fluid Dynamics. Neft. Khozyaystvo—Oil Ind. 2023, 10, 117–122. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B.; Sazankova, E.S.; Cherevko, M.A.; Dengaev, A.V. A study of the structural defects impact on the strength of rocks. Ugol 2025, 5, 97–100. (In Russian) [Google Scholar] [CrossRef]

- Li, M.; Yan, Y.; Dai, H.; Zhang, Z. Study on Rock and Surface Subsidence Laws of Super-High Water Material Backfilling and Mining Technology: A Case Study in Hengjian Coal Mine. Sustainability 2023, 15, 8713. [Google Scholar] [CrossRef]

- Kovalskiy, E.R.; Kongar-Syuryun, C.B.; Sirenko, Y.G.; Mironov, N.A. Modeling of rheological deformation processes for room and pillar mining at the Verkhnekamsk potash salt deposit. Sustain. Dev. Mt. Territ. 2024, 16, 1017–1030. (In Russian) [Google Scholar] [CrossRef]

- Rankine, R.; Pacheco, M.; Sivakugan, N. Underground Mining with Backfills. Soils Rocks 2007, 30, 93–101. [Google Scholar] [CrossRef]

- Esterhuizen, G.S.; Dolinar, D.R.; Ellenberger, J.L. Pillar strength in underground stone mines in the United States. Int. J. Rock Mech. Min. 2011, 48, 42–50. [Google Scholar] [CrossRef]

- Skrzypkowski, K. Decreasing Mining Losses for the Room and Pillar Method by Replacing the Inter-Room Pillars by the Construction of Wooden Cribs Filled with Waste Rocks. Energies 2020, 13, 3564. [Google Scholar] [CrossRef]

- Korshak, A.A.; Korshak, A.A.; Pshenin, V.V. Calculation of phase transitions in condensation units for recovery of oil and oil products vapors. Neft. Khozyaystvo—Oil Ind. 2021, 6, 98–101. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B. Influence of mine water on the strength of artificial mass based on industrial waste. Ugol’ 2024, 12, 75–78. (In Russian) [Google Scholar] [CrossRef]

- Onyeneke, C.; Harper, B.; Thompson, S. Mining versus Indigenous Protected and Conserved Areas: Traditional Land Uses of the Anisininew in the Red Sucker Lake First Nation, Manitoba, Canada. Land 2024, 13, 830. [Google Scholar] [CrossRef]

- Skorobogatov, A.A.; Pshenin, V.V.; Tsvetkova, C.P.; Borisov, R.A. Multiphase Oil-water Flow in Horizontal and Inclined Pipelines. Effect of Flow Velocity on Flow Patterns. Int. J. Eng. Trans. B Appl. 2025, 38, 1820–1830. [Google Scholar] [CrossRef]

- Aznar-Sánchez, J.A.; García-Gómez, J.J.; Velasco-Muñoz, J.F.; Carretero-Gómez, A. Mining Waste and Its Sustainable Management: Advances in Worldwide Research. Minerals 2018, 8, 284. [Google Scholar] [CrossRef]

- Sharghi, M.; Jeong, H. The Potential of Recycling and Reusing Waste Materials in Underground Construction: A Review of Sustainable Practices and Challenges. Sustainability 2024, 16, 4889. [Google Scholar] [CrossRef]

- Soloviev, S.V.; Kuziev, D.A. Dragline ESH-10/70 linkage stiffness parameters study. Ugol’ 2017, 1, 37–38. [Google Scholar]

- Agafonov, V.V.; Oganesyan, A.S.; Solovykh, D.Y.; Kozlova, O.Y. Effect of polypropylene fiber on cement backfill based on tailings. Sustain. Dev. Mt. Territ. 2023, 15, 1108–1118. (In Russian) [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Babyr, N.; Klyuev, R.; Khayrutdinov, M.; Zaalishvili, V.; Agafonov, V. Model for Assessing Efficiency of Processing Geo-Resources, Providing Full Cycle for Development—Case Study in Russia. Resources 2025, 14, 51. [Google Scholar] [CrossRef]

- Pawłuszek-Filipiak, K.; Wielgocka, N.; Rudziński, Ł. The Detectability of Post-Seismic Ground Displacement Using DInSAR and SBAS in Longwall Coal Mining: A Case Study in the Upper Silesian Coal Basin, Poland. Remote Sens. 2024, 16, 2533. [Google Scholar] [CrossRef]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M. Creation of a backfill composite based on coal industry waste. Ugol’ 2024, 10, 24–27. (In Russian) [Google Scholar] [CrossRef]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M.; Gorelkina, E.I. Increasing Classification of georesources in the paradigm of their integrated development. Russ. Min. Ind. 2024, 6, 140–143. (In Russian) [Google Scholar] [CrossRef]

- Gabov, V.V.; Babyr, N.V.; Zadkov, D.A. Mathematical modelling of operation of the hydraulic support system of the powered support sections with impulse-free continuous regulation of its resistance to the roof rock lowering. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Mechanical Engineering, Automation and Control Systems (MEACS 2020), Novosibirsk, Russia, 17 September 2020; IOP Publishing: Bristol, UK, 2021; Volume 1064. [Google Scholar] [CrossRef]

- Khairutdinov, M.M.; Shaimyardyanov, I.K. Underground geotechnology with backfilling: Shortcomings, opportunities for improvement. MIAB Min. Inf. Anal. Bull. 2009, 1, 240–250. (In Russian) [Google Scholar]

- Repin, S.V.; Afanasyev, A.S.; Dobromirov, V.N.; Barsukov, V.O. Innovative method for disposal of waste of monolithic building structures. Sustain. Dev. Mt. Territ. 2023, 15, 771–783. (In Russian) [Google Scholar] [CrossRef]

- Zakirova, G.S.; Pshenin, V.V.; Gustov, A.A. Compensation of Temperature Deformations of Gas Pipelines. Int. J. Eng. Trans. A Basics 2025, 38, 1699–1707. [Google Scholar] [CrossRef]

- Nikitin, V.I.; Nechaeva, O.A.; Zhivaeva, V.V. Software for calculating the volume of drilling fluid filtrate penetrating into the reservoir during well completion. Neft. Khozyaystvo—Oil Ind. 2022, 8, 126–128. [Google Scholar] [CrossRef]

- Afanasyev, A.S.; Egoshin, A.M.; Alekseev, S.V. Feasibility study of speed regulation on motor roads of mining operations. Russ. Min. Ind. 2025, 1, 82–87. (In Russian) [Google Scholar] [CrossRef]

- Klyuev, R.V.; Bosikov, I.I.; Majer, A.V.; Gavrina, O.A. Comprehensive analysis of the effective technologies application to increase sustainable development of the natural-technical system. Sustain. Dev. Mt. Territ. 2020, 12, 283–290. (In Russian) [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.B.; Khayrutdinov, A.M.; Dengaev, A.V.; Abdulrahman, B. Research on the mechanical properties of backfill composite made from coal mining waste. Ugol’ 2025, 3, 145–148. (In Russian) [Google Scholar] [CrossRef]

- Cui, P.; Zhang, Q.; Yang, K.; Lv, H.; Cao, J.; Wang, W. Classification and Design of Backfill Coal Mining Systems Based on Typical Engineering Cases. Energies 2023, 16, 8074. [Google Scholar] [CrossRef]

- Avksentiev, S.Y.; Semenov, P.A.; Afanasev, A.S. Comprehensive solutions for tailings management at the Usolsky potash plant. Sustain. Dev. Mt. Territ. 2024, 16, 7–18. (In Russian) [Google Scholar] [CrossRef]

- Wang, S.; Ma, L. Characteristics and Control of Mining Induced Fractures above Longwall Mines Using Backfilling. Energies 2019, 12, 4604. [Google Scholar] [CrossRef]

- Korshak, A.A.; Gaisin, M.T.; Pshenin, V.V. Method of Structural Minimization of the Average Risk for Identification of Mass Transfer of Evaporating Oil at Tanker Loading. Neft. Khozyaystvo—Oil Ind. 2019, 10, 108–111. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, Y.; Zhao, T.; Tan, Y.; Yu, F. Experimental Research on Deformation Characteristics of Waste-Rock Material in Underground Backfill Mining. Minerals 2019, 9, 102. [Google Scholar] [CrossRef]

- Yu, Y.; Ma, L.; Zhang, D. Characteristics of Roof Ground Subsidence While Applying a Continuous Excavation Continuous Backfill Method in Longwall Mining. Energies 2020, 13, 95. [Google Scholar] [CrossRef]

- Denisov, E.F.; Yamilev, M.Z.; Tigulev, E.A.; Pshenin, V.V. Analysis of the current level of technologies for determining the location of non-metallic underground services. Neft. Khozyaystvo—Oil Ind. 2022, 9, 121–125. [Google Scholar] [CrossRef]

- Kovalsky, E.; Kongar-Syuryun, C.; Morgoeva, A.; Klyuev, R.; Khayrutdinov, M. Backfill for Advanced Potash Ore Mining Technologies. Technologies 2025, 13, 60. [Google Scholar] [CrossRef]

- Afanasyev, A.S.; Evtyukov, S.A.; Chudakova, N.V. Experimental study of the factors affecting the parameters of emergency braking process for vehicles of category M1. In IOP Conference Series: Materials Science and Engineering, Proceedings of the XIII International Scientific Conference on Architecture and Construction 2020, Novosibirsk, Russia, 22–24 September 2020; IOP Publishing: Bristol, UK, 2020; Volume 953, p. 12092. [Google Scholar] [CrossRef]

- Nikitin, V.I.; Agrelkina, M.M. Justification for the Selection of a Relative Permeability Model in the Task of Predicting Drilling Fluid Filtrate Invasion into the Formation. Int. J. Eng. 2025, 38, 2312–2320. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Hao, Y. Experimental Study and Application of Rheological Properties of Coal Gangue-Fly Ash Backfill Slurry. Processes 2020, 8, 284. [Google Scholar] [CrossRef]

- Xu, W.B.; Li, Q.L.; Tian, M.M. Strength and deformation properties of polypropylene fiber-reinforced cemented tailings backfill. Chin. J. Eng. 2019, 41, 1618–1626. [Google Scholar]

- Khayrutdinov, M.M.; Votyakov, M.V. Development of compositions of hardening stowing mixtures from ore processing wastes of potash enterprises. MIAB Min. Inf. Anal. Bull. 2007, 10, 220–222. [Google Scholar]

- Kongar-Syuryun, C.B. Industrial Waste in Backfill Composite—The Paradigm of Environmental and Process Safety during Field Development. Bezop. Tr. Promyshlennost 2025, 3, 73–78. [Google Scholar] [CrossRef]

- Nikitin, V.I.; Nechaeva, O.A.; Mozgovoi, G.S. Analysis of the results of the experiment to determine the saturation of the filtrate of drilling fluid of the core sample. In AIP Conference Proceedings, Proceedings of the III International Scientific Practical Conference “breakthrough Technologies and Communications in Industry and City” (BTCI 2020), Volgograd, Russia, 2–3 December 2020; AIP Publishing: Melville, NY, USA, 2021; Volume 2410, p. 20014. [Google Scholar] [CrossRef]

- Monteiro, M.; Santos, P.; Espinha Marques, J.; Flores, D.; Azenha, M.; Ribeiro, J.A. Assessment of Potential Environmental Risks Posed by Soils of a Deactivated Coal Mining Area in Northern Portugal—Impact of Arsenic and Antimony. Pollutants 2025, 5, 15. [Google Scholar] [CrossRef]

- Stadnik, D.A. Objectives of functional subsystems within the unified industrial system automated design of coal mines. Ugol’ 2017, 10, 52–56. [Google Scholar] [CrossRef]

- Terrones-Saeta, A.; Terrones-Saeta, J.M.; Suárez-Macías, J.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A. Development and Mechanical Analysis of Geopolymers Formed with Mining Residue and Fly Ash from Municipal Solid Waste Incineration Obtained After the Neutralisation Stage. Polymers 2025, 17, 1704. [Google Scholar] [CrossRef]

- Sáez-Navarrete, C.; Baraza, X.; Ramos-Grez, J.; Sans, C.; Arauzo, C.; Coca, Y. Laser-Induced Surface Vitrification for the Sustainable Stabilization of Copper Tailings. Sustainability 2025, 17, 5676. [Google Scholar] [CrossRef]

- Nikitin, V.I.; Zhivaeva, V.V.; Nechaeva, O.A.; Kamaeva, E.A. Influence of capillary pressure on the restoration of the bottomhole zone permeability at the filtrate-oil interfacial phase. In Topical Issues of Rational Use of Natural Resources; CRC Press: Boca Raton, FL, USA, 2019; pp. 558–562. [Google Scholar] [CrossRef]

- Cao, H.; Wang, A.; Yilmaz, E.; Cao, S. Machine Learning Algorithm-Based Prediction Model and Software Implementation for Strength Efficiency of Cemented Tailings Fills. Minerals 2025, 15, 405. [Google Scholar] [CrossRef]

- Jastrzębska, M.; Kazimierowicz-Frankowska, K.; Chiaro, G.; Rybak, J. New Frontiers in Sustainable Geotechnics. Appl. Sci. 2023, 13, 562. [Google Scholar] [CrossRef]

- Nikitin, V.I. Problem solution analysis on finding the velocity distribution for laminar flow of a non-linear viscous flushing fluid in the annular space of a well. J. Min. Inst. 2022, 258, 964–975. [Google Scholar] [CrossRef]

- Marimuthu, M.; Krishnan, V.; Sudhakaran, S.D.; Vigneswari, S.; Senthilkumar, S.; Veerapandian, M. Electrochemical-Based Biosensor Platforms in Lab-Chip Models for Point-of-Need Toxicant Analysis. Electrochem 2023, 4, 537–552. [Google Scholar] [CrossRef]

- Đurđevac, V.; Staletović, N.; Ignjatović, L.Đ.; Jovanović, V.; Vuković, N.; Krstić, V. Application of Flotation Tailings as a Substitute for Cement in Concrete Structures for Environmental Protection and Sustainable Development—Part I: Sulfide Neutralization. Materials 2025, 18, 2804. [Google Scholar] [CrossRef]

- Elokhova, I.; Vyatkin, K.; Ilyushin, P.; Krutova, A.; Pepelyaeva, A.; Sliusar, N. Evaluating the Eco-Intensity Dynamics of the Mining Industry in Russia: Towards a Circular Economy. Recycling 2023, 8, 31. [Google Scholar] [CrossRef]

- Abdulkadir, S.B.; Chen, Q.; Yilmaz, E.; Wang, D. Comparative and Meta-Analysis Evaluation of Non-Destructive Testing Methods for Strength Assessment of Cemented Paste Backfill: Implications for Sustainable Pavement and Concrete Materials. Materials 2025, 18, 2888. [Google Scholar] [CrossRef]

- Zhang, Z.-X. Lost-ore mining—A supplementary mining method to sublevel caving. Int. J. Rock Mech. Min. Sci. 2023, 168, 105420. [Google Scholar] [CrossRef]

- GOST 5802-86; Cements. Methods for Determination of True Density. State Committee for Standards of the USSR: Moscow, Russia, 1986.

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Control Specimens. Standartinform: Moscow, Russia, 2012.

- Li, Z.; Yin, D.; Jiang, N.; Wang, F.; Ding, Y.; Li, F. Deformation and Failure Characteristics of Bimaterial Samples Consisting of Sandstone and Cemented Coal Gangue–Fly Ash Backfill under Uniaxial Loading. Minerals 2022, 12, 1546. [Google Scholar] [CrossRef]

- Egoshin, A.M.; Afanasyev, A.S.; Alekseev, S.V. Procedure of mineral delivery system selection based on economic analysis of alternatives. MIAB Min. Inf. Anal. Bull. 2024, 6, 135–148. (In Russian) [Google Scholar] [CrossRef]

- Komokhov, P.G.; Kharitonov, A.M. Nanostructural model of cement stone for assessing the properties of a composite material. Pop. Concr. Sci. 2007, 2, 125–127. [Google Scholar]

- Hanehara, S.; Ichikawa, M. Nanotechnology of cement and concrete. Taiheiyo Cem. Kenkyu Hokoku 2001, 141, 47–58. [Google Scholar]

- Tyulyaeva, Y.S.; Khayrutdinov, A.M.; Galachieva, I.D.; Totrukova, I.K. Creation of a high-strength backfill composite based on sulfide-bearing technogenic waste from mining production. Sustain. Dev. Mt. Territ. 2024, 16, 1384–1396. (In Russian) [Google Scholar] [CrossRef]

- Khetagurov, V.N.; Kamenetsky, E.S.; Gegelashvili, M.V.; Marzoev, A.T. Granulometric composition study of fine product obtained by dolomite grinding in a centrifugal mill of Vertical type. Sustain. Dev. Mt. Territ. 2024, 16, 197–204. (In Russian) [Google Scholar] [CrossRef]

- Aleksakhin, A.; Sala, D.; Golovin, K.; Kovalev, R. Reducing energy costs for pipeline transportation. Transp. Res. Procedia 2021, 57, 24–32. [Google Scholar] [CrossRef]

- Fedorov, G.B.; Dudchenko, O.L.; Kurenkov, D.S. Development of vibroacoustic module for fine filtration of drilling muds. J. Min. Inst. 2018, 234, 647–651. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.L. Alkali-Activated Materials: State of the Art Report, RILEM TC 224-AAM; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Kropachev, A.N.; Podrezov, S.V.; Aleksakhin, A.V.; Gudilin, A.A.; Kondratyeva, O.A.; Korshunova, L.N. Thermodynamic Studies and Optimization of the Method for Obtaining Neodymium Fluoride for the Production of Magnetic Sensors’ Sensitive Elements. Sensors 2021, 21, 8361. [Google Scholar] [CrossRef] [PubMed]

- Melnik, V.V.; Efimov, V.I.; Korchagina, T.V.; Popov, A.I.; Muzafarov, G.G. Experience of steeply dipping coal seam mining. MIAB Min. Inf. Anal. Bull. 2018, 11, 18–38. [Google Scholar]

- Vasyuchkov, Y.F.; Melnik, V.V. Mining of coal deposit on the base of “Local coal gas electric complexes”. Eurasian Min. 2017, 2, 20–24. [Google Scholar] [CrossRef][Green Version]

- Zhang, Z.; Zhang, F.; Wu, C.; Chen, Y. Experimental Study on the Performance of Sustainable Epoxy Resin-Modified Concrete Under Coupled Salt Corrosion and Freeze–Thaw Cycles. Sustainability 2025, 17, 6186. [Google Scholar] [CrossRef]

- Shinkevich, A.I.; Kostyukhin, Y.Y.; Savon, D.Y.; Safronov, A.E.; Aleksakhin, A.V. Optimization of Energy-Efficient Functioning of the Oil and Gas Sector of the Economy through Digitalization and Resource Conservation. Int. J. Energy Econ. Policy 2021, 11, 321–330. [Google Scholar] [CrossRef]

- Novoselov, S.V.; Melnik, V.V.; Agofonov, V.V. Year of ecology in Russia and approaches to resolving geoecological problems in Kuzbass. Ugol 2017, 3, 78–79. [Google Scholar] [CrossRef][Green Version]

- Gusev, V.N.; Odintsov, E.E.; Zherlygina, E.S. Calculation of Displacements and Deformations in Rock Mass with Regard to Field Data. Gornyi Zhurnal 2025, 18–25. [Google Scholar] [CrossRef]

- Odintsov, E.E.; Gusev, V.N. Rock Mass Condition Control by the Method of Predicting of Water-Conducting Fracture Zone Parameters for the Deposits of Polymetallic Ores. Int. J. Eng. Trans. C Aspects 2025, 39, 1326–1333. [Google Scholar] [CrossRef]

- Stadnik, D.A.; Stadnik, N.M.; Grigoryan, K.L.; Kozhiev, Z.V. Technological Updating of Mineral Mining Projects Using Computer Technologies. MIAB Min. Inf. Anal. Bull. 2023, 2023, 170–184. (In Russian) [Google Scholar] [CrossRef]

- Stadnik, D.A.; Stadnik, N.M.; Zhilin, A.G.; Lopushnyak, E.V. Methodological Framework for Implicit Modeling of Solid Mineral Deposits in Automated Design. MIAB Min. Inf. Anal. Bull. 2023, 2023, 185–197. (In Russian) [Google Scholar] [CrossRef]

- Tian, H.; Zhao, Y.; Xie, J.; Fan, G.; Zhao, Y.; Zhang, N. Life-Cycle Assessment of Backfill Paste Using Fly-Ash and Tailings. Resour. Policy 2019, 64, 101449. [Google Scholar] [CrossRef]

- Attom, M.F.; Vandanapu, R.; Khan, Z.; Yamin, M.; Astillo, P.V.; Eltayeb, A.; Khalil, A. Prediction of Internal Erosion Parameters of Clay Soils Using Initial Physical Properties. Water 2024, 16, 232. [Google Scholar] [CrossRef]

| No. | Component | Waste Rock | Cement | Fly Ash | Glass Fiber | Nano-SiO2 |

|---|---|---|---|---|---|---|

| 1 | % | 99 | 1 | 0 | 0 | 0 |

| 2 | % | 65 | 0 | 34.5 | 0 | 0.5 |

| 3 | % | 65 | 0 | 34.7 | 0.3 | 0 |

| 4 | % | 65 | 0 | 34.2 | 0.3 | 0.5 |

| 5 | % | 65 | 0 | 33.7 | 0 | 1.0 |

| Type | Surface Area | Bulk Density | Density | Crystalline Type | Color | Purity |

|---|---|---|---|---|---|---|

| Nano-SiO2 | 240 m2/g | 0.06 g/cm3 | 2.2~2.6 g/cm3 | Spherical Shape | White | ≥99.99% |

| Type | Diameter (µm) | Length (mm) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Density (g/cm3) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| fiberglass | 19 | 6 | 369 | 4.8 | 2699 | 36.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khayrutdinov, M.M.; Aleksakhin, A.V.; Kibuk, T.N.; Korshunova, L.N.; Lozinskaya, M.A.; Legoshina, O.Y.; Skryabin, O.O.; Kruzhkova, G.V. Technogenic Waste in Backfill Composite Is a Paradigm of Circular Economy. Mining 2025, 5, 57. https://doi.org/10.3390/mining5030057

Khayrutdinov MM, Aleksakhin AV, Kibuk TN, Korshunova LN, Lozinskaya MA, Legoshina OY, Skryabin OO, Kruzhkova GV. Technogenic Waste in Backfill Composite Is a Paradigm of Circular Economy. Mining. 2025; 5(3):57. https://doi.org/10.3390/mining5030057

Chicago/Turabian StyleKhayrutdinov, Marat M., Alexander V. Aleksakhin, Tatiana N. Kibuk, Lyudmila N. Korshunova, Maria A. Lozinskaya, Olga Yu. Legoshina, Oleg O. Skryabin, and Galina V. Kruzhkova. 2025. "Technogenic Waste in Backfill Composite Is a Paradigm of Circular Economy" Mining 5, no. 3: 57. https://doi.org/10.3390/mining5030057

APA StyleKhayrutdinov, M. M., Aleksakhin, A. V., Kibuk, T. N., Korshunova, L. N., Lozinskaya, M. A., Legoshina, O. Y., Skryabin, O. O., & Kruzhkova, G. V. (2025). Technogenic Waste in Backfill Composite Is a Paradigm of Circular Economy. Mining, 5(3), 57. https://doi.org/10.3390/mining5030057