A Solution Surface in Nine-Dimensional Space to Optimise Ground Vibration Effects Through Artificial Intelligence in Open-Pit Mine Blasting

Abstract

1. Introduction

- 1.

- Perform optimisation computations to find the minimum ground vibration using random initial points.

- 2.

- Perform blast design by setting the desired value of ground vibration and searching in the solution space for the values of the corresponding input parameters. Alternatively, we can assign the value of ground vibration and some input parameters as constraints, and we can search in the solution space for the values of the remaining input parameters.

1.1. Empirical Methods

1.2. Machine Learning Methods

- We present data from Debswana Diamond Company recorded from 100 blast events.

- We develop machine learning models, each with five different architectures, eight input parameters, and one output of ground vibration. The four models are compared against a statistical method.

- We optimise the architecture of the best performing machine learning model using the Monte Carlo method.

- A solution space is created from the optimised machine learning model. Other machine learning models did not yield a solution space, as their results only predicted the output parameter ground vibration. Our solution space is capable of inverse solution, i.e., we can search for the solution space, given the input parameters and the expected output, to help blast design engineers in adjusting the input parameters to arrive at an expected output of ground vibration.

- We optimise ground vibration using the gradient descent method from the created solution space.

- Sensitivity analysis is performed using a statistical method and the results are confirmed from the created solution space.

1.3. Mine Case Study

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

| Best Model | Other Models | Inputs | Dataset | Reference | |

|---|---|---|---|---|---|

| ANFIS | L, B, S, T, Q, DI | 25 | 0.89 | [25] | |

| RF | CART, CHAID, | BS, DI, T | 102 | 0.94 | [15] |

| ANN, SVM, RF | MC, PF, L | ||||

| HKM-ANN | ANN, SVR, FCM-ANN | S, Pf, B | 185 | 0.98 | [17] |

| HKM-SVR, FCM-SVR | DI, MC | ||||

| ANFIS-GA | ANFIS, ANFIS-PSO | B, S, T | 86 | 0.98 | [18] |

| USBM, Indian Standard | Pf, MC, DI | ||||

| GEP | BS, L, T, Pf, Q, DI | 102 | 0.88 | [22] | |

| SVM | USBM, MLR, PSO power, PSO linear | DI, MC | 80 | 0.96 | [32] |

| WOA-XGBoost | GWO-XGBoost, BO-XGBoost, | D, L, B, S, MC | 150 | 0.97 | [16] |

| CatBoost, RF, GBR | CL, DI, BI | ||||

| E, PR, Pv, VOD, DOE | |||||

| ANFIS | ANN | DI, MC | 109 | 0.97 | [31] |

| PSO-ANN | ANN, DA-ANN | Q, Nh, DI, RMR | 56 | 1.00 | [13] |

| ANN | MC, DI, TC | 20 | 0.93 | [33] | |

| ANN | MVRA, Indian Standard | L, MC | 174 | 0.99 | [34] |

| Langefors-Kihlstrom, USBM | B, S | ||||

| General Predictor, Ambraseys-Hendron | DI, BI, E, PR, Pv | ||||

| GRNN | USBM, CMRI, Indian Standard | MC, DI | 14 | 0.99 | [35] |

| Langefors-Kihlstrom, Ambraseys-Hendron | |||||

| ANN | USBM, Indian Standard, MVRA | MC, DI, BS, L, T, D, Pf | 180 | 0.99 | [36] |

| Langefors-Kihlstrom, Ambraseys-Hendron | |||||

| FIS | USBM, Indian Standard | B, S | 120 | 0.94 | [37] |

| Langefors-Kihlstrom, Ambraseys-Hendron | T, N | ||||

| CMRI, Ghosh-Daemen 1, Ghosh-Daemen 2 | MC, DI | ||||

| MVRA, General Predictor | |||||

| ANN | GEP | D, L, N, B, S | 15 | 0.81 | [30] |

| RDI, HDI, T, Q | |||||

| SVM | USBM, Indian Standard, MVRA | DI, MC | 174 | 0.96 | [38] |

| Langefors-Kihlstrom, Ambraseys-Hendron | |||||

| Ghosh-Daemen, CMRI, General Predictor | |||||

| FS-RF | FS-BN, Langefors-Kihlstrom | MC, DI, B, D, TC, S | 102 | 0.90 | [5] |

| Ghosh-Daemen, Roy, Indian Standard | L, T, Sd, N, Pf, Q | ||||

| ANN-KNN | ANN, USBM | MC, DI | 75 | 0.88 | [23] |

| RVR-GWO | BA-GWO | MC, BS, D, T | 95 | 0.84 | [28] |

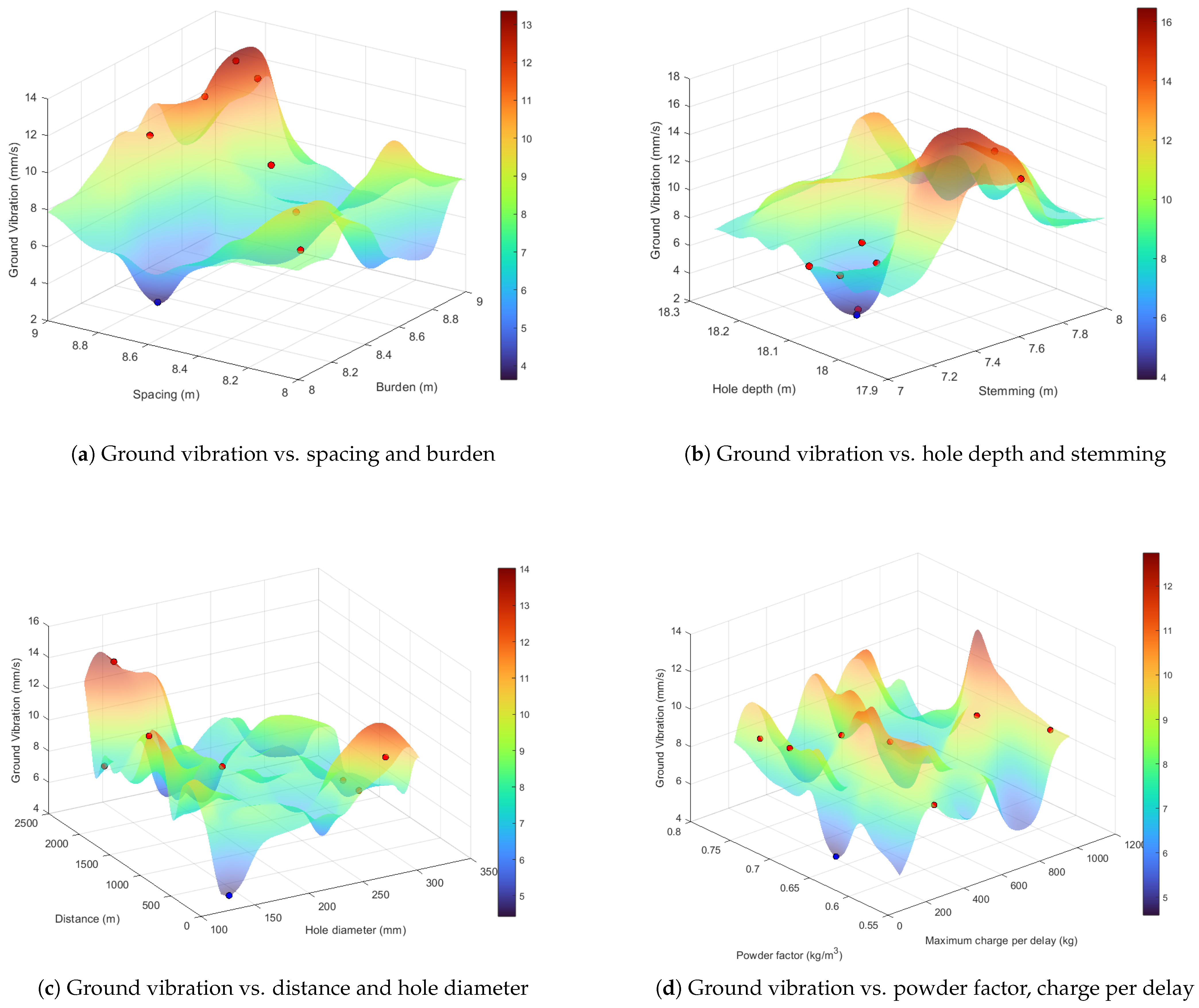

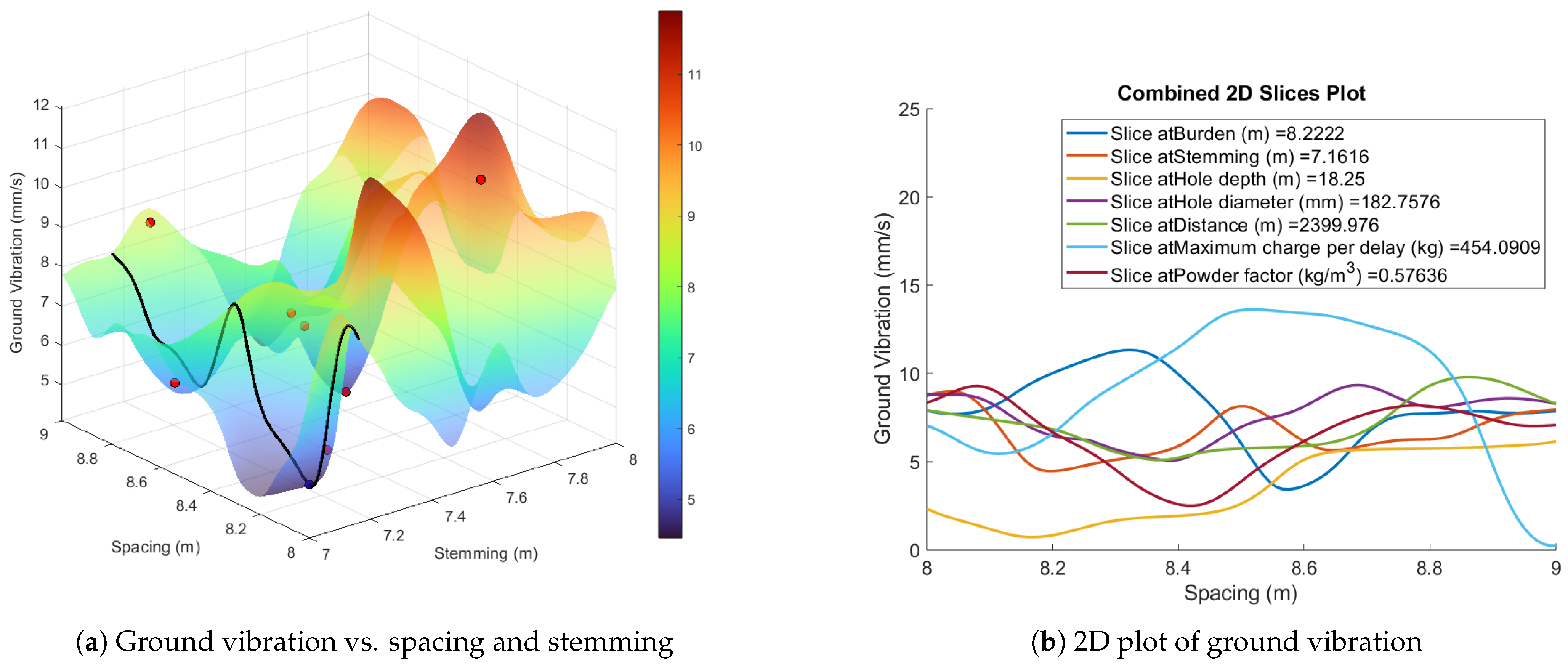

3.1. Sensitivity Analysis

3.2. Analysis of the Optimisation Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, G.; Huang, S. Analysis of ground vibration caused by open pit production blast. In Explosive and Blasting Technique; A.A. Balkema: Rotterdam, The Netherlands, 2000; pp. 63–70. [Google Scholar]

- Ak, H.; Konuk, A. The effect of discontinuity frequency on ground vibrations produced from bench blasting: A case study. Soil Dyn. Earthq. Eng. 2008, 28, 686–694. [Google Scholar] [CrossRef]

- Nateghi, R.; Kiany, M.; Gholipouri, O. Control negative effects of blasting waves on concrete of the structures by analyzing of parameters of ground vibration. Tunn. Undergr. Space Technol. 2009, 24, 608–616. [Google Scholar] [CrossRef]

- Dumakor-Dupey, N.K.; Arya, S.; Jha, A. Advances in blast-induced impact prediction—A review of machine learning applications. Minerals 2021, 11, 601. [Google Scholar] [CrossRef]

- Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Pham, B.T. Prediction of ground vibration induced by blasting operations through the use of the Bayesian Network and random forest models. Soil Dyn. Earthq. Eng. 2020, 139, 106390. [Google Scholar] [CrossRef]

- Ambraseys, N.; Hendron, A. Dynamic Behavior of Rock Masses, Rock Mechanics in Engineering Practice; John Wiley: London, UK, 1968. [Google Scholar]

- Hustrulid, W.A. Blasting Principles for Open Pit Mining, Volume 1: General Design Concepts; A.A. Balkema: Rotterdam, The Netherlands, 1999. [Google Scholar]

- Langefors, U.; Kihlström, B. The Modern Technique of Rock Blasting; John Wiley & Sons: Hoboken, NJ, USA, 1963. [Google Scholar]

- Lawal, A.I.; Kwon, S. Application of artificial intelligence to rock mechanics: An overview. J. Rock Mech. Geotech. Eng. 2021, 13, 248–266. [Google Scholar] [CrossRef]

- Mitchell, T.M. Does machine learning really work? AI Mag. 1997, 18, 11. [Google Scholar]

- Samuel, A.L. Some studies in machine learning using the game of checkers. IBM J. Res. Dev. 2000, 44, 206–226. [Google Scholar] [CrossRef]

- Hu, J.; Niu, H.; Carrasco, J.; Lennox, B.; Arvin, F. Voronoi-based multi-robot autonomous exploration in unknown environments via deep reinforcement learning. IEEE Trans. Veh. Technol. 2020, 69, 14413–14423. [Google Scholar] [CrossRef]

- Lawal, A.I.; Kwon, S.; Kim, G.Y. Prediction of an environmental impact of tunnel blasting using ordinary artificial neural network, particle swarm and Dragonfly optimized artificial neural networks. Appl. Acoust. 2021, 181, 108122. [Google Scholar] [CrossRef]

- Lawal, A.I.; Kwon, S.; Hammed, O.S.; Idris, M.A. Blast-induced ground vibration prediction in granite quarries: An application of gene expression programming, ANFIS, and sine cosine algorithm optimized ANN. Int. J. Min. Sci. Technol. 2021, 31, 265–277. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Jahed Armaghani, D.; Tahir, M.; Pham, B.T.; Huynh, V.V. A combination of feature selection and random forest techniques to solve a problem related to blast-induced ground vibration. Appl. Sci. 2020, 10, 869. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhou, J.; Khandelwal, M.; Yang, H.; Yang, P.; Li, C. Performance evaluation of hybrid WOA-XGBoost, GWO-XGBoost and BO-XGBoost models to predict blast-induced ground vibration. Eng. Comput. 2021, 38, 4145–4162. [Google Scholar] [CrossRef]

- Nguyen, H.; Drebenstedt, C.; Bui, X.N.; Bui, D.T. Prediction of blast-induced ground vibration in an open-pit mine by a novel hybrid model based on clustering and artificial neural network. Nat. Resour. Res. 2020, 29, 691–709. [Google Scholar] [CrossRef]

- Yang, H.; Hasanipanah, M.; Tahir, M.; Bui, D.T. Intelligent prediction of blasting-induced ground vibration using ANFIS optimized by GA and PSO. Nat. Resour. Res. 2020, 29, 739–750. [Google Scholar] [CrossRef]

- Lawal, A.I.; Olajuyi, S.I.; Kwon, S.; Onifade, M. A comparative application of the Buckingham π (pi) theorem, white-box ANN, gene expression programming, and multilinear regression approaches for blast-induced ground vibration prediction. Arab. J. Geosci. 2021, 14, 1073. [Google Scholar] [CrossRef]

- Toraño, J.; Ramírez-Oyanguren, P.; Rodríguez, R.; Diego, I. Analysis of the environmental effects of ground vibrations produced by blasting in quarries. Int. J. Min. Reclam. Environ. 2006, 20, 249–266. [Google Scholar] [CrossRef]

- Kaklis, K.; Saubi, O.; Jamisola, R.; Agioutantis, Z. Machine learning prediction of the load evolution in three-point bending tests of marble. Min. Metall. Explor. 2022, 39, 2037–2045. [Google Scholar] [CrossRef]

- Faradonbeh, R.S.; Monjezi, M.; Armaghani, D.J. Genetic programing and non-linear multiple regression techniques to predict backbreak in blasting operation. Eng. Comput. 2016, 32, 123–133. [Google Scholar] [CrossRef]

- Amiri, M.; Amnieh, H.B.; Hasanipanah, M.; Khanli, L.M. A new combination of artificial neural network and K-nearest neighbors models to predict blast-induced ground vibration and air-overpressure. Eng. Comput. 2016, 32, 631–644. [Google Scholar] [CrossRef]

- Saubi, O.; Gaopale, K.; Jamisola, R.S.; Suglo, R.S.; Matsebe, O. Enhancing Blast Design Efficiency for Rock Fragmentation with Gradient Descent and Artificial Neural Networks: An Optimization Study. In Proceedings of the 2023 4th International Conference on Computers and Artificial Intelligence Technology (CAIT), Macau, China, 13–15 December 2023; pp. 1–5. [Google Scholar]

- Xue, X.; Yang, X.; Li, P. Evaluation of ground vibration due to blasting using fuzzy logic. Geotech. Geol. Eng. 2017, 35, 1231–1237. [Google Scholar] [CrossRef]

- Lawal, A.I.; Kwon, S.; Kim, G.Y. Prediction of the blast-induced ground vibration in tunnel blasting using ANN, moth-flame optimized ANN, and gene expression programming. Acta Geophys. 2021, 69, 161–174. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, Y.; Qiu, Y. State-of-the-art review of machine learning and optimization algorithms applications in environmental effects of blasting. Artif. Intell. Rev. 2024, 57, 5. [Google Scholar] [CrossRef]

- Fattahi, H.; Hasanipanah, M. Prediction of blast-induced ground vibration in a mine using relevance vector regression optimized by metaheuristic algorithms. Nat. Resour. Res. 2021, 30, 1849–1863. [Google Scholar] [CrossRef]

- Fitch, F.B. Warren S. McCulloch and Walter Pitts. A logical calculus of the ideas immanent in nervous activity. Bulletin of mathematical biophysics, vol. 5 (1943), pp. 115–133. J. Symb. Log. 1944, 9, 49–50. [Google Scholar] [CrossRef]

- Dindarloo, S.R. Prediction of blast-induced ground vibrations via genetic programming. Int. J. Min. Sci. Technol. 2015, 25, 1011–1015. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hajihassani, M.; Monjezi, M.; Mohamad, E.T.; Marto, A.; Moghaddam, M.R. Application of two intelligent systems in predicting environmental impacts of quarry blasting. Arab. J. Geosci. 2015, 8, 9647–9665. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Naderi, R.; Kashir, J.; Noorani, S.A.; Zeynali Aaq Qaleh, A. Prediction of blast-produced ground vibration using particle swarm optimization. Eng. Comput. 2017, 33, 173–179. [Google Scholar] [CrossRef]

- Monjezi, M.; Hasanipanah, M.; Khandelwal, M. Evaluation and prediction of blast-induced ground vibration at Shur River Dam, Iran, by artificial neural network. Neural Comput. Appl. 2013, 22, 1637–1643. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T. Prediction of blast-induced ground vibration using artificial neural network. Int. J. Rock Mech. Min. Sci. 2009, 46, 1214–1222. [Google Scholar] [CrossRef]

- Ragam, P.; Nimaje, D. Assessment of blast-induced ground vibration using different predictor approaches-a comparison. Chem. Eng. Trans. 2018, 66, 487–492. [Google Scholar]

- Tiile, R.N. Artificial Neural Network Approach to Predict Blast-Induced Ground Vibration, Airblast and Rock Fragmentation; Scholars’ Mine, Missouri S&T Library and Learning Resources; Missouri University of Science and Technology: Rolla, MO, USA, 2016. [Google Scholar]

- Ghasemi, E.; Ataei, M.; Hashemolhosseini, H. Development of a fuzzy model for predicting ground vibration caused by rock blasting in surface mining. J. Vib. Control 2013, 19, 755–770. [Google Scholar] [CrossRef]

- Khandelwal, M. Evaluation and prediction of blast-induced ground vibration using support vector machine. Int. J. Rock Mech. Min. Sci. 2010, 47, 509–516. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Q. A hierarchical analysis for rock engineering using artificial neural networks. Rock Mech. Rock Eng. 1997, 30, 207–222. [Google Scholar] [CrossRef]

| Parameter | Type | Unit | Symbol | Min | Max |

|---|---|---|---|---|---|

| Burden | Input | m | B | 4 | 6 |

| Spacing | Input | m | S | 5 | 8 |

| Stemming length | Input | m | T | 4 | 6 |

| Hole depth | Input | m | L | 12 | 15 |

| Hole diameter | Input | mm | D | 165 | 250 |

| Distance from blast to monitoring point | Input | m | DI | 438 | 1500 |

| Maximum charge per delay | Input | kg | MC | 216 | 552.6 |

| Powder factor | Input | kg/m3 | Pf | 0.3 | 1.17 |

| Ground vibration | Output | mm/s | GV | 0.163 | 6.5 |

| Method | RMSE | Composite Score | |

|---|---|---|---|

| k-nearest neighbor | |||

| n-neighbors = 10 | 0.728 | 1.030 | 1.454 |

| n-neighbors = 20 | 0.643 | 1.180 | 1.329 |

| n-neighbors = 30 | 0.528 | 1.670 | 1.084 |

| n-neighbors = 40 | 0.550 | 1.884 | 1.049 |

| n-neighbors = 50 | 0.582 | 2.002 | 1.050 |

| Support vector machine | |||

| sigma = 1 | 0.675 | 1.130 | 1.374 |

| sigma = 3 | 0.696 | 1.145 | 1.391 |

| sigma = 5 | 0.720 | 1.035 | 1.445 |

| sigma = 7 | 0.596 | 1.215 | 1.275 |

| sigma = 9 | 0.590 | 1.245 | 1.260 |

| Random forest | |||

| n-estimators = 5 | 0.904 | 0.510 | 1.768 |

| n-estimators = 15 | 0.892 | 0.545 | 1.748 |

| n-estimators = 25 | 0.865 | 0.605 | 1.705 |

| n-estimators = 35 | 0.856 | 0.680 | 1.676 |

| n-estimators = 45 | 0.848 | 0.760 | 1.646 |

| Artificial neural network | |||

| model 1 (10 neurons) | 0.941 | 0.286 | 1.864 |

| model 2 (20 neurons) | 0.912 | 0.315 | 1.829 |

| model 3 (30 neurons) | 0.898 | 0.456 | 1.778 |

| model 4 (40 neurons) | 0.890 | 0.410 | 1.800 |

| model 5 (50 neurons) | 0.862 | 0.472 | 1.737 |

| Multivariate regression analysis | 0.664 | 3.760 | 0.664 |

| Measured Ground Vibration | Predicted Ground Vibration |

|---|---|

| 0.312 | 0.480 |

| 1.990 | 1.880 |

| 3.195 | 3.077 |

| 3.551 | 3.576 |

| 0.145 | 0.180 |

| 0.388 | 0.361 |

| 0.511 | 0.491 |

| 3.915 | 4.076 |

| 5.226 | 5.063 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saubi, O.; Jamisola, R.S., Jr.; Gaopale, K.; Suglo, R.S.; Matsebe, O. A Solution Surface in Nine-Dimensional Space to Optimise Ground Vibration Effects Through Artificial Intelligence in Open-Pit Mine Blasting. Mining 2025, 5, 40. https://doi.org/10.3390/mining5030040

Saubi O, Jamisola RS Jr., Gaopale K, Suglo RS, Matsebe O. A Solution Surface in Nine-Dimensional Space to Optimise Ground Vibration Effects Through Artificial Intelligence in Open-Pit Mine Blasting. Mining. 2025; 5(3):40. https://doi.org/10.3390/mining5030040

Chicago/Turabian StyleSaubi, Onalethata, Rodrigo S. Jamisola, Jr., Kesalopa Gaopale, Raymond S. Suglo, and Oduetse Matsebe. 2025. "A Solution Surface in Nine-Dimensional Space to Optimise Ground Vibration Effects Through Artificial Intelligence in Open-Pit Mine Blasting" Mining 5, no. 3: 40. https://doi.org/10.3390/mining5030040

APA StyleSaubi, O., Jamisola, R. S., Jr., Gaopale, K., Suglo, R. S., & Matsebe, O. (2025). A Solution Surface in Nine-Dimensional Space to Optimise Ground Vibration Effects Through Artificial Intelligence in Open-Pit Mine Blasting. Mining, 5(3), 40. https://doi.org/10.3390/mining5030040