Prospect for Fine and Coarse Coal Waste Deployment for a Constructed Technosol and Eragrostis Tef Growth

Abstract

:1. Introduction

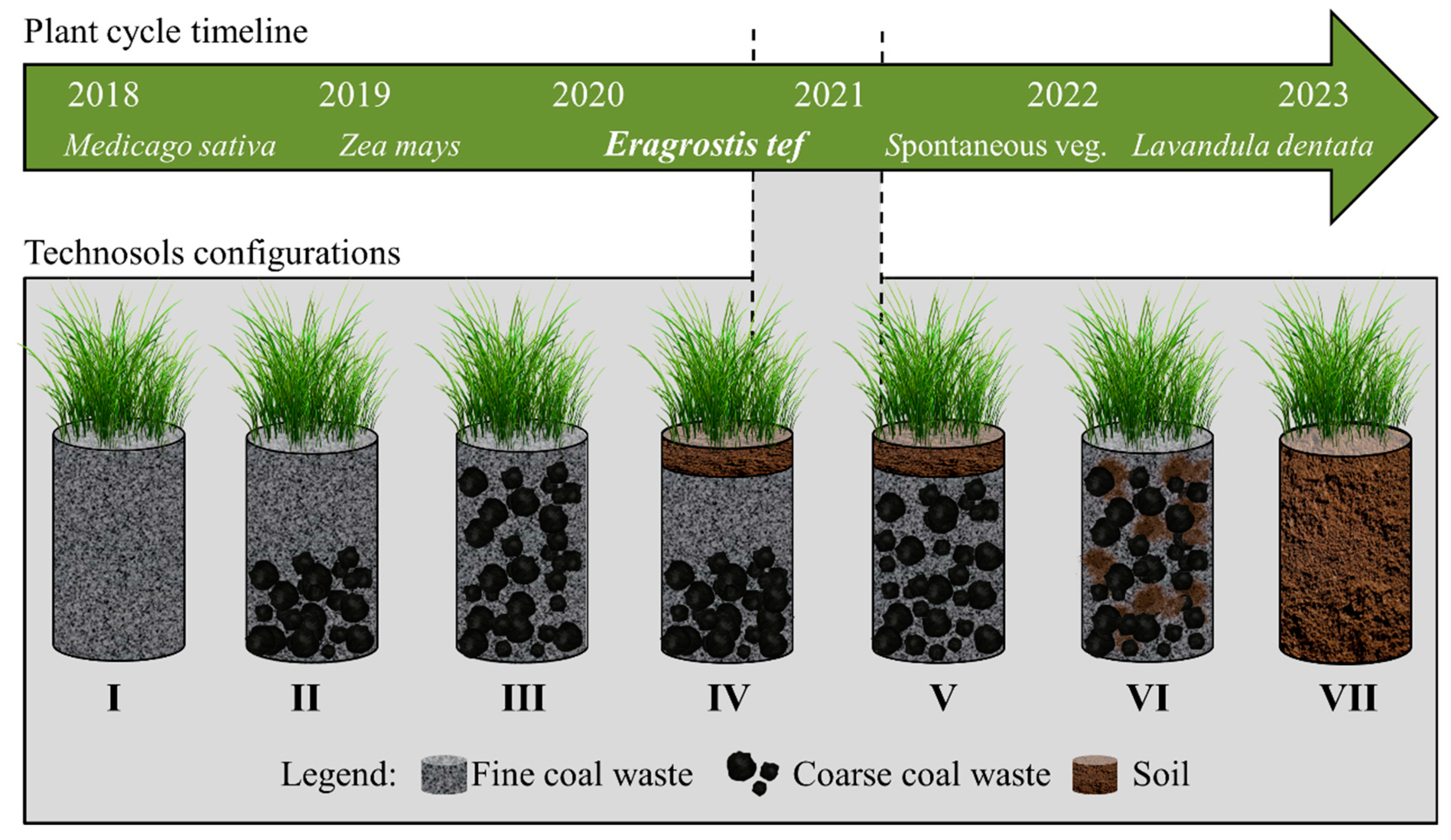

2. Materials and Methods

- Fine coal waste (FCW);

- FCW + coarse coal waste (CCW), composing two seams;

- FCW + CCW as a mixture;

- Agricultural soil (AS) + FCW + CCW, composing three seams;

- AS + a mixture of FCW + CCW, composing two seams;

- AS +FCW + CCW as mixture;

- Agricultural soil (AS) used as control.

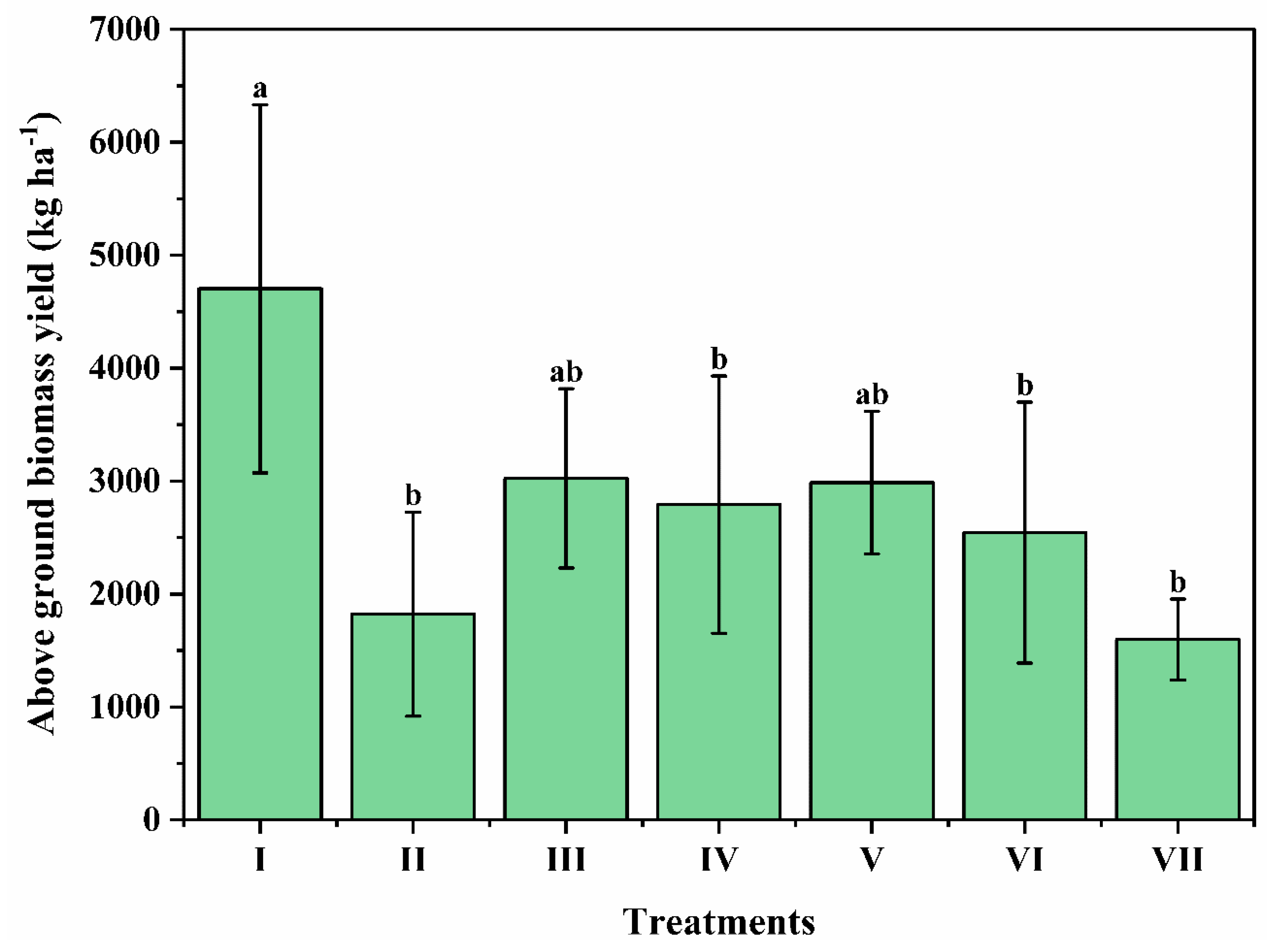

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bian, Z.; Inyang, H.I.; Daniels, J.L.; Otto, F.; Struthers, S. Environmental issues from coal mining and their solutions. Min. Sci. Technol. 2010, 20, 215–223. [Google Scholar] [CrossRef]

- Reddick, J.F.; Von Blottnitz, H.; Kothuis, B. Cleaner production in the South African coal mining and processing industry: A case study investigation. Int. J. Coal Prep. Util. 2008, 28, 224–236. [Google Scholar] [CrossRef]

- Franks, D.M.; Boger, D.V.; Côte, C.M.; Mulligan, D.R. Sustainable development principles for the disposal of mining and mineral processing wastes. Resour. Policy 2011, 36, 114–122. [Google Scholar] [CrossRef]

- Batterham, R.J. The mine of the future—Even more sustainable. Miner. Eng. 2017, 107, 2–7. [Google Scholar] [CrossRef]

- Epstein, P.R.; Buonocore, J.J.; Eckerle, K.; Hendryx, M.; Stout, B.M.; Heinberg, R.; Clapp, R.W.; May, B.; Reinhart, N.L.; Ahern, M.M.; et al. Full cost accounting for the life cycle of coal. Ann. N. Y. Acad. Sci. 2011, 1219, 73–98. [Google Scholar] [CrossRef] [PubMed]

- Bian, Z.; Dong, J.; Lei, S.; Leng, H.; Mu, S.; Wang, H. The impact of disposal and treatment of coal mining wastes on environment and farmland. Environ. Geol. 2009, 58, 625–634. [Google Scholar] [CrossRef]

- Li, H.; Guo, G.; Zha, J.; Wang, T.; Chen, Y.; Yuan, Y.; Huo, W. A new method of regional mining subsidense control for sustainable development in coal areas. Sustainability 2023, 15, 7100. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Zhang, C.; Liao, J.; Lin, H.; Wang, Y. Coupled seepage-damage effect in fractured rock masses: Model development and a case study. Int. J. Rock Mech. Min. Sci. 2021, 144, 104822. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, K.; He, X.; Zhao, X.; Wei, Z.; He, S. Research status of comprehensive utilization of coal-based solid waste (CSW) and key technologies of filling mining in China: A review. Sci. Total Environ. 2024, 926, 171855. [Google Scholar] [CrossRef]

- Fan, G.; Zhang, D.; Wang, X. Reduction and utilization of coal mine waste rock in China: A case studyin Tiefa coalfield. Resour. Conserv. Recycl. 2014, 83, 24–33. [Google Scholar] [CrossRef]

- Kalisz, S.; Kibort, K.; Mioduska, J.; Lieder, M.; Małachowska, A. Waste management in the mining industry of metals ores, coal, oil and natural gas—A review. J. Environ. Manag. 2022, 304, 114239. [Google Scholar] [CrossRef] [PubMed]

- Bian, Z.; Miao, X.; Lei, S.; Chen, S.; Wang, W.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef]

- Komnitsas, K.; Paspaliaris, I.; Zilberchmidt, M.; Groudev, S.N. Environmental impacts at coal waste disposal sites-efficiency of desulfurization technologies. Glob. Nest Int. J 2001, 3, 109–116. [Google Scholar]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef]

- Reid, I. Non-Energy Uses of Coal; Report Number CCC/291; IEA Clean Coal Centre: London, UK, 2018. [Google Scholar]

- Subba, R.D.V.; Gouricharan, T. Coal Processing and Utilization; CRC Press/Taylor & Francis Group: London, UK, 2016. [Google Scholar]

- Patil, D.P.; Honaker, R.; Parekh, B.K. Paste Thickening of Fine Coal Refuse. Int. J. Coal Prep. Util. 2007, 27, 191–209. [Google Scholar] [CrossRef]

- Leonard, J.W. Coal Preparation, 4th ed.; The American Institute of Mining, Metallurgical and Petroleum Engineers: New York, NY, USA, 1979. [Google Scholar]

- Feng, Y.; Wang, J.; Bai, Z.; Reading, L. Effects of surface coal mining and land reclamation on soil properties: A review. Earth-Sci. Rev. 2019, 191, 12–25. [Google Scholar] [CrossRef]

- Sun, Y.Z.; Fan, J.S.; Qin, P.; Niu, H.Y. Pollution extents of organic substances from a coal gangue dump of Jiulong Coal Mine, China. Environ. Geochem. Health 2009, 31, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Daniels, W.L.; Stewart, B.R. Reclamation of Appalachian Coal Refuse Disposal Areas. In Reclamation of Drastically Disturbed Lands; Barnhisel, R.I., Darmody, R.G., Daniels, W.L., Eds.; American Society of Agronomy, Crop Science Society of America, Soil Science Society of America: Madison, WI, USA, 2000; pp. 433–459. [Google Scholar] [CrossRef]

- Ghose, M.K. Soil conservation for rehabilitation and revegetation of mine-degraded land. TIDEE Teri Inf. Dig. Energy Environ. 2005, 4, 137–150. [Google Scholar]

- Daniels, W.; Zipper, C. Creation and Management of Productive Minesoils; Virginia Cooperative Extension: Blacksburg, Estados Unidos, 2010. [Google Scholar]

- Séré, G.; Schwartz, C.; Ouvrard, S.; Sauvage, C.; Renat, J.-C.; Morel, J.L. Soil construction: A step for ecological reclamation of derelict lands. J. Soils Sediments 2008, 8, 130–136. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2014, update 2015. In International Soil Classification System for Naming Soils and Creating Legends for Soil Maps; 2014; World Soil Resources Reports No. 106; FAO: Rome, Italy, 2015. [Google Scholar]

- Echevarria, G.; Louis Morel, J. Technosols of mining areas. Tópicos Ci. Solo 2015, 9, 92–111. [Google Scholar]

- Firpo, B.A.; Amaral Filho, J.R.D.; Schneider, I.A.H. A brief procedure to fabricate soils from coal mine wastes based on mineral processing, agricultural, and environmental concepts. Miner. Eng. 2015, 76, 81–86. [Google Scholar] [CrossRef]

- Weiler, J.; Firpo, B.A.; Schneider, I.A.H. Coal waste derived soil-like substrate: An opportunity for coal waste in a sustainable mineral scenario. J. Clean. Prod. 2018, 174, 739–745. [Google Scholar] [CrossRef]

- Weiler, J.; Firpo, B.A.; Schneider, I.A.H. Technosol as an integrated management tool for turning urban and coal mining waste into a resource. Miner. Eng. 2020, 147, 106179. [Google Scholar] [CrossRef]

- Amaral Filho, J.R.; Firpo, B.A.; Broadhurst, J.L.; Harrison, S.T.L. On the feasibility of South African coal waste for production of ‘FabSoil’, a Technosol. Miner. Eng. 2020, 146, 106059. [Google Scholar] [CrossRef]

- Firpo, B.A.; Weiler, J.; Schneider, I.A.H. Technosol made from coal waste as a strategy to plant growth and environmental control. Energy Geosci. 2021, 2, 160–166. [Google Scholar] [CrossRef]

- Halecki, W.; Klatka, S. Aplication of soil productivity index after eight years of soil reclamation with sewage sludge amendments. Environ. Manag. 2021, 67, 822–832. [Google Scholar] [CrossRef]

- Bauerek, A.; Diatta, J.; Pierzchala, L.; Wieckol-Ryk, A.; Krzemien, A. Development of soil substitutes for the sustainable land reclamation of coal mine-affected area. Sustainability 2022, 14, 4604. [Google Scholar] [CrossRef]

- Zocche, J.J.; Sehn, L.M.; Pillon, J.G.; Schneider, C.H.; Olivo, E.F.; Raupp-Pereira, F. Technosols in coal mining areas: Viability of combined use of agro-industry waste and synthetic gypsum in the restoration of areas degraded. Clean. Eng. Technol. 2023, 13, 100618. [Google Scholar] [CrossRef]

- Fernández-Caliani, J.C.; Giráldez, I.; Fernández-Landero, S.; Barba-Brioso, C.; Morales, E. Long-term sustainability of marble waste sludge in reducing soil acidity and heavy metal release in a contaminated mine technosol. Appl. Sci. 2022, 12, 6998. [Google Scholar] [CrossRef]

- Carvalho, L.C.; Santos, E.S.; Saraiva, J.A.; Magalhães, M.C.F.; Macías, F.; Abreu, M.M. The potential of Cistus salviifolius L. to phytostabilize Gossan mine wates amended with and organic residues. Plants 2022, 11, 588. [Google Scholar] [CrossRef]

- Bolan, M.B.; Kirkham, Y.S.O. Spoil to Soil Mine Site Rehabilitation and Revegetation, 1st ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ruiz, F.; Cherubin, M.R.; Ferreira, T.O. Soil quality assessment of constructed Technosols: Towards the validation of a promising strategy for land reclamation, waste management and the recovery of soil functions. J. Environ. Manag. 2020, 276, 111344. [Google Scholar] [CrossRef] [PubMed]

- Ruiz, F.; Andrade, G.R.P.; Sartor, L.R.; dos Santos, J.C.B.; de Souza Júnior, V.S.; Ferreira, T.O. The rhizosphere of tropical grasses as driver of soil weathering in embryonic Technosols (SE-Brazil). Catena 2022, 208, 105764. [Google Scholar] [CrossRef]

- Hobbs, R.J.; Higgs, E.; Harris, J.A. Novel ecosystems: Implications for conservation and restoration. Trends Ecol. Evol. 2009, 24, 599–605. [Google Scholar] [CrossRef]

- Weiler, J.; da Silva, A.C.; Firpo, B.A.; Fernandes, E.Z.; Schneider, I.A.H. Using static, kinetic and metal mobility procedures to evaluate possibilities of coal waste land disposal at Moatize Mine, Mozambique. REM-Int. Eng. J. 2020, 73, 587–596. [Google Scholar] [CrossRef]

- Pondja, J.R.; Persson, K.M.; Matsinhe, N.P. Assessment of coal mine water in Moatize by static and leaching tests. Sustain. Water Resour. Manag. 2017, 3, 403–412. [Google Scholar] [CrossRef]

- Ketema, S. Tef Eragrostis tef (Zucc.) Trotter; International Plant Genetic Resources Institute: Rome, Italy, 1997. [Google Scholar]

- Society for Ecological Restoration International Science & Policy Working Group. SER International Primer on Ecological Restoration 2004. Available online: https://floridalivingshorelines.com/wp-content/uploads/2015/05/Clewell.Aronson.Winterhalder.2004-SER-Primer.pdf (accessed on 10 June 2024).

- Hatton, W.; Fardell, A. New discoveries of coal in Mozambique—Development of the coal resource estimation methodology for International Resource Reporting Standards. Int. J. Coal Geol. 2012, 89, 2–12. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Ambrós, W.M.; Cazacliu, B.; Moncunill, J.O.; José, D.S.; Miltzarek, G.L.; de Brum, I.A.S.; Petter, C.O.; Fernandes, E.Z.; Oliveira, L.F.S. Destoning the moatize coal seam, mozambique, by dry jigging. Minerals 2020, 10, 771. [Google Scholar] [CrossRef]

- Sobek, A.A.; William, A.S.; Freeman, J.R.; Smith, R.M. Field and Laboratory Methods Applicable to Overburdens and Minesoils; Industrial Environmental Research Laboratory, Office of Research and Development, US Environmental Protection Agency: Cincinnati, OH, USA, 1978. [Google Scholar]

- Sparks, D.L. Chemistry of Soil Organic Matter. In Environmental Soil Chemistry; Sparks, D.L., Ed.; Academic Press: Singapore, 2003; pp. 75–113. ISBN 978-0-12-656446-4. [Google Scholar]

- INMET Dados Meteorológicos. Estação: Porto Alegre—Jardim Botânico A801. Available online: https://portal.inmet.gov.br/ (accessed on 13 October 2023).

- Reichardt, K. Capacidade de campo. Rev. Bras. Ciênc. Solo 1988, 12, 211–216. [Google Scholar]

- Darcy, H. Les Fontaines Publiques de la ville de Dijon: Exposition et Application des Principes à Suivre et des Formules à Employer dans les Questions de Distribution d’eau; Victor Dalmont: Paris, France, 1856; Volume 1. [Google Scholar]

- Embrapa. Manual de Métodos de Análise de Solo, 3rd ed.; Teixeira, P.C., Donagemma, G.K., Fontana, A., Teixeira, W.G., Eds.; Embrapa: Brasília, Brazil, 2017; ISBN 9788570357717. [Google Scholar]

- SBCS. Manual de Adubação e de Calagem para os Estados do Rio Grande so Sul e Santa Catarina; Sociedade Brasileira de Ciência do Solo - Núcleo Regional Sul: Porto Alegre, Brazil, 2016; ISBN 978-85-66301-80-9. [Google Scholar]

- van Raij, B.; Cantarella, H.; Quaggio, J.A.; Furlani, Â.M.C. Recomendações de Adubação e Calagem para o Estado de São Paulo; Fundação IAC: Campinas, Brasil, 1996; Volume 100. [Google Scholar]

- Indoria, A.K.; Sharma, K.L.; Reddy, K.S. Hydraulic properties of soil under warming climate. In Climate change and soil interactions; Prasad, M.N.V., Pietrzykowski, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 473–508. [Google Scholar]

- Brady, N.C.; Weil, R.R. The Nature and Properties of Soils; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2008; Volume 13, ISBN 978-0-13-227939-0. [Google Scholar]

- Perie, C.; Ouimet, R. Organic carbon, organic matter and bulk density relationships in boreal forest soils. Can. J. Soil Sci. 2008, 88, 315–325. [Google Scholar] [CrossRef]

- Avnimelech, Y.; Ritvo, G.; Meijer, L.E.; Kochba, M. Water content, organic carbon and dry bulk density in flooded sediments. Aquac. Eng. 2001, 25, 25–33. [Google Scholar] [CrossRef]

- Sakin, E.; Deliboran, A.; Tutar, E. Bulk density of Harran plain soils in relation to other soil properties. Afr. J. Agric. Res. 2011, 6, 1750–1757. [Google Scholar]

- da Silva, V.R.; Reinert, D.J.; Reichert, J.M. Densidade do solo, atributos químicos e sistema radicular do milho afetados pelo pastejo e manejo do solo. Rev. Bras. Ciênc. Solo 2000, 24, 191–199. [Google Scholar] [CrossRef]

- Rabot, E.; Wiesmeier, M.; Schlüter, S.; Vogel, H.-J. Soil structure as an indicator of soil functions: A review. Geoderma 2018, 314, 122–137. [Google Scholar] [CrossRef]

- Reynolds, W.D.; Drury, C.F.; Tan, C.S.; Fox, C.A.; Yang, X.M. Use of indicators and pore volume-function characteristics to quantify soil physical quality. Geoderma 2009, 152, 252–263. [Google Scholar] [CrossRef]

- White, R.E. Principles and Practice of Soil Science: The Soil as a Natural Resource; John Wiley & Sons: Hoboken, NJ, USA, 2005; ISBN 0632064552. [Google Scholar]

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2017.

- Miller, D. Teff Grass: A new alternative. In Proceedings of the 2009 California Alfalfa & Forage Symposium and Western Seed Conference, Reno, NV, USA, 2–4 December 2009; Citeseer: University Park, PA, USA, 2009; pp. 2–4. [Google Scholar]

- Mihretie, F.A.; Tesfaye, K.; Hoogenboom, G.; Tsunekawa, A.; Molla, A.; Ebabu, K.; Sato, S.; Masutomi, Y. Identifying low risk and profitable crop management practices for irrigated Teff production in northwestern Ethiopia. Eur. J. Agron. 2022, 139, 126572. [Google Scholar] [CrossRef]

- Araya, A.; Stroosnijder, L.; Girmay, G.; Keesstra, S.D. Crop coefficient, yield response to water stress and water productivity of teff (Eragrostis tef (Zucc.). Agric. Water Manag. 2011, 98, 775–783. [Google Scholar] [CrossRef]

- Mihretie, F.A.; Tsunekawa, A.; Haregeweyn, N.; Adgo, E.; Tsubo, M.; Masunaga, T.; Meshesha, D.T.; Tsuji, W.; Ebabu, K.; Tassew, A. Tillage and sowing options for enhancing productivity and profitability of teff in a sub-tropical highland environment. F. Crop. Res. 2021, 263, 108050. [Google Scholar] [CrossRef]

- Moro, D.C.; Weiler, J.; Schneider, I.A.H. Effects of vegetation on erosion in technosols produced from coal waste. In Proceedings of the International Mine Water Association Congress (14.: 2021: Online). Mine Water Management for Future Generations; International Mine Water Association: Cardiff, Wales, 2021. [Google Scholar]

- Lemos, C.M.G.; Ferreira, G.C. Viabilidade do uso de nucleação no auxílio da regularização ambiental das atividades de extração de argila em região de intensa alteração da paisagem. Geosci. Geociênc. 2017, 36, 65–75. [Google Scholar] [CrossRef]

- Bechara, F.C.; Campos Filho, E.M.; Barretto, K.D.; Gabriel, V.A.; Antunes, A.Z.; Reis, A. Unidades demonstrativas de restauração ecológica através de técnicas nucleadoras de biodiversidade. Rev. Bras. Biociênc. 2007, 5, 9–11. [Google Scholar]

- Colombini, G.; Watteau, F.; Auclerc, A. Technosol rehabilitation strategies drive soil physico-chemical properties and fauna diversity on a former coking plant area. Appl. Soil Ecol. 2022, 177, 104542. [Google Scholar] [CrossRef]

| Country | Amendments | Vegetation | Reference |

|---|---|---|---|

| Brazil | Steel slag and sewage sludge | Sorghum bicolor | Firpo et al., 2015 [27] |

| Brazil | Husk ash, steel slag, and sewage sludge | Megathyrsus maximus | Weiler et al., 2018 [28] |

| Mozambique | Organic compost from urban waste | Medicago sativa | Weiler et al., 2020 [29] |

| South Africa | Compost, anaerobic digester sludge, and malt residue | Eragrostis tef | Amaral Filho et al., 2020 [30] |

| Brazil | Husk ash, steel slag, and sewage sludge | Avena strigosa Zea mays | Firpo et al., 2021 [31] |

| Poland | Sewage sludge, post-flotation waste, crushed stone (angular sandstone), and fly ash | Elaeagnus angustifolia, Tamarix parviflora, Hippophae rhamnoides, Robinia pseudoacacia, Betula verrucosa, Acer negundo, and Pseudotsuga menziesii | Halecki and Klatka, 2021 [32] |

| Poland | Fly ash from coal combustion, fly ash from plant biomass combustion, decarbonization lime from water softening process, sealing material from coal processing, sewage sludge, and spent mushroom compost | Sinapis alba | Bauerek et al., 2022 [33] |

| Brazil | Rice processing waste, poultry agroindustry sludge, gypsum | Not measured | Zocche et al., 2023 [34] |

| Property | Fine Waste (<1.0 mm) | Coarse Waste (1.0–50 mm) |

|---|---|---|

| Proximate analysis | ||

| Ashes (%) | 58.4 | 58.9 |

| Volatile material (%) | 16.6 | 16.5 |

| Fixed carbon (%) | 25.0 | 24.6 |

| Sulfur | ||

| Pyritic (%) | 0.6 | 0.4 |

| Sulfate (%) | 0.2 | 0.1 |

| Organic (%) | 0.5 | 0.4 |

| Total (%) | 1.3 | 0.9 |

| Crystalline compounds | ||

| Majority | Quartz | Quartz and alumina |

| Minority | Calcite, hematite, and halite | Calcite and hematite |

| Acid generation according to modified acid–base accounting (ABA) method [47] | ||

| AP (kg CaCO3 t−1) | 19.0 | 14.0 |

| NP (kg CaCO3 t−1) | 25.3 | 23.5 |

| NNP (kg CaCO3 t−1) | +6.3 | +9.5 |

| Treatment | Fine Coal Waste (kg) | Coarse Coal Waste (kg) | Soil (kg) | Sewage Sludge (kg) | Total (kg) |

|---|---|---|---|---|---|

| I | 18.9 | - | - | 1.1 | 20 |

| II | 7.7 | 11.2 | - | 1.1 | 20 |

| III | 7.7 | 11.2 | - | 1.1 | 20 |

| IV | 5.1 | 7.4 | 6.3 | 1.1 | 20 |

| V | 5.1 | 7.4 | 6.3 | 1.1 | 20 |

| VI | 5.1 | 7.4 | 6.3 | 1.1 | 20 |

| VII | - | - | 18.9 | 1.1 | 20 |

| Treatment | Bulk Density Dry (kg m−3) | Bulk Density Saturated (kg m−3) | Available Water Capacity (m3 m−3) | Permeability (k) (cm s−1) | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| I | 944.0 | 14 | 1152 | 22 | 0.21 | 0.02 | 0.04 | 0.01 |

| II | 1166 | 23 | 1256 | 48 | 0.09 | 0.03 | 0.04 | 0.02 |

| III | 1285 | 16 | 1441 | 0.1 | 0.16 | 0.02 | 0.03 | 0.01 |

| IV | 1140 | 48 | 1288 | 54 | 0.15 | 0.03 | 0.06 | 0.01 |

| V | 1207 | 147 | 1388 | 8.7 | 0.18 | 0.15 | 0.03 | 0.02 |

| VI | 1245 | 43 | 1409 | 67 | 0.16 | 0.04 | 0.03 | 0.02 |

| VII | 1101 | 23 | 1325 | 17 | 0.22 | 0.01 | 0.07 | 0.01 |

| Treatment | Macronutrients | Micronutrients | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pH | SOM | CEC | Al | N | P | K | Ca | Mg | Cu | Zn | Mn | Fe | B | |

| % | cmolc dm−3 | % | mg dm−3 | cmolc dm−3 | mg dm−3 | |||||||||

| I | 6.1 | 3.5 | 7.2 | bdl * | 0.42 | 146 | 17.2 | 3.1 | 2.7 | 9.5 | 25.6 | 4.6 | >5.0 | 0.30 |

| II | 6.0 | 3.5 | 6.7 | bdl | 0.49 | 136 | 22.6 | 3.2 | 2.1 | 11 | 26.0 | 5.1 | >5.0 | 0.17 |

| III | 6.0 | 3.5 | 5.6 | bdl | 0.54 | 76.0 | 17.2 | 1.5 | 1.7 | 11 | 25.6 | 3.7 | >5.0 | 0.30 |

| IV | 5.9 | 3.2 | 8.6 | bdl | 0.51 | 114 | 33.4 | 4.3 | 1.7 | 7.3 | 23.7 | 6.0 | >5.0 | 0.27 |

| V | 6.4 | 3.2 | 15 | 0.1 | 0.56 | 98.8 | 71.1 | 11 | 2.4 | 5.9 | 24.1 | 16 | >5.0 | 0.23 |

| VI | 5.7 | 4.1 | 8.7 | bdl | 0.61 | 94.5 | 43.1 | 3.9 | 2.7 | 7.5 | 23.8 | 16 | >5.0 | 0.40 |

| VII | 6.5 | 2.0 | 16.5 | bdl | 0.16 | 71.9 | 304 | 11 | 2.8 | 3.4 | 23.9 | 23 | >5.0 | 0.27 |

| Ref. | 6.1 | 3.5 | 7.2 | bdl | 0.42 | 146 | 17.2 | 3.1 | 2.7 | 9.5 | 25.6 | 4.6 | >5.0 | 0.30 |

| Treatment | Macronutrients (g kg−1) | Micronutrients (mg kg−1) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| N | P | K | Ca | Mg | Fe | Mn | Cu | B | |

| I | 21.0 | 3.8 | 8.20 | 8.6 | 3.2 | 170 | 170 | 9.6 | 0.7 |

| II | 20.3 | 4.2 | 10.2 | 6.6 | 3.0 | 150 | 240 | 8.7 | 0.5 |

| III | 17.5 | 3.6 | 10.8 | 7.9 | 3.8 | 120 | 250 | 6.4 | 0.9 |

| IV | 18.2 | 4.5 | 12.2 | 9.3 | 2.7 | 130 | 120 | 5.5 | 0.9 |

| V | 21.0 | 4.1 | 13.6 | 7.8 | 2.6 | 120 | 150 | 5.3 | 0.6 |

| VI | 25.9 | 5.1 | 14.6 | 9.8 | 3.2 | 89.0 | 110 | 4.0 | 3.2 |

| VII | 25.2 | 6.6 | 22.8 | 8.9 | 1.6 | 130 | 69.0 | 4.5 | 8.2 |

| Ref. | 12.0–26.0 | 1.0–3.0 | 12.0–30.0 | 2.0–8.0 | 1.5–5.0 | 50.0–250 | 20.0–300 | 4.0–20 | 5.0–30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, E.K.; Venturella, A.C.; Weiler, J.; Schneider, I.A.H. Prospect for Fine and Coarse Coal Waste Deployment for a Constructed Technosol and Eragrostis Tef Growth. Mining 2024, 4, 806-817. https://doi.org/10.3390/mining4040045

de Oliveira EK, Venturella AC, Weiler J, Schneider IAH. Prospect for Fine and Coarse Coal Waste Deployment for a Constructed Technosol and Eragrostis Tef Growth. Mining. 2024; 4(4):806-817. https://doi.org/10.3390/mining4040045

Chicago/Turabian Stylede Oliveira, Eduardo Kercher, Arthur Cesa Venturella, Jéssica Weiler, and Ivo André Homrich Schneider. 2024. "Prospect for Fine and Coarse Coal Waste Deployment for a Constructed Technosol and Eragrostis Tef Growth" Mining 4, no. 4: 806-817. https://doi.org/10.3390/mining4040045

APA Stylede Oliveira, E. K., Venturella, A. C., Weiler, J., & Schneider, I. A. H. (2024). Prospect for Fine and Coarse Coal Waste Deployment for a Constructed Technosol and Eragrostis Tef Growth. Mining, 4(4), 806-817. https://doi.org/10.3390/mining4040045