Sulphuric Acid Digestion of Anatase Concentrate

Abstract

1. Introduction

2. Materials and Experimental Procedure

2.1. Material

2.2. Chemical and Mineralogical Characterization

2.3. Sulphuric Digestion

3. Results and Discussion

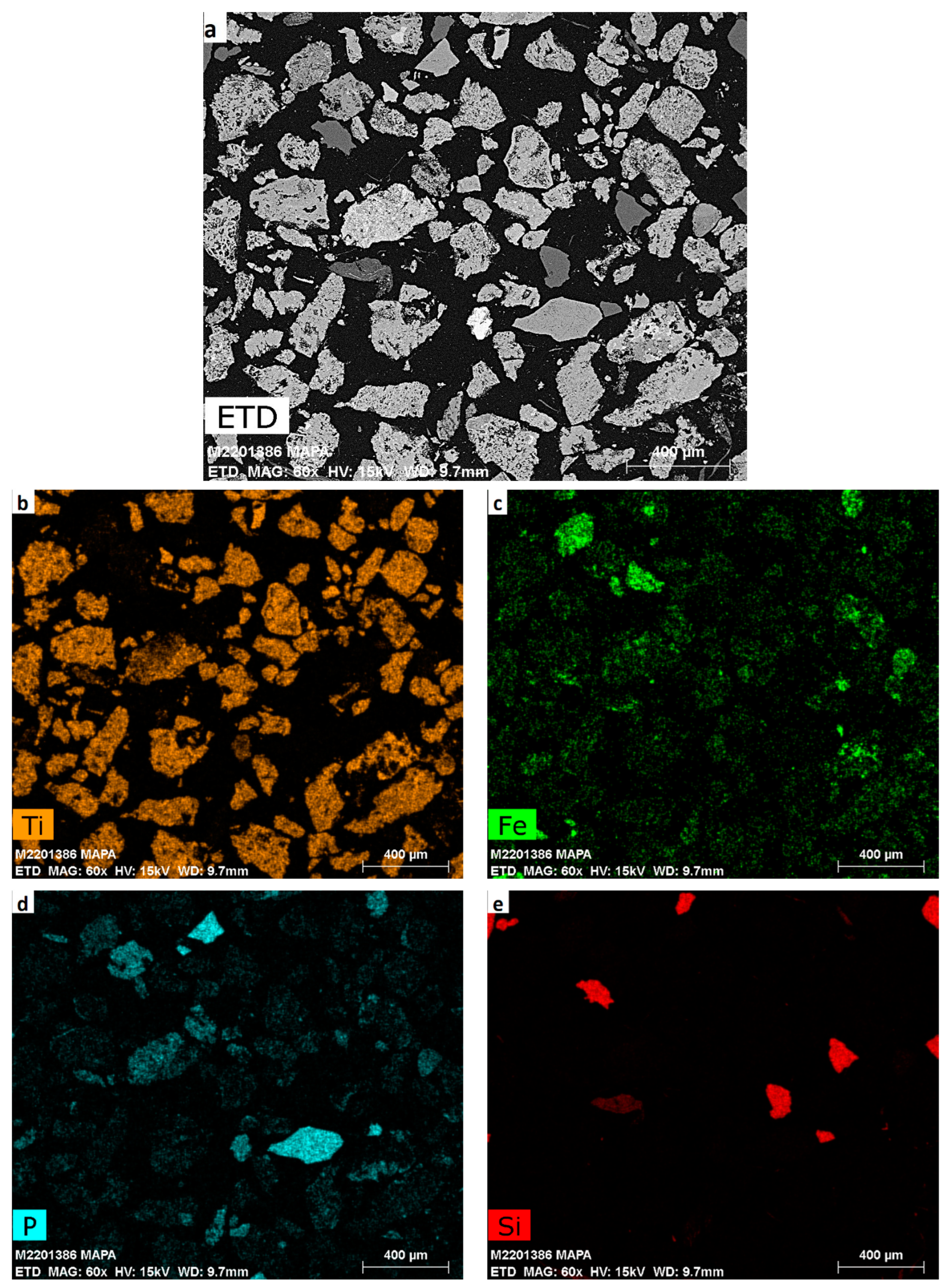

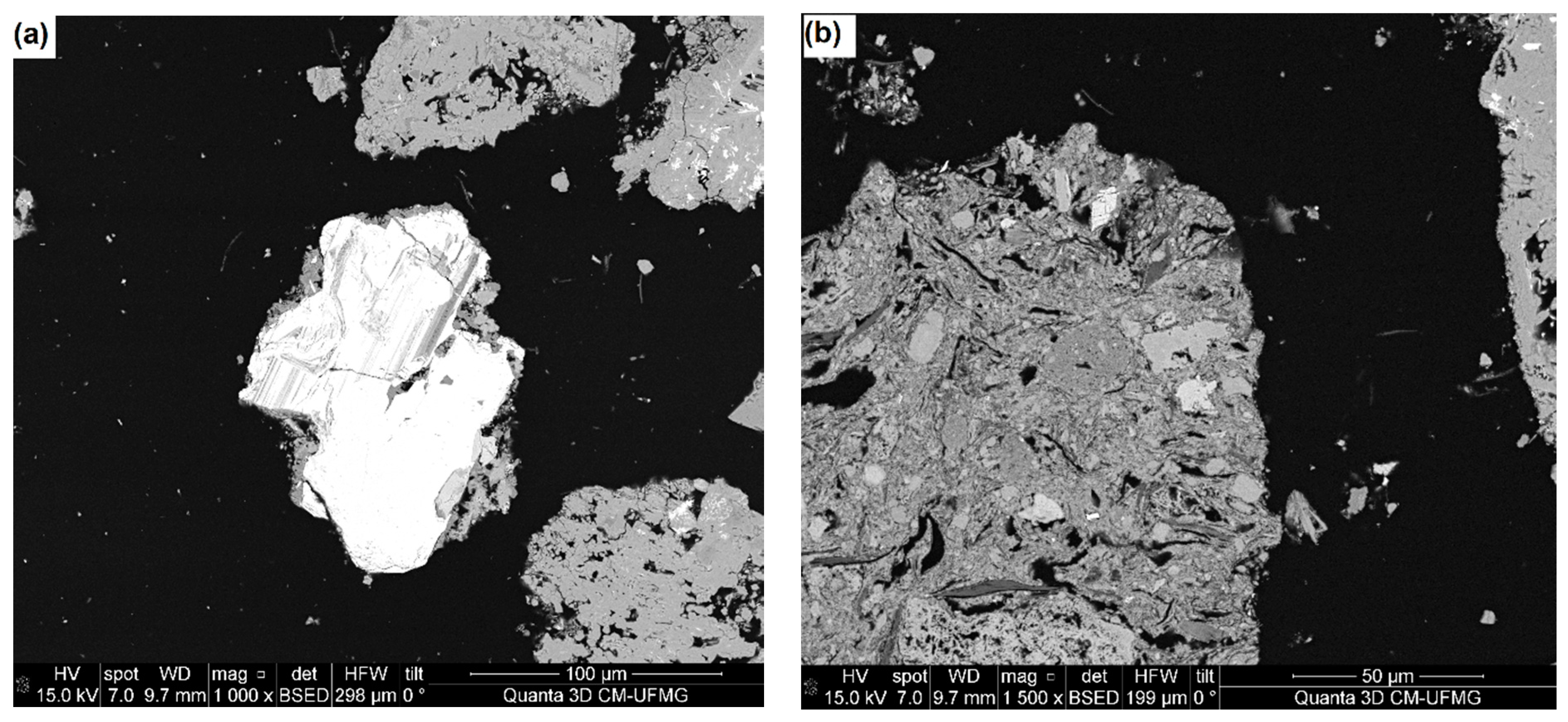

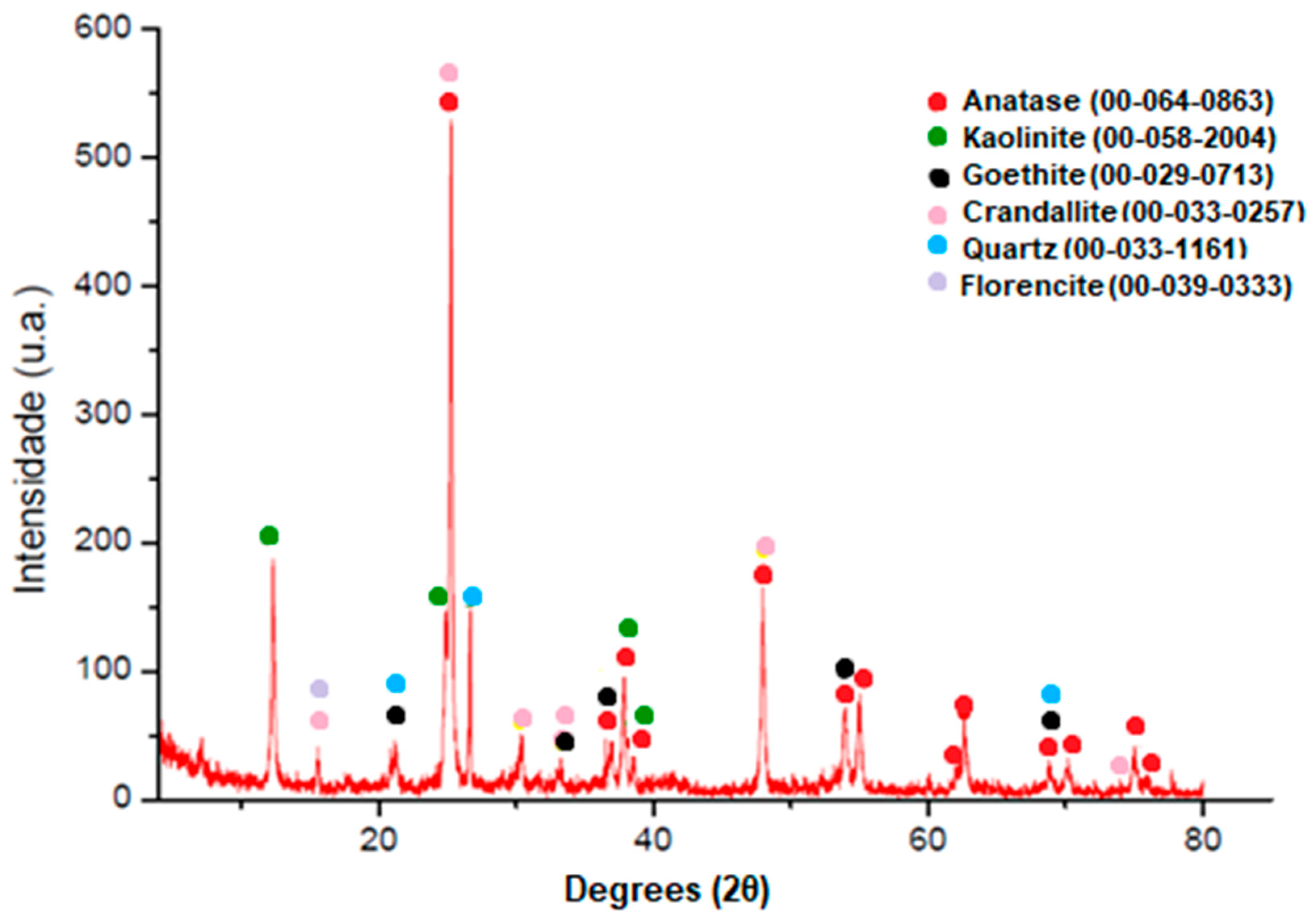

3.1. Chemical and Mineralogical Characterization of the Anatase Concentrate

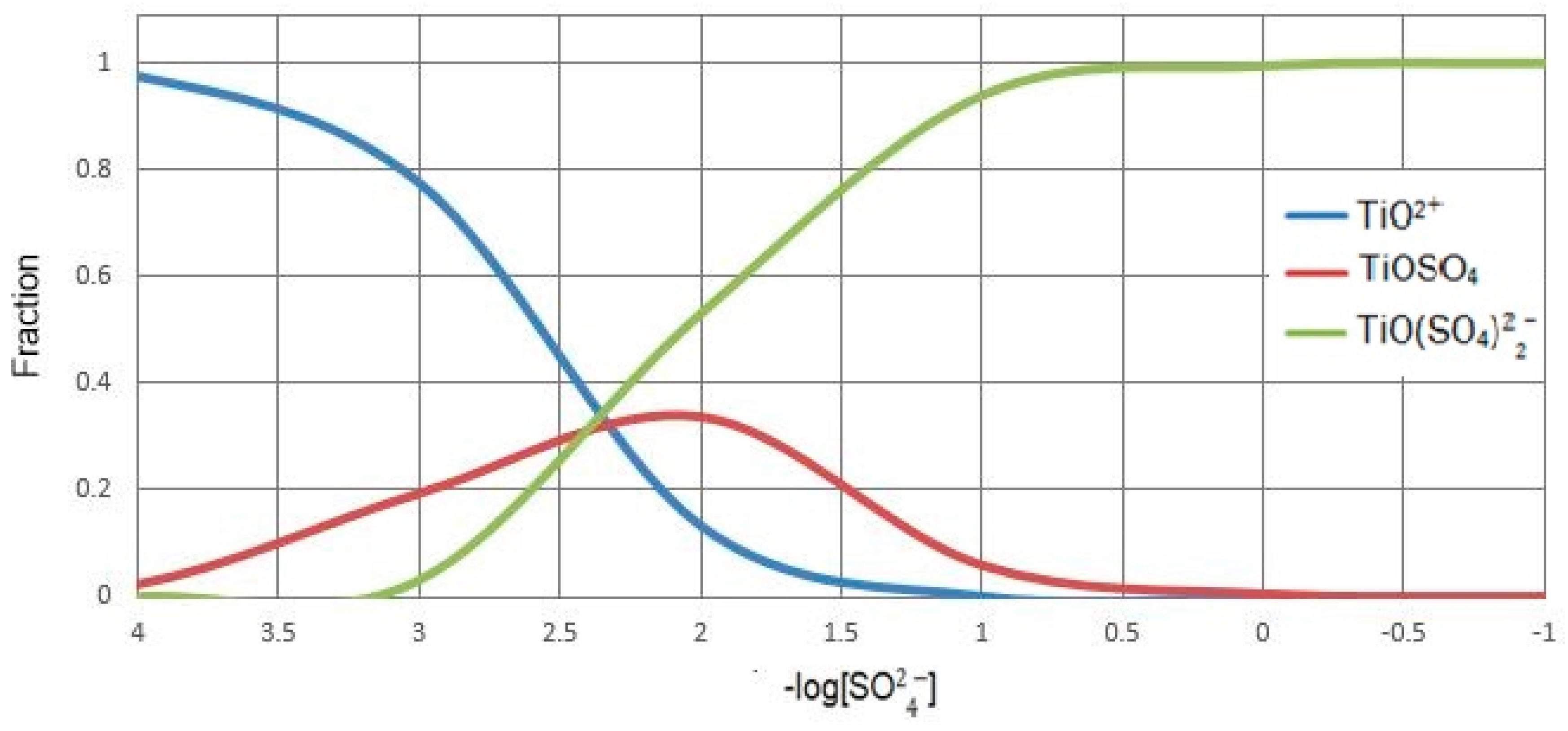

3.2. Sulphuric Acid Digestion

3.2.1. Effect of Temperature on Sulphuric Digestion of the Concentrate

3.2.2. Effect of the Anatase Concentrate:Sulphuric Acid Ratio in the Digestion

3.2.3. Effect of Time in Sulphuric Digestion

3.2.4. Effect of Using Dilute Sulphuric Acid as a Leaching Agent

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gasik, M. (Ed.) Technology of Titanium Ferroalloys. In Handbook of Ferroalloys: Theory and Technology; Butterworth-Heinemann: Espoo, Finland, 2013; pp. 428–429. [Google Scholar]

- Barnard, K.R.; Mcdonald, R.G.; Pownceby, M.I.; Sparrow, G.J.; Zhang, W. Processing anatase ores for pigment production. Hydrometallurgy 2019, 185, 226–237. [Google Scholar] [CrossRef]

- Kordzadeh-Kermani, V.; Schaffie, M.; Rafsanjani, H.H.; Ranjbar, M. A modified process for leaching of ilmenite and production of TiO2 nanoparticles. Hydrometallurgy 2020, 198, 105507. [Google Scholar] [CrossRef]

- Meysami, A.; Golestani, A.; Khangah, A.H.; Meysami, M.; Dehghanpour, H. Experimental Investigation of TiO2 Pigment Production by Electrodialysis Process from Ilmenite Concentrate. JOM 2023, 75, 5176–5187. [Google Scholar] [CrossRef]

- Gao, L.; Rao, B.; Daí, H.; Xie, H.; Wang, P.; Ma, F. Kinetics of sulphuric acid leaching of titanium from refractory anatase under atmospheric pressure. Physicochem. Probl. Miner. Process. 2019, 55, 467–478. [Google Scholar]

- Filho, A.A.Q.; Neto, A.A.A. Titânio. In Agência Nacional de Mineração; Sumário Mineral 2017; ANM: Brasília, Brazil, 2019; Volume 37, pp. 167–169. [Google Scholar]

- Baltar, C.A.M.; Sampaio, J.A.; Andrade, M.C.; Pinto, D.C. Minerais de Titânio. In Rochas & Minerais Industriais, 2nd ed.; Luz, A.B., Lins, F.A.F., Eds.; CETEM/MCT: Rio de Janeiro, Brazil, 2009; Volume 1, pp. 841–864. [Google Scholar]

- Oliveira, A.L.B.; Silva, G.D.S.; Aguiar, P.F.; Neumann, R.; Alcover Neto, A.; Carneiro, M.C.; Afonso, J.C. Optimization of alkaline roasting to enable acid leaching of titanium from anatase ores. J. Sustain. Metall. 2023, 9, 183–193. [Google Scholar] [CrossRef]

- Woodruff, L.G.; Bedinger, G.M.; Piatak, N.M. Titanium. In Critical Mineral Resources of the United States—Economic and Environmental Geology and Prospects for Future Supply; Schulz, K.J., Deyoung, J.H., Jr., Seal, R.R., II, Bradley, D.C., Eds.; U.S. Geological Survey: Reston, VA, USA, 2017; pp. T1–T23. [Google Scholar] [CrossRef]

- Lakshmanan, V.I.; Bhowmick, A.; Halim, M.A. Titanium Dioxide: Production, Properties and Applications. In Titanium Dioxide: Chemical Properties, Applications and Environmental Effects; Brown, J., Ed.; Nova Science Publishers: New York, NY, USA, 2014; pp. 75–130. [Google Scholar]

- Trindade, R.B.E.; Teixeira, L.A. Beneficiamento de concentrado de titânio (anatásio) por lixiviação oxidante de impurezas. In Encontro Nacional de Tratamento de Minérios e Hidrometalurgia; ABM/APEMI/EPUSP: São Paulo, Brazil, 1988; Volume 12, pp. 823–836. [Google Scholar]

- Gazquez, M.J.; Bolívar, J.P.; Garcia-Tenorio, R.; Vaca, F. A review of the production cycle of Titanium Dioxide Pigment. Mater. Sci. Appl. 2014, 5, 441–458. [Google Scholar] [CrossRef]

- Xue, T.; Wang, L.; Qi, T.; Chu, J.; Qu, J.; Liu, C. Decomposition kinectics of titanium slag in sodium hydroxide system. Hydrometallurgy 2009, 95, 22–27. [Google Scholar] [CrossRef]

- Gontijo, V.L.; Teixeira, L.A.V.; Ciminelli, V.S.T. The reactivity of iron oxides and hydroxide during low-temperature sulphation. Hydrometallurgy 2020, 197, 105452. [Google Scholar] [CrossRef]

- Freitas, L.R.; Brocchi, E.A. Digestão Sulfúrica de Materiais à base de Titânio. In Encontro Nacional de Tratamento de Minérios e Metalurgia Extrativa; CETEM/CNPq: Rio de Janeiro, Brazil, 1995; Volume 16, pp. 17–30. [Google Scholar]

- Ismael, M.H.; El Hussaini, O.; El-Shahat, M.F. New method to prepare high purity anatase TiO2 through alkaline roasting and acid leaching from non-conventional minerals resource. Hydrometallurgy 2020, 195, 105399. [Google Scholar] [CrossRef]

- Jablonski, M.; Tylutka, S. The influence of initial concentration of sulphuric acid on the degree of leaching of the main elements of ilmenite raw materials. J. Therm. Anal. Calorim. 2016, 124, 355–361. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Lee, M.S. A review on the recovery of titanium dioxide from ilmenite ores by direct leaching technologies. Miner. Process. Extr. Metall. Rev. 2019, 40, 231–247. [Google Scholar] [CrossRef]

- Sun, L.; Yu, H.; Meng, F.; Qi, T.; Wang, L.; Peng, Y. Recovery of niobium and titanium from ilmenorutile by NaOH roasting-H2SO4 leaching process. J. Mater. Res. Technol. 2021, 15, 2575–2583. [Google Scholar] [CrossRef]

- Chao, T.; Senkler, G.H. Method for Purifying TiO2 Ore. US Patent 5011666, 30 April 1991. [Google Scholar]

- Chao, T.; Kremer, W.L.; Fonseca Mourão, M.J.; Jardim Paixão, J.M. Process for Purifying Anatase TiO2 Ore. PCT Patent WO93/22465, 11 November 1993. [Google Scholar]

- Freitas, L.R.; Horta, R.M.; Tude, J.A.L. Process for Enrichment of Anatase Mechanical Concentrates in Order to Obtain Synthetic Rutile with Low Contents of Rare Earths and Radioactive Elements. PCT Patent WO2007/048210 A1, 17 November 2008. [Google Scholar]

- Freitas, L.R.; Gracioso, J.E. Abertura do anatásio por sulfatação. In Encontro Nacional de Tratamento de Minérios e Hidrometalurgia; CNEN/CDTN: Natal, Brazil, 1985; Volume II, pp. 96–108. [Google Scholar]

- Jha, A.; Tathavadkar, V.D. Process for the Recovery of Titanium Dioxide from Titanium- Containing Compositions. PCT Patent WO2005/028369 A1, 19 May 2005. [Google Scholar]

- Mineração Vale Do Paranaíba, S.A. A Method for Obtaining Higher TiO2 Grade Anatase Concentrates from Lower TiO2 Grade Anatase Concentrates. GB Patent 1568333, 29 May 1980. [Google Scholar]

- Paixão, J.M.J.; Mendonça, P.A.F. Process for Concentration of Titanium Containing Anatase Ore. US Patent 4176159, 27 November 1979. [Google Scholar]

- Smith, E.M., Jr.; De Castro Sheldon, A. Titaniferous Ore Beneficiation. PCT Patent WO2007/046975 A2, 26 April 2007. [Google Scholar]

- Lane, G.R.; Martin, C.; Pirard, E. Techniques and applications for predictive metallurgy and ore characterization using optical image analysis. Miner. Eng. 2008, 21, 568–577. [Google Scholar] [CrossRef]

- Demol, J.; Ho, E.; Senanayake, G. Sulphuric acid baking and leaching of rare earth elements, thorium and phosphate from a monazite concentrate: Effect of bake temperature from 200 to 800 °C. Hydrometallurgy 2018, 179, 254–267. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Wang, L.; Xue, T.; Qi, T. Preparation of Rutile Titanium Dioxide White Pigment via Doping and Calcination of Metatitanic Acid Obtained by the NaOH Molten Salt Method. Ind. Eng. Chem. Res. 2010, 49, 7693–7696. [Google Scholar] [CrossRef]

- Sukla, L.B.; Panda, S.C.; Jena, P.K. Recovery of cobalt, nickel and copper from converter slag through roasting with ammonium sulphate and sulphuric acid. Hydrometallurgy 1986, 16, 153–165. [Google Scholar] [CrossRef]

- Aguiar, E.M.M.M. Recuperação de Titânio e Vanádio de Fonte Secundária. Master’s Dissertation, USP (Escola Politécnica da Universidade de São Paulo), São Paulo, Brazil, 2021. [Google Scholar]

- Tian, C. Internal influences of hydrolysis conditions on rutile TiO2 pigment production via short sulfate process. Mater. Res. Bull. 2018, 103, 83–88. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, Z.; Cheng, C.Y. A literature review of titanium metallurgical processes. Hydrometallurgy 2011, 108, 177–188. [Google Scholar] [CrossRef]

- Bekker, J.H.; Dutton, D.F. Recovery of Titanium Dioxide from Titanium Oxide Bearing Materials like Steelmaking Slags. PCT Patent US2004/0136899A1, 15 July 2004. [Google Scholar]

| Authors | Anatase Ore Concentrate— TiO2 (%) | Processes |

|---|---|---|

| Chao and Senkler (1991) [20] | 74.5 | Upgrade: chloride leaching, alkaline leaching, chloride leaching |

| Chao et al. (1993) [21] | 62.9 | Upgrade: a reducing roasting, magnetic separation, pressure chloride leaching |

| Freitas et al. (2007) [22] | 53.8 | Upgrade: calcination, reduction in H2, magnetic separation, chloride leaching |

| Freitas and Gracioso (1985) [23] | 70.0 | Chloride leaching, alkaline digestion, sulphuric digestion, hydrolysis- precipitation |

| Jha and Tathavadkar (2005) [24] | 57.8 | Alkaline digestion, leaching with water, |

| Patent: Mineração Vale do Paranaíba (1980) [25] | 78.1 | Upgrade: Acid digestion under pressure, chloride leaching, magnetic separation |

| Paixão and Mendonça (1979) [26] | 75.6 | Upgrade: roasting, magnetic separation, HCl chloride leaching, NaOH neutralization |

| Smith Jr and Castro Sheldon (2007) [27] | 52.9 | Upgrade: leaching in autoclave with H2SO4 and FeSO4, drying with NaCl addition, calcination, chloride leaching |

| Trindade e Teixeira (1988) [11] | 76.5 | Upgrade: chloride leaching in 4 stages |

| Elements | Anatase Concentrate (%) |

|---|---|

| TiO2 | 56.5 |

| Fe2O3 | 15.0 |

| P2O5 | 4.11 |

| SiO2 | 6.01 |

| Al2O3 | 5.34 |

| CaO | 1.61 |

| ZrO2 | 0.59 |

| Nb2O5 | 0.62 |

| REE | 2.19 |

| T (°C) | TiO2 (%) | Fe2O3 (%) | P2O5 (%) | ZrO2 (%) | Nb2O5 (%) | Mass Reduction (%) | |

|---|---|---|---|---|---|---|---|

| 190 | Residue | 57.2 ± 1.2 | 8.14 ± 0.13 | 1.60 ± 0.08 | 0.83 ± 0.14 | 1.08 ± 0.03 | 68.9 |

| Metallurgical recovery | 68.6 | 83.1 | 87.9 | 56.3 | 45.9 | ||

| 200 | Residue | 50.9 ± 0.0 | 7.52 ± 0.42 | 2.59 ± 0.06 | 0.51 ± 0.04 | 0.95 ± 0.05 | 63.4 |

| Metallurgical recovery | 67.0 | 81.6 | 76.9 | 68.6 | 43.4 | ||

| 210 | Residue | 47.8 ± 0.6 | 8.24 ± 0.35 | 2.71 ± 0.06 | 0.63 ± 0.02 | 1.04 ± 0.02 | 70.9 |

| Metallurgical recovery | 75.4 | 84.1 | 80.8 | 68.9 | 51.0 | ||

| 220 | Residue | 35.8 ± 1.7 | 7.87 ± 0.17 | 4.40 ± 0.36 | 0.46 ± 0.07 | 0.66 ± 0.14 | 78.0 |

| Metallurgical recovery | 86.0 | 88.4 | 76.5 | 82.9 | 76.4 |

| Anatase:H2SO4 | TiO2 (%) | Fe2O3 (%) | P2O5 (%) | ZrO2 (%) | Nb2O5 (%) | Mass Reduction (%) | |

|---|---|---|---|---|---|---|---|

| 1:1.3 | Residue | 51.9 ± 0.8 | 7.62 ± 0.89 | 2.32 ± 0.37 | 0.46 ± 0.05 | 1.00 ± 0.07 | 69.0 |

| Metallurgical recovery (%) | 71.6 | 84.5 | 82.2 | 76.1 | 50.4 | ||

| 1:2 | Residue | 35.8 ± 1.7 | 7.87 ± 0.17 | 4.40 ± 0.36 | 0.46 ± 0.07 | 0.66 ± 0.14 | 78.0 |

| Metallurgical recovery (%) | 86.0 | 88.4 | 76.5 | 82.9 | 76.4 |

| Digestion Time (h) | TiO2 (%) | Fe2O3 (%) | P2O5 (%) | ZrO2 (%) | Nb2O5 (%) | Mass Reduction (%) | |

|---|---|---|---|---|---|---|---|

| 3 | Residue | 39.3 ± 1.3 | 8.72 ± 0.39 | 3.41 ± 0.17 | 0.52 ± 0.07 | 0.96 ± 0.09 | 87.3 |

| Metallurgical recovery (%) | 82.3 | 85.2 | 78.9 | 77.4 | 60.3 | ||

| 4 | Residue | 35.8 ± 1.7 | 7.87 ± 0.17 | 4.40 ± 0.36 | 0.46 ± 0.07 | 0.66 ± 0.14 | 78.0 |

| Metallurgical recovery (%) | 86.0 | 88.4 | 76.5 | 82.9 | 76.4 | ||

| 5 | Residue | 44.0 ± 0.6 | 7.43 ± 0.32 | 3.17 ± 0.08 | 0.44 ± 0.06 | 0.82 ± 0.05 | 72.0 |

| Metallurgical recovery (%) | 78.2 | 86.1 | 78.4 | 79.2 | 62.7 |

| Leaching Agent | TiO2 (%) | Fe2O3 (%) | P2O5 (%) | ZrO2 (%) | Nb2O5 (%) | Mass Reduction (%) | |

|---|---|---|---|---|---|---|---|

| H2SO4 5% | Residue | 40.7 ± 2.9 | 6.44 ± 0.52 | 3.54 ± 0.28 | 0.48 ± 0.09 | 0.87 ± 0.07 | 75.3 |

| Metallurgical recovery (%) | 81.2 | 88.9 | 77.7 | 78.42 | 63.2 | ||

| Milli-Q water | Residue | 35.8 ± 1.7 | 7.87 ± 0.17 | 4.40 ± 0.36 | 0.46 ± 0.07 | 0.66 ± 0.14 | 78.0 |

| Metallurgical recovery (%) | 86.0 | 88.4 | 76.5 | 82.9 | 76.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silva, C.N.; Nazareth, L.P.T.; de Freitas, M.E.; Ladeira, A.C.Q. Sulphuric Acid Digestion of Anatase Concentrate. Mining 2024, 4, 79-90. https://doi.org/10.3390/mining4010006

da Silva CN, Nazareth LPT, de Freitas ME, Ladeira ACQ. Sulphuric Acid Digestion of Anatase Concentrate. Mining. 2024; 4(1):79-90. https://doi.org/10.3390/mining4010006

Chicago/Turabian Styleda Silva, Carolina Nogueira, Liliani Pacheco Tavares Nazareth, Mônica Elizetti de Freitas, and Ana Claudia Queiroz Ladeira. 2024. "Sulphuric Acid Digestion of Anatase Concentrate" Mining 4, no. 1: 79-90. https://doi.org/10.3390/mining4010006

APA Styleda Silva, C. N., Nazareth, L. P. T., de Freitas, M. E., & Ladeira, A. C. Q. (2024). Sulphuric Acid Digestion of Anatase Concentrate. Mining, 4(1), 79-90. https://doi.org/10.3390/mining4010006