Electrification Alternatives for Open Pit Mine Haulage

Abstract

:1. Introduction

- Dynamic charging BT systems;

- Stationary charging BT systems;

- Dual trolley BT systems.

2. Decarbonization and Mining Challenges

2.1. World Energy Outlook in Carbon Emissions

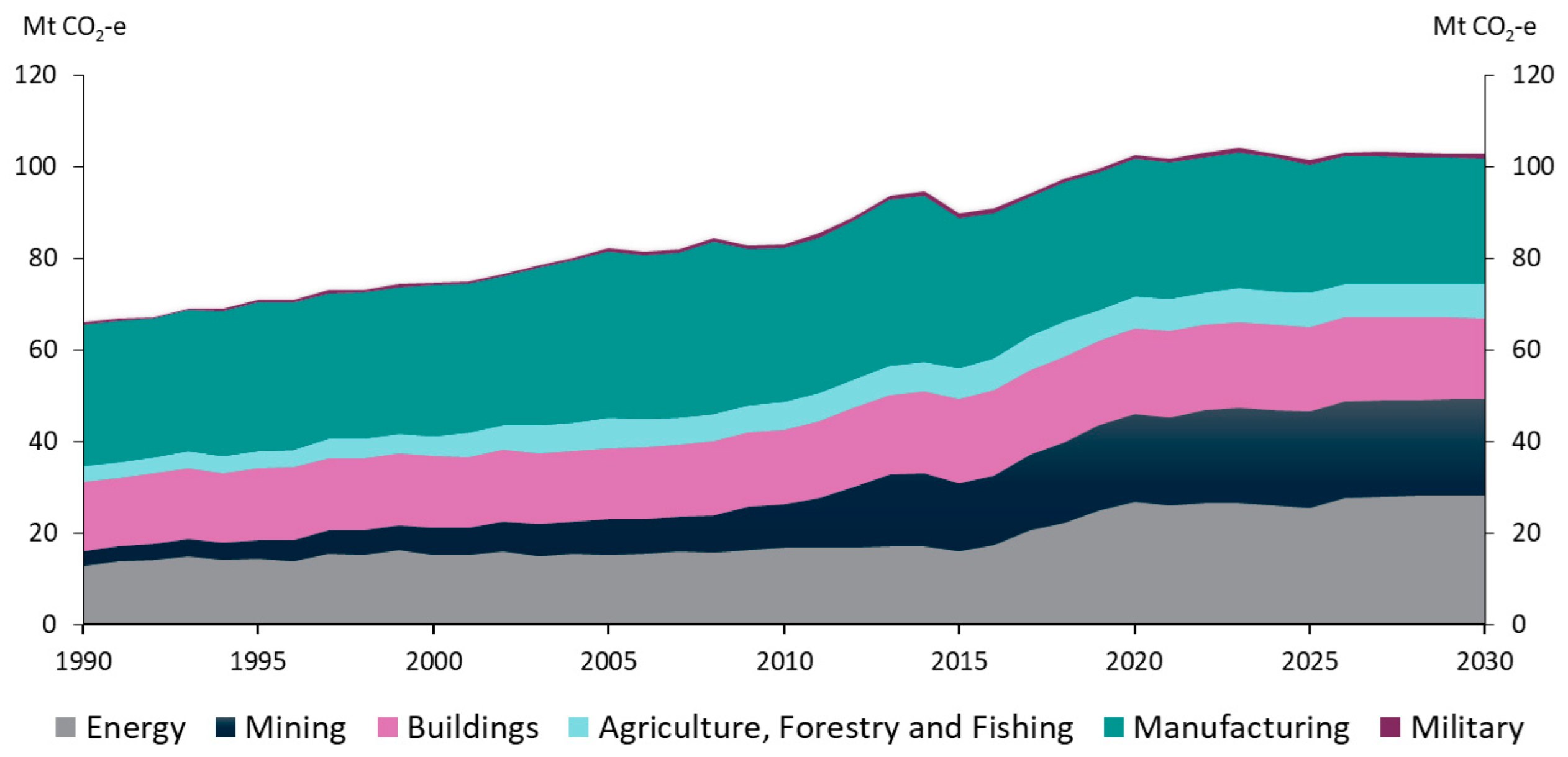

2.2. Australian Mining Sector Emissions

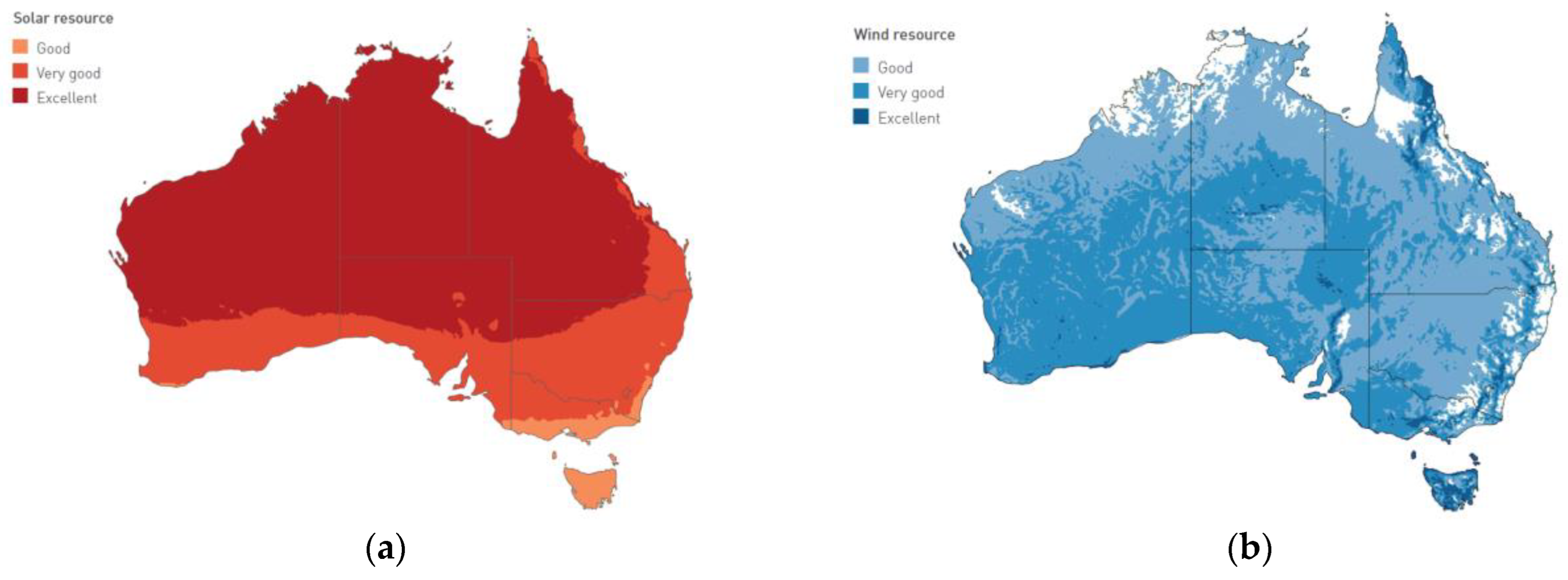

2.3. Renewable Energy Development

2.4. Technology Trends

2.5. Mining Challenges

- Greater depths and lower grades: Open pit mining depths have significantly expanded over the last two decades. Some open pit mines go down more than 1000 m in depth [10]. It is worth noting that future deposit extraction will inevitably be conducted at greater depths and lower grades compared to current practices, and this tendency is anticipated to continue [11,12].

- High operating cost: As mines become deeper and stripping ratios increase with a lower grade, more waste material needs to be extracted. The haulage truck fleet grows correspondingly, requiring more operators and maintenance staff and a subsequent increase in diesel consumption [12,13,14]. In addition, as copper ore grades decline, more ore needs to be processed to attain similar metal production. A decrease in copper ore grade between 0.2% to 0.4% requires seven times more energy than present-day operations [15,16]. Reducing the cost of truck haulage, which makes up about half of the operating expenses of a mining operation, is now more essential than ever [17].

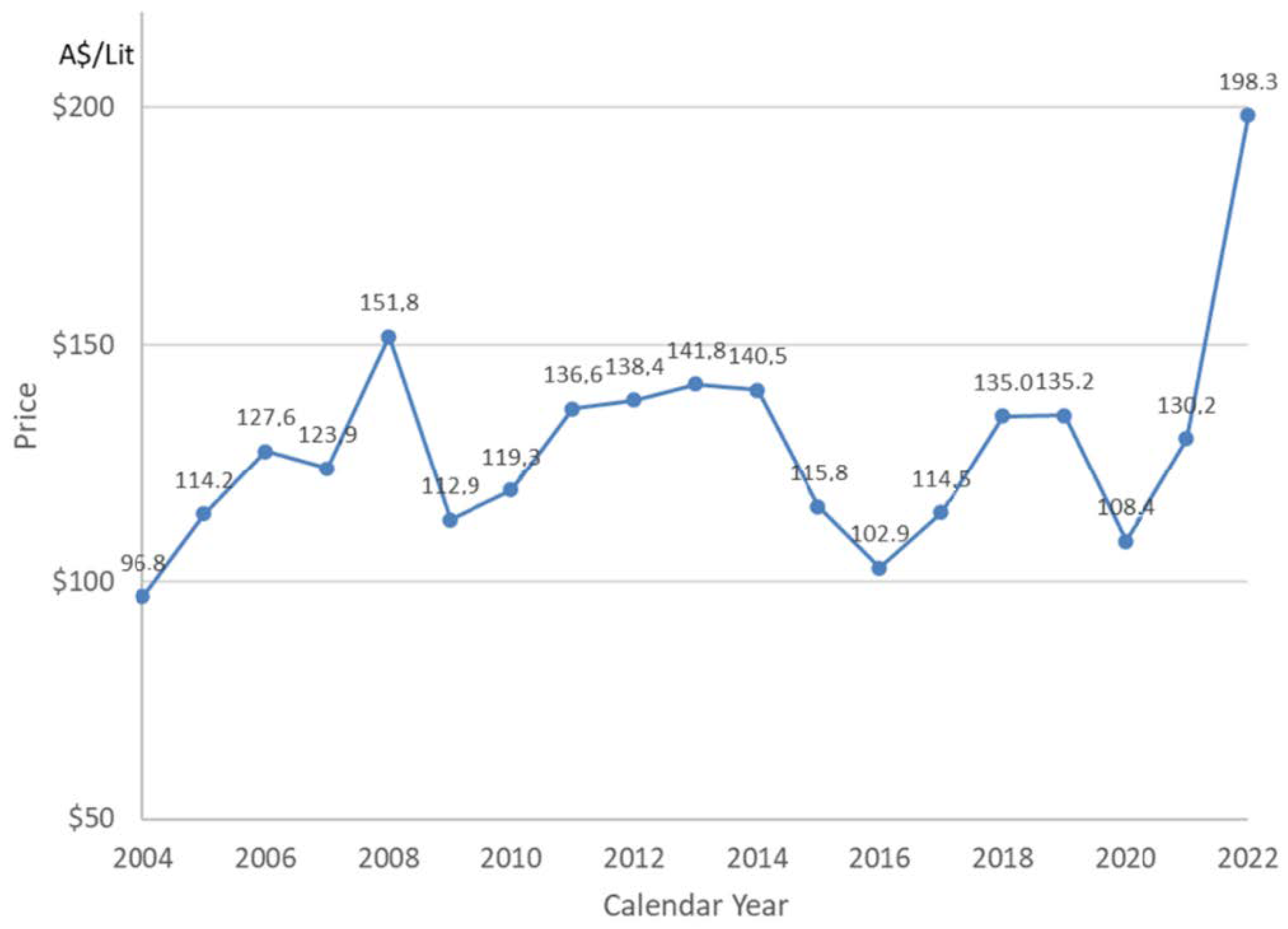

- Fuel price volatility: Fossil fuel price volatility significantly impacts mining viability but is outside the control of most miners [9]. Figure 4 shows historical Australia diesel Terminal Gate Price (TGP) data. In the short term, the price of fossil fuels shows a propensity towards volatility, while it shows a significant rise from the long-term perspective.

3. Methodology

- Safety and productivity are indicators to measure system implementation scenarios.

- Energy efficiency, CAPEX, OPEX, maintenance requirements, service life, additional infrastructure requirements and heat generation are system financial metrics.

- Emissions and environmental footprint (noise/dust/DPM/vibration) are system environmental parameters.

- Flexibility, Capacity, Scalability, Refuelling/Recharging/Swapping methods are system productivity parameters.

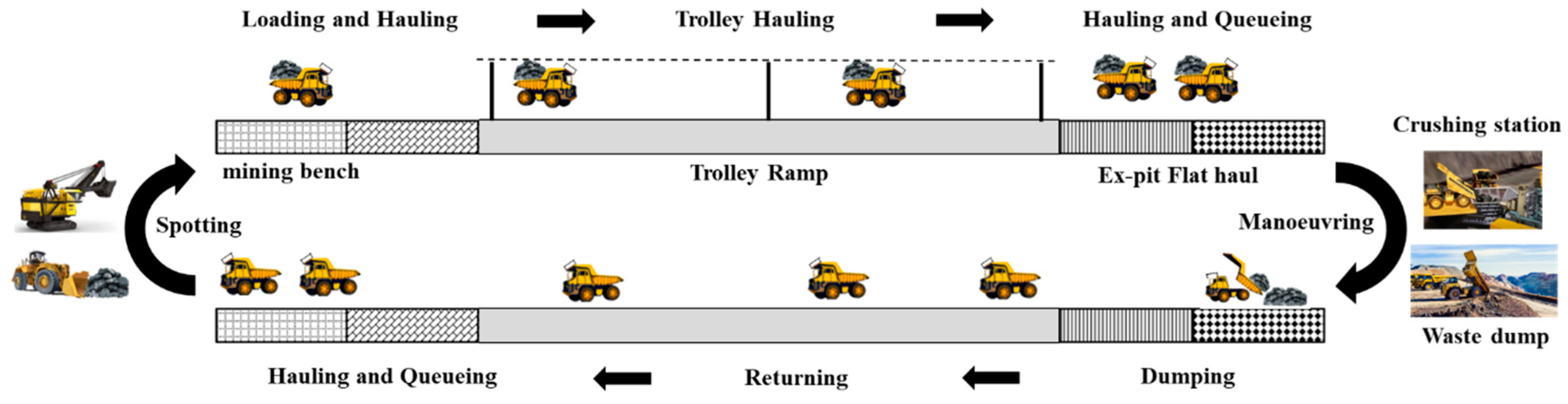

4. Conventional Truck-Shovel Systems

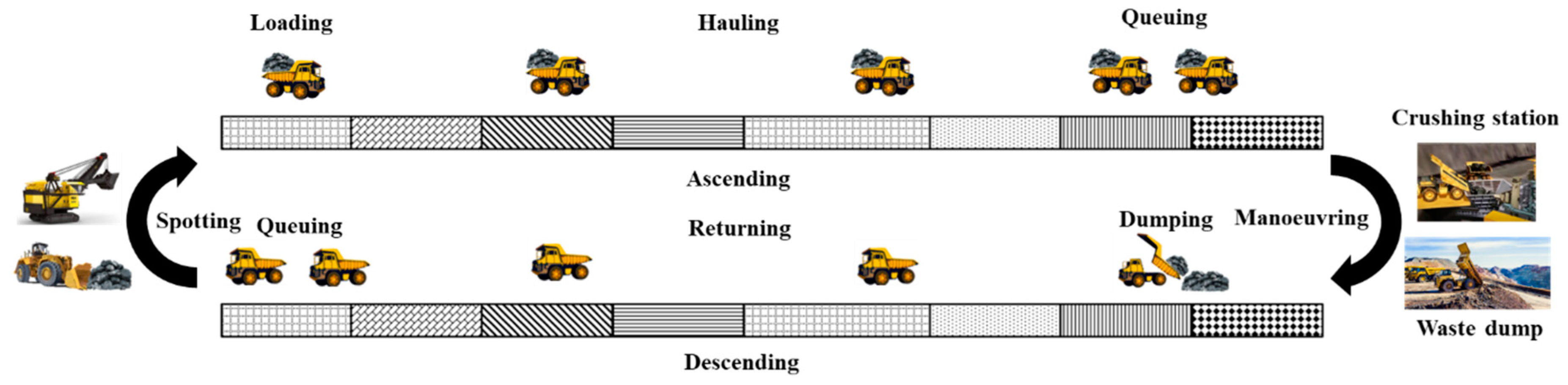

4.1. Conventional Truck-Shovel System Operating Process

4.2. Truck-Shovel Systems’ Characteristics

- 1.

- Ease of implementation

- 2.

- High flexibility

- 3.

- High scalability

- 1.

- High operating costs

- 2.

- CO2 and diesel particular emissions

- 3.

- Labour force shortage

- 4.

- Fuel price volatility

- 5.

- Safety risks

- 6.

- Maintenance

4.3. Truck-Shovel Systems’ Energy Consumption

5. Electrification Alternatives for Open Pit Mine Haulage

5.1. In-Pit Crushing and Conveying Systems

5.1.1. IPCC Systems’ Configurations

- 1.

- Fixed In-pit Crushing and Conveying systems (F-IPCC)

- 2.

- Semi-Fixed In-pit Crushing and Conveying systems (SF-IPCC)

- 3.

- Semi-Mobile In-pit Crushing and Conveying systems (SM-IPCC)

- 4.

- Fully Mobile In-pit Crushing and Conveying systems (FM-IPCC)

5.1.2. IPCC Systems’ Characteristics

- 1.

- Operational expenditure

- 2.

- CO2 emissions

- 3.

- Energy saving

- 4.

- Production efficiency

- 5.

- Environmental footprint (noise and dust)

- 6.

- Maintenance

- 7.

- Workforce reduction

- 8.

- Safety

- 9.

- Total cost operation over the mine life

- 1.

- Flexibility

- (a)

- Mine design limitation. The decision-makers must cater to the installation requirements of the IPCC systems when they design the mine layout. Take FM-IPCC as an example, the optimization of ultimate pit limit (UPL), considering the geometric constraints connected with the installation of FM-IPCC systems, is one study field that requires substantial further investigation [11]. Throughout each sinking phase of a mine, truck haulage may still be required, but the distance of the haul may be decreased by deploying and scheduling the trucks to dump into the fully mobile crusher close to the mining activity [14].

- (b)

- Relocation limitations. The IPCC has its specific extraction sequence. It is crucial to design its optimal location and relocation strategy to minimize operating costs. Mine designers need to trade-off large bench widths against production for an optimal location and relocation strategy [37]. For instance, because FM-IPCC systems are better suited to flat or gently dipping applications such as coal overburden or iron ore mining, it reduces the ability of a mine to switch mining to a different zone to adapt to unforeseen changes in market conditions or geology [14].

- (c)

- Capacity limitations. Compared with the TS system, IPCC systems cannot be scaled up or down as mining requirements change [38]. This is because IPCC’s major components (crusher, conveyor, spreader/stacker) have their own capacity limitations. An IPCC system also has a rated capacity, which reduces the ability to scale mining rates up or down according to market conditions.

- 2.

- Reliability

- 3.

- Material requirements

- 4.

- Contractual constraints

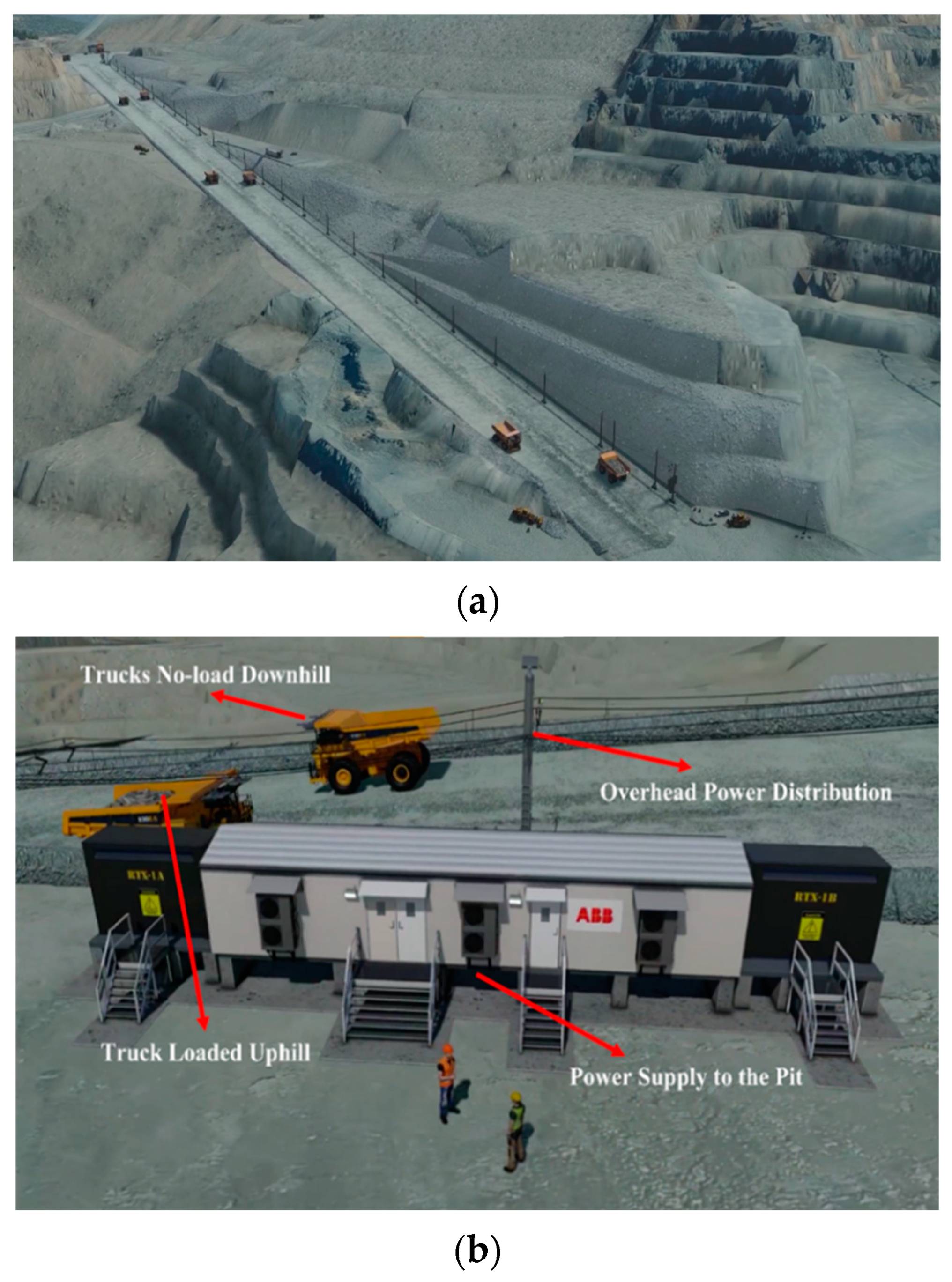

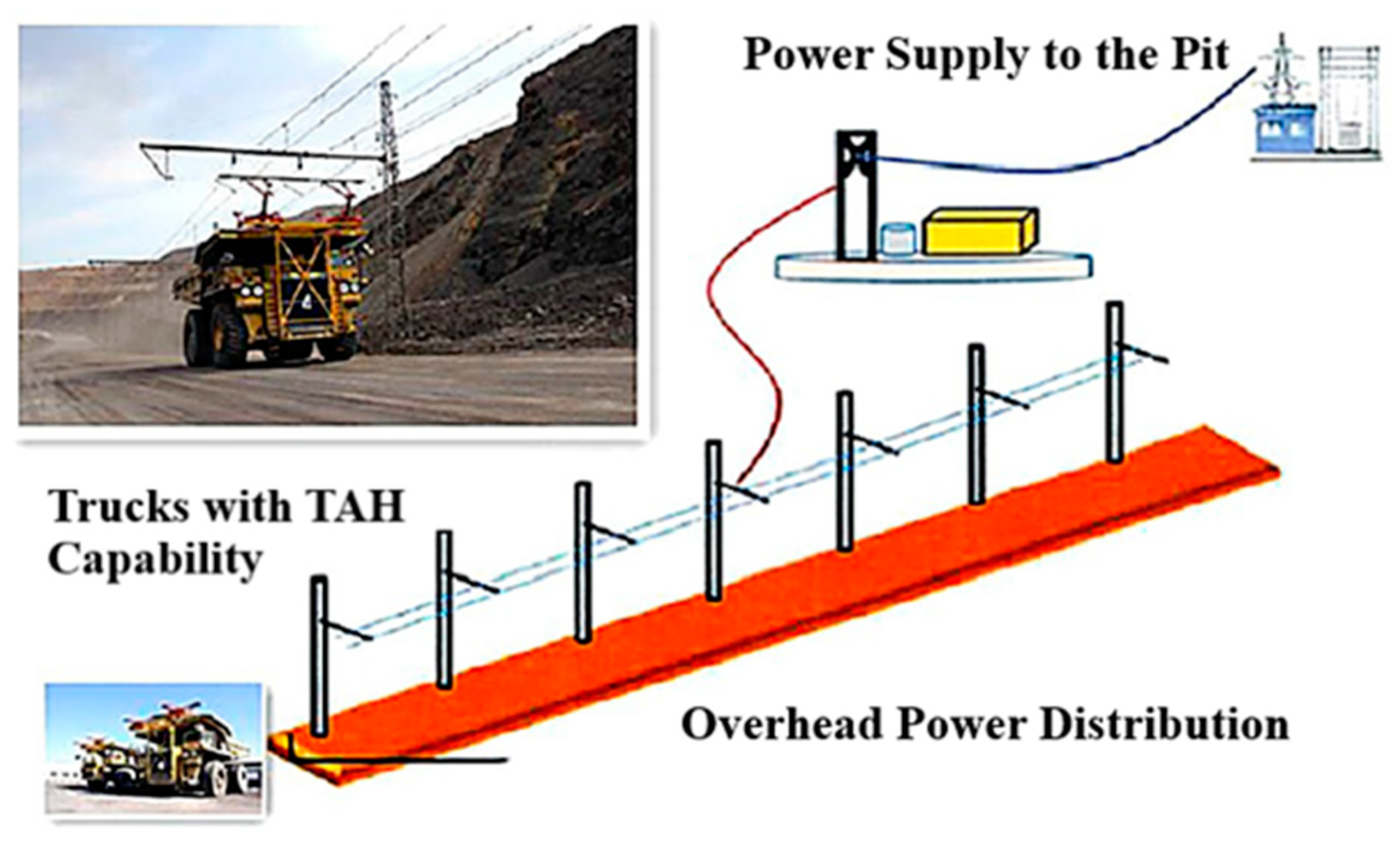

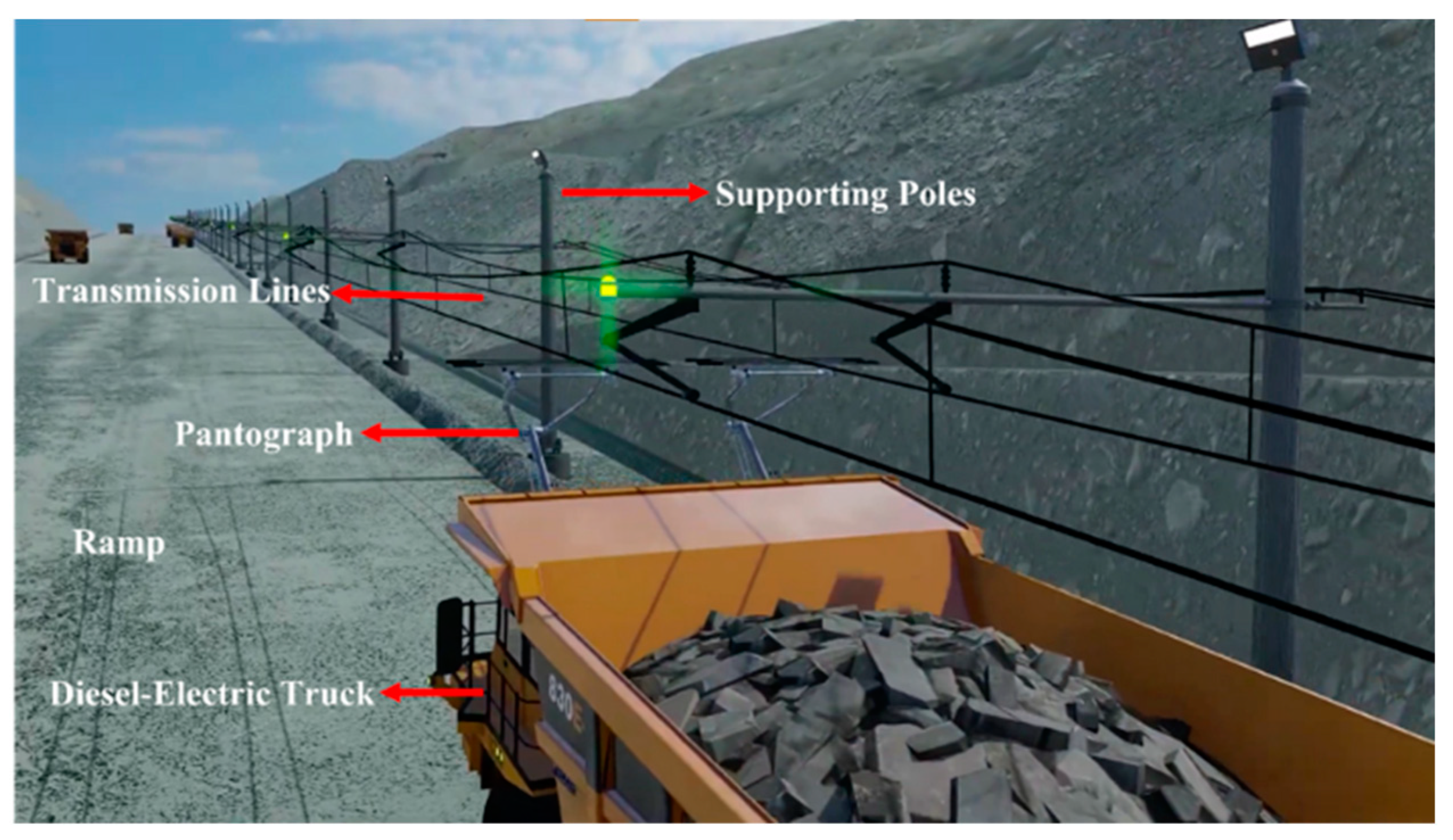

5.2. Trolley Assist Systems

5.2.1. Theory of Trolley Assist

5.2.2. Configuration of Trolley Assist

- 1.

- Power Supply to the Pit

- 2.

- Overhead Power Distribution

- 3.

- Trucks with Trolley Assist Capability

5.2.3. Advantages and Disadvantages of Trolley Assist System

- 1.

- Reduced Emissions

- 2.

- Reduced diesel fuel consumption

- 3.

- Productivity improvements

- 4.

- Increase engine and wheel motor life

- 5.

- Reduced fleet size

- 6.

- Lower maintenance cost

- 7.

- Lower overall operating cost

- 1.

- High upfront capital outlay

- 2.

- Mine design and planning restriction

- 3.

- Trolley Assist system maintenance

- 4.

- System capacity

- 5.

- Access to Electricity

- 6.

- Operator requirement

5.3. Battery Trolley Systems

5.3.1. Theory of Battery Trolley

5.3.2. Technology Uptake

- 1.

- Battery-electric power technology

- 2.

- Autonomous technology

- 3.

- Trolley Assist technology

- 4.

- Energy recovery system

5.3.3. Battery Trolley Advantages and Disadvantages

5.3.4. Battery Trolley Systems Configurations

- 1.

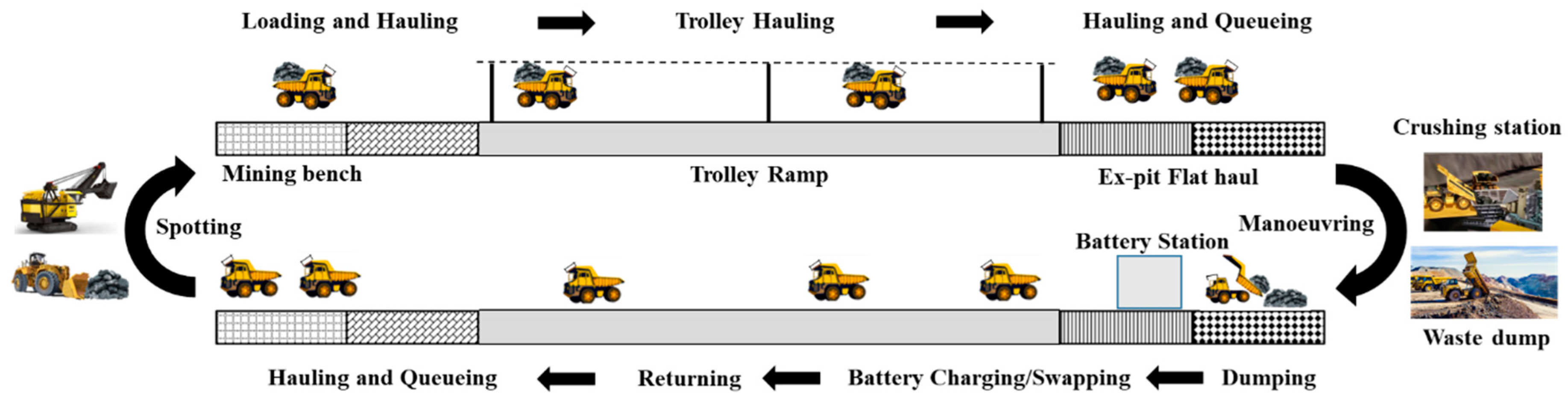

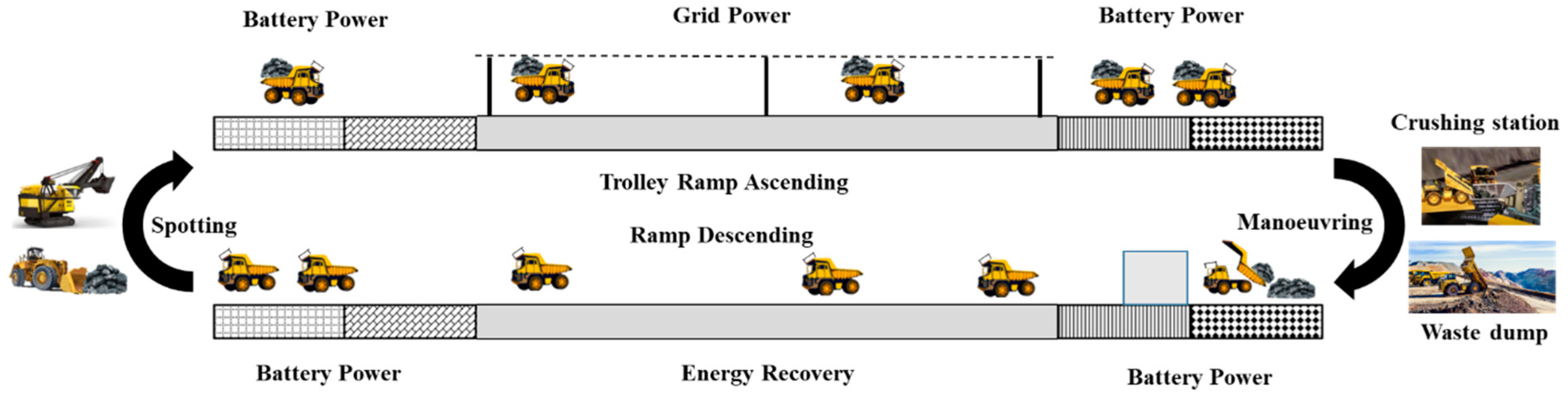

- Dynamic charging BT configuration

- 2.

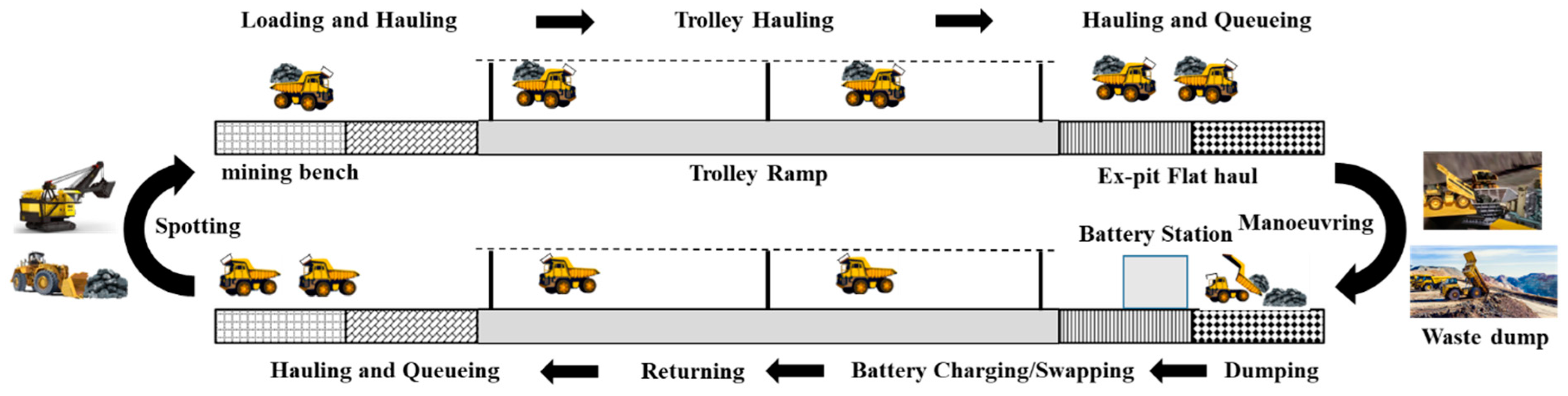

- Stationary charging BT configuration

- 3.

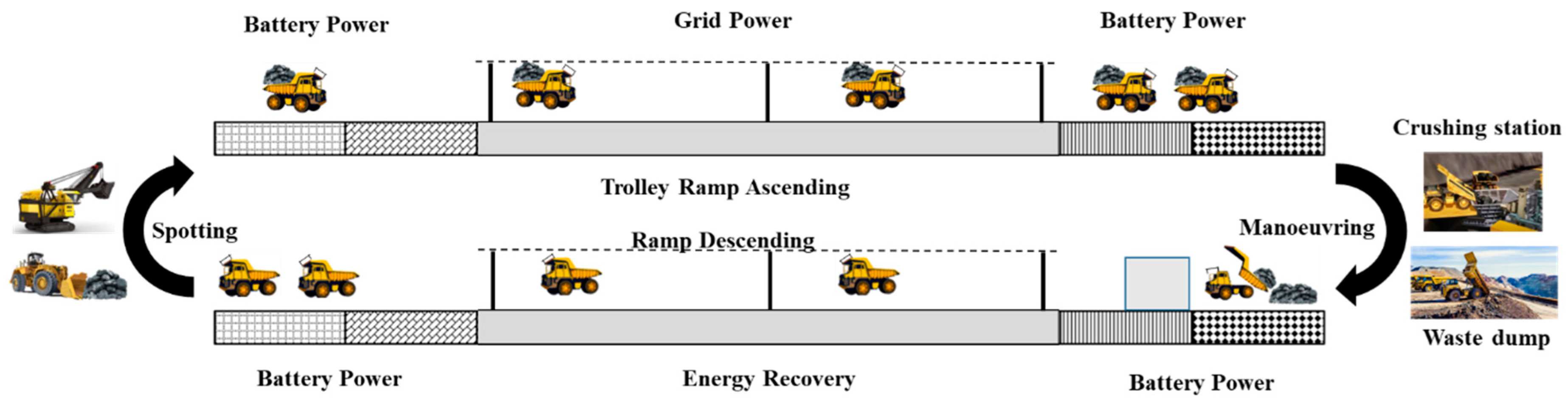

- Dual trolley BT configuration

6. Discussions

7. Conclusions

Data Availability Statement

Conflicts of Interest

Abbreviations

| TS | Truck-Shovel |

| IPCC | In-pit Crushing and Conveying |

| TA | Trolley Assist |

| BT | Battery Trolley |

| ERSs | Energy Recovery Systems |

| CAPEX | Capital Expenditures |

| OPEX | Operating Expenses |

| STEPS | Stated Policies Scenario |

| APC | Announced Pledges Case |

| SDS | Sustainable Development Scenario |

| NZE | Net Zero Emissions |

| IEA | International Energy Agency |

| GHG | Greenhouse Gas |

| PV | Photovoltaic |

| NEM | National Electricity Market |

| TGP | Terminal Gate Price |

| DPM | Diesel Particulate Matter |

| AHTs | Autonomous Haulage Trucks |

| FIPCC | Fixed In-pit Crushing and Conveying |

| SFIPCC | Semi-Fixed In-pit Crushing and Conveying |

| SMIPCC | Semi-Mobile In-pit Crushing and Conveying |

| FMIPCC | Fully Mobile In-pit Crushing and Conveying |

| UPL | Ultimate Pit Limit |

| AC | Alternative Current |

| DC | Direct Current |

| BEVs | Battery-electric vehicles |

References

- Plazas-Niño, F.A.; Ortiz-Pimiento, N.R.; Montes-Páez, E.G. National energy system optimization modelling for decarbonization pathways analysis: A systematic literature review. Renew. Sustain. Energy Rev. 2022, 162, 112406. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Net Zero by 2050—A Roadmap for the Global Energy Sector. Available online: https://iea.blob.core.windows.net/assets/deebef5d-0c34-4539-9d0c%2010b13d840027/NetZeroby2050ARoadmapfortheGlobalEnergySector_CORR.pdf (accessed on 1 November 2022).

- International Energy Agency (IEA). World Energy Outlook. 2021. Available online: https://www.iea.org/reports/world-energy-outlook-2021 (accessed on 1 November 2022).

- Zuliani, J.E.; Guilbaud, J.; Carreau, M. Decarbonization of remote mine electricity supply and vehicle fleets. CIM J. 2021, 12, 135–148. [Google Scholar] [CrossRef]

- Department of Industry, Science, Energy and Resources. Australia’s Emissions Projections. 2020. Available online: https://www.industry.gov.au/data-and-publications/australias-emissions%20projections-2020 (accessed on 1 November 2022).

- Vatalis, K.I.; Avlogiaris, G.; Tsalis, T.A. Just transition pathways of energy decarbonization under the global environmental changes. J. Environ. Manag. 2022, 309, 114713. [Google Scholar] [CrossRef] [PubMed]

- Burke, P.J.; Beck, F.J.; Aisbett, E.; Baldwin, K.G.; Stocks, M.; Pye, J.; Venkataraman, M.; Hunt, J.; Bai, X. Contributing to regional decarbonization: Australia’s potential to supply zero-carbon commodities to the Asia-Pacific. Energy 2022, 248, 123563. [Google Scholar] [CrossRef]

- Australian Renewable Energy Agency. Renewable Energy in the Australian Mining Sector White Paper. Available online: https://arena.gov.au/assets/2017/11/renewable-energy-in-the-australian-mining-sector.pdf (accessed on 1 November 2022).

- Department of Industry, Science, Energy and Resources. Australian Energy Update. 2021. Available online: https://www.energy.gov.au/publications/australian-energy-update-2021 (accessed on 1 November 2022).

- Parra, A.; Morales, N. Qualitative Review of Alternative Transport Systems for Open Pit Mines. Available online: https://delphoslab.cl/Publicaciones/2016/PM2_M2016.pdf (accessed on 1 November 2022).

- Nehring, M.; Knights, P.F.; Kizil, M.S.; Hay, E. A comparison of strategic mine planning approaches for in-pit crushing and conveying, and truck/shovel systems. Int. J. Min. Sci. Technol. 2018, 28, 205–214. [Google Scholar] [CrossRef]

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing ore grades in global metallic mining: A theoretical issue or a global reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef] [Green Version]

- Purhamadani, E.; Bagherpour, R.; Tudeshki, H. Energy consumption in open-pit mining operations relying on reduced energy consumption for haulage using in-pit crusher systems. J. Clean. Prod. 2021, 291, 125228. [Google Scholar] [CrossRef]

- Dean, M.; Knights, P.; Kizil, M.S.; Nehring, M. Selection and planning of fully mobile in-pit crusher and conveyor systems for deep open pit metalliferous applications. In Proceedings of the Third International Future Mining Conference, Sydney, Australia, 4–6 November 2015; pp. 219–225. [Google Scholar]

- Igogo, T.; Awuah-Offei, K.; Newman, A.; Lowder, T.; Engel-Cox, J. Integrating renewable energy into mining operations: Opportunities, challenges, and enabling approaches. Appl. Energy 2021, 300, 117375. [Google Scholar] [CrossRef]

- Lezak, S.; Cannon, C.; Blank, K. Low-Carbon Metals for a Low-Carbon World: A New Energy Paradigm for Mines; Rocky Mountain Institute: Basalt, CO, USA, 2019. [Google Scholar]

- Osanloo, M.; Paricheh, M. In-pit crushing and conveying technology in open-pit mining operations: A literature review and research agenda. Int. J. Min. Reclam. Environ. 2020, 34, 430–457. [Google Scholar] [CrossRef]

- Soofastaei, A.; Karimpour, E.; Knights, P.; Kizil, M. Energy-Efficient Loading and Hauling Operations. In Energy Efficiency in the Minerals Industry. Green Energy and Technology; Awuah-Offei, K., Ed.; Springer: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Aguayo, I.A.O.; Nehring, M.; Ullah, W. Simulating the productivity improvements of incorporating a surge loader into the open pit loading and haulage system. Int. J. Min. Reclam. Environ. 2022, 36, 1–18. [Google Scholar] [CrossRef]

- Bao, H.; Zhang, R. Study on optimization of coal truck flow in open-pit mine. Adv. Civ. Eng. 2020, 2020, 8848140. [Google Scholar] [CrossRef]

- Bakhtavar, E.; Mahmoudi, H. Development of a scenario-based robust model for the optimal truck-shovel allocation in open-pit mining. Comput. Oper. Res. 2020, 115, 104539. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, R.; Lv, S.; Wang, Y. Open-pit mine truck fuel consumption pattern and application based on multi-dimensional features and XGBoost. Sustain. Energy Technol. Assess. 2021, 43, 100977. [Google Scholar] [CrossRef]

- De Lemo Pires, D. Surface mining technology: Managing the paradigm shift. Min. Eng. 2013, 6, 36–41. [Google Scholar]

- Hay, E.; Nehring, M.; Knights, P.; Kizil, M. Ultimate pit limit determination for semi mobile in-pit crushing and conveying system: A case study. Int. J. Min. Reclam. Environ. 2020, 34, 498–518. [Google Scholar] [CrossRef]

- Moniri-Morad, A.; Pourgol-Mohammad, M.; Aghababaei, H.; Sattarvand, J. A methodology for truck allocation problems considering dynamic circumstances in open pit mines, case study of the sungun copper mine. Rud.-Geološko-Naft. Zb. 2019, 34, 4. [Google Scholar] [CrossRef]

- Kumral, M.; Sari, Y.A. An application of possibilistic programming to production sequencing of mining parcels. Int. J. Manag. Sci. Eng. Manag. 2017, 12, 79–88. [Google Scholar] [CrossRef]

- Abbaspour, H.; Drebenstedt, C. Environmental Comparison of Different Transportation Systems—Truck-Shovel and IPCCs—In Open-Pit Mines by System Dynamic Modeling. In Proceedings of the 27th International Symposium on Mine Planning and Equipment Selection—MPES 2018; Widzyk-Capehart, E., Hekmat, A., Singhal, R., Eds.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- ABB-ABB Ability™eMine. For Your World, and Mine. In Proceedings of the Electric Mine Conference, Stockholm, Sweden, 14–17 September 2022.

- Abbaspour, H.; Drebenstedt, C.; Dindarloo, S.R. Evaluation of safety and social indexes in the selection of transportation system alternatives (Truck-Shovel and IPCCs) in open pit mines. Saf. Sci. 2018, 108, 1–12. [Google Scholar] [CrossRef]

- Bozorgebrahimi, E. The Evaluation of Haulage Truck Size Effects on Open Pit Mining. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2004. [Google Scholar]

- Sánchez, F.; Hartlieb, P. Innovation in the mining industry: Technological trends and a case study of the challenges of disruptive innovation. Mining. Metall. Explor. 2020, 37, 1385–1399. [Google Scholar] [CrossRef]

- Bellamy, D.; Pravica, L. Assessing the impact of driverless haul trucks in Australian surface mining. Resour. Policy 2011, 36, 149–158. [Google Scholar] [CrossRef]

- Dzakpata, I.; Knights, P.; Kizil, M.S.; Nehring, M.; Aminossadati, S.M. Truck and shovel versus in-pit conveyor systems: A comparison of the valuable operating time. In Proceedings of the 16th Coal Operators’ Conference, Mining Engineering, University of Wollongong, Dubai, United Arab Emirates, 10–12 February 2016; pp. 463–476. [Google Scholar]

- Ritter, R.; Herzog, A.; Drebenstedt, C. Automated dozer concept aims to cut IPCC downtime. Eng. Min. J. 2014, 215, 52–55. [Google Scholar]

- Terezopoulos, N. Continuous haulage and in-pit crushing in surface mining. Min. Sci. Technol. 1988, 7, 253–263. [Google Scholar] [CrossRef]

- Abbaspour, H.; Drebenstedt, C.; Paricheh, M.; Ritter, R. Optimum location and relocation plan of semi-mobile in-pit crushing and conveying systems in open-pit mines by transportation problem. Int. J. Min. Reclam. Environ. 2019, 33, 297–317. [Google Scholar] [CrossRef]

- McCarthy, M.; Cenisio, B. Update on studies for implementation of IPCC at the Moatize coal project. In Proceedings of the IPCC 2013, Cologne, Germany, 25–26 June 2013. [Google Scholar]

- Czaplicki, J. Shovel-Truck Systems: Modelling, Analysis and Calculations; CRC Press/Balkema, Taylor and Francis Group: London, UK, 2009. [Google Scholar]

- McCarthy, B. Evaluating the lack of flexibility against the benefits of in-pit crushing and conveying. In Proceedings of the Optimizing Mine Operations Conference, Toronto, ON, Canada, 10–13 September 2013. [Google Scholar]

- Schroder, D.L. The use of in-pit crushing and conveying methods to significantly reduce transportation costs by truck. In Proceedings of the Coaltrans Asia Conference, Bali, Indonesia, 8–11 June 2003. [Google Scholar]

- Raaz, V.; Mentges, U. In-pit crushing and conveying with fully mobile crushing plants in regard to energy efficiency and CO2 reduction. In Proceedings of the IPCC 2011, Belo Horizonte, Brazil, 28 June 2011. [Google Scholar]

- Foley, M. In-pit crushing: Wave of the future. Aust. J. Min. 2012, 46–53. [Google Scholar]

- Lake, D.M.; Brzezniak, W. Trolley assist truck haulage cuts fuel and increases productivity. Part two. Aust. Coal Min. 1981, 3, 11, 13, 15–16. [Google Scholar]

- Mazumdar, J. Performance improvement of mining haul trucks operating on trolley systems. In Proceedings of the 2011 IEEE Industry Applications Society Annual Meeting, Orlando, FL, USA, 9–13 October 2011; pp. 1–6. [Google Scholar]

- Moore, P. Surface Mining Trucks. Int. Min. 2022, 17, 50–67. [Google Scholar]

- Gleeson, D. Battery and Electric. Int. Min. 2022, 17, 26–47. [Google Scholar]

- Engineering and Mining Journal. Freeport Taps Wärtsilä for 128-MW Plant for Grasberg: Engineering, Geology, Mineralogy, Metallurgy, Chemistry, etc.; Engineering and Mining Journal: Jacksonville, FL, USA, 2020; Volume 221, pp. 48–49. [Google Scholar]

- Crosson, C.C.; Sumner, H.B. Trolley assisted truck haulage. United States. Eng. Min. J. 1982, 183. Available online: https://www.osti.gov/biblio/6730531 (accessed on 30 December 2022).

- Morton, J. Truck Innovations Show Shape of Things to Come. Eng. Min. J. 2021, 222, 24–30. [Google Scholar]

- Freeman, S.; Golosinski, T.S. Economic feasibility of introducing trolly assisted haulage to an Australian open pit mine. Int. J. Surf. Min. Reclam. 1994, 8, 141–144. [Google Scholar] [CrossRef]

- Lake, D.M.; Brzezniak, W. Truck haulage using overhead electrical power to conserve diesel fuel and improve haulage economics. United Kingdom. Min. Technol. 1982, 64, 157–164. [Google Scholar]

- Marsden, O.W.; Marsden, J.O. Potential Pathways for Mining Operations to Transition to Renewable Energy—A Case Study. Min. Metall. Explor. 2021, 38, 1689–1699. [Google Scholar] [CrossRef]

- Ertugrul, N.; Kani, A.P.; Davies, M.; Sbarbaro, D.; Morán, L. Status of Mine Electrification and Future Potentials. In Proceedings of the 2020 International Conference on Smart Grids and Energy Systems (SGES), Perth, Australia, 23–26 November 2020; pp. 151–156. [Google Scholar]

- Vorster, B.J. Trolley assist aids haulage at Iscor’s Shishen iron ore mine in South Africa. Min. Eng. 1986. [Google Scholar]

- Caterpillar, Products Services. Available online: https://www.cat.com/en_US/articles/customer-stories/mining/autonomous-haulage-making-mining-safer-and-more-productive-today.html (accessed on 1 November 2022).

- Terblanche, P.J. Technical and economic potential of energy recovery and re-use on board surface mining haul trucks. 2019. Available online: https://core.ac.uk/reader/200258120 (accessed on 1 November 2022).

| IPCC Systems Type | Fixed IPCC | Semi-Fixed IPCC | Semi-Mobile IPCC | Fully Mobile IPCC |

|---|---|---|---|---|

| Crusher Type | Gyratory or jaw | Gyratory or jaw | Twin roll or sizer | Twin roll or sizer |

| Locations | Near the pit rim and crest | A strategic junction point in the pit | Near the operational level | Bench level in production |

| Relocations Time | Rarely or never relocated | Relocations every 3 to 5 years | Relocations every 6 to 18 months | Relocations as required to follow the shovel |

| Feed Systems | Shovel-Trucks | Shovel-Trucks | Shovel-Trucks and/or dozers | Shovels |

| Use | Deep hard rock mines—ore | Deep hard rock mines -waste or ore | Not common in deep hard rock mines -waste or ore | Not common in deep hard rock mines -waste or ore |

| Parameter | Diesel TS | SF/M IPCC | FM-IPCC | TA | Dynamic Charging BT | Stationary Charging BT | Dual Trolley BT |

|---|---|---|---|---|---|---|---|

| Flexibility | High | Medium | Low | Medium | Low | Medium | Medium |

| Energy Efficiency | Low | Medium | High | Medium | High | High | High |

| CAPEX | Low | High | High | High | High | High | High |

| OPEX | High | Medium | Low | Low | Low | Low | Low |

| Maintenance Requirements | High | Medium | Low | Medium | Medium | Medium | High |

| Service Life | Short | Medium | Long | Long | Long | Long | Long |

| Additional Infrastructure | No | No | No | Yes | Yes | Yes | Yes |

| Refuelling/Recharging/Swapping | Fast | None | None | Fast | None | Low | Low |

| Emissions | High | Low | None | Low | None | None | None |

| Heat Generation | High | Medium | Low | Medium | Low | Low | Low |

| Environmental Footprint (Noise/Dust/DPM/Vibration) | High | Medium | Low | Medium | Low | Low | Low |

| Reliability | High | Medium | Low | Medium | Low | Medium | Low |

| Scalability | High | Low | Low | Medium | Low | Medium | Low |

| Capability | No | Yes | Yes | Yes | Yes | Yes | Yes |

| Safety | Low | Low | Medium | Low | Medium | Medium | Medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, H.; Knights, P.; Kizil, M.; Nehring, M. Electrification Alternatives for Open Pit Mine Haulage. Mining 2023, 3, 1-25. https://doi.org/10.3390/mining3010001

Bao H, Knights P, Kizil M, Nehring M. Electrification Alternatives for Open Pit Mine Haulage. Mining. 2023; 3(1):1-25. https://doi.org/10.3390/mining3010001

Chicago/Turabian StyleBao, Haiming, Peter Knights, Mehmet Kizil, and Micah Nehring. 2023. "Electrification Alternatives for Open Pit Mine Haulage" Mining 3, no. 1: 1-25. https://doi.org/10.3390/mining3010001

APA StyleBao, H., Knights, P., Kizil, M., & Nehring, M. (2023). Electrification Alternatives for Open Pit Mine Haulage. Mining, 3(1), 1-25. https://doi.org/10.3390/mining3010001