An Investigation of Thermal Effects on Micro-Properties of Sudbury Norite by CT Scanning and Image Processing Method

Abstract

:1. Introduction

2. Specimen and Laboratory Test

2.1. Specimen

2.2. Thermal Treatment

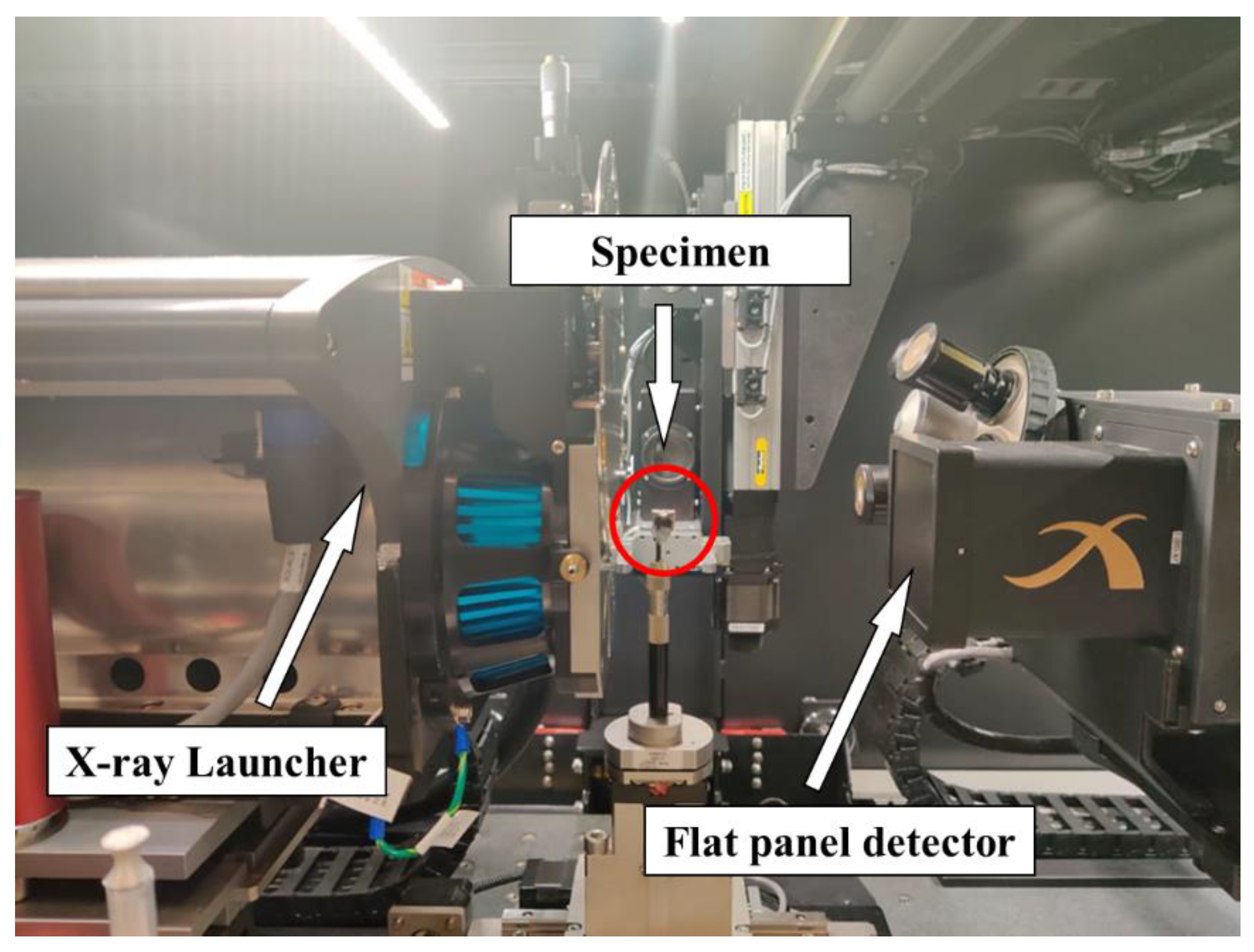

2.3. CT Scan

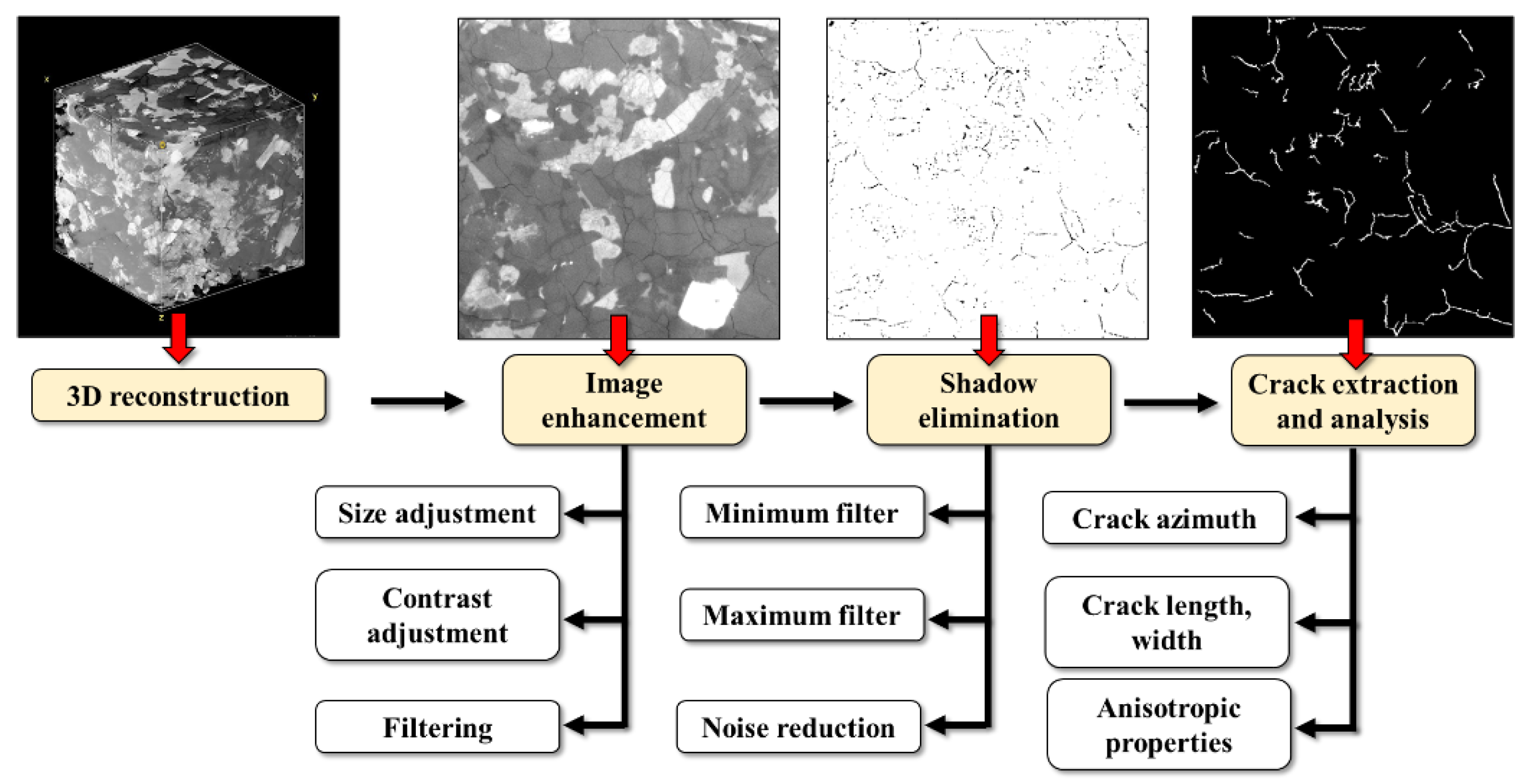

2.4. Image Processing Method

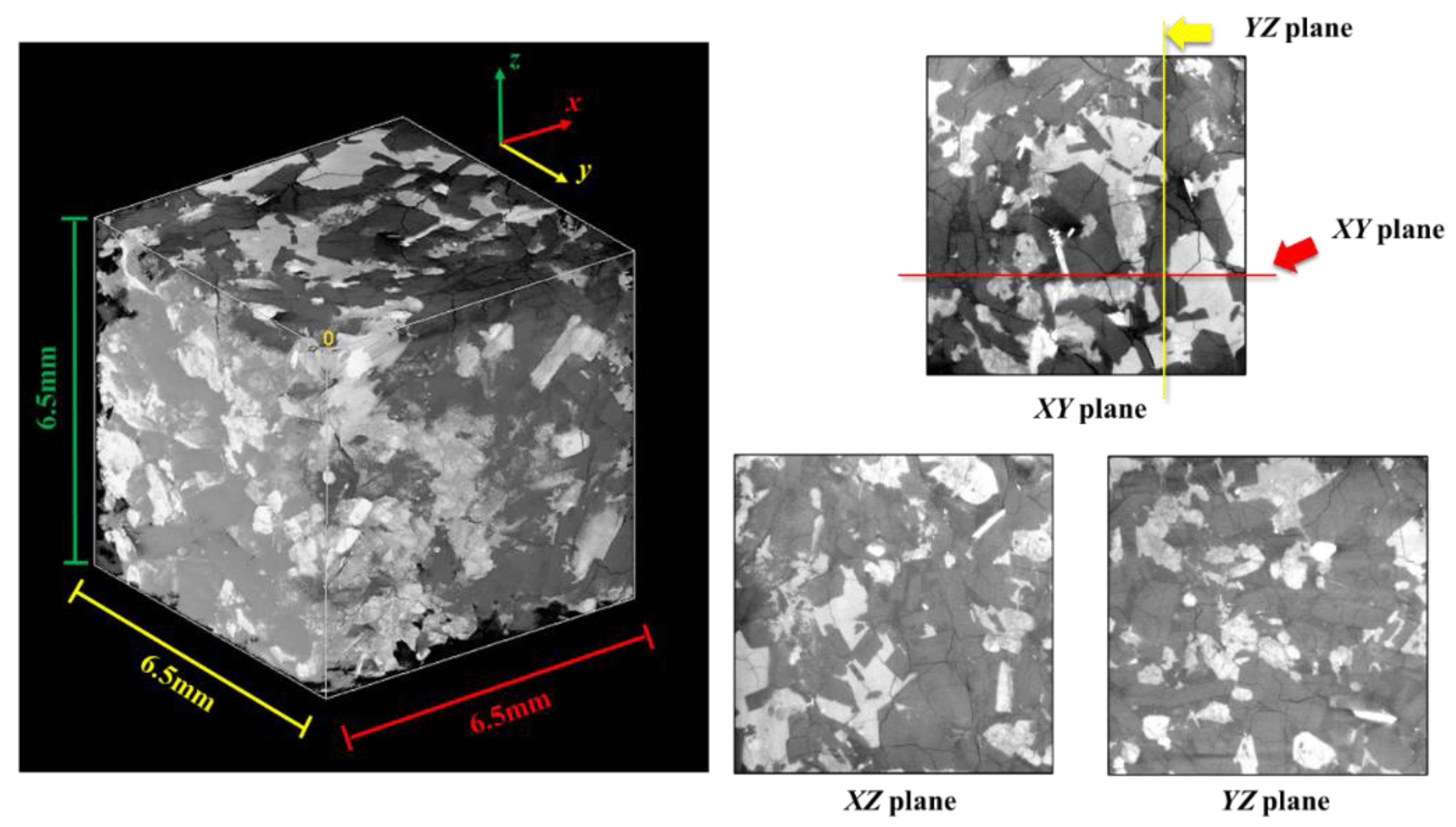

2.4.1. Three-Dimensional Reconstruction

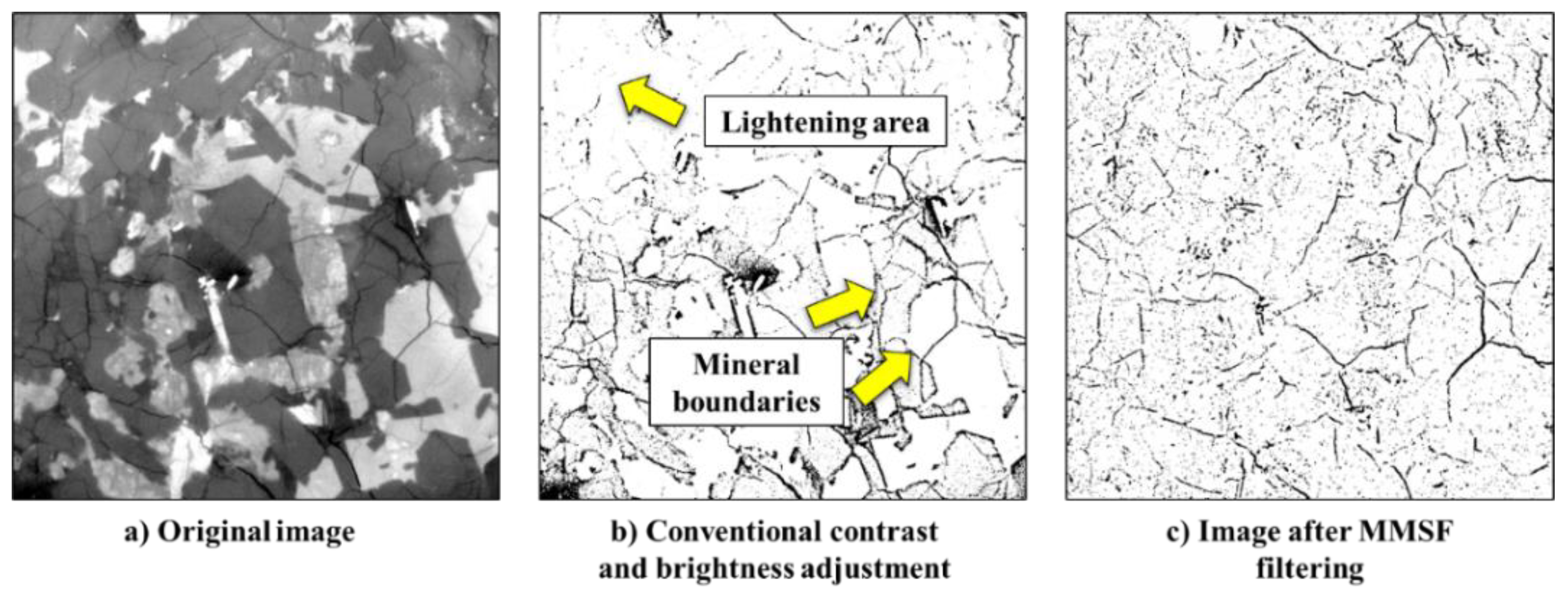

2.4.2. Maximum–Minimum Shadow Filtering (MMSF)

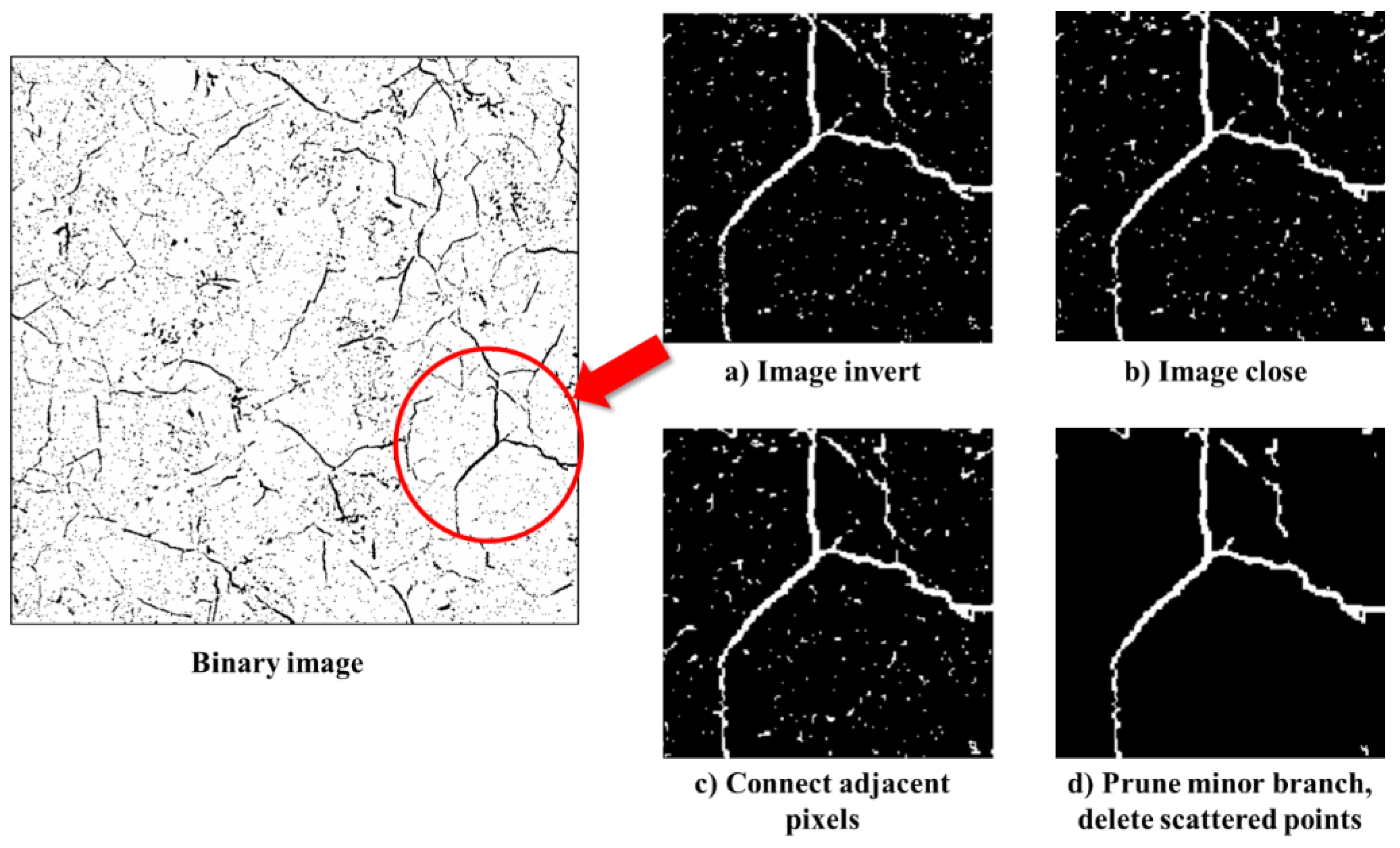

2.4.3. Crack Extraction and Analysis

- (1)

- Image binarization and invert. Use adaptive thresholding to binarize the image and highlight the thermal cracks in white;

- (2)

- Image close. It performed the morphological closing on the binary image using the structuring element, SE. SE is a linear element used to connect broken segments with a length of three pixels;

- (3)

- Bridge of unconnected segments. Automatically connect the broken segments with infinite calculations until the image became stable;

- (4)

- Small objects delete and minor branch prune. Clear the noise and cut the minor branches generated during the previous image restore steps. Figure 5 illustrates the details of the image restoration process.

3. Results and Discussion

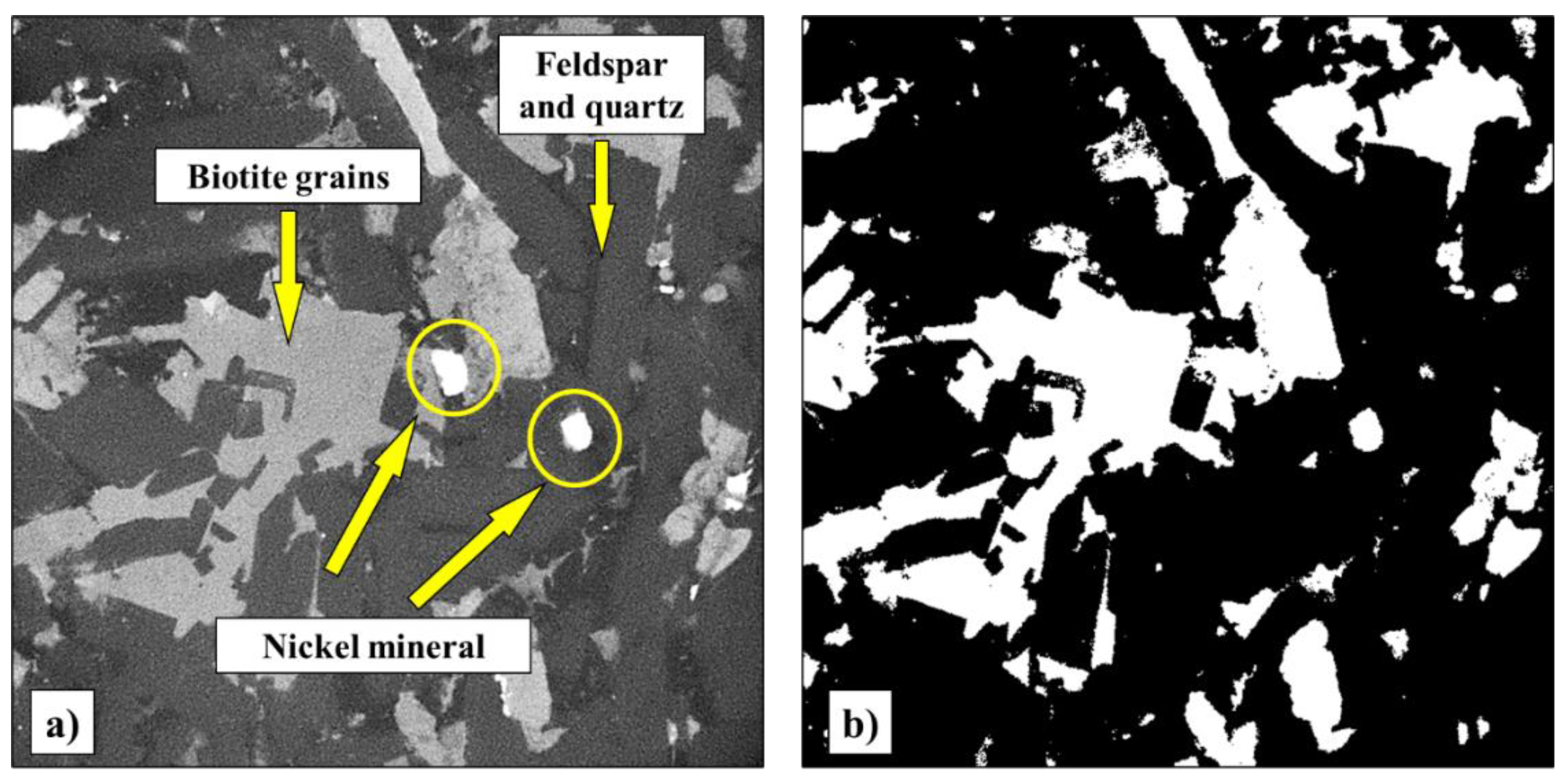

3.1. Structure of Norite

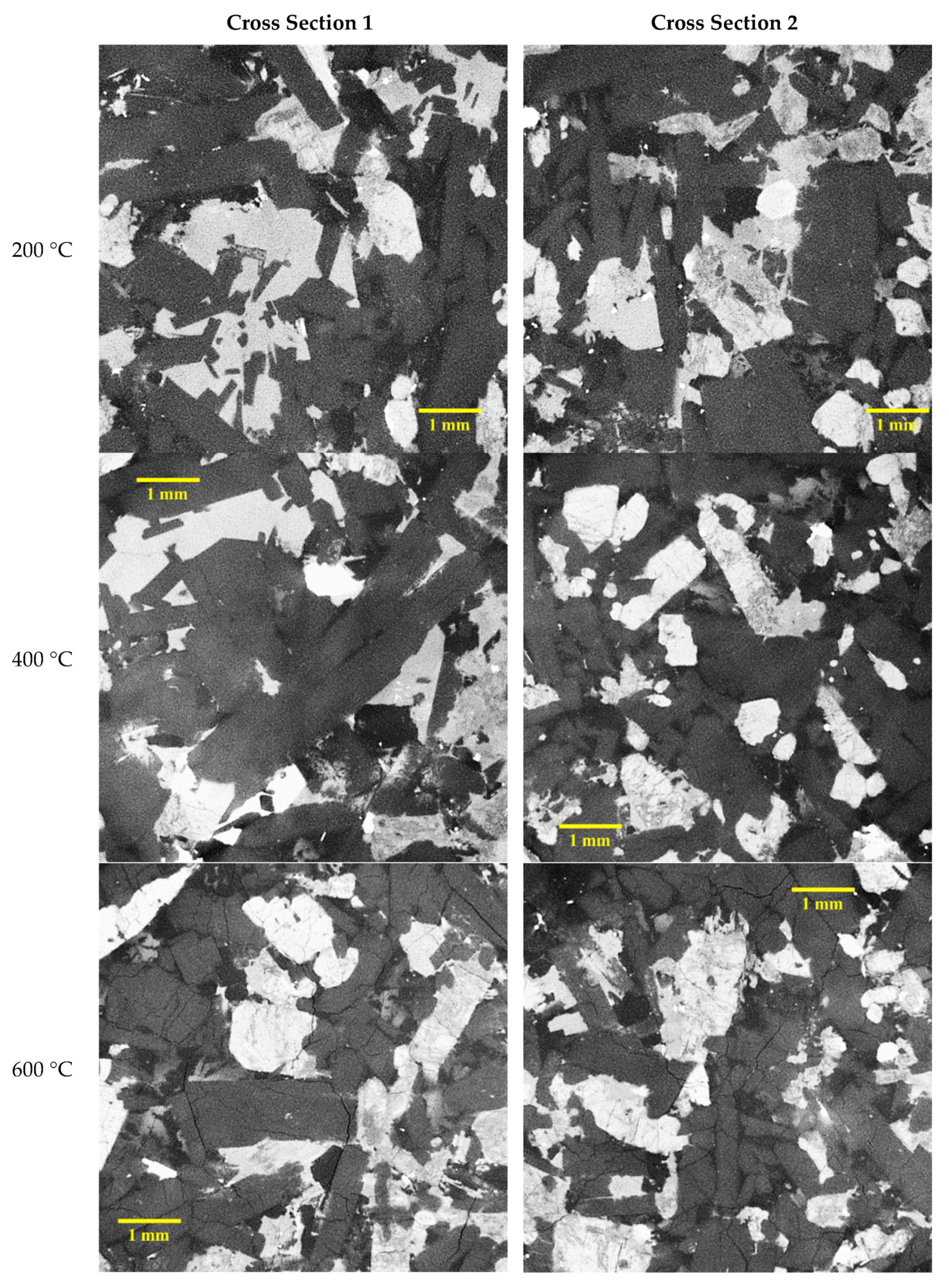

3.2. Effects of Thermal Treatment

3.3. Quantitative Analysis of Micro-Cracks

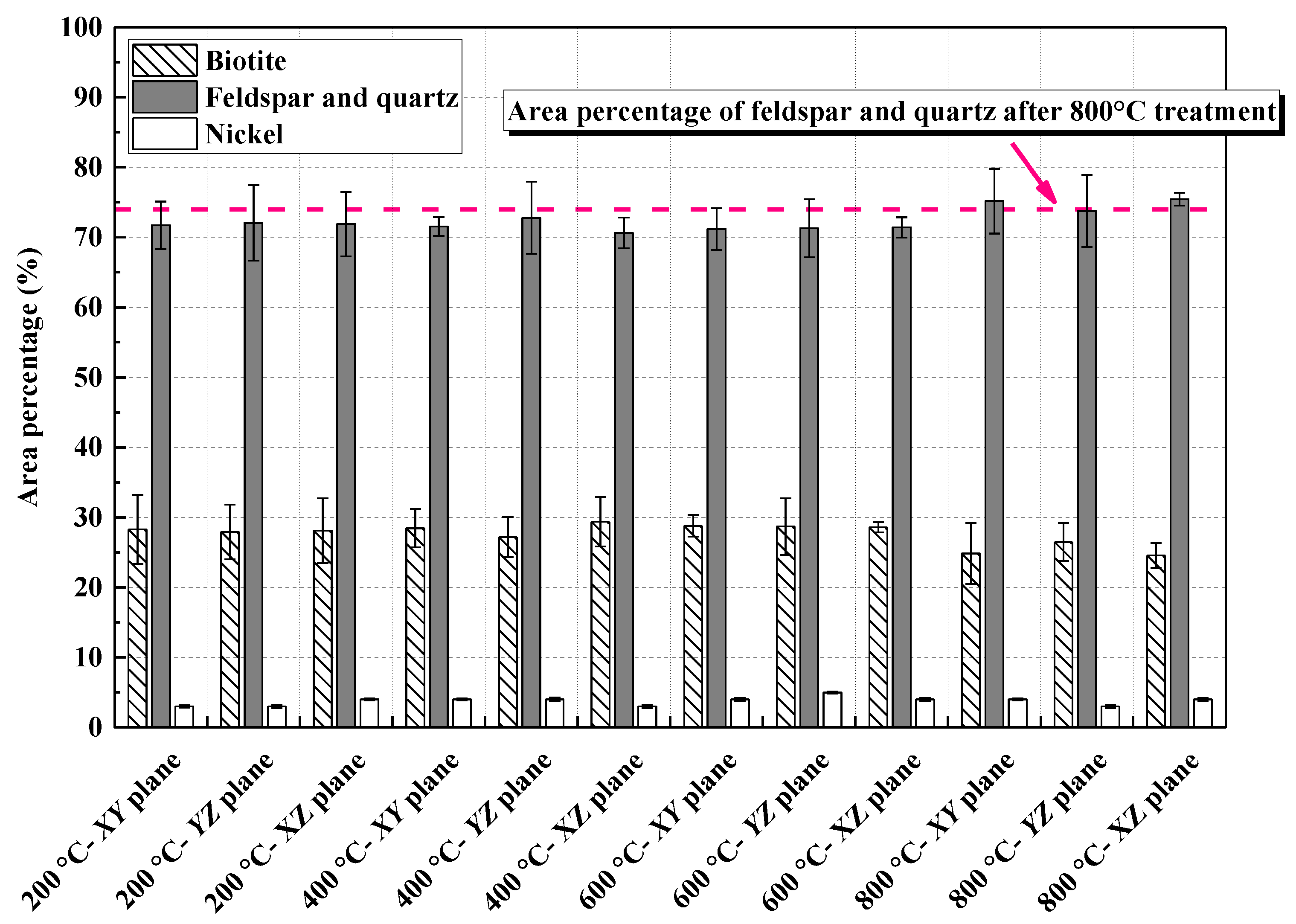

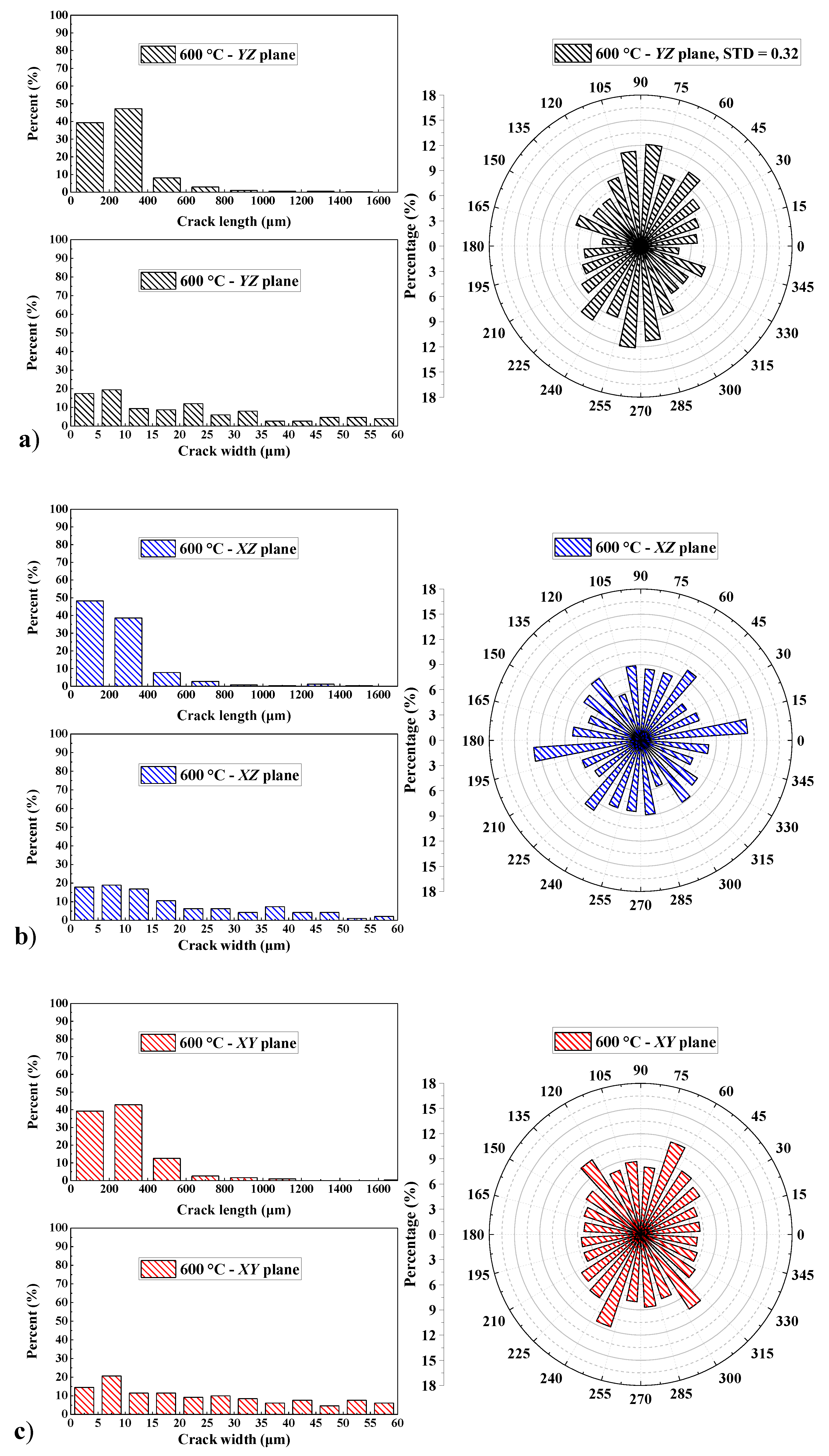

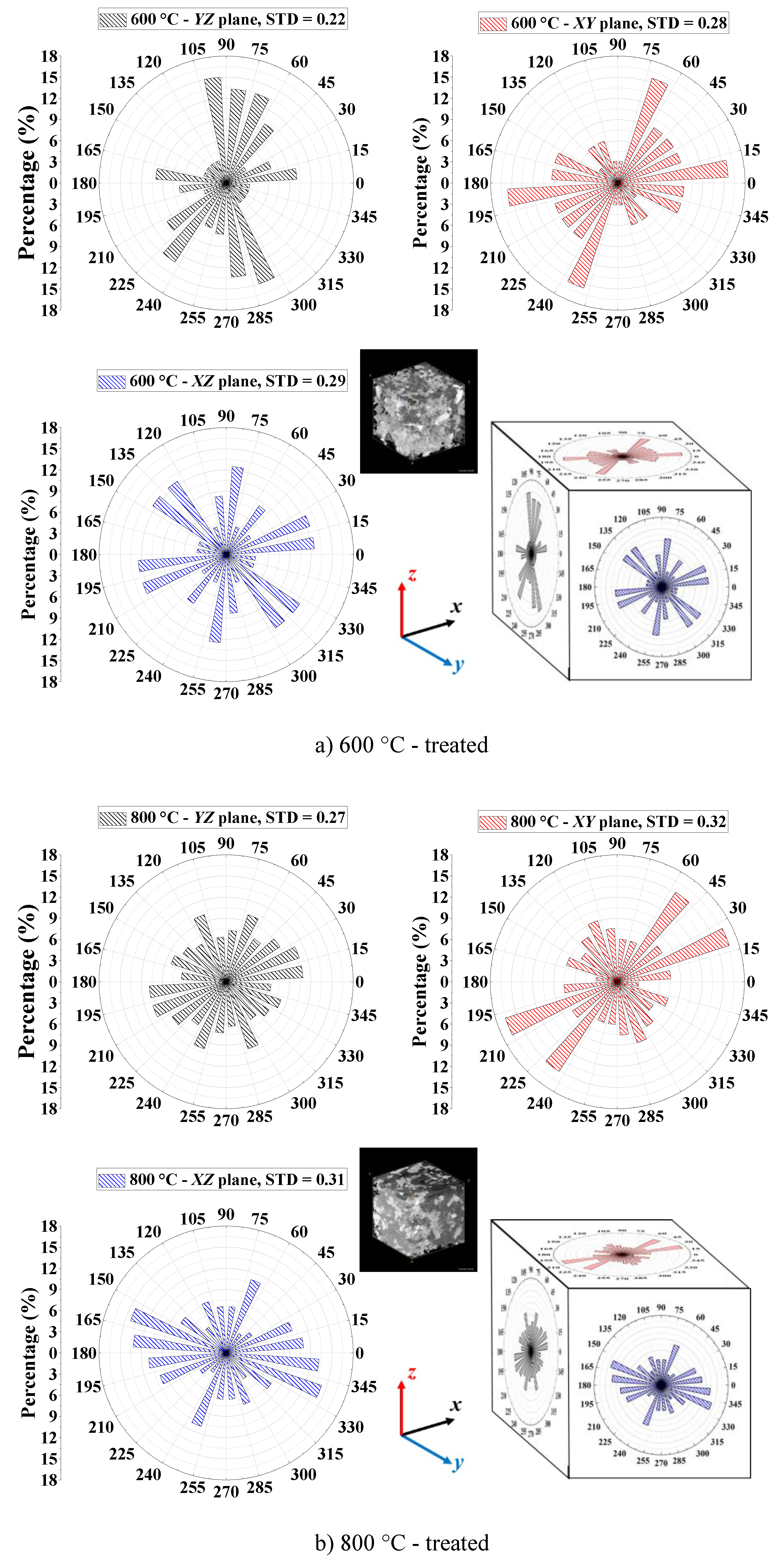

3.4. Anisotropic Analysis of Treated SIC Norite

- Si,n = area of cracks and voids;

- Si,n = total area of each image;

- i = direction of each plane = x (YZ plane), y (XZ plane), z (XY plane);

- n = number of each image at the same direction = 1, 2, 3, …

4. Conclusions

- (1)

- The areal percentage of biotite ranged between 22% and 27%. The rest was occupied with felspar, quartz, and a small amount of metal minerals. Small-scale micro-cracking was first observed in the middle of biotite grains at the temperature of 400 °C. A further increase in temperature would generate more micro-cracks not only in biotite but also in quartz and feldspar. With the preheating temperature further developed to 800 °C, different micro-cracks started to connect, thus dividing the integral mineral into smaller segments;

- (2)

- The image processing method together with the MMSF introduced in this study clearly identified the thermal-induced cracks. Quantitative analysis of pre-treated images indicated that most micro-crack lengths fell into the two categories (0~200 μm and 200~400 μm). On the other hand, the overall length of micro-cracks developed with the increase in preheating temperature, especially when it reached and exceeded 600 °C;

- (3)

- The orientation of cracks exhibited two major trends with the increase in temperature: they followed a similar distribution pattern (in the XZ and XY planes) or became more evenly distributed (in the YZ plane);

- (4)

- A linear relationship between the average porosity of SIC norite and the treatment temperature was found in each direction. Such relationships for the YZ and XZ planes were very similar, with a slight difference from plane XY. This indicated the anisotropic properties between vertical and horizontal directions of norite. This fact was further confirmed by the anisotropic coefficients which soared sharply from 200° C to 400 °C and then declined at 600 °C and 800 °C.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fan, L.; Gao, J.; Wu, Z.; Yang, S.; Ma, G. An investigation of thermal effects on micro-properties of granite by X-ray CT technique. Appl. Therm. Eng. 2018, 140, 505–519. [Google Scholar] [CrossRef]

- Ashraf, U.; Zhang, H.; Anees, A.; Mangi, H.N.; Ali, M.; Zhang, X.; Imraz, M.; Abbasi, S.S.; Abbas, A.; Ullah, Z.; et al. A Core Logging, Machine Learning and Geostatistical Modeling Interactive Approach for Subsurface Imaging of Lenticular Geobodies in a Clastic Depositional System, SE Pakistan. Nonrenew. Resour. 2021, 30, 2807–2830. [Google Scholar] [CrossRef]

- Ullah, J.; Luo, M.; Ashraf, U.; Pan, H.; Anees, A.; Li, D.; Ali, M.; Ali, J. Evaluation of the geothermal parameters to decipher the thermal structure of the upper crust of the Longmenshan fault zone derived from borehole data. Geothermics 2022, 98, 102268. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H.; Chang, F.; Xie, P.; Li, H.; Wu, H.; Ouyang, C.; Liu, F.; Peng, W.; Zhang, Y.; et al. Long-range transport of aeolian deposits during the last 32 kyr inferred from rare earth elements and grain-size analysis of sediments from Lake Lugu, Southwestern China. Palaeogeogr. Palaeoclim. Palaeoecol. 2021, 567, 110248. [Google Scholar] [CrossRef]

- Riaz, M.S.; Bin, S.; Naeem, S.; Kai, W.; Xie, Z.; Gilani, S.M.M.; Ashraf, U. Over 100 years of faults interaction, stress accumulation, and creeping implications, on Chaman Fault System, Pakistan. Int. J. Earth Sci. 2019, 108, 1351–1359. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, Q.; He, H.; Cao, L.; Zhang, W.; Wang, B. Pore characteristics and mechanical properties of sandstone under the influence of temperature. Appl. Therm. Eng. 2017, 113, 537–543. [Google Scholar] [CrossRef]

- Suo, Y.; Chen, Z.; Rahman, S.S. Changes in Shale Rock Properties and Wave Velocity Anisotropy Induced by Increasing Temperature. Nonrenew. Resour. 2020, 29, 4073–4083. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, Q.; Jia, H.; Dong, Z.; Luo, T. Effects of high-temperature thermal treatment on the porosity of red sandstone: An NMR analysis. Acta Geophys. 2021, 69, 113–124. [Google Scholar] [CrossRef]

- Zhou, C.; Xie, H.; Zhu, J.; Zhou, T. Failure criterion considering high temperature treatment for rocks from a micromechanical perspective. Theor. Appl. Fract. Mech. 2022, 118, 103226. [Google Scholar] [CrossRef]

- Isaka, B.A.; Ranjith, P.; Rathnaweera, T.; Perera, M.; De Silva, V. Quantification of thermally-induced microcracks in granite using X-ray CT imaging and analysis. Geothermics 2019, 81, 152–167. [Google Scholar] [CrossRef]

- Nguyen, D.K.; Morishita, T.; Soda, Y.; Tamura, A.; Ghosh, B.; Harigane, Y.; France, L.; Liu, C.; Natland, J.H.; Sanfilippo, A.; et al. Occurrence of Felsic Rocks in Oceanic Gabbros from IODP Hole U1473A: Implications for Evolved Melt Migration in the Lower Oceanic Crust. Minerals 2018, 8, 583. [Google Scholar] [CrossRef] [Green Version]

- Waterton, P.; Hyde, W.R.; Tusch, J.; Hollis, J.A.; Kirkland, C.L.; Kinney, C.; Yakymchuk, C.; Gardiner, N.J.; Zakharov, D.; Olierook, H.K.H.; et al. Geodynamic Implications of Synchronous Norite and TTG Formation in the 3 Ga Maniitsoq Norite Belt, West Greenland. Front. Earth Sci. 2020, 8, 562062. [Google Scholar] [CrossRef]

- Riller, U.; Schwerdtner, W.M. Mid-crustal deformation at the southern flank of the Sudbury Basin, central Ontario, Canada. GSA Bull. 1997, 109, 841–854. [Google Scholar] [CrossRef]

- Lightfoot, P.C.; Doherty, W. Chemical Evolution and Origin of Nickel Sulfide Mineralization in the Sudbury Igneous Complex, Ontario, Canada. Econ. Geol. 2001, 96, 1855–1875. [Google Scholar] [CrossRef]

- Deutsch, A.; Grieve, R.A.F.; Avermann, M.; Bischoff, L.; Brockmeyer, P.; Buhl, D.; Lakomy, R.; Müller-Mohr, V.; Ostermann, M.; Stöffler, D. The Sudbury Structure (Ontario, Canada): A tectonically deformed multi-ring impact basin. Geol. Rundsch. 1995, 84, 697–709. [Google Scholar] [CrossRef]

- Wang, S.-L.; Lv, Q.-F.; Baaj, H.; Li, X.-Y.; Zhao, Y.-X. Volume change behaviour and microstructure of stabilized loess under cyclic freeze–thaw conditions. Can. J. Civ. Eng. 2016, 43, 865–874. [Google Scholar] [CrossRef] [Green Version]

- Chai, G.; Eckstrand, R. Rare-earth element characteristics and origin of the Sudbury Igneous Complex, Ontario, Canada. Chem. Geol. 1994, 113, 221–244. [Google Scholar] [CrossRef]

- Rybacki, E.; Evans, B.; Janssen, C.; Wirth, R.; Dresen, G. Influence of stress, temperature, and strain on calcite twins constrained by deformation experiments. Tectonophysics 2013, 601, 20–36. [Google Scholar] [CrossRef]

- Heap, M.J.; Coats, R.; Chen, C.-F.; Varley, N.; Lavallée, Y.; Kendrick, J.; Xu, T.; Reuschlé, T. Thermal resilience of microcracked andesitic dome rocks. J. Volcanol. Geotherm. Res. 2018, 367, 20–30. [Google Scholar] [CrossRef]

- Nadan, B.J.; Engelder, T. Microcracks in New England granitoids: A record of thermoelastic relaxation during exhumation of intracontinental crust. GSA Bull. 2009, 121, 80–99. [Google Scholar] [CrossRef]

- Takemura, T.; Golshani, A.; Oda, M.; Suzuki, K. Preferred orientations of open microcracks in granite and their relation with anisotropic elasticity. Int. J. Rock Mech. Min. Sci. 2003, 40, 443–454. [Google Scholar] [CrossRef]

| Recourse | Rock Type | Heating Method | Key Findings |

|---|---|---|---|

| [6] | Sandstone | 25–600 °C Rate: 5 °C/min Condition: 2 h | Between 400 and 600 °C, the pore volume, porosity and peak strain increased rapidly, while the strength decreases rapidly. |

| [1] | Granite | 25–800 °C Rate: 2.5 °C/min Condition: 6 h | The heterogeneity coefficient reached its peak at around 500 °C. The anisotropy coefficient remained steady from 20 °C to 500 °C. It then decreased sharply after 600 °C. |

| [10] | Granite | 100–1000 °C Rate: 5 °C/min Condition: 24 h | The pore network models (PNMs) of thermally treated rock were developed and enabled the quantifications of the size and distribution of the pores in granite. |

| [7] | Shale rock | 25–500 °C Rate: 1 °C/min Condition: 24 h | P-wave velocity and brittleness index of shale decreased due to dehydration and organic matter burning. In addition, the temperature rising made the shale more homogeneous and less anisotropic. |

| [8] | Red sandstone | 10–1300 °C Rate: 10 °C/min Condition: 1 h | The porosity of sandstone increased at temperatures starting from 500 °C and peaking at 1000 °C. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.-L.; Simser, B.; Yin, S.; Huyan, J. An Investigation of Thermal Effects on Micro-Properties of Sudbury Norite by CT Scanning and Image Processing Method. Mining 2022, 2, 511-527. https://doi.org/10.3390/mining2030027

Wang S-L, Simser B, Yin S, Huyan J. An Investigation of Thermal Effects on Micro-Properties of Sudbury Norite by CT Scanning and Image Processing Method. Mining. 2022; 2(3):511-527. https://doi.org/10.3390/mining2030027

Chicago/Turabian StyleWang, Sheng-Lin, Brad Simser, Shunde Yin, and Ju Huyan. 2022. "An Investigation of Thermal Effects on Micro-Properties of Sudbury Norite by CT Scanning and Image Processing Method" Mining 2, no. 3: 511-527. https://doi.org/10.3390/mining2030027

APA StyleWang, S.-L., Simser, B., Yin, S., & Huyan, J. (2022). An Investigation of Thermal Effects on Micro-Properties of Sudbury Norite by CT Scanning and Image Processing Method. Mining, 2(3), 511-527. https://doi.org/10.3390/mining2030027