Encapsulation of Extract from Tomato Pomace Applicable as Natural Colorant and Antioxidant in Low-Nitrite Sausage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. TP Extraction and Encapsulation

2.3. Characterization of ETPE

2.3.1. Water Activity and Moisture Content

2.3.2. Bulk Density

2.3.3. Total Lycopene Content

2.3.4. DPPH Radical Scavenging Ability

2.3.5. Color Analysis

2.4. Preparation of Low-Nitrite Sausages

2.5. Quality Evaluation of Low-Nitrite Pork Sausage

2.5.1. Cooking Yield

2.5.2. Expressible Moisture Content

2.5.3. Color Analysis

2.5.4. Textural Profile Analysis

2.5.5. Thiobarbituric Acid Reactive Substances (TBARS)

2.5.6. Total Microbial Count (TPC)

2.6. Statistical Analysis

3. Results

3.1. Encapsulation Parameters of TP Extract

3.1.1. Effect of Wall Materials

3.1.2. Effect of Inlet Drying Temperature

3.2. Effect ETPE on Properties of Sausage

3.2.1. Technological Properties

3.2.2. Textural Properties

3.2.3. Color Values

3.3. Effect of ETPE on Stability of Sausage

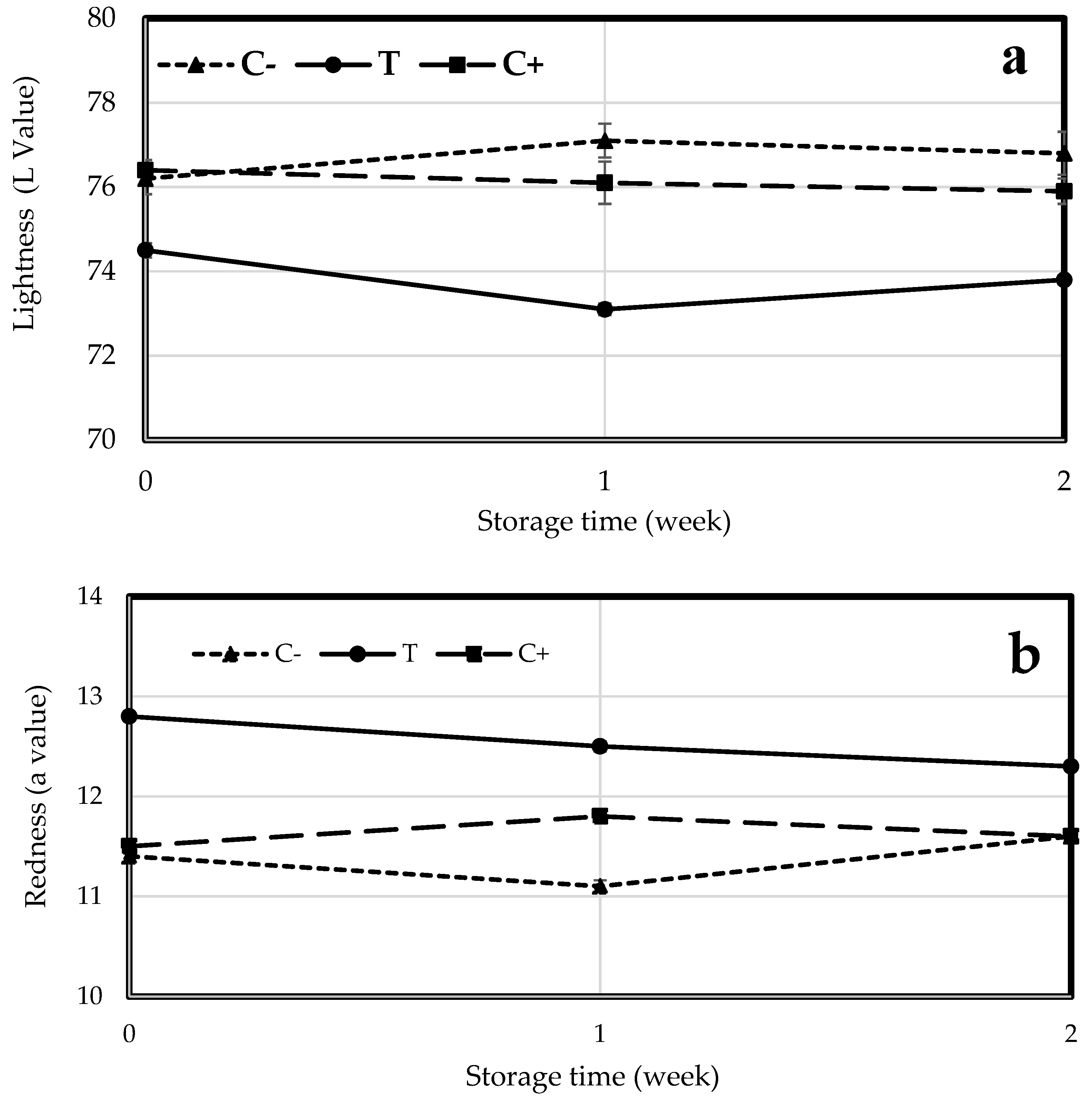

3.3.1. Color Stability

3.3.2. Oxidative Stability

3.3.3. Microbial Stability

4. Discussion

4.1. Encapsulation Parameters of TP Extract

4.1.1. Effect of Wall Material

4.1.2. Effect Drying Temperature

4.2. Effect of ETPE on Properties of Sausage

4.2.1. Technological Properties

4.2.2. Textural Properties

4.2.3. Color Values

4.3. Effect of ETPE on Stability of Sausage

4.3.1. Color Stability

4.3.2. Oxidative Stability

4.3.3. Microbial Stability

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GA | Gum Arabic |

| ETPE | Encapsulated Tomato Pomace Extract |

| MD | Maltodextrin |

| TBARS | Thiobarbituric Acid Reactive Substance |

| TP | Tomato Pomace |

| TPC | Total Plate Count |

References

- Lu, Z.; Wang, J.; Gao, R.; Ye, F.; Zhao, G. Sustainable valorisation of tomato pomace: A comprehensive review. Trends Food Sci. Technol. 2019, 86, 172–187. [Google Scholar] [CrossRef]

- Silva, Y.P.A.; Borba, B.C.; Pereira, V.A.; Reis, M.G.; Caliari, M.; Brooks, M.S.L.; Ferreira, T.A.P.C. Characterization of tomato processing by-product for use as a potential functional food ingredient: Nutritional composition, antioxidant activity and bioactive compounds. Int. J. Food Sci. Nutr. 2019, 70, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Chabi, I.B.; Zannou, O.; Dedehou, E.S.C.A.; Ayegnon, B.P.; Odouaro, B.O.; Maqsood, S.; Galanakis, C.M.; Kayodé, A.P.P. Tomato pomace as a source of valuable functional ingredients for improving physicochemical and sensory properties and extending the shelf life of foods: A review. Heliyon 2024, 10, e25261. [Google Scholar] [CrossRef] [PubMed]

- Garofalo, S.F.; Mallen, V.; Fino, D. Extraction of carotenoids from tomato pomace using deep eutectic solvents composed of short and medium-chain fatty acids and menthol. Food Chem. 2025, 484, 144342. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Pettinato, M.; Casazza, A.A.; Perego, P. A comprehensive optimization of ultrasound-assisted extraction for lycopene recovery from tomato waste and encapsulation by spray drying. Processes 2022, 10, 308. [Google Scholar] [CrossRef]

- Lasunon, P.; Phonkerd, N.; Tettawong, P.; Sengkhamparn, N. Effect of microwave-assisted extraction on bioactive compounds from industrial tomato waste and its antioxidant activity. Food Res. 2021, 5, 468–474. [Google Scholar] [CrossRef]

- Özbek, Z.A.; Yildiz, K.; Ergönül, P.G.; Iyilikeden, E.; Uzlaşir, T. Comparison of the effect of oven-and microwave-roasting on the physical properties and bioactive composition of tomato seeds and oils. Eur. J. Lipid Sci. Technol. 2023, 125, 2300024. [Google Scholar] [CrossRef]

- Bakhshizadeh, M.; Moghaddam, T.N.; Tavassoli, M.; Khaneghah, A.M.; Ansarifar, E. Characterization, extraction, and encapsulation technologies of lycopene and application in functional food products: An updated review. Food Bioprocess. Technol. 2025, 18, 3059–3099. [Google Scholar] [CrossRef]

- Shi, K.; Hu, T.; Zhang, P.; Zhang, S.; Xu, Y.; Zhang, Z.; Pan, S. Thermal conditions and active substance stability affect the isomerization and degradation of lycopene. Food Res. Int. 2022, 162, 111987. [Google Scholar] [CrossRef]

- Ashaq, B.; Wani, S.M.; Rasool, K.; Habib, S.; Rouf, M.A.; Parveen, S.; Ganai, S.A.; Dhekale, B.; Rashid, R. Nanoencapsulation of ultrasound-assisted extracted lemongrass essential oil and bioactive from residues using gum arabic and maltodextrin as wall material. Int. J. Biol. Macromol. 2025, 32, 146800. [Google Scholar] [CrossRef]

- Chanshotikul, N.; Bung-Orn, H. Encapsulation of Gac Powder Extract and Its Application in Low-Nitrite Chicken Sausage. Int. J. Food Eng. 2019, 5, 146–151. Available online: http://www.ijfe.org/uploadfile/2019/0618/20190618044857897.pdf (accessed on 2 August 2025). [CrossRef]

- Hussain, A.; Hussain, M.; Ashraf, W.; Ali, K.; Hussain, A.; Phyo, H.M.; Khalid, M.U.; Hussain, M.; Lianfu, Z. Encapusulation, optimization, and characterization of lycopene using soy protein isolate-peach gum conjugate as wall material. Food Biosci. 2024, 62, 105548. [Google Scholar] [CrossRef]

- Alam, M.; Sid, S.; Giri, S.; Das, R.; Kishore, A.; Kumar, N. Encapsulated kinnow peel powder using freeze drying: Effect of maltodextrin and gum Arabic concentrations on physiochemical, functional and thermal properties. Food Humanit. 2025, 4, 100546. [Google Scholar] [CrossRef]

- Mishra, P.; Mishra, S.; Mahanta, C.L. Effect of maltodextrin concentration and inlet temperature during spray drying on physicochemical and antioxidant properties of amla (Emblica officinalis) juice powder. Food Bioprod. Process. 2014, 92, 252–258. [Google Scholar] [CrossRef]

- Gill, A.O.; Holley, R.A. Interactive inhibition of meat spoilage and pathogenic bacteria by lysozyme, nisin and EDTA in the presence of nitrite and sodium chloride at 24 °C. Int. J. Food Microbiol. 2003, 83, 251–259. [Google Scholar] [CrossRef] [PubMed]

- Šojić, B.; Pavlić, B.; Tomović, V.; Kocić-Tanackov, S.; Đurović, S.; Zeković, Z.; Belović, M.; Torbica, A.; Jokanović, M.; Urumović, N.; et al. Tomato pomace extract and organic peppermint essential oil as effective sodium nitrite replacement in cooked pork sausages. Food Chem. 2020, 330, 127202. [Google Scholar] [CrossRef] [PubMed]

- AOAC. Official Methods of Analysis, 21st ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2019. [Google Scholar]

- Figueiredo Muniz, V.R.G.; Freitas, A.S.; Rabelo, L.S.D.; Rodrigues, L.F.P.; Honorato, K.R.; Rorato, A.C.; Ruiz, A.L.T.G.; Oliveira Sousa, I.M.; Igarashi-Mafra, L.; Foglio, M.A.; et al. Microencapsulation of Fridericia chica extract: Stability, anthocyanin retention, and antioxidant properties for food and therapeutic applications. Bioact. Carbohydr. Diet. Fibre. 2025, 34, 100483. [Google Scholar] [CrossRef]

- Savadkoohi, S.; Hoogenkamp, H.; Shamsi, K.; Farahnaky, A. Color, sensory and textural attributes of beef frankfurter, beef ham and meat-free sausage containing tomato pomace. Meat Sci. 2014, 97, 410–418. [Google Scholar] [CrossRef]

- Thammawong, W.; Chanshotikul, N.; Sriuttha, M.; Kwantrairat, S.; Hemung, B.O. Utilization of a hydrogel made from mixed pectin/fish bone powder as a fat replacer in beef patty. Appl. Food Res. 2025, 5, 101067. [Google Scholar] [CrossRef]

- Silva, P.I.; Stringheta, P.C.; Teófilo, R.F.; Oliveira, I.R.N. Parameter optimization for spray-drying microencapsulation of jaboticaba (Myrciaria jaboticaba) peel extracts using simultaneous analysis of responses. J. Food Eng. 2013, 117, 538–544. [Google Scholar] [CrossRef]

- Özkan, G.; Bilek, S.E. Microencapsulation of natural food colourants. Int. J. Nutr. Food Sci. 2014, 3, 145–156. [Google Scholar] [CrossRef]

- Tran, T.H.; Nguyen, M.H.; Zabaras, D.; Vu, L.T.T. Process development of Gac powder by using different enzymes and drying techniques. J. Food Eng. 2008, 85, 359–365. [Google Scholar] [CrossRef]

- Savadkoohi, S.; Farahnaky, A. Dynamic rheological and thermal study of the heat-induced gelation of tomato-seed proteins. J. Food Eng. 2012, 113, 479–485. [Google Scholar] [CrossRef]

- Deda, M.S.; Bloukas, J.G.; Fista, G.A. Effect of tomato paste and nitrite level on processing and quality characteristics of frankfurters. Meat Sci. 2007, 76, 501–508. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Xu, M.; Gao, X.; Zhang, Z. Influence of chitosan/lycopene on myoglobin and meat quality of beef during storage. Coatings 2024, 14, 1445. [Google Scholar] [CrossRef]

- Sucu, C.; Turp, G.Y. The investigation of the use of beetroot powder in Turkish fermented beef sausage (sucuk) as nitrite alternative. Meat Sci. 2018, 140, 158–166. [Google Scholar] [CrossRef]

- Torbica, A.; Belović, M.; Mastilović, J.; Kevrešan, Z.; Pestorić, M.; Škrobot, D.; Hadnađev, T.D. Nutritional, rheological, and sensory evaluation of tomato ketchup with increased content of natural fibres made from fresh tomato pomace. Food Bioprod. Process. 2016, 98, 299–309. [Google Scholar] [CrossRef]

- Raposo, A.; Pérez, E.; de Faria, C.T.; Ferrús, M.A.; Carrascosa, C. Food Spoilage by Pseudomonas spp.—An Overview. In Food Borne Pathogens and Antibiotic Resistance; Singh, O.V., Ed.; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2017; pp. 41–71. [Google Scholar] [CrossRef]

- Chabi, I.B.; Omiyalé, O.J.; Dèdéhou, S.E.C.; Ayégnon, B.P.; Idrissou, I.; Boya, B.; Kpoclou, Y.E.; Kayodé, A.P.P. Tomato seed (Solanum lycopersicum) meal derived from agrifood waste as functional ingredient: Nutritional value, antioxidant and antimicrobial activities, and functional properties. J. Food Process. Preserv. 2024, 1, 8824581. [Google Scholar] [CrossRef]

| Component (%) | Sausage Recipe | ||

|---|---|---|---|

| Negative Control (Without Nitrite) | Treatment | Positive Control (Nitrite 125 mg/kg) | |

| Minced pork | 60 | 60 | 60 |

| Back fat | 20 | 20 | 20 |

| Ice | 18 | 18 | 18 |

| Sodium tripolyphosphate | 1.5 | 1.5 | 1.5 |

| Erythrobate | 0.4 | 0.4 | 0.4 |

| Sodium nitrite | 0.0025 | 0.0025 | 0.0125 |

| ETPE | 0.0 | 1.0 | 0.0 |

| MD | 0.9 | 0.0 | 0.9 |

| Properties | Wall Materials | |

|---|---|---|

| Maltodextrin | Gum Arabic | |

| Moisture content (%) | 3.01 ± 0.32 a | 1.89 ± 0.71 b |

| Water activity | 0.26 ± 0.01 a | 0.27 ± 0.06 a |

| Bulk density (g/cm3) | 0.569 ± 0.029 a | 0.561 ± 0.015 a |

| DPPH Radical scavenging ability (%) | 14.022 ± 0.225 a | 10.100 ± 0.612 b |

| Properties | Inlet Drying Temperature (°C) | ||

|---|---|---|---|

| 140 | 160 | 180 | |

| Lycopene content (g/L) | 0.137 ± 0.003 a | 0.112 ± 0.001 b | 0.090 ± 0.001 c |

| DPPH Radical scavenging ability (%) | 11.46 ± 1.21 b | 14.02 ± 0.23 a | 11.12 ± 0.16 b |

| Color | |||

| L | 90.04 ± 0.18 a | 89.76 ± 0.41 ab | 89.03 ± 0.73 b |

| a | 5.08 ± 0.76 a | 5.57 ± 1.54 a | 6.09 ± 0.89 a |

| b | 16.87 ± 1.16 a | 17.52 ± 2.69 a | 18.61 ± 1.48 a |

| Technical Properties | Sausage Recipe | ||

|---|---|---|---|

| Negative Control Without ETPE | Treatment with ETPE | Positive Control Nitrite (125 mg/kg) | |

| Cooking yield (%) | 97.13 ± 1.25 a | 93.55 ± 1.38 b | 95.38 ± 1.31 ab |

| Expressible moisture (%) | 23.28 ± 1.06 a | 21.98 ± 1.77 a | 22.28 ± 1.44 a |

| Properties | Sausage Recipe | ||

|---|---|---|---|

| Negative Control (Without ETPE) | Treatment (With ETPE) | Positive Control (With Nitrite 125 mg/kg) | |

| Hardness (g) | 1922 ± 106 | 1952 ± 180 | 1678 ± 88 |

| Chewiness | 61.48 ± 0.4 | 68.71 ± 2.7 | 59.69 ± 6.7 |

| Cohesiveness | 0.0075 ± 0.0005 | 0.0077 ± 0.0003 | 0.0071 ± 0.0008 |

| Springiness | 4.30 ± 0.55 | 4.60 ± 0.35 | 4.95 ± 0.24 |

| Gumminess | 14.56 ± 1.8 | 15.41 ± 1.8 | 11.97 ± 1.9 |

| Color Value | Sausage Recipe | ||

|---|---|---|---|

| Negative Control (Without ETPE) | Treatment (With ETPE) | Positive Control (With Nitrite 125 ppm) | |

| Lightness (L value) | 76.2 ± 0.37 a | 74.5 ± 0.17 b | 75.6 ± 0.24 a |

| Redness (a value) | 11.4 ± 0.04 b | 12.3 ± 0.04 a | 11.5 ± 0.04 b |

| Yellowness (b value) | 5.8 ± 0.11 c | 7.4 ± 0.14 a | 6.1 ± 0.06 b |

| Storage Time (Week) | Sausage Recipe | ||

|---|---|---|---|

| Negative Control Without ETPE | Treatment with ETPE 1% | Positive Control with Nitrite (125 mg/kg) | |

| 0 | nd | nd | nd |

| 1 | 3.03 ± 0.05 | 2.57 ± 0.01 | nd |

| 2 | 4.48 ± 0.04 a | 3.70 ± 0.10 b | 1.87 ± 0.06 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chanshotikul, N.; Hemung, B.-O. Encapsulation of Extract from Tomato Pomace Applicable as Natural Colorant and Antioxidant in Low-Nitrite Sausage. Macromol 2025, 5, 51. https://doi.org/10.3390/macromol5040051

Chanshotikul N, Hemung B-O. Encapsulation of Extract from Tomato Pomace Applicable as Natural Colorant and Antioxidant in Low-Nitrite Sausage. Macromol. 2025; 5(4):51. https://doi.org/10.3390/macromol5040051

Chicago/Turabian StyleChanshotikul, Nachayut, and Bung-Orn Hemung. 2025. "Encapsulation of Extract from Tomato Pomace Applicable as Natural Colorant and Antioxidant in Low-Nitrite Sausage" Macromol 5, no. 4: 51. https://doi.org/10.3390/macromol5040051

APA StyleChanshotikul, N., & Hemung, B.-O. (2025). Encapsulation of Extract from Tomato Pomace Applicable as Natural Colorant and Antioxidant in Low-Nitrite Sausage. Macromol, 5(4), 51. https://doi.org/10.3390/macromol5040051