Thermal Evaluation of Biocomposites Made from Poly(Lactic Acid) and Cottonseed Byproducts

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Instrumental Analysis

2.3. Kinetic Calculation

3. Results and Discussion

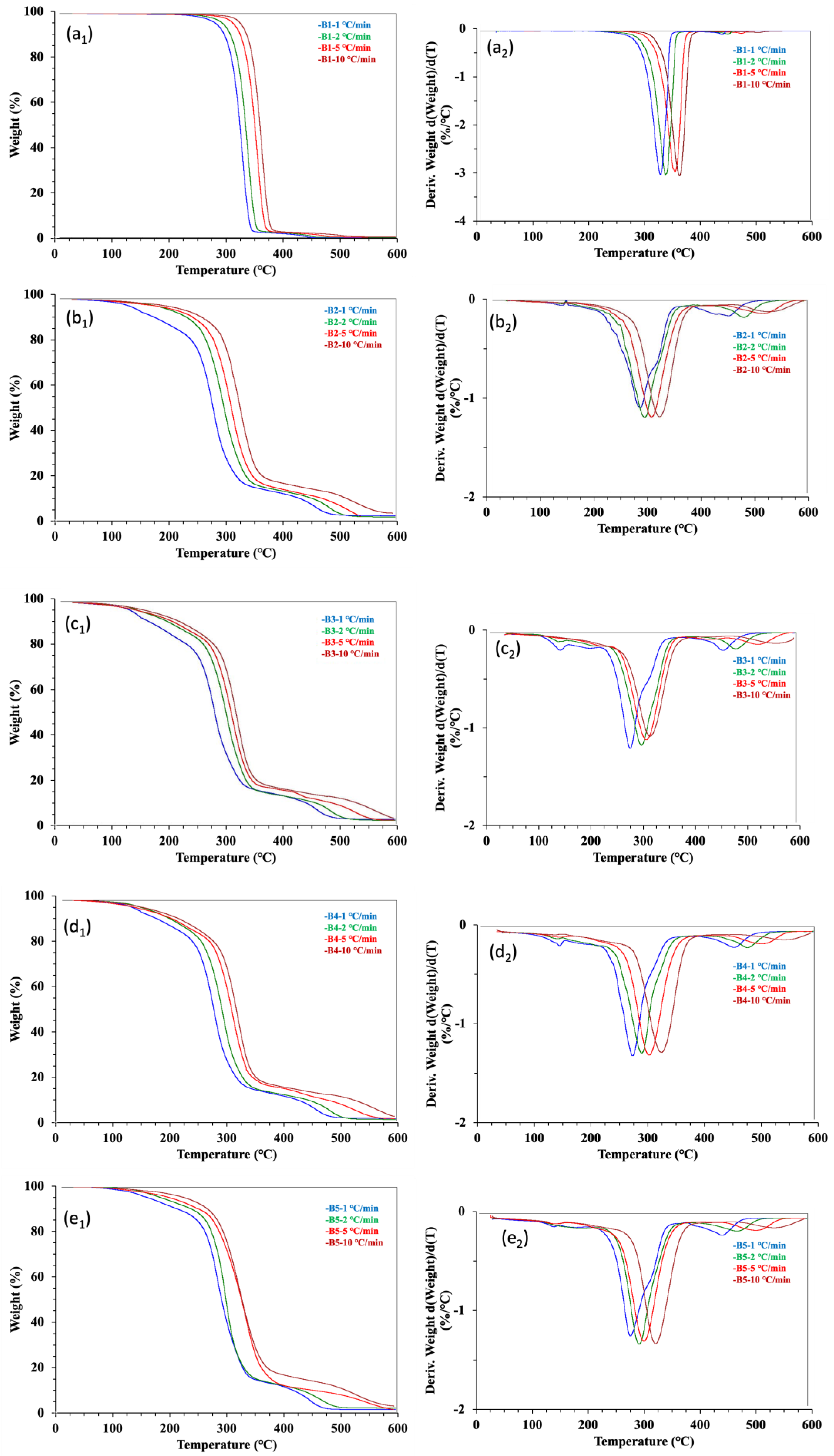

3.1. Thermal Degradation Process

3.2. Thermo-Oxidative Degradation Process

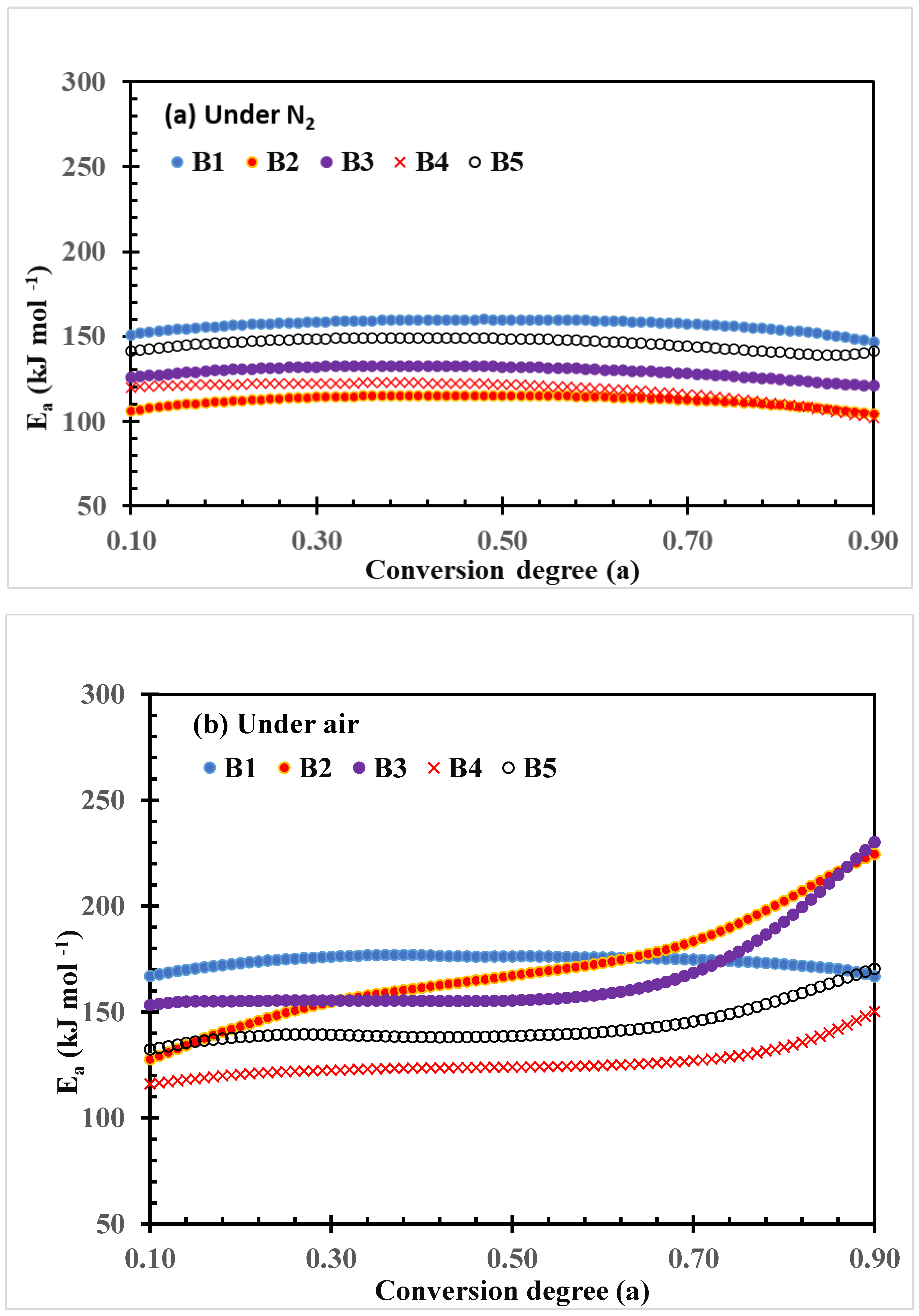

3.3. Thermal and Thermo-Oxidative Decomposition Kinetics

3.4. TG-FTIR Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bai, Z.; Gao, Z.; Sun, J.; Wu, B.; He, B. D-Lactic acid production by Sporolactobacillus inulinus YBS1-5 with simultaneous utilization of cottonseed meal and corncob residue. Bioresour. Technol. 2016, 207, 346–352. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Wang, L.; Ju, J.; Yu, B.; Ma, Y. Efficient production of polymer-grade D-lactate by Sporolactobacillus laevolacticus DSM442 with agricultural waste cottonseed as the sole nitrogen source. Bioresour. Technol. 2013, 142, 186–191. [Google Scholar] [CrossRef] [PubMed]

- Hamad, K.; Kaseem, M.; Ayyoob, M.; Joo, J.; Deri, F. Polylactic acid blends: The future of green, light and tough. Prog. Polym. Sci. 2018, 85, 83–127. [Google Scholar] [CrossRef]

- Anuar, H.; Nur Fatin Izzati, A.; Sharifah Nurul Inani, S.; Siti Nur E’zzati, M.; Siti Munirah Salimah, A.; Ali, F.; Manshor, M. Impregnation of cinnamon essential oil into plasticised polylactic acid biocomposite film for active food packaging. J. Packag. Technol. Res. 2017, 1, 149–156. [Google Scholar] [CrossRef]

- Zamir, S.S.; Fathi, B.; Ajji, A.; Robert, M.; Elkoun, S. Biodegradation of modified starch/poly lactic acid nanocomposite in soil. Polym. Degrad. Stab. 2022, 199, 109902. [Google Scholar] [CrossRef]

- Biswas, A.; Cheng, H.N.; Kuzniar, G.; He, Z.; Kim, S.; Furtado, R.F.; Alves, C.R.; Sharma, B.K. Bilayer films of poly(lactic acid) and cottonseed protein for packaging applications. Polymers 2023, 15, 1425. [Google Scholar] [CrossRef]

- He, Z.; Cheng, H.N.; Ford, C.V.; Nam, S.; Fortier, C.; Santiago Cintron, M.; Olanay, O.M.; Uknalis, J. Four-ingredient blends of poly(lactic acid) with cottonseed oil and meal for biocomposite utilization. Macromol 2024, 4, 708–722. [Google Scholar] [CrossRef]

- Lu, H.; Madbouly, S.A.; Schrader, J.A.; Srinivasan, G.; McCabe, K.G.; Grewell, D.; Kessler, M.R.; Graves, W.R. Biodegradation behavior of poly(lactic acid)(PLA)/distiller’s dried grains with solubles (DDGS) composites. ACS Sust. Chem. Eng. 2014, 2, 2699–2706. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, C.; Xie, L.; Chen, X.; Xiao, G.; Qin, S.; Guo, J.; He, Y. The combined plasticization of jute and tung oil anhydride for jute fiber reinforced poly(lactic acid) composites. Polym. Polym. Compos. 2021, 29 (Suppl. S9), S1569–S1577. [Google Scholar] [CrossRef]

- Wu, C.-S.; Tsou, C.-H. Fabrication, characterization, and application of biocomposites from poly(lactic acid) with renewable rice husk as reinforcement. J. Polymer Res. 2019, 26, 44. [Google Scholar] [CrossRef]

- Rahman, M.M.; Dey, A.; Yodo, N.; Lee, C.W.; Grewell, D. Soybean by-products bioplastic (polylactic acid)-based plant containers: Sustainable development and performance study. Sustainability 2023, 15, 5373. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, L.; Zhang, J. Extrusion foaming of poly(lactic acid)/soy protein concentrate blends. Macromol. Mater. Eng. 2011, 296, 835–842. [Google Scholar] [CrossRef]

- Yang, S.; Madbouly, S.A.; Schrader, J.A.; Srinivasan, G.; Grewell, D.; McCabe, K.G.; Kessler, M.R.; Graves, W.R. Characterization and biodegradation behavior of bio-based poly(lactic acid) and soy protein blends for sustainable horticultural applications. Green Chem. 2015, 17, 380–393. [Google Scholar]

- Stoll, L.; Rech, R.; Flôres, S.H.; Nachtigall, S.M.B.; de Oliveira Rios, A. Poly(acid lactic) films with carotenoids extracts: Release study and effect on sunflower oil preservation. Food Chem. 2019, 281, 213–221. [Google Scholar] [CrossRef]

- Kocak, E.; Cetin, M.S.; Kizilirmak Esmer, O.; Karahan Toprakci, H.A. Effects of tomato peel extract on morphological, chemical, thermal, and mechanical properties of poly (lactic acid). Iran. Polymer J. 2023, 32, 1135–1148. [Google Scholar]

- Lv, S.; Liu, X.; Gu, J.; Jiang, Y.; Tan, H.; Zhang, Y. Microstructure analysis of polylactic acid-based composites during degradation in soil. Int. Biodeterior. Biodegrad. 2017, 122, 53–60. [Google Scholar] [CrossRef]

- Karimpour-Motlagh, N.; Khonakdar, H.A.; Jafari, S.M.A.; Mahjub, A.; Panahi-Sarmad, M.; Kasbi, S.F.; Shojaei, S.; Goodarzi, V.; Arjmand, M. Influence of polypropylene and nanoclay on thermal and thermo-oxidative degradation of poly (lactide acid): TG-FTIR, TG-DSC studies and kinetic analysis. Thermochim. Acta 2020, 691, 178709. [Google Scholar]

- Nam, S.; Condon, B.D.; White, R.H.; Zhao, Q.; Yao, F.; Cintrón, M.S. Effect of urea additive on the thermal decomposition kinetics of flame retardant greige cotton nonwoven fabric. Polymer Degrad. Stabili. 2012, 97, 738–746. [Google Scholar]

- Çepelioğullar, Ö.; Haykırı-Açma, H.; Yaman, S. Kinetic modelling of RDF pyrolysis: Model-fitting and model-free approaches. Waste Manag. 2016, 48, 275–284. [Google Scholar] [CrossRef]

- Ozawa, T. A new method of analyzing thermogravimetric data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef]

- Flynn, J.H.; Wall, L.A. General treatment of thermogravimetry of polymers. J. Res. Nat. Bur. Stand. 1966, 70, 487–523. [Google Scholar]

- Friedman, H.L. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Part C Polym. Symp. 1964, 6, 183–195. [Google Scholar] [CrossRef]

- Chrysafi, I.; Ainali, N.M.; Bikiaris, D.N. Thermal degradation mechanism and decomposition kinetic studies of poly (lactic acid) and its copolymers with poly (hexylene succinate). Polymers 2021, 13, 1365. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qiang, Z.; Chen, X.; Ren, J. Understanding thermal decomposition kinetics of flame-retardant thermoset polylactic acid. RSC Adv. 2019, 9, 3128–3139. [Google Scholar]

- Aly, S.T.; Mahmoud, F.E.Z.; Sorour, M.A.; Abadir, M.F.; Saidy, M.I.E. Kinetics of pyrolysis of de-oiled neem seeds (Azadirachta indica). Biomass Conv. Bioref. 2025, 15, 7809–7826. [Google Scholar] [CrossRef]

- He, Z.; Nam, S.; Zhang, H.; Olanya, O.M. Chemical composition and thermogravimetric behaviors of glanded and glandless cottonseed kernels. Molecules 2022, 27, 316. [Google Scholar] [CrossRef]

- Nam, S.; Condon, B.D.; Liu, Y.; He, Q. Natural resistance of raw cotton fiber to heat evidenced by the suppressed depolymerization of cellulose. Polymer Degrad. Stabili. 2017, 138, 133–141. [Google Scholar] [CrossRef]

- Li, C.; Liu, Q.; Gong, W.; Zhou, Z.; Yao, Z.; Meng, X. Study on the atomic scale of thermal and thermo-oxidative degradation of polylactic acid via reactive molecular dynamics simulation. Thermochim. Acta 2022, 709, 179144. [Google Scholar] [CrossRef]

- Lv, S.; Zhang, Y.; Tan, H. Thermal and thermo-oxidative degradation kinetics and characteristics of poly(lactic acid) and its composites. Waste Manag. 2019, 87, 335–344. [Google Scholar]

- Sutivisedsak, N.; Cheng, H.; Dowd, M.; Selling, G.; Biswas, A. Evaluation of cotton byproducts as fillers for poly(lactic acid) and low density polyethylene. Ind. Crop. Prod. 2012, 36, 127–134. [Google Scholar]

- Zhou, L.; He, H.; Li, M.-C.; Huang, S.; Mei, C.; Wu, Q. Enhancing mechanical properties of poly(lactic acid) through its in-situ crosslinking with maleic anhydride-modified cellulose nanocrystals from cottonseed hulls. Ind. Crop. Prod. 2018, 112, 449–459. [Google Scholar] [CrossRef]

- Sangeetha, V.; Varghese, T.; Nayak, S.K. Isolation and characterisation of nanofibrillated cellulose from waste cotton: Effects on thermo-mechanical properties of polylactic acid/MA-g-SEBS blends. Iran. Polym. J. 2019, 28, 673–683. [Google Scholar] [CrossRef]

- He, Z.; Klasson, K.T.; Wang, D.; Li, N.; Zhang, H.; Zhang, D.; Wedegaertner, T.C. Pilot-scale production of washed cottonseed meal and co-products. Mod. Appl. Sci. 2016, 10, 25–33. [Google Scholar] [CrossRef]

- Nam, S.; Baek, I.-S.; Hillyer, M.B.; He, Z.; Barnaby, J.Y.; Condon, B.D.; Kim, M.S. Thermosensitive textiles made from silver nanoparticle-filled brown cotton fiber. Nanoscale Adv. 2022, 4, 3725–3736. [Google Scholar] [CrossRef]

- Lv, S.; Gu, J.; Cao, J.; Tan, H.; Zhang, Y. Effect of annealing on the thermal properties of poly (lactic acid)/starch blends. Inter. J. Biol. Macromol. 2015, 74, 297–303. [Google Scholar] [CrossRef]

- Mandal, D.K.; Bhunia, H.; Bajpai, P.K. Thermal degradation kinetics of PP/PLA nanocomposite blends. J. Thermoplast. Compos. Mater. 2019, 32, 1714–1730. [Google Scholar] [CrossRef]

- Noori, N.; Khanjari, A.; Rezaeigolestani, M.; Karabagias, I.K.; Mokhtari, S. Development of antibacterial biocomposites based on poly(lactic acid) with spice essential oil (Pimpinella anisum) for food applications. Polymers 2021, 13, 3791. [Google Scholar] [CrossRef]

- He, Z.; Zhang, H.; Olk, D.C. Chemical composition of defatted cottonseed and soy meal products. PLoS ONE 2015, 10, e0129933. [Google Scholar] [CrossRef]

- He, Z.; Nam, S.; Tewolde, H.; Ford, C.V.; Dhandapani, R.; Barretto, R.; Wang, D. Morphologic features and thermal characteristics of nine cotton biomass byproducts. Biomass 2025, 5, 12. [Google Scholar] [CrossRef]

- He, Z.; Nam, S.; Klasson, K.T. Oxidative stability of cottonseed butter products under accelerated storage conditions. Molecules 2023, 28, 1599. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Arrigo, R.; Gambarotti, C.; Carroccio, S.; Filippone, G.; Cicogna, F.; Guenzi, M. α-Tocopherol-induced radical scavenging activity in carbon nanotubes for thermo-oxidation resistant ultra-high molecular weight polyethylene-based nanocomposites. Carbon 2014, 74, 14–21. [Google Scholar] [CrossRef]

- Arora, S.; Bagoria, R.; Kumar, M. Effect of alpha-tocopherol (vitamin E) on the thermal degradation behavior of edible oils: Multiple-heating rate kinetics. J. Therm. Anal. Calorim. 2010, 102, 375–381. [Google Scholar] [CrossRef]

- Yuzay, I.E.; Auras, R.; Soto-Valdez, H.; Selke, S. Effects of synthetic and natural zeolites on morphology and thermal degradation of poly(lactic acid) composites. Polymer Degrad. Stabili. 2010, 95, 1769–1777. [Google Scholar] [CrossRef]

- Das, P.; Tiwari, P. Thermal degradation kinetics of plastics and model selection. Thermochim. Acta 2017, 654, 191–202. [Google Scholar] [CrossRef]

- Steel, C.J.; Dobarganes, M.C.; e Gorduras, D.L.d.Ó. Formation of polymerization compounds during thermal oxidation of cottonseed oil, partially hydrogenated cottonseed oil and their blends. Grasas Y Aceites 2006, 57, 284–291. [Google Scholar] [CrossRef]

- Sedeek, S.; El-Ghobashy, R.; Tawfik, M. Thermal stability of cottonseed oil mixed with jojoba or castor oil during frying process. J. Biol. Chem. Environ. Sci. 2012, 7, 39–56. [Google Scholar]

- Kmiecik, D.; Fedko, M.; Siger, A.; Kulczyński, B. Degradation of tocopherol molecules and its impact on the polymerization of triacylglycerols during heat treatment of oil. Molecules 2019, 24, 4555. [Google Scholar] [CrossRef]

- Zou, H.; Yi, C.; Wang, L.; Liu, H.; Xu, W. Thermal degradation of poly (lactic acid) measured by thermogravimetry coupled to Fourier transform infrared spectroscopy. J. Therm. Anal. Calorim. 2009, 97, 929–935. [Google Scholar] [CrossRef]

| Label | PLA (Matrix) | WCSM (Filler) | CSO (Compatibilizer) | GLY (Plasticizer) |

|---|---|---|---|---|

| B1 | 100 | 0 | 0 | 0 |

| B2 | 80 | 20 | 8 | 8 |

| B3 | 80 | 20 | 15 | 4 |

| B4 | 80 | 20 | 15 | 8 |

| B5 | 80 | 20 | 15 | 15 |

| (a) Temperature (T) parameters 1 | |||||||||||||

| To (°C) | Tm (°C) | Te (°C) | |||||||||||

| N2 | Air | N2 | Air | N2 | Air | ||||||||

| B1 | 278.5 a 2 | 280.3 a | 342.6 a | 343.3 a | 388.8 a | 396.8 a | |||||||

| B2 | 233.2 b | 223.3 b | 296.5 b | 301.7 b | 345.1 b | 375.3 ab | |||||||

| B3 | 245.7 b | 245.0 b | 298.1 b | 303.0 b | 341.4 b | 372.1 ab | |||||||

| B4 | 240.0 b | 243.7 b | 296.6 b | 294.2 b | 347.8 b | 364.3 b | |||||||

| B5 | 247.5 b | 242.4 b | 305.1 b | 307.1 b | 340.1 b | 373.5 ab | |||||||

| (b) Mass loss (WL) and residual char parameters 1 | |||||||||||||

| WLo (%) | WLm (%) | WLe (°C) | Char (%) | ||||||||||

| N2 | Air | N2 | Air | N2 | Air | N2 | Air | ||||||

| B1 | 1.0 d 2 | 0.7 d | 65.9 a | 59.0 a | 98.2 a | 97.7 a | 0.9 c | 1.4 b | |||||

| B2 | 6.7 c | 9.1 c | 55.8 b | 47.9 b | 84.7 b | 84.5 cd | 2.3 ab | 6.2 ab | |||||

| B3 | 16.4 ab | 18.7 a | 62.5 ab | 54.6 ab | 84.8 b | 84.4 d | 3.7 a | 7.5 a | |||||

| B4 | 13.7 b | 14.2 b | 61.1 ab | 56.0 ab | 87.5 b | 86.3 bc | 1.9 ab | 5.9 ab | |||||

| B5 | 11.2 b | 12.9 b | 57.2 ab | 49.1 b | 84.5 b | 87.4 b | 1.7 ab | 5.3 ab | |||||

| Under N2 | Under Air | |||

|---|---|---|---|---|

| FWO | Friedman | FWO | Friedman | |

| B1 | 147–160 (156.8 ± 3.3) | 114–159 (145.1 ± 12.1) | 166–177 (174.0 ± 2.7) | 138–179 (167.5 ± 11.6) |

| B2 | 104–115 (112.4 ± 3.0) | 75–119 (104.9 ± 13.6) | 128–224 (170.2 ± 24.0) | 144–253 (170.2 ± 31.5) |

| B3 | 122–133 (129.1 ± 3.4) | 104–134 (120.9 ± 10.6) | 153–230 (166.5 ± 20.0) | 154–276 (186.6 ± 41.5) |

| B4 | 102–123 (118.2 ± 5.6) | 66–121 (102.7 ± 19.0) | 116–150 (125.9 ± 6.9) | 119–187 (135.2 ± 18.6) |

| B5 | 139–149 (145.6 ± 3.3) | 123–161 (140.8 ± 10.5) | 132–170 (154.3 ± 9.1) | 133–191 (154.3 ± 19.6) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Nam, S.; Kulkarni, S.; Bagheri Kashani, M.; Nagarajan, R. Thermal Evaluation of Biocomposites Made from Poly(Lactic Acid) and Cottonseed Byproducts. Macromol 2025, 5, 16. https://doi.org/10.3390/macromol5020016

He Z, Nam S, Kulkarni S, Bagheri Kashani M, Nagarajan R. Thermal Evaluation of Biocomposites Made from Poly(Lactic Acid) and Cottonseed Byproducts. Macromol. 2025; 5(2):16. https://doi.org/10.3390/macromol5020016

Chicago/Turabian StyleHe, Zhongqi, Sunghyun Nam, Sourabh Kulkarni, Mohammad Bagheri Kashani, and Ramaswamy Nagarajan. 2025. "Thermal Evaluation of Biocomposites Made from Poly(Lactic Acid) and Cottonseed Byproducts" Macromol 5, no. 2: 16. https://doi.org/10.3390/macromol5020016

APA StyleHe, Z., Nam, S., Kulkarni, S., Bagheri Kashani, M., & Nagarajan, R. (2025). Thermal Evaluation of Biocomposites Made from Poly(Lactic Acid) and Cottonseed Byproducts. Macromol, 5(2), 16. https://doi.org/10.3390/macromol5020016