Review of Biomass Gasifiers: A Multi-Criteria Approach

Abstract

1. Introduction

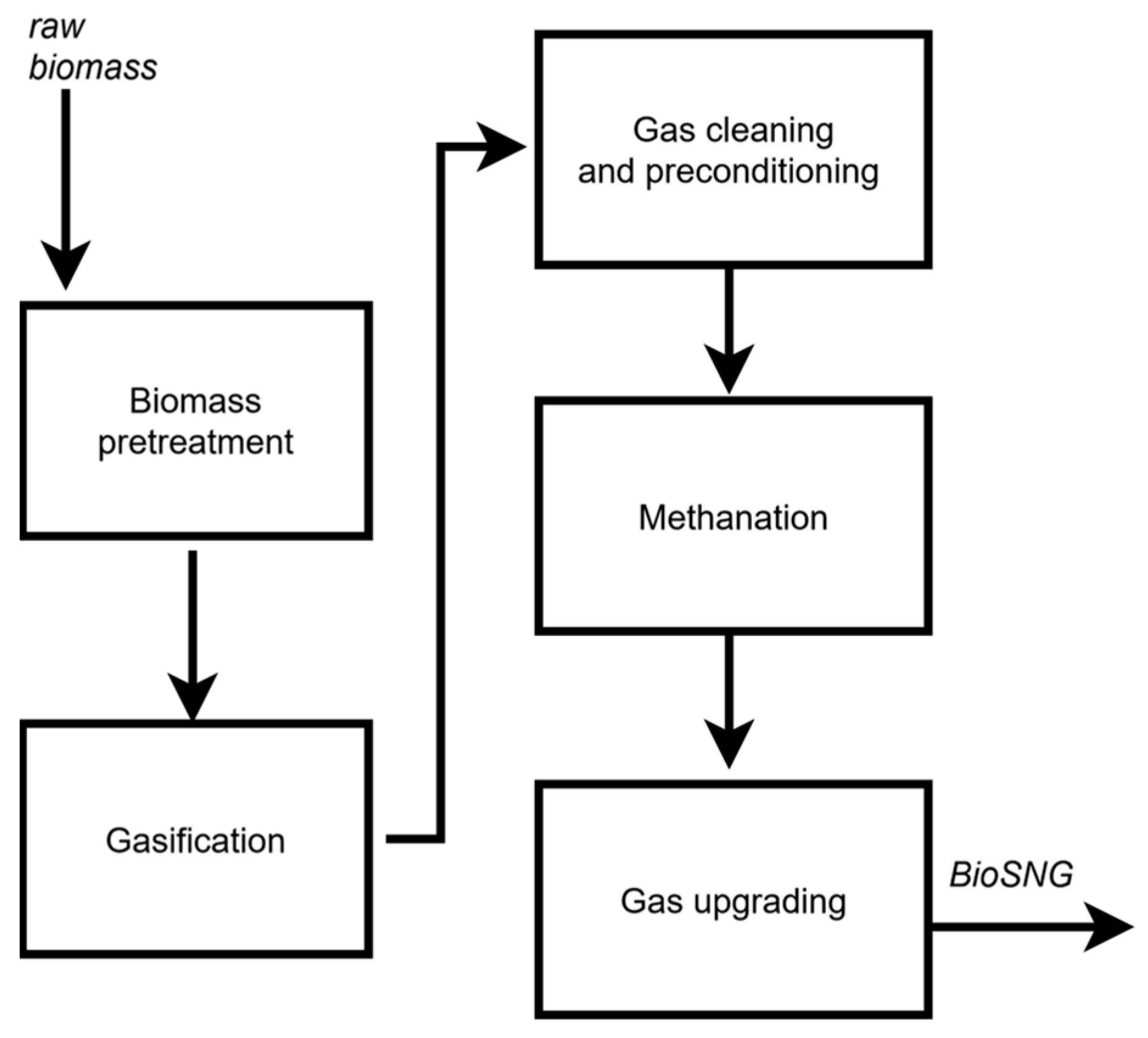

2. Biomass Gasification for BioSNG Production

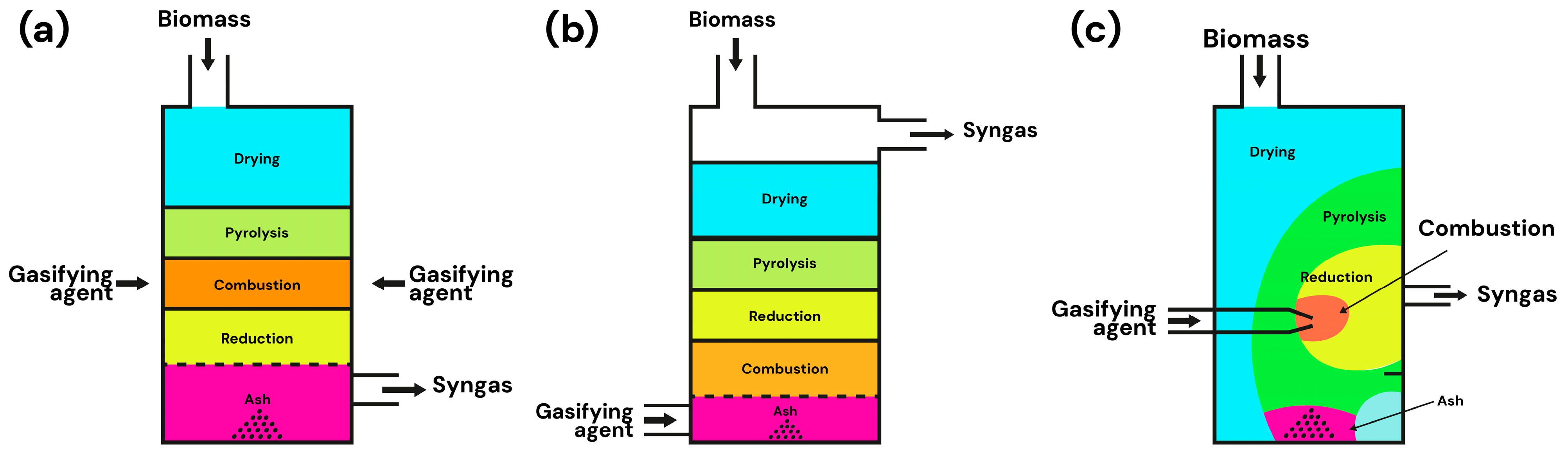

- (1)

- Heating and drying involves the removal of moisture from the biomass through heating, and many gasification systems utilize biomass with a moisture range of 10 to 20% to produce a high-calorific-value gas [6,16,17]. Drying is considered complete when the process temperature exceeds 150 °C [6,18]. The steam released during moisture evaporation can contribute to additional chemical reactions, significantly impacting gasification efficiency and product composition.

- (2)

- Pyrolysis is the thermochemical decomposition of the carbonaceous materials matrix, promoting the formation of molecules with lower molecular weight. This occurs at temperatures ranging from 200 to 700 °C in the absence of an oxidizing agent [6,17,18]. The process yields solid, liquid, and gaseous fractions. The solid fraction, high in carbon content and heating value, consists of inert materials like ash and char. The liquid fraction, known as tars, comprises complex organic substances condensable at relatively low temperatures. The gaseous fraction, called pyrolysis gas, mainly consists of hydrogen, carbon monoxide, carbon dioxide, and light hydrocarbons [19].

- (3)

- The partial oxidation step is essential to generate the thermal energy required for endothermic processes, maintaining the operating temperature at the necessary level. Executed under low oxygen supply, this step oxidizes a small portion of the carbonaceous species. Primary reactions in this phase include char combustion, partial oxidation, and hydrogen combustion, resulting in a gas mixture of carbon monoxide, carbon dioxide, and water [17].

- (4)

- The reduction phase involves products from the pyrolysis and oxidation stages, where gas mixtures and char react to form the final syngas [6]. Key reactions in this step include shift conversion, Boudouard reaction, water-gas shift (WGS) and methanation [15,20]. The temperature during the reduction step significantly influences the syngas composition and properties [21]. Additionally, char’s reactivity, controlled by factors such as heating rate, pyrolysis temperature, inorganic components, and pyrolysis pressure, determines the pace of the reduction reaction and the residence time of the gasification process [22].

3. Gasification Technologies

3.1. Fixed-Bed Gasifiers

3.2. Fluidized-Bed Gasifiers

3.3. Entrained Flow Gasifier

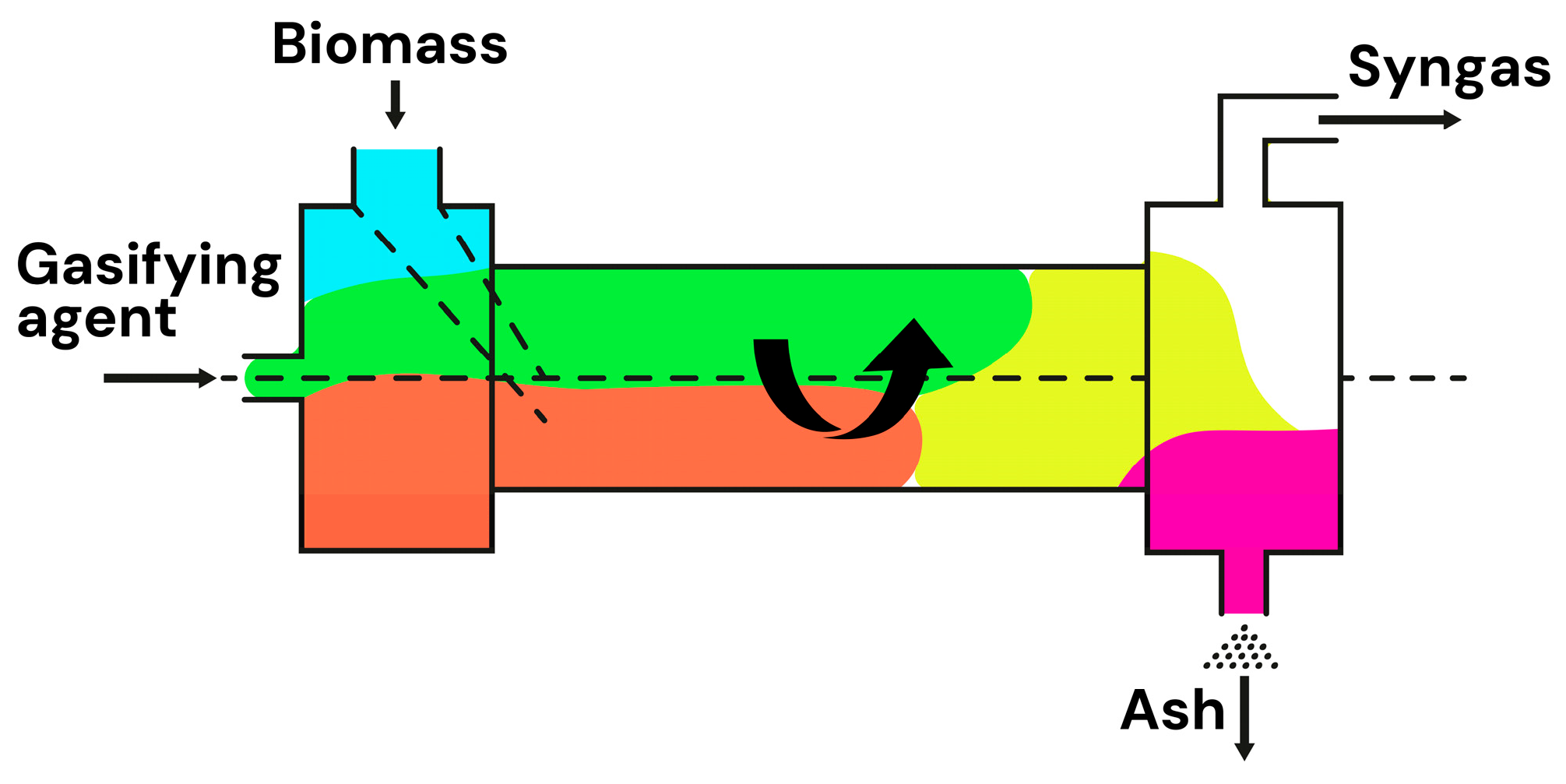

3.4. Rotary Kiln Gasifier

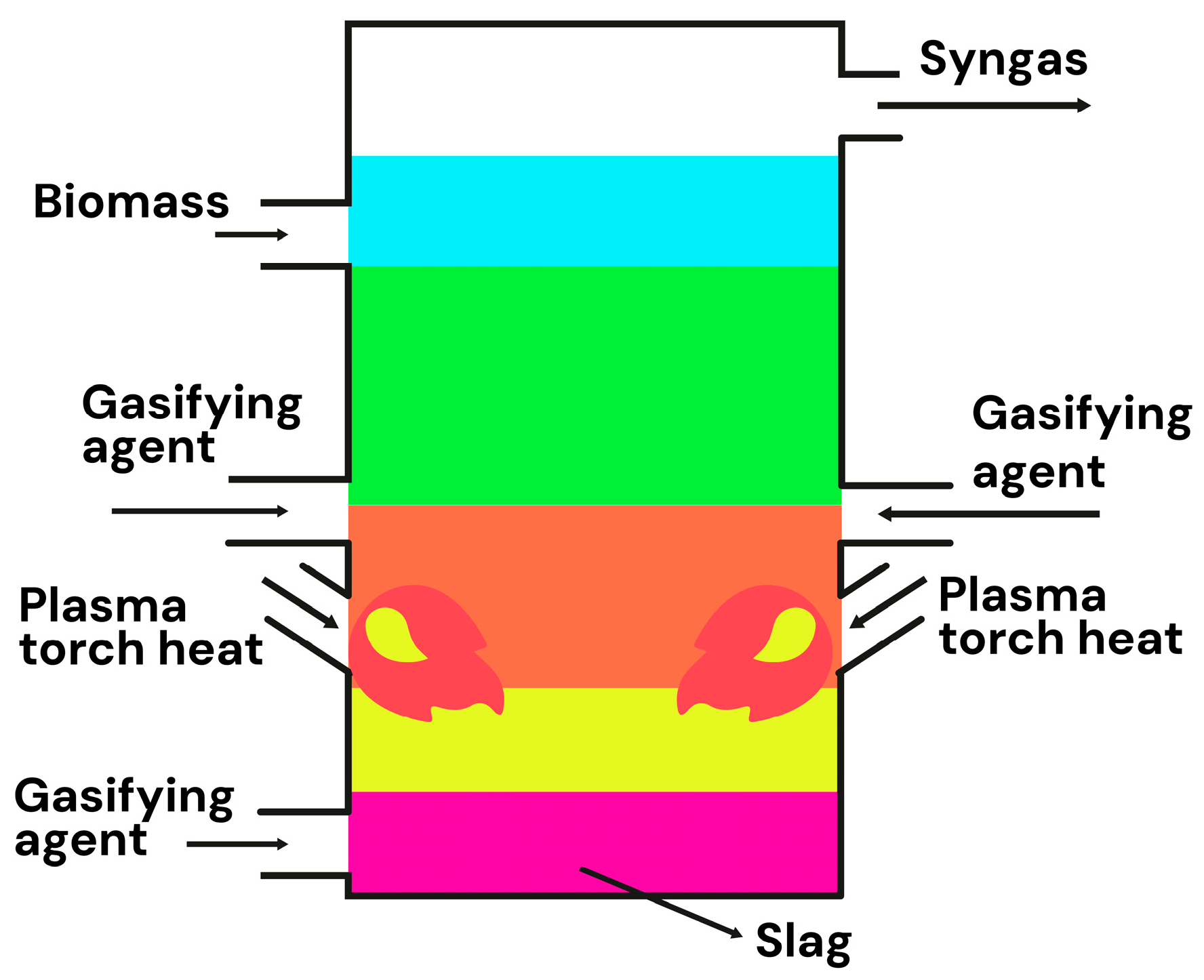

3.5. Plasma Gasifier

3.6. Emerging Technologies

3.7. Comparison of Gasification Technologies

4. Gasifier Selection for BioSNG

5. Conclusions and Future Outlook

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AHP | Analytic Hierarchy Process |

| BioSNG | Bio-based Synthetic Natural Gas |

| CH4 | Methane |

| CO2 | Carbon Dioxide |

| EN | European Norm (Standard) |

| CO2eq | CO2 Equivalent Emissions |

| GIS | Geographic Information Systems |

| H2 | Hydrogen gas |

| H2/CO | Hydrogen to Carbon Monoxide Ratio |

| LCA | Life Cycle Assessment |

| MCDM | Multi-Criteria Decision Making |

| Nm3 | Normal Cubic Meter |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| %w/w | Percent Weight by Weight |

| %v/v | Percent Volume by Volume |

References

- Millinger, M.; Hedenus, F.; Zeyen, E.; Neumann, F.; Reichenberg, L.; Berndes, G. Diversity of Biomass Usage Pathways to Achieve Emissions Targets in the European Energy System. Nat. Energy 2025, 10, 226–242. [Google Scholar] [CrossRef]

- MarketsandMarkets. Biomass Gasification Market Growth, Drivers, & Opportunities. Available online: https://www.marketsandmarkets.com/Market-Reports/biomass-gasification-market-105152418.html (accessed on 13 June 2025).

- Research and Marckets, Ltd. Biomass Gasifier Market Size, Competitors, Trends & Forecast. Available online: https://www.researchandmarkets.com/reports/5867942/biomass-gasifier-market-size-market-share (accessed on 13 June 2025).

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An Overview of Advances in Biomass Gasification. Energy Environ. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Higman, C.; Tam, S. Advances in coal gasification, hydrogenation, and gas treating for the production of chemicals and fuels. Chem. Rev. 2014, 114, 1673–1708. [Google Scholar] [CrossRef] [PubMed]

- Tezer, Ö.; Karabağ, N.; Öngen, A.; Çolpan, C.Ö.; Ayol, A. Biomass Gasification for Sustainable Energy Production: A Review. Int. J. Hydrogen Energy 2022, 47, 15419–15433. [Google Scholar] [CrossRef]

- Ravikiran, A.; Renganathan, T.; Pushpavanam, S.; Voolapalli, R.K.; Cho, Y.S. Generalized Analysis of Gasifier Performance Using Equilibrium Modeling. Ind. Eng. Chem. Res. 2012, 51, 1601–1611. [Google Scholar] [CrossRef]

- Chengzao, J.; Yongfeng, Z.; Xia, Z. Prospects of and Challenges to Natural Gas Industry Development in China. Nat. Gas Ind. B 2014, 1, 1–13. [Google Scholar] [CrossRef]

- Yaman, C. A Review on the Process of Greenhouse Gas Inventory Preparation and Proposed Mitigation Measures for Reducing Carbon Footprint. Gases 2024, 4, 18–40. [Google Scholar] [CrossRef]

- Radosits, F.K.; Ajanovic, A.; Harasek, M. The Relevance of Biomass-Based Gases as Energy Carriers: A Review. WIREs Energy Environ. 2024, 13, e527. [Google Scholar] [CrossRef]

- Kohl, T.; Laukkanen, T.; Tuomaala, M.; Niskanen, T.; Siitonen, S.; Järvinen, M.P.; Ahtila, P. Comparison of Energy Efficiency Assessment Methods: Case Bio-SNG Process. Energy 2014, 74, 88–98. [Google Scholar] [CrossRef]

- IEA Bioenergy Task 33, Gasification of Waste for Energy Carriers, IEA Bioenergy. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/01/IEA-Bioenergy-Task-33-Gasification-of-waste-for-energy-carriers-20181205-1.pdf (accessed on 8 August 2025).

- van der Meijden, C.M.; Veringa, H.J.; Rabou, L.P.L.M. The Production of Synthetic Natural Gas (SNG): A Comparison of Three Wood Gasification Systems for Energy Balance and Overall Efficiency. Biomass Bioenergy 2010, 34, 302–311. [Google Scholar] [CrossRef]

- Pollex, A.; Ortwein, A.; Kaltschmitt, M. Thermo-Chemical Conversion of Solid Biofuels. Biomass Convers. Biorefinery 2012, 2, 21–39. [Google Scholar] [CrossRef]

- Basu, P. Chapter 1—Introduction. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar] [CrossRef]

- Kalita, P.; Baruah, D. Investigation of Biomass Gasifier Product Gas Composition and Its Characterization. In Coal and Biomass Gasification: Recent Advances and Future Challenges; De, S., Agarwal, A.K., Moholkar, V.S., Thallada, B., Eds.; Springer: Singapore, 2018. [Google Scholar] [CrossRef]

- Dogru, M.; Howarth, C.R.; Akay, G.; Keskinler, B.; Malik, A.A. Gasification of Hazelnut Shells in a Downdraft Gasifier. Energy 2002, 27, 415–427. [Google Scholar] [CrossRef]

- Paiva, M.; Vieira, A.; Gomes, H.T.; Brito, P. Simulation of a Downdraft Gasifier for Production of Syngas from Different Biomass Feedstocks. ChemEngineering 2021, 5, 20. [Google Scholar] [CrossRef]

- Fortunato, B.; Brunetti, G.; Camporeale, S.M.; Torresi, M.; Fornarelli, F. Thermodynamic Model of a Downdraft Gasifier. Energy Convers. Manag. 2017, 140, 281–294. [Google Scholar] [CrossRef]

- Basu, P. Chapter 7—Gasification Theory. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Basu, P., Ed.; Academic Press: Cambridge, MA, USA, 2018; pp. 211–262. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S.; et al. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Kushwah, A.; Reina, T.R.; Short, M. Modelling Approaches for Biomass Gasifiers: A Comprehensive Overview. Sci. Total Environ. 2022, 834, 155243. [Google Scholar] [CrossRef] [PubMed]

- Jordan, C.A.; Weatherby, J.; Barclay, A. Advanced Gasification Technologies—Review and Benchmarking: Review of Current Status of Advanced Gasification Technologies, Task Report 2; BEIS Research Paper Number 2021/038; AECOM & Fichtner Consulting Engineers: London, UK, 2021; pp. 1–196. [Google Scholar]

- Santos, S.M.; Assis, A.C.; Gomes, L.; Nobre, C.; Brito, P. Waste Gasification Technologies: A Brief Overview. Waste 2023, 1, 140–165. [Google Scholar] [CrossRef]

- Rey, J.R.C.; Longo, A.; Rijo, B.; Pedrero, C.M.; Tarelho, L.A.C.; Brito, P.S.D.; Nobre, C. A Review of Cleaning Technologies for Biomass-Derived Syngas. Fuel 2024, 377, 132776. [Google Scholar] [CrossRef]

- Abdoulmoumine, N.; Adhikari, S.; Kulkarni, A.; Chattanathan, S. A Review on Biomass Gasification Syngas Cleanup. Appl. Energy 2015, 155, 294–307. [Google Scholar] [CrossRef]

- Mondal, P.; Dang, G.S.; Garg, M.O. Syngas Production through Gasification and Cleanup for Downstream Applications—Recent Developments. Fuel Process. Technol. 2011, 92, 1395–1410. [Google Scholar] [CrossRef]

- Lotfi, S. Technologies for Tar Removal from Biomass-Derived Syngas. Pet. Petrochem. Eng. J. 2021, 5, 1–35. [Google Scholar] [CrossRef]

- Worley, M.; Yale, J. Biomass Gasification Technology Assessment: Consolidated Report; NREL/SR--5100-57085, 1059145, LFA-2-22480-01; NREL: Golden, CO, USA, 2012. [Google Scholar] [CrossRef]

- Wu, Y.; Ye, X.; Wang, Y.; Wang, L. Methane Production from Biomass by Thermochemical Conversion: A Review. Catalysts 2023, 13, 771. [Google Scholar] [CrossRef]

- González-Vázquez, M.P.; García, R.; Gil, M.V.; Pevida, C.; Rubiera, F. Comparison of the Gasification Performance of Multiple Biomass Types in a Bubbling Fluidized Bed. Energy Convers. Manag. 2018, 176, 309–323. [Google Scholar] [CrossRef]

- Kambolis, A.; Schildhauer, T.J.; Kröcher, O. CO Methanation for Synthetic Natural Gas Production. Chimia 2015, 69, 608–613. [Google Scholar] [CrossRef] [PubMed]

- Materazzi, M.; Grimaldi, F.; Foscolo, P.U.; Cozens, P.; Taylor, R.; Chapman, C. Analysis of Syngas Methanation for Bio-SNG Production from Wastes: Kinetic Model Development and Pilot Scale Validation. Fuel Process. Technol. 2017, 167, 292–305. [Google Scholar] [CrossRef]

- Kopyscinski, J.; Schildhauer, T.J.; Biollaz, S.M.A. Production of Synthetic Natural Gas (SNG) from Coal and Dry Biomass—A Technology Review from 1950 to 2009. Fuel 2010, 89, 1763–1783. [Google Scholar] [CrossRef]

- Gröbl, T.; Walter, H.; Haider, M. Biomass Steam Gasification for Production of SNG—Process Design and Sensitivity Analysis. Appl. Energy 2012, 97, 451–461. [Google Scholar] [CrossRef]

- Kumar, A.; Jones, D.D.; Hanna, M.A. Thermochemical Biomass Gasification: A Review of the Current Status of the Technology. Energies 2009, 2, 556–581. [Google Scholar] [CrossRef]

- Patra, T.K.; Sheth, P.N. Biomass Gasification Models for Downdraft Gasifier: A State-of-the-Art Review. Renew. Sustain. Energy Rev. 2015, 50, 583–593. [Google Scholar] [CrossRef]

- Martínez, J.D.; Mahkamov, K.; Andrade, R.V.; Silva Lora, E.E. Syngas Production in Downdraft Biomass Gasifiers and Its Application Using Internal Combustion Engines. Renew. Energy 2012, 38, 1–9. [Google Scholar] [CrossRef]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of Lignocellulosic Biomass in Fluidized Beds for Renewable Energy Development: A Review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Leckner, B. Modeling of Biomass Gasification in Fluidized Bed. Prog. Energy Combust. Sci. 2010, 36, 444–509. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Q.; Zhao, H.; Cao, X.; Mei, Q.; Luo, Z.; Cen, K. Biomass–Oxygen Gasification in a High-Temperature Entrained-Flow Gasifier. Biotechnol. Adv. 2009, 27, 606–611. [Google Scholar] [CrossRef]

- Oliveira, M.; Ramos, A.; Ismail, T.M.; Monteiro, E.; Rouboa, A. A Review on Plasma Gasification of Solid Residues: Recent Advances and Developments. Energies 2022, 15, 1475. [Google Scholar] [CrossRef]

- Shi, H.; Si, W.; Li, X. The Concept, Design and Performance of a Novel Rotary Kiln Type Air-Staged Biomass Gasifier. Energies 2016, 9, 67. [Google Scholar] [CrossRef]

- Mishra, S.; Upadhyay, R.K. Review on Biomass Gasification: Gasifiers, Gasifying Mediums, and Operational Parameters. Mater. Sci. Energy Technol. 2021, 4, 329–340. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Bruno, J.C.; Coronas, A. Review and Analysis of Biomass Gasification Models. Renew. Sustain. Energy Rev. 2010, 14, 2841–2851. [Google Scholar] [CrossRef]

- Ismail, T.M.; El-Salam, M.A. Parametric Studies on Biomass Gasification Process on Updraft Gasifier High Temperature Air Gasification. Appl. Therm. Eng. 2017, 112, 1460–1473. [Google Scholar] [CrossRef]

- Kuo, P.-C.; Wu, W.; Chen, W.-H. Gasification Performances of Raw and Torrefied Biomass in a Downdraft Fixed Bed Gasifier Using Thermodynamic Analysis. Fuel 2014, 117, 1231–1241. [Google Scholar] [CrossRef]

- Monteiro, E.; Ramos, A.; Rouboa, A. Fundamental Designs of Gasification Plants for Combined Heat and Power. Renew. Sustain. Energy Rev. 2024, 196, 114305. [Google Scholar] [CrossRef]

- Nwakaire, J.N.; Ugwuishiwu, B.O. Development of a Natural Cross Draft Gasifier Stove for Application in Rural Communities in Sub-Saharan Africa. J. Appl. Sci. 2015, 15, 1149–1157. [Google Scholar] [CrossRef]

- Ren, J.; Cao, J.-P.; Zhao, X.-Y.; Yang, F.-L.; Wei, X.-Y. Recent Advances in Syngas Production from Biomass Catalytic Gasification: A Critical Review on Reactors, Catalysts, Catalytic Mechanisms and Mathematical Models. Renew. Sustain. Energy Rev. 2019, 116, 109426. [Google Scholar] [CrossRef]

- Couhert, C.; Salvador, S.; Commandré, J.-M. Impact of Torrefaction on Syngas Production from Wood. Fuel 2009, 88, 2286–2290. [Google Scholar] [CrossRef]

- Hrbek, J. Status Report on Thermal Gasification of Biomass and Waste 2021, IEA Bioenergy Task 33; IEA Bioenergy: Paris, France, 2022; pp. 1–69. [Google Scholar]

- Sheth, P.N.; Babu, B.V. Experimental Studies on Producer Gas Generation from Wood Waste in a Downdraft Biomass Gasifier. Bioresour. Technol. 2009, 100, 3127–3133. [Google Scholar] [CrossRef]

- Siedlecki, M.; De Jong, W.; Verkooijen, A.H.M. Fluidized Bed Gasification as a Mature and Reliable Technology for the Production of Bio-Syngas and Applied in the Production of Liquid Transportation Fuels—A Review. Energies 2011, 4, 389–434. [Google Scholar] [CrossRef]

- Morris, J.D.; Daood, S.S.; Chilton, S.; Nimmo, W. Mechanisms and Mitigation of Agglomeration during Fluidized Bed Combustion of Biomass: A Review. Fuel 2018, 230, 452–473. [Google Scholar] [CrossRef]

- Gray, D. Chapter 8—Major Gasifiers for IGCC Systems. In Integrated Gasification Combined Cycle (IGCC) Technologies; Wang, T., Stiegel, G., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 305–355. [Google Scholar] [CrossRef]

- Corella, J.; Toledo, J.M.; Molina, G. A Review on Dual Fluidized-Bed Biomass Gasifiers. Ind. Eng. Chem. Res. 2007, 46, 6831–6839. [Google Scholar] [CrossRef]

- Latif, A. A Study of the Design of Fluidized Bed Reactors for Biomass Gasification. Doctoral Thesis, University of London, London, UK, 1999. Available online: https://discovery.ucl.ac.uk/id/eprint/1349342/ (accessed on 19 June 2025).

- Zhao, Y.; Sun, S.; Zhou, H.; Sun, R.; Tian, H.; Luan, J.; Qian, J. Experimental Study on Sawdust Air Gasification in an Entrained-Flow Reactor. Fuel Process. Technol. 2010, 91, 910–914. [Google Scholar] [CrossRef]

- Chanthakett, A.; Arif, M.T.; Khan, M.M.K.; Oo, A.M.T. Performance Assessment of Gasification Reactors for Sustainable Management of Municipal Solid Waste. J. Environ. Manag. 2021, 291, 112661. [Google Scholar] [CrossRef]

- Guo, X.; Dai, Z.; Gong, X.; Chen, X.; Liu, H.; Wang, F.; Yu, Z. Performance of an Entrained-Flow Gasification Technology of Pulverized Coal in Pilot-Scale Plant. Fuel Process. Technol. 2007, 88, 451–459. [Google Scholar] [CrossRef]

- Babler, M.U.; Phounglamcheik, A.; Amovic, M.; Ljunggren, R.; Engvall, K. Modeling and Pilot Plant Runs of Slow Biomass Pyrolysis in a Rotary Kiln. Appl. Energy 2017, 207, 123–133. [Google Scholar] [CrossRef]

- Molino, A.; Iovane, P.; Donatelli, A.; Braccio, G.; Chianese, S.; Musmarra, D. Steam gasification of refuse-derived fuel in a rotary kiln pilot plant: Experimental tests. Chem. Eng. Trans. 2013, 32, 337–342. [Google Scholar] [CrossRef]

- Willis, K.P.; Osada, S.; Willerton, K.L. Plasma Gasification: Lessons Learned at Eco-Valley WTE Facility. In Proceedings of the 18th Annual North American Waste-to-Energy Conference, Orlando, FL, USA, 11–13 May 2010. [Google Scholar] [CrossRef]

- Pang, Y.; Bahr, L.; Fendt, P.; Zigan, L.; Will, S.; Hammer, T.; Baldauf, M.; Fleck, R.; Müller, D.; Karl, J. Plasma-Assisted Biomass Gasification with Focus on Carbon Conversion and Reaction Kinetics Compared to Thermal Gasification. Energies 2018, 11, 1302. [Google Scholar] [CrossRef]

- Rueda, Y.G.; Helsen, L. The Role of Plasma in Syngas Tar Cracking. Biomass Convers. Biorefinery 2020, 10, 857–871. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Yin, X.L.; Wu, C.Z. A Review on the Development and Commercialization of Biomass Gasification Technologies in China. Renew. Sustain. Energy Rev. 2004, 8, 565–580. [Google Scholar] [CrossRef]

- Jafri, Y.; Waldheim, L.; Lundgren, J. Emerging Gasification Technologies for Waste & Biomass; IEA Bioenergy: Paris, France, 2020; pp. 3–80. [Google Scholar]

- Devi, L.; Ptasinski, K.J.; Janssen, F.J.J.G.; van Paasen, S.V.B.; Bergman, P.C.A.; Kiel, J.H.A. Catalytic Decomposition of Biomass Tars: Use of Dolomite and Untreated Olivine. Renew. Energy 2005, 30, 565–587. [Google Scholar] [CrossRef]

- Arpia, A.A.; Nguyen, T.-B.; Chen, W.-H.; Dong, C.-D.; Ok, Y.S. Microwave-Assisted Gasification of Biomass for Sustainable and Energy-Efficient Biohydrogen and Biosyngas Production: A State-of-the-Art Review. Chemosphere 2022, 287, 132014. [Google Scholar] [CrossRef] [PubMed]

- HelioStorm. Heartland. Available online: https://www.oneheartland.com/heliostorm/ (accessed on 20 June 2025).

- Guo, L.; Cao, C.; Lu, Y.; Guo, L.; Cao, C.; Lu, Y. Chapter 9. Supercritical Water Gasification of Biomass and Organic Wastes. In Biomass; IntechOpen: London, UK, 2010. [Google Scholar] [CrossRef]

- Murugan, P.C.; Joseph Sekhar, S. Investigation on the Yield of Producer Gas from Tamarind Shell (Tamarindus indica) as Feedstock in an Imbert Type Biomass Gasifier. Fuel 2021, 292, 120310. [Google Scholar] [CrossRef]

- Havilah, P.R.; Sharma, A.K.; Govindasamy, G.; Matsakas, L.; Patel, A. Biomass Gasification in Downdraft Gasifiers: A Technical Review on Production, Up-Gradation and Application of Synthesis Gas. Energies 2022, 15, 3938. [Google Scholar] [CrossRef]

- Manali, A.; Pothoulaki, A.; Gikas, P. The State of the Art in Biosolids Gasification. J. Environ. Manag. 2024, 364, 121385. [Google Scholar] [CrossRef]

- Thomson, R.; Kwong, P.; Ahmad, E.; Nigam, K.D.P. Clean Syngas from Small Commercial Biomass Gasifiers; a Review of Gasifier Development, Recent Advances and Performance Evaluation. Int. J. Hydrogen Energy 2020, 45, 21087–21111. [Google Scholar] [CrossRef]

- Ahrenfeldt, J.; Thomsen, T.P.; Henriksen, U.; Clausen, L.R. Biomass Gasification Cogeneration—A Review of State of the Art Technology and Near Future Perspectives. Applied thermal engineering 2013, 50, 1407–1417. [Google Scholar] [CrossRef]

- Crouse, D.; Gangwal, S.; Knudsen, S.; Munson, C.; Shilling, N.; Slettehaugh, B.; Sorensen, J.; Turk, B.; Ramezan, M.; Lyons, D.; et al. Guidelines/Handbook for the Design of Modular Gasification Systems; U.S. Department of Energy: Washington, DC, USA, 2022.

- Arregi, A.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Evaluation of Thermochemical Routes for Hydrogen Production from Biomass: A Review. Energy Convers. Manag. 2018, 165, 696–719. [Google Scholar] [CrossRef]

- Asadullah, M. Barriers of Commercial Power Generation Using Biomass Gasification Gas: A Review. Renew. Sustain. Energy Rev. 2014, 29, 201–215. [Google Scholar] [CrossRef]

- Ayub, Y.; Ren, J.; Shi, T. Exploring Gasification Process and Technology for Biomass-Waste Utilization: A Comprehensive Review on the Path to Sustainable Energy. Process Saf. Environ. Prot. 2024, 188, 1489–1501. [Google Scholar] [CrossRef]

- Bridgwater, A.V. The Technical and Economic Feasibility of Biomass Gasification for Power Generation. Fuel 1995, 74, 631–653. [Google Scholar] [CrossRef]

- Ciliberti, C.; Biundo, A.; Albergo, R.; Agrimi, G.; Braccio, G.; de Bari, I.; Pisano, I. Syngas Derived from Lignocellulosic Biomass Gasification as an Alternative Resource for Innovative Bioprocesses. Processes 2020, 8, 1567. [Google Scholar] [CrossRef]

- Couto, N.; Rouboa, A.; Silva, V.; Monteiro, E.; Bouziane, K. Influence of the Biomass Gasification Processes on the Final Composition of Syngas. Energy Procedia 2013, 36, 596–606. [Google Scholar] [CrossRef]

- Faizan, M.; Song, H. Critical Review on Catalytic Biomass Gasification: State-of-Art Progress, Technical Challenges, and Perspectives in Future Development. J. Clean. Prod. 2023, 408, 137224. [Google Scholar] [CrossRef]

- Fang, Z. (Ed.) Pretreatment Techniques for Biofuels and Biorefineries; Green Energy and Technology; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Heidenreich, S.; Foscolo, P.U. New Concepts in Biomass Gasification. Prog. Energy Combust. Sci. 2015, 46, 72–95. [Google Scholar] [CrossRef]

- Khlifi, S.; Pozzobon, V.; Lajili, M. A Comprehensive Review of Syngas Production, Fuel Properties, and Operational Parameters for Biomass Conversion. Energies 2024, 17, 3646. [Google Scholar] [CrossRef]

- Kumar, J.; Vyas, S. Comprehensive Review of Biomass Utilization and Gasification for Sustainable Energy Production. Environ. Dev. Sustain. 2025, 27, 1–40. [Google Scholar] [CrossRef]

- Makwana, J.; Dhass, A.D.; Ramana, P.V.; Sapariya, D.; Patel, D. An Analysis of Waste/Biomass Gasification Producing Hydrogen-Rich Syngas: A Review. Int. J. Thermofluids 2023, 20, 100492. [Google Scholar] [CrossRef]

- Mednikov, A.S. A Review of Technologies for Multistage Wood Biomass Gasification. Therm. Eng. 2018, 65, 531–546. [Google Scholar] [CrossRef]

- Molino, A.; Larocca, V.; Chianese, S.; Musmarra, D. Biofuels Production by Biomass Gasification: A Review. Energies 2018, 11, 811. [Google Scholar] [CrossRef]

- Ramalingam, S.; Rajendiran, B.; Subramiyan, S. Recent Advances in the Performance of Co-Current Gasification Technology: A Review. Int. J. Hydrogen Energy 2020, 45, 230–262. [Google Scholar] [CrossRef]

- Samiran, N.A.; Jaafar, M.N.M.; Ng, J.-H.; Lam, S.S.; Chong, C.T. Progress in Biomass Gasification Technique—With Focus on Malaysian Palm Biomass for Syngas Production. Renew. Sustain. Energy Rev. 2016, 62, 1047–1062. [Google Scholar] [CrossRef]

- Sanni, S.E.; Oni, B.A.; Okoro, E.E. Heterogeneous Catalytic Gasification of Biomass to Biofuels and Bioproducts: A Review. Korean J. Chem. Eng. 2024, 41, 965–999. [Google Scholar] [CrossRef]

- Shahabuddin, M.; Krishna, B.B.; Bhaskar, T.; Perkins, G. Advances in the Thermo-Chemical Production of Hydrogen from Biomass and Residual Wastes: Summary of Recent Techno-Economic Analyses. Bioresour. Technol. 2020, 299, 122557. [Google Scholar] [CrossRef]

- Sharma, P.; Gupta, B.; Pandey, M.; Singh Bisen, K.; Baredar, P. Downdraft Biomass Gasification: A Review on Concepts, Designs Analysis, Modelling and Recent Advances. Mater. Today Proc. 2021, 46, 5333–5341. [Google Scholar] [CrossRef]

- Singh, D.K.; Raj, R.; Tirkey, J.V.; Jena, P.; Parthasarathy, P.; Mckay, G.; Al-Ansari, T. Progress and Utilization of Biomass Gasification for Decentralized Energy Generation: An Outlook & Critical Review. Environ. Technol. Rev. 2023, 12, 1–36. [Google Scholar] [CrossRef]

- Solarte-Toro, J.C.; González-Aguirre, J.A.; Poveda Giraldo, J.A.; Cardona Alzate, C.A. Thermochemical Processing of Woody Biomass: A Review Focused on Energy-Driven Applications and Catalytic Upgrading. Renew. Sustain. Energy Rev. 2021, 136, 110376. [Google Scholar] [CrossRef]

- Speight, J.G. Handbook of Gasification Technology: Science, Processes, and Applications; Wiley: Hoboken, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Susastriawan, A.A.P.; Saptoadi, H.; Purnomo. Small-Scale Downdraft Gasifiers for Biomass Gasification: A Review. Renew. and Sustain. Energy Rev. 2017, 76, 989–1003. [Google Scholar] [CrossRef]

- Syed-Hassan, S.S.A.; Wang, Y.; Hu, S.; Su, S.; Xiang, J. Thermochemical Processing of Sewage Sludge to Energy and Fuel: Fundamentals, Challenges and Considerations. Renew. Sustain. Energy Rev. 2017, 80, 888–913. [Google Scholar] [CrossRef]

- You, S.; Ok, Y.S.; Tsang, D.C.W.; Kwon, E.E.; Wang, C.-H. Towards Practical Application of Gasification: A Critical Review from Syngas and Biochar Perspectives. Crit. Rev. Environ. Sci. Technol. 2018, 48, 1165–1213. [Google Scholar] [CrossRef]

- Eberhard, M.; Santo, U.; Michelfelder, B.; Günther, A.; Weigand, P.; Matthes, J.; Waibel, P.; Hagenmeyer, V.; Kolb, T. The Bioliq® Entrained-Flow Gasifier—A Model for the German Energiewende. ChemBioEng Rev. 2020, 7, 106–118. [Google Scholar] [CrossRef]

- Ryzhkov, A.F.; Bogatova, T.F.; Lingyan, Z.; Osipov, P.V. Development of Entrained-Flow Gasification Technologies in the Asia-Pacific Region (Review). Therm. Eng. 2016, 63, 791–801. [Google Scholar] [CrossRef]

- Watanabe, H.; Kurose, R. Modeling and Simulation of Coal Gasification on an Entrained Flow Coal Gasifier. Adv. Powder Technol. 2020, 31, 2733–2741. [Google Scholar] [CrossRef]

- Frolov, S.M. Organic Waste Gasification: A Selective Review. Fuels 2021, 2, 556–650. [Google Scholar] [CrossRef]

- Elhambakhsh, A.; Van Duc Long, N.; Lamichhane, P.; Hessel, V. Recent Progress and Future Directions in Plasma-Assisted Biomass Conversion to Hydrogen. Renew. Energy 2023, 218, 119307. [Google Scholar] [CrossRef]

- Fabry, F.; Rehmet, C.; Rohani, V.; Fulcheri, L. Waste Gasification by Thermal Plasma: A Review. Waste Biomass Valorization 2013, 4, 421–439. [Google Scholar] [CrossRef]

- Indrawan, N.; Kumar, A.; Kumar, S. Recent Advances in Power Generation Through Biomass and Municipal Solid Waste Gasification. In Coal and Biomass Gasification: Recent Advances and Future Challenges; De, S., Agarwal, A.K., Moholkar, V.S., Thallada, B., Eds.; Springer: Singapore, 2018; pp. 369–401. [Google Scholar] [CrossRef]

- Nagar, V.; Kaushal, R. A Review of Recent Advancement in Plasma Gasification: A Promising Solution for Waste Management and Energy Production. Int. J. Hydrogen Energy 2024, 77, 405–419. [Google Scholar] [CrossRef]

- Sanlisoy, A.; Carpinlioglu, M.O. A Review on Plasma Gasification for Solid Waste Disposal. Int. J. Hydrogen Energy 2017, 42, 1361–1365. [Google Scholar] [CrossRef]

- Seo, M.W.; Lee, S.H.; Nam, H.; Lee, D.; Tokmurzin, D.; Wang, S.; Park, Y.-K. Recent Advances of Thermochemical Conversion Processes for Biorefinery. Bioresour. Technol. 2022, 343, 126109. [Google Scholar] [CrossRef]

- Aranda Usón, A.; López-Sabirón, A.M.; Ferreira, G.; Llera Sastresa, E. Uses of Alternative Fuels and Raw Materials in the Cement Industry as Sustainable Waste Management Options. Renew. Sustain. Energy Rev. 2013, 23, 242–260. [Google Scholar] [CrossRef]

- Lombardi, L.; Carnevale, E.; Corti, A. A Review of Technologies and Performances of Thermal Treatment Systems for Energy Recovery from Waste. Waste Manag. 2015, 37, 26–44. [Google Scholar] [CrossRef] [PubMed]

- Hutahaean, J.; Cilliers, J.; Brito-Parada, P.R. A Multicriteria Decision Framework for the Selection of Biomass Separation Equipment. Chem. Eng. Technol. 2018, 41, 2346–2357. [Google Scholar] [CrossRef] [PubMed]

- Verma, P.K.; Kumar, R.; Goindi, G.S. Evaluation of Material Handling Using MCDM Techniques: A Case Study. In Advances in Production and Industrial Engineering; Pandey, P.M., Kumar, P., Sharma, V., Eds.; Springer: Singapore, 2021; pp. 389–401. [Google Scholar] [CrossRef]

- Serna, J.; Díaz Martinez, E.N.; Narváez Rincón, P.C.; Camargo, M.; Gálvez, D.; Orjuela, Ÿ. Multi-Criteria Decision Analysis for the Selection of Sustainable Chemical Process Routes during Early Design Stages. Chem. Eng. Res. Des. 2016, 113, 28–49. [Google Scholar] [CrossRef]

- Osei, I.; Addo, A.; Kemausuor, F.; Abunde, F. Optimal Design of Gasifier Reactor for Crop Residues Gasification Using Integrated MCDM Techniques/QFD Approach. Ghana Min. J. 2023, 23, 44–58. [Google Scholar] [CrossRef]

- Kaneesamkandi, Z.; Rehman, A.U.; Usmani, Y.S.; Sayeed, A.; Alabi, H.S. Methodology for Selecting an Ideal Thermal Gasification Technique for Municipal Solid Waste Using Multi-Criteria Decision Analysis. Appl. Sci. 2023, 13, 12675. [Google Scholar] [CrossRef]

- Lourinho, G.; Alves, O.; Garcia, B.; Rijo, B.; Brito, P.; Nobre, C. Costs of Gasification Technologies for Energy and Fuel Production: Overview, Analysis, and Numerical Estimation. Recycling 2023, 8, 49. [Google Scholar] [CrossRef]

- IRENA. Renewable Power Generation Costs in 2018. Available online: https://www.irena.org/publications/2019/May/Renewable-power-generation-costs-in-2018 (accessed on 19 June 2025).

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic Assessment of Advanced Biofuel Production via Gasification Using Cost Data from the GoBiGas Plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- IRENA. Renewable Energy Cost Analysis—Biomass for Power Generation. Available online: https://www.irena.org/publications/2012/Jun/Renewable-Energy-Cost-Analysis---Biomass-for-Power-Generation (accessed on 19 June 2025).

- Börjesson, M.; Ahlgren, E.O. Biomass Gasification in Cost-Optimized District Heating Systems—A Regional Modelling Analysis. Energy Policy 2010, 38, 168–180. [Google Scholar] [CrossRef]

- Molino, A.; Chianese, S.; Musmarra, D. Biomass Gasification Technology: The State of the Art Overview. J. Energy Chem. 2016, 25, 10–25. [Google Scholar] [CrossRef]

- Göransson, K.; Söderlind, U.; He, J.; Zhang, W. Review of Syngas Production via Biomass DFBGs. Renew. Sustain. Energy Rev. 2011, 15, 482–492. [Google Scholar] [CrossRef]

- Zolfani, S.H.; Yazdani, M.; Pamucar, D.; Zarate, P. A VIKOR and TOPSIS focused reanalysis of the MADM methods based on logarithmic normalization. Facta Univ. Ser. Mech. Eng. 2020, 18, 341–355. [Google Scholar] [CrossRef]

- Anes, V.; Abreu, A. Adaptive Cluster-Based Normalization for Robust TOPSIS in Multicriteria Decision-Making. Appl. Sci. 2025, 15, 4044. [Google Scholar] [CrossRef]

- Vafaei, N.; Ribeiro, R.A.; Matos, L.M.C. Data Normalisation Techniques in Decision Making: Case Study with TOPSIS Method. Int. J. Inf. Decis. Sci. 2018, 10, 19. [Google Scholar] [CrossRef]

- Sarraf, R.; McGuire, M.P. Effect of Normalization on TOPSIS and Fuzzy TOPSIS. In 2021 Proceedings of the Conference on Information Systems Applied Research; ISCAP (Information Systems and Computing Academic Professionals): Washington DC, USA, 2021; Volume 14, pp. 1–11. [Google Scholar]

- Mukhametzyanov, I. Specific Character of Objective Methods for Determining Weights of Criteria in MCDM Problems: Entropy, CRITIC and SD. Decis. Mak. Appl. Manag. Eng. 2021, 4, 76–105. [Google Scholar] [CrossRef]

- Atanasova, T.; Lapevski, M.; Timovski, R. Analytical Hierarchical Process (AHP) Method Application in the Process of Selection and Evaluation. In Proceedings of the International Scientific Conference UNITECH’2024, Gabrovo, Bulgaria, 21–22 November 2024. [Google Scholar]

- Ishizaka, A.; Nemery, P. Multi-criteria decision analysis: Methods and software. Wiley: Chichester, UK, 2013.

- EN 16723-1:2016; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 1: Specifications for Biomethane for Injection in the Natural Gas Network. iTeh Standards: Toronto, ON, Canada, 2016. Available online: https://standards.iteh.ai/catalog/standards/cen/55154af1-529b-407d-890c-b9e16c935898/en-16723-1-2016 (accessed on 19 June 2025).

- EN 16723-2:2017; Natural Gas and Biomethane for Use in Transport and Biomethane for Injection in the Natural Gas Network—Part 2: Automotive Fuels Specification. iTeh Standards: Toronto, ON, Canada, 2017. Available online: https://standards.iteh.ai/catalog/standards/cen/bb646037-ec22-4cd4-aad4-902ea1b8e0d5/en-16723-2-2017 (accessed on 19 June 2025).

- Patil, S.C.; Schulze-Netzer, C.; Korpås, M. Current and Emerging Waste-to-Energy Technologies: A Comparative Study with Multi-Criteria Decision Analysis. Smart Energy 2024, 16, 100157. [Google Scholar] [CrossRef]

- Shahnazari, A.; Rafiee, M.; Rohani, A.; Bhushan Nagar, B.; Ebrahiminik, M.A.; Aghkhani, M.H. Identification of Effective Factors to Select Energy Recovery Technologies from Municipal Solid Waste Using Multi-Criteria Decision Making (MCDM): A Review of Thermochemical Technologies. Sustain. Energy Technol. Assess. 2020, 40, 100737. [Google Scholar] [CrossRef]

- Rubio-Aliaga, A.; García-Cascales, M.S.; Sánchez-Lozano, J.M.; Molina-Garcia, A. MCDM-Based Multidimensional Approach for Selection of Optimal Groundwater Pumping Systems: Design and Case Example. Renew. Energy 2021, 163, 213–224. [Google Scholar] [CrossRef]

| Technology | Advantages | Disadvantages |

|---|---|---|

| Fixed-bed |

|

|

| Fluidized-bed |

|

|

| Entrained flow |

|

|

| Rotary kiln |

|

|

| Plasma |

|

|

| Parameter | Downdraft [21,22,23,37,52,58,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99] | Updraft [21,22,23,37,52,58,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100] | BFB [21,28,37,38,52,58,73,75,77,79,80,81,82,83,84,86,88,90,94,96,97,100,101,102] | CFB [21,28,37,38,52,58,72,73,74,75,77,79,84,86,88,90,94,96,97,100,101,102] | Entrained Flow [22,38,54,60,76,78,79,81,82,83,85,86,91,92,96,98,99,103,104,105,106] | Plasma [38,60,76,86,87,90,92,98,99,107,108,109,110,111,112] | Rotary Kiln [38,60,75,78,79,82,90,92,107,113,114,115] |

|---|---|---|---|---|---|---|---|

| Capital cost | Low | Low | Moderate | High | Very high | Very high | Low |

| Operating Cost | Low | Low | Low | High | Very high | Very high | High |

| Biomass flexibility | Medium | High | Medium | Medium | Low | Very high | Very high |

| Feedstock size flexibility (mm) | 10–100 | 2–100 | 0.2–40 | 0.2–20 | 0.05–1 | Any | any |

| Moisture flexibility (%w/w) | 15–40 | 15–60 | 10–55 | 9–55 | 10–60 | Any | any |

| Technical complexity | Simple | Simple | Medium | Medium | high | Very high | Medium |

| Feed rate (ton/h) | 0.1–13 | 0.2–10 | 0.5–73 | 2–39 | 20–125 | 2–21 | 1–17 |

| Syngas yield (dry Nm3/kg-biomass) | 0.4–2.6 | 0.5–1.3 | 0.6–3.8 | 1.0–2.6 | 0.5–0.8 | 1.0–2.6 | 0.8–2.0 |

| Cold gas efficiency (%) | 30–97 | 20–95 | 57–96 | 50–98 | 30–90 | 41–98 | 47–67 |

| H2/CO molar ratio | 0.3–3.7 | 0.7–3.9 | 0.2–3.7 | 0.4–4.6 | 0.2–3.9 | 0.2–3.9 | 1.6–3.8 |

| CO (%v/v) | 8–53 | 9–40 | 1–36 | 2–40 | 11–64 | 4–54 | 2–25 |

| H2 (%v/v) | 7–30 | 1–60 | 3–60 | 5–56 | 5–58 | 10–87 | 40–67 |

| CO2 (%v/v) | 4–16 | 2–42 | 8–30 | 12–50 | 7–37 | 4–57 | 5–25 |

| Tar yield (g/Nm3) | 0.01–6 | 1–200 | 0.5–40 | 0.27–30 | 0–30 | 0–0.543 | 1.2–6 |

| CO2eq (kg CO2eq/Ton) | 150 | 324 | 236 | 226 | 65 | 10 | 524 |

| Particulate matter (mg/Nm3) | 0.7 | 0.7 | 1.0 | 1.0 | 2.5 | 2.4 | 1.0 |

| Subgroup | Criteria | Units |

|---|---|---|

| Economical | Capital cost | Scored |

| Operating Cost | Scored | |

| Feedstock flexibility | Flexibility-moisture | %w/w |

| Biomass flexibility | Scored | |

| Flexibility-size | mm | |

| Equipment features | Technical complexity | Scored |

| Capacity | Feed rate | ton biomass/h |

| Syngas production rate | Nm3 syngas/h | |

| Process performance | Syngas yield | Nm3 dry syngas /kg biomass |

| Cold gas efficiency | % | |

| Syngas quality | Tar yield | Scored |

| CO2 Concentration in syngas | %v/v | |

| H2/CO molar ratio | mol H2/mol CO | |

| Environmental | CO2eq | kg CO2eq/Ton |

| Particulate matter | mg/Nm3 |

| Criteria | Economical | Feedstock Flexibility | Equipment Features | Process Performance | Syngas Quality | Capacity | Environmental |

|---|---|---|---|---|---|---|---|

| Economical | 1 | 8 | 8 | 1 | 1/2 | 4 | 3 |

| Feedstock flexibility | 1 | 2 | 1/8 | 1/8 | 1 | 1/2 | |

| Equipment features | 1 | 1/8 | 1/9 | 1 | 1/2 | ||

| Process performance | 1 | 1/2 | 4 | 6 | |||

| Syngas quality | 1 | 7 | 7 | ||||

| Capacity | 1 | 1/2 | |||||

| Environmental | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardona-Giraldo, J.; Velandia, L.C.G.; Marin, D.; Argel, A.; García-Freites, S.; Sanjuan, M.; Acosta, D.; Aristizabal, A.; Builes, S.; Botero, M.L. Review of Biomass Gasifiers: A Multi-Criteria Approach. Gases 2025, 5, 22. https://doi.org/10.3390/gases5040022

Cardona-Giraldo J, Velandia LCG, Marin D, Argel A, García-Freites S, Sanjuan M, Acosta D, Aristizabal A, Builes S, Botero ML. Review of Biomass Gasifiers: A Multi-Criteria Approach. Gases. 2025; 5(4):22. https://doi.org/10.3390/gases5040022

Chicago/Turabian StyleCardona-Giraldo, Julián, Laura C. G. Velandia, Daniel Marin, Alejandro Argel, Samira García-Freites, Marco Sanjuan, David Acosta, Adriana Aristizabal, Santiago Builes, and Maria L. Botero. 2025. "Review of Biomass Gasifiers: A Multi-Criteria Approach" Gases 5, no. 4: 22. https://doi.org/10.3390/gases5040022

APA StyleCardona-Giraldo, J., Velandia, L. C. G., Marin, D., Argel, A., García-Freites, S., Sanjuan, M., Acosta, D., Aristizabal, A., Builes, S., & Botero, M. L. (2025). Review of Biomass Gasifiers: A Multi-Criteria Approach. Gases, 5(4), 22. https://doi.org/10.3390/gases5040022