Reducing Greenhouse Gas Emission through Energy-Saving Technologies for Heating Modular Buildings †

Abstract

:1. Introduction

2. Materials and Methods

3. Computations and Results

4. Conclusions

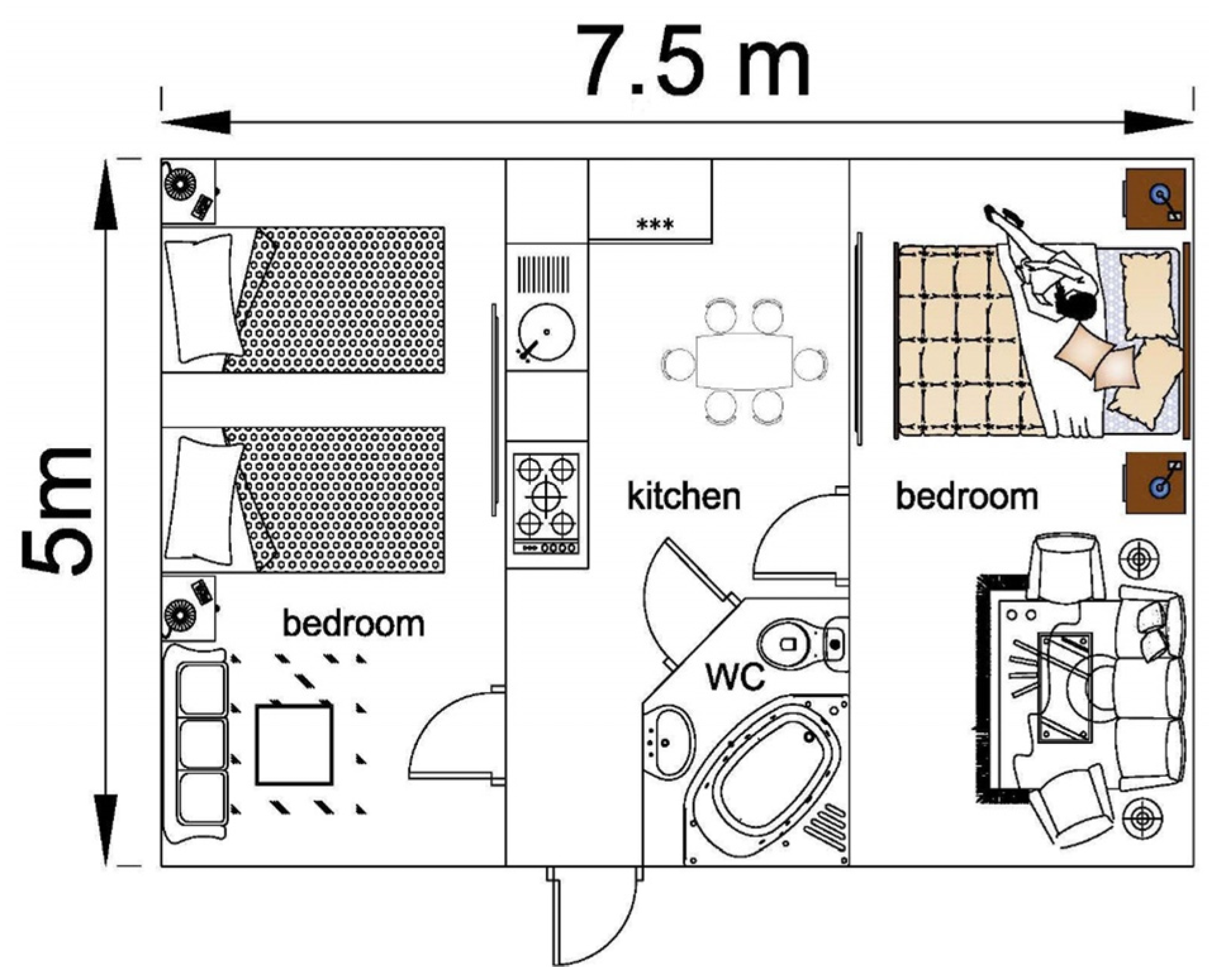

- The possibility of using modular buildings for residential and public needs is considered. Due to the peculiarities of technology and the use of thermal insulation materials, such structures are erected in a short time with the help of ready-made modules, which are characterized by simplicity and speed of installation.

- Condensation of water vapor in the protection layer of the house was checked.

- The comparative analysis of energy consumption for two variants of heat supply of the modular house is carried out.

- The total annual reduction of greenhouse gas emissions is obtained, taking into account the proposed method of heat supply of the building.

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

References

- Huang, C.J.; Krawczyk, R.; Huang, C.J. A Choice Model of Consumer Participatory Design for Modular Houses. In Proceedings of the Future 25th eCAADe Conference Proceedings, Frankfurt am Main, Germany, 26–29 September 2007; pp. 679–686. [Google Scholar]

- Marza, C.; Corsiuc, G.; Ana-Maria, G. Study on modular houses design. J. Ind. Des. Eng. Graph. 2019, 14, 75–78. [Google Scholar]

- Zhelykh, V.M.; Furdas, Y.V.; Shapoval, S.P. Selection of the optimal thickness of thermal insulation of modular buildings based on multicriteria analysis. In Proceedings of the International Scientific-Practical Conference “Problems of Modern Heat Energy, Dedicated to the 100th Anniversary of Professor Dragan Kharanov.”-Kyiv -2020. “Енергетика і автoматика”, Volgograd, Russia, 23–29 May 2020. [Google Scholar] [CrossRef]

- Zhelykh, V.; Furdas, Y.; Kozak, K.; Rebman, M. Research on the aerodynamic characteristics of zero-energy house modular type. Theory Build. Pract. 2020, 2, 16–22. [Google Scholar] [CrossRef]

- Ulewicz, M.; Zhelykh, V.; Furdas, Y.; Kozak, K. Assessment of the Economic Feasibility of Using Alternative Energy Sources in Ukraine. In Proceedings of the International Scientific Conference EcoComfort and Current Issues of Civil Engineering, LNCE 100; Springer: Cham, Switzerland, 2021; pp. 482–489. [Google Scholar] [CrossRef]

- Shapoval, S.; Zhelykh, V.; Venhryn, I.; Kozak, K. Simulation of Thermal Processes in the Solar Collector Which Is Combined with External Fence of an Energy Efficient House. Lect. Notes Civ. Eng. 2020, 47, 510–515. [Google Scholar]

- Ulewicz, M.; Zhelykh, V.; Kozak, K.; Furdas, Y. Application of Thermosiphon Solar Collectors for Ventilation of Premises. Lect. Notes Civ. Eng. 2020, 47, 180–187. [Google Scholar]

- Adamski, M. Longitudinal spiral recuperators in ventilation systems of healthy buildings. In Proceedings of the 8th International Conference and Exhibition on Healthy Buildings 2006 (HB 2006), Lisboa, Portugal, 4–8 June 2006; de Oliveira Fernandes, E., Rosado Pinto, J., Gameiro da Silva, M., Eds.; Curran Associates, Inc.: Red Hook, NY, USA, 2006; Volume 4, pp. 341–344. [Google Scholar]

- Adamski, M. Mini longitudinal flow spiral recuperator. In Proceedings of the Healthy Buildings Europe 2017, Lublin, Poland, 2–5 July 2017; Curran Associates, Inc.: Red Hook, NY, USA, 2017; Volume 1, pp. 474–475. [Google Scholar]

- Adamski, M. Poradnik oszczędzania energii w mikro i małych przedsiębiorstwach. In Energijos taupymo smulkiose ir mikroimonese vadovas; FOTON Agnieszka Morysewicz: Suwałki, Poland, 2014; ISBN 978-83-937279-6-4. [Google Scholar]

| Thickness, mm | Weight, kg/m2 | Thermal Conductivity Resistance R (m2K/W) | Fire Resistance | λ, W/mK |

|---|---|---|---|---|

| 200 | 16.9 | 8.51 | EI-15 | 0.022 |

| Estimated heat consumption—house | 79.88 kWh/m2 |

| Maximum allowable heat consumption—Emax | 242.46 kWh/m2 |

| Compliance with norms | Yes |

| Units | Location | |

|---|---|---|

| Latitude | 49.8 | |

| Longitude | 24.0 | |

| Heaven | Cool–wet | |

| Altitude | m | 323 |

| Estimated heating temperature | °C | −19.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhelykh, V.; Furdas, Y.; Adamski, M.; Rebman, M. Reducing Greenhouse Gas Emission through Energy-Saving Technologies for Heating Modular Buildings. Environ. Sci. Proc. 2021, 9, 10. https://doi.org/10.3390/environsciproc2021009010

Zhelykh V, Furdas Y, Adamski M, Rebman M. Reducing Greenhouse Gas Emission through Energy-Saving Technologies for Heating Modular Buildings. Environmental Sciences Proceedings. 2021; 9(1):10. https://doi.org/10.3390/environsciproc2021009010

Chicago/Turabian StyleZhelykh, Vasyl, Yurii Furdas, Mariusz Adamski, and Maksym Rebman. 2021. "Reducing Greenhouse Gas Emission through Energy-Saving Technologies for Heating Modular Buildings" Environmental Sciences Proceedings 9, no. 1: 10. https://doi.org/10.3390/environsciproc2021009010

APA StyleZhelykh, V., Furdas, Y., Adamski, M., & Rebman, M. (2021). Reducing Greenhouse Gas Emission through Energy-Saving Technologies for Heating Modular Buildings. Environmental Sciences Proceedings, 9(1), 10. https://doi.org/10.3390/environsciproc2021009010