Abstract

The research presented analyzes the influence exerted on the efficiency of a vertical axis cross-flow hydrokinetic microturbine by modifying the geometry of the channel by means of a deflector located upstream of the turbine. To this end, a series of laboratory tests were carried out in the water tunnel at the University of Oviedo, including the measurement of electrical power and the rotational speeds of the turbine. Additionally, the results obtained were used to adjust a computational fluid dynamics model that allows studying the pressure and velocity fields of the water, where to delve into the analysis of the different types of forces applied to the faces of the blades. The results clearly indicate that the baffle increases the turbine power output up to 250% more than without including any device in the water flow.

1. Introduction

The energy obtained from hydrokinetic turbines depends mainly on the speed of the water [1] and to achieve the profitability necessary to compete with conventional energy sources, speeds from 1–2 m/s are required [2]. Usually, the water that circulates through canals or riverbeds does not reach these magnitudes; thus, currently, obtaining energy in this type of installation does not represent a real alternative to the current energy system [3]. Considering that the energy potential available in the case of low-velocity water currents of rivers and channels is greater than 840 TWh [4], progress should be made towards the development of these types of turbines to improve their efficiency, even in operating conditions with very low speeds.

To date, different solutions have been studied to increase the efficiency of a turbine in a channel, such as developing control algorithms to guarantee the maximum power of the turbine at any time [5,6], study in depth the effects of the blockage caused by the turbine in [7,8,9], or the installation of flow modifiers to increase the performance of the turbine [10,11,12].

This study analyzes the consequences derived from placing a baffle plate in a channel, in order to direct the flow of water to improve the rotational speed of the turbine (N) and therefore, the power generated (P). The original idea for this app was inspired by the ancient Persian windmills of Nashtifan, northwestern Iran [13]. These windmills are considered the oldest in the world and have been in operation since the 7th century.

The mills are wooden turbines included in a structure that acts as a conduit for the wind. In order to maximize the wind power gain, its structure has a deflector plate that directs the wind to the area in favor of the rotation of the turbine [14].

2. Materials and Methods

Lab Tests

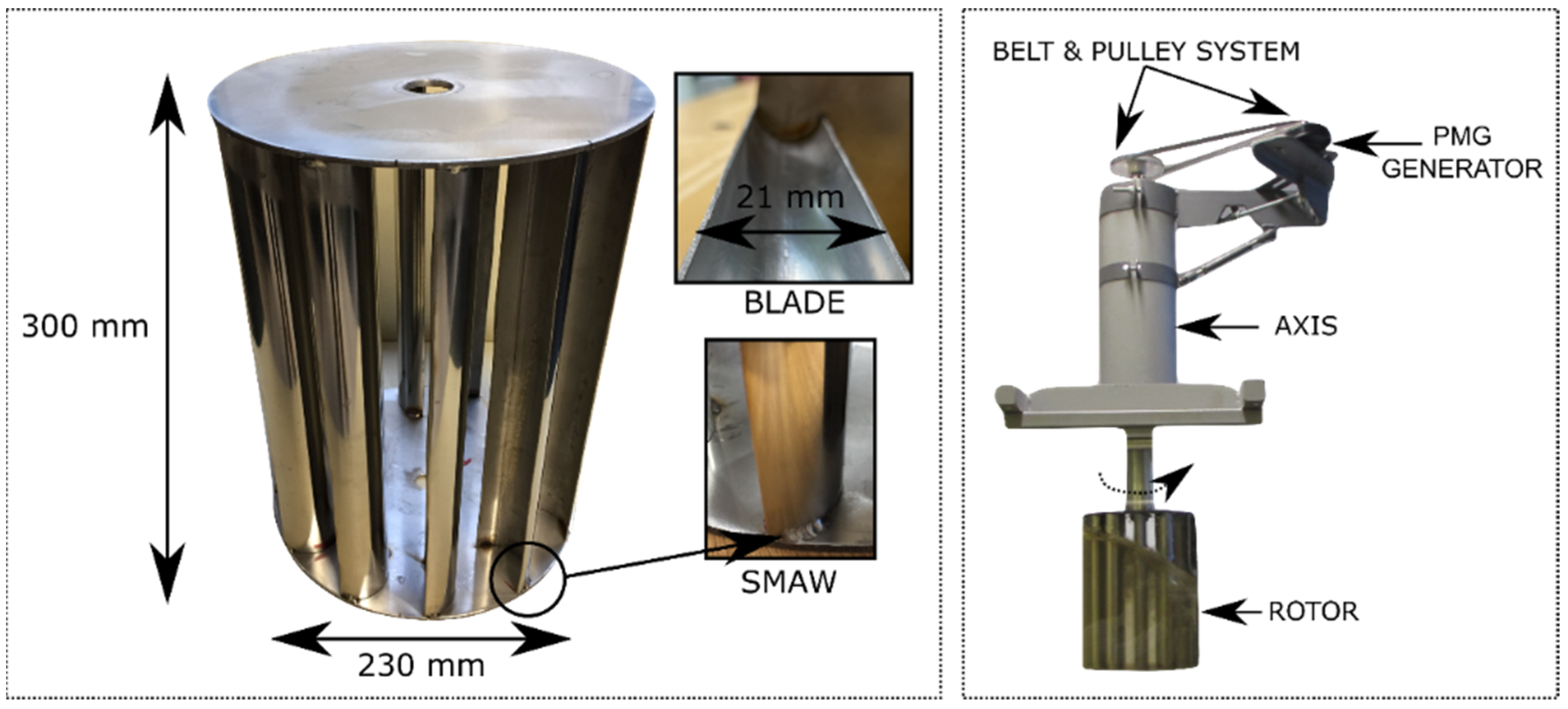

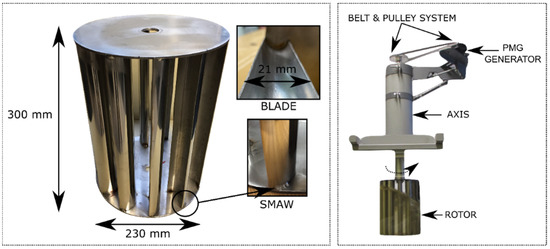

The elements used to carry out the tests were a vertical axis turbine, a hydrodynamic water tunnel, a baffle plate, and a control system. The turbine is made up of 12 semicircular stainless-steel blades, 0.3 m high and 0.23 m wide (Figure 1). The blades have an angular separation of 30° with a semicircular section of 21 mm in diameter. At the top of the shaft is a system of belts and pulleys designed to multiply the speed of rotation mechanically connected to a permanent magnet generator (PMG).

Figure 1.

Turbine design.

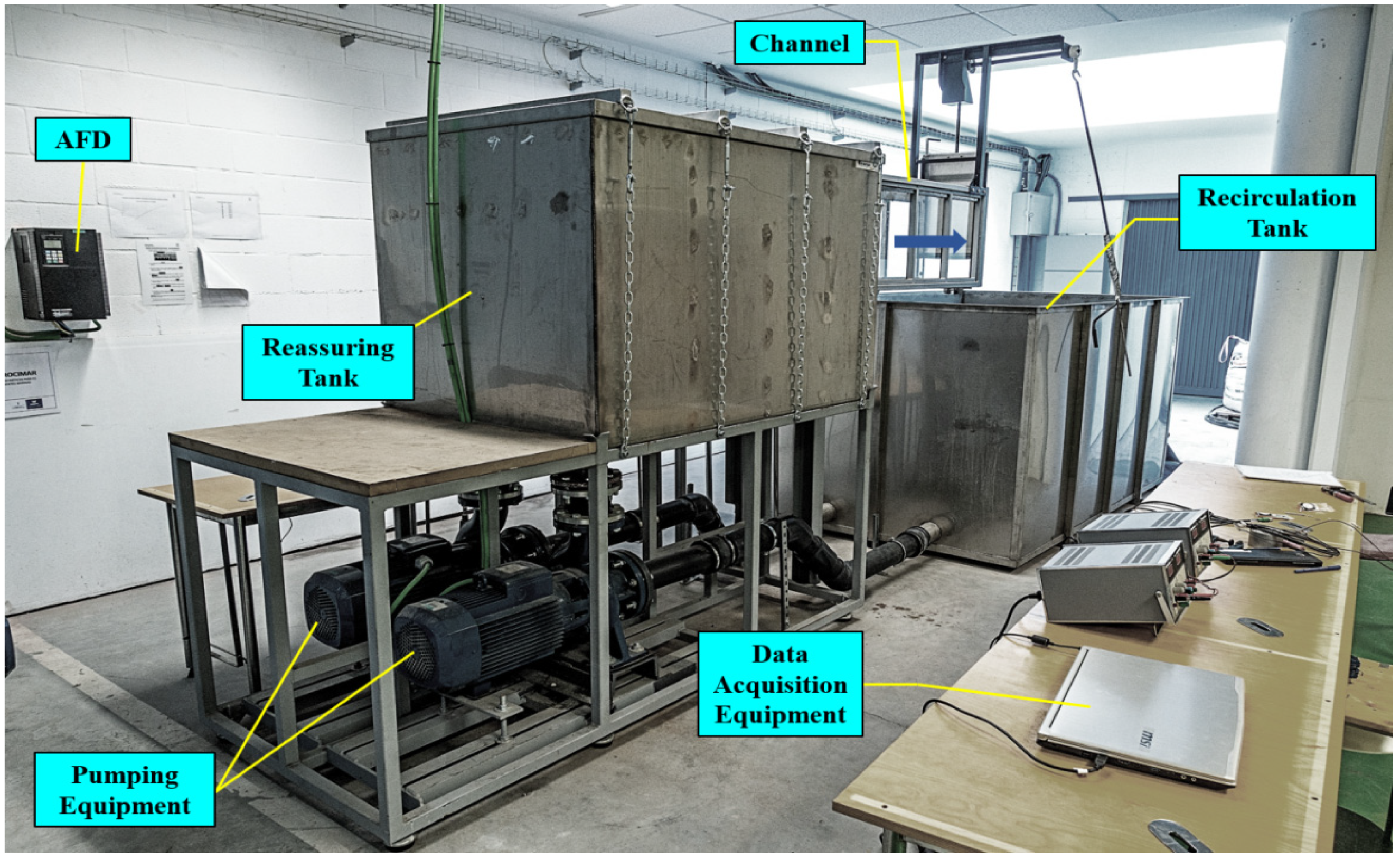

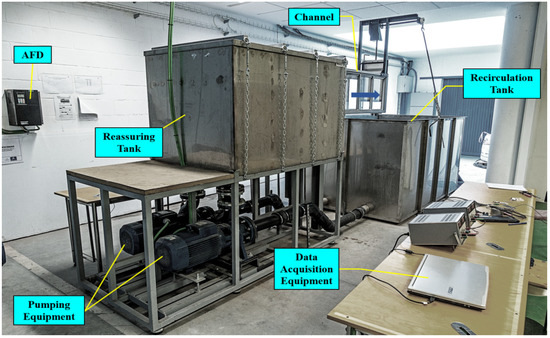

The experimental tests were carried out in a hydrodynamic water tunnel (HWT) (Figure 2) made up of tanks (reassuring and recirculation), hydraulic pumps, adjustable frequency drive (AFD), glass channel (0.5 m height, 0.3 m width and 1.5 length) and a monitoring–control system. This system, called TURbine Test Laboratory Equipment, TURTLE, is made up of ultrasonic water height sensors, an electronic board and a PC, which together with specially designed software allow the test to be carried out and the data obtained to be collected.

Figure 2.

Hydrodynamic water tunnel.

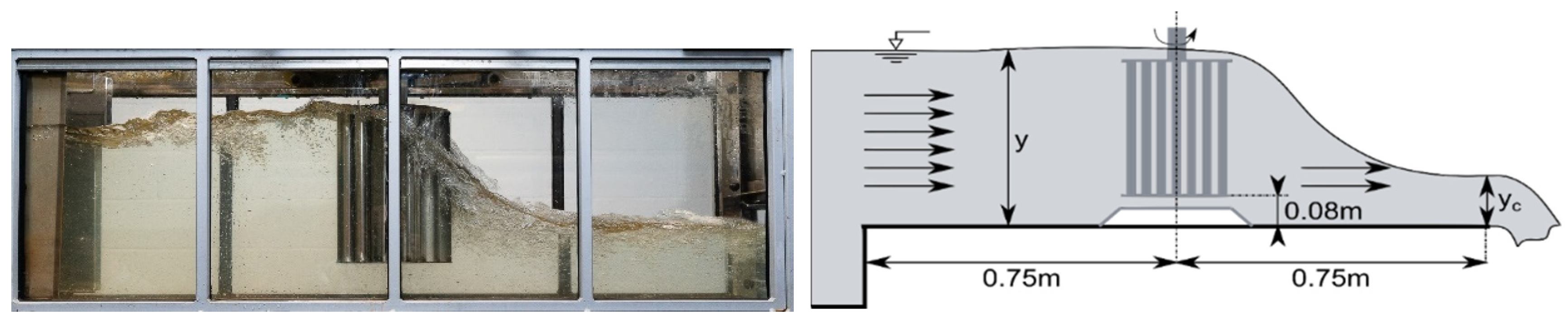

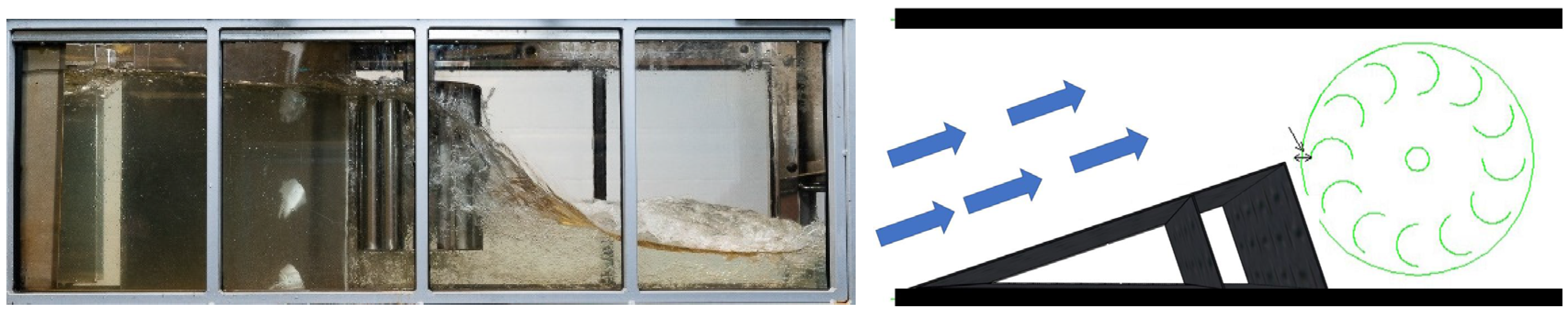

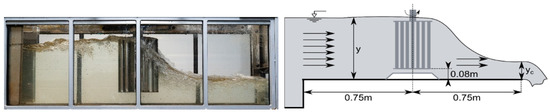

The tests were carried out with two flow rates: 0.055 m3/s (Q1) and 0.064 m3/s (Q2). First, the channel was tested without modifying its geometry (scenario 1) (Figure 3), and then, the baffle was added (scenario 2) (Figure 4).

Figure 3.

Scenario 1.

Figure 4.

Scenario 2.

The main elements of the test are located upstream of the discharge channel where the critical flow conditions are reached. Table 1 shows the main values of the operating ranges.

Table 1.

Operative ranges.

3. Lab Results

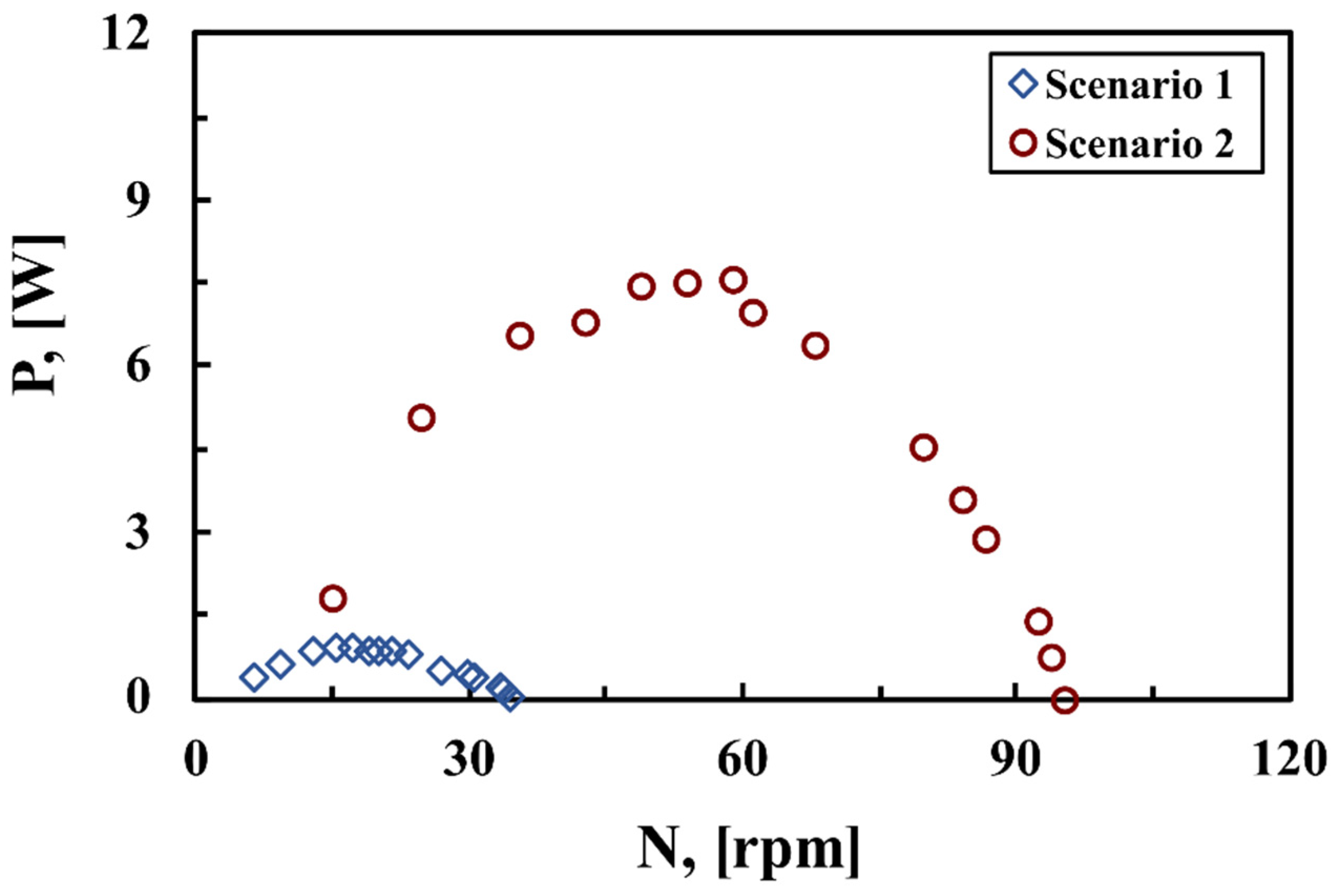

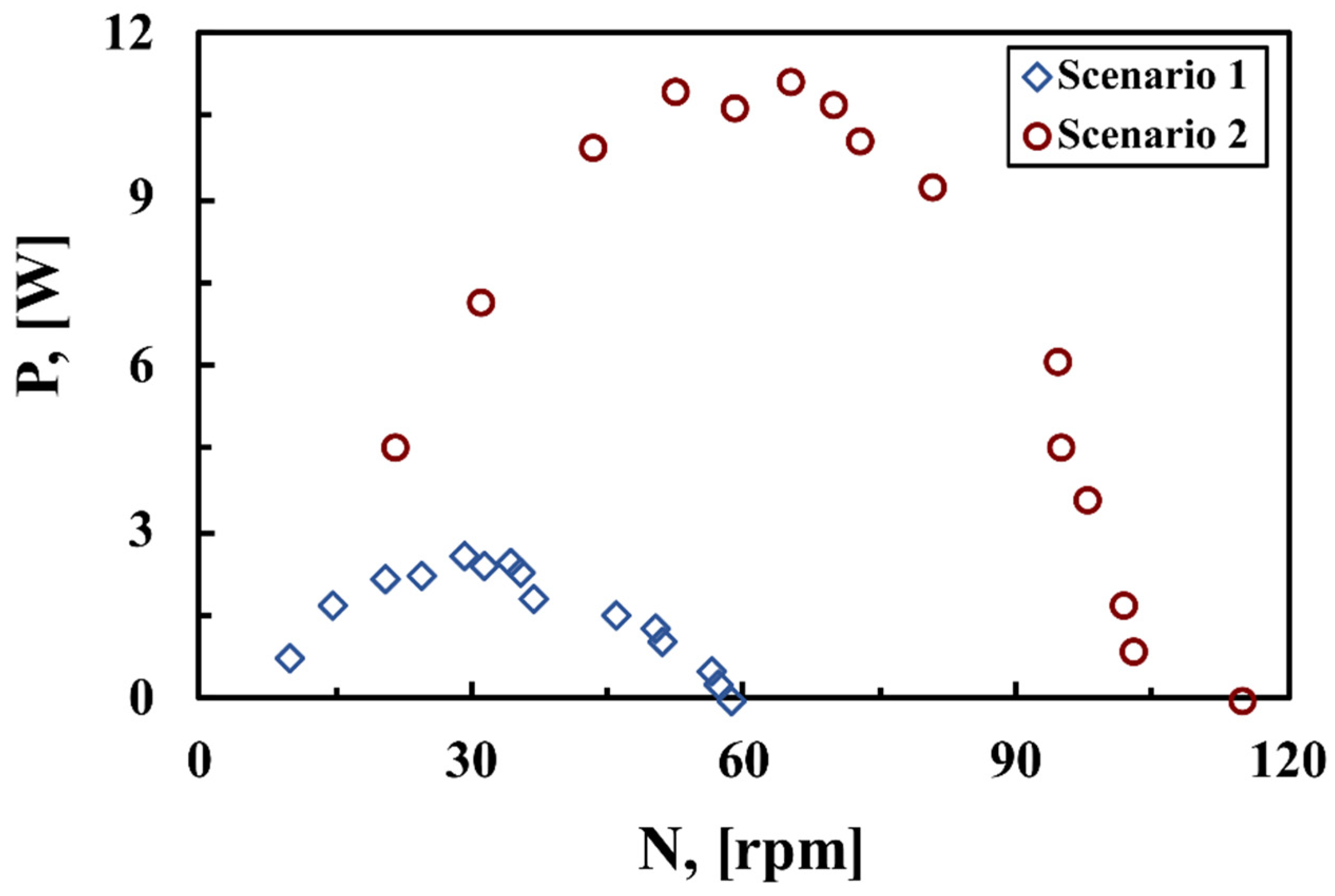

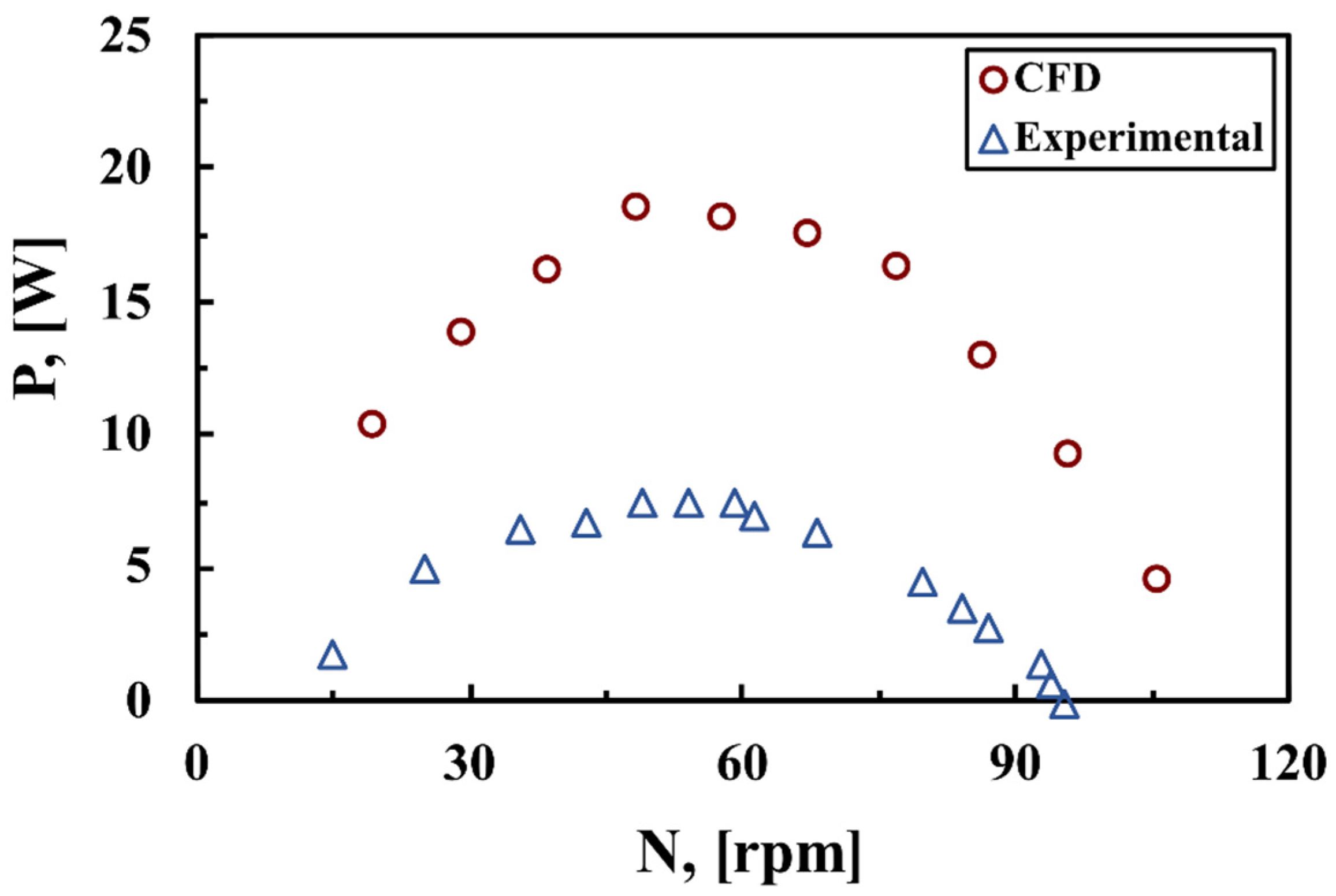

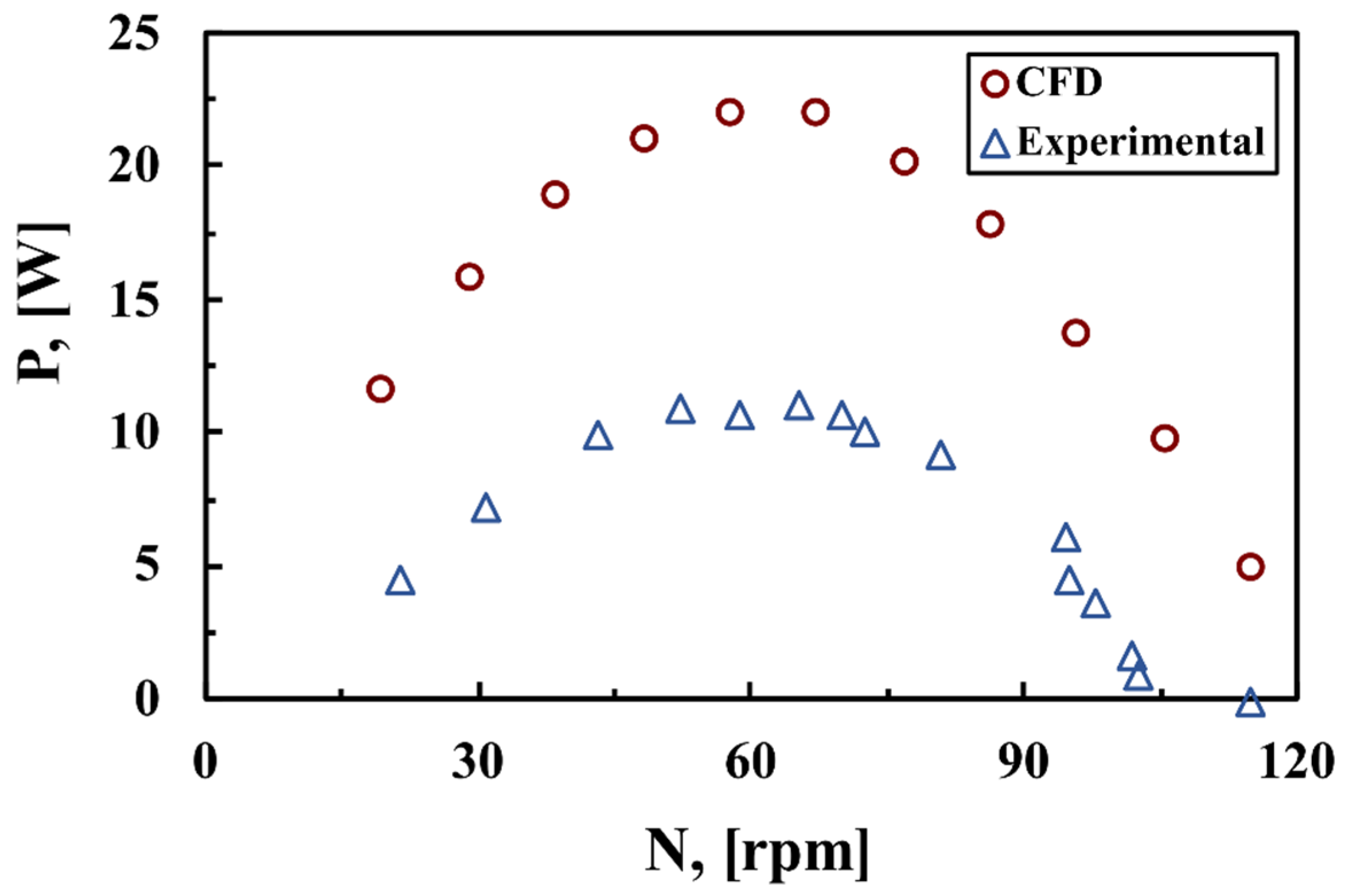

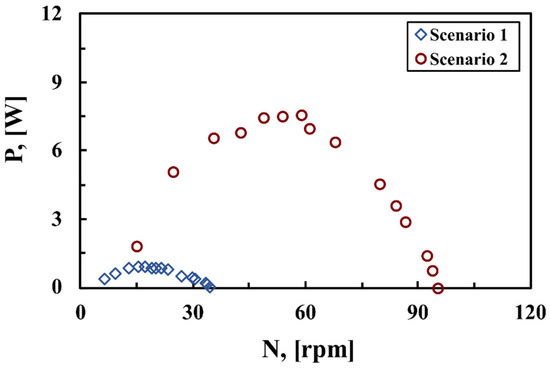

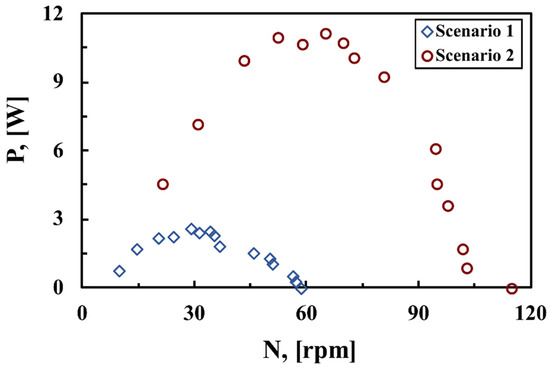

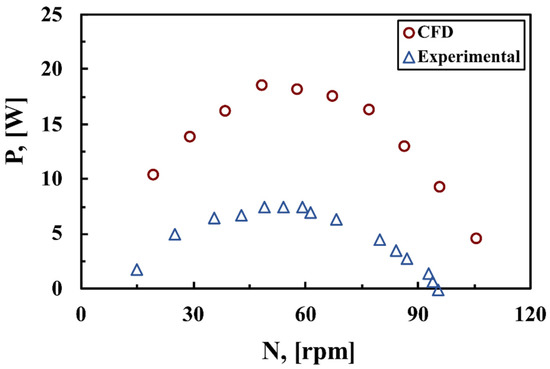

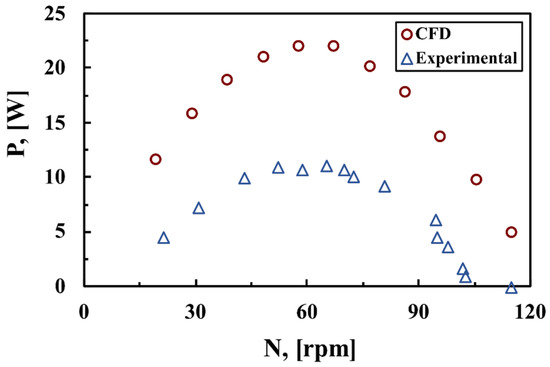

The results obtained for the two flows in the two proposed scenarios are shown in Figure 5 and Figure 6.

Figure 5.

P vs. N comparison of scenarios 1 and 2 with Q1 flow.

Figure 6.

P vs. N comparison of scenarios 1 and 2 with Q2 flow.

The tests carried out with the plate inclined at 22 degrees achieved the best results both in power increase and in the turbine speed range.

4. CFD Numerical Model

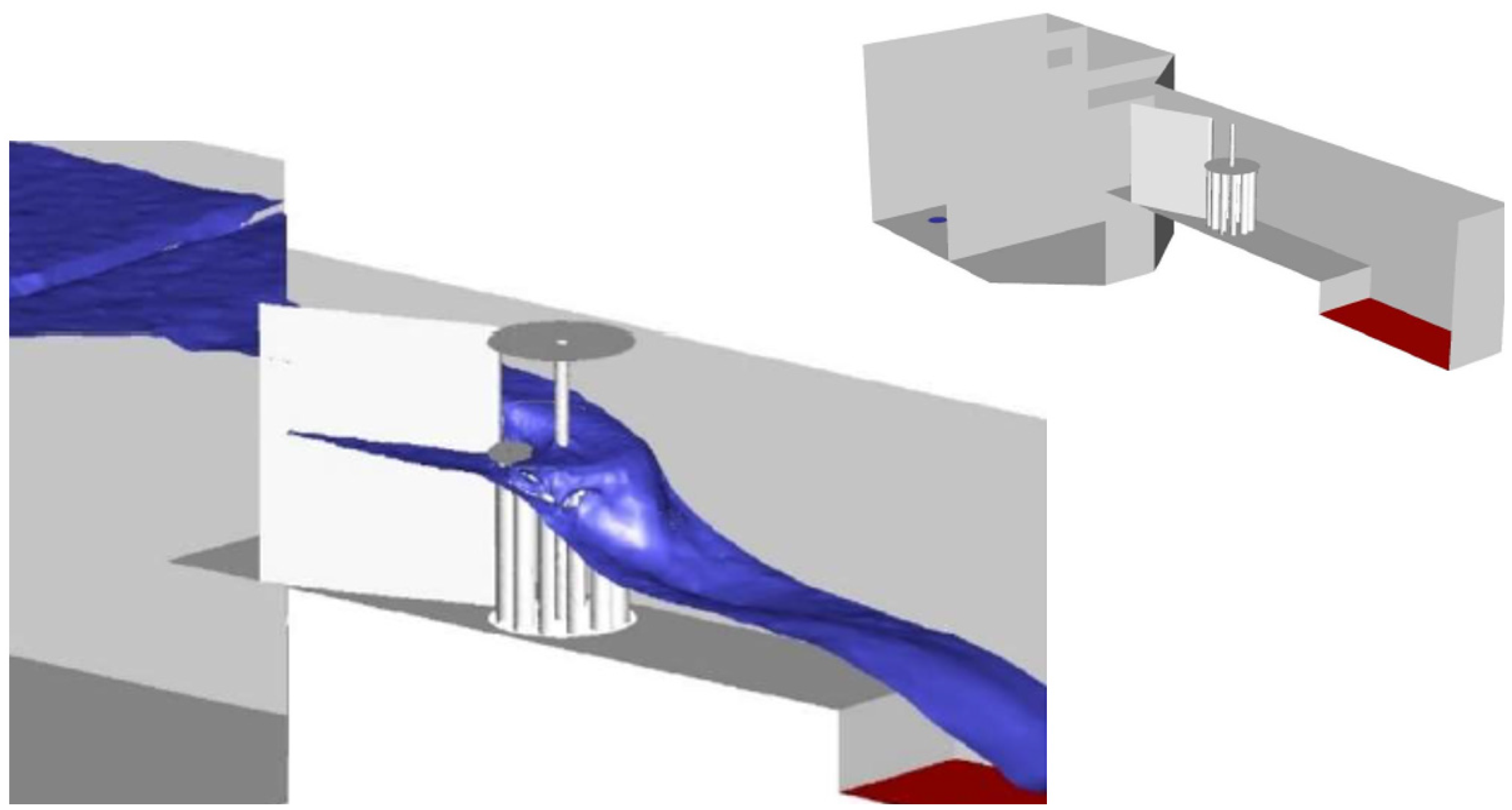

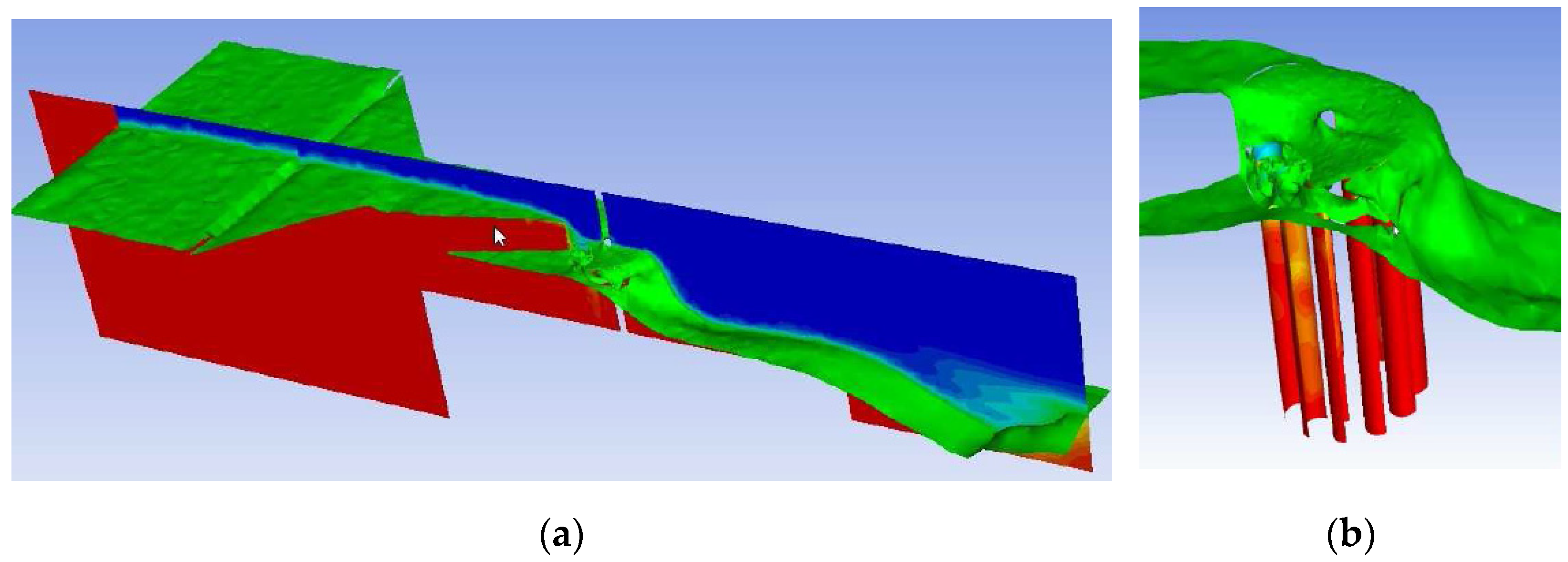

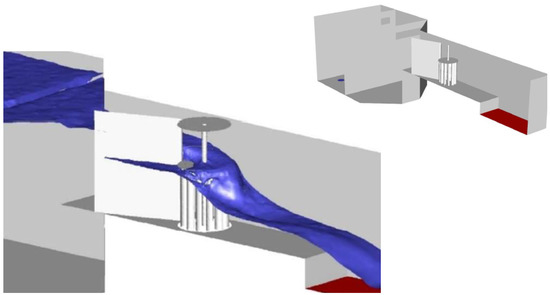

To build the numerical model, a complete three-dimensional geometry was generated incorporating the turbine, the stilling tank, the test flume, and the baffle. The geometric design has the actual dimensions of the hydrodynamic tunnel, including a rectangular prism-shaped area for the discharge of water from the channel (outlet) and two water inlet holes at the bottom of the reassuring tank. Furthermore, to ensure the correct functioning of the model, the upper part of the domain was completely exposed to air in order to replicate the free surface of water flow (Figure 7).

Figure 7.

HWT geometry and free surface detail.

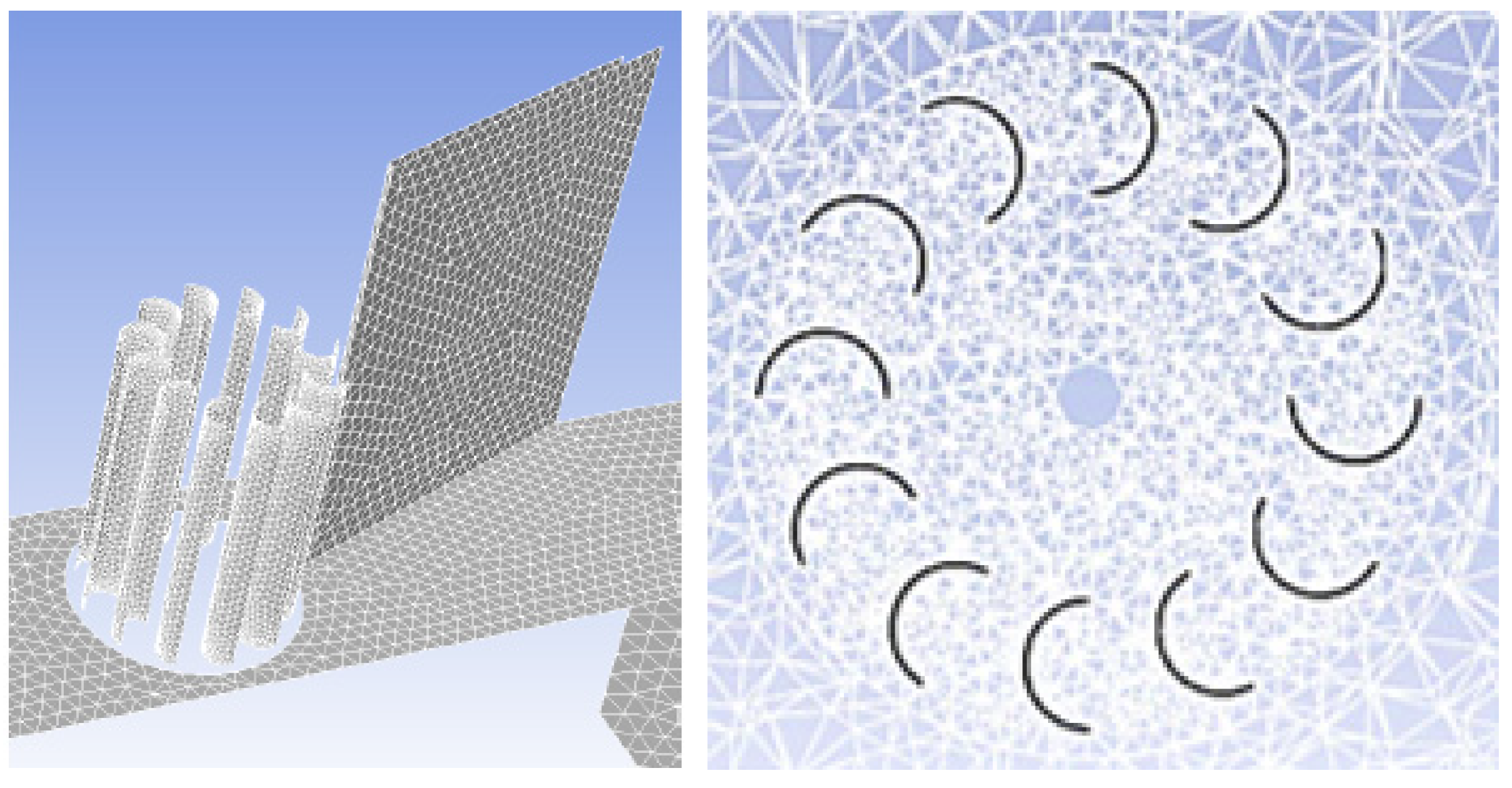

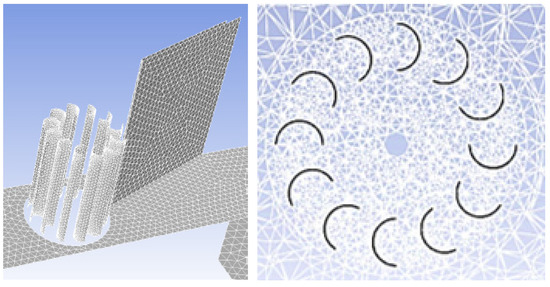

To obtain the numerical CFD model, a grid of cells was prepared where the flow equations were solved. To solve the rotation of the turbine, the geometry was divided into eight different volumes in which an unstructured mesh based on tetrahedrons was used to achieve a good adaptation to the complex areas, except in the water discharge area where a structured mesh based on rectangular prisms was used due to its simple cubic shape. A cylindrical volume was incorporated that helped to simulate the movement of the turbine with a good degree of precision (Figure 8), as the unstructured mesh adapts perfectly to the turbine blades. The number of grid cells was set at 1,200,000 with satisfactory quality: 99.99% of the cells had an asymmetry value of less than 0.7. To study the dependence of the grid on the power results and its influence on the calculation time, four numbers of cells were evaluated: 200,000, 500,000, 800,000, 1,200,000, and 1,500,000 with the same flow rate and the range of rotational speeds that define the turbine power characteristics. With 1,200,000 cells, the ideal compromise between accuracy and calculation time was achieved.

Figure 8.

Meshing around the rotor.

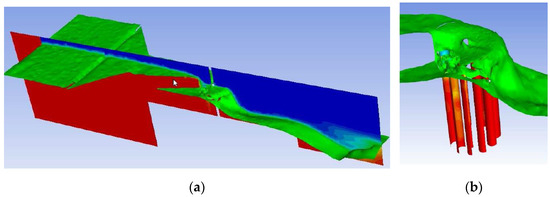

The volume of fluid (VOF) model was selected to resolve the behavior of the free surface at its boundary between air and water (Figure 9). The model solved the unsteady Reynolds-average Navier–Stokes (URANS) for each cell included in the domain. The boundary conditions applied were mass flow at the water inlets, pressure outlet at the discharge, and the upper part of the model (tank and channel) with normal atmospheric pressure (101,325 Pa). The surfaces of the tank, the channel, and the turbine blades were defined as walls with a no-slip condition. Water and air densities and viscosities were set to constant values (water: 1.025 Kg/m3 and 1.003 × 10−3 Kg/m·s; air: 1.225 Kg/m3 and 1.789 × 10−5 Kg/m·s). To solve the URANS equations, the pressure-implicit solver algorithm with splitting of operators was used. In addition, second-order schemes were applied for the discretization of the spatial and temporal derivatives in the equations. The semi-implicit method for pressure-bound equations (SIMPLE) was used to solve the velocity–pressure coupling and turbulence was simulated using the shear stress transport (SST) k-ω turbulence model, suitable for complex flows. ANSYS FLUENT V18.0 software was used to perform the simulations of the numerical model [15].

Figure 9.

(a) Longitudinal section of the channel with the free surface; (b) detail of the free surface in the turbine.

5. Validation of the Numerical Model

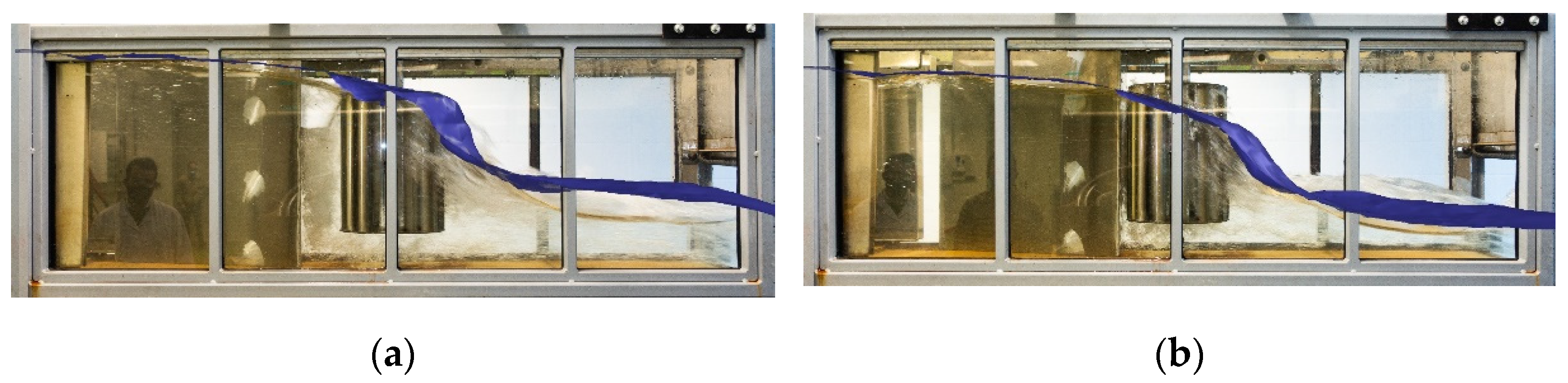

The numerical model was validated with the experimental model (scenario 2) by comparing its degree of similarity between the results of the rotational speed (N) and power characteristics, and the positions of the free surfaces.

The experimental and numerical results of N (rpm) and power (W) for the two flow rates tested were analyzed for Q1 (Figure 10) and Q2 (Figure 11).

Figure 10.

P vs. N comparison in scenario 2 and Q1.

Figure 11.

P vs. N comparison in scenario 2 and Q2.

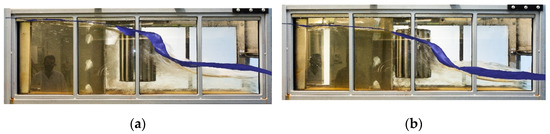

In addition, the profiles of the free surface of the experimental and the numerical model were compared (Figure 12). The high similarity between both confirms the analytical results.

Figure 12.

(a) Experimental vs. CFD for Q1; (b) experimental vs. CFD for Q2.

6. Conclusions

Tests of a vertical axis hydrokinetic turbine were carried out in the hydrodynamic channel of the University of Oviedo under two scenarios: (a) with the original configuration of the channel; and (b) introducing a baffle plate oriented 22° towards the center of the turbine with respect to the channel wall.

The tests carried out with the baffle plate inclined at 22° achieved an increase in the results both in terms of power increase (greater than 250%) and in the speed range of the turbine. It was proven that simply inserting the plate increases the efficiency of the turbine considerably.

In addition, a CFD model was built and validated with the results of the experiment. Thanks to this, in future works, it is possible to deepen the study of how the forces work around the blades from the analysis of the speed and pressure field, as well as to carry out parametric studies on the ideal inclination of the baffle plate to optimize the installation.

Author Contributions

R.E.-V.: investigation, methodology, validation, formal analysis, and writing—original draft. V.M.F.-Á.: investigation, methodology, data curation, validation, and formal analysis. A.G.-Y.: investigation, methodology, and formal analysis. A.F.-J.: investigation, methodology, data curation, validation, and formal analysis. E.Á.-Á.: conceptualization ideas, writing—original draft, writing—review and editing, formal analysis, and supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohammadi, S.; Hassanalian, M.; Arionfard, H.; Bakhtiyarov, S. Optimal Design of Hydrokinetic Turbine for Low-Speed Water Flow in Golden Gate Strait. Renew. Energy 2020, 150, 147–155. [Google Scholar] [CrossRef]

- Güney, M.S.; Kaygusuz, K. Hydrokinetic Energy Conversion Systems: A Technology Status Review. Renew. Sustain. Energy Rev. 2010, 14, 2996–3004. [Google Scholar] [CrossRef]

- Kumar, D.; Sarkar, S. A Review on the Technology, Performance, Design Optimization, Reliability, Techno-Economics and Environmental Impacts of Hydrokinetic Energy Conversion Systems. Renew. Sustain. Energy Rev. 2016, 58, 796–813. [Google Scholar] [CrossRef]

- IDAE Plan de Energías Renovables 2011–2020. Available online: https://www.idae.es/sites/default/files/documentos/publicaciones_idae/documentos_11227_per_2011-2020_def_93c624ab.pdf (accessed on 7 February 2022).

- Syahputra, R.; Soesanti, I. Performance Improvement for Small-Scale Wind Turbine System Based on Maximum Power Point. Energies 2019, 12, 3938. [Google Scholar] [CrossRef]

- Nicolaie, S.; Tudor, E.; Dumitru, C. Improving the Energy Conversion Efficiency for Hydrokinetic Turbines Using MPPT Controller. Appl. Sci. 2020, 10, 7560. [Google Scholar] [CrossRef]

- Vogel, C.R.; Houlsby, G.T.; Willden, R.H.J. Effect of Free Surface Deformation on the Extractable Power of a Finite Width Turbine Array. Renew. Energy 2016, 88, 317–324. [Google Scholar] [CrossRef]

- Houlsby, G.T.; Vogel, C.R. The Power Available to Tidal Turbines in an Open Channel Flow. Proc. Inst. Civ. Eng.-Energy 2016, 170, 12–21. [Google Scholar] [CrossRef]

- Kolekar, N.; Vinod, A.; Banerjee, A. On Blockage Effects for a Tidal Turbine in Free Surface Proximity. Energies 2019, 12, 3325. [Google Scholar] [CrossRef]

- Salleh, M.B.; Kamaruddin, N.M.; Mohamed-Kassim, Z. The Effects of Deflector Longitudinal Position and Height on the Power Performance of a Conventional Savonius Turbine. Energy Convers. Manag. 2020, 226, 113584. [Google Scholar] [CrossRef]

- Mosbahi, M.; Lajnef, M.; Derbel, M.; Mosbahi, B.; Aricò, C.; Sinagra, M.; Driss, Z. Performance Improvement of a Drag Hydrokinetic Turbine. Water 2021, 13, 273. [Google Scholar] [CrossRef]

- Sahim, K.; Ihtisan, K.; Santoso, D.; Sipahutar, R. Experimental Study of Darrieus-Savonius Water Turbine with Deflector: Effect of Deflector on the Performance. Int. J. Rotating Mach. 2014, 2014. [Google Scholar] [CrossRef]

- Naiemi, A.H.; Yeganehfarzand, S. Nashtifan Windmills in Their Environmental Context, Khurasan, Iran. Vernac. Archit. 2019, 50, 57–77. [Google Scholar] [CrossRef]

- Ramin Nashtifan Windmills. Available online: http://historicaliran.blogspot.com/2012/03/nashtifan-windmills.html (accessed on 17 February 2022).

- Ansys. ANSYS Fluent User’s Guide; 18.1; ANSYS: Canonsburg, PA, USA, 2018; Available online: http://users.abo.fi/rzevenho/ansys%20fluent%2018%20tutorial%20guide.pdf (accessed on 10 February 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).