Abstract

This study investigates the feasibility of establishing an environmentally sustainable ultra-high performance concrete from seawater and sea sand (SWSS-UHPC) which utilizes industrial byproducts (i.e., ground slag and silica fume) by partially substituting ordinary Portland cement (OPC). Several SWSS-UHPC trial mixes were prepared with varying cement substitution ratio and water-to-binder ratio to reach desired cube compressive strength and workability. A maximum of 50% OPC was successfully replaced by 37.5% slag and 12.5% silica fume without sacrificing the strength and workability. Finally, influences of vibration during molding and thermal curing were evaluated by comparing identical mixes prepared with and without these treatments. Results suggest that locally available marine resources and high volume of industrial byproducts can be incorporated in UHPC fabrication without any special treatments.

1. Introduction

Cement based concrete production not only contributes to significant CO2 emission (5–8% of the CO2 produced globally [1]), but also aggravates the natural resource shortages (i.e., river sand, fresh water, etc.) [2]. Several studies have reported the utilization of seawater, sea sand, and industrial wastes to produce seawater and sea sand concrete (SWSSC) [3]. Ultra-high performance concrete (UHPC) is usually defined by a remarkable compressive strength exceeding 120 MPa [4], enhanced interfacial transition zone (ITZ) and improved durability [5] due to the incorporation of very fine powders and supplementary cementitious materials (SCMs). Although numerous literatures have focused on UHPC using river sand and fresh water, very few works have been performed on producing UHPC from marine resources (i.e., seawater and sea sand) [6]. To the best of the authors’ knowledge, there is no published research on slag-based marine UHPC.

Desalting of sea sand is highly recommended before use [2], which requires additional cost and contradicts the sustainability aspect of marine concrete. Furthermore, UHPC requires various special treatments to maintain its superior characteristics [7] which leads to increased cost. Furthermore, proper management of hazardous industrial byproducts can be facilitated through incorporating them in SWSS-UHPC, thus achieving sustainable development. Hence, this paper explores the possibility of directly utilizing seawater, sea sand, and industrial byproducts in UHPC production with no special preparation. Several trial mixes of seawater and sea sand based ultra-high performance concrete (SWSS-UHPC) were prepared through substituting ordinary Portland cement (OPC) by ground slag and silica fume in different replacement percentages and altering water-to-binder ratio to achieve the desired compressive strength and workability. Effects of vibration at the time of molding and thermal curing on compressive strength were assessed.

2. Materials and Methods

A general purpose cement from Cement Australia and two types SCMs, i.e., ground slag and undensified silica fume, were acquired from Australian Builders and Simcoa, Western Australia, respectively. Natural river sand was procured from Bagged Product Supplies, Taren Point, New South Wales. Sea sand and seawater were collected from Malabar beach of Sydney, New South Wales, Australia. Sea sand was dried and sieved to exclude the natural and man-made impurities, such as stone chips, fragments of sea-shells, organic substances, plastics, etc. MasterGlenium SKY 8700 from BASF, a polycarboxylate-based high-range water reducer (HRWR) was used to achieve sufficient workability and self-compacting properties of UHPC mixes. As opposed to most convention UHPC, no steel fibers were utilized in order to achieve a cost-effective concrete and to avoid the possibility of steel corrosion.

Seven trial mixes of SWSS-UHPC were prepared which included 100% OPC (TM1) along with 25%, 33.33% and 50% replacements of OPC by slag (TM2–6). TM7 included 37.5% slag and 12.5% silica fume as cement substitutes. TM8 was prepared from tap water and river sand, with the same mix ratio as TM7. The water-to-binder ratio was varied from 0.17 to 0.2 until a sufficiently workable mix is achieved. The proportions of fine aggregate and HRWR-to-binder ratio were kept constant throughout the trial mixes (1000 kg/m3 and 0.02, respectively). The mix proportions are listed in Table 1. The mixing procedure and tests on workability as well as cube compressive strength were carried out according to the relevant standard [4]. A temperature of 23 ± 2 °C and a relative humidity of 50% were adopted for standard water curing. The specimens were cured under standard environment up to 365 days. For thermal curing, specimens were immersed in a hot-water bath with an elevated temperature of 60 ± 1 °C for 72 h.

Table 1.

Mixing proportions for trial mixes of SWSS-UHPC.

3. Results and Discussion

3.1. Workability and Compressive Strength of Trial Mixes

A proper mix of SWSS-UHPC was chosen from the trial mixes based on its compressive strength and workability. Flowability of fresh UHPC reduced with the increase in slag. A 33.33% OPC replacement with slag at a water-to-binder ratio of 0.17 yielded an unworkable mix (Table 1). Increasing water-to-binder ratio improved the workability. Silica fume was added in TM7 to escalate the mechanical strength, even with high substitution of OPC. Strength and workability of SWSS-UHPC were similar to that presented in previous studies [6], nonetheless, this study aims to determine the maximum OPC replacement possible by industrial byproducts in marine UHPC. A maximum 50% of OPC replacement (by 37.5% slag and 12.5% silica fume) was successfully achieved at 0.2 water-to-binder ratio with satisfactory strength and workability.

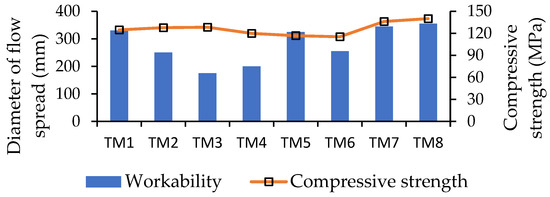

Figure 1 illustrates the diameter of flow spread and compressive strength of cube specimens after hot-water curing. With a constant water-to-binder ratio of 0.17, the compressive strength slightly increased with the increase in slag incorporation. However, the workability of slag-based mix substantially decreased (175 mm spread in 33.33% slag incorporated mix compared to 330 mm in 100% OPC based mix). Irregular shape of slag particles and accelerated calcium reaction are primarily responsible for the reduced flowability. Adding silica fume significantly improved the workability and strength. Spherical silica fume particles are well-known to have lubricating effect, which enhances flowability of the paste by reducing inter-particle friction [8]. Very fine silica fume particles act as fillers and enhances the particle-packing density. Additionally, accelerated pozzolanic reactions of silica fume induces higher mechanical strength [9]. OPC-slag-silica fume ternary mix yielded 35% increased flow spread and 18% more compressive strength at 50% OPC replacement level. The same ternary mix was prepared with river sand and tap water for comparison purposes, which produced comparable results to SWSS-UHPC.

Figure 1.

Workability and compressive strength of SWSS-UHPC trial mixes.

3.2. Effect of Vibration during Molding

The trial mixes were poured into molds on a vibrating table and vibrated for around 30 s in order to eliminate trapped air bubbles. TM7 and TM8 mixes were further casted without applying any tamping or vibration to assess their self-compacting ability. Insignificant increase in 28-day strength was noticed in vibrated specimens (3.2% and 2.8% for TWRS-UHPC and SWSS-UHPC, respectively), whereas slightly higher increase in 7-day strength was observed (6.6% and 3.9%, respectively). With the passage of time under curing, hydration products (especially calcium silicate hydrates) are formed, which occupy the voids within the cementitious matrix. Hence, the differences in compressive strength between non-vibrated and vibrated specimens continue to reduce with the increase in curing time. The mere improvement in strength proves the self-compacting characteristics of UHPC pastes. As the air content in the dense matrix is extremely low, vibration during molding can be avoided while casting of SWSS-UHPC.

3.3. Effect of Thermal Curing

Thermal curing treatment produced slightly higher compressive strength compared to 28-day standard curing (8.4% and 1.7%, respectively for TWRS-UHPC and SWSS-UHPC). However, long-term standard water curing generated a further improvement in strength. An extended standard curing for 365 days yielded 2.6% and 3.7% more strength than hot-water curing regime for TWRS and SWSS based UHPC, respectively.

UHPC possesses negligible porosity due to its extremely dense microstructure [10]. As very small amount of water can penetrate and the matrix itself contains incredibly low water content, a significant portion of cementitious particles remain unhydrated. From visual inspection on the failure surfaces of SWSS-UHPC, a substantial portion of particles were found to be unreacted after 7- and 28-day standard curing (Figure 2). A few unreacted particles were observed after thermal curing, whereas all the particles were reacted after long-term standard curing. Hot-water curing for 72 h was not sufficient to hydrate all particles in the matrix, while water slowly penetrated during the 365-day standard curing period and facilitated hydration of all the particles in the dense microstructure. Hence, the mechanical strength of long-term cured samples was found to be the largest.

Figure 2.

Failure surfaces of UHPC-SWSS cubes after (a) 7-day standard curing; (b) 28-day standard curing; (c) thermal curing; (d) 365-day standard curing.

4. Conclusions

Direct utilization of seawater and sea sand in UHPC without any special treatment (i.e., vibration, thermal curing) was effective based on its mechanical and flowability performances. A maximum 50% replacement of OPC by industrial waste was successfully obtained without compromising the strength and workability of UHPC.

Author Contributions

Conceptualization, S.S., X.-L.Z. and E.H.; methodology, S.S., X.-L.Z. and E.H.; software, S.S.; validation, S.S. and X.-L.Z.; formal analysis, S.S.; investigation, S.S.; resources, X.-L.Z.; data curation, S.S.; writing—original draft preparation, S.S.; writing—review and editing, X.-L.Z. and E.H.; visualization, S.S., X.-L.Z. and E.H.; supervision, X.-L.Z. and E.H.; project administration, S.S., X.-L.Z. and E.H.; funding acquisition, X.-L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Australian Research Council (ARC) through an ARC Discovery Grant (DP160100739).

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank Randwick Council for their permission to collect seawater and sea sand from Malabar beach, Sydney, NSW, Australia.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nagrockiene, D.; Barkauskas, K. Utilization of waste glass powder in cement mortar. Environ. Sci. Proc. 2021, 9, 25. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhao, X.L.; Raman Singh, R.K.; Al-Saadi, S. Experimental study on seawater and sea sand concrete filled GFRP and stainless steel tubular stub columns. Thin Wall Struct. 2016, 106, 390–406. [Google Scholar] [CrossRef]

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Mishra, O.; Singh, S.P. An overview of microstructural and material properties of ultra-high-performance concrete. J. Sustain. Cem Based Mater. 2019, 8, 97–143. [Google Scholar] [CrossRef]

- Teng, J.G.; Xiang, Y.; Yu, T.; Fang, Z. Development and mechanical behaviour of ultra high-performance seawater sea-sand concrete. Adv. Struct. Eng. 2019, 22, 3100–3120. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Z.; Xiao, J.; Wang, D.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part I. Raw materials and mixture design. Constr. Build. Mater. 2015, 101, 741–751. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y. The mechanical properties and microstructure of ultra-high-performance concrete containing various supplementary cementitious materials. J. Sustain. Cem Based Mater. 2017, 6, 254–266. [Google Scholar] [CrossRef]

- Sakir, S.; Raman, S.N.; Safiuddin, M.; Amrul Kaish, A.B.M.; Mutalib, A.A. Utilization of by-products and wastes as supplementary cementitious materials in structural mortar for sustainable construction. Sustainability 2020, 12, 3888. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).