Design, Prototyping, and Integration of Battery Modules for Electric Vehicles and Energy Storage Systems

Abstract

1. Introduction

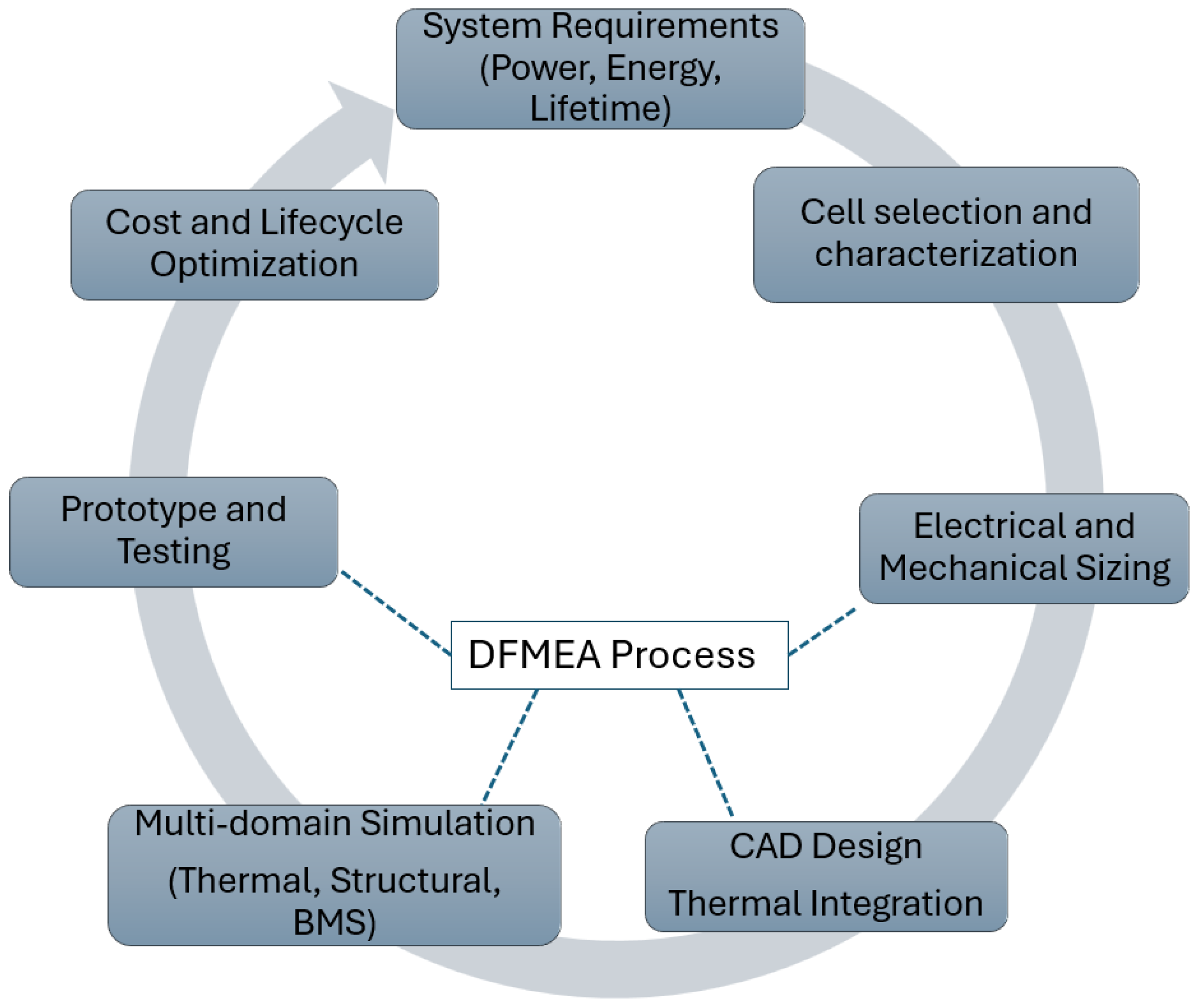

- It presents a comprehensive design framework for modular architecture for EV/ESS battery systems.

- It demonstrates the application of the Design Failure Mode Effect Analysis (DFMEA) concept to identify and mitigate potential design-level failure modes to enhance safety and reliability.

- It presents prototype development of battery modules, BDU and BMS hardware/software with functional verification of some of the components.

- It provides practical, implementation-focused guidance for conventional lithium-ion battery system.

2. Battery Architecture and Design

2.1. Cell Selection

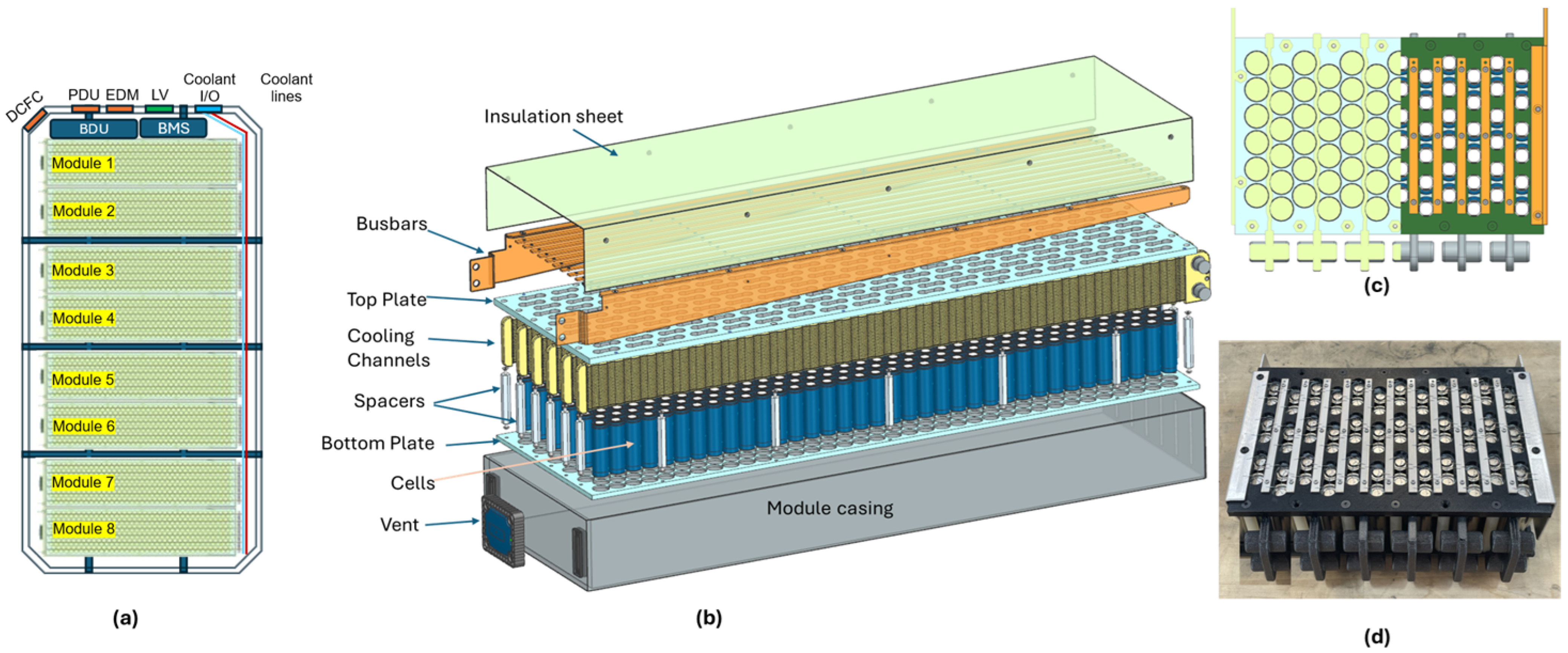

2.2. Mechanical Integration

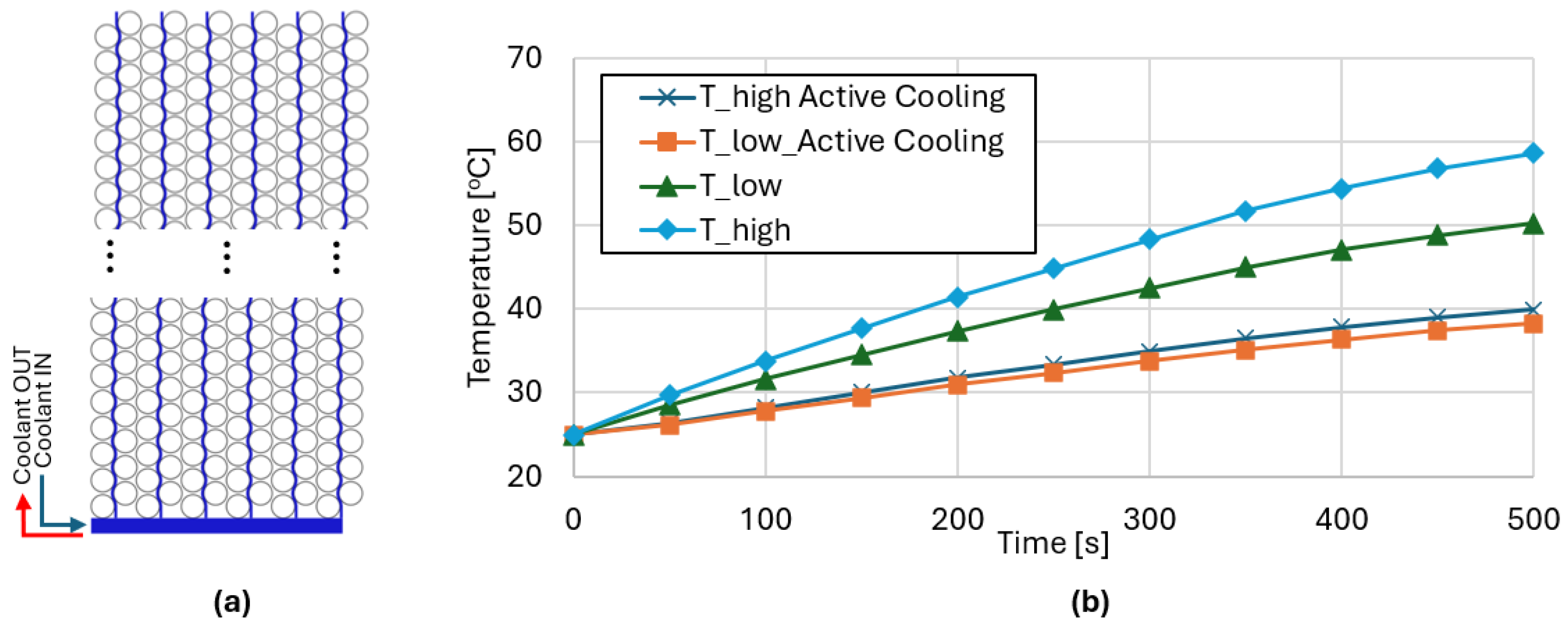

2.3. Thermal Management

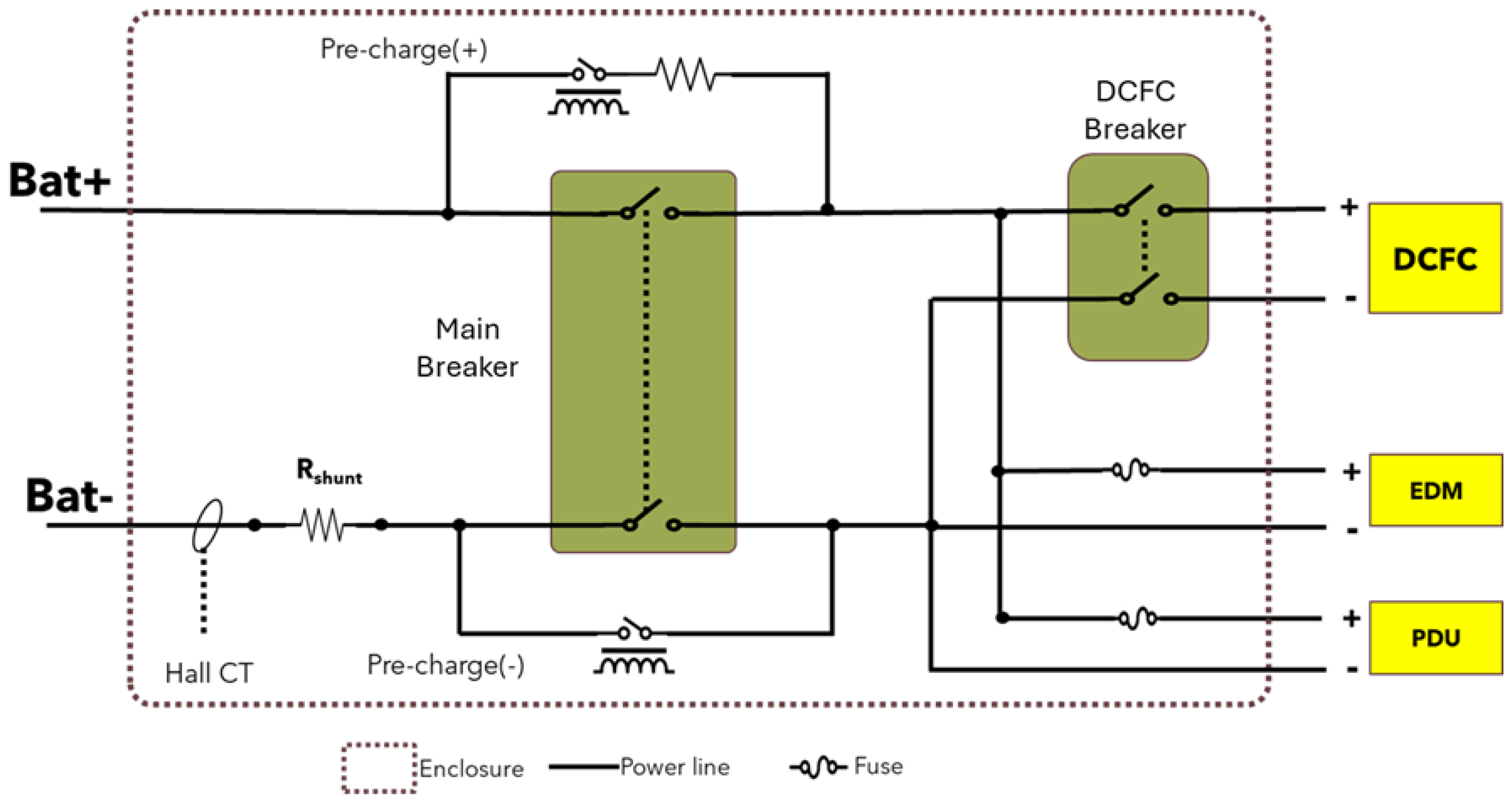

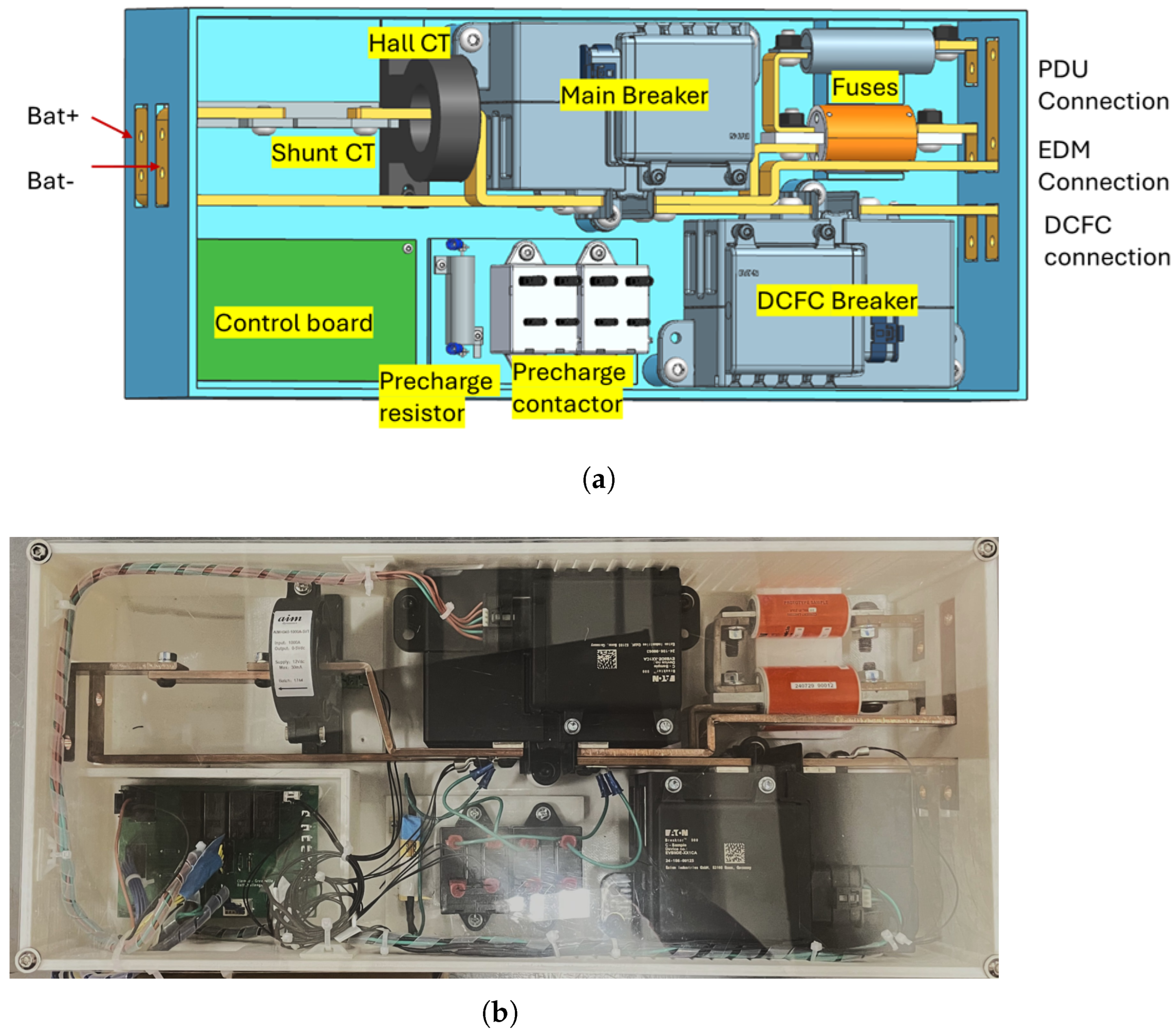

3. Battery Disconnect Unit (BDU)

- HV contactors/breaker: These electromechanical switches open/close the battery terminals. There are usually two main contactors (high power) and a precharge contactor to charge the circuit capacitance safely. EV battery packs may include another set of high-power contactors for Direct Current (DC) fast charging (DCFC).

- Precharge resistor: The precharge resistor limits the inrush current during initial connection by slowly charging the downstream capacitance before switching the main HV contactor.

- HV Fuses: HV fuses provide overcurrent protection. There can be multiple fuses within the BDU.

- Busbars: These connect the battery terminals to the contactors and the power distribution terminals.

- Current Sensor: These measure the current flowing in/out of the battery. For failsafe design, redundant measurement using a shunt-type and a Hall-effect current sensor is common.

- Temperature Sensor: These measure the temperature at the busbars and precharge resistor.

- Low Voltage (LV) connectors: These include control cables for contactor control, temperature sensors, diagnostics, and status feedback, and connect to the BMS.

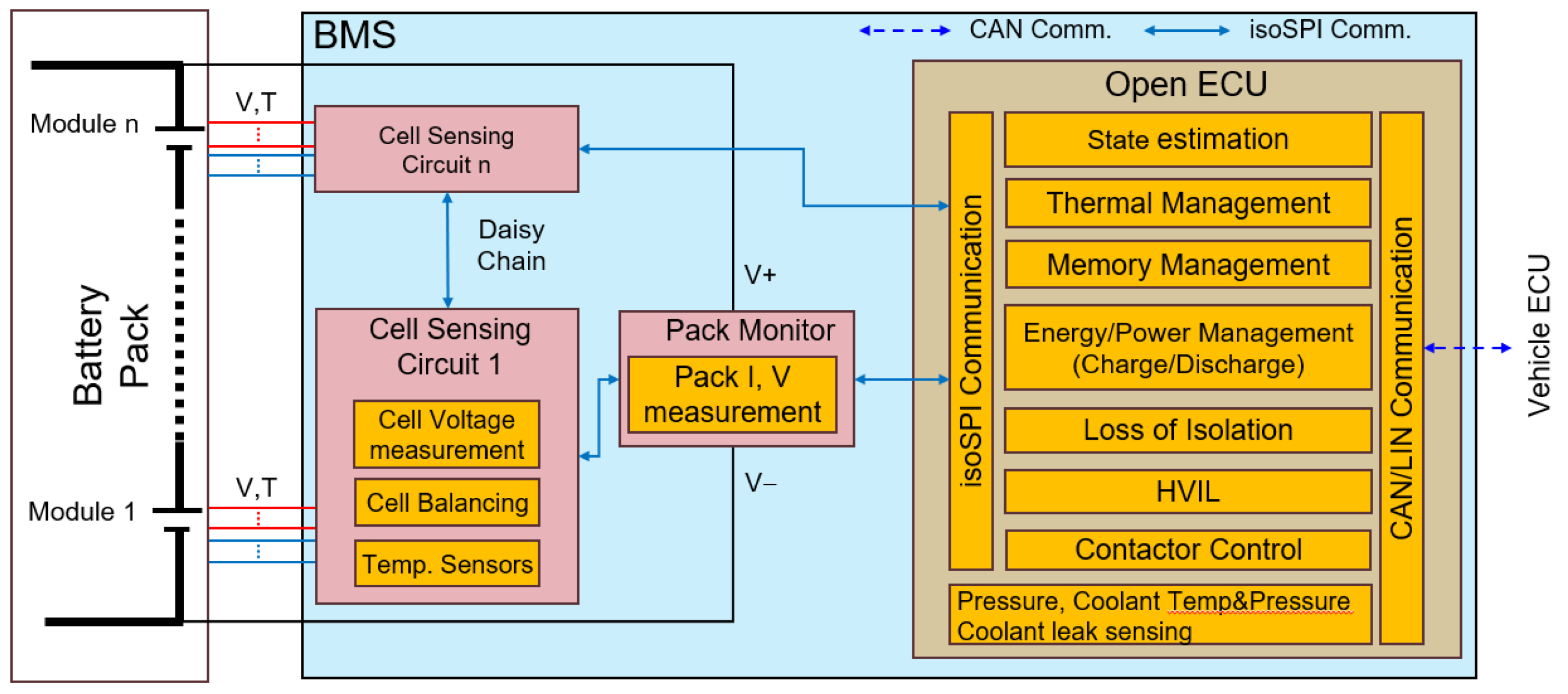

4. Battery Management System (BMS)

- Monitoring voltage, current and temperature of cells or module in the battery pack;

- Protection by preventing over-charging, over-discharging, over-current and over-heating;

- Estimation of states such as state of charge (SOC), State of Health (SOH), State of Power (SOP), etc.;

- Thermal management by coordinating with the cooling/heating system;

- Balancing by equalizing charge across cells to extend battery life and maintain performance;

- Communicating to the rest of the system (to the vehicle system using, for example, Controller Area Network (CAN) or Local Interconnect Network (LIN) protocols, or to the Energy Management System (EMS) using the Distributed Network Protocol 3 (DNP3), IEC 61850, Modbus protocols).

4.1. Hardware Architecture

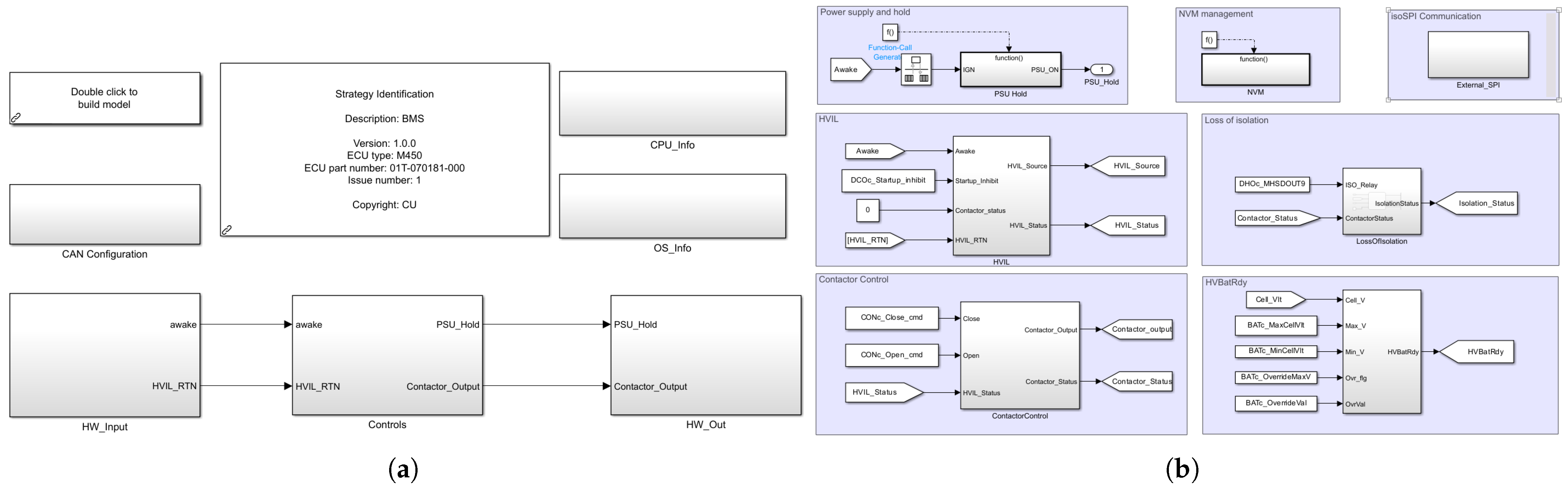

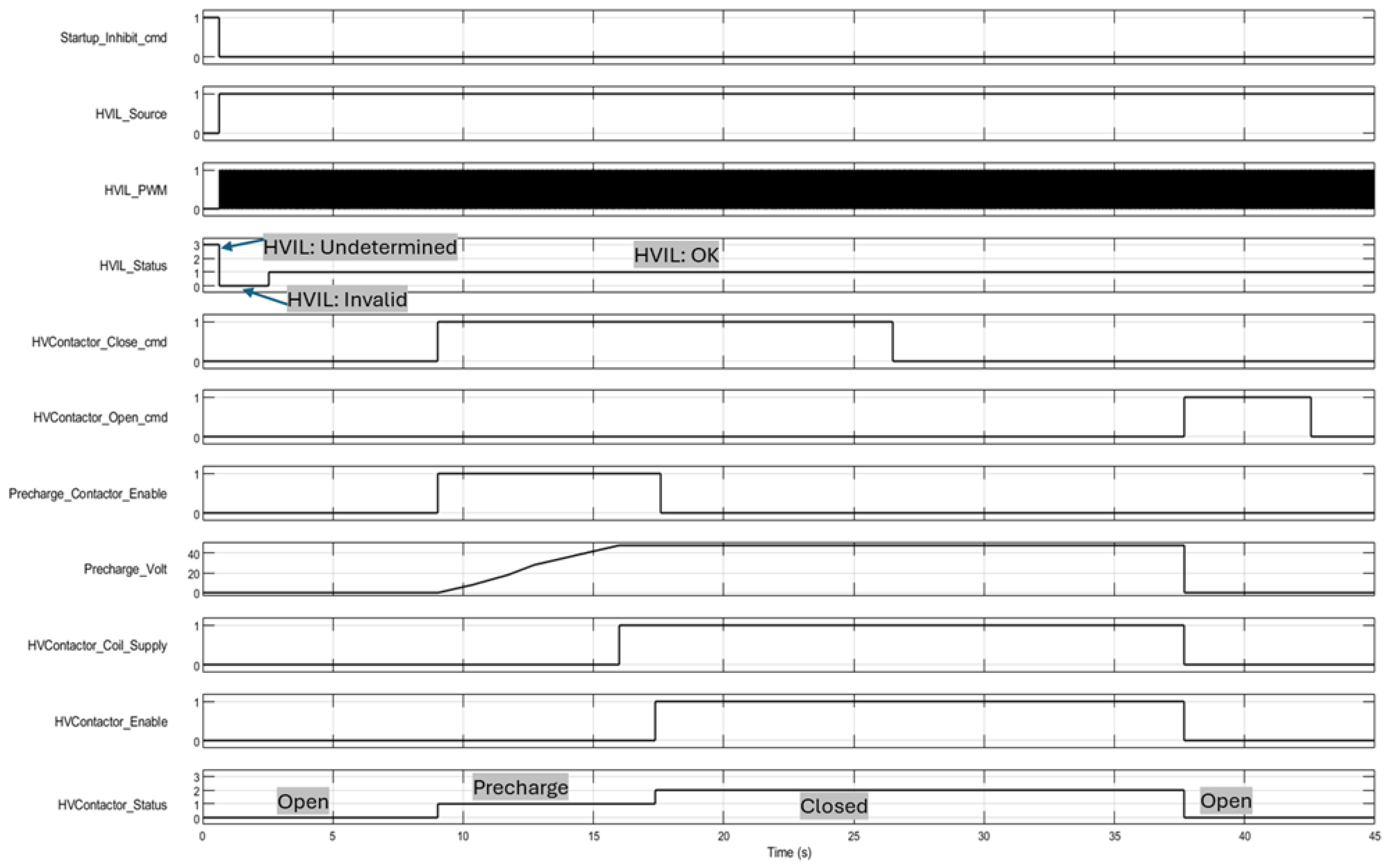

4.2. Software Architecture

4.3. Cost Analysis and Scalability

5. Case Study of Design and Prototyping

5.1. Cell Configuration and Module Design

5.2. BDU Design

5.3. BMS Design

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Abbr. | Full Form | Abbr. | Full Form |

| CAD | Computer-Aided Design | CAN | Controller Area Network |

| CT | Current Transducer | CSC | Cell Sensing Circuit |

| DC | Direct Current | DNP3 | Distributed Network Protocol 3 |

| DCFC | DC Fast Charging | EMI | Electromagnetic Interference |

| EMS | Energy Management System | EIS | Electrochemical Impedance Spectroscopy |

| ESS | Energy Storage System | HVBS | High Voltage Battery System |

| HV | High Voltage | HVIL | High Voltage Interlock Loop |

| I/O | Input/Output | IEC | International Electrotechnical Commission |

| ISO | International Organization for Standardization | isoSPI | Isolated Serial Peripheral Interface |

| LCOS | Levelized Cost of Storage | LIN | Local Interconnect Network |

| LFP | Lithium Iron Phosphate | NCA | Nickel Cobalt Aluminum |

| NMC | Nickel Manganese Cobalt | NTC | Negative Temperature Coefficient |

| PCM | Phase Change Material | PDU | Power Distribution Unit |

| PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene | PWM | Pulse Width Modulation |

| SCADA | Supervisory Control and Data Acquisition | SOC | State of Charge |

| SOP | State of Power | SOH | State of Health |

| TIM | Thermal Interface Material | UN | United Nations |

| USABC | U.S. Advanced Battery Consortium | UL | Underwriters Laboratories |

References

- IEA. Global EV Outlook. 2024. Licence: CC BY 4.0. Available online: https://www.iea.org/reports/global-ev-outlook-2024 (accessed on 22 July 2025).

- Nyamathulla, S.; Dhanamjayulu, C. A review of battery energy storage systems and advanced battery management system for different applications: Challenges and recommendations. J. Energy Storage 2024, 86, 111179. [Google Scholar] [CrossRef]

- Ngoy, K.R.; Lukong, V.T.; Yoro, K.O.; Makambo, J.B.; Chukwuati, N.C.; Ibegbulam, C.; Eterigho-Ikelegbe, O.; Ukoba, K.; Jen, T.C. Lithium-ion batteries and the future of sustainable energy: A comprehensive review. Renew. Sustain. Energy Rev. 2025, 223, 115971. [Google Scholar] [CrossRef]

- Farakhor, A.; Wu, D.; Wang, Y.; Fang, H. A Novel Modular, Reconfigurable Battery Energy Storage System: Design, Control, and Experimentation. arXiv 2023, arXiv:2301.05168. [Google Scholar] [CrossRef]

- IEC TS 62933-3-1; Electrical Energy Storage (EES) Systems—Part 3-1: Planning and Installation–General Specification. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- United Nations. UN Manual of Tests and Criteria: Lithium Metal and Lithium Ion Batteries; United Nations: New York, NY, USA; Geneva, Switzerland, 2019. [Google Scholar]

- ISO 26262-4; Road Vehicles–Functional Safety: Part 4: Product Development at the System Level, 2nd ed. International Organization for Standardization: Geneva, Switzerland, 2018.

- UL 2580; Batteries for Use in Electric Vehicles. Underwriters Laboratories Inc.: Northbrook, IL, USA, 2020.

- USABC. Goals for Advanced High-Performance Batteries for Electric Vehicle (EV) Applications. 2023. Available online: https://uscar.org/download/246/energy-storage-system-goals/12837/goals-for-advanced-high-performance-batteries-for-electric-vehicle-ev-applications.pdf (accessed on 22 July 2025).

- Lunz, B.; Yan, Z.; Gerschler, J.B.; Sauer, D.U. Influence of plug-in hybrid electric vehicle charging strategies on charging and battery degradation costs. Energy Policy 2012, 46, 511–519. [Google Scholar] [CrossRef]

- IEA. Tracking Clean Energy Progress. 2023. Available online: https://www.iea.org/reports/tracking-clean-energy-progress-2023 (accessed on 22 July 2025).

- Lazard. Levelized Cost of Storage Analysis–Version 10.0. 2025. Available online: https://www.lazard.com/media/uounhon4/lazards-lcoeplus-june-2025.pdf (accessed on 22 July 2025).

- USCAR. USABC Low-Cost/Fast Charge EV Goals. 2024. Available online: https://uscar.org/download/246/energy-storage-system-goals/12840/low-cost-fast-charge-ev-goals.pdf (accessed on 22 July 2025).

- Trevizan, R.D.; Obert, J.; De Angelis, V.; Nguyen, T.A.; Rao, V.S.; Chalamala, B.R. Cyberphysical Security of Grid Battery Energy Storage Systems. IEEE Access 2022, 10, 59675–59722. [Google Scholar] [CrossRef]

- UL 9540A; Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems. Underwriters Laboratories Inc.: Northbrook, IL, USA, 2019.

- ISO 15118; Road Vehicles – Vehicle to Grid Communication Interface. International Organization for Standardization: Geneva, Switzerland, 2019.

- IEC 61850; Communication Networks and Systems for Power Utility Automation. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- Andrea, D. Lithium-Ion Batteries and Applications: A Practical and Comprehensive Guide to Lithium-Ion Batteries and Arrays from Toys to Towns, Volume 1; Artech House: Norwood, MA, USA, 2020. [Google Scholar]

- Divakaran, A.M.; Hamilton, D.; Manjunatha, K.N.; Minakshi, M. Design, Development and Thermal Analysis of Reusable Li-Ion Battery Module for Future Mobile and Stationary Applications. Energies 2020, 13, 1477. [Google Scholar] [CrossRef]

- Astaneh, M.A.; Hosseinzadeh, E.; Marzband, M.; Ghosh, A.; Guerrero, J.M. Multiphysics simulation optimization framework for lithium-ion battery pack design for electric vehicle applications. Energy 2022, 239, 122092. [Google Scholar] [CrossRef]

- Pierri, E.; Cirillo, V.; Vietor, T.; Sorrentino, M. Adopting a Conversion Design Approach to Maximize the Energy Density of Battery Packs in Electric Vehicles. Energies 2021, 14, 1939. [Google Scholar] [CrossRef]

- Paudel, S.; De Boever, Q.; Zhang, J.; Ayalew, B.; Pisu, P.; Castanier, M. Design optimization of mobile vehicle-borne microgrids. Sustain. Energy Grids Netw. 2024, 39, 101480. [Google Scholar] [CrossRef]

- Gómez Díaz, K.Y.; De León Aldaco, S.E.; Aguayo Alquicira, J.; Ponce Silva, M.; Portillo Contreras, S.; Sánchez Vargas, O. Thermal Management Systems for Lithium-Ion Batteries for Electric Vehicles: A Review. World Electr. Veh. J. 2025, 16, 346. [Google Scholar] [CrossRef]

- Belingardi, G.; Scattina, A. Battery Pack and Underbody: Integration in the Structure Design for Battery Electric Vehicles—Challenges and Solutions. Vehicles 2023, 5, 498–514. [Google Scholar] [CrossRef]

- Schröder, R.; Aydemir, M.; Seliger, G. Comparatively Assessing different Shapes of Lithium-ion Battery Cells. Procedia Manuf. 2017, 8, 104–111. [Google Scholar] [CrossRef]

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Stock, S.; Hagemeister, J.; Grabmann, S.; Kriegler, J.; Keilhofer, J.; Ank, M.; Dickmanns, J.L.; Schreiber, M.; Konwitschny, F.; Wassiliadis, N.; et al. Cell teardown and characterization of an automotive prismatic LFP battery. Electrochim. Acta 2023, 471, 143341. [Google Scholar] [CrossRef]

- Zhu, J.; Koch, M.M.; Lian, J.; Li, W.; Wierzbicki, T. Mechanical Deformation of Lithium-Ion Pouch Cells under In-Plane Loads—Part I: Experimental Investigation. J. Electrochem. Soc. 2020, 167, 090533. [Google Scholar] [CrossRef]

- Lu, J.; Wu, T.; Amine, K. State-of-the-art characterization techniques for advanced lithium-ion batteries. Nat. Energy 2017, 2, 17011. [Google Scholar] [CrossRef]

- Battery2030+ Consortium. Battery 2030+ Roadmap Update 2023. Available online: https://battery2030.eu/research/roadmap/ (accessed on 22 July 2025).

- Rodrigues, V.; Kasaei, M.; Marques, E.; da Silva, L. Adhesive bonding in automotive battery pack manufacturing and dismantling: A review. Discov. Mech. Eng. 2025, 4, 25. [Google Scholar] [CrossRef]

- Alma’asfa, S.I.; Abdul Aziz, M.S.; Khor, C.Y.; Al-Sulaiman, F.A.; Khan, M.S. Thermal management of cylindrical lithium-ion batteries with different fin configurations and phase change material: A numerical analysis. J. Therm. Anal. Calorim. 2025, 150, 12643–12662. [Google Scholar] [CrossRef]

- Munari, B.; Schneer, A. How to Design a Precharge Circuit for Hybrid and Electric Vehicle Applications, Sensata Technologies, Technical White Paper. 2020. Available online: https://www.sensata.com/sites/default/files/a/sensata-how-to-design-precharge-circuits-evs-whitepaper (accessed on 22 July 2025).

- MathWorks. Model-Based Design for Embedded Systems. 2021. Available online: https://www.mathworks.com/model-based-design (accessed on 22 July 2025).

- Lorentz, V.R.H.; Schwarz, R.; Kanzler, P.; Waldhör, S.; Wenger, M.; Gepp, M.; Koffel, S.; Wacker, S.; Wachtler, J.; Huf, T.; et al. foxBMS—The Most Advanced Open Source BMS Platform: FoxBMS 2, 2021. Available online: https://https://foxbms.org (accessed on 22 July 2025).

- OpenECU Technical Overview. 2020. Available online: https://www.openecu.com (accessed on 22 July 2025).

- An, C.; Zheng, K.; Wang, S.; Wang, T.; Liu, H.; Lin, L.; Deng, Q.; Zhang, K.; Hu, N. Advances in sensing technologies for monitoring states of lithium-ion batteries. J. Power Sources 2025, 625, 235633. [Google Scholar] [CrossRef]

- Marcos, D.; Garmendia, M.; Crego, J.; Cortajarena, J.A. Functional Safety BMS Design Methodology for Automotive Lithium-Based Batteries. Energies 2021, 14, 6942. [Google Scholar] [CrossRef]

- Diab Compiler for Automotive Safety Applications. 2019. Available online: https://www.windriver.com/products/diab-compiler (accessed on 22 July 2025).

- Paudel, S.; Zhang, J.; Ayalew, B.; Singh, R. Systematic Characterization of Lithium-Ion Cells for Electric Mobility and Grid Storage: A Case Study on Samsung INR21700-50G. Batteries 2025, 11, 313. [Google Scholar] [CrossRef]

- Mishra, D.; Paudel, S.; Zhang, J.; Lawler, B.; Castanier, M.P. From Cell to Module: A Holistic Approach to Identification, Modeling, Simulation, and Validation of 21700 Li-Ion Batteries for Electric Vehicles. 2025. Available online: https://ssrn.com/abstract=5398447 (accessed on 22 July 2025).

- Intercell eCooler. Available online: https://www.borgwarner.com/technologies/thermal-management (accessed on 22 July 2025).

- Eaton. Breaktor: Advanced Protection for High Voltage Circuits in Electric Vehicles. Available online: https://www.eaton.com/content/dam/eaton/products/emobility/power-distribution-protection/breaktor/eaton-breaktor-whitepaper-en.pdf (accessed on 22 July 2025).

| Parameter | EV Target | ESS Target |

|---|---|---|

| Energy Density (Gravimetric) | >275 Wh/kg | Not a primary focus |

| Energy Density (Volumetric) | >650 Wh/L | Not a primary focus |

| Charging/Discharge Rate | ≤15 min to 80% SOC; up to 10C | 2–4 h discharge duration |

| Cycle Life | ≥1000 cycles at 80% DoD | Long duration, varies by use case |

| Calendar Life | ≥10 years | ≥10–15 years |

| System Voltage | 400 V/800 V | 600–1500 V |

| Round-Trip Efficiency | >90% | >90% |

| Operating Temperature | −30 C to +55 C | Typically −20 C to +50 C |

| Type approval/Safety Standards | UN 38.3, ISO 26262, UL 2580 | UL 9540A [15], IEC 62933 |

| Environmental Protection | IP67 or higher | IP65 or higher |

| Communication Protocols | CAN, ISO 15118 [16] | Modbus, DNP3, IEC 61850 [17] |

| System Integration | Vehicle systems, charging infrastructure | SCADA/EMS platforms |

| Cybersecurity Focus | Basic vehicle-level protection | Critical for grid-tied systems |

| Cost Target | <$75/kWh | $124–$296/kWh (LCOS, 4-h) |

| Parameter | Cylindrical | Prismatic | Pouch |

|---|---|---|---|

| Energy Density (Wh/kg) | Medium–High | Medium | High |

| Volumetric Efficiency | Moderate | High | High |

| Thermal Uniformity | High | Moderate | Low |

| Mechanical Robustness | High | Medium | Low |

| Manufacturing Maturity | High | High | Moderate |

| Packaging Efficiency | Medium | High | Low |

| EV Deployment | ✓ | ✓ | ✓ |

| ESS Deployment | Niche | Mainstream | Dense racks |

| Parameter | Specification |

|---|---|

| Operating Voltage Range | 250–420 V |

| Operating Voltage Range | 250–420 V |

| Installed Energy | 60 kWh |

| Fast Charge Time | 36 min (to 80% SOC) |

| Maximum Charge Power | 60 kW |

| Maximum Discharge Power | 175 kW (10 s at 20% SOC) |

| Continuous Discharge Rate | 1C |

| Gross Weight | 450 kg |

| BMS Measurement Accuracy | ±3% |

| Target Lifetime | >10 years |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Paudel, S.; Zhang, J.; Ayalew, B.; Griddaluru, V.Y.; Singh, R. Design, Prototyping, and Integration of Battery Modules for Electric Vehicles and Energy Storage Systems. Electricity 2025, 6, 63. https://doi.org/10.3390/electricity6040063

Paudel S, Zhang J, Ayalew B, Griddaluru VY, Singh R. Design, Prototyping, and Integration of Battery Modules for Electric Vehicles and Energy Storage Systems. Electricity. 2025; 6(4):63. https://doi.org/10.3390/electricity6040063

Chicago/Turabian StylePaudel, Saroj, Jiangfeng Zhang, Beshah Ayalew, Venkata Yagna Griddaluru, and Rajendra Singh. 2025. "Design, Prototyping, and Integration of Battery Modules for Electric Vehicles and Energy Storage Systems" Electricity 6, no. 4: 63. https://doi.org/10.3390/electricity6040063

APA StylePaudel, S., Zhang, J., Ayalew, B., Griddaluru, V. Y., & Singh, R. (2025). Design, Prototyping, and Integration of Battery Modules for Electric Vehicles and Energy Storage Systems. Electricity, 6(4), 63. https://doi.org/10.3390/electricity6040063