In the context of ceramic manufacturing, additive manufacturing or 3D printing creates new opportunities and perspectives, allowing the fabrication of parts with complex shapes, which by traditional means would be impossible to produce or would be very expensive [

1]. This is the case for dinnerware and artworks (stoneware, porcelain and clay-based products).

After piece forming, the greenware is gas or electrically fired at high temperatures to achieve its mechanical strength and aesthetic properties. These conventional firing processes usually require long processing times, in the present case taking 10 h to reach temperatures around 1200 °C [

2].

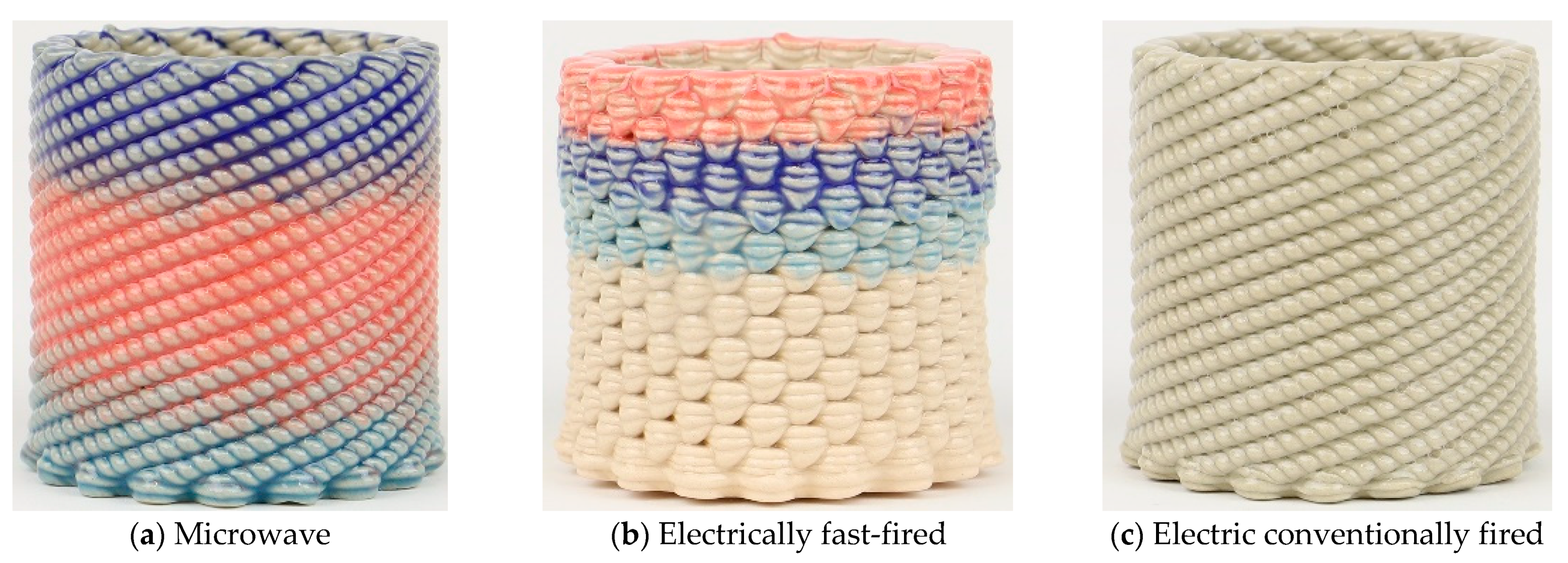

In the search for faster firing processes, small size and cup shaped 3D printed stoneware pieces were fired using microwave radiation as the energy source. As microwave radiation has the potential to penetrate the material to be sintered, volumetric heating can be achieved, and faster firing processes are possible to implement without cracks formation and other thermal related defects.

Pieces were fired in 10% of the conventional manufacturing time in a six magnetrons (energy sources) microwave furnace [

3]. The microwave, the electrically-fast-fired and conventionally-fired pieces are presented in

Figure 1. The conventionally-fired pieces are seen as reference samples.

Temperature was controlled through a calibrated pyrometer [

3], and using Process Temperature Control Rings (PTCR) the temperature of the pieces of (1207 ± 15) °C was determined. An error of only 1.25% was calculated between the temperature measured by the pyrometer and the PTCR in the piece where the pyrometer is measuring the temperature. The PTCR elements give a better representation of the real heating process at its location, concomitantly of each piece when they are placed inside it.

The results show that microwave-fast-fired pieces present comparable mechanical strength to the references (10 h electrically fired) and to the electrically fast-fired pieces (41, 46 and 34 (N/mm2), respectively), and present aesthetic features closer to the reference ones. Porosity quantification does not fully agree with the mechanical strength of the pieces, of ~5% for electrically fast-fired, ~9% for the references and ~4% for microwave-fired ones.

Overall, microwave heating can be used as an alternative stoneware firing technology, without compromising its quality and features with gains in the manufacturing time. Another advantage attributed to microwave heating is the reduction in the firing temperature, as claimed by the literature [

4,

5]. However, this possibility still requires confirmation in 3D-printed stoneware.

Author Contributions

Conceptualization, T.S.; methodology, T.S. and M.R.; software, T.S.; validation, T.S., M.R., S.D., C.B. and M.F.; formal analysis, T.S., S.D., C.B., M.F. and I.D.; investigation, T.S., M.R., S.D., C.B., M.F. and I.D.; resources, T.S., M.R., S.D., C.B., M.F., I.D., L.C., N.F., N.A. and P.P.-F.; data curation, T.S., M.R., S.D., C.B., M.F. and I.D.; writing—original draft preparation, T.S. and S.D.; writing—review and editing, T.S., M.R., S.D., C.B., M.F., N.F., N.A. and P.P.-F.; visualization, T.S., M.R., S.D., C.B., M.F. and I.D.; supervision, T.S., N.F. and N.A.; project administration, T.S., N.F. and N.A.; funding acquisition, N.F., N.A. and P.P.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Fundação para a Ciência e a Tecnologia FCT/MCTES (PIDDAC) through the following Projects: UIDB/04044/2020; UIDP/04044/2020; Associate Laboratory ARISE LA/P/0112/2020; PAMI—ROTEIRO/0328/2013 (Nº 022158), and by Stimuli2BioScaffold—Stimuli modelling for BioScaffolds: from numerical modelling to in vitro tests co-financed by COMPETE2020 under the PT2020 programme and MATIS (CENTRO-01-0145-FEDER-000014—3362).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the support of the project i3N, UIDB/50025/2020 & UIDP/50025/2020, financed by national funds through the FCT/MEC. The authors also acknowledge the support by the projects UIDB/00481/2020 and UIDP/00481/2020—Fundação para a Ciência e a Tecnologia; and CENTRO-01-0145-FEDER-022083—Centro Portugal Regional Operational Programme (Centro2020), under the PORTUGAL 2020 Partnership Agreement, through the European Regional Development Fund.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Taylor, L. The Ceramics Bible: The Complete Guide to Materials and Techniques; Chronicle Books: San Francisco, CA, USA, 2011. [Google Scholar]

- Santos, T.; Hennetier, L.; Costa, V.A.F.; Costa, L.C. Microwave vs conventional porcelain firing: Macroscopic properties. Int. J. Appl. Ceram. Technol. 2021, 17, 2277–2285. [Google Scholar] [CrossRef]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave material processing—A review. AIChE J. 2012, 58, 330–363. [Google Scholar] [CrossRef]

- Oghbaei, M.; Mirzaee, O. Microwave versus conventional sintering: A review of fundamentals, advantages and applications. J. Alloys Compd. 2010, 494, 175–189. [Google Scholar] [CrossRef]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).