1. Introduction

In this proceeding, recently published projects based on the combination of metal-free semiconductor graphitic carbon nitride (g-C3N4) and polymers will be summarized. The proceeding will briefly focus on how graphitic carbon nitride is successfully integrated into different reaction environments, such as in dispersion, or as a heterogeneous photo initiator, to evolve the properties and synthesis of polymer materials.

A relatively old material, g-C

3N

4 is a polymeric semiconductor discovered in 2009. Its synthesis is based on thermal polymerization (around 550 °C) of abundant and nitrogen-rich molecules, such as urea and melamine, that result in a semiconductor with photoactivity in the visible and UV range [

1]. Its thermal reaction mechanism can be considered as recondensation of decomposed gaseous molecules of precursors to form a thermodynamically stable matter at elevated temperatures. It is different than a typical solid state condensation reaction; therefore, reaction conditions such as temperature ramp and applied atmosphere play a curial role in forming the desired and reproducible g-C

3N

4. Since it is a type of polymerization, the condensation degree can be also tuned by the variability of reaction conditions (mainly temperature). Moreover, further modifications, such as edge functioning and tuning repeating motifs, are just some possibilities to form diverse g-C

3N

4′s. g-C

3N

4 exhibits high stability in acidic and basic environments, as well as thermal stability up to 620 °C.

Selected precursor and preparation methods directly affect all final properties, such as surface area, morphology, surface charge, crystallinity and optical properties. Photophysical features of the resulting g-C

3N

4 may vary depending on the performed techniques. Synthesized g-C

3N

4s in powder form demonstrates a slightly negative surface charge; however, the synthesis of g-C

3N

4 thin films and membranes are known in the literature as well [

2,

3]. Furthermore, as a typical semiconductor, g-C

3N

4 exhibits reductive and oxidative pathways upon photo-formed electrons and holes, which are a vital role of photoredox-based science. g-C

3N

4 has been a haven for photocatalysis, and has been integrated into many appealing applications by acting as a heterogeneous photocatalyst [

4]. Furthermore, under light irradiation, it can form radical species which can be harnessed to conduct radical photopolymerization techniques. From a polymer perspective, g-C

3N

4 was employed as a heterogeneous photoinitator for free radical and controlled radical polymerization methodologies.

However, some drawbacks based on dominant π-π interactions between g-C

3N

4 sheets cause problems, such as processability and dispersion preparation, which hinder its further possibilities. Recently, the surface modification of g-C

3N

4 materials introduced dispersible g-C

3N

4 colloids which, addressed both in aqueous and organic environments, are attractive for new possibilities [

5,

6]. There are numerous well-established techniques that deal with the integration of g-C

3N

4 colloids in soft materials, membranes and polymer particles to form hybrid materials. Yet, there are still many materials to be explored that are based on g-C

3N

4 and polymer materials.

Herein, the following proceeding will highlight three recently published reports based on g-C3N4 and polymer combination. It will start with an organic dispersion of g-C3N4 to form crosslinked porous polymer beads named poly(styrene-co-divinylbenzene) through suspension polymerization, to sculpt photoactive bead materials. Aqueous dispersion of g-C3N4 will be employed for porous hydrogel synthesis, and the embedded g-C3N4 nanosheets will act as anchoring points for further light-induced modifications, i.e., pore substructuring and the synthesis of ‘hydrophobic hydrogel’. Finally, g-C3N4 will be utilized as a heterogeneous photoinitiator to polymerize 3,4-ethylenedioxythiophene (EDOT) to form a non-doped oligoEDOT material that is prone to processing prior to doping.

2. Results

2.1. Upgrading Poly(styrene-co-divinylbenzene) Beads through Suspension Photopolymerization via Carbon Nitride

Metal-free semiconductor graphitic carbon nitride (g-C

3N

4) can act as a heterogeneous photoredox polymer initiator. This study introduces g-C

3N

4 integration into the inner surface (interfaces) of porous poly(styrene-co-divinylbenzene) beads via one-pot suspension photopolymerization (

Scheme 1).

Regarding suspension polymerization principles, reaction conditions such as crosslinking ratio (25, 35, 50 wt.% divinylbenzene), the presence of porogens (toluene as co-solvent, 1-octanol as dispersion agent of vTA-CMp), and mechanical agitation (slow and medium) are investigated. According to results, 25 wt.% divinylbenzene, the presence of toluene along with 1-octanol, and medium agitation speed, were elucidated as optimal conditions.

As shown in

Figure 1, bead morphology was investigated via SEM, and the resulting images revealed a highly porous structure (

Figure 1(a1,a2)). In addition, the EDX investigation exhibiting homogeneous nitrogen distribution indicated successful vTA-CMp corporation, since none of the reaction ingredients, except vTA-CMp, bear nitrogen (

Figure 1b).

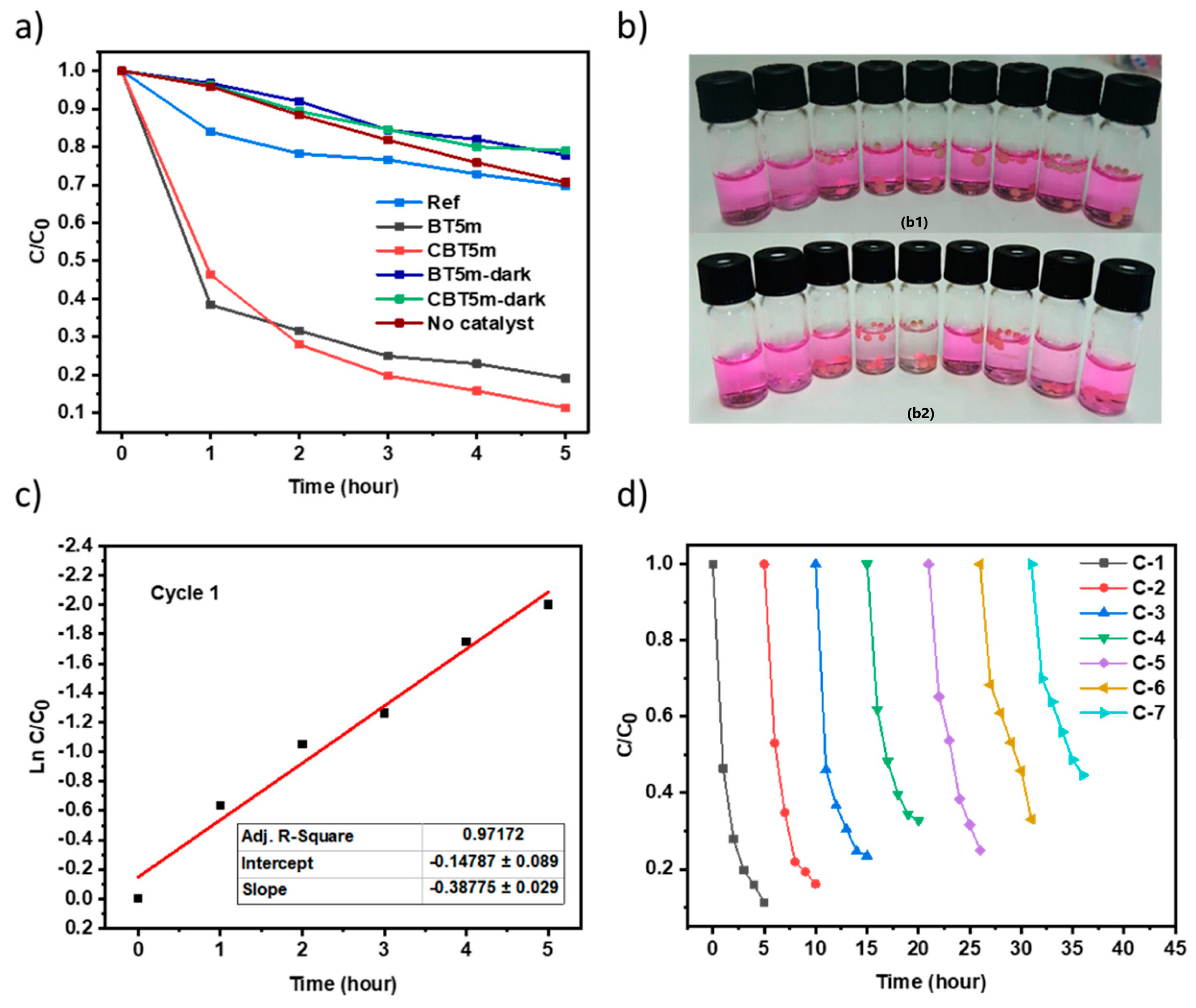

Photocatalytic properties of the selected beads were investigated by performing an aqueous Rhodamine B dye degradation experiment under visible light illumination and dark conditions (

Figure 2a,b). Among the as-synthesized beads, the g-C

3N

4 photo-initiated bead (CBT5m) exhibited 89% degradation efficiency in 5 h, within the

R2 value of 0.971 (

Figure 2c). Moreover, cyclic photocatalytic cycles ran up to 7 cycles and resulted in moderate loss of activity, 55.6% (

Figure 2d). Lastly, the pH effect on photodegradation explicated the stability of the applied beads with no host degradation. In addition, dye adsorption/desorption properties were tested in both aqueous and organic dyes.

Afterwards, g-C3N4-incorporated beads were subjected to a photo-induced surface modification by employing vinylsulfonic acid (VSA) and 4-vinyl pyridine (VP) under visible light irradiation. According to the results, VSA photo-grafting was analyzed successfully by elemental mapping via EDX along with elemental analysis via detected sulfur content. On the other hand, VP photo-grafting was confirmed via combustive elemental analysis together with FT-IR successfully.

In other words, beads donated with photoactivity via metal-free semiconductor g-C3N4 integration can be exploited for dye photodegradation and as an acid-base catalyst after post-functionalization through a simple photo-induced surface modification.

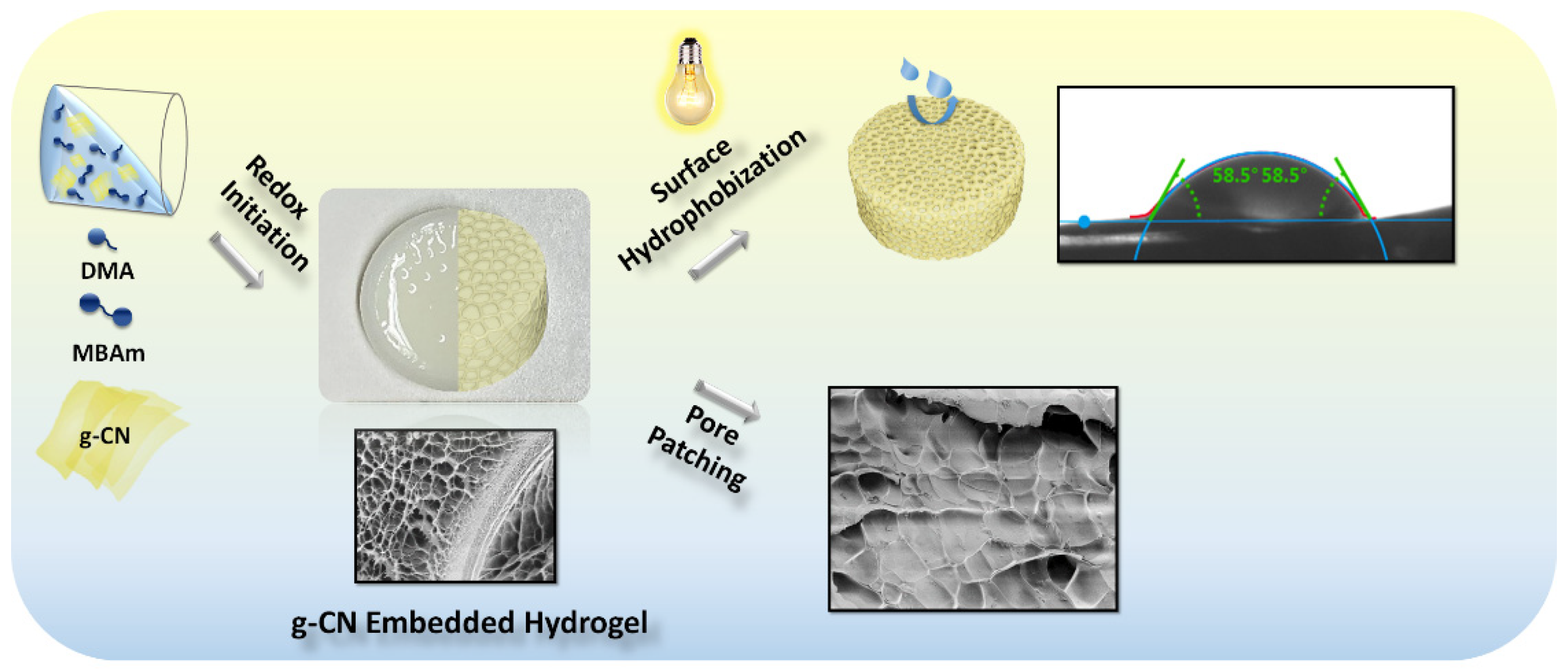

2.2. Synthesis of g-C3N4 Integrated Hydrogels and Subsequent Post-Modifications

As a particular class of hydrophilic polymers, hydrogels possess a high water content through their crosslinked porous networks. A facile synthesis of a hydrogel can be simply described as a combination of a water-soluble monomer and a multi-functional crosslinker in the presence of an initiator (mainly radical-based systems). In this context, firstly, g-C

3N

4 embedded hydrogel synthesis, thereafter its further subsequent visible light-assisted post modifications will be described (

Scheme 2).

Template g-C

3N

4-embedded hydrogel was formed by free-radical polymerization in the presence of a redox couple (ascorbic acid-hydrogen peroxide), water-soluble monomer (

N,

N-Dimethylacrylamide, DMA) with a crosslinker (

N,

N′-methylenebisacrylamide, MBA), in an aqueous dispersion of g-C

3N

4. Gelation proceeded in 3 h and the resulting hydrogel further employed surface hydrophobization by being immersed into 4-methyl-5-vinylthiazole (vTA) under visible light irradiation. Drastic morphology change over the pore closure, observed via SEM investigation (

Figure 3(a1,a2)), and sulfur detection via EDX measurement were supportive evidences of performed surface photo-modification (

Figure 3b). Moreover, resulting hydrophobized hydrogel showed an enhanced water contact angle result (58.5° over 40 s), unlike the initial hydrophilic hydrogel (

Figure 3c). In addition, the sustained cation release performance by investigating several cations in both samples was confirmed, based on controlled release after surface hydrophobization (

Figure 3d).

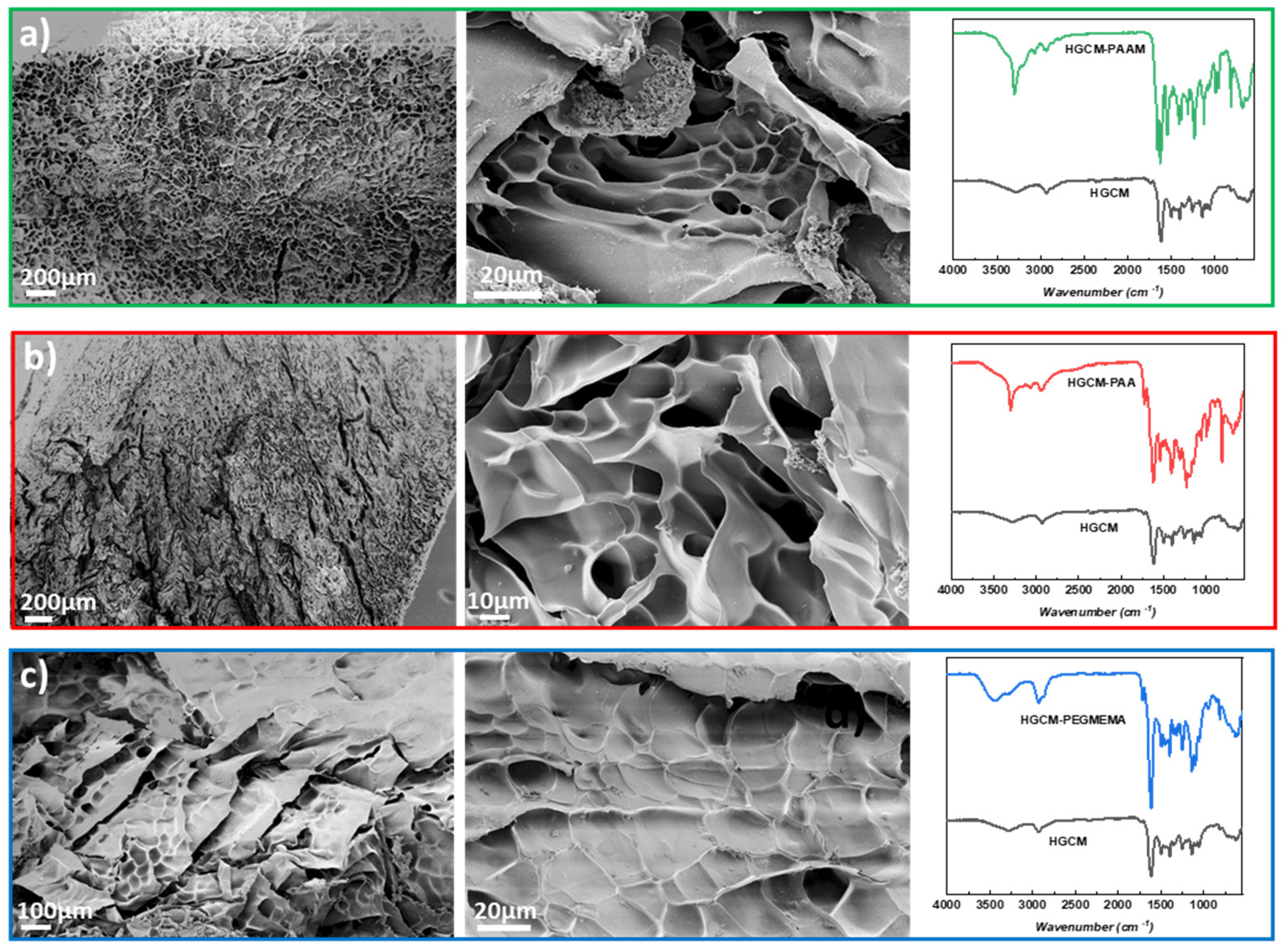

Considering the SEM results exhibited the highly porous structure of host hydrogel, pore substructuring was performed by taking advantage of the embedded g-C

3N

4 photoactivity. Regarding that, host hydrogel was swollen by various vinyl monomers and exposed to visible light. According to the SEM investigation, the closure of pores via polymer layer formation was observed, and the detection of functional groups via FT-IR underlined the efficient modification (

Figure 4a–c).

The enrichment of hydrogels via embedding photoactive g-C3N4 nanosheets can be a promising subject with a variety of target applications for the future, especially when the simplicity of post-functionalization via light illumination is considered.

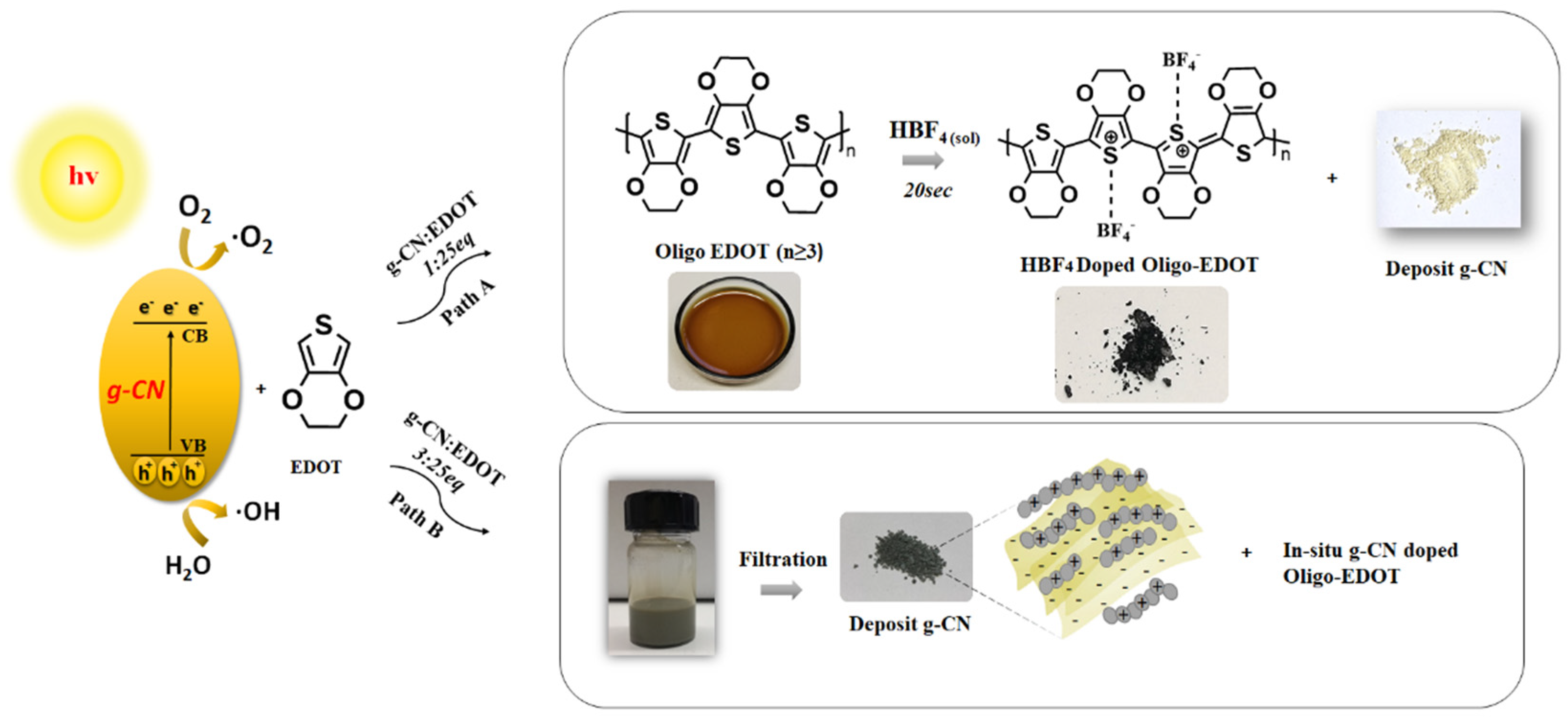

2.3. Oxidative Photopolymerization of 3,4-Ethylenedioxythiophene (EDOT) via g-C3N4

Conductive polymers have been playing a vital role in a broad range of materials, from optoelectronic to conductive composites. PEDOT is a functional polymer possessing high conductivity and stability even after doping process. However, the lack of processability of PEDOT requires external factors, which in return negatively influence its conductivity. As an alternative way to overcome this, g-C

3N

4 was employed as photoredox-type photo-initiator to achieve the oxidative photopolymerization of EDOT under visible light irradiation. A one-pot reaction in the presence of oxygen allowed neutral oligo-EDOT formation (path 1) and a reusable deposit of g-C

3N

4. The alternative addition of excess g-C

3N

4 in the reaction led to a hybrid heterojunction material which possessed the deposited oligo-EDOT on g-C

3N

4 power, based on surface polaron formation (path 2) (

Scheme 3).

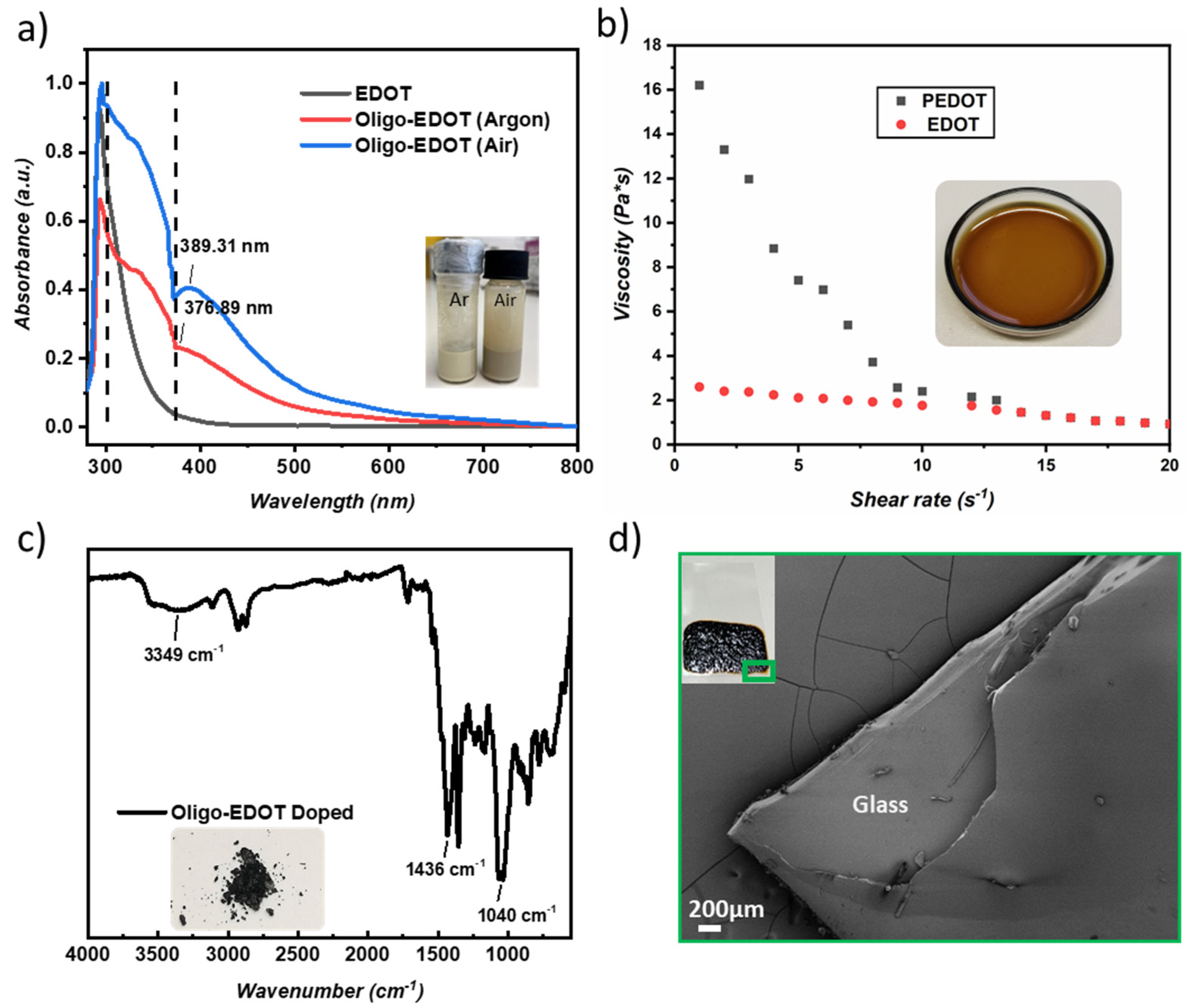

The eventual molecular weight was analyzed via UV-vis spectroscopy. According to the literature, the so-formed oxidative photopolymerization product explicit oligomer formation, in comparison to established PEDOT products, was thus named as ‘oligo-EDOT’ (n ≥ 3) based upon its intensified and slightly red-shifted UV-vis spectrum (

Figure 5a). Furthermore, the enhanced viscosity within its darkened color after polymerization (as EDOT is a colorless monomer) supported success in photo-oxidative polymerization (

Figure 5b). Resulting viscous oligo-EDOT was further post-doped with HBF

4, and finally the dried product was confirmed via FT-IR (

Figure 5c). From a manufacturing perspective, a facile formation of film and coatings without the further addition of chemical substances yielded homogeneous conductive matter (

Figure 5d).

Oxidative photopolymerization to form non-doped conducting polymers and conjugated systems, that are promising for optoelectronic and energy devices, was achieved via g-C3N4 acting as a photocatalyst. When used in excess, surface polaron-based novel hybrid materials can be accessible.

3. Conclusions

The combination of a metal-free semiconductor g-C3N4 with polymer materials is highly exciting, and offers many advanced materials, as shown in the present contribution. Photoactivity of g-C3N4 can be harnessed to synthesize polymers through photoredox chemistry (either forming active radicals through charge transfer processes, excited electrons, or a positive hole can be directly employed), or alternatively g-C3N4 can be dispersed and embedded in polymer networks to grant photoactivity. Merging polymers with colloidal g-C3N4 materials is still at the infant stage; however, one can distill versatile synthetic-polymer chemistry knowledge with semiconductor science to design functional materials that can address soft materials, conducting polymers, hybrid polymer materials, agricultural delivery systems and catalysis.