Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Deactivation of Ground Tire Rubber Hydroxyl Groups

2.3. Preparation of Polyurethane/Ground Tire Rubber Composite Foams

2.4. Characterization Techniques

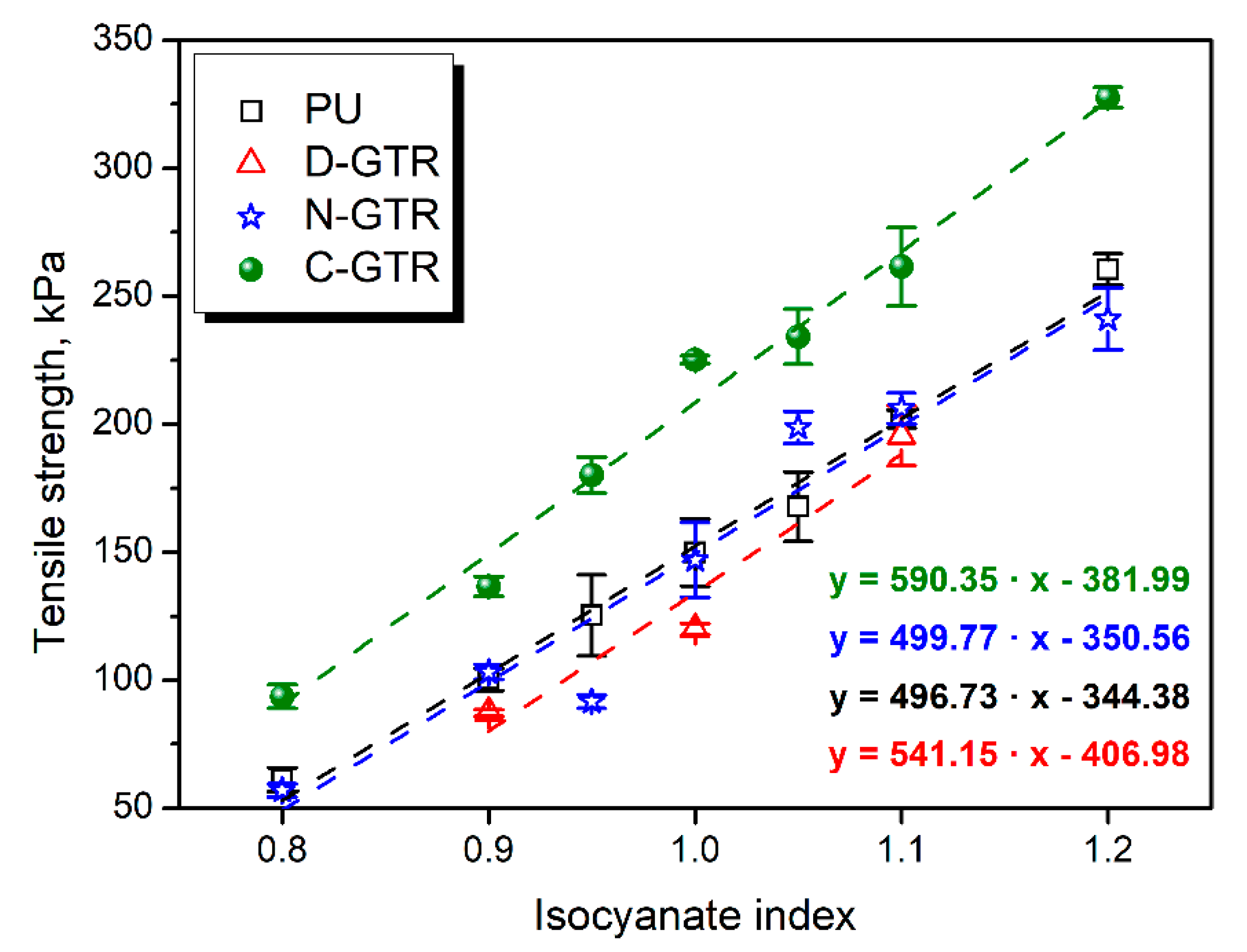

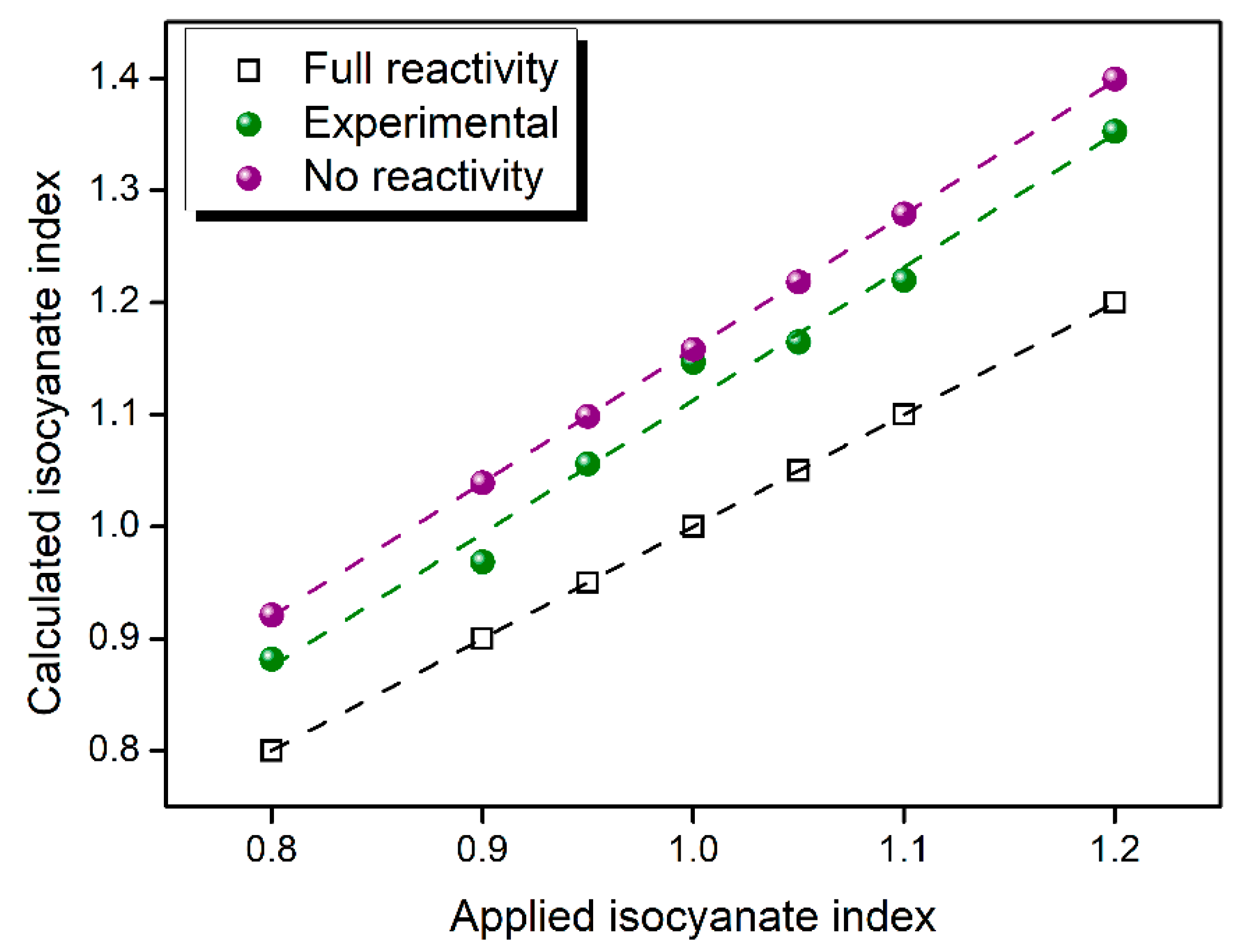

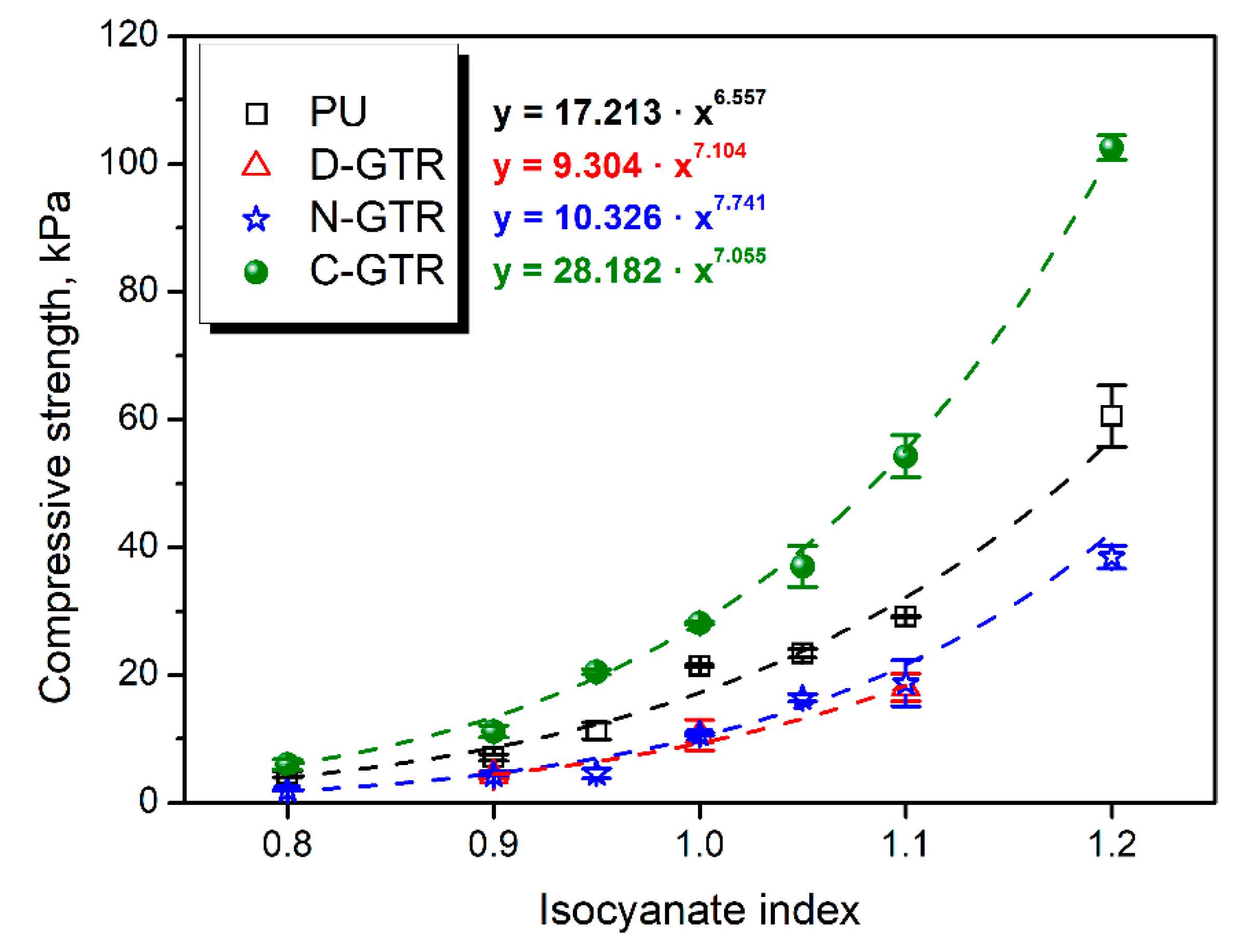

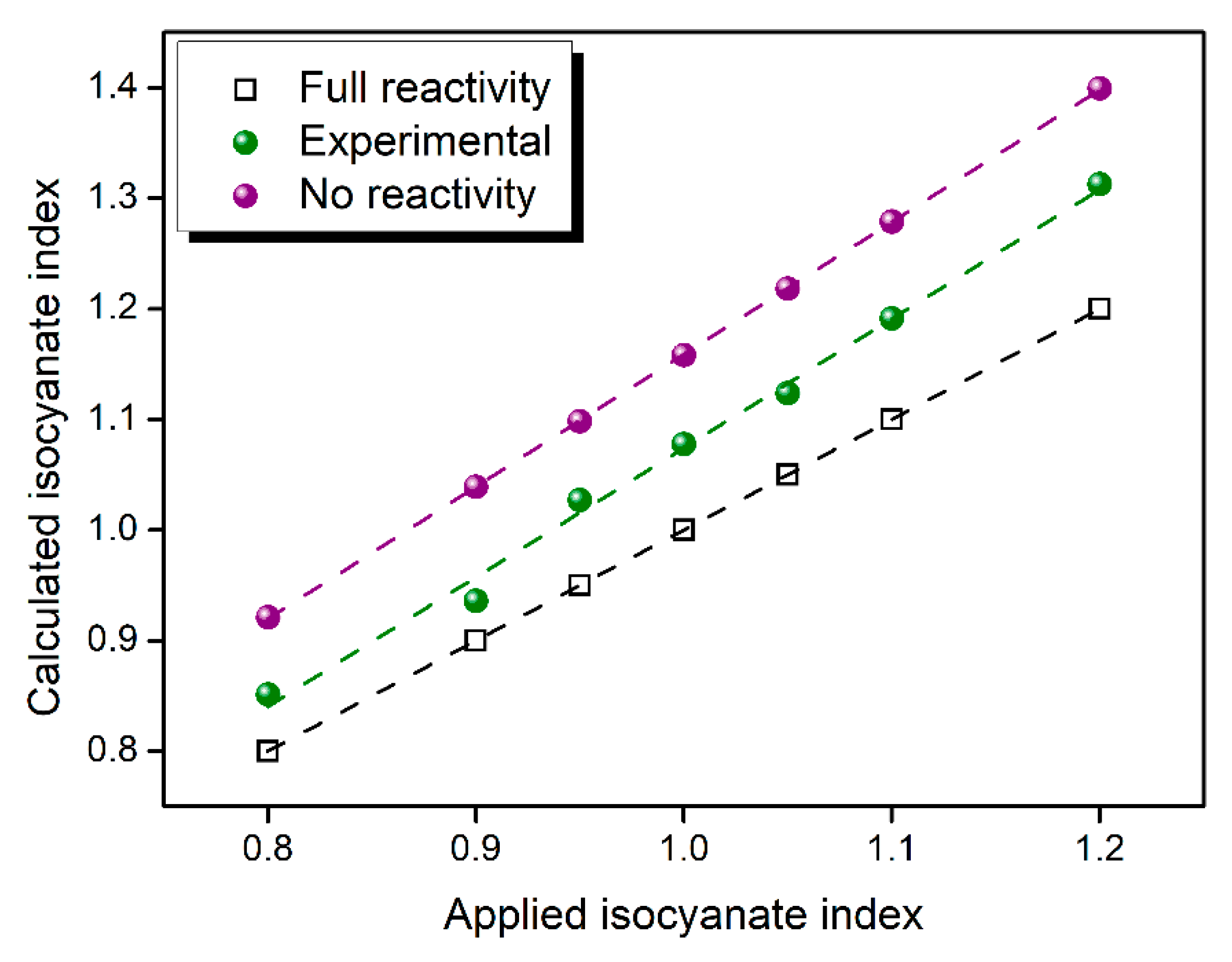

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hejna, A.; Kosmela, P.; Kirpluks, M.; Cabulis, U.; Klein, M.; Haponiuk, J.; Piszczyk, Ł. Structure, Mechanical, Thermal and Fire Behavior Assessments of Environmentally Friendly Crude Glycerol-Based Rigid Polyisocyanurate Foams. J. Polym. Environ. 2017, 26, 1854–1868. [Google Scholar] [CrossRef] [Green Version]

- Gosz, K.; Kosmela, P.; Hejna, A.; Gajowiec, G.; Piszczyk, Ł. Biopolyols obtained via microwave-assisted liquefaction of lignin: Structure, rheological, physical and thermal properties. Wood Sci. Technol. 2018, 52, 599–617. [Google Scholar] [CrossRef] [Green Version]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef] [PubMed]

- Kosmela, P.; Olszewski, A.; Zedler, Ł.; Burger, P.; Formela, K.; Hejna, A. Structural Changes and Their Implications in Foamed Flexible Polyurethane Composites Filled with Rapeseed Oil-Treated Ground Tire Rubber. J. Compos. Sci. 2021, 5, 90. [Google Scholar] [CrossRef]

- Hejna, A.; Korol, J.; Przybysz-Romatowska, M.; Zedler, Ł.; Chmielnicki, B.; Formela, K. Waste tire rubber as low-cost and environmentally-friendly modifier in thermoset polymers—A review. Waste Manag. 2020, 108, 106–118. [Google Scholar] [CrossRef] [PubMed]

- Piszczyk, Ł.; Hejna, A.; Formela, K.; Danowska, M.; Strankowski, M. Effect of ground tire rubber on structural, mechanical and thermal properties of flexible polyurethane foams. Iran. Polym. J. 2015, 24, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Przyjemska, K.; Chojnacki, P.; Ryszkowska, J. Modification of flexible polyurethane foams by the addition of natural origin fillers. Polym. Degrad. Stabil. 2016, 132, 32–40. [Google Scholar] [CrossRef]

- Piszczyk, Ł.; Hejna, A.; Danowska, M.; Strankowski, M.; Formela, K. Polyurethane/ground tire rubber composite foams based on polyglycerol: Processing, mechanical and thermal properties. J. Reinf. Plast. Compos. 2015, 34, 708–717. [Google Scholar] [CrossRef]

- Silva, N.G.S.; Cortat, L.I.C.O.; Orlando, D.; Mulinari, D.R. Evaluation of rubber powder waste as reinforcement of the polyurethane derived from castor oil. Waste Manag. 2020, 116, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Hejna, A.; Haponiuk, J.; Piszczyk, Ł.; Klein, M.; Formela, K. Performance properties of rigid polyurethane-polyisocyanurate/brewers’ spent grain foamed composites as function of isocyanate index. e-Polymers 2017, 17, 427–437. [Google Scholar] [CrossRef]

- Hejna, A.; Olszewski, A.; Zedler, Ł.; Kosmela, P.; Formela, K. The Impact of Ground Tire Rubber Oxidation with H2O2 and KMnO4 on the Structure and Performance of Flexible Polyurethane/Ground Tire Rubber Composite Foams. Materials 2021, 14, 499. [Google Scholar] [CrossRef] [PubMed]

- Zedler, Ł.; Kosmela, P.; Olszewski, A.; Burger, P.; Formela, K.; Hejna, A. Recycling of Waste Rubber by Thermo-Mechanical Treatment in a Twin-Screw Extruder. Proceedings 2021, 69, 10. [Google Scholar] [CrossRef]

- Prociak, A.; Malewska, E.; Bąk, S. Influence of Isocyanate Index on Selected Properties of Flexible Polyurethane Foams Modified with Various Bio-Components. J. Renew. Mater. 2016, 4, 78–85. [Google Scholar] [CrossRef]

- Lee, C.S.; Ooi, T.L.; Chuah, C.H.; Ahmad, S. Effect of isocyanate index on physical properties of flexible polyurethane foams. Malays. J. Sci. 2007, 26, 91–98. [Google Scholar]

- Zedler, Ł.; Kowalkowska-Zedler, D.; Colom, X.; Cañavate, J.; Saeb, M.R.; Formela, K. Reactive Sintering of Ground Tire Rubber (GTR) Modified by a Trans-Polyoctenamer Rubber and Curing Additives. Polymers 2020, 12, 3018. [Google Scholar] [CrossRef] [PubMed]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed Polyurethane Composites with Different Types of Ash—Morphological, Mechanical and Thermal Behavior Assessments. Cell. Polym. 2016, 35, 287–308. [Google Scholar] [CrossRef]

- Vilar, W.D. Química e Tecnologia dos Poliuretanos, 2nd ed.; Vilar Consultoria Técnica Ltd.: Rio de Janeiro, Brazil, 1998. [Google Scholar]

- Abdel Hakim, A.A.; Nassar, M.; Emam, A.; Sultan, M. Preparation and characterization of rigid polyurethane foam prepared from sugar-cane bagasse polyol. Mater. Chem. Phys. 2011, 129, 301–307. [Google Scholar] [CrossRef]

- Olcay, H.; Kocak, E.D. The mechanical, thermal and sound absorption properties of flexible polyurethane foam composites reinforced with artichoke stem waste fibers. J. Ind. Text. 2020, 152808372093419. [Google Scholar] [CrossRef]

| Material | Origin | Details |

|---|---|---|

| PU foams preparation | ||

| Rokopol® F3000 | PCC Group (Brzeg Dolny, Poland) | Polyol, hydroxyl value (LOH) = 53–59 mg KOH/g |

| Rokopol® V700 | Polyol, LOH = 225–250 mg KOH/g | |

| Glycerol | Sigma Aldrich (Poznań, Poland) | LOH = 1800 mg KOH/g |

| SPECFLEX NF 434 | M. B. Market Ltd. (Baniocha, Poland) | Polymeric methylenediphenyl-4,4′-diisocyanate, free -NCO content = 29.5% |

| PC CAT® TKA30 | Performance Chemicals (Belvedere, UK) | Catalyst, potassium acetate |

| Dabco33LV | Air Products (Allentown, PA, USA) | Catalyst, 1,4-diazabicyclo [2.2.2]octane in dipropylene glycol, 3 wt% solution |

| Dibutyltin dilaurate | Sigma Aldrich (Poznań, Poland) | Catalyst, organic tin compound |

| Distilled water | - | Chemical blowing agent |

| Ground tire rubber | Recykl S.A. (Śrem, Poland) | Filler, mean particle size = 0.6 mm, LOH = 61.7 ± 3.0 mg KOH/g |

| Deactivation of GTR -OH groups | ||

| Acetone | Sigma Aldrich (Poznań, Poland) | Solvent |

| Toluene diisocyanate | Free -NCO content = 42% | |

| Dibutylamine | Analyte solution | |

| Chlorobenzene | Solvent | |

| Hydrochloric acid | Titrant | |

| 3′,3″,5′,5″-Tetrabromophenol-sulfonphthalein | Indicator | |

| Component | Neat Foam | GTR Deactivated/Not Considered | GTR Considered | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Content, wt% | |||||||||||||||||||||

| F3000 | 35.4 | 34.2 | 33.7 | 33.2 | 32.7 | 32.2 | 31.2 | 29.5 | 28.5 | 28.1 | 27.6 | 27.2 | 26.8 | 26.0 | 28.3 | 27.3 | 26.8 | 26.4 | 25.9 | 25.5 | 24.6 |

| V700 | 35.4 | 34.2 | 33.7 | 33.2 | 32.7 | 32.2 | 31.2 | 29.5 | 28.5 | 28.1 | 27.6 | 27.2 | 26.8 | 26.0 | 28.3 | 27.3 | 26.8 | 26.4 | 25.9 | 25.5 | 24.6 |

| Glycerol | 0.9 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | 0.6 | 0.6 | 0.7 | 0.7 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| DBTDL | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.4 |

| 33LV | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| TKA30 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Water | 0.4 | 0.4 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| pMDI | 26.6 | 28.9 | 30.0 | 31.1 | 32.2 | 33.2 | 35.2 | 22.1 | 24.1 | 25.0 | 25.9 | 26.8 | 27.7 | 29.3 | 24.5 | 26.6 | 27.7 | 28.7 | 29.6 | 30.6 | 32.3 |

| GTR/modified GTR | - | - | - | - | - | - | - | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 | 16.7 |

| Isocyanate:hydroxyl ratio | 0.8 | 0.9 | 0.95 | 1.0 | 1.05 | 1.1 | 1.2 | 0.8 | 0.9 | 0.95 | 1.0 | 1.05 | 1.1 | 1.2 | 0.8 | 0.9 | 0.95 | 1.0 | 1.05 | 1.1 | 1.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olszewski, A.; Kosmela, P.; Zedler, Ł.; Formela, K.; Hejna, A. Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing. Mater. Proc. 2021, 7, 12. https://doi.org/10.3390/IOCPS2021-11244

Olszewski A, Kosmela P, Zedler Ł, Formela K, Hejna A. Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing. Materials Proceedings. 2021; 7(1):12. https://doi.org/10.3390/IOCPS2021-11244

Chicago/Turabian StyleOlszewski, Adam, Paulina Kosmela, Łukasz Zedler, Krzysztof Formela, and Aleksander Hejna. 2021. "Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing" Materials Proceedings 7, no. 1: 12. https://doi.org/10.3390/IOCPS2021-11244

APA StyleOlszewski, A., Kosmela, P., Zedler, Ł., Formela, K., & Hejna, A. (2021). Optimization of Foamed Polyurethane/Ground Tire Rubber Composites Manufacturing. Materials Proceedings, 7(1), 12. https://doi.org/10.3390/IOCPS2021-11244