1. Introduction

The Wastes of Electrical and Electronic Equipment (WEEE) make up one of the most complex waste-streams that includes a wide variety of products, from mechanical devices to hi-tech systems [

1]. WEEE contain recyclable materials of high added value, such as ferrous and non-ferrous metals, plastics, electronic components, and others. The target of the recyclers is to increase the recovery rate and the purity of each recoverable product [

2,

3]. This work aimed toward the separation and recovery of stainless steel from dishwashers. It is very important to determine a proper processing method for the separation and characterization of stainless-steel components that will result in the recovery of a large quantity of stainless steel with minimum, or even being free from, impurities.

2. Experimental Procedure

An efficient method for stainless steel separation and recovery requires complete characterization of the dishwashers’ components. As a result, different types of sensors and separators were used in this project. Furthermore, hand sorting is absolutely necessary whenever the stainless-steel pieces are folded and twisted. As a result of folding and twisting, impurities are held inside the folds, decreasing the purity of the stainless-steel stream.

Preparation of Samples

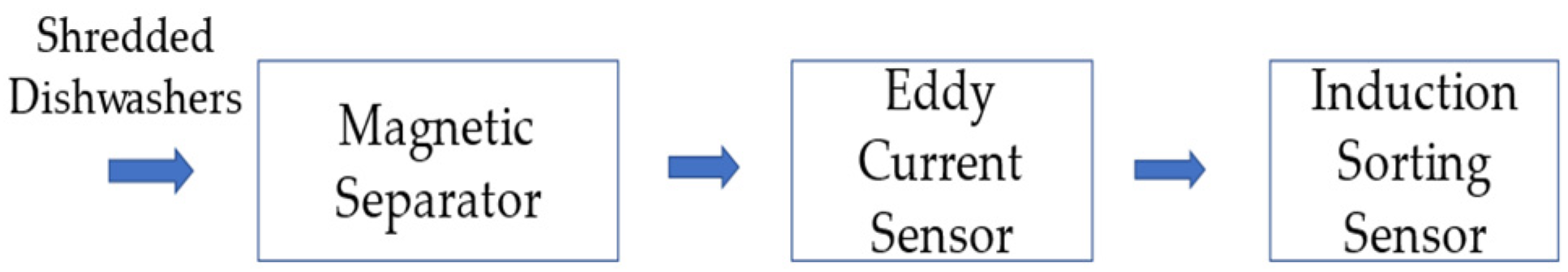

The preparation of the samples consisted of distinct steps (

Figure 1). To begin with, the dishwashers were submitted to manual removal of their external, large components. Afterwards, size reduction occurred, using shredding machines. The shredded products successively went through a magnetic separator, eddy current sensor, and induction sorting sensor. The magnetic separator removed any ferrous pieces. The eddy current sensor detected and separated pieces consisting of copper, aluminum, and brass. The induction sorting sensor identified metal pieces that could not be detected before. Two outcome streams were created from this separation line. The first one consisted of stainless-steel pieces and a low percentage of impurities, such as copper cables and printed circuit boards (PCBs). The second one consisted of any other material existing in dishwashers, such as plastics.

Even though copper cables should be removed by induction sorting sensors, their size does not permit their detection.

3. Experimental Results

The samples’ preparation was followed by separation of the stainless-steel stream through a high-intensity magnetic separator, resulting in two products, magnetic and non-magnetic. The magnetic product contained stainless-steel pieces and any impurities entrapped. Meanwhile, the non-magnetic product contained other materials that could not be removed during samples’ preparation. The magnetic and non-magnetic products were separated by adjusting the tilt of the product separation blade. Each one of the samples was tested three times, with the tilt of the blade being set at 30, 50, and 70 degrees, correspondingly. As the tilt of the blade increased, the opening of the magnetic product receptor decreased.

3.1. High Intensity Magnetic Separator

The following

Table 1 describes the % weight of magnetic stream of each sample. Furthermore,

Table 2,

Table 3 and

Table 4 provide details concerning the % weight of stainless steel that was contained in each magnetic product.

The magnetic stream of Samples 1 and 2 is characterized as being of high purity. The non-metallic portion of the magnetic product is really low. From these tables, it is shown that the procedure of separation and recovery is very efficient.

3.2. Hand Sorting

When the magnetic separation was completed, hand sorting was applied to the non-magnetic product. The magnetic product was not submitted to hand sorting due to its low content in impurities. The results of hand sorting are described in

Table 5 and

Table 6.

4. Chemical Analysis

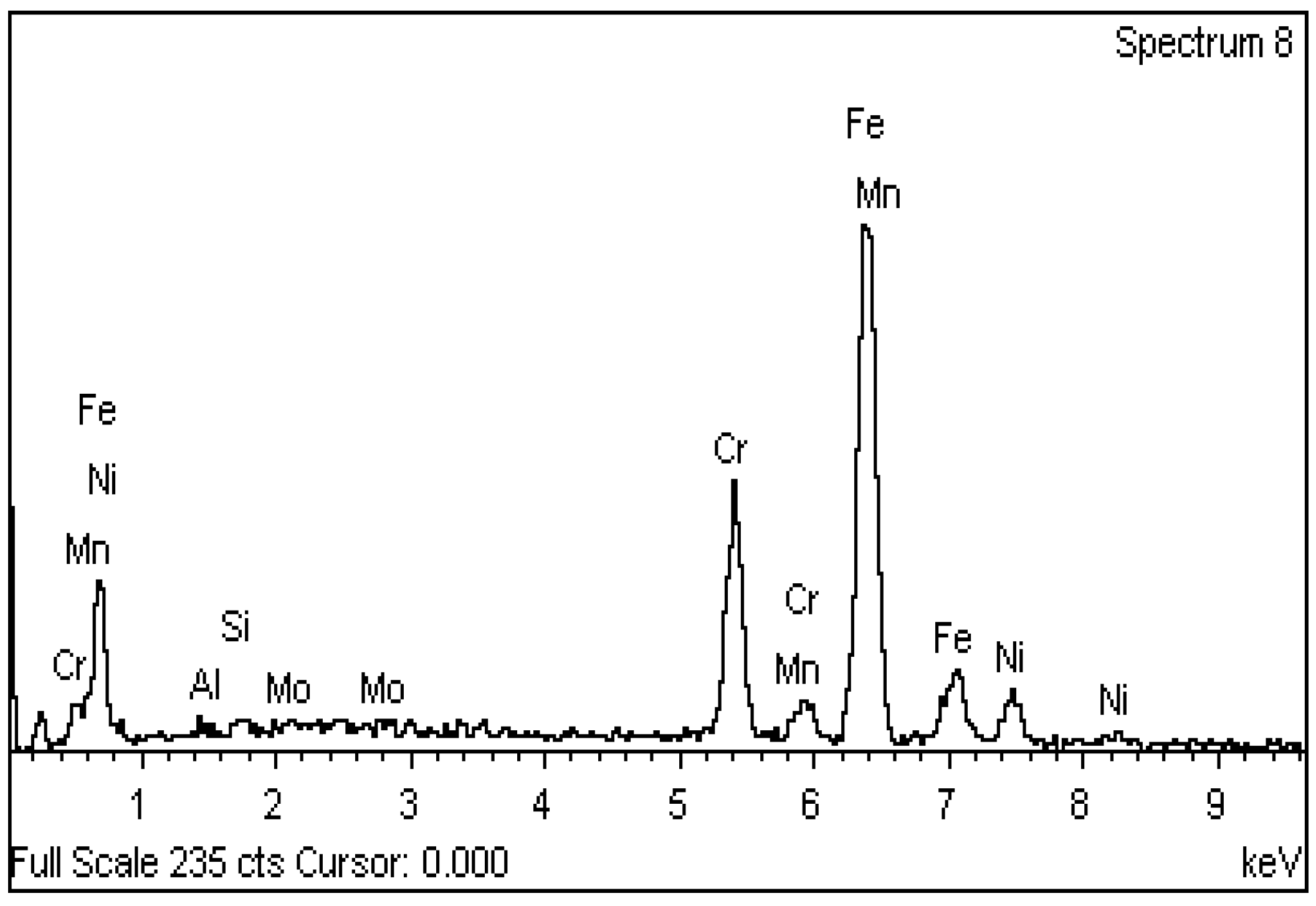

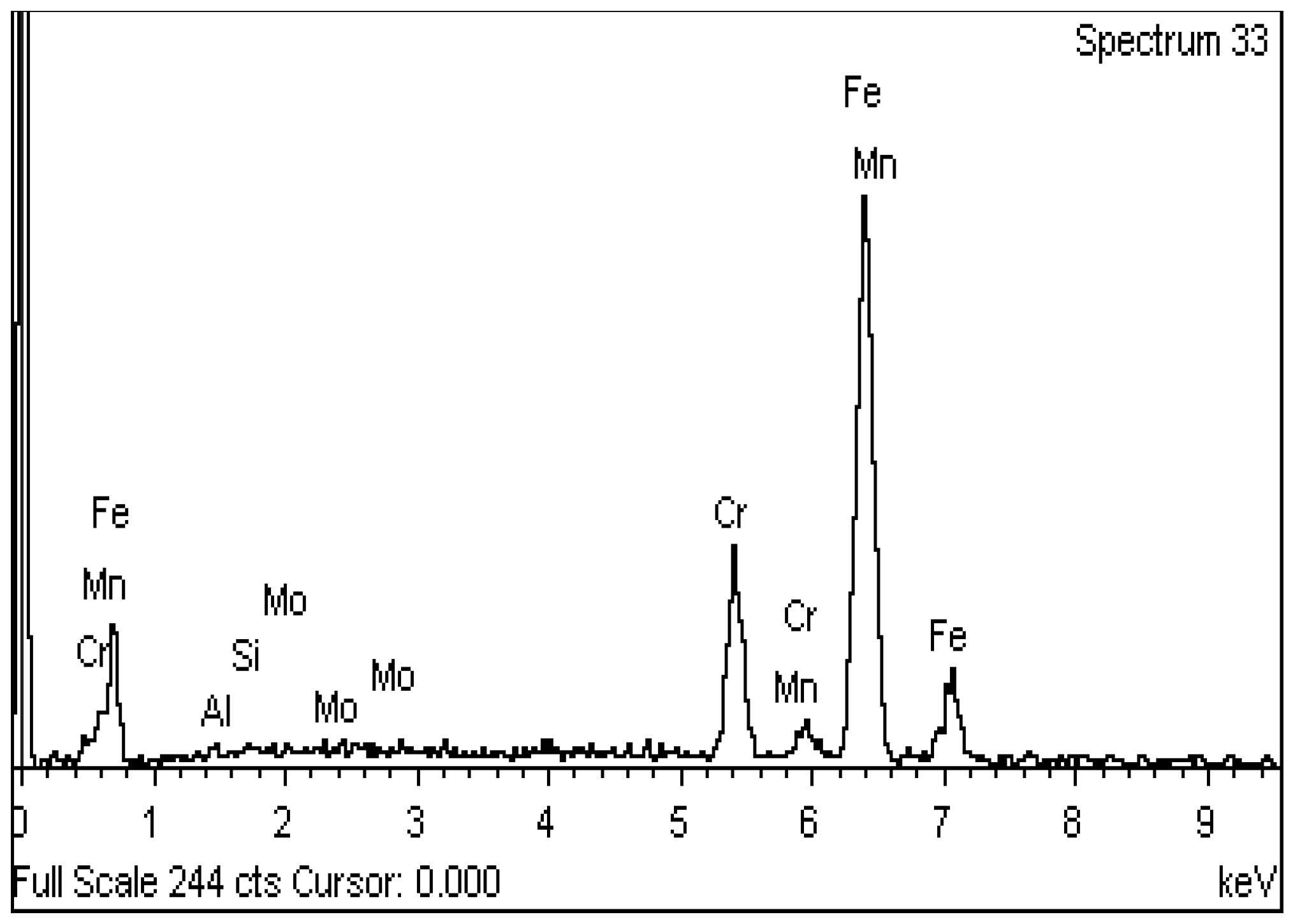

After the separation and characterization of the samples, they were submitted to Scanning Electron Microscopy. Through the EDS analysis of the samples, an attempt was made to define the elements composing each sample.

The results of SEM analysis show that Sample 1 is γ-Fe stainless steel, containing approximately 18% Chromium (Cr) and 9% Nickel (Ni). Concerning Sample 2, it is α-Fe stainless steel containing approximately 17% Chromium (Cr) and 1% Manganese (Mn). The results are provided in the following

Table 7 and in the following

Figure 2 and

Figure 3.

5. Discussion

Observing

Table 1 and

Table 2, it is concluded that, as the tilt increases, the weight of the magnetic stream decreases, because larger or twisted stainless steel pieces cannot pass through the opening of magnetic receptor and, eventually, are rejected as a non-magnetic product. Further size reduction of stainless-steel pieces could lead to an increase in the weight of the magnetic stream, as long as the pieces are able to pass the opening of the magnetic receptor.

Additionally, from

Table 2,

Table 3 and

Table 4, it is derived that the stainless-steel stream’s impurities content is low. It would be interesting to ascertain if this finding applies to the industrial scale.

The results of

Table 5 and

Table 6 reveal that plastic impurities make up the highest impurity content for both samples.

Concerning the results from SEM analyses (

Table 7), it is derived that Sample 1 is γ-Fe stainless steel, and Sample 2 is α-Fe stainless steel, as Nickel (Ni) was not detected in this sample.

Author Contributions

Conceptualization, G.N.A., S.D.K. and A.S.; methodology, E.E., G.N.A., S.D.K. and A.S.; software: not applied here; validation, E.E., G.N.A., S.D.K. and A.S.; formal analysis, E.E. and G.N.A.; investigation, E.E.; resources, S.D.K. and A.S.; data curation, E.E.; writing-original draft, E.E. All authors have read and agreed to the published version of the manuscript.

Funding

Τhis research was funded by the General Secretariat for Research and Innovation (GSRI) of Greece under the bilateral research project Greece-China No. Τ7ΔΚΙ-00364.

Data Availability Statement

Not applied here.

Acknowledgments

The contribution of P. Tsakiridis, Laboratory of Physical Metallurgy in the School of Mining and Metallurgical Engineering-NTUA, is acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lula, R.A. Stainless Steel; American Society for Metals: Materials Park, OH, USA, 1986. [Google Scholar]

- Beddoes, J.; Parr, J.G. Introduction to Stainless Steels, 3rd ed.; ASM Inter-National: Materials Park, OH, USA, 1999. [Google Scholar]

- Peckner, D.; Bernstein, I.M. (Eds.) Handbook of Stainless Steels; McGraw-Hill Inc.: New York, NY, USA, 1977. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).