Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions †

Abstract

:1. Introduction

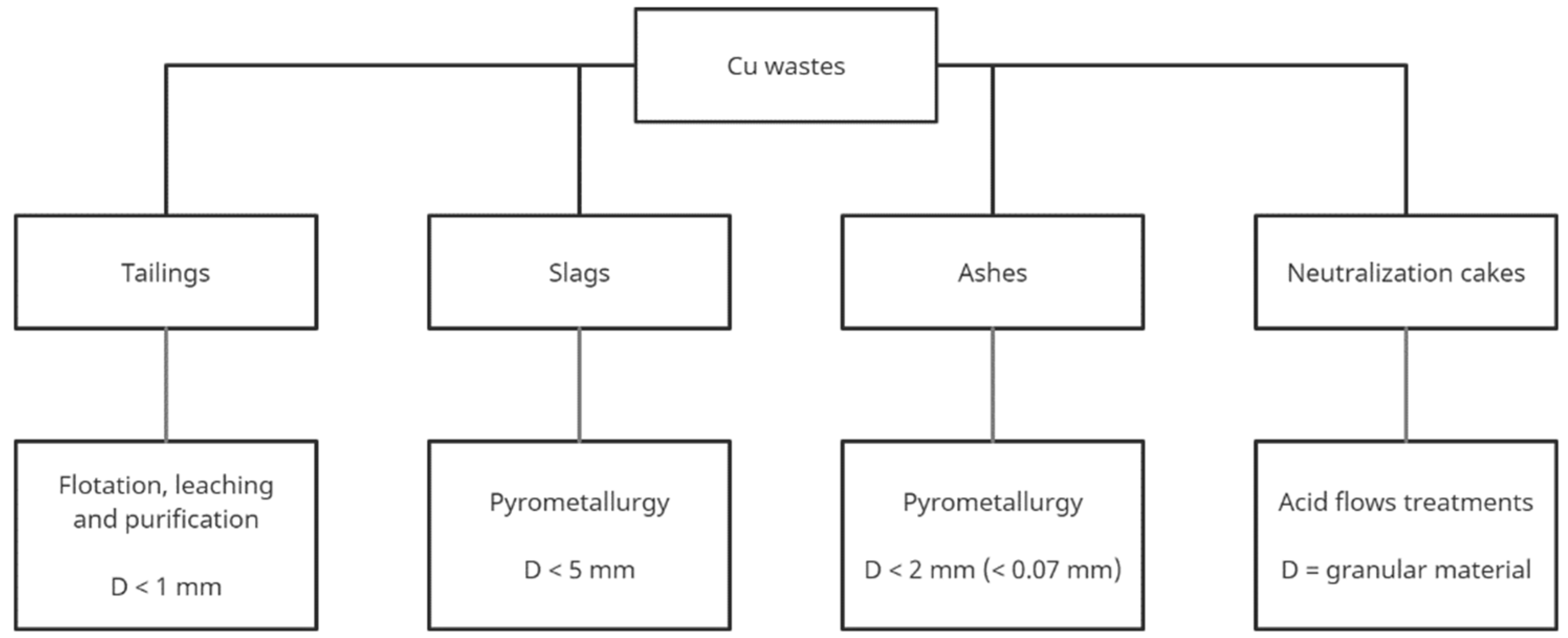

2. General Characteristics of Copper Waste

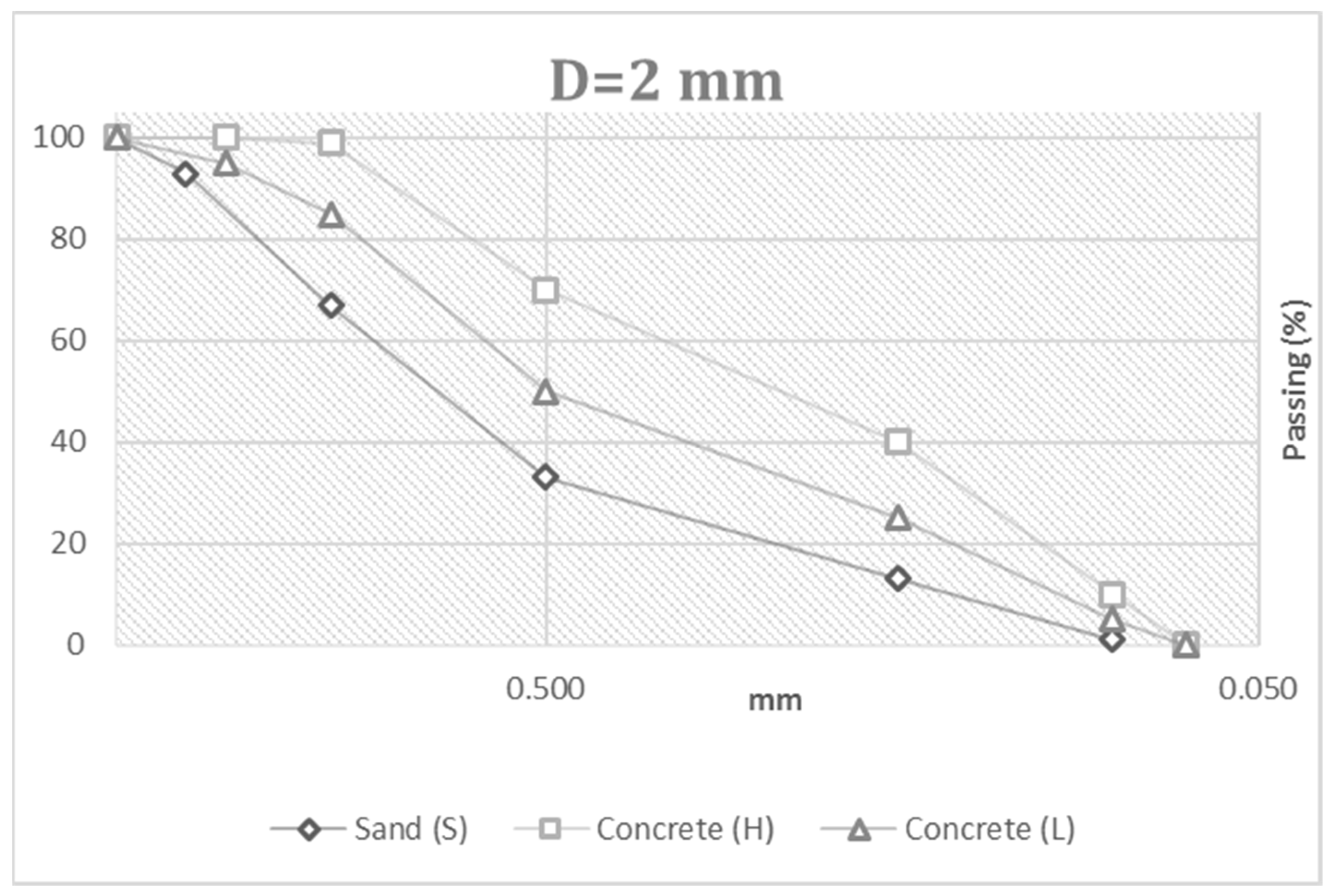

3. Definitions and Requirements of Concretes and Mortars

4. Discussion: Issues and Possible Solutions

4.1. Cement

4.2. Aggregates

5. Conclusions

Funding

References

- Overview-Waste-Eurostat Disponible, en. Available online: https://ec.europa.eu/eurostat/web/waste/overview (accessed on 13 May 2021).

- Gordon, R.B. Production residues in copper technological cycles. Resour. Conserv. Recycl. 2002, 36, 87–106. [Google Scholar] [CrossRef]

- European Council. Directive 2006/21/EC of the European Parliament and of the Council of 15 March 2006 on the Management of Waste from Extractive Industries and Amending Directive 2004/35/EC; Official Journal of the European Union; European Union: Brussels, Belgium, 2006. [Google Scholar]

- Kinnunen, P.; Ismailov, A.; Solismaa, S.; Sreenivasan, H.; Räisänen, M.L.; Levänen, E.; Illikainen, M. Recycling mine tailings in chemically bonded ceramics—A review. J. Clean. Prod. 2018, 174, 634–649. [Google Scholar] [CrossRef] [Green Version]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- de Bastos, L.A.C.; Silva, G.C.; Mendes, J.C.; Peixoto, R.A.F. Using Iron Ore Tailings from Tailing Dams as Road Material. J. Mater. Civ. Eng. 2016, 28, 04016102. [Google Scholar] [CrossRef]

- Cristelo, N.; Coelho, J.; Oliveira, M.; Consoli, N.C.; Palomo, Á.; Fernández-Jiménez, A. Recycling and application of mine tailings in alkali-activated cements and mortars-strength development and environmental assessment. Appl. Sci. 2020, 10, 2084. [Google Scholar] [CrossRef] [Green Version]

- Al-Jabri, K.S.; Al-Saidy, A.H.; Taha, R. Effect of copper slag as a fine aggregate on the properties of cement mortars and concrete. Constr. Build. Mater. 2011, 25, 933–938. [Google Scholar] [CrossRef]

- Panda, S.; Sarkar, P. Leaching behavior of copper slag aggregate cement-mortar by atomic absorption spectroscopy (AAS). Mater. Today Proc. 2020, 33, 5123–5129. [Google Scholar] [CrossRef]

- Muleya, F.; Mulenga, B.; Zulu, S.L.; Nwaubani, S.; Tembo, C.K.; Mushota, H. Investigating the suitability and cost-benefit of copper tailings as partial replacement of sand in concrete in Zambia: An exploratory study. J. Eng. Des. Technol. 2020. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Fisonga, M.; Wang, F.; Mutambo, V. Sustainable utilization of copper tailings and tyre-derived aggregates in highway concrete traffic barriers. Constr. Build. Mater. 2019, 216, 29–39. [Google Scholar] [CrossRef]

- Benarchid, Y.; Taha, Y.; Argane, R.; Tagnit-Hamou, A.; Benzaazoua, M. Concrete containing low-sulphide waste rocks as fine and coarse aggregates: Preliminary assessment of materials. J. Clean. Prod. 2019, 221, 419–429. [Google Scholar] [CrossRef]

- Jordán, M.M.; Montero, M.A.; Pardo-Fabregat, F. Technological behaviour and leaching tests in ceramic tile bodies obtained by recycling of copper slag and MSW fly ash wastes. J. Mater. Cycles Waste Manag. 2021, 23, 707–716. [Google Scholar] [CrossRef]

- Zhang, L. Production of bricks from waste materials—A review. Constr. Build. Mater. 2013, 47, 643–655. [Google Scholar] [CrossRef]

- Sheikhhosseini Lori, I.; Toufigh, M.M.; Toufigh, V. Improvement of poorly graded sandy soil by using copper mine tailing dam sediments-based geopolymer and silica fume. Constr. Build. Mater. 2021, 281, 122591. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Production of eco-friendly bricks from copper mine tailings through geopolymerization. Constr. Build. Mater. 2012, 29, 323–331. [Google Scholar] [CrossRef]

- Ahmari, S.; Zhang, L. Utilization of cement kiln dust (CKD) to enhance mine tailings-based geopolymer bricks. Constr. Build. Mater. 2013, 40, 1002–1011. [Google Scholar] [CrossRef]

- Solouki, A.; Viscomi, G.; Lamperti, R.; Tataranni, P. Quarry waste as precursors in geopolymers for civil engineering applications: A decade in review. Materials 2020, 13, 3146. [Google Scholar] [CrossRef]

- Samarakoon, M.H.; Ranjith, P.G.; Rathnaweera, T.D.; Perera, M.S.A. Recent advances in alkaline cement binders: A review. J. Clean. Prod. 2019, 227, 70–87. [Google Scholar] [CrossRef]

- Liu, J.; Guo, R.; Shi, P.; Huang, L. Hydration mechanisms of composite binders containing copper slag at different temperatures. J. Therm. Anal. Calorim. 2019, 137, 1919–1928. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Zhao, X. Hydration kinetics of composite cementitious materials containing copper tailing powder and graphene oxide. Materials 2018, 11, 2499. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ostermeyer, P.; Bonin, L.; Folens, K.; Verbruggen, F.; García-Timermans, C.; Verbeken, K.; Rabaey, K.; Hennebel, T. Effect of speciation and composition on the kinetics and precipitation of arsenic sulfide from industrial metallurgical wastewater. J. Hazard. Mater. 2021, 409, 124418. [Google Scholar] [CrossRef]

- Li, J.S.; Chen, L.; Zhan, B.; Wang, L.; Poon, C.S.; Tsang, D.C.W. Sustainable stabilization/solidification of arsenic-containing soil by blast slag and cement blends. Chemosphere 2021, 271, 129868. [Google Scholar] [CrossRef]

- Henne, A.; Hamilton, J.; Craw, D.; Paterson, D.; Southam, G. The influence of metal mobility on resource potential in circumneutral pH iron-rich copper mine waste rocks. J. Geochem. Explor. 2020, 219, 106632. [Google Scholar] [CrossRef]

- Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Moustakas, K.; Witek-Krowiak, A.; Chojnacka, K. Value-added strategies for the sustainable handling, disposal, or value-added use of copper smelter and refinery wastes. J. Hazard. Mater. 2021, 403, 123602. [Google Scholar] [CrossRef]

- Karamanov, A.; Aloisi, M.; Pelino, M. Vitrification of copper flotation waste. J. Hazard. Mater. 2007, 140, 333–339. [Google Scholar] [CrossRef] [PubMed]

- Mikoda, B.; Gruszecka-Kosowska, A. Mineral and chemical characteristics, textural parameters, and the mobility of the selected elements of flotation waste, originating from the Polish copper-mining industry. Hum. Ecol. Risk Assess. 2018, 24, 1216–1232. [Google Scholar] [CrossRef]

- Liu, D.G.; Min, X.B.; Ke, Y.; Chai, L.Y.; Liang, Y.J.; Li, Y.C.; Yao, L.W.; Wang, Z.B. Co-treatment of flotation waste, neutralization sludge, and arsenic-containing gypsum sludge from copper smelting: Solidification/stabilization of arsenic and heavy metals with minimal cement clinker. Environ. Sci. Pollut. Res. 2018, 25, 7600–7607. [Google Scholar] [CrossRef]

- Çoruh, S.; Ergun, O.N.; Cheng, T.W. Treatment of copper industry waste and production of sintered glass-ceramic. Waste Manag. Res. 2006, 24, 234–241. [Google Scholar] [CrossRef]

- Fuentes, I.; Ulloa, C.; Jiménez, R.; García, X. The reduction of Fe-bearing copper slag for its use as a catalyst in carbon oxide hydrogenation to methane. A contribution to sustainable catalysis. J. Hazard. Mater. 2020, 387, 121693. [Google Scholar] [CrossRef]

- Gupta, N.; Siddique, R. Durability characteristics of self-compacting concrete made with copper slag. Constr. Build. Mater. 2020, 247, 118580. [Google Scholar] [CrossRef]

- Shi, G.; Liao, Y.; Su, B.; Zhang, Y.; Wang, W.; Xi, J. Kinetics of copper extraction from copper smelting slag by pressure oxidative leaching with sulfuric acid. Sep. Purif. Technol. 2020, 241, 116699. [Google Scholar] [CrossRef]

- Arslan, C.; Arslan, F. Recovery of copper, cobalt, and zinc from copper smelter and converter slags. Hydrometallurgy 2002, 67, 1–7. [Google Scholar] [CrossRef]

- Maweja, K.; Mukongo, T.; Mutombo, I. Cleaning of a copper matte smelting slag from a water-jacket furnace by direct reduction of heavy metals. J. Hazard. Mater. 2009, 164, 856–862. [Google Scholar] [CrossRef]

- Miganei, L.; Gock, E.; Achimovičová, M.; Koch, L.; Zobel, H.; Kähler, J. New residue-free processing of copper slag from smelter. J. Clean. Prod. 2017, 164, 534–542. [Google Scholar] [CrossRef]

- Vítková, M.; Ettler, V.; Mihaljevič, M.; Šebek, O. Effect of sample preparation on contaminant leaching from copper smelting slag. J. Hazard. Mater. 2011, 197, 417–423. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Moreno, S.M.; Gázquez, M.J.; Ruiz-Oria, I.; Ríos, G.; Bolívar, J.P. Diagnose for valorisation of reprocessed slag cleaning furnace fl ue dust from copper smelting. J. Clean. Prod. 2018, 194, 383–395. [Google Scholar] [CrossRef]

- Grudinsky, P.I.; Dyubanov, V.G.; Kozlov, P.A. Copper Smelter Dust Is a Promising Material for the Recovery of Nonferrous Metals by the Waelz Process. Inorg. Mater. Appl. Res. 2019, 10, 496–501. [Google Scholar] [CrossRef]

- Qiang, L.; Pinto, I.S.S.; Youcai, Z. Sequential stepwise recovery of selected metals from flue dusts of secondary copper smelting. J. Clean. Prod. 2014, 84, 663–670. [Google Scholar] [CrossRef]

- Chen, Y.; Liao, T.; Li, G.; Chen, B.; Shi, X. Recovery of bismuth and arsenic from copper smelter flue dusts after copper and zinc extraction. Miner. Eng. 2012, 39, 23–28. [Google Scholar] [CrossRef]

- Morales, A.; Cruells, M.; Roca, A.; Bergó, R. Treatment of copper flash smelter flue dusts for copper and zinc extraction and arsenic stabilization. Hydrometallurgy 2010, 105, 148–154. [Google Scholar] [CrossRef]

- López-Arce, P.; Garrido, F.; García-Guinea, J.; Voegelin, A.; Göttlicher, J.; Nieto, J.M. Historical roasting of thallium- and arsenic-bearing pyrite: Current Tl pollution in the Riotinto mine area. Sci. Total Environ. 2019, 648, 1263–1274. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- UNE-EN 206:2013+A1:2018 Hormigón. Especificaciones, Prestacion…. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma/?c=N0060253 (accessed on 24 May 2021).

- UNE-EN 998-1:2018 Especificaciones de los Morteros para albañi…. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0059828 (accessed on 24 May 2021).

- UNE-EN 998-2:2018 Especificaciones de los Morteros para albañi…. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0060256 (accessed on 24 May 2021).

- UNE-EN 197-1:2011 Cemento. Parte 1: Composición, Especificacio…. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0048623 (accessed on 24 May 2021).

- UNE-EN 12620:2003+A1:2009 Áridos para Hormigón. Available online: https://www.une.org/encuentra-tu-norma/busca-tu-norma/norma?c=N0043155 (accessed on 24 May 2021).

- European Council. 2003/33/EC: Council Decision of 19 December 2002 Establishing Criteria and Procedures for the Acceptance of Waste at Landfills Pursuant to Article 16 of and Annex II to Directive 1999/31/EC; Official Journal of the European Union; European Union: Brussels, Belgium, 2002. [Google Scholar]

- Palfy, P.; Vircikova, E.; Molnar, L. Processing of arsenic waste by precipitation and solidification. Waste Manag. 1999, 19, 55–59. [Google Scholar] [CrossRef]

- Chintalapati, P.K.; Davis, A.D.; Hansen, M.R.; Sorensen, J.L.; Dixon, D. Encapsulation of limestone waste in concrete after arsenic removal from drinking water. Environ. Earth Sci. 2009, 59, 185–190. [Google Scholar] [CrossRef]

- Akhter, H.; Cartledge, F.K.; Roy, A.; Tittlebaum, M.E. Solidification/stabilization of arsenic salts: Effects of long cure times. J. Hazard. Mater. 1997, 52, 247–264. [Google Scholar] [CrossRef]

- Dutré, V.; Vandecasteele, C. Immobilization Mechanism of Arsenic in Waste Solidified Using Cement and Lime. Am. Chem. Soc. 1998. [Google Scholar] [CrossRef]

- Shih, C.J.; Lin, C.F. Arsenic contaminated site at an abandoned copper smelter plant: Waste characterization and solidification/stabilization treatment. Chemosphere 2003, 53, 691–703. [Google Scholar] [CrossRef]

- Jing, C.; Liu, S.; Meng, X. Arsenic leachability and speciation in cement immobilized water treatment sludge. Chemosphere 2005, 59, 1241–1247. [Google Scholar] [CrossRef]

- Bhunia, P.; Pal, A.; Bandyopadhyay, M. Assessing arsenic leachability from pulverized cement concrete produced from arsenic-laden solid CalSiCo-sludge. J. Hazard. Mater. 2007, 141, 826–833. [Google Scholar] [CrossRef]

- Choi, W.H.; Lee, S.R.; Park, J.Y. Cement based solidification/stabilization of arsenic-contaminated mine tailings. Waste Manag. 2009, 29, 1766–1771. [Google Scholar] [CrossRef]

- Nastac, D.C.; Fechet, R.; Cristina Năstac, D.; Fechet, R.M. The Influence of Mine Tailings and Oily Sludge on the Portland Cement Clinker Manufacture Influenţa Sterilului Minier Şi A Nămolului De Petrol Asupra Fabricării Clincherului De Ciment Portland The Influence Of Mine Tailings And Oily Sludge On The Portland. Rom. J. Mater. 2017, 47, 176–182. [Google Scholar]

- Qiu, G.; Luo, Z.; Shi, Z.; Ni, M. Utilization of coal gangue and copper tailings as clay for cement clinker calcinations. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 1205–1210. [Google Scholar] [CrossRef]

| Size | 2D 1 | 1.4D | D | d | d/2 | |

|---|---|---|---|---|---|---|

| Coarse aggregate | D/d < 2 or D < 11.2 | 100 | 98–100 | 85–99 | 0–20 | 0–5 |

| 100 | 98–100 | 85–99 | 0–20 | 0–5 | ||

| D/d > 2 or D > 11.2 | 100 | 98–100 | 90–99 | 0–15 | 0–5 | |

| Fine aggregate | D < 4 mm and d = 0 | 100 | 95–100 | 85–99 | - | - |

| Mixed | D < 45 mm and d = 0 | 100 | 98–100 | 90–99 | - | - |

| 100 | 98–100 | 85–99 | - | - |

| Component | Leaching Test (L/S = 10 L/kg) (mg/kg Dry Matter) | Percolation (mg/L) |

|---|---|---|

| As | 0.5 | 0.06 |

| Ba | 20 | 4 |

| Cd | 0.04 | 0.02 |

| Cr total | 0.5 | 0.1 |

| Cu | 2 | 0.6 |

| Hg | 0.01 | 0.002 |

| Mo | 0.5 | 0.2 |

| Ni | 0.4 | 0.12 |

| Pb | 0.5 | 0.15 |

| Sb | 0.06 | 0.1 |

| Se | 0.1 | 0.04 |

| Zn | 4 | 1.2 |

| Chlorides | 800 | 460 |

| Fluorides | 10 | 2.5 |

| Sulphates | 1000 | 1500 |

| Phenol index | 1 | 0.3 |

| DOC 1 | 500 | 160 |

| TDS 2 | 4000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosado, S.; Gullón, L.; Martínez, L.F.M.; Llamas Borrajo, J.F. Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions. Mater. Proc. 2021, 5, 25. https://doi.org/10.3390/materproc2021005025

Rosado S, Gullón L, Martínez LFM, Llamas Borrajo JF. Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions. Materials Proceedings. 2021; 5(1):25. https://doi.org/10.3390/materproc2021005025

Chicago/Turabian StyleRosado, Santiago, Lidia Gullón, Luis Felipe Mazadiego Martínez, and Juan Francisco Llamas Borrajo. 2021. "Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions" Materials Proceedings 5, no. 1: 25. https://doi.org/10.3390/materproc2021005025

APA StyleRosado, S., Gullón, L., Martínez, L. F. M., & Llamas Borrajo, J. F. (2021). Potential Uses of Copper Wastes in the Building Sector: Inertization and Added Value Solutions. Materials Proceedings, 5(1), 25. https://doi.org/10.3390/materproc2021005025