Experimental Evaluation of a Portable Oxygen Concentrator Based on Pressure Swing Adsorption †

Abstract

1. Introduction

2. Materials and Methodology

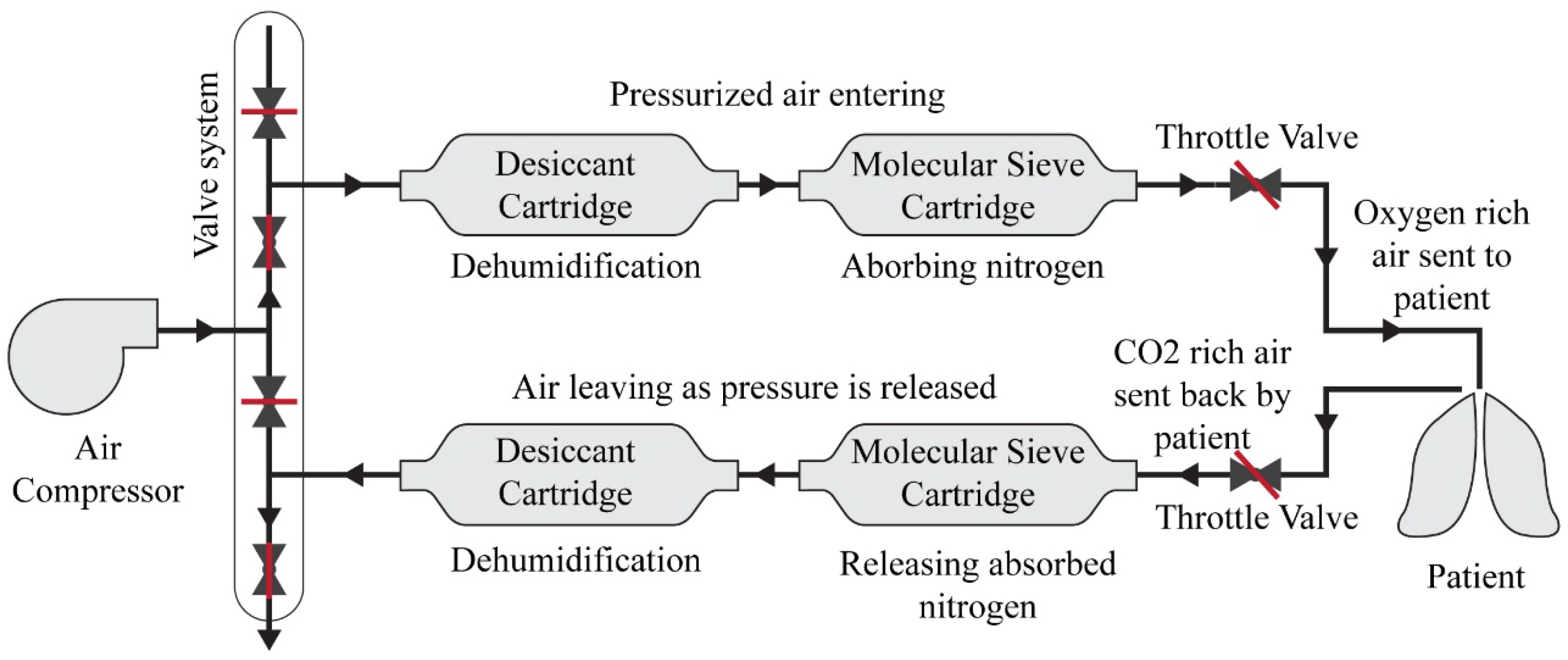

2.1. Materials and Process

2.2. Data Collection

2.3. Uncertainty Analysis

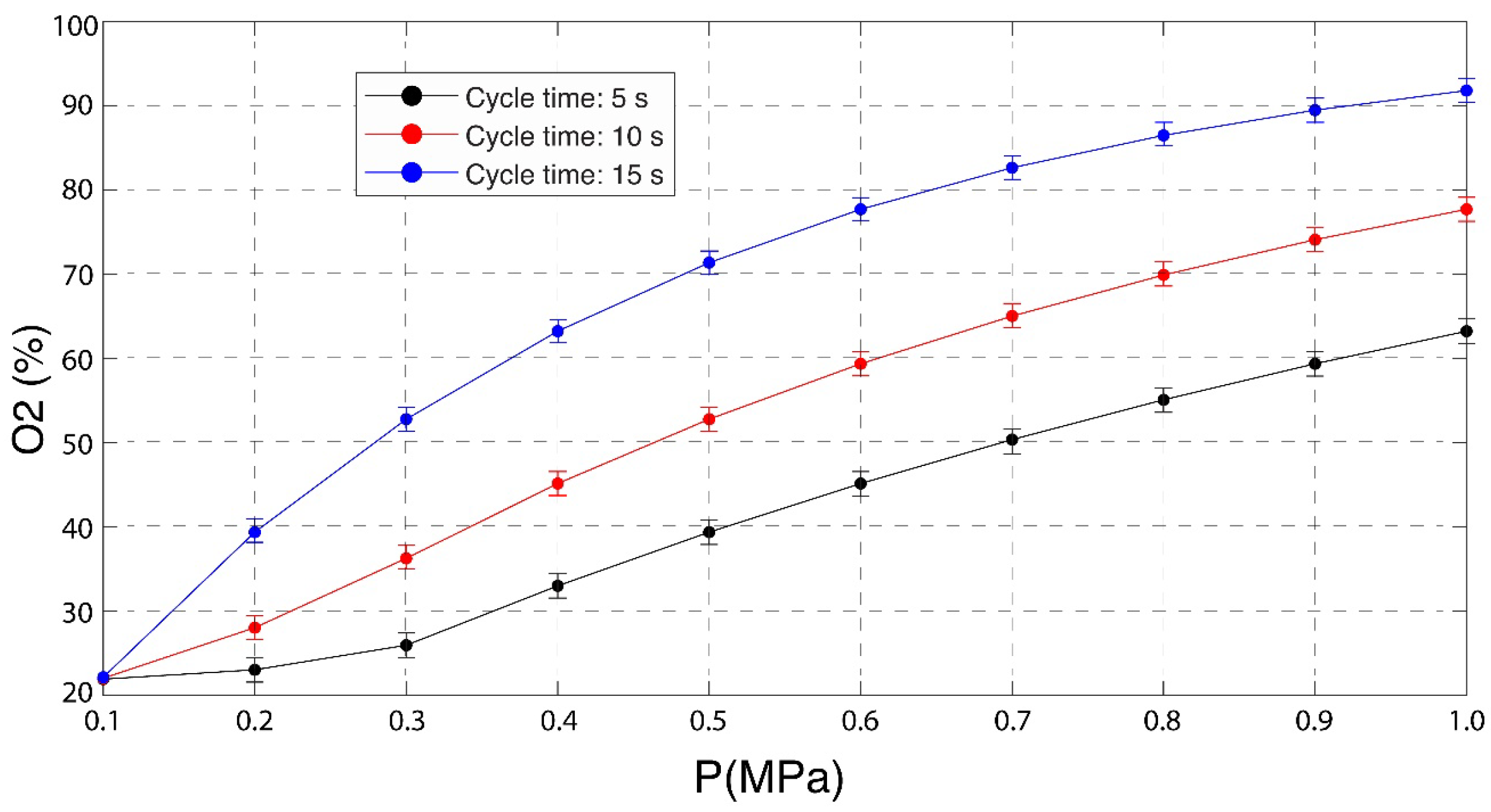

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ingoen Inc. Portable Oxygen Concentrator for HME Providers. Available online: https://provider.inogen.com/en (accessed on 9 June 2024).

- Kronenberg, R.S.; Drage, C.W. Attenuation of the ventilatory and heart rate responses to hypoxia and hypercapnia with aging in normal men. J. Clin. Investig. 1973, 52, 1812–1819. [Google Scholar] [CrossRef] [PubMed]

- Martin, D.C. Contemporary Portable Oxygen Concentrators and Diverse Breathing Behaviours-a Bench Comparison. BMC Pulm. Med. 2019, 19, 217. [Google Scholar] [CrossRef] [PubMed]

- Santos, J.C.; Cruz, P.; Regala, T.; Magalhães, F.D.; Mendes, A. High-Purity Oxygen Production by Pressure Swing Adsorption. Ind. Eng. Chem. Res. 2007, 46, 591–599. [Google Scholar] [CrossRef]

- Arora, A.; Hasan, M.M.F. Flexible Oxygen Concentrators for Medical Applications. Sci. Rep. 2021, 11, 14317. [Google Scholar] [CrossRef] [PubMed]

- Urich, M.D.; Vemula, R.R.; Kothare, M.V. Multi-Model Predictive Control of a Novel Rapid Pressure Swing Adsorption System. In Proceedings of the American Control Conference, Seattle, WA, USA, 24–26 May 2017; pp. 4392–4397. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, X. Experimental Study of a Rotary Valve Multi-Bed Rapid Cycle Pressure Swing Adsorption Process Based Medical Oxygen Concentrator. Adsorption 2020, 26, 1267–1274. [Google Scholar] [CrossRef]

- Sivalingam, V.; Jayaraj, J.; Hency, S.; Paul, J. Measuring Flow Rate and Purity in Portable Oxygen Concentrators. Bull. Natl. Res. Cent. 2024, 48, 58. [Google Scholar] [CrossRef]

- ETH Zurich. Cost-Effective Oxygen Concentrators. Available online: https://ethz.ch/en/news-and-events/eth-news/news/2020/04/cost-effective-oxygen-concentrators.html (accessed on 11 June 2024).

- Usama, M.; Ali, Z.; Ndukwu, M.C.; Sathyamurthy, R. The Energy, Emissions, and Drying Kinetics of Three-Stage Solar, Microwave and Desiccant Absorption Drying of Potato Slices. Renew Energy 2023, 219, 119509. [Google Scholar] [CrossRef]

- Chatburn, R.L.; Faarc, R.-N.; Williams, T.J.; Rrt, M. Performance Comparison of 4 Portable Oxygen Concentrators. Respir. Care 2010, 55, 433–442. [Google Scholar] [PubMed]

- Pan, M.; Omar, H.M.; Rohani, S. Application of Nanosize Zeolite Molecular Sieves for Medical Oxygen Concentration. Nanomaterials 2017, 7, 195. [Google Scholar] [CrossRef] [PubMed]

- Jee, J.G.; Kim, M.B.; Lee, C.H. Pressure Swing Adsorption Processes to Purify Oxygen Using a Carbon Molecular Sieve. Chem. Eng. Sci. 2005, 60, 869–882. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, C.; Zuo, J.; Lou, X. Application of Molecular Sieve Oxygen Generation Mini-Plant under Harsh Environment. Glob. Clin. Eng. J. 2023, 5, 11–19. [Google Scholar] [CrossRef]

| Item | Manufacturer | Model | Specifications | Dimensions (L × W × H) |

|---|---|---|---|---|

| Compressor | Ingersoll Rand | T30 | 30 CFM, 1 MPa | 30” × 20” × 15” |

| Solenoid Valve | Parker Hannifin | 5-2-W24V | 2-way, 1/4” NPT | 10” × 5” × 5” |

| Zeolite Columns | Zeochem | ZC-28-5 | 28” L, 5” D, 1/4” NPT | 28” × 5” |

| Polyurethane Tubing | McMaster-Carr | 5233K11 | - | 1 mL, 1/4” OD, 1/8” ID |

| Sensor | Manufacturer | Model | Range | Accuracy |

|---|---|---|---|---|

| Thermometer | Fluke | 62 Max | −20 °C to 100 °C | ±1.0 °C |

| Hygrometer | XH | XH-M452 | 0% to 100% RH | ±1.0% RH |

| Pressure gauge | Anhui Qidian | QDW90-A | 0 to 100 kPa | ±1.0 kPa |

| Stopwatch | - | Cell phone watch | 0 to 1000 s | ±0.1 s |

| Anemometer | Metravi | AVM-10 | 0 to 30 m/s | ±1.0 m/s |

| Weighing scale | iBELL | WHB28 | 0 to 200 g | ±0.1 g |

| Oxygen sensor | Maxell | KE-25 | 0 to 100% | ±1.0% |

| Measurement | Unit | σR |

|---|---|---|

| Temperature | °C | ±1.0 |

| Time | s | ±0.1 |

| Relative Humidity | % | ±1 |

| Gas Pressure | kPa | ±0.1 |

| Gas Flow Speed | m/s | ±0.5 |

| Gas Flow Rate | Lpm | ±0.5 |

| Mass | g | ±0.7 |

| O2 Concentration | % | ±1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ajmal, M.B.; Usama, M.; Bangash, Z.; Aziz, H.; Nadeem, O.B.; Masud, A.B. Experimental Evaluation of a Portable Oxygen Concentrator Based on Pressure Swing Adsorption. Mater. Proc. 2025, 23, 25. https://doi.org/10.3390/materproc2025023025

Ajmal MB, Usama M, Bangash Z, Aziz H, Nadeem OB, Masud AB. Experimental Evaluation of a Portable Oxygen Concentrator Based on Pressure Swing Adsorption. Materials Proceedings. 2025; 23(1):25. https://doi.org/10.3390/materproc2025023025

Chicago/Turabian StyleAjmal, Muhammad Bin, Muhammad Usama, Zafar Bangash, Humayun Aziz, Osama Bin Nadeem, and Ahmed Bin Masud. 2025. "Experimental Evaluation of a Portable Oxygen Concentrator Based on Pressure Swing Adsorption" Materials Proceedings 23, no. 1: 25. https://doi.org/10.3390/materproc2025023025

APA StyleAjmal, M. B., Usama, M., Bangash, Z., Aziz, H., Nadeem, O. B., & Masud, A. B. (2025). Experimental Evaluation of a Portable Oxygen Concentrator Based on Pressure Swing Adsorption. Materials Proceedings, 23(1), 25. https://doi.org/10.3390/materproc2025023025