Abstract

Paper-based microfluidics provides an economical and flexible approach to fluid handling for simple and complex assays. Many applications still require ease of flow control with the added advantage of low-cost fabrication for commercial applications. In this study, we develop a fluid control strategy using glycerol as a barrier within paper channels. Glycerol reduces porosity and increases resistance, causing delayed flow times. As glycerol is hydrophilic in nature and can establish hydrogen bonds with water molecules, it is an efficient substrate for creating these delay zones in paper strips. The Lucas–Washburn model describes the physics for flow of liquid water through the porous substrate. From our findings, we observed that the water flow time was delayed from 5 to 20 min and penetration reduced from 43 mm to 24 mm by increasing glycerol concentration from 0% to 30%. Using oleic acid (fatty acid) as the working fluid instead of water extended the delay further, causing it to take up to 1 day to transport 35 mm with 30% glycerol investigation into the effects of glycerol concentration on flow behavior highlights the importance of understanding absorption time delays and the physics of wet-out flow in porous media., and we hope that, ultimately, our findings will be applicable for a variety of paper-based microfluidic devices for commercial applications

1. Introduction

Filter paper is a porous substrate widely used for many chemical and biological applications. Fluid passing through these porous materials goes through a complex maze of microcapillaries intertwined within the fibrous nature of the cellulose material. These paper substrates have helped in solving global diagnostic problems, due to their affordability and biodegradable nature. Their implementation will drastically improve the global health index and assist resource-limited countries in improving quality of living [1], helping to create a pollution-free environment and ensure sufficient dietary quality, both promoting health. Microfluidic technologies hold significant promise for affordable diagnostics and food safety. These instruments allow for faster reactions without the requirement for large samples. Integrated conventional microfluidic devices have several uses, including in drug delivery, energy conversion and storage, environmental sensing, disease diagnosis, drug discovery, and chemical and biological processes [2,3,4]. These devices are mostly utilized for point of care sensing (POC), immuno-sensing, and lab and organ-on-a-chip applications. Because paper is a more affordable, flexible, portable, and biodegradable material than other materials, creating µPADs requires less effort. Because of its capillary force, the fluid in the paper flows without the need for an external power source, removing the complexity of control systems and costly associated equipment.

Studies have demonstrated fluid manipulation in paper-based microfluidic devices for applications in diagnostics and controlled reagent delivery [5]. Andres W. Martinez introduced patterned paper networks enabling capillary-driven flow without external pumps. Subsequent works to reduce flow rates have explored delay zones, wax barriers, and hydrophobic treatments to modulate wicking speed and timing in paper substrates. Understanding flow control is crucial for precision and predictability in paper-based microfluidic systems. Flow regulation in two-dimensional paper-based microfluidic devices works either through changing fluid chemistry or adjusting pathway design. To modify wicking times, one needs to adjust either the channel length, which relates to basic geometric control, or vary the chemical nature of the channel. Hence, reduced flow time and controlled fluid imbibition can be achieved by creating obstacles on paper [6].

In this study, we applied a simple method involving the use of glycerol to create barriers within the fluid flow path. Although glycerol is hygroscopic and has high viscosity, small amounts of it can have a significant impact on the flow rate. The porosity of the paper channel reduces with the glycerol partial barriers, which results in a decrease in the imbibition of the working fluid into the paper [7]. The flowing fluid in the paper channel will encounter increasing resistance as the pore size of the paper decreases; this resistance will extend the time it requires for the fluid to reach the desired point.

2. Theoretical Background

In a porous medium, there are essentially two types of flow, wet-out flow and fully wetted flow. A one-dimensional (1D) fluid flowing into a dry porous paper tube is called “wet-out flow”. The traditional Lucas–Washburn (L-W) model is used to describe this process. It provides a useful starting point for understanding fluid absorption, which can be modified for understanding the variations caused by channel modifications. It demonstrates that the length of liquid imbibition is directly proportional to the square root of time (t). This results from the fluid’s viscous force and the surface tension of the paper’s capillary force:

where L is the absorption length of the imbibing fluid, μ is the fluid’s dynamic viscosity, θ is the contact angle, t is the wetting time, and r is the paper strip’s pore size. Surface tension γ at the fluid surface is the capillary force that drives the fluid in the paper. The higher the surface tension, the stronger the capillary drawing, resulting in faster fluid flow in the paper channel.

3. Material and Methods

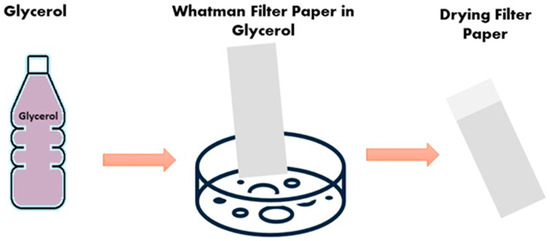

Whatman filter paper (Grade 42) filter paper manufactured by Whatman International plc, were used as the main substrate used in this study. Solutions of varying concentrations were made by adding glycerol to distilled water in percentage by volume from 0% (DI water only), 10%, and 30%. All the reagents used in the experiment were from Sigma-Aldrich. These solutions were then allowed to wick into paper a channel (1.8 cm width and 5 cm height) until the solution was wicked to the desired region on the strip. Afterwards, the wicking strips were allowed to dry at room temperature for 24 h. The creation of the glycerol delay zone at various doses is shown in Figure 1.

Figure 1.

Setting up the delay zone for glycerol.

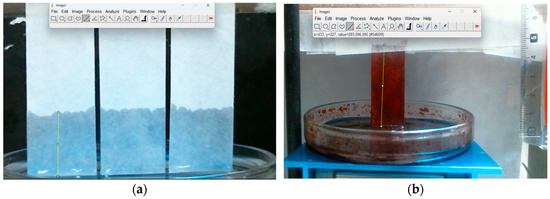

Through using ImageJ software (version 1.53), the imbibition length of liquid in the paper strip was measured against time, as shown in Figure 2.

Figure 2.

Fluid imbibition in glycerol-based flow barriers: (a) The flow of water in 10% glycerol barrier; (b) flow of oleic acid (with red dye) with 30% concentration glycerol strip.

4. Results and Discussion

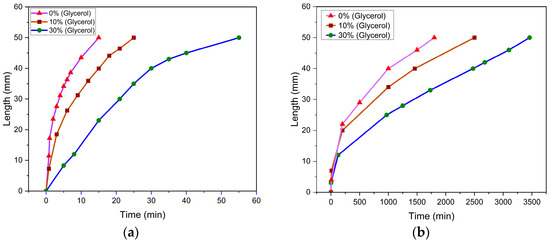

The results indicate that as we increase the glycerol concentration, the liquid velocity in the paper channel is reduced. The fluid takes longer to travel the complete channel length with the increase in concentration from 0 to 30% (Figure 3).

Figure 3.

Length–time curve: (a) Flow of distilled water in glycerol delay zone at varying proportions; (b) flow of oleic acid at varying quantities in the glycerol delay zone.

As shown in Figure 2a, DI water flows through strips of paper with different amounts of glycerol. The 0% glycerol channel (wetted and dried in DI water) allowed fluid to travel to a channel length of 43 mm within five minutes. Adding glycerol with a concentration of 10%, the liquid then takes 20 min to reach 46 mm. With an increase of 30% in glycerol concentration, DI water travels to 24 mm in 60 min but is unable to travel further due to the significant resistance to liquid flow.

Glycerol is highly soluble in water; it is sometimes referred to as glycerin and is utilized at room temperature. Its three hydroxyl (OH) groups in its molecular structure are responsible for its solubility. Glycerol is hydrophilic (attractive to water) due to these groups and forms strong hydrogen bonds with water molecules. In our experiments, a dilute glycerol solution was first impregnated into the porous paper channel and then allowed to dry, leaving behind a thin, hygroscopic film lining the channel walls. When liquid water flows through this glycerol-coated, rectangular paper channel, the retained glycerol molecules rapidly rehydrate and increase the local fluid viscosity, causing the pore size to reduce as well. This elevated viscosity and reduced porosity enhances viscous drag along the channel length, dissipating more of the fluid’s capillary force and thereby reducing its flow velocity as it advances.

However, oleic acid, a highly viscous fluid with higher viscosity than water, was added to further enhance the delay period from hours to days. As shown in Figure 3b, oleic acid takes a total of two hours to cover 50 mm in the untreated paper strip with 0% glycerol. Within a de-lay zone containing 30% glycerol, 40 mm of oleic acid are covered in a day. The results, therefore, show that the time delay may be substantially prolonged by employing a more viscous liquid, such as oleic acid, and by establishing glycerol delay zones of different proportions.

These results highlight the tunability of fluid transport in paper-based devices through both compositional and fluid property modifications. The significant differences in wicking behavior between water and oleic acid demonstrate how fluid viscosity, combined with glycerol-induced hydrophilic modulation, can be used to design customizable time delay mechanisms. This approach offers a low-cost, scalable method for integrating passive fluid control into paper-based diagnostic or reaction platforms, with potential applications in sequential reagent delivery, timed assays, and sample preconditioning.

5. Conclusions

This study concludes that, seeing as glycerol is hydrophilic and forms hydrogen bonds with water molecules, adding it to Whatman filter paper strips can greatly increase the liquid flow’s delay time. The experimental results show that higher glycerol concentrations increase viscous drag, which lowers flow velocity. There is a certain relationship between glycerol content and flow rate reduction, as seen by the considerable rise in wicking delay time for water with an increasing glycerol concentration. To further increase the delay duration, one might use a more viscous liquid, such as oleic acid, which can cause delays that range from hours to days. To investigate the impact of different concentrations of glycerol liquid solution on flow delays, stream obstacles were created using paper medium.

We hope the method applied herein will become widely considered as feasible for developing new, cutting-edge technologies in the domain of fluid mechanics and other related subjects. The results of this work could help researchers in their continued quest for the most efficient method for extending flow delays, which will be useful for studying food quality, environmental sensing, and the use of paper-based microfluidic devices.

Author Contributions

Conceptualization, N.N.; methodology, M.A. and A.T.J.; software, M.A. and H.U.; validation, N.N. and I.A.K.; formal analysis, N.N. and H.U.; investigation, N.N. and A.T.J.; data curation, H.A.; writing—original draft preparation, N.N.; writing—review and editing, N.N. and A.T.J.; supervision, A.T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the Technology Transfer Support Fund through the Higher Education Commission (HEC) Pakistan funded by the World Bank (Grant No. TTSF-74), Rapid Technology Transfer Grant through the Higher Education Commission (HEC) Pakistan funded by the World Bank (Grant No. RTTG-70), National Research Program for Universities funded by the Higher Education Commission (HEC) Pakistan (Grant No. NRPU-14816), Erasmus+ Capacity Building for Higher Education (CBHE) Strand 2 funded by European Union (EU) (Grant No. Catch VR – 101129191), Technology Development Fund funded by the Higher Education Commission (HEC) Pakistan (Grant No. TDF04-167), and Patent and Prototyping Support Program funded by the Directorate General of Science and Technology (DoST) KP Pakistan (Grant No. DGST25-1245).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| µPADs | Microfluidic paper-based analytical devices |

| POC | Point of care |

References

- Melander, D.; Sivarasu, S.; Yekinni, I.; Yunzhang, C.; Erdman, A. Diagnostics as the Key to Advances in Global Health: Proposed Methods for Making Reliable Diagnostics Widely Available. J. Med. Devices 2020, 14, 014702. [Google Scholar] [CrossRef] [PubMed]

- Fateha Samad, M.; Kouzani, A.Z. Integrated microfluidic drug delivery devices: A component view. Microsyst. Technol. 2013, 19, 957–970. [Google Scholar] [CrossRef]

- Wu, X.; Chen, A.; Yu, X.; Tian, Z.; Li, H.; Jiang, Y.; Xu, J. Microfluidic Synthesis of Multifunctional Micro-/Nanomaterials from Process Intensification: Structural Engineering to High Electrochemical Energy Storage. ACS Nano 2024, 18, 20957–20979. [Google Scholar] [CrossRef] [PubMed]

- Alhalaili, B.; Popescu, I.N.; Rusanescu, C.O.; Vidu, R. Microfluidic Devices and Microfluidics-Integrated Electrochemical and Optical (Bio)Sensors for Pollution Analysis: A Review. Sustainability 2022, 14, 12844. [Google Scholar] [CrossRef]

- Abbas, H.; Ali, M.; Naeem, N.; Ullah, H.; Ali, M.; Jafry, A.T. Effect of Storage Reservoir on Fluid Velocity in Lateral Flow Paper Device. Eng. Proc. 2023, 45, 5. [Google Scholar] [CrossRef]

- Fu, E.; Downs, C. Progress in the development and integration of fluid flow control tools in paper microfluidics. Lab A Chip 2017, 17, 614–628. [Google Scholar] [CrossRef] [PubMed]

- Castro, C.; Rosillo, C.; Tsutsui, H. Characterizing effects of humidity and channel size on imbibition in paper-based microfluidic channels. Microfluid. Nanofluidics 2017, 21, 21. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).