1. Introduction

The building sector consumes about 40% of the global primary energy, with a HVAC share of approximately 50% of this energy demand. The environmental impacts of conventional HVAC systems has increased with rising energy consumption worldwide [

1]. These systems rely on conventional energy resources and refrigerants like chlorofluorocarbons (CFCs), which leads to added greenhouse gas emissions and the global warming effect. The global share of HVAC-related energy consumption is expected to reach 35% by 2035, severely affecting the environment and energy resources [

2]. Modern HVAC systems are required to provide precise humidity control to ensure occupant comfort, specifically in commercial and industrial buildings [

3]. In dry winter climates, conventional air conditioning systems were unable to provide optimal levels of humidification, resulting in poor indoor air quality [

4]. These systems primarily focus on temperature control and often fail to achieve the humidity level.

Desiccant-based HVAC systems can be a suitable alternative to these limitations. Desiccant-based systems use moisture-absorbing materials such as zeolite and silica gel to effectively control humidity and regulate the temperature of the produced air. Silica gel is commonly used due to its high absorption capacity. A low regeneration temperature and porous structure make it equally effective under various climate conditions [

5]. In contrast to electricity-driven conventional HVAC, desiccant-based systems use thermal energy for regeneration process, which can be sourced from renewable energy technology such as solar thermal collectors [

6].

Recent studies have investigated solar-assisted desiccant systems in HVAC applications. For instance, a study reported up to a 64.3% increase in the coefficient of performance (COP) by incorporating desiccant wheels (DWs) into HVAC systems with improved thermal comfort [

7]. Similarly, desiccant systems showed higher performance in handling latent loads and achieving humidity levels as compared to a traditional humidifier system [

8]. However, most of the desiccant-based studies focus on cooling applications or idealized conditions. The performance evaluation of desiccant-based systems in heating and humidification modes needs further investigation.

This study fills this gap by examining how a solar-assisted solid desiccant wheel system designed for heating and humidification performs during the winter (December to February). The performance metrics include humidification capacity, heating capacity, and indoor conditions. By integrating renewable energy with advanced desiccant technologies, this study presents a holistic HVAC solution that reduces reliance on fossil fuels while enhancing energy efficiency and indoor climate control.

2. Description of Integrated System for Heating and Humidification

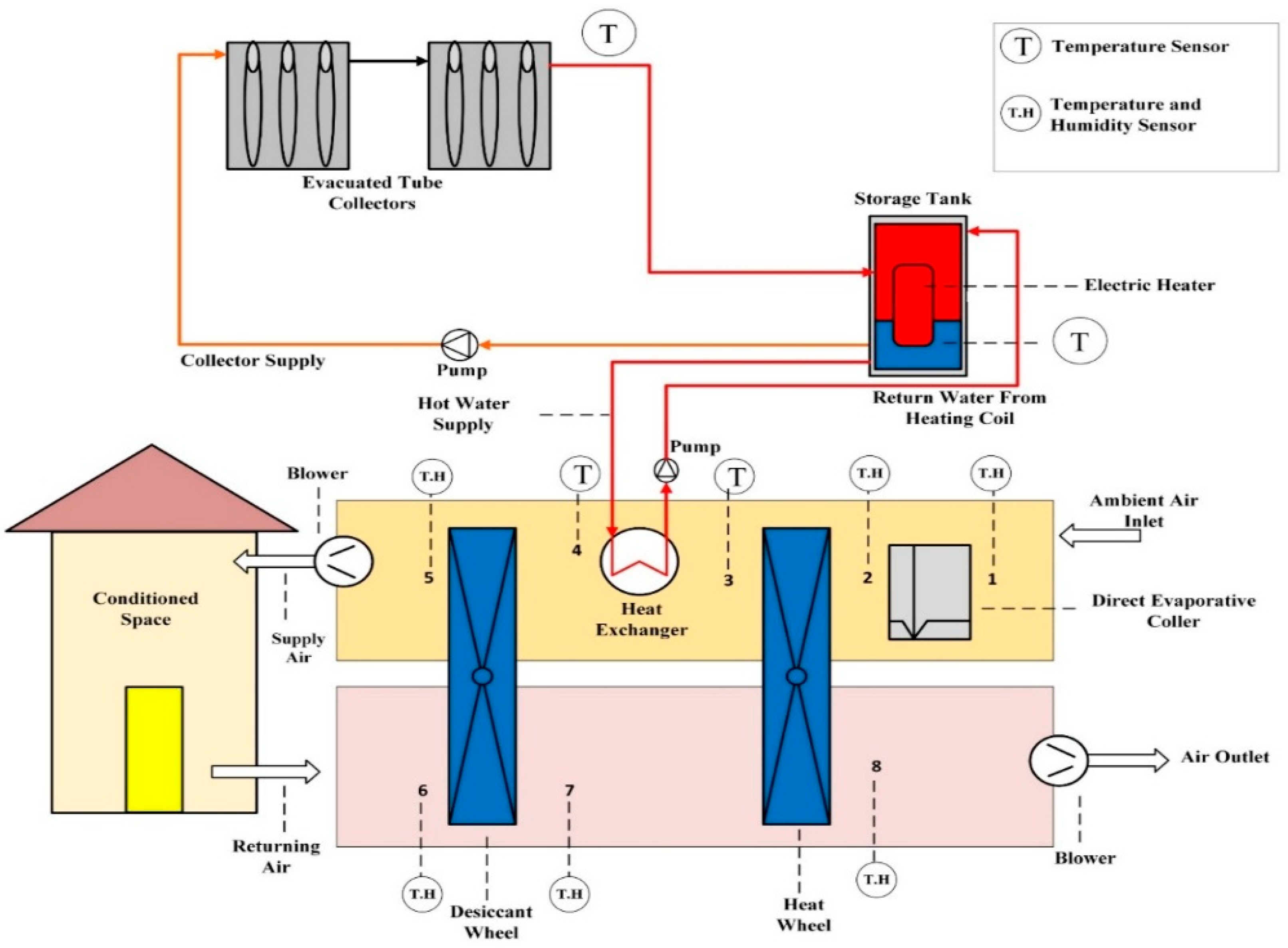

The mechanism of operation of an SDHH for heating and humidification mode is shown in

Figure 1. The main heat source derives from solar energy, making the process sustainable and effective. Flat plate collectors accumulate solar energy to heat water, which is stored in a tank with an electric heater for backup. The heat exchanger transfers thermal energy from the hot water to the air, raising its temperature.

Ambient air enters the system through the inlet and passes through a direct evaporative cooler (1–2), where it is cooled, and its humidity increases. The air moves to the heat wheel (2–3), where residual heat from the working air is transferred to the product air, slightly raising its temperature. The pre-conditioned air is then directed to the heat exchanger (3–4), where hot water further raises its temperature. It moves into the DW (process 4–5), where the product air loses some temperature but gains moisture. The warm and humid air is supplied to the conditioned space, ensuring thermal comfort. Returning (working) air from the conditioned space passes through the DW (6–7), releasing moisture to recharge it. Then it moves through the heat wheel (7–8), transferring the remaining heat to product air and optimizing energy use. This process guarantees that indoor comfort is maintained using solar energy while minimizing energy losses.

3. Model Development and Transient Simulation

The system configuration described in the paper was modeled and simulated in TRNSYS 18 to assess the performance of a heating and humidification system for the climate zone of Taxila (33.7° N, 72.8° E). The weather data were extracted from the meteorological TMY files for accurate simulation.

3.1. Test Room Envelope

The test room of 28.32 m

3 was modeled using type 56 in TRNBuild, allowing for sufficient space for testing under various climate conditions. The U-value of the test room envelope was set to 0.454

. It can operate within a temperature range of 7–45 °C and humidity levels from 5 g/kg (dehumidified) to 20 g/kg (humidified), ensuring a controlled and adaptable testing environment.

Table 1 presents the properties of the test room envelope.

3.2. Solar Thermal Model Development

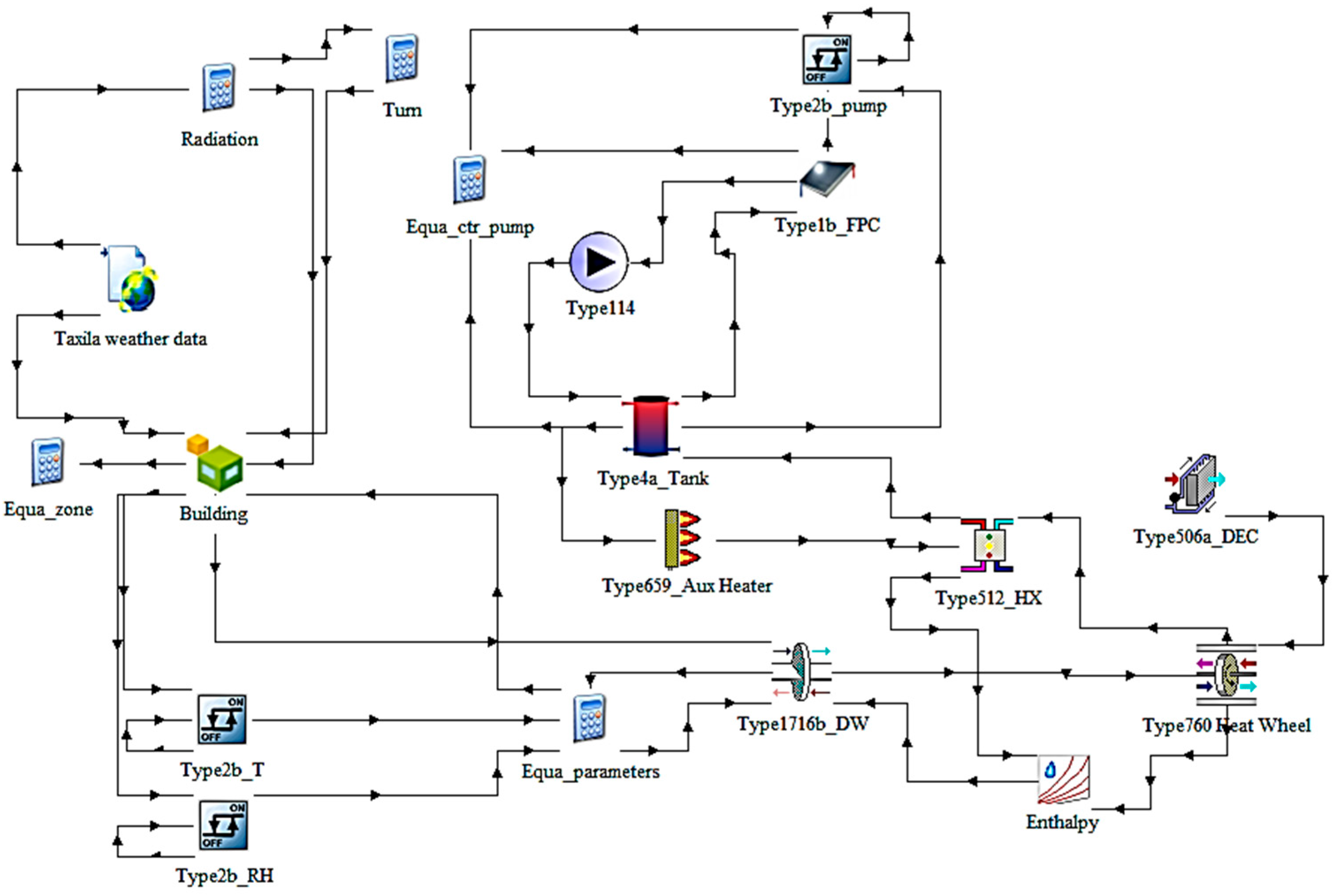

Figure 2 shows the TRNSYS model of the heating and humidification system. The pump control signal (Type 14b) was on when both the season schedule and pump schedule signals were active. A differential controller (Type 2d) allowed water to flow in the storage tank and solar collector loop when the temperature difference (ΔT) reaches a minimum of 2 °C. The flat plate solar collectors (Type 1b) heated the water, which was then directed to a stratified storage tank (Type 4a). Heated water passed through the auxiliary heater (Type 659), where its temperature was further increased before flowing into the air–water heat exchanger. Ambient (product) air first entered the evaporator cooler (Type 506a) and moved to the heat wheel (Type 760), where its temperature rises. The air then passed through the water-to-air heat exchanger (Type 512), further increasing its temperature before entering the DW (Type 1716b). Ambient air properties are obtained from TMY (Type 15) weather data files, while building thermal loads for heating and humidification are integrated via the zone model (Type 56).

Table 2 shows the parameters of the different components employed in the TRNSYS model.

4. Results and Discussion

The current study focused on a detailed investigation of SDHH performance in the winter season. Taxila was chosen as a geographical location for system performance analysis. The climate conditions for heating and humidification were considered in terms of ambient dry bulb temperature, ambient relative humidity, and solar radiation for the winter season spanning three months (December to February).

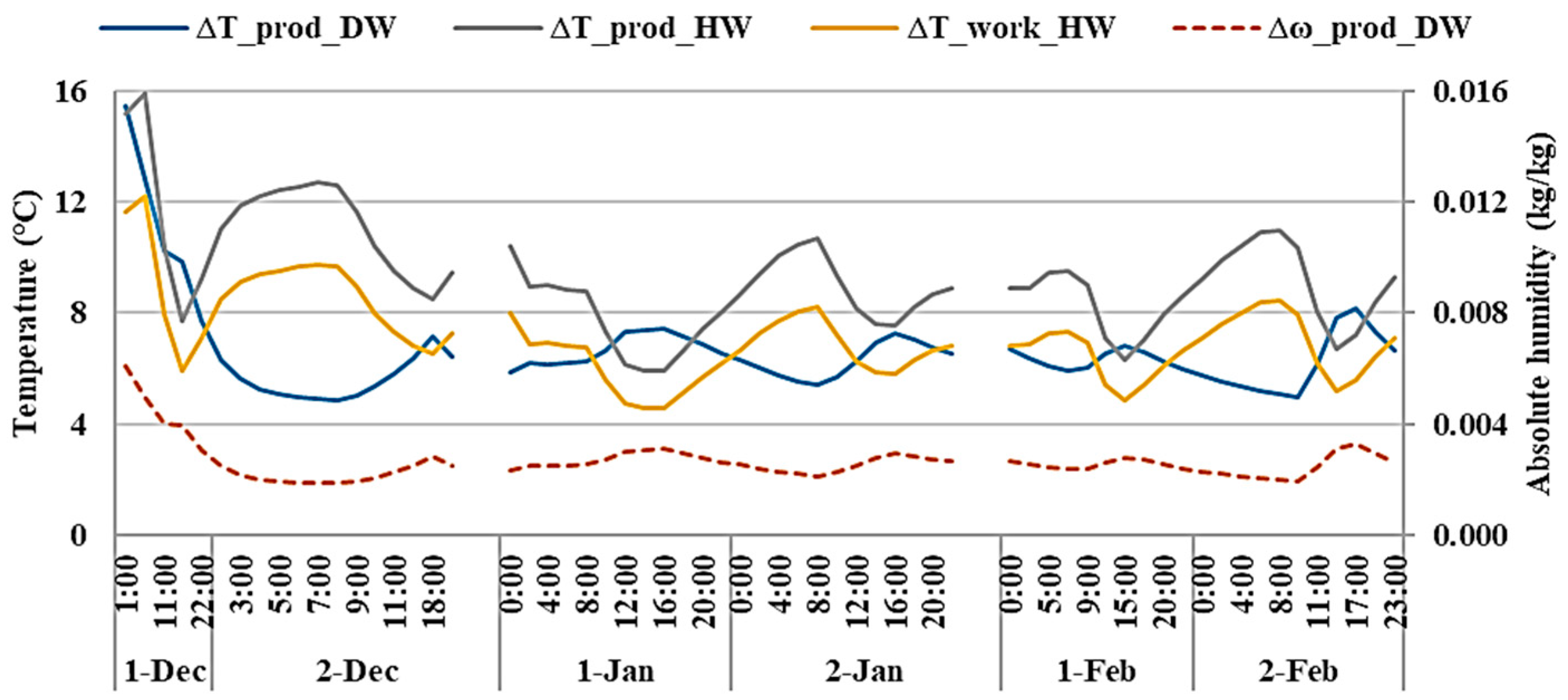

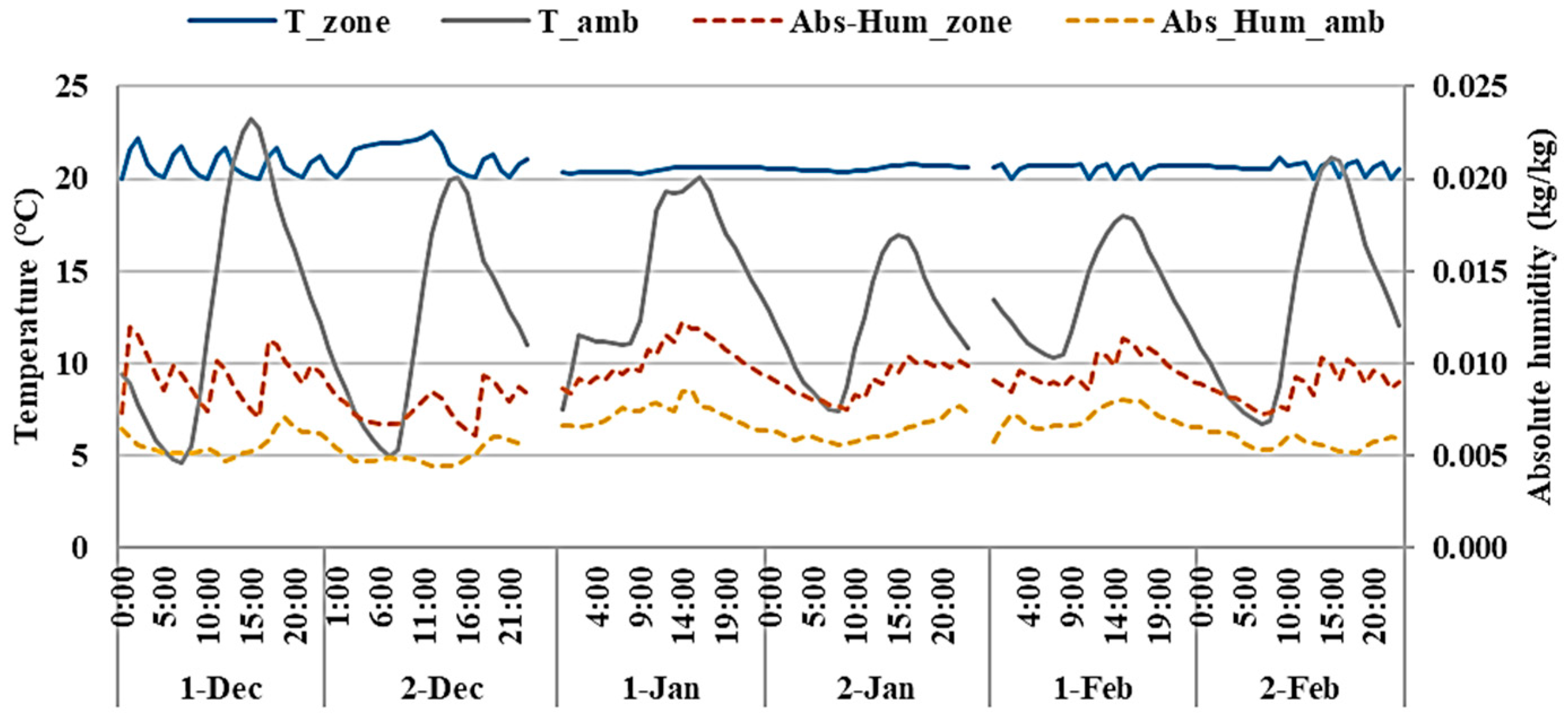

The temperature difference (ΔT) and absolute humidity difference (Δω) of product air across the DW and heat wheel (HW) are shown in

Figure 3 for the first two days of December, January, and February. The DW consistently increased absolute humidity (Δω_prod_DW) by an average of about 0.003 kg/kg, and increasing moisture resulted in a temperature drop (ΔT_prod_DW), illustrating the energy exchange mechanism where latent heat is absorbed as moisture is added to the product air. The product air temperature dropped across the desiccant wheel and ranged from 5 °C to 8 °C depending on the external conditions. Due to the significant temperature differential between the two sides, which caused a significant temperature drop across the desiccant wheel (ΔT_prod_DW) during the day, the humidification on the product side was more noticeable during the hours of maximum sunshine. As the ambient temperature changed, so did the temperature decrease throughout the HW (ΔT_prod_HW). Depending on the outdoor conditions, the temperature varied between 5 °C and 10 °C as it descended throughout the HW (ΔT_prod_HW).

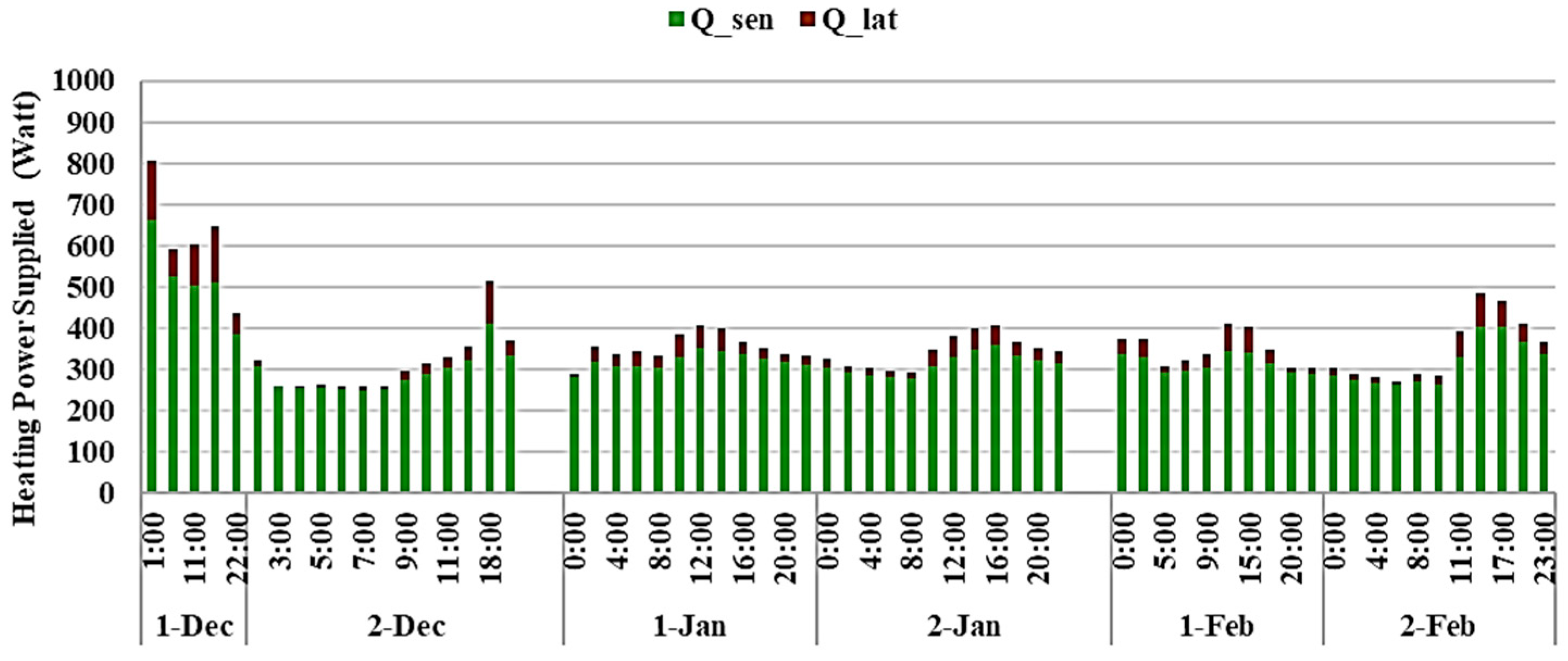

The trends in the heating power supplied, which include both sensible and latent components, over the winter months of December to February can be seen in

Figure 4. The system’s ability to control humidification and heating is demonstrated by the hourly profiles. The sensible heat transfer rate, represented by Q_sen, has a distinct and constant trend, with maximal values in the early morning hours. The heating load needed to maintain indoor comfort increased at these peaks, when the outside temperature was lower. On the other hand, there were only slight variations in Q_lat, which represents the latent heat transfer rate.

The system efficiently controlled indoor humidity, as shown by the steady trend of latent heat transfer. The sensible heating provided by SDHH ranged between 250 and 661 W during different times of the day. For the case of latent load, it reached a maximum load of 136 W.

Figure 5 displays daily changes in ambient and zone temperature (°C) and the humidity ratio (kg/kg) on different days of the winter season. The ambient dry bulb temperature fluctuated significantly during the day, ranging from approximately 5 °C to 20 °C. The temperature within the zone stayed comparatively constant, at around 20 °C over the measured period. This demonstrated the system’s capability to ensure constant indoor thermal comfort even in fluctuating outside conditions. An approximately constant humidity level was achieved within the system, with an average value of 0.008 kg/kg with variation between 0.005 kg/kg and 0.014 kg/kg. On the other hand, the ambient humidity varied significantly, ranging from 0.003 kg/kg to 0.011 kg/kg.

5. Conclusions

This study successfully developed SDHH for cold and dry climates, simulated in the climate conditions of Taxila, Pakistan. This study justified implementing SDHH to maintain indoor temperature and humidity levels in winter. The desiccant wheel could increase the moisture content of product air by an average value of 0.003 kg/kg, while the temperature drop across the desiccant wheel ranged from 5 to 8 °C and across the HW from 5 to 10 °C. Though outdoor temperature and humidity showed large variations, an indoor temperature of 21 °C and indoor humidity of 0.008 kg/kg on average were observed.

The proposed SDHH system can be effectively applied in real-life indoor environments that include furniture, appliances, and occupants. These elements may affect heat distribution and moisture levels, but the system’s performance—maintaining an average indoor temperature and humidity—demonstrates its potential. With minor design adaptations like optimizing airflow and accounting for internal moisture loads, the system can function efficiently in typical residential or commercial settings.

Overall, the findings demonstrated the potential of solar-assisted desiccant wheel-based heating and a humidification system to reduce the dependence on conventional energy sources and control global warming. The integration of solar technology and thermal storage ensures system reliability, making it a sustainable solution for energy-efficient heating.

Author Contributions

M.U. (Muhammad Usman 1): methodology, TRNSYS modeling, formal analysis, writing—original draft, data support. M.U. (Muhammad Usman 2): conceptualization, review, technical supervision. O.A.: investigation, literature review, experimental support. A.M. (Awais Mansoor): investigation, literature review, experimental support. F.A.: resources, data curation, analysis. A.M. (Abdul Moiz): assistance in TRNSYS simulation, analysis. M.A.: project administration, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request. Simulation files and results generated using TRNSYS software can be shared for academic and research purposes.

Acknowledgments

The authors gratefully acknowledge the support provided by the Department of Mechanical Engineering at the University of Engineering and Technology Taxila for facilitating this research. Special thanks to Muzaffar Ali for his valuable guidance, supervision, and continuous support throughout the course of this study.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| DW | Desiccant Wheel |

| HW | Heat Wheel |

| COP | Coefficient of Performance |

| HX | Heat Exchanger |

| EH | Electric Heater |

| Δω | Humidity Difference |

| ΔT | Temperature Difference |

| HVAC | Heat Ventilation and Air Conditioning |

| SDHH | Solar-Assisted Desiccant Wheel-Based Heating and Humidification |

| DEC | Direct Evaporated Cooler |

| HVAC | Heat Ventilation and Air Conditioning |

References

- Mandow, W.; Micus, F.; Völker, L.; Fleig, D.; Jordan, U. Solar driven liquid desiccant dehumidification system: Measurements and annual system simulations. Appl. Therm. Eng. 2024, 242, 122485. [Google Scholar] [CrossRef]

- Srimuk, J.; Chirarattananon, S.; Chaiwiwatworakul, P.; Nathakaranakule, A.; Rakkwamsuk, P.; Chiarakorn, S. An experiment and simulation on a solar-regenerated dehumidifier fabricated from composite desiccant coated fin-tube heat exchanger. Appl. Therm. Eng. 2024, 245, 122780. [Google Scholar] [CrossRef]

- Nain, S.; Parinam, A.; Kajal, S. Experimental study and analysis of solar based winter air conditioning system using desiccant coated heat exchanger. Mater. Today Proc. 2021, 46, 9938–9943. [Google Scholar] [CrossRef]

- Dezfouli, M.; Sopian, K.; Kadir, K. Energy and performance analysis of solar solid desiccant cooling systems for energy efficient buildings in tropical regions. Energy Convers. Manag. X 2022, 14, 100186. [Google Scholar] [CrossRef]

- Alrwashdeh, S.S.; Ammari, H.; Madanat, M.A.; Al-Falahat, A.a.M. The effect of heat exchanger design on heat transfer rate and temperature distribution. Emerg. Sci. J. 2022, 6, 128–137. [Google Scholar] [CrossRef]

- Maka, A.O.; Alabid, J.M. Solar energy technology and its roles in sustainable development. Clean Energy 2022, 6, 476–483. [Google Scholar] [CrossRef]

- Yang, B.; Wang, C.; Ji, X.; Nie, J.; Zhang, R.; Li, Y.; Chen, Q. A solar-assisted regenerative desiccant air conditioning with indirect evaporative cooling for humid climate region. Appl. Therm. Eng. 2024, 243, 122598. [Google Scholar] [CrossRef]

- Jani, D.; Mishra, M.; Sahoo, P.K. A critical review on application of solar energy as renewable regeneration heat source in solid desiccant–vapor compression hybrid cooling system. J. Build. Eng. 2018, 18, 107–124. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).