Designing a Sustainable Organic Rankine Cycle for Remote Geothermal Heat Sources in Pakistan †

Abstract

1. Introduction

2. Methodology

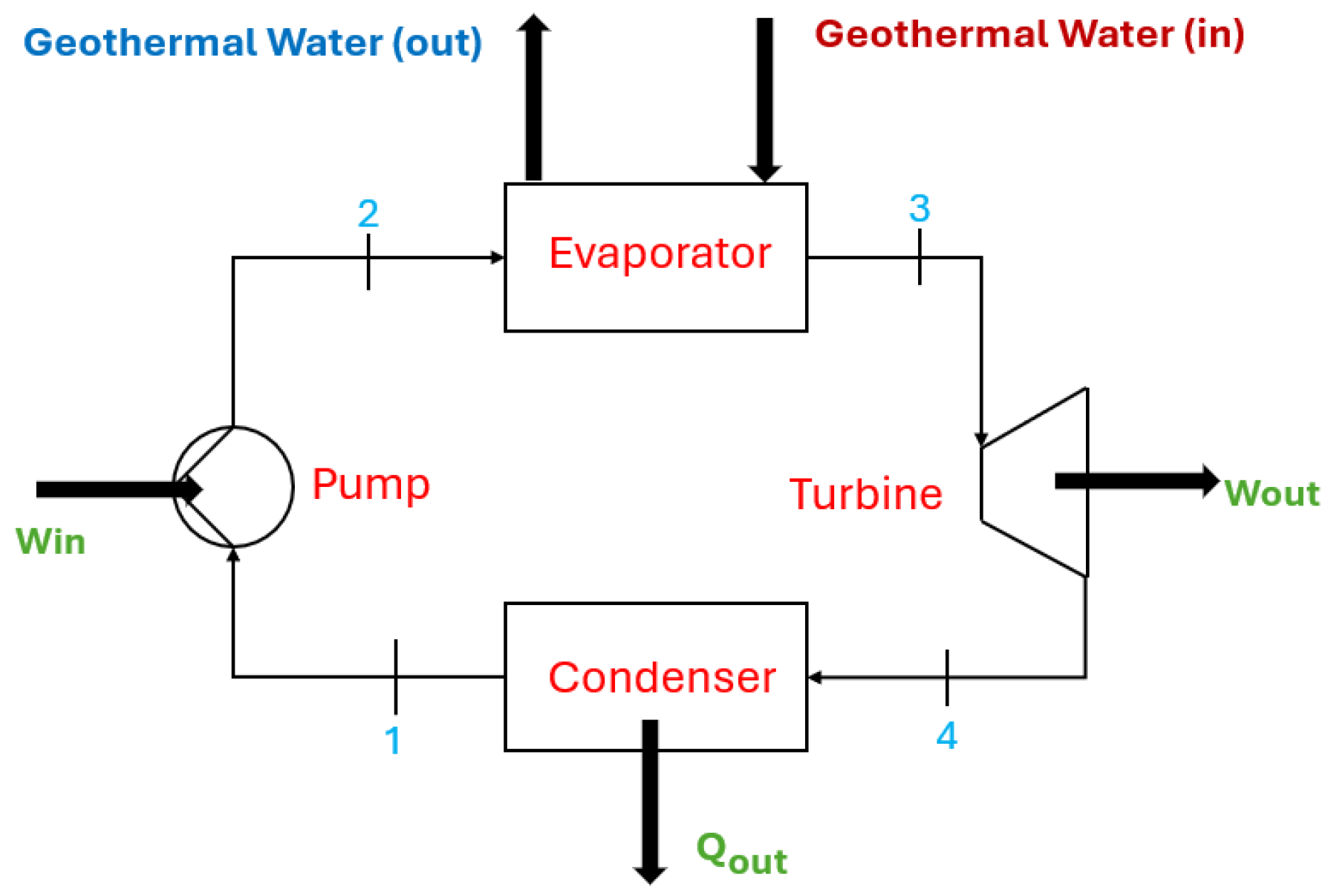

2.1. The System Overview

2.2. Assumptions and Modeling

2.3. Mathematical Modeling

3. Results and Discussion

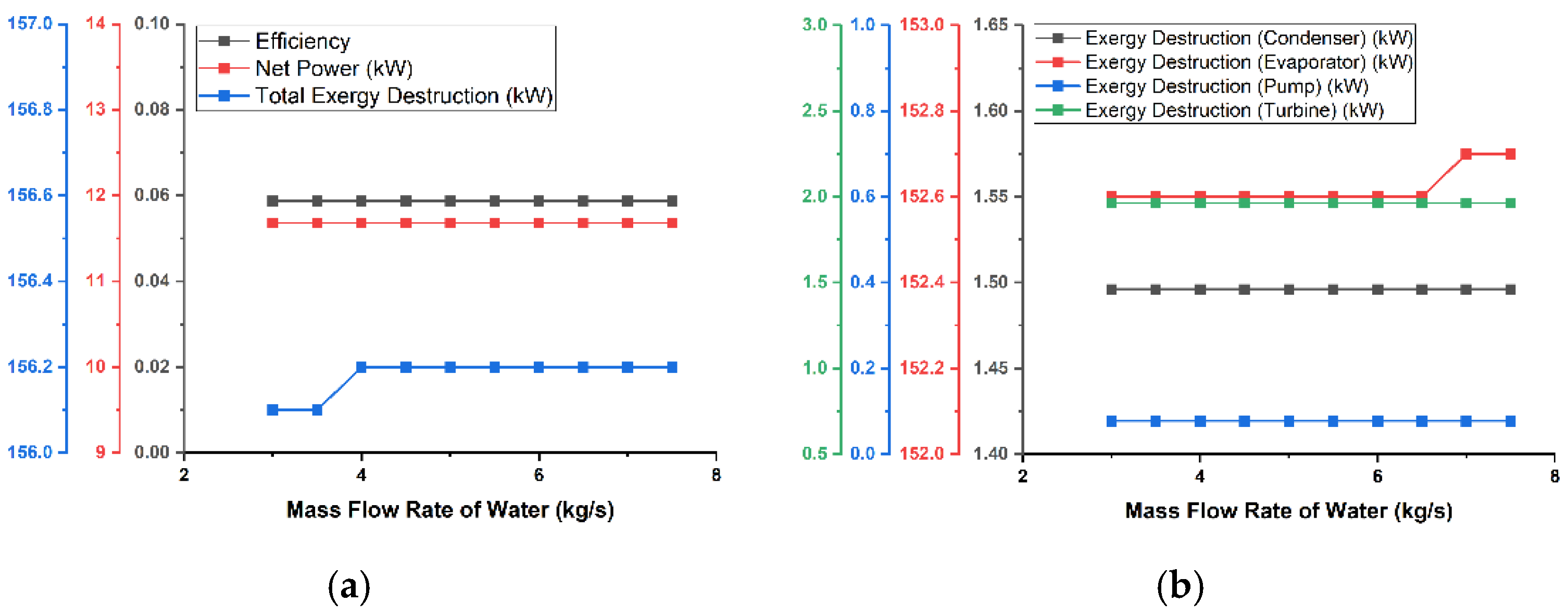

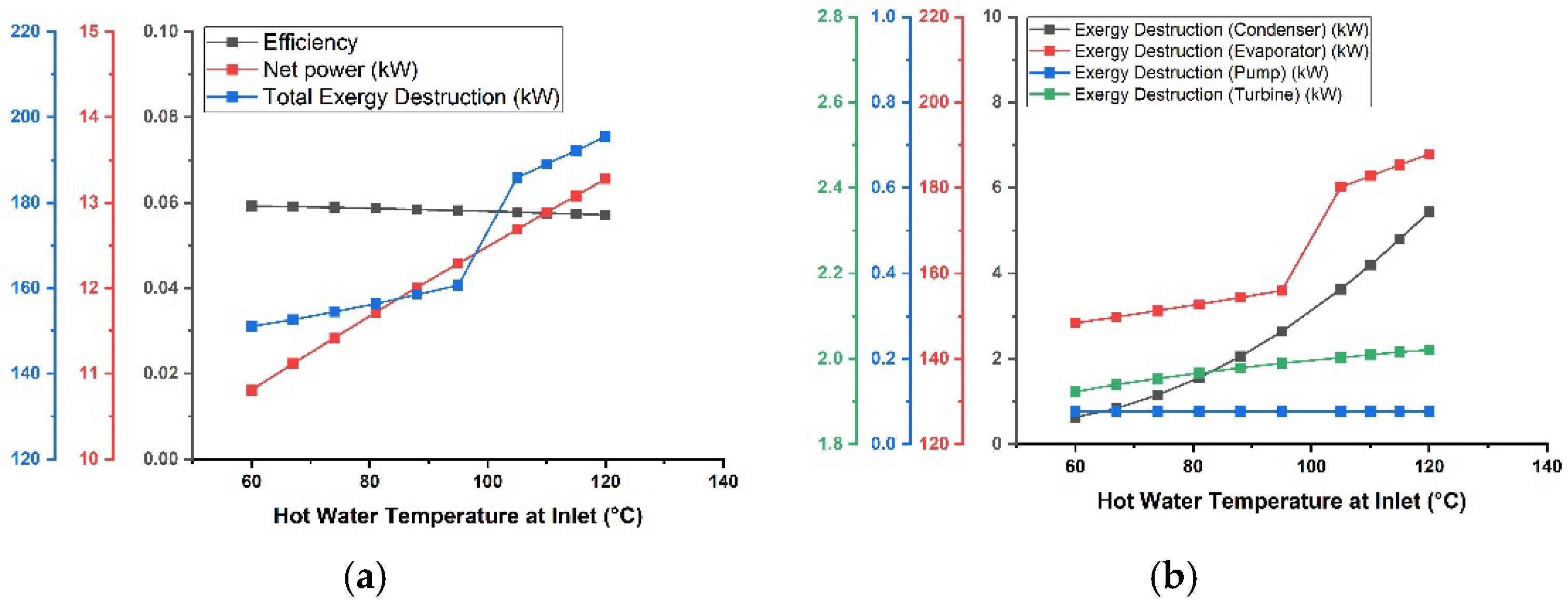

3.1. The Geothermal Parameters

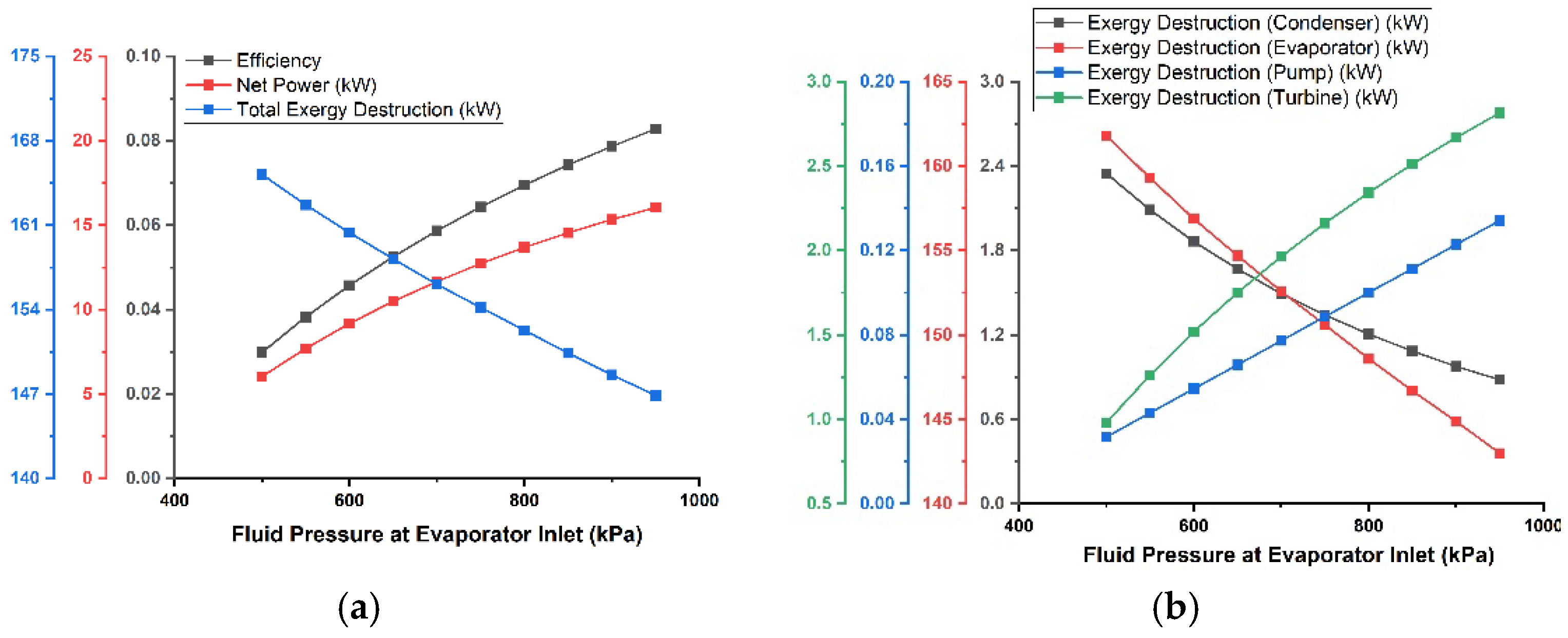

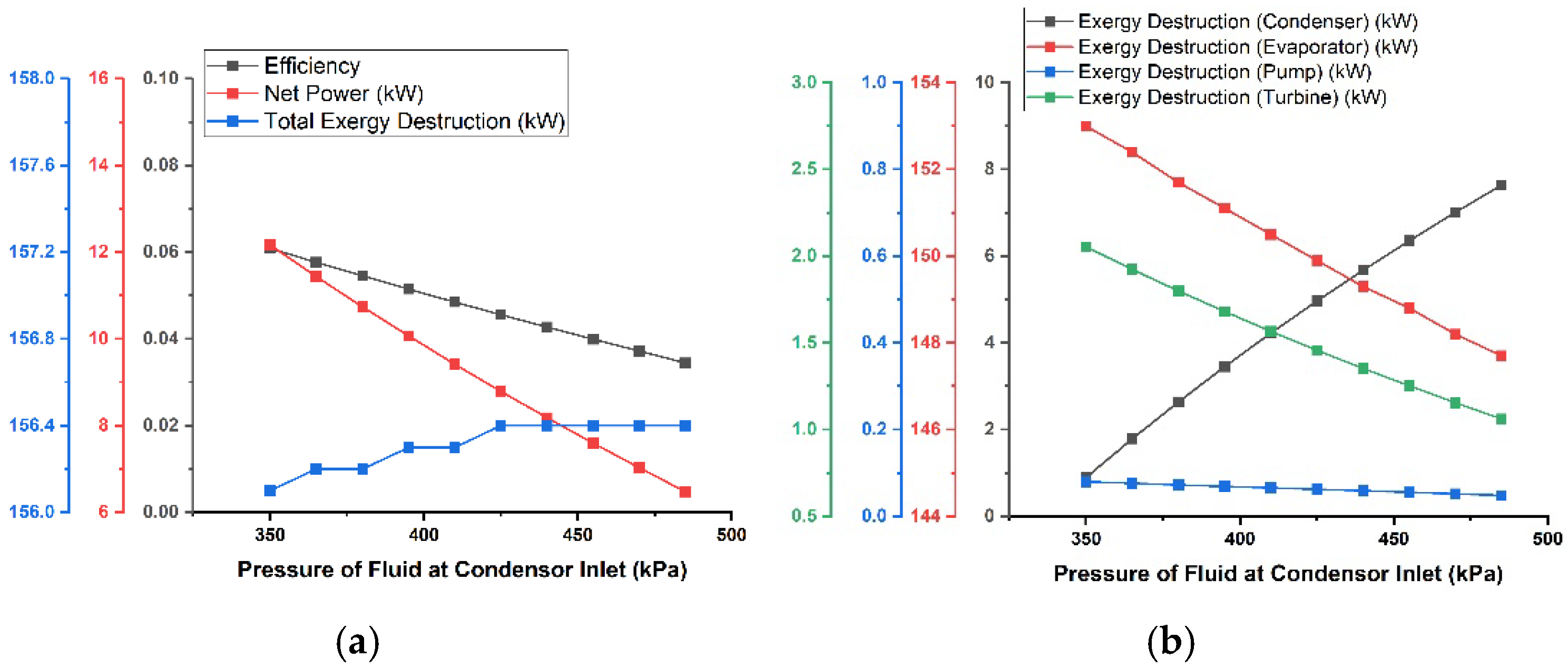

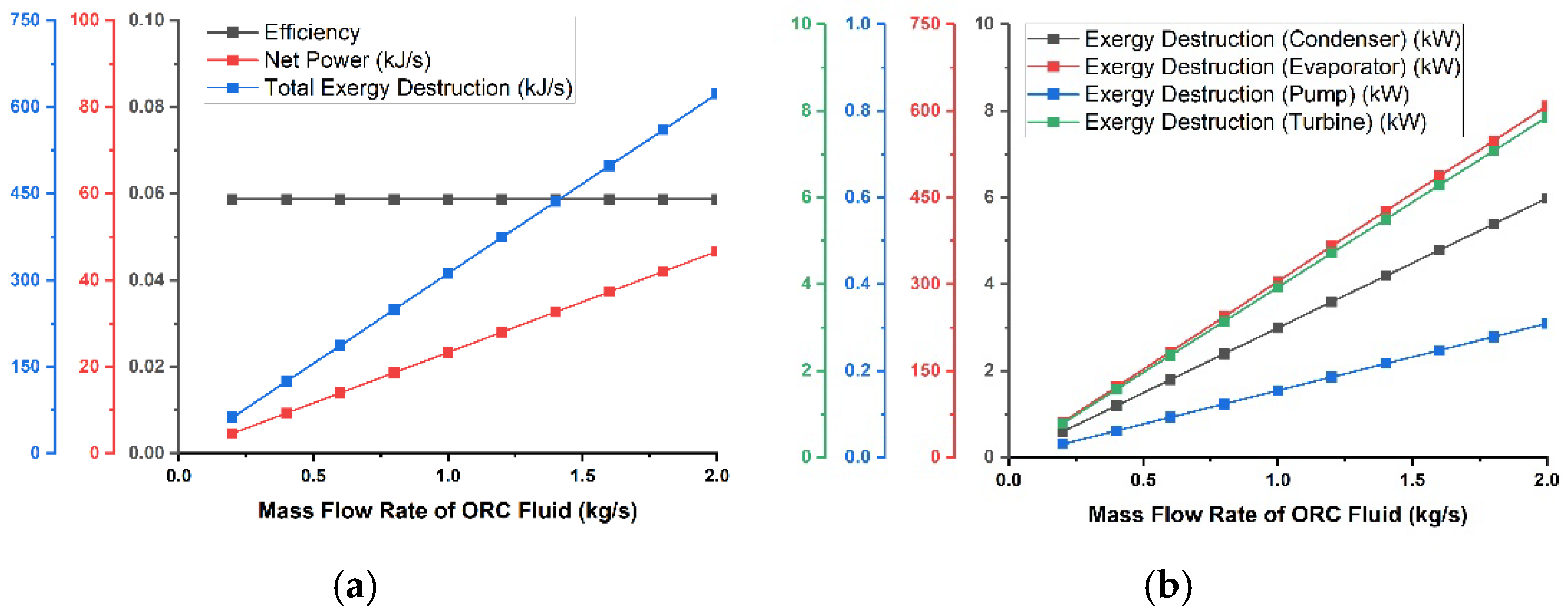

3.2. Organic Rankine Cycle (ORC) Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alam Zaigham, N.; Alam Nayyar, Z.; Hisamuddin, N. Review of geothermal energy resources in Pakistan. Renew. Sustain. Energy Rev. 2009, 13, 223–232. [Google Scholar] [CrossRef]

- The Friday Times. Available online: https://thefridaytimes.com/05-Mar-2024/geothermal-renewable-energy-and-pakistan-s-power-crisis (accessed on 2 February 2025).

- The Express Tribune. Available online: https://tribune.com.pk/article/97488/how-to-solve-pakistans-energy-crisis (accessed on 3 February 2025).

- Hu, B.; Guo, J.; Yang, Y.; Shao, Y. Selection of working fluid for organic Rankine cycle used in low temperature geothermal power plant. Energy Rep. 2022, 8, 179–186. [Google Scholar] [CrossRef]

- Rehman, A.; Deyuan, Z.; Chandio, A.A.; Hussain, I. An empirical analysis of rural and urban populations’ access to electricity: Evidence from Pakistan. Energy Sustain. Soc. 2018, 8, 40. [Google Scholar] [CrossRef]

- Energy Update. Available online: https://www.energyupdate.com.pk/2024/06/12/pakistans-installed-electricity-capacity-reaches-42131mw/ (accessed on 5 February 2025).

- Munir, M.M.; Shakir, A.S.; Rehman, H.-U.; Khan, N.M.; Rashid, M.U.; Tariq, M.a.U.R.; Sarwar, M.K. Simulation-Optimization of Tarbela Reservoir Operation to Enhance Multiple Benefits and to Achieve Sustainable Development Goals. Water 2022, 14, 2512. [Google Scholar] [CrossRef]

- Pili, R.; Romagnoli, A.; Spliethoff, H.; Wieland, C. Techno-economic analysis of waste heat recovery with ORC from fluctuating industrial sources. Energy Procedia 2017, 129, 503–510. [Google Scholar] [CrossRef]

- Yu, H.; Helland, H.; Yu, X.; Gundersen, T.; Sin, G. Optimal design and operation of an Organic Rankine Cycle (ORC) system driven by solar energy with sensible thermal energy storage. Energy Convers. Manag. 2021, 244, 114494. [Google Scholar] [CrossRef]

- Lavine, T.L. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 1977. [Google Scholar]

- Song, Y.; Sun, X.; Huang, D. Preliminary design and performance analysis of a centrifugal turbine for Organic Rankine Cycle (ORC) applications. Energy 2017, 140, 1239–1251. [Google Scholar] [CrossRef]

- Wang, R.; Kuang, G.; Zhu, L.; Wang, S.; Zhao, J. Experimental Investigation of a 300 kW Organic Rankine Cycle Unit with Radial Turbine for Low-Grade Waste Heat Recovery. Entropy 2019, 21, 619. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Zhang, J.; Zhao, L.; Deng, S.; Zhang, Y. Novel experimental research on the compression process in organic Rankine cycle (ORC). Energy Convers. Manag. 2017, 137, 1–11. [Google Scholar] [CrossRef]

- Javanshir, A.; Sarunac, N. Effect of the Working Fluid on Performance of the ORC and Combined Brayton/ORC Cycle. In Proceedings of the ASME 2017 11th International Conference on Energy Sustainability collocated with the ASME 2017 Power Conference Joint With ICOPE-17, the ASME 2017 15th International Conference on Fuel Cell Science, Engineering and Technology, and the ASME 2017 Nuclear Forum, Charlotte, NC, USA, 26–30 June 2017. [Google Scholar] [CrossRef]

| Working Fluid | Molar Mass (kg/kmol) | Tcr (°C) | Pcr (MPa) | GWP |

| r245fa | 134.05 | 154.01 | 3.65 | 1030 |

| r141b | 116.95 | 204.35 | 4.21 | 600 |

| r600a | 58.122 | 134.66 | 3.62 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ijaz, M.S.; Ansari, M.S.; Sabghatullah, A.; Alam, I.; Zafar, M.Q. Designing a Sustainable Organic Rankine Cycle for Remote Geothermal Heat Sources in Pakistan. Mater. Proc. 2025, 23, 10. https://doi.org/10.3390/materproc2025023010

Ijaz MS, Ansari MS, Sabghatullah A, Alam I, Zafar MQ. Designing a Sustainable Organic Rankine Cycle for Remote Geothermal Heat Sources in Pakistan. Materials Proceedings. 2025; 23(1):10. https://doi.org/10.3390/materproc2025023010

Chicago/Turabian StyleIjaz, Muhammad Shoaib, Marig Shabbir Ansari, Aftab Sabghatullah, Intesar Alam, and Muhammad Qasim Zafar. 2025. "Designing a Sustainable Organic Rankine Cycle for Remote Geothermal Heat Sources in Pakistan" Materials Proceedings 23, no. 1: 10. https://doi.org/10.3390/materproc2025023010

APA StyleIjaz, M. S., Ansari, M. S., Sabghatullah, A., Alam, I., & Zafar, M. Q. (2025). Designing a Sustainable Organic Rankine Cycle for Remote Geothermal Heat Sources in Pakistan. Materials Proceedings, 23(1), 10. https://doi.org/10.3390/materproc2025023010