Low-Cost Solar Heating Reservoir Manufactured by Double-Coating a Water Tank with Polymeric Materials †

Abstract

:1. Introduction

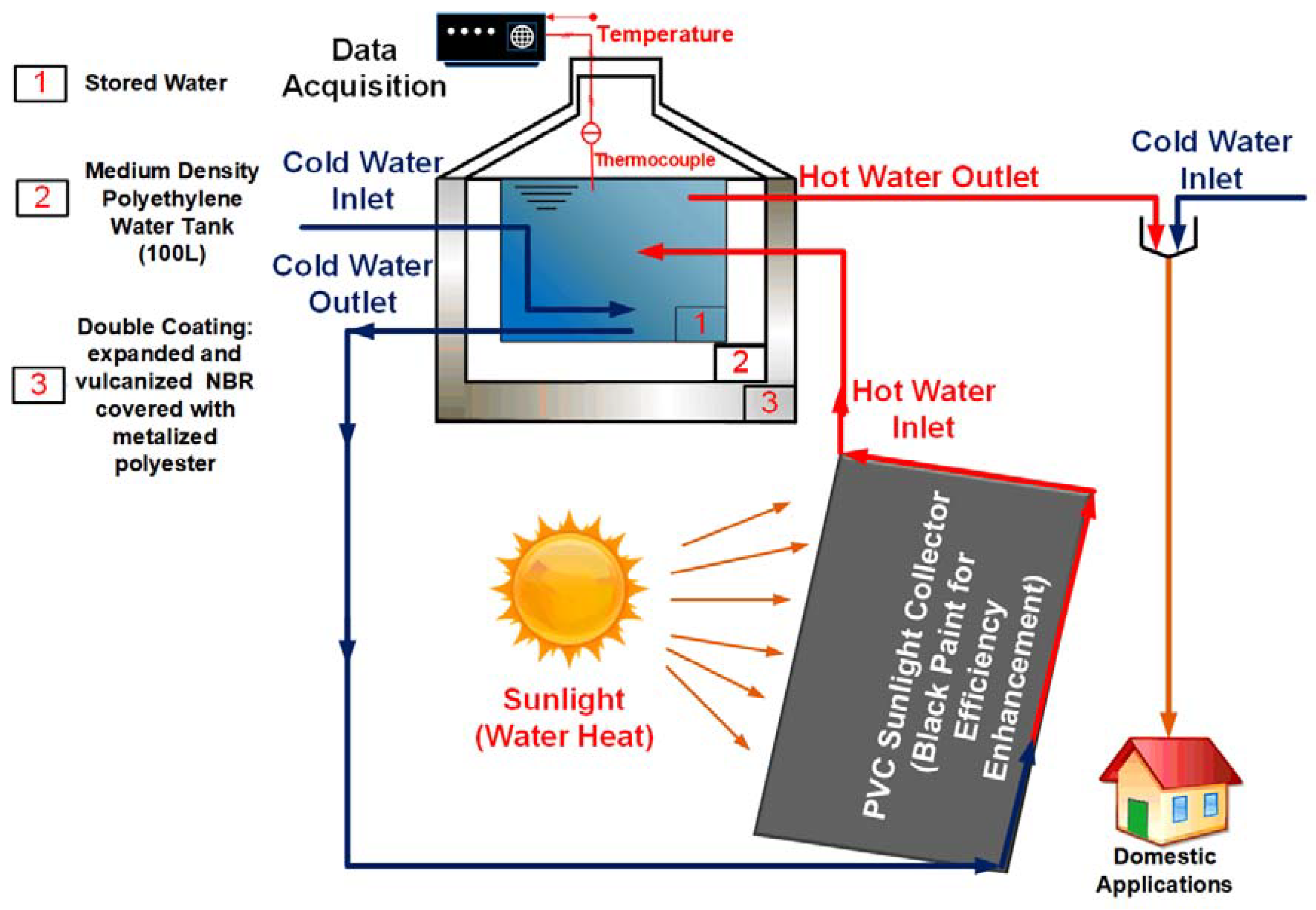

2. Materials and Methods

2.1. Low-Cost Solar System Fabrication

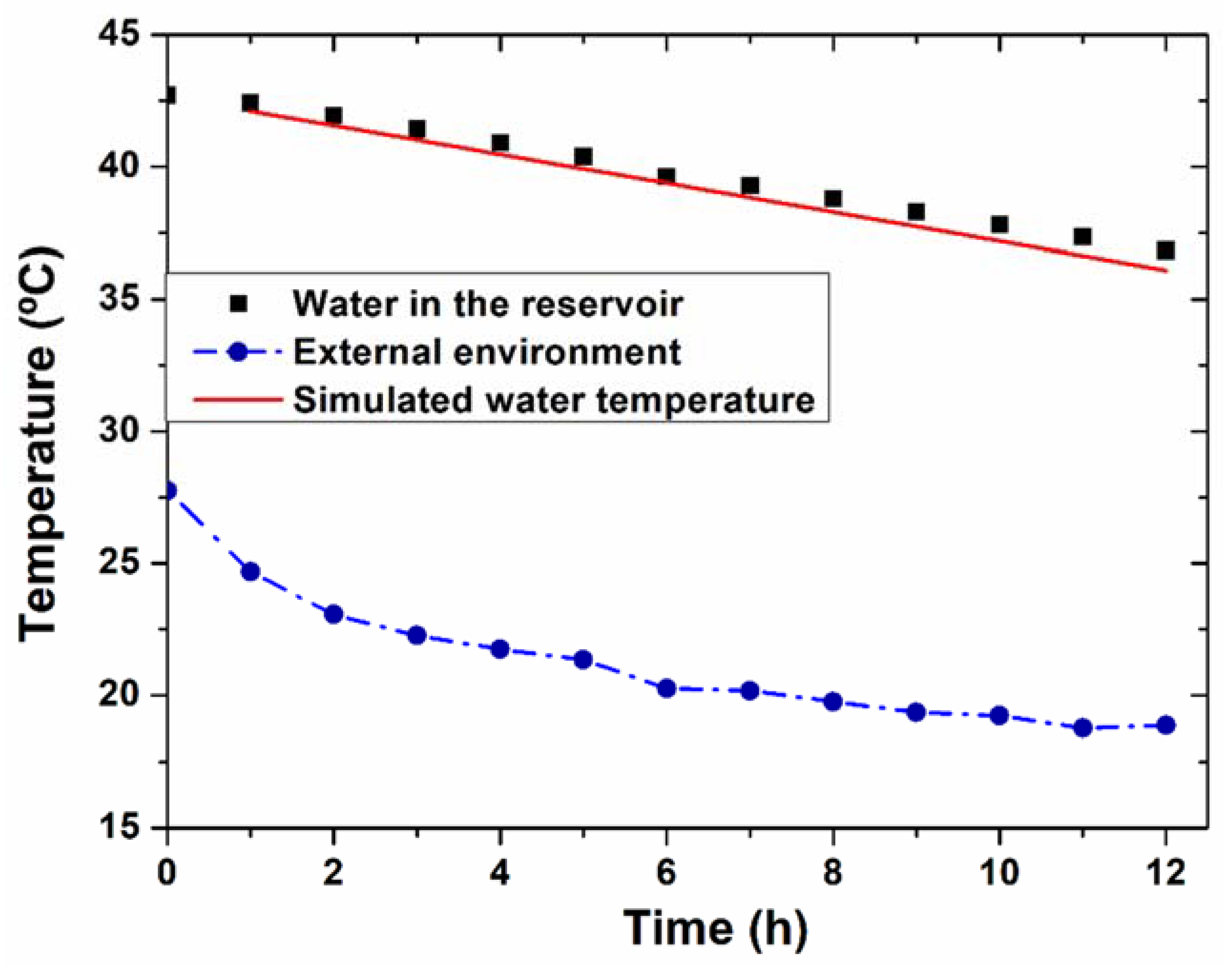

2.2. Performance Analysis of the Double-Coated Heat Reservoir

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Alva, G.; Liu, L.; Huang, X.; Fang, G. Thermal energy storage materials and systems for solar energy applications. Renew. Sustain. Energy Rev. 2017, 68, 693–706. [Google Scholar] [CrossRef]

- Liu, M.; Saman, W.; Bruno, F. Review on storage materials and thermal performance enhancement techniques for high temperature phase change thermal storage systems. Renew. Sustain. Energy Rev. 2012, 16, 2118–2132. [Google Scholar] [CrossRef]

- Rodríguez-Hidalgo, M.D.C.; Rodríguez-Aumente, P.A.; Lecuona, A.; Legrand, M.; Ventas, R. Domestic hot water consumption vs. solar thermal energy storage: The optimum size of the storage tank. Appl. Energy 2012, 97, 897–906. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Zhang, S. Novel organic solar thermal energy storage materials: Efficient visible light-driven reversible solid–liquid phase transition. J. Mater. Chem. 2012, 22, 18145–18150. [Google Scholar] [CrossRef]

- Chen, H.S.; Cong, T.N.; Yang, W.; Tan, C.Q.; Li, Y.L.; Ding, Y.L. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Pereira, R.C.; Shiota, R.T.; Mello, S.F.; Assis, V., Jr.; Bartoli, J.R. Eficiência Térmica de Coletores Solares de Baixo Custo dos Materiais (CSBC). In Proceedings of the 17° CBECIMat- Cong. Brasileiro de Engenharia e Ciências dos Materiais de Foz do Iguaçu, Foz do Iguaçu, Brasil, 15–19 November 2006; pp. 9607–9617. [Google Scholar]

- Pereira, R.C.; Netzel, M.A.; Assis, V., Jr.; Vizintim, J.V.; Campos, J.S.C.; Bartoli, J.R. Construção e Teste de Coletores Solares de Baixo Custo a Base de PVC. In Proceedings of the 8°CBPol-Cong de Polímeros, Águas de Lindóia, Brasil, 6–10 November 2005; pp. 444–445. [Google Scholar]

- Bartoli, J.R.; Prado, B.R.; Pereira, R.C. Study of the Natural Aging of PVC Flat-plate Absorber Used for Low Cost Solar Collectors. In Proceedings of the EPF 2011, XII GEP Congress, Granada, Spain, 3–6 September 2011. [Google Scholar]

- Caixa d’água Polietileno 100L Azul Fortlev. Available online: https://www.leroymerlin.com.br/caixa-dagua-polietileno-100l-azul-fortlev_89866700 (accessed on 10 March 2020).

- Forro Pvc Modular Magiore 10 X 625 X 1250 Mm (caixa). Available online: https://www.americanas.com.br/produto/46271712/forro-pvc-modular-magiore-10-x-625-x-1250-mm-caixa?WT.srch=1&acc=e789ea56094489dffd798f86ff51c7a9&epar=bp_pl_00_go_pla_casaeconst_geral_gmv&gclid=Cj0KCQjwsYb0BRCOARIsAHbLPhEAHyFPD2eFtpdSSJAJVAXKgM_p3NnjRpNEBKSX_zgg2l1wAw6jjUwaAkrCEALw_wcB&i=59f7f6c4eec3dfb1f8a76b6b&o=5bfe85c7ebb19ac62cf1ae1d&opn=YSMESP&sellerid=55010060000187&wt.srch=1 (accessed on 1 April 2020).

- TINTA ESMALTE CORALIT FOSCO PRETO 225ML—CORAL. Available online: https://lojaagrometal.com.br/tintas-acessorios/pintura/16825-tinta-esmalte-sintetico-premium-brilhante-coralit-tradicional-zero-branco-3-6-litros-coral-5202788.html?gclid=Cj0KCQjw0pfzBRCOARIsANi0g0u03R6Ciu3NK15Qxn1v3eD2hR1pnNp0ZF_c1gUHwROGHbm7oUP_L4MaAsW7EALw_wcB (accessed on 10 March 2020).

- Manta Isolante Térmico Espuma Elastomérica 10mm—Rolo 20m. Available online: https://produto.mercadolivre.com.br/MLB-1432517978-manta-isolante-termico-espuma-elastomerica-10mm-rolo-20m- _JM#position=4&type=item&tracking_id=0ff89828-9614-4051-9148-c95780ac0c39 (accessed on 10 March 2020).

- Cano Marrom PVC Soldável 32mm ou 1” 3m Tigre. Available online: https://www.leroymerlin.com.br/cano-marrom-pvc-soldavel-32mm-ou-1-3m-tigre_85949892 (accessed on 10 March 2020).

- Luva Soldável 32mm Marrom. Available online: https://www.cec.com.br/material-hidraulico/tubos-e-conexoes/luvas/luva-soldavel-32mm-marrom?produto=1034314 (accessed on 10 March 2020).

- Luva de Correr para Tubo Soldável 32mm Marrom. Available online: https://www.cec.com.br/material-hidraulico/tubos-e-conexoes/luvas/luva-de-correr-para-tubo-soldavel-32mm-marrom?produto=1050978 (accessed on 10 March 2020).

- União Soldável 32mm Marrom. Available online: https://www.cec.com.br/material-hidraulico/tubos-e-conexoes/unioes/uniao-soldavel-32mm-marrom?produto=1034327 (accessed on 10 March 2020).

- Aquecedor Solar—Boiler 100 Litros Nível/Desnível Baixa Pressão + 1 placa 2 × 1m cobre. Available online: https://www.patrosol.com.br/kits/kits-residenciais/kit-aquecedor-solar-100-litros (accessed on 10 March 2020).

- USD to BRL Exchange Rate—Bloomberg Markets. Available online: https://www.bloomberg.com/quote/USDBRL:CUR (accessed on 12 March 2020).

- ArmWin® Professional Insulation Thickness Calculator. Available online: https://armwin.armacell.com/ (accessed on 12 March 2020).

- ISO 12241:2008. Thermal Insulation for Building Equipment and Industrial Installations—Calculation Rules; International Organization for Standardization: Geneva, Switzerland, 2008; pp. 1–45. [Google Scholar]

- Powell, K.M.; Edgar, T.F. Modeling and control of a solar thermal power plant with thermal energy storage. Chem. Eng. Sci. 2012, 71, 138–145. [Google Scholar] [CrossRef]

- Pintaldi, S.; Perfumo, C.; Sethuvenkatraman, S.; White, S.; Rosengarten, G. A review of thermal energy storage technologies and control approaches for solar cooling. Renew. Sustain. Energy Rev. 2015, 41, 975–995. [Google Scholar] [CrossRef]

- Fath, H.E.S. Technical Assessment of Solar Thermal Energy Storage Technologies. Renew. Energy 1998, 14, 35–40. [Google Scholar] [CrossRef]

- Federeci, C.; Giannota, G. Polimeri Clorurati. In Polimeri termoplastici. Guida plastica; Tecniche Nuove: Milano, Italy, 1991; pp. 63–80. [Google Scholar]

- MISTURADOR PARA CHUVEIRO TERMOSTATO 2430.C.034—DECA. Available online: https://www.padovani.com.br/misturador-para-chuveiro-termostato-2430-c---deca/p?idsku=5499&gclid=Cj0KCQjw3qzzBRDnARIsAECmryreoEE0266diT1nsVUAmko9_JKSSVPtTiGzg9MM-gqMYyWZkGPlxy8aAjp4EALw_wcB (accessed on 13 March 2020).

| Component | Cost (BRL) | Cost (USD) | Total Required | Total (USD) | Source |

|---|---|---|---|---|---|

| Water tank (100 L) | 133.90 | 27.95 | 1 | 27.95 | [9] |

| PVC panel (solar collector) of 0.78 m2 | 28.90 | 6.03 | 0.78 m2 | 6.03 | [10] |

| Black paint (225 mL and yield of 5 m2) | 11.90 | 2.48 | 0.78 m2 | 2.48 | [11] |

| Coating of NBR and metalized polyester (1 m2, thickness: 10 mm), plus adhesive | 156.75 | 32.72 | 1 m2 | 32.72 | [12] |

| PVC tubes (3 m, diameter: 32 mm) | 24.90 | 5.20 | 6 m | 10.40 | [13] |

| Weldable sleeve (diameter: 32 mm) | 2.79 | 0.58 | 2 units | 1.16 | [14] |

| Sliding sleeve for weldable pipe (diameter: 32 mm) | 28.99 | 6.05 | 2 units | 12.10 | [15] |

| Weldable union (diameter: 32 mm) | 18.99 | 3.96 | 2 units | 7.93 | [16] |

| Total low-cost system (100 L) | 493.77 | 100.77 | - | - | - |

| Commercial solar heat system (100 L, reservoir in stainless steel AISI 304 and copper collector) | 1598.00 | 333.61 | - | - | [17] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Negri, B.R.; Soares, M.C.P.; Lisboa, A.C.L.; Bartoli, J.R. Low-Cost Solar Heating Reservoir Manufactured by Double-Coating a Water Tank with Polymeric Materials. Mater. Proc. 2020, 2, 14. https://doi.org/10.3390/CIWC2020-06784

Negri BR, Soares MCP, Lisboa ACL, Bartoli JR. Low-Cost Solar Heating Reservoir Manufactured by Double-Coating a Water Tank with Polymeric Materials. Materials Proceedings. 2020; 2(1):14. https://doi.org/10.3390/CIWC2020-06784

Chicago/Turabian StyleNegri, Brino Ruy, Marco César Prado Soares, Antonio Carlos Luz Lisboa, and Julio Roberto Bartoli. 2020. "Low-Cost Solar Heating Reservoir Manufactured by Double-Coating a Water Tank with Polymeric Materials" Materials Proceedings 2, no. 1: 14. https://doi.org/10.3390/CIWC2020-06784

APA StyleNegri, B. R., Soares, M. C. P., Lisboa, A. C. L., & Bartoli, J. R. (2020). Low-Cost Solar Heating Reservoir Manufactured by Double-Coating a Water Tank with Polymeric Materials. Materials Proceedings, 2(1), 14. https://doi.org/10.3390/CIWC2020-06784