Impact Test Applications Supported by FEA Models in Surface Engineering for Coating Characterization †

Abstract

:1. Introduction

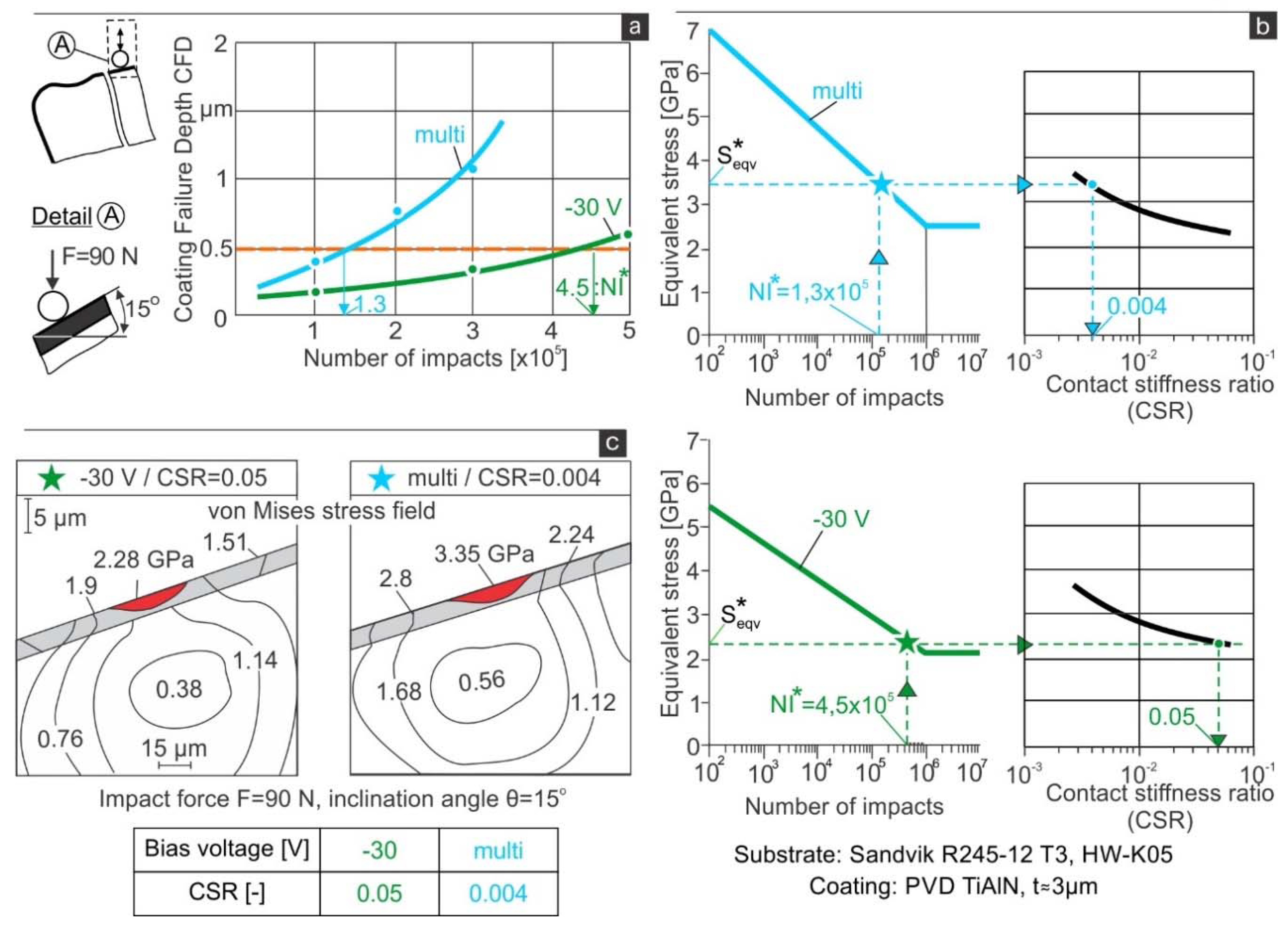

2. PVD Coating’s Fatigue Strength and Adhesion

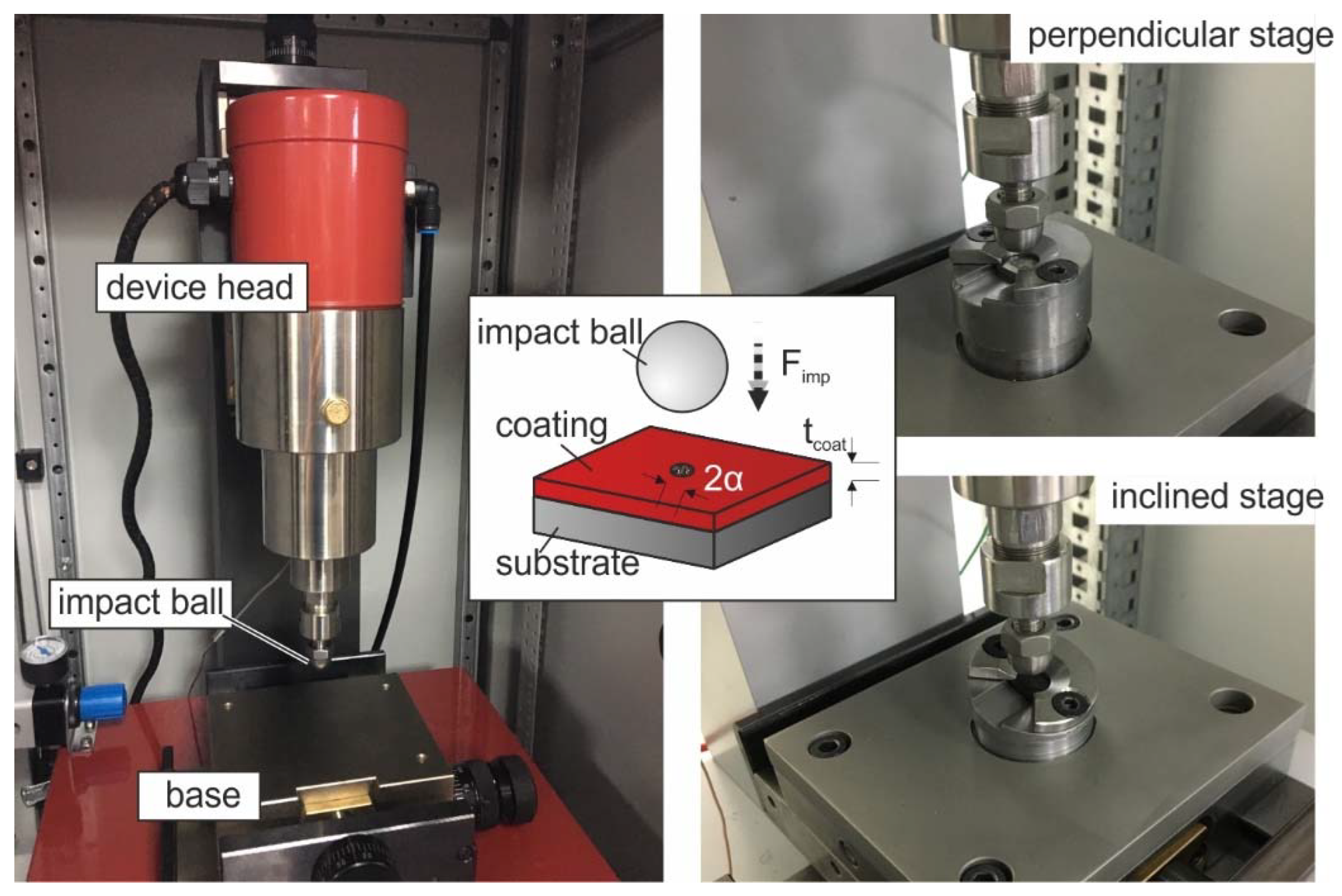

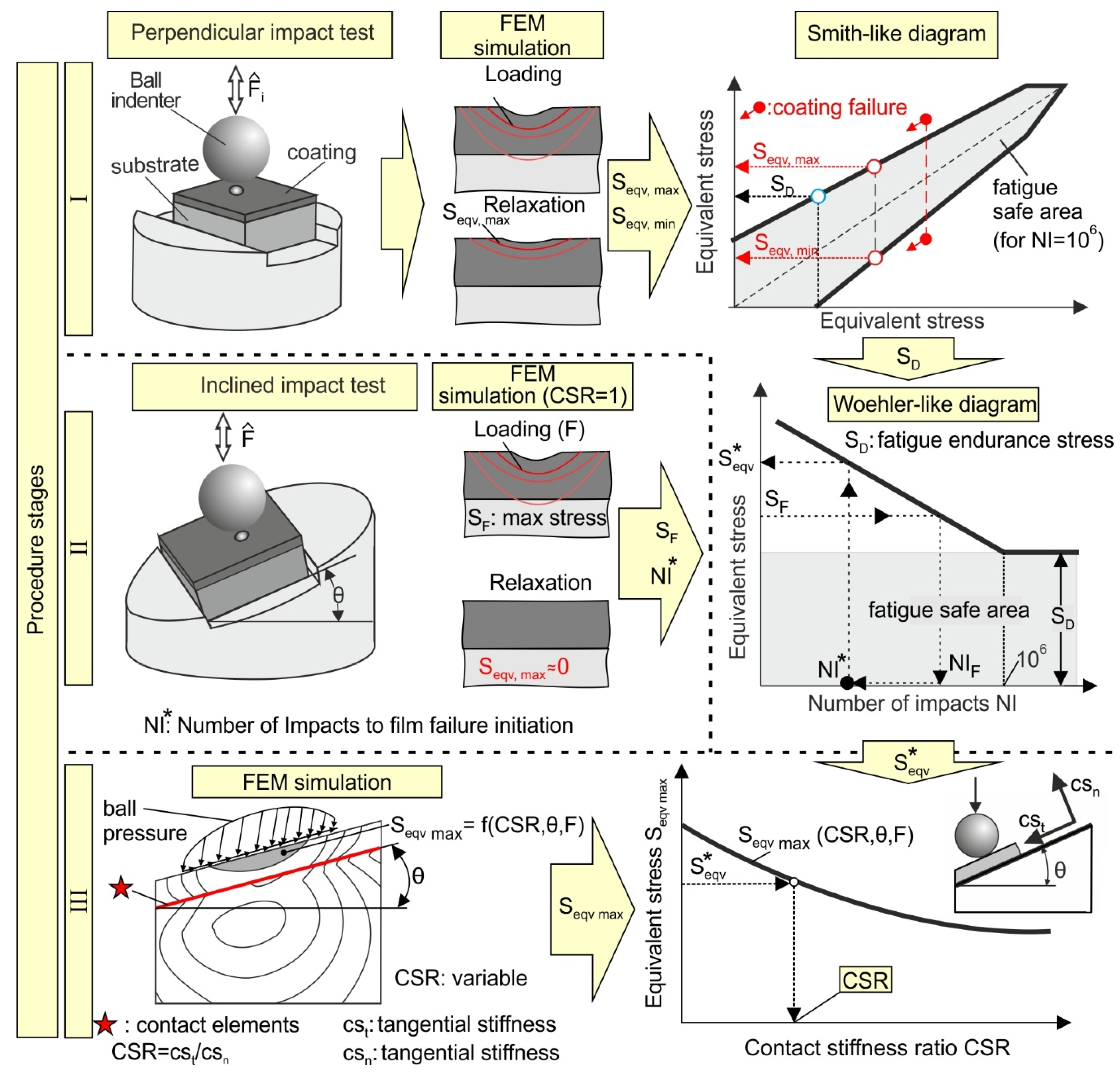

2.1. Methodology

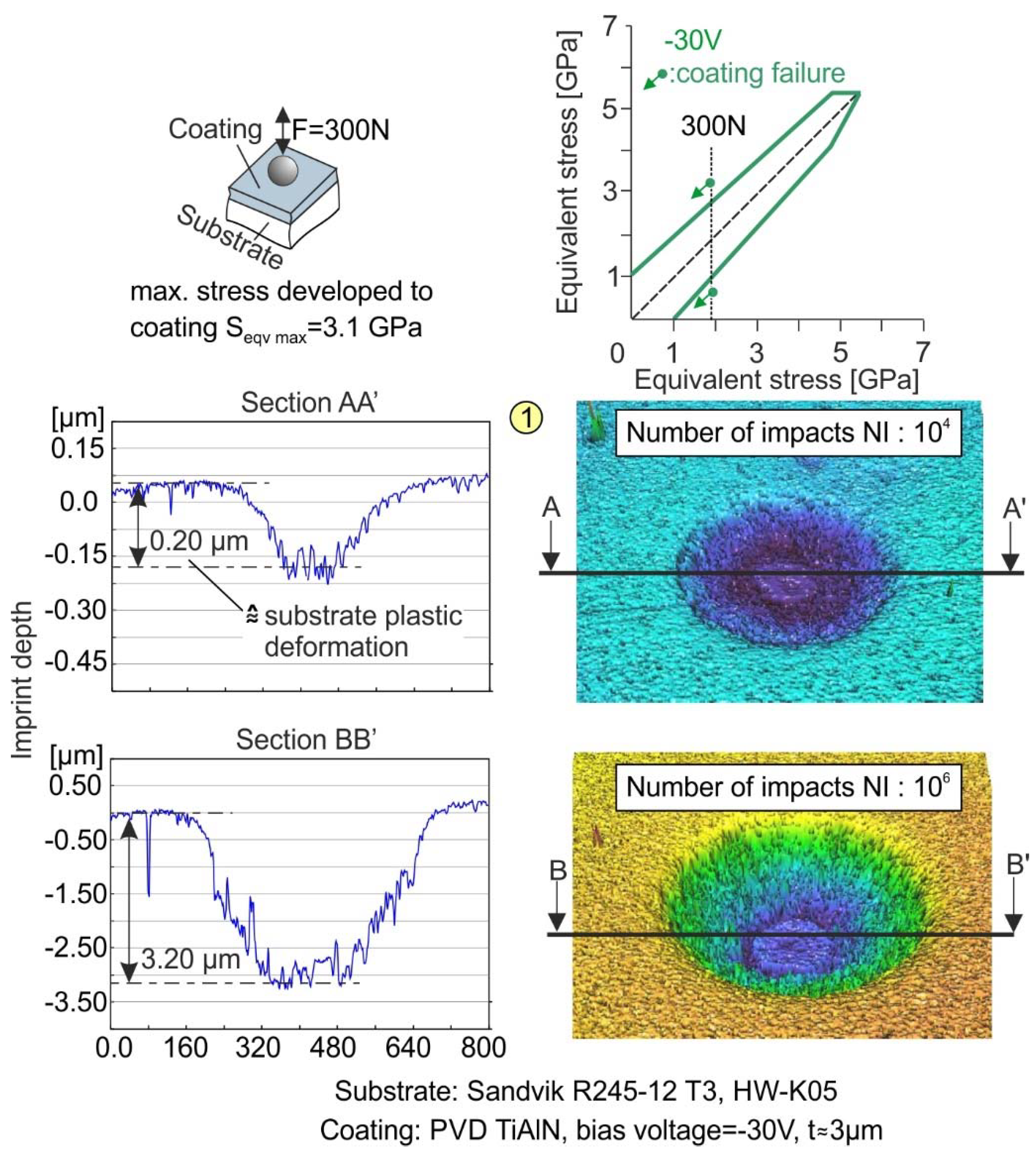

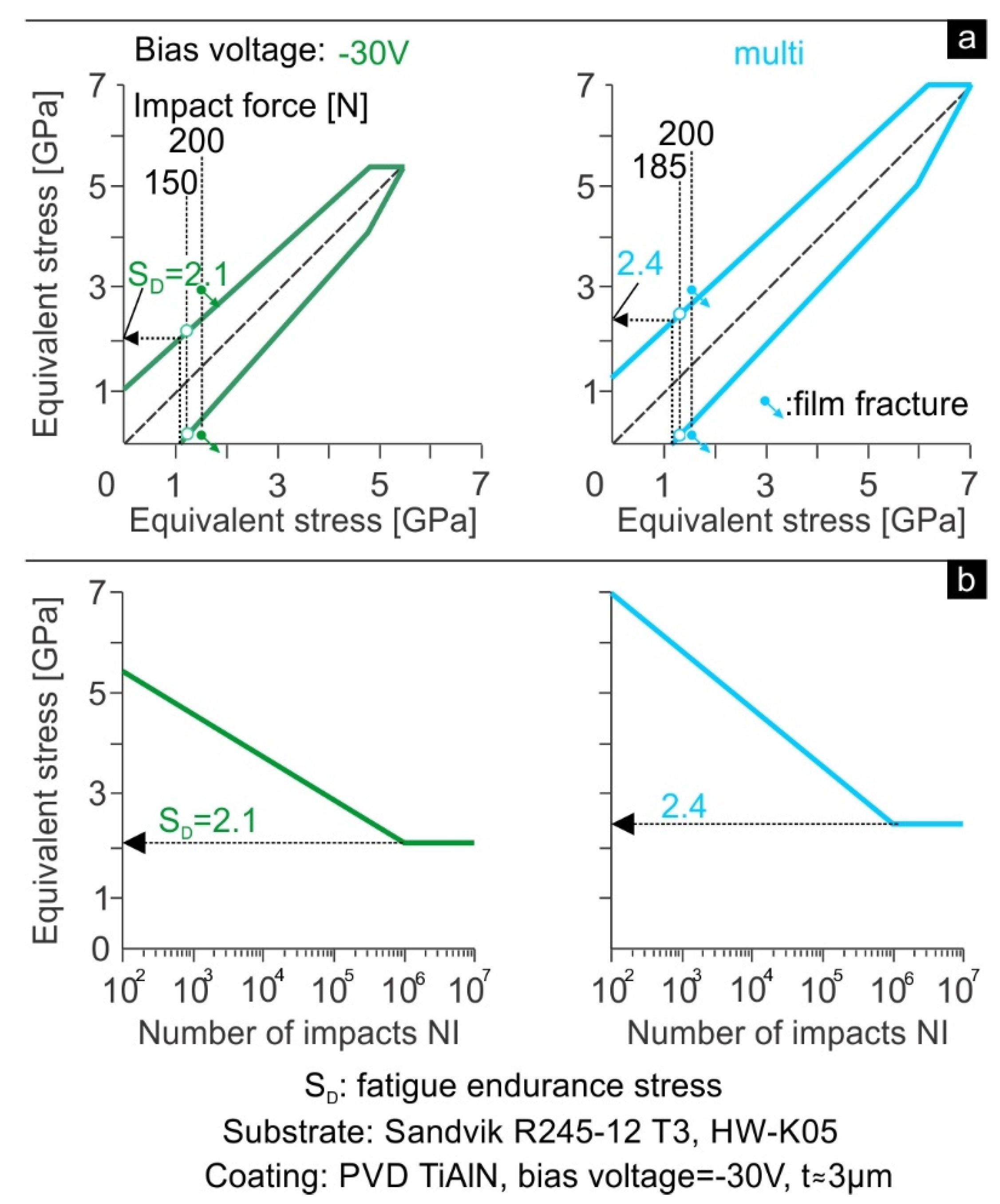

2.2. Characteristic Examples

2.3. Association of the CSR with Critical Shear Failure Stress (SFLS)

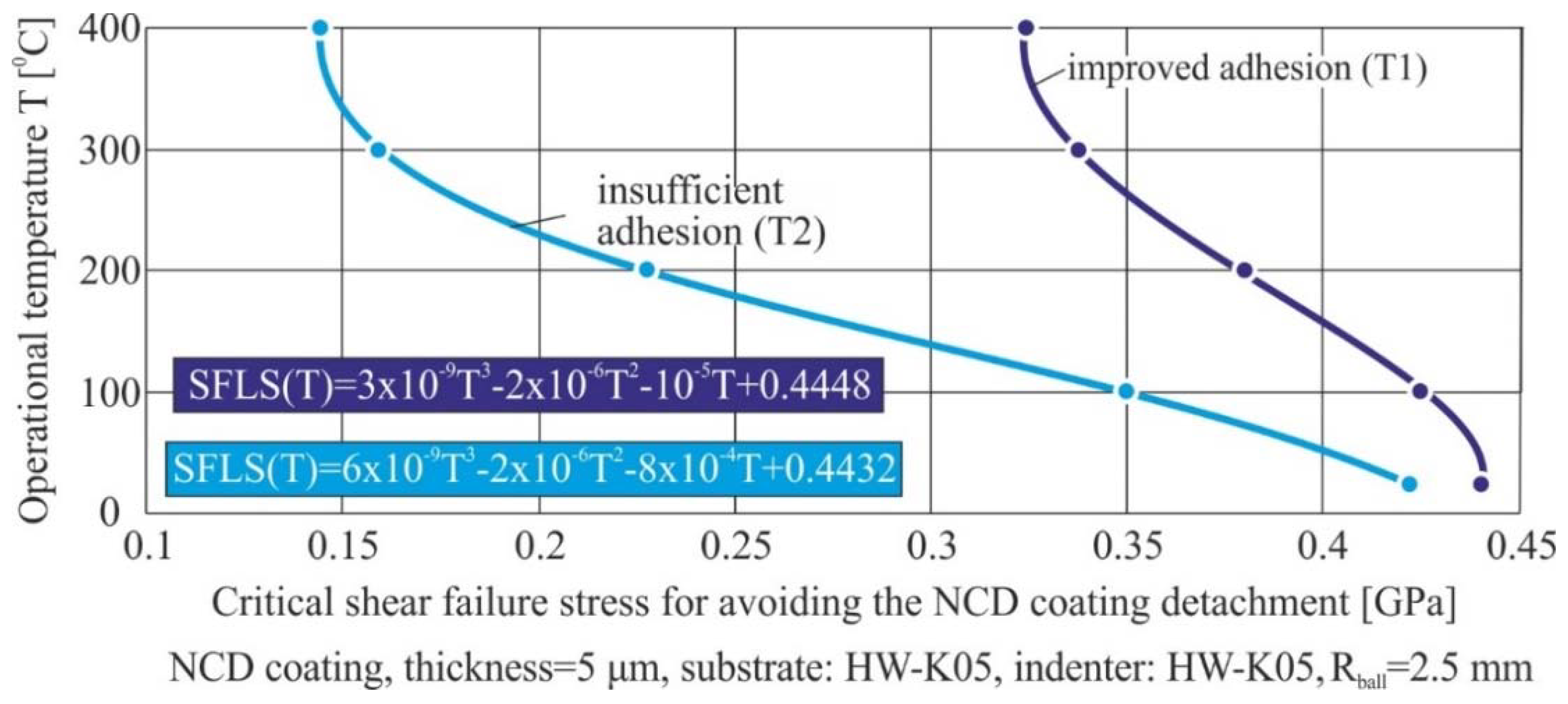

3. Diamond Coating Interfacial Fatigue Strength

4. Conclusions

Funding

Conflicts of Interest

References

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Tönshoff, H.; Blawit, C.; Rie, K.; Gebauer, A. Effects of surface properties on coating adhesion and wear behaviour of PACVD-coated cermets in interrupted cutting. Surf. Coat. Technol. 1997, 97, 224–231. [Google Scholar] [CrossRef]

- Yamamoto, K.; Abdoos, M.; Ahmed, Y.S.; Stolf, P.; Beake, B.D.; Rawal, S.; Fox-Rabinovich, G.; Veldhuis, S.C. Cutting Performance of Low Stress Thick TiAlN PVD Coatings during Machining of Compacted Graphite Cast Iron (CGI). Coatings 2018, 8, 38. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. CIRP Ann. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Beake, B.D.; Fox-Rabinovich, G.S.; Veldhuis, S.C.; Goodes, S.R. Coating Optimization for High Speed Machining with Advanced Nanomechanical Test Methods. Surf. Coat. Technol. 2009, 203, 1919–1925. [Google Scholar] [CrossRef]

- Constantinides, G.; Tweedie, C.A.; Holbrook, D.M.; Barragan, P.; Smith, J.F.; Van Vliet, K.J. Quantifying deformation and energy dissipation of polymeric surfaces under localized impact. Mater. Sci. Eng. A 2008, 489. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Vidakis, N.; David, K. The concept of an advanced impact tester supported by evaluation software for the fatigue strength characterization of hard layered media. Thin Solid Film. 1999, 355, 322–329. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Maliaris, G.; Makrimallakis, S. Strain rate effect on the fatigue failure of thin PVD coatings: An investigation by a novel impact tester with adjustable repetitive force. Int. J. Fatigue 2012, 44, 89–97. [Google Scholar] [CrossRef]

- Coatings Testing Experts. Available online: http://www.impact-bz.com (accessed on 30 April 2020).

- Bouzakis, K.-D.; Asimakopoulos, A.; Skordaris, G.; Pavlidou, E.; Erkens, G. The inclined impact test: A novel method for the quantification of the adhesion properties of PVD films. Wear 2007, 262, 1471–1478. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Charalampous, P.; Skordaris, G.; Dimofte, F.; Ene, N.; Ehinger, R.; Gardner, S.; Modrzejewski, B.; Fetty, J. Fatigue and adhesion characterization of DLC coatings on steel substrates by perpendicular and inclined impact tests. Surf. Coat. Technol. 2015, 275, 207–213. [Google Scholar] [CrossRef]

- Skordaris, G.; Bouzakis, K.-D.; Charalampous, P.; Kotsanis, T.; Bouzakis, E.; Bejjani, R. Bias voltage effect on the mechanical properties, adhesion and milling performance of PVD films on cemented carbide inserts. Wear 2018, 50–61. [Google Scholar] [CrossRef]

- Skordaris, G. Fatigue Strength of Diamond Coating-Substrate Interface Quantified by a Dynamic Simulation of the Inclined Impact Test. J. Mater. Eng. Perform. 2014, 23, 3497–3504. [Google Scholar] [CrossRef]

- Skordaris, G. Temperature-Dependent Fatigue Strength of Diamond Coating-Substrate Interface Quantified via the Shear Failure Stress. J. Mater. Eng. Perform. 2015, 24, 3335–3342. [Google Scholar] [CrossRef]

- Skordaris, G. Effect of the temperature dependent residual stresses of diamond coated tools with different adhesion qualities on their interfacial fatigue strength. J. Balk. Tribol. Assoc. 2016, 22, 1776–1786. [Google Scholar]

- Woehrl, N.; Hirte, T.; Posth, O.; Buck, V. Investigation of the coefficient of thermal expansion in nanocrystalline diamond films. Diam. Relat. Mater. 2009, 18, 224–228. [Google Scholar] [CrossRef]

- Lee, D.-G.; Fitz-Gerald, J.M.; Singh, R.K. Novel method for adherent diamond coatings on cemented carbide substrates. Surf. Coat. Technol. 1998, 100, 187–191. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skordaris, G.; Bouzakis, A.; Bouzakis, K.-D. Impact Test Applications Supported by FEA Models in Surface Engineering for Coating Characterization. Mater. Proc. 2020, 2, 13. https://doi.org/10.3390/CIWC2020-06809

Skordaris G, Bouzakis A, Bouzakis K-D. Impact Test Applications Supported by FEA Models in Surface Engineering for Coating Characterization. Materials Proceedings. 2020; 2(1):13. https://doi.org/10.3390/CIWC2020-06809

Chicago/Turabian StyleSkordaris, Georgios, Antonios Bouzakis, and Konstantinos-Dionysios Bouzakis. 2020. "Impact Test Applications Supported by FEA Models in Surface Engineering for Coating Characterization" Materials Proceedings 2, no. 1: 13. https://doi.org/10.3390/CIWC2020-06809

APA StyleSkordaris, G., Bouzakis, A., & Bouzakis, K.-D. (2020). Impact Test Applications Supported by FEA Models in Surface Engineering for Coating Characterization. Materials Proceedings, 2(1), 13. https://doi.org/10.3390/CIWC2020-06809