Abstract

Perovskite solar cells (PSCs) have rapidly become a hot area of research in the photovoltaic field due to their (e.g., 26.2%), ease of fabrication, and low cost. Over the last decade the electron transport layer (ETL) has been one of the most critical elements in achieving high-performing solar cells, necessitating a higher electron mobility and superior charge extraction ability. Consequently, there is a significant demand for an improved ETL that is not only cost-effective but also exhibits high charge extraction and mobility, particularly in the context of planar solar cell architecture. Tin Oxide (SnO2) has emerged as one of the most promising high-performance inorganic ETLs suitable for PSCs. In this work, we synthesize solution-processed SnO2. The spin-coated SnO2 thin films undergo annealing at relatively low temperatures ranging from 130 °C to 180 °C and various characterization tools are employed for the evaluation of thin films.

1. Introduction

PSCs are emerging third-generation photovoltaic (PV) devices, and serve as the frontiers of science in PV due to superior optoelectronic properties and high charge diffusion length (e.g., 175 μm) [1]. Although PSCs have shown a significant increase in PV efficiency in the last decade, they are still fairly behind the theoretical limit (31%) of single-junction solar cells due to possible structural and architectural defects and shortcomings. One of the best-practiced architectures of PSCs is planer structure, which mainly consists of an electron transport layer (ETL), perovskite absorber and hole transport layers (HTL). There is a need to optimize the whole structural elements of PSCs [1,2].

ETLs should possess some characteristic properties, e.g., transparency within the visible region, high conductivity, continuity in the film, low resistivity, and low temperature processibility [1]. There is numerous metal oxide-based ETL materials that are under the limelight in the PSC research domain, e.g., TiO2, ZnO2, and SnO2, etc. Among these SnO2 thin films is an attractive material to enhance the efficiency of planner PSCs. Tin oxide films are emerging as one of the most successful ETLs due to favorable electrical, optical, and electrochemical characteristics in addition to chemical inertness against acids and bases [2,3].

Typically, SnO2 thin film deposition is performed by physical vapor deposition (PVD), as well as solution-processable techniques such as spray pyrolysis, spin coating dip coating, and so on. Besides the PVD method, solution-processable techniques are cost-effective and easy to perform, but this is a challenge to get pin-hole-free, highly adhered, and defect-free film formation via solution-processable fabrication under ambient conditions. High-temperature post-annealing is mostly needed after fabricating thin films [2].

The literature indicates that SnO2 ETL films exhibit low resistivity (higher than 10−3), as well as high optical transparency (more than 80%) within the visible region. It is also evident that the optical transparency rises with an increasing annealing temperature. The XRD crystallinity peaks become more intense and sharper as we increase the annealing temperature [4,5].

This study is motivated by the prevalent use of elevated temperatures (e.g., 500 °C and higher) for applying SnO2 as an electron transport layer (ETL) in perovskite solar cells (PSCs) [6,7]. However, the obstacle to utilizing this effective ETL material in commercial PSCs lies in costly deposition techniques like physical vapor deposition (PVD) and molecular beam epitaxy (MBE) [2].

The objective of this study is to make SnO2 thin films using a cost-effective method and decrease the post-annealing temperature considerably below 200 °C to achieve comparable properties of high-temperature-annealed SnO2 thin films [2,6]. In our research, we used the spin coating technique for film deposition because it is inexpensive and simple, and the film thickness is controllable. Additionally, the effect of post-annealing at low temperatures (130–180 °C) was performed, and the effect of post-annealing on the optical, electrical, and structural properties of SnO2 thin films was studied to make it more suitable for application in PSCs as a low-temperature-processable ETL.

2. Materials and Methods

We synthesized the SnO2 nanoparticle (NP) dispersion as per the previously reported method via the sol-gel reflux method [8]. The synthesized NP dispersion was then spin-coated on a cleaned glass substrate of 10 by 10 mm at 3000 rpm and subject to post-annealing at different temperatures, e.g., 130 °C, 150 °C, and 180 °C. It then underwent glass cleaning, i.e., sequential bath sonication in soap water, DI water, acetone, and ethanol for 15 min each, followed by 30 min of UV ozone cleaning.

3. Results and Discussions

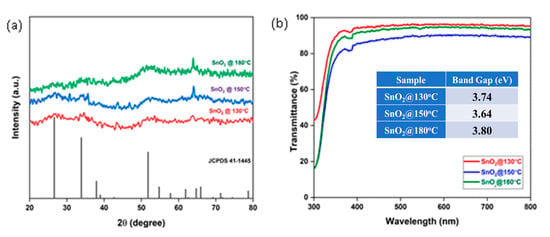

The XRD analysis (Figure 1a) of the SnO2 thin films was studied for all three samples. As per the XRD results, the crystallinity was altered from the amorphous phase because of the annealing treatment with the increasing peak intensity. The annealing temperature influences the properties of the thin film of SnO2. When the temperature increases, the XRD pattern becomes sharper and less noisy. Decreasing peak broadening shows crystallite size enhancement. Varying annealing temperature also affects other film characteristics such as absorbance in the visible region, as evident from the given data in Figure 2b. The minor change in UV transmittance spectra also indicates the alteration in the electronic structure of the material that possibly happened due to the improved crystallinity of the material.

Figure 1.

(a) XRD analysis of the SnO2 thin films post-treated at various temperatures. (b) UV-Vis absorbance spectra of the SnO2 annealed thin films.

Figure 2.

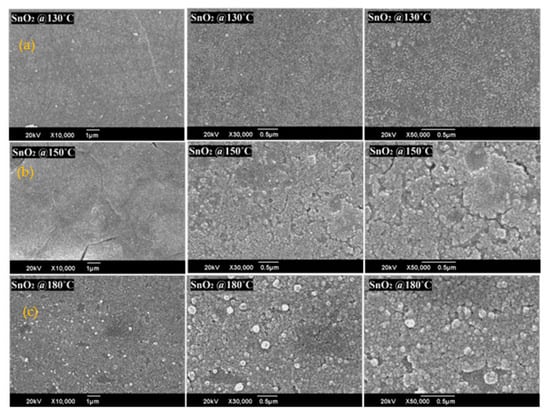

SEM images of the SnO2 thin film post-treated at (a) 130 °C; (b) 150 °C; and (c) 180 °C.

Scanning electron microscopy (SEM) (Figure 2) revealed the surface morphology of post-annealed films of the SnO2 thin films. SEM analysis is one of the most prominent tools for topographical analysis; hence, the surface morphology of all three different temperature-treated thin films was analyzed at various resolutions to reveal that varying annealing temperatures cause major effects on the grain size, surface roughness, and surface coverage.

The alteration in the surface morphology could be attributed to the heightened thermal enrgy, enabling the atoms to move more freely, consequently boosting electron mobility. These freely moving electrons fill the gaps/defects, promoting grain growth. Due to the reduction in the defects, the surface becomes smoother. But at higher temperatures (180 °C), the grain growth is non-uniform and additional phases are evident in the SEM graph (Figure 1c), possibly due to the phase transition of SnO2 from rutile to cassiterite. On the other hand, good surface coverage and highly crystalline film show improved charge transport and extraction capabilities, along with films treated at 150 °C (Figure 1b), which show a good surface area and grain size.

Additionally, good crystallinity will also improve conductivity, as evident from the hall effect measurements (Table 1). Hall effect data reveal that 150 °C-annealed film shows enhanced sheet resistivity and high charge carrier mobility, possibly due to an increase in grain size.

Table 1.

Hall effect measurements of the SnO2 thin films at varying temperatures.

4. Conclusions

SnO2 thin films exhibited enhanced charge carrier and optical properties when subjected to treatment at 150 °C. A low-temperature-processable electron transport layer (ETL) was fabricated, demonstrating a high surface area, high transmittance in the visible region, good film coverage, and high charge carrier mobility observed at 150 °C. Fabricated SnO2 thin films showcase promising potential for application as the ETL in PSCs. However, further performance evaluation is required specifically in a functioning solar cell to comprehensively assess their efficacy and suitability.

Author Contributions

S.H. wrote the paper with input from all the authors. Conceptualized by Sumbal Hakeem and S.A. Methodology and investigation carried out by S.H., S.A., A.J., M.B. and M.A.L. Supervision and resources provided by S.J. and M.T.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The study was conducted in accordance with the Declaration of Helsinki, and approved by the Institutional Ethics Committee of SCME, NUST, Islamabad, Pakistan.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request.

Conflicts of Interest

The authors have no conflicts of interest to declare.

References

- Stadler, A. Transparent conducting oxides—An up-to-date overview. Materials 2012, 5, 661–683. [Google Scholar] [CrossRef] [PubMed]

- Timofeev, V.A.; Mashanov, V.I.; Nikiforov, A.I.; Azarov, I.A.; Loshkarev, I.D.; Korolkov, I.V.; Gavrilova, T.A.; Yesin, M.Y.; Chetyrin, I.A. Effect of annealing temperature on the morphology, structure, and optical properties of nanostructured SnO(x) films. Mater. Res. Express 2020, 7, 015027. [Google Scholar] [CrossRef]

- Sun, J.; Lu, A.; Wang, L.; Hu, Y.; Wan, Q. High-mobility transparent thin-film transistors with an Sb-doped SnO2 nanocrystal channel fabricated at room temperature. Nanotechnology 2009, 20, 335204. [Google Scholar] [CrossRef] [PubMed]

- Gu, F.; Wang, S.F.; Lü, M.K.; Zhou, G.J.; Xu, D.; Yuan, D.R. Photoluminescence properties of SnO2 nanoparticles synthesized by sol− gel method. J. Phys. Chem. B 2004, 108, 8119–8123. [Google Scholar] [CrossRef]

- Habte, A.G.; Hone, F.G.; Dejene, F.B. Influence of annealing temperature on the structural, morphological and optical properties of SnO2 nanoparticles. Phys. B Condens. Matter 2020, 580, 411760. [Google Scholar] [CrossRef]

- Hoseinpour, V.; Shariatinia, Z.; Echegoyen, L. Thickness optimization of SnO2 electron transporting layer in perovskite solar cells assembled under ambient atmosphere. Synth. Met. 2023, 297, 117965. [Google Scholar] [CrossRef]

- Maharnavar, B.; Pardeshi, A.; Patil, M.; Pingale, P.; Padvi, M.; Bagal, M. Effect of thermal treatment of the SnO2 thin film prepared by spray pyrolysis method. AIP Conf. Proc. 2023, 2716, 117965. [Google Scholar]

- Chen, C.; Jiang, Y.; Guo, J.; Wu, X.; Zhang, W.; Wu, S.; Gao, X.; Hu, X.; Wang, Q.; Zhou, G.; et al. Solvent-Assisted Low-Temperature Crystallization of SnO2 Electron-Transfer Layer for High-Efficiency Planar Perovskite Solar Cells. Adv. Funct. Mater. 2019, 29, 1900557. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).