Performance Analysis of Advanced Nuclear Power Plant with Variation of Sea Water Temperature †

Abstract

1. Introduction

2. Methodology

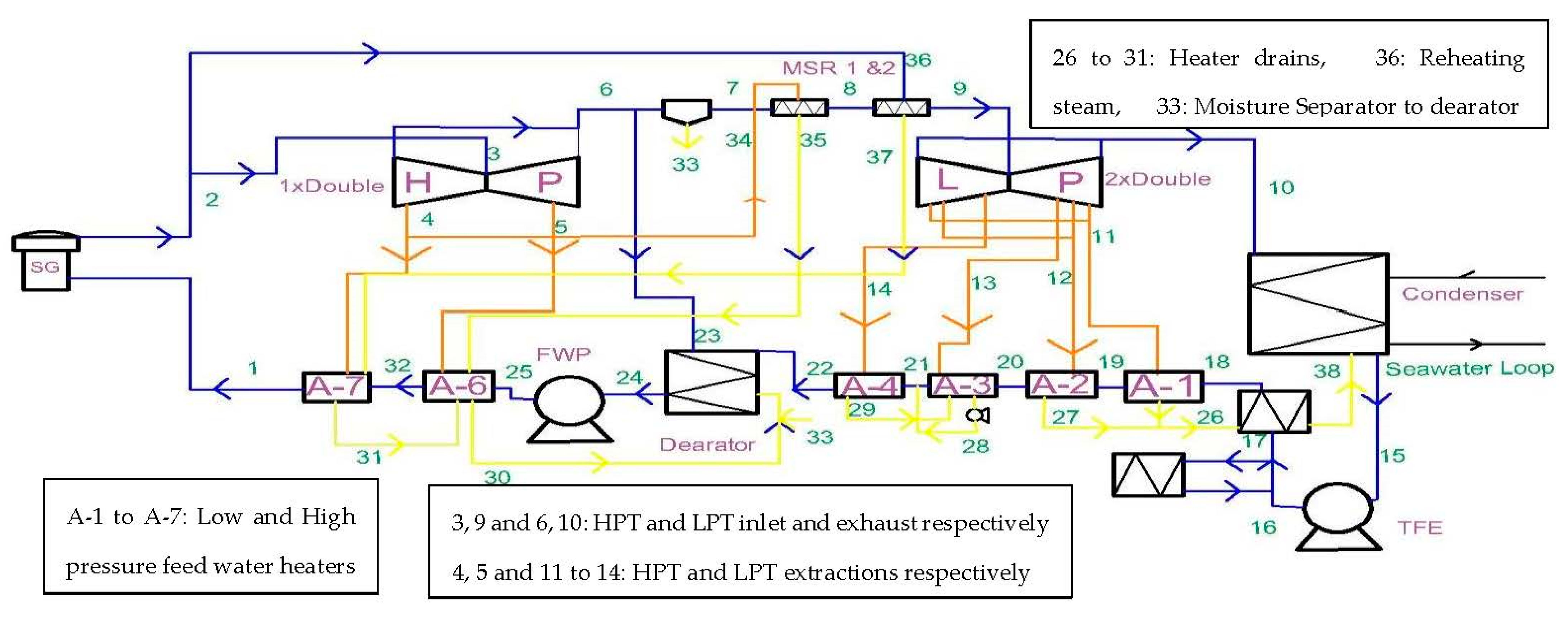

2.1. The Selected NPP Description

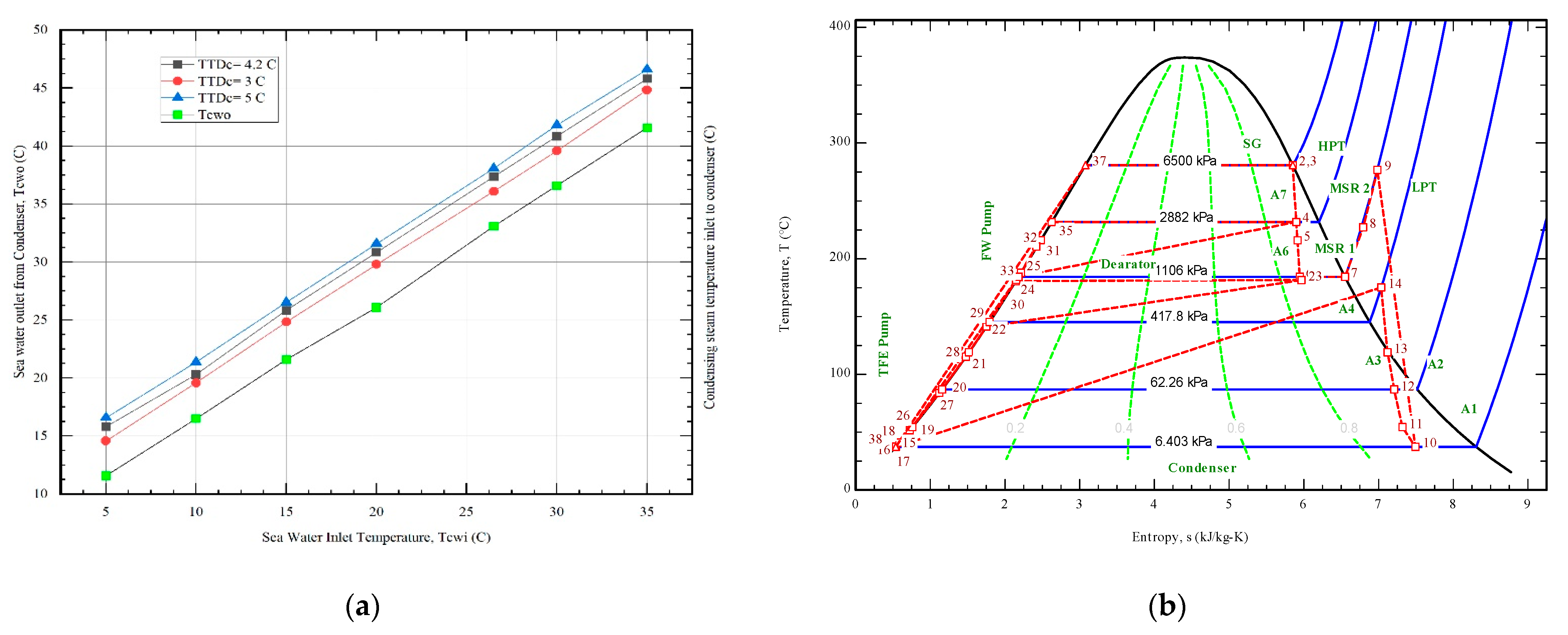

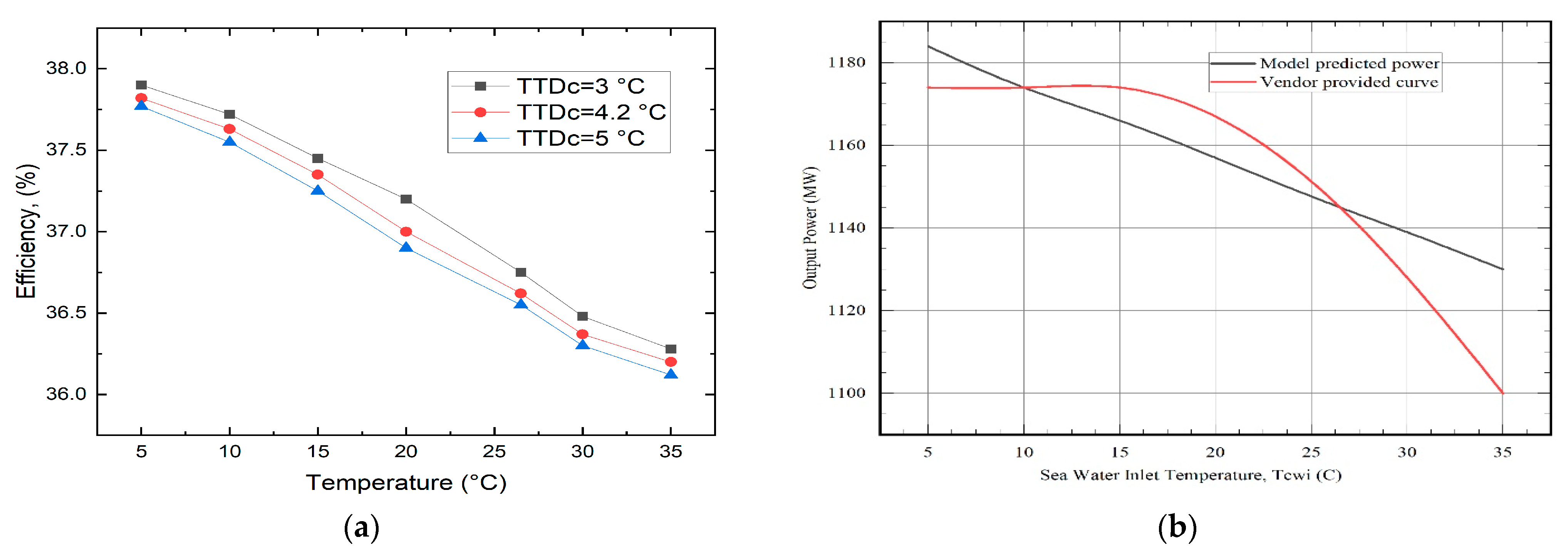

2.2. Cycle Efficiency

2.3. Condenser Heat Balance Equations

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pakistan, F.D.G.O. Pakistan Economic Survey 2021-22; Finance Department: Islamabad, Pakistan, 2022. [Google Scholar]

- Henry, C.L.; Pratson, L.F. Effects of Environmental Temperature Change on the Efficiency of Coal- and Natural Gas-Fired Power Plants. Environ. Sci. Technol. 2016, 50, 9764–9772. [Google Scholar] [CrossRef] [PubMed]

- Attia, S.I. The influence of condenser cooling water temperature on the thermal efficiency of a nuclear power plant. Ann. Nucl. Energy 2015, 80, 371–378. [Google Scholar] [CrossRef]

- Darmawan, N.; Yuwono, T. Effect of Increasing Sea Water Temperature on Performance of Steam Turbine of Muara Tawar Power Plant. IPTEK J. Technol. Sci. 2019, 30, 60. [Google Scholar] [CrossRef]

- Teguh, N.H.; Yuliati, L.; Darmadi, D.B. Effect of seawater temperature rising to the performance of Northern Gorontalo small scale power plant. Case Stud. Therm. Eng. 2022, 32, 101858. [Google Scholar] [CrossRef]

- Vodeniktov, A.; Minibaev, A.; Melnikova, V.; Egorochkin, K.; Samoilov, A.; Ovechkin, A. The problem of the surface condenser overall heat transfer coefficient determining at high temperatures of cooling water. Results Eng. 2023, 18, 101193. [Google Scholar] [CrossRef]

- Junior, N.P.; Gazoli, J.R.; Sete, A.; Velasquez, R.M.; Hunt, J.D.; Bindemann, F.T.; Wounnsoscky, W.; de Freitas, M.A.V.; Condessa, G.d.; Ismail, K.A.R. Climate impact on combined cycle thermoelectric power plant in hot and humid regions. Results Eng. 2023, 19, 101342. [Google Scholar] [CrossRef]

- Bojeldain, A.; Aldali, Y.; Alshaikh, M. Energy and exergy analysis of derna steam power plant and the impact of varying the different parameters 25 on exergy destruction. Al-Jabal Acad. J. Pure Appl. Sci. 2022, 1, 10–18. [Google Scholar]

- Huy, N.M.; Van Hai, D.; Phu, N.M. Energy, Exergy and Economic (3E) Analysis and Optimization of a Combined Heat and Power (CHP) Plant. In Proceedings of the 2021 24th International Conference on Mechatronics Technology (ICMT), Singapore, 18–22 December 2021; pp. 1–7. [Google Scholar]

- Kim, B.K.; Jeong, Y.H. High cooling water temperature effects on design and operational safety of npps in the gulf region. Nucl. Eng. Technol. 2013, 45, 961–968. [Google Scholar] [CrossRef]

- Laskowski, R.; Theibech, M.; Uzunow, N. The effect of cooling water temperature on the performance of a BWR nuclear power plant. Mod. Eng. 2021, 3, 5–13. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tariq, M.U.; Ali, R.; Haris, S.M.; Ali, S. Performance Analysis of Advanced Nuclear Power Plant with Variation of Sea Water Temperature. Mater. Proc. 2024, 17, 21. https://doi.org/10.3390/materproc2024017021

Tariq MU, Ali R, Haris SM, Ali S. Performance Analysis of Advanced Nuclear Power Plant with Variation of Sea Water Temperature. Materials Proceedings. 2024; 17(1):21. https://doi.org/10.3390/materproc2024017021

Chicago/Turabian StyleTariq, Muhammad Umair, Rashid Ali, Syed Muhammad Haris, and Sajjad Ali. 2024. "Performance Analysis of Advanced Nuclear Power Plant with Variation of Sea Water Temperature" Materials Proceedings 17, no. 1: 21. https://doi.org/10.3390/materproc2024017021

APA StyleTariq, M. U., Ali, R., Haris, S. M., & Ali, S. (2024). Performance Analysis of Advanced Nuclear Power Plant with Variation of Sea Water Temperature. Materials Proceedings, 17(1), 21. https://doi.org/10.3390/materproc2024017021