1. Introduction

Waste electrical and electronic equipment (WEEE) is generally classified under hazardous waste [

1]. The determination of process methods and the quantities of WEEE to be processed are of significant importance since this enables the efficient operation and management of recycling systems. Recycling is the process of retrieving the material content of used and nonfunctioning products through a series of operations, including sorting, disassembly and bulk recycling [

1].

The recycling of WEE is important not only to reduce the amount of waste requiring treatment, but also to promote the recovery of valuable materials as well as the elimination of its intrinsic hazardous and deleterious components and compounds [

2].

WEEE may consist of more than 1000 different substances of various shapes and sizes [

3]. Due to hazardous materials contained in WEEE, such as lead, mercury and cadmium, it is absolutely necessary to recover WEEE in order to avoid environmental contamination [

4]. Moreover, since WEEE contains considerable amounts of valuable materials, such as gold, palladium and copper, the recovery of WEEE offers a potential economic gain [

5]. Today, there are various recovery options for WEEE, including reuse, repair, recycling, remanufacturing and disposal.

WEEE contains recyclable materials with high added value [

6], such as ferrous and non-ferrous metals, plastics, electronic components and others (

Table 1). Efforts are made in order to increase the recovery rate and the purity of the recoverable stainless stream. Consequently, the recycling and reuse of stainless steel play an important role in primary raw materials saving, environmental protection and in decreasing the production cost.

This research project targets a specific WEEE product—the dishwasher—because, regardless of the brand, they have largely the same types and number of parts. The difference lies in how these parts are assembled. The main material fractions of dishwashers are stainless steel, steel, copper and other materials. It is really important to recover stainless steel concentrates of high purity, as copper contamination is accepted only at a low percentage (less than 0.25%) [

7].

2. Experimental Procedure

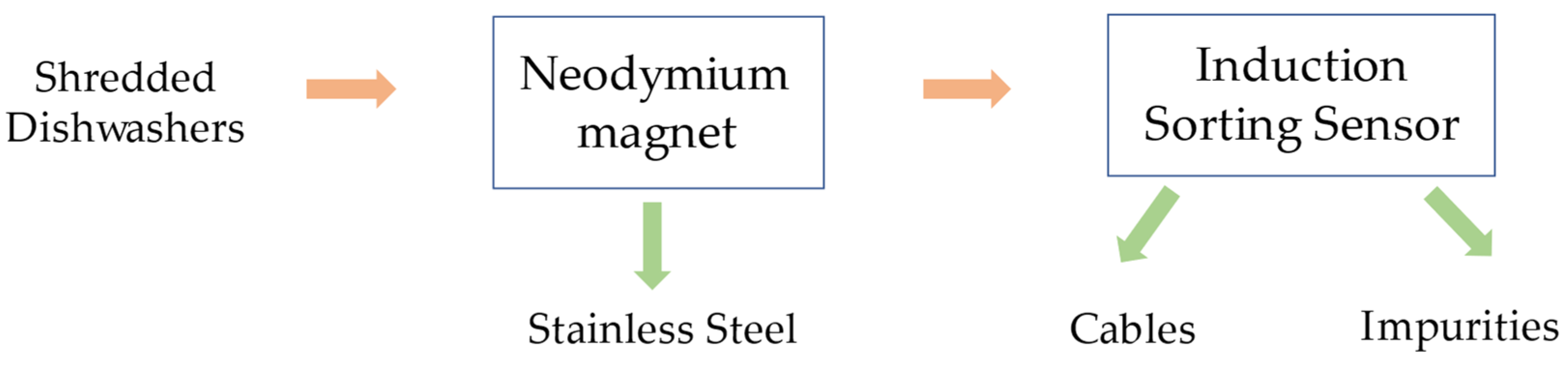

The separation of dishwasher components consists of definite steps [

8]. Size reduction, the manual removal of large components, such as external cables, magnetic separation, eddy current separation and induction-sensor sorting compose the flowsheet of the procedure. Two outcome streams are created: the stainless steel stream with some impurities and the impurity stream. Impurities that are present in the stainless steel stream contain plastics, copper cables, paper, printed circuit boards (PCBs) and other materials. Despite their low conductivity, all these materials are detected by the sensor and sorted along with stainless steel pieces (

Chart 1).

In a second stage, the modification of the parameters of the induction sorter result in the separation of copper cables, which exhibit lower conductivity due to their size and morphology, from the stainless steel pieces. This procedure takes place in Ecoreset S.A. plant, at Aspropyrgos, Greece.

When the previous procedure had been completed, the final step occurred at Mineral Processing Laboratory, NTUA. The stainless steel stream goes through a high-intensity magnetic separator (Photo 1), resulting in two products: the magnetic product, consisting of stainless steel pieces and any impurities, and the non-magnetic stream consisting of any other materials. It is pointed out that, as the tilt of the blade increases, the opening of the magnetic receptor decreases. As a result, the larger stainless steel pieces are concentrated in the non-magnetic receptor as the tilt of the blade increases.

Five different samples (models/producers) were used for this study. Details concerning the manufacturing company and the specific model of each dishwasher are provided in

Table 2. The efficient results obtained in all cases, and the variety of the models used in the experimental procedure, confirm the universality of the separation method, independent of the manufacturer and/or the dishwasher model.

The results concerning the percent weight of stainless steel in the magnetic stream and the recovery of stainless steel are presented in

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7. Moreover, the tables provide information concerning the characterization of the non-magnetic product of each sample.

The stainless steel recovery, depicted in

Table 7, is calculated as follows:

A: stainless steel in magnetic stream (%)

B: weight of magnetic stream (%)

C: stainless steel in non-magnetic stream (%)

D: weight of non-magnetic stream (%)

From

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7, it is obvious that, as the tilt of the blade increases, the percent weight of stainless steel stream decreases. Furthermore, the magnetic stream is of high purity, independent of the tilt of the blade.

Image 1,

Image 2 and

Image 3 depict the dishwasher materials after their treatment in the Minera Processing Laboratory, NTUA.

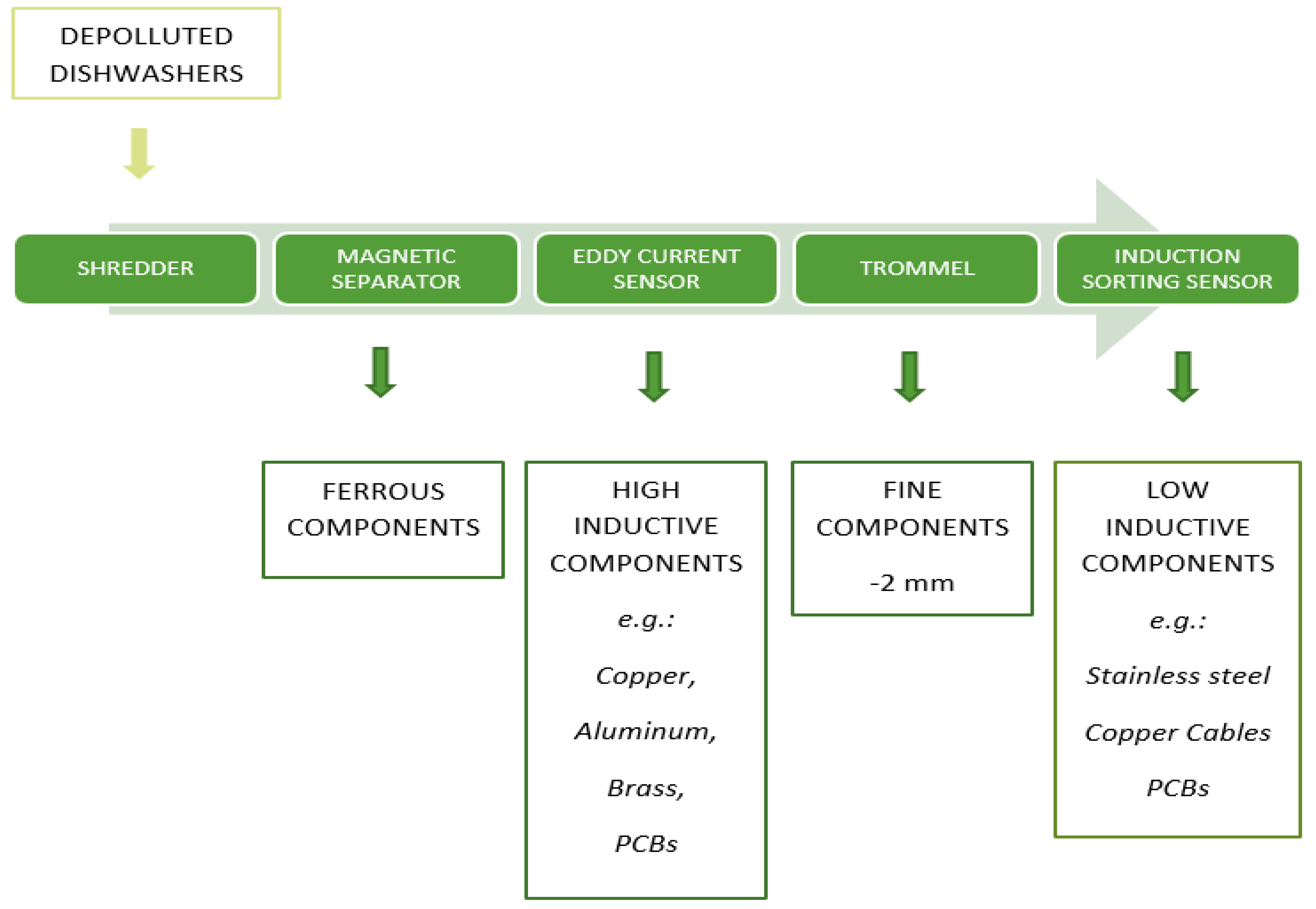

A similar procedure to that previously described takes place in the plant of Ecoreset S.A (

Chart 2). A pilot separation unit was established by Ecoreset S.A., including a neodymium magnet and an induction sorting sensor (

Image 4 and

Image 5). The high-intensity neodymium magnet holds the stainless steel pieces; subsequently, an induction sorting sensor is used to separate all cables from plastic, including copper cables. Materials such as plastics or paper are rejected and concentrated in a different stream. The results are described in

Table 8 and

Table 9. The recovery of stainless steel (

Table 9) is calculated according to the methodology previously described.

Chart 2.

Flowchart of the components’ separation line on an industrial scale.

Chart 2.

Flowchart of the components’ separation line on an industrial scale.

Image 3.

The non-magnetic product of Sample 3, with the blade tilt set at 50°—the left basket contains the stainless steel pieces that could not be held and were rejected as the non-magnetic product, while the right basket contains the non-magnetic product.

Image 3.

The non-magnetic product of Sample 3, with the blade tilt set at 50°—the left basket contains the stainless steel pieces that could not be held and were rejected as the non-magnetic product, while the right basket contains the non-magnetic product.

Image 4.

The back view of the neodymium magnet.

Image 4.

The back view of the neodymium magnet.

Image 5.

The right view of the neodymium magnet.

Image 5.

The right view of the neodymium magnet.

Table 8.

Weight of magnetic and non-magnetic products on industrial scale.

Table 8.

Weight of magnetic and non-magnetic products on industrial scale.

| Samples | % Weight of Magnetic Product | % Weight of Non-Magnetic Product |

|---|

| Sample 1 | 54.4 | 45.6 |

| Sample 2 | 76.6 | 23.4 |

| Sample 3 | 57.6 | 42.4 |

| Sample 4 | 64.2 | 35.8 |

| Sample 5 | 63.5 | 36.5 |

Table 9.

Grade and stainless steel recovery of magnetic separation products on industrial scale.

Table 9.

Grade and stainless steel recovery of magnetic separation products on industrial scale.

| Samples | Magnetic Stream | Non-Magnetic Stream | % Recovery of Stainless Steel |

|---|

| % Stainless Steel | % Others | % Stainless Steel | % Others |

|---|

| Sample 1 | 98.4 | 1.6 | 10.8 | 89.2 | 91.6 |

| Sample 2 | 100.0 | 0.0 | 12.6 | 87.4 | 96.3 |

| Sample 3 | 100.0 | 0.0 | 15.5 | 84.5 | 89.8 |

| Sample 4 | 99.1 | 0.9 | 20.2 | 79.8 | 89.8 |

| Sample 5 | 98.6 | 1.4 | 27.1 | 72.9 | 86.4 |

The results of

Table 9 clearly show that the magnetic product is pure or almost pure stainless steel as its grade ranges between 98.4 and 100% in all cases; correspondingly, the stainless steel recovery in the magnetic product is very high, exceeding 90% in all cases except that of Sample 5, which is slightly lower.

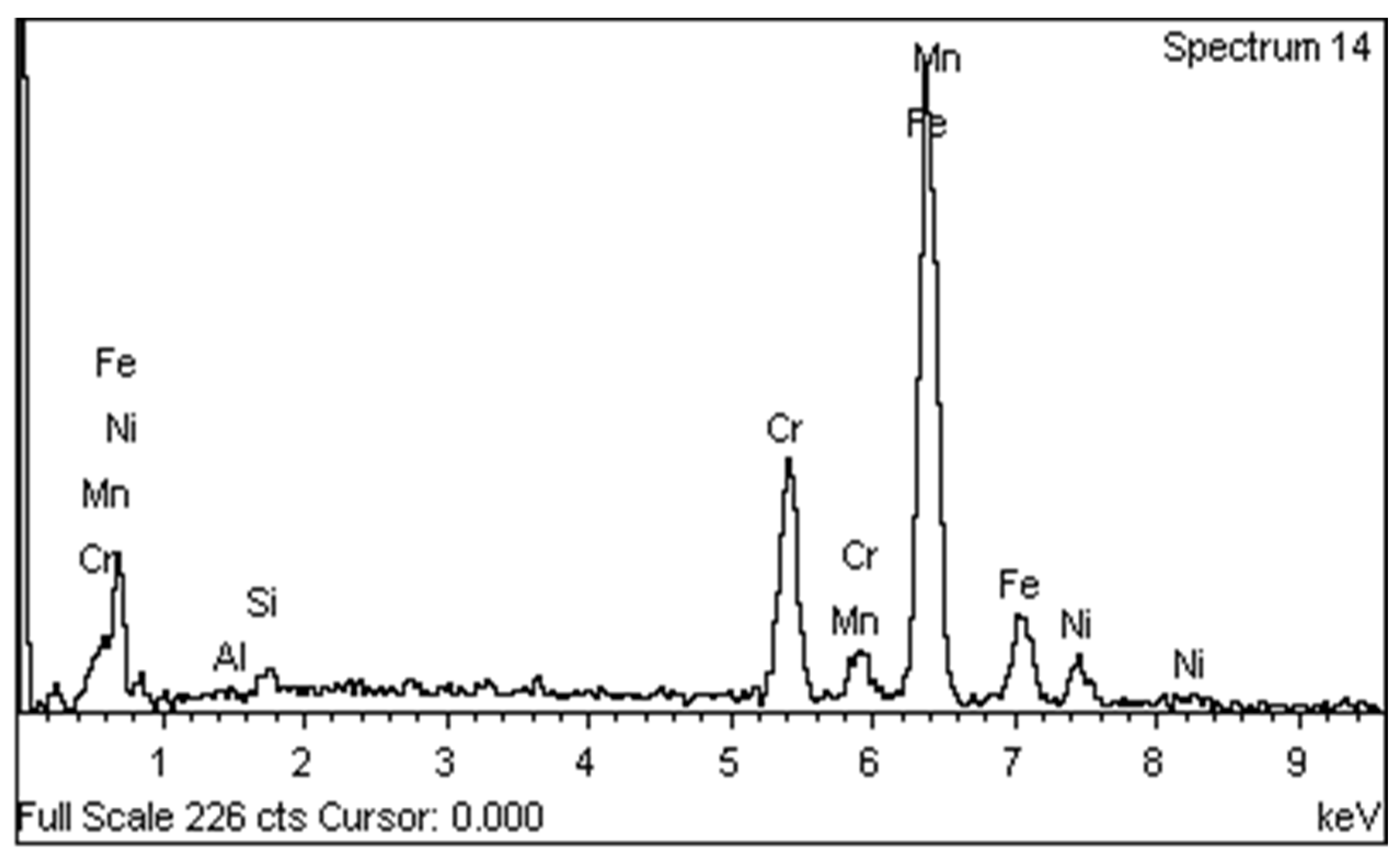

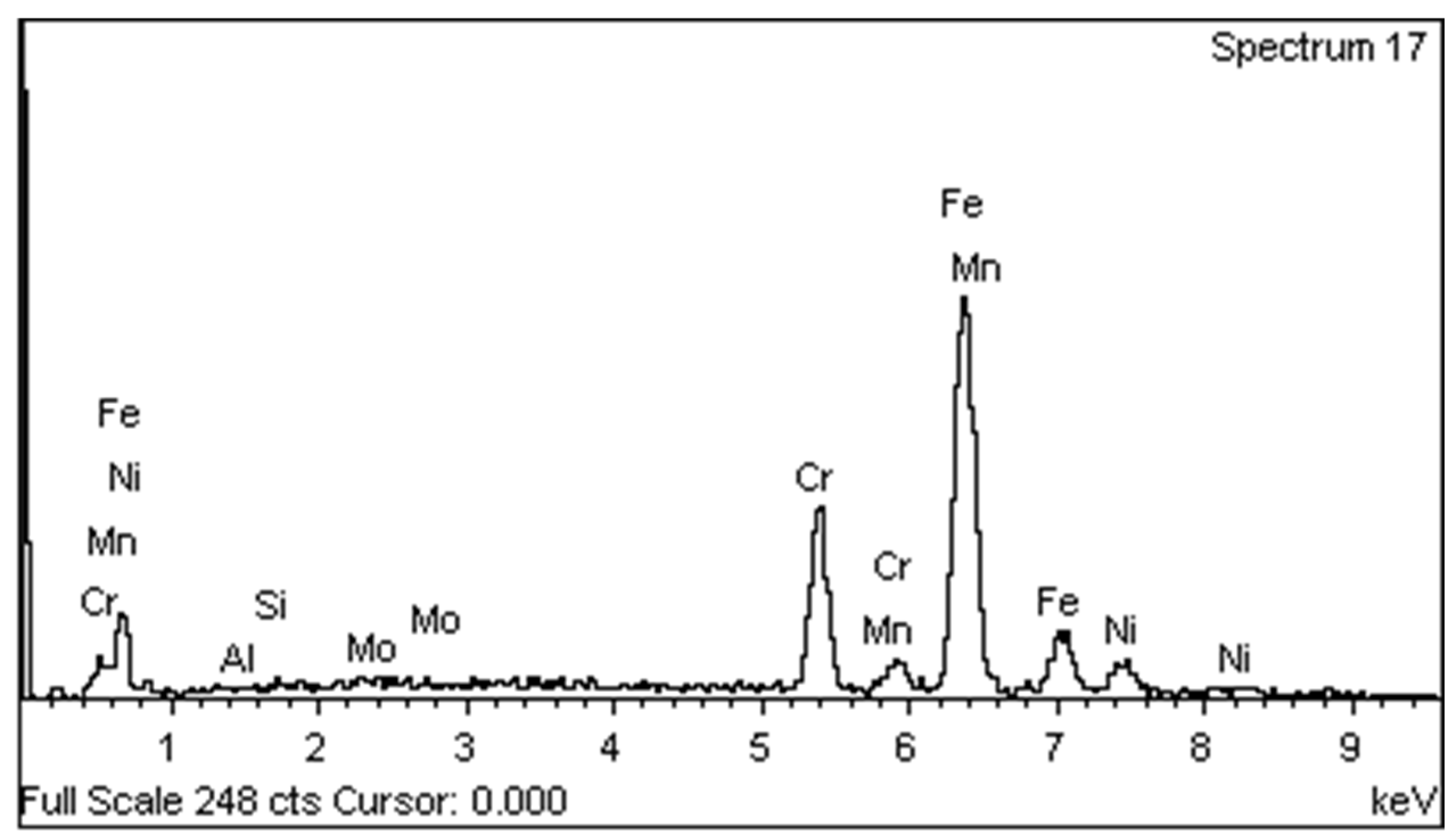

After the completion of the separation and the characterization of the dishwashers’ components, efforts were made to specify the composing elements of each sample (

Table 10). Scanning Electron Microscopy (SEM) was used for element identification.

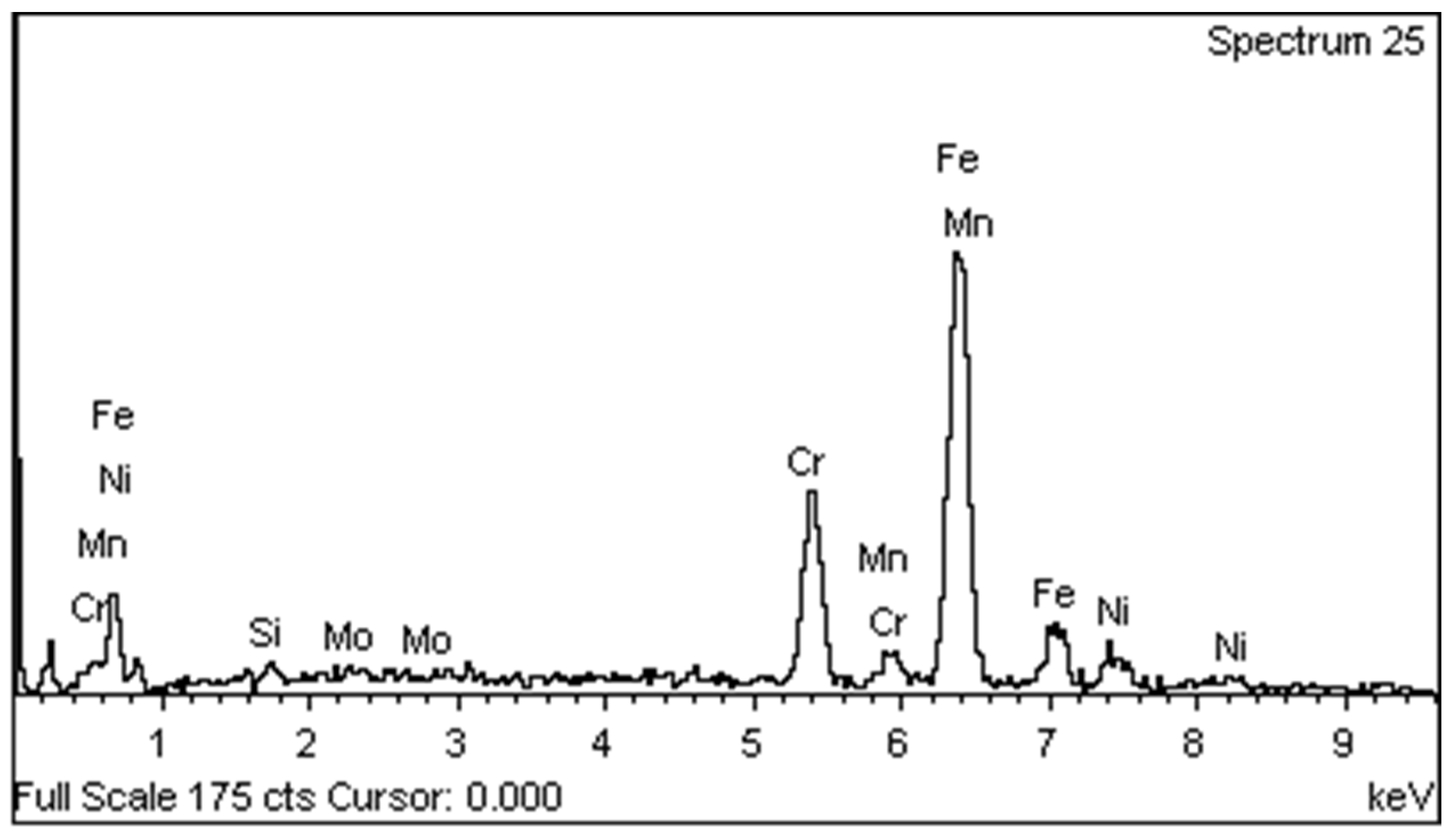

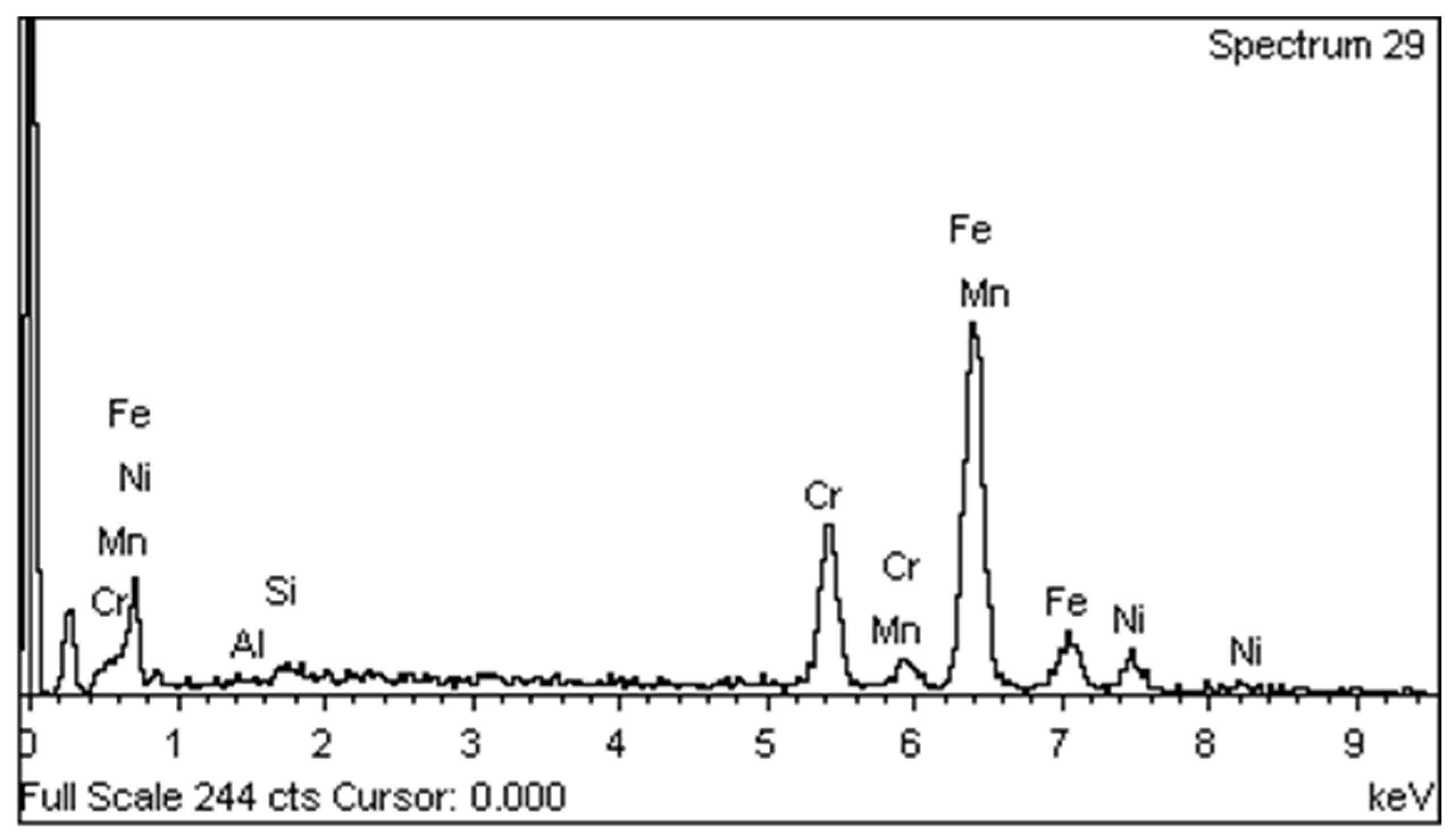

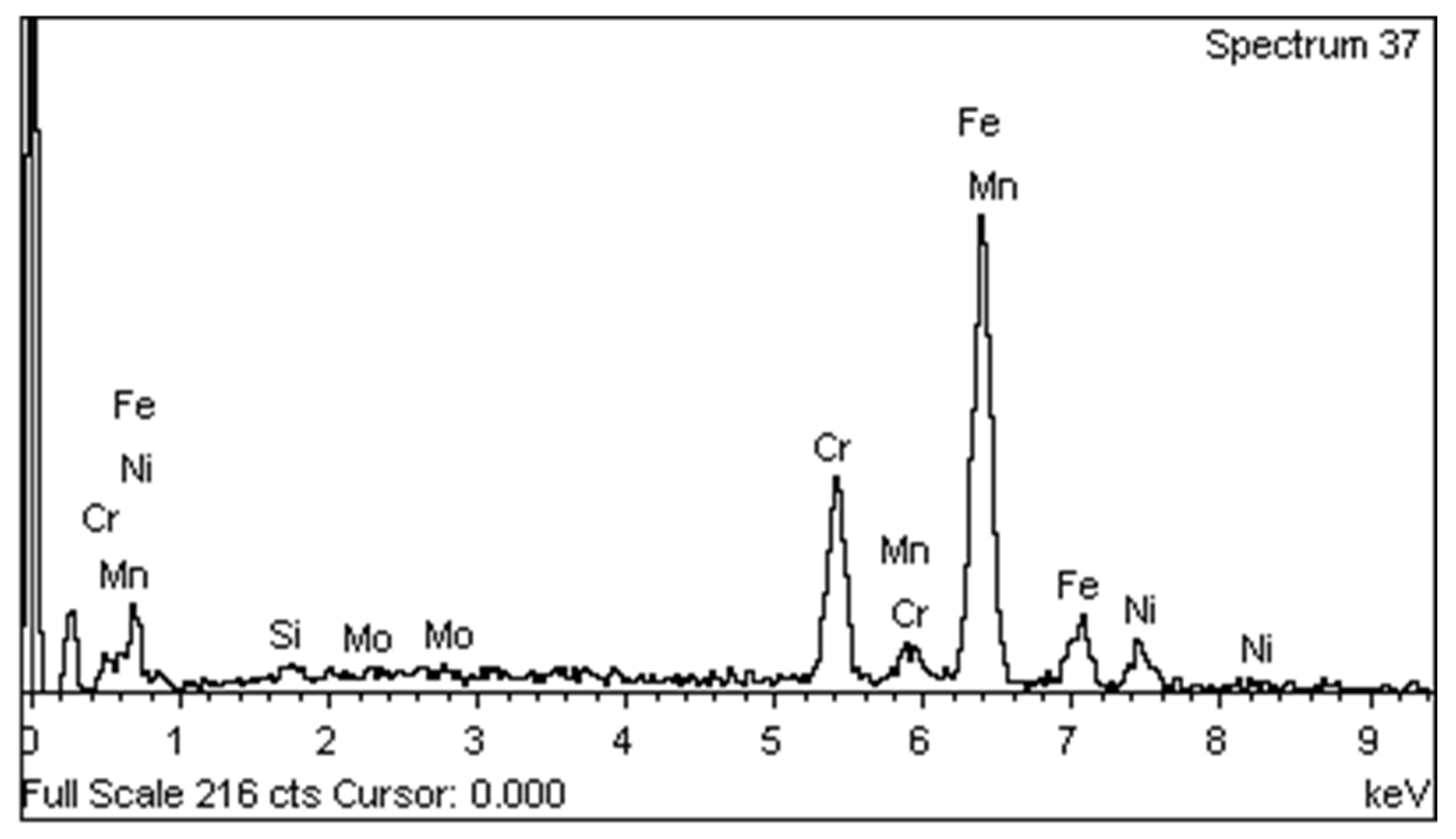

According to

Table 10, the main components of the stainless steel of the dishwashers examined are as follows. The major component is Fe (as γ-Fe),with a content between 70 and 72% in all cases; the second most abundant element is Chromium (Cr), with content ranging between 17.7 and 20%; third in abundance is nickel (Ni) whose content varies between approximately 7 and 8.5%, followed by Manganese (Mn) with a much lower content (0.3 to 2.1% approx.).

Figure 1,

Figure 2,

Figure 3,

Figure 4 and

Figure 5 provide more detailed information about the samples’ composition.

3. Results

Based on the results of lab-scale tests (

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7), the separation of stainless steel from dish washers is considered successful and very promising for application on an industrial scale. More specifically, the results of lab-scale tests (

Table 4,

Table 5 and

Table 6) indicate that stainless steel pieces can be efficiently separated from other components by magnetic separation, as the grade of the magnetic product in stainless steel ranges, in all cases, from 85.1% to 98.7%; although there is not a clear dependence of the stainless steel content on the tilt, it seems that the magnetic products are purer for blade-tilts up to 50°. Therefore, the tilt plays a critical role in stainless steel recovery (

Table 7), as it appears extremely low, while the tilt of the blade is increased. An increase in the tilt denotes that the opening of the magnetic products bin decreases, leading to a significantly lower recovery of stainless steel. On the other hand, the reduced bin-opening results in a higher purity product, as plastic pieces or any other contaminants cannot pass through it and, eventually, they are rejected. Concluding with lab-scale tests, optimum results seem to be obtained for a blade-tilt set at 30

ο, as, under this condition, a higher recovery is achieved, combined with minimum impurities in the magnetic product.

The results of the experiments conducted on an industrial scale (

Table 8 and

Table 9) confirmed those in the lab. From

Table 8, it can be derived that the percent weight of the magnetic products ranges between approximately 54% and 77% for the five samples. Comparing the corresponding weight of each sample for lab- and industrial-scale tests, we can derive that they are close for a lab-scale tilt of a 30° blade-tilt. Regarding the purity of the magnetic products in stainless steel and the recovery, they both appear to be better on an industrial scale than that in a lab (

Table 9).

The results arising from the SEM analysis of each sample demonstrate that all five samples are γ-Fe stainless steel, as Nickel (Ni) is detected in all samples (

Table 10) with its content ranging between approximately 7 and 8.5%.

4. Discussion

The constantly growing use of electrical and electronic equipment results in huge amounts of WEEE. To properly treat these amounts, it is absolutely necessary for the producers and designers to choose the proper components for their products, which are reusable and recyclable. The direction of “it has been produced, so it can be recycled” should dominate in every production sector, from smartphones to household appliances and heavy industrial machines.

Moreover, the environmental impact should not be ignored. The production of stainless steel from primary raw materials is a highly energy-consuming process and, consequently, of a high cost, as is true for all pyro-metallurgical processes. CO2 emissions and high energy consumption for raw material treatment impose major difficulties on the metallurgical industry, as environmental legislations become more and more strict.

Laboratory experiments proved the successful magnetic separation of stainless steel pieces from dishwasher components; the magnetic products were characterized as high-purity stainless steel, with corresponding minimum contamination from other components. The results were highly dependent on the blade-tilt, as an increase in the tilt (smaller cross-section of magnetic-product bin) leads to diminished separation and stainless steel recovery. The results can be further improved by reducing the size of stainless steel pieces for magnetic separation. Size reduction is crucial, as it provides the opportunity for the more efficient separation and characterization of dishwashers components. The promising lab-scale results were absolutely confirmed by industrial-scale magnetic separation tests.