Abstract

The rapid advancement of digital technologies, referred to as Industry 4.0, has profoundly transformed the manufacturing landscape, necessitating a reevaluation of engineering education. Future engineers must possess diverse skills and competencies to effectively navigate this new era of intelligent, interconnected, and data-driven production systems. In response to this challenge, this research paper introduces a framework for a virtual laboratory in mechanical and industrial engineering that creates a laboratory in virtual reality (VR) by integrating Lean Manufacturing principles to optimize flow shop processes, thereby preparing engineering students for the demands of Industry 4.0. This approach prepares students to navigate the challenges of modern manufacturing, bridging the gap between theoretical knowledge and its practical application. This paper will discuss the concept of the virtual laboratory for mechanical and industrial engineering education in the Moroccan context based on lean principles.

1. Introduction

The emergence of Industry 4.0, characterized by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and virtual reality, has notably reshaped the manufacturing landscape. This transformation has created a growing demand for engineers who are not only technically proficient but also capable of applying their knowledge in the real world [1].

However, traditional engineering education often falls short in providing students with the hands-on experience necessary to navigate these complex systems, particularly in countries like Morocco, where access to cutting-edge industrial infrastructure remains limited. In this context, virtual reality (VR) has emerged as a transformative tool, offering immersive and interactive learning environments that bridge the gap between theoretical knowledge and its practical application [2].

This research paper introduces a VR-based virtual laboratory designed for mechanical and industrial engineering education, incorporating Lean Manufacturing principles to optimize the flow shop processes in the designed virtual laboratory.

By simulating real-world manufacturing scenarios, the virtual laboratory allows students to experiment with lean techniques, such as waste reduction and process optimization, in a controlled, immersive setting. This innovative approach not only deepens students’ understanding of Industry 4.0 concepts but also equips them with the skills needed to excel in modern manufacturing environments [3,4].

Focusing on the Moroccan context, this study explores how VR can revolutionize engineering education by providing accessible, cost-effective, and scalable learning solutions. The proposed framework demonstrates the potential of VR to enhance traditional pedagogy, preparing students to meet the challenges of an increasingly digitalized industrial world [5].

By leveraging VR technology, this research aims to contribute to developing a more dynamic and practical engineering education system, aligned with the demands of Industry 4.0.

2. The Literature Review

2.1. Virtual Reality in Industry 4.0

Virtual reality (VR) has become a transformative tool in Industry 4.0. By creating an immersive experience, VR enables realistic simulations for workforce training, allowing operators to practice complex tasks in a safe and controlled setting [6,7].

In manufacturing, VR facilitates process optimization and product design by enabling virtual prototyping and real-time collaboration, reducing development times and material waste; for example, automotive companies like Ford, BMW, and Peugeot use VR to design vehicles and simulate assembly lines, minimizing errors and accelerating the time-to-market [8].

In healthcare, VR supports surgical training, patient rehabilitation, and medical education by providing immersive simulations that enhance skill acquisition and patient outcomes [9]. The construction and architecture sector leverages VR for building design, project visualization, and safety training, allowing stakeholders to explore virtual models and identify potential issues before construction begins [10].

In retail and e-commerce, VR enhances the customer experience by enabling virtual showrooms and product demonstrations, increasing engagement and sales [11]. Finally, in energy and utilities, VR aids in equipment maintenance and safety training.

Despite its potential, challenges such as high implementation costs, technical complexity, and data security concerns hinder its widespread adoption, particularly for small and medium-sized enterprises [12].

2.2. Virtual Reality in Higher Education

Virtual reality (VR) has emerged as a powerful tool in education, transforming traditional teaching methods by providing immersive, interactive, and engaging learning experiences. VR enables students to explore complex concepts and environments that would otherwise be inaccessible, such as historical sites, microscopic biological structures, or outer space, enhancing their understanding and retention of knowledge [6]. In STEM (Science, Technology, Engineering, and Mathematics) education, VR is used to simulate laboratory experiments, engineering designs, and mathematical models, allowing students to practice their skills in a risk-free, hands-on environment [13].

For example, medical students can perform virtual surgeries, while engineering students can interact with 3D models of machinery, bridging the gap between theory and practice [14]. Despite its potential, challenges such as high costs, technical requirements, and the need for teacher training limit its widespread adoption in educational institutions [12].

However, as VR technology becomes more affordable and accessible, its role in education is expected to grow, offering innovative solutions to enhance learning outcomes and prepare students for the demands of the digital age.

2.3. Virtual Reality in Industry and Education: Highlights from Morocco

As a developing country, Morocco is gradually adopting virtual reality (VR) to modernize its industrial and educational sectors.

In industry, VR is being used in automotive manufacturing, aerospace, and renewable energy for training, process simulation, and maintenance optimization. For example, Moroccan automotive plants, serving global companies like Renault, Peugeot, Yazaki, OCP, Lydec, etc., use VR to enhance their workforces’ skills and production efficiency [15].

In education, Morocco’s “Digital Morocco 2030” and “pact ESRI 2030” strategies promote VR to improve access to quality training, particularly in engineering and vocational fields. Universities and technical schools are piloting VR programs to provide immersive, hands-on learning experiences, such as OFPPT, UM6P, UIR, etc. [16,17].

However, challenges such as high costs, limited infrastructure, and uneven access between urban and rural areas hinder widespread adoption.

To address these issues, Morocco is fostering public–private partnerships and seeking international support to build its VR capabilities. These efforts highlight Morocco’s commitment to leveraging VR for industrial growth and educational advancement, positioning it as a regional leader in digital innovation [18].

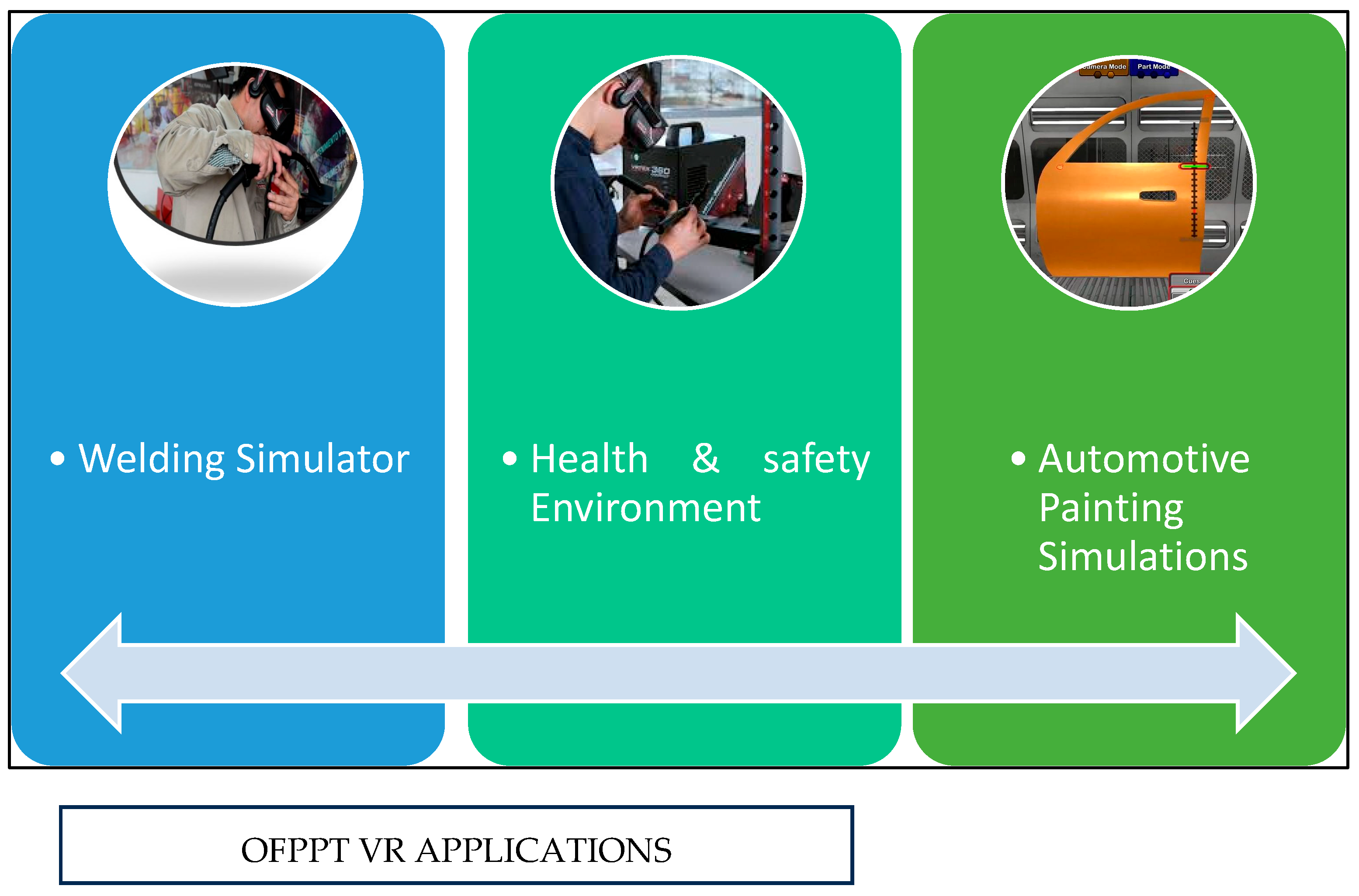

2.4. Illustrative Applications of Virtual Reality in the Educational Landscape of Morocco

Virtual reality presents a transformative opportunity for Moroccan higher education, offering immersive learning solutions that could democratize the access to quality practical training across geographical and socioeconomic divides. Meanwhile, leading institutions such as UM6P, EMSI, IAV Hassan II, and especially OFPPT have adopted VR applications to teach various practical skills, as illustrated here.

3. Methodology

3.1. Defining the Problem: Assessing the Need for the Integration of VR into Moroccan Engineering Education Through Participant Observation

To identify the challenges faced by students in practical engineering sessions and to explore how virtual reality (VR) could address these issues, we employed **participant observation** [19] as a key qualitative research method.

By immersing ourselves in practical sessions within Moroccan engineering schools and TVET institutions, we actively engaged with students and educators, observing their interactions, workflows, and learning processes. During these sessions, we participated in hands-on activities, such as lab experiments, technical workshops, and project-based tasks, while carefully documenting the difficulties that students encountered.

For instance, we observed challenges such as limited access to advanced equipment, overcrowded labs, and the inability to visualize complex engineering concepts in a tangible way.

These observations were complemented by informal conversations with students and educators, who expressed frustration over the lack of immersive learning tools that could bridge the gap between theory and practice.

Through this immersive approach, we identified specific problems that VR could resolve. For example, VR could provide students with access to virtual labs, enabling them to conduct experiments and practice skills in a risk-free, scalable environment. It could also help them visualize abstract concepts, such as 3D modeling or structural dynamics, in an interactive and engaging manner.

By participating in these sessions, we gained firsthand insights into how VR could address these pain points, offering a transformative solution to enhance practical education.

This method not only allowed us to define the problems clearly but also provided a platform for educators and students to share their perspectives on how VR could be integrated effectively into the curriculum.

The combination of direct observations and active participation ensured that our findings were grounded in real-world experiences, making a compelling case for the adoption of VR in Moroccan engineering education.

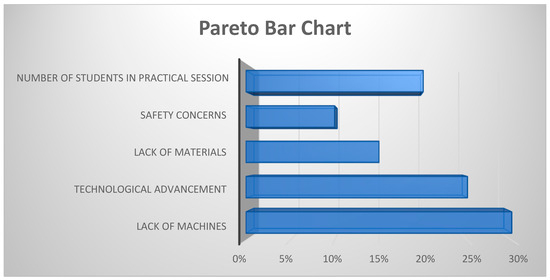

3.2. Prioritizing the Need for VR in Engineering Education: A Pareto Analysis of Participant Observation Data

This strategic approach has the potential to significantly enhance the employability of graduates and contribute to the development of a more skilled and robust engineering workforce in Morocco. Based on the study conducted with the educators, the following results were compiled:

The findings underscore a clear demand for virtual laboratories as a viable solution to address the existing limitations in engineering education.

However, this study also highlights the necessity of allocating adequate resources and providing comprehensive faculty training to ensure the effective implementation of such technologies.

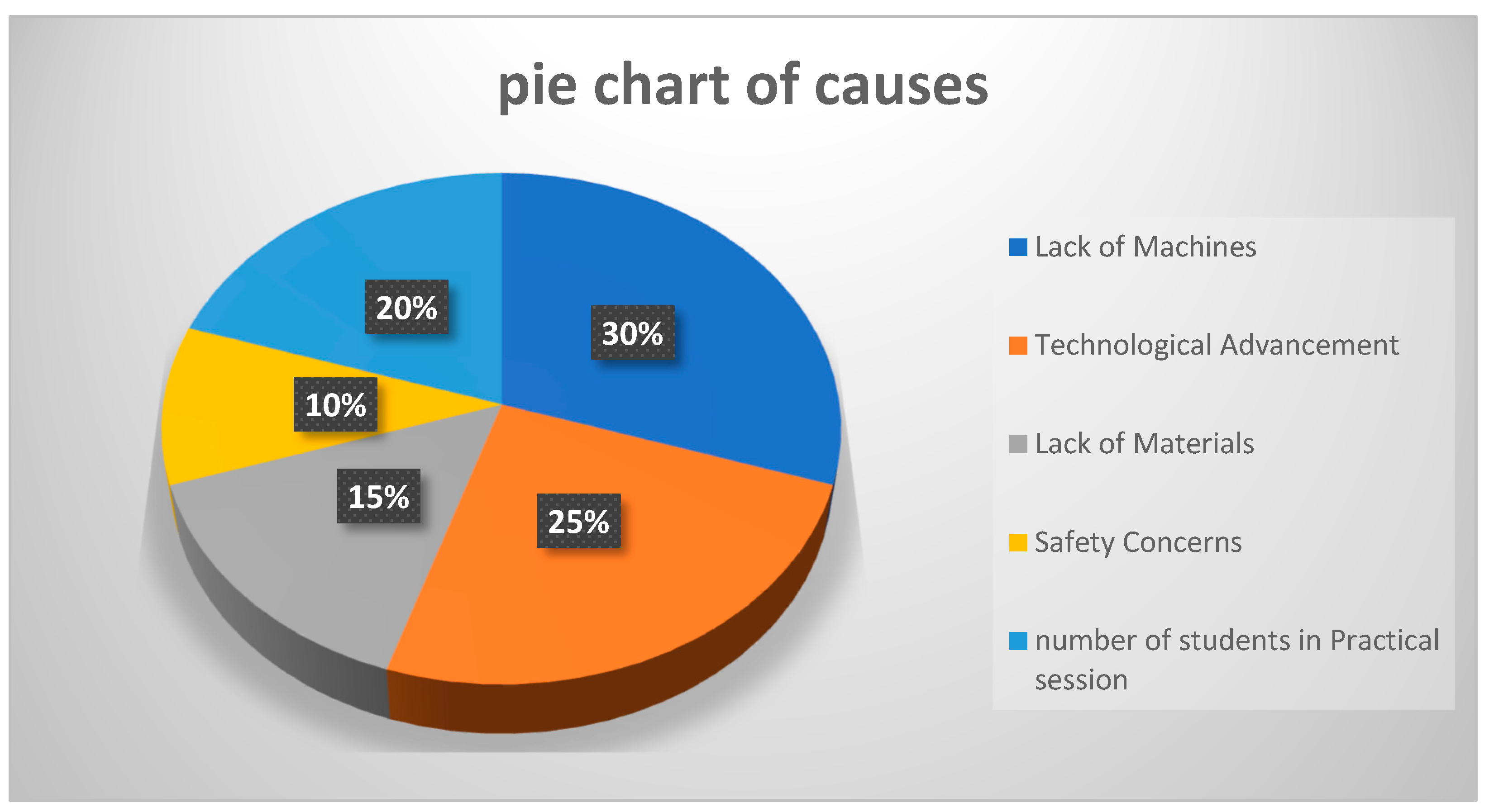

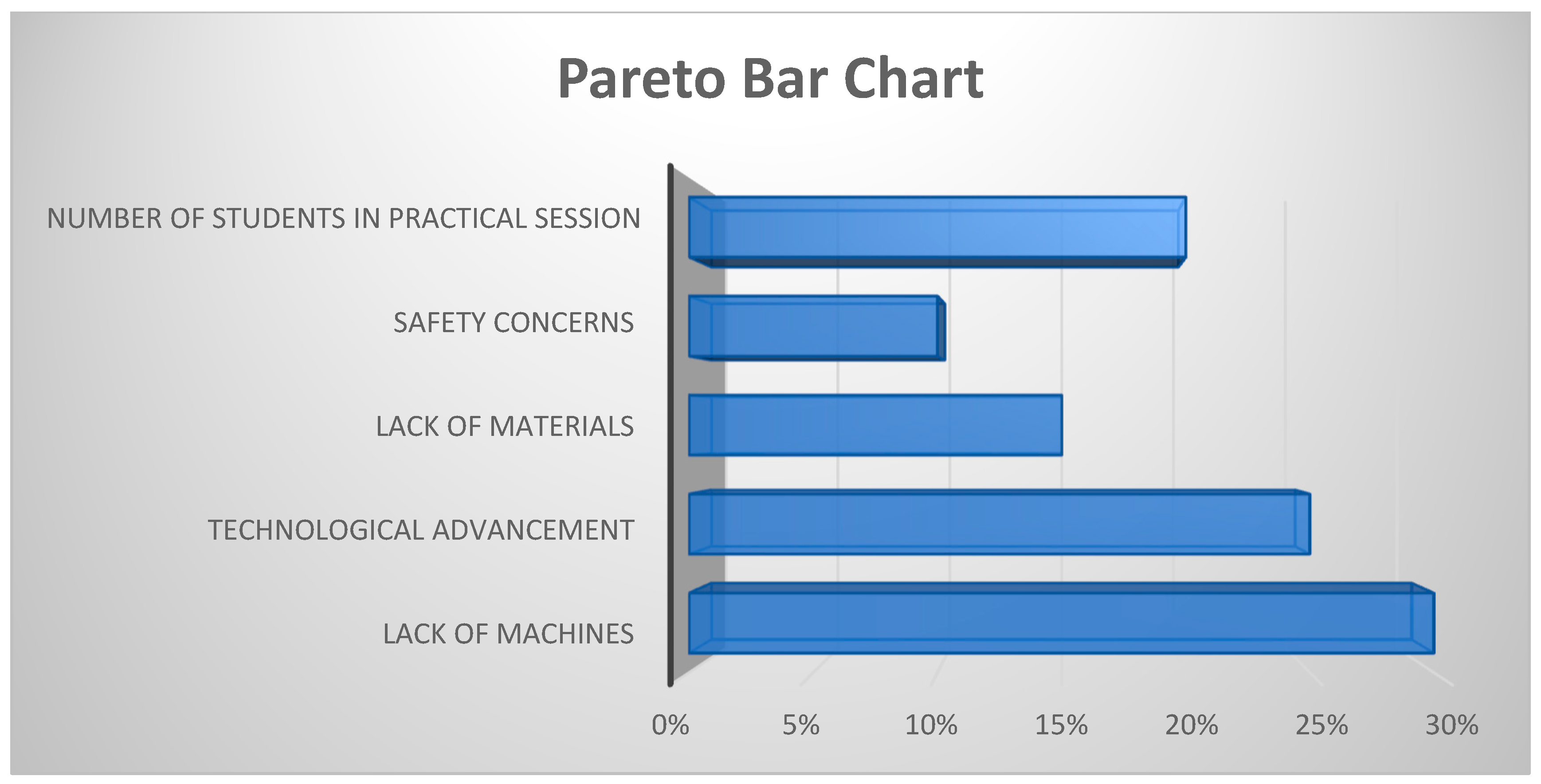

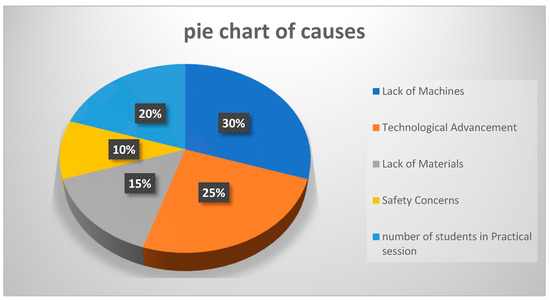

To prioritize the key reasons for implementing VR laboratories, a Pareto analysis was conducted [20]. The results of this analysis are presented below:

As we can see in the Figure 1 The analysis highlights that a lack of machines (30%), technological advancement (25%), and the number of students in practical sessions (20%) are the primary factors in VR adoption in practical work, as shown by the Pareto chart and supported by the other visualizations. These factors contribute to most of the cumulative impact, reinforcing the Pareto principle. Addressing these key challenges would be the most effective strategy for accelerating VR integration; these factors outweigh others such as material shortages (15%) and safety concerns (10%), which appear to be relatively less significant, as we can see in the Figure 2.

Figure 1.

A pie chart of the Pareto analysis of implementing VR in education.

Figure 2.

A bar chart of the Pareto analysis of implementing VR in education.

This study supports focusing resources and efforts on improving the availability of equipment and embracing modern technology to meet the needs of engineering education effectively.

4. The Conception of a Virtual Laboratory: From Concept to Implementation

4.1. The Conception of a Virtual Laboratory for Mechanical Engineering in the Moroccan Context

The conception of the virtual laboratory for Moroccan mechanical engineering education followed a structured process aiming to align practical skills with modern industrial demands. The key steps are as follows:

- ➢

- An In-Depth Look at Moroccan Mechanical Engineering Program Curricula

This step focuses on carefully reviewing the current curricula to understand their structure and goals and how they include hands-on learning opportunities. By taking a closer look, educators can acquire a clear picture of what students are expected to learn, the topics being taught, and the skills they should develop.

This process ensures that the virtual lab is designed to fit seamlessly into Morocco’s educational system, meeting both local standards and the needs of students. It also helps pinpoint areas where students might benefit from more practical experiences, allowing the virtual lab to fill these gaps with interactive experiments and simulations.

By aligning the virtual lab with the curriculum, it becomes a tool that not only supports classroom learning but also enhances it, making education more engaging and effective. Ultimately, this approach ensures that the virtual lab is relevant, practical, and tailored to helping students succeed in their studies while staying true to Morocco’s educational vision [21].

- ➢

- Using the APC to Extracting Key Practical Skills

Implementing the Competency-Based Approach (APC) in designing a practical laboratory involves a targeted focus on developing industry-aligned competencies. The process begins by identifying essential practical skills—technical, cognitive, and behavioral—that meet industry demands. Clear, measurable learning outcomes must then be defined for each lab activity, ensuring they directly contribute to these competencies.

The laboratory should be equipped with tools and resources that enable hands-on, real-world applications, integrating industry-specific projects and scenarios to connect theory with practice. Active learning methods, such as project-based tasks, should be employed to foster critical thinking and collaboration. Assessments must prioritize the application of skills, supported by continuous feedback for improvement. Additionally, soft skills like communication and teamwork should be embedded into activities, ensuring the well-rounded development of practical competencies aligned with the APC framework.

Finally, it is crucial to regularly evaluate and update the laboratory based on feedback, ensuring it remains aligned with technological advancements and industry standards [22].

- ➢

- Integrating Industry 4.0-Relevant Skills into the Curriculum

To remain competitive in a rapidly changing industrial landscape, this step focuses on identifying and incorporating cutting-edge competencies that align with the demands of Industry 4.0. Key areas of focus include digital fabrication, which encompasses advanced manufacturing techniques like 3D printing and CNC machining; IoT (Internet of Things) applications, which involve the integration of connected devices and data-driven decision-making; automation, including robotics and process optimization; and smart systems, which leverage artificial intelligence and machine learning to enhance efficiency and innovation.

These competencies are critical for preparing students and professionals to navigate and excel in a technology-driven industrial environment. By embedding these skills into the curriculum, educational programs can ensure that learners are equipped with the practical knowledge and technical expertise required to meet the challenges and opportunities of Industry 4.0, fostering innovation and adaptability in the workforce [22,23].

4.2. The Lean Approach to the Laboratory Implementation of Machines

The lean methodology applied to laboratory design emphasizes maximizing value by addressing the core needs of students and faculty while aligning the laboratory’s objectives with industry standards and curriculum requirements.

This process involves systematically mapping the value stream (VSM) to identify inefficiencies, such as redundant steps and unnecessary resources, and subsequently eliminating waste through the optimal utilization of space and the careful procurement of equipment.

This approach advocates an incremental development strategy, establishing the laboratory with the essential equipment and functionalities while continuously refining its setup based on feedback from users. Ongoing evaluation ensures that the laboratory remains efficient and adaptable to advancements in technology and pedagogy [24].

The implementation of a lean approach offers several key advantages, including enhanced cost-effectiveness, scalability, and resource efficiency. It also facilitates the integration of emerging technologies and teaching methods, ensuring the laboratory remains responsive to future educational and technological challenges [25].

4.3. Lean Tools and Techniques in Virtual Laboratory Design: Optimizing Its Conception

Integrating lean tools such as SMED (Single-Minute Exchange of Die), KANBAN, 5S, and JIT into the design of the virtual workshop for engineering education can significantly enhance its efficiency, organization, and effectiveness. SMED principles can be applied to streamlining the setup and transition processes within the virtual environment, ensuring that students can quickly switch between tasks or experiments without delays.

KANBAN, a visual workflow management tool, can be used to monitor progress, manage resources, and maintain a steady flow of activities, helping students and educators track their work in real time.

Meanwhile, the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) can be implemented to organize the virtual workspace, ensuring that tools, materials, and information are easily accessible and systematically arranged. By embedding these lean tools into the virtual workshop, we create a structured, user-friendly, and efficient learning environment that mirrors real-world engineering practices, preparing students to apply lean principles in their future careers.

This approach not only improves educational experience but also fosters a culture of continuous improvement and operational excellence [26].

5. Results and Discussion

The implementation of a lean approach in the mechanical engineering laboratory has led to a more efficient and cost-effective setup by eliminating inefficiencies and optimizing the use of space and equipment. The lab commenced with the essential equipment and evolved based on user feedback, maintaining adaptability to technological advancements. By integrating the APC, we ensured that key competencies were aligned with industry requirements.

With clearly defined learning outcomes and hands-on activities, including real-world projects, students’ engagement and development of practical skills in a virtual environment have been significantly enhanced. The laboratory’s focus on Industry 4.0 competencies has equipped students to address contemporary industrial challenges. The skills–equipment matrix guarantees that the virtual lab is outfitted with the appropriate tools to support both traditional and digital learning [27].

Ongoing feedback from students and industry professionals has driven continuous improvements, ensuring that the lab remains relevant and effective in meeting both educational and industry standards. All of these elements will be leveraged to advance the foundational concept of the virtual laboratory.

6. Conclusions

In conclusion, the development of a virtual laboratory rooted in Lean Manufacturing principles offers a forward-thinking solution for addressing the skill requirements of Industry 4.0. By leveraging advanced technologies such as simulations, data analytics, and collaborative platforms, this initiative not only improves educational outcomes but also ensures alignment with the dynamic needs of the industrial sector. Looking ahead, the incorporation of artificial intelligence (AI) and machine learning holds a significant promise for enhancing the learning experience further.

These technologies can enable personalized learning pathways, optimize the accuracy of simulations, and streamline assessment processes, ensuring that students acquire the competencies needed to navigate the complexities of modern manufacturing and technological innovation. Ultimately, this approach fosters a seamless connection between academic training and industry expectations, equipping students with the tools and knowledge necessary to thrive in the evolving workforce landscape.

Author Contributions

Conceptualization, K.T. and Z.A.H.; methodology, S.B. and S.A.;validation, S.B. and S.A.; formal analysis, Z.A.H.; investigation, K.T.; resources, K.T. and Z.A.H.; data curation, S.A.; writing—original draft preparation, K.T.; writing—review and editing, K.T. and Z.A.H. and S.B. and S.A.; visualization, S.B.; supervision, S.A. nd Z.A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors sincerely thank the NATIONAL HIGHER SCHOOL OF ELECTRICITY AND MECHANICS.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios. In Proceedings of the 2016 49th Hawaii International Conference on System Sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; pp. 3928–3937. [Google Scholar]

- Liao, Y.; Deschamps, F.; Loures, E.d.F.R.; Ramos, L.F.P. Past, Present and Future of Industry 4.0—A Systematic Literature Review and Research Agenda Proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Nounou, A.; Jaber, H.; Aydin, R. A Cyber-Physical System Architecture Based on Lean Principles for Managing Industry 4.0 Setups. Int. J. Comput. Integr. Manuf. 2022, 35, 890–908. [Google Scholar] [CrossRef]

- Elmqaddem, N. Augmented Reality and Virtual Reality in Education. Myth or Reality? Int. J. Emerg. Technol. Learn. 2019, 14, 234. [Google Scholar] [CrossRef]

- Talbi, K.; Zergout, I.; Souad, A. ZinebAithaddouchane Analytical Study of Virtual Reality in Moroccan Higher Education. In Proceedings of the 2023 7th IEEE Congress on Information Science and Technology (CiSt), Essaouira, Morocco, 16–22 December 2023; pp. 503–507. [Google Scholar]

- Liyuan, L. The Application of Virtual Reality and Augmented Reality Technology in the Field of Education. J. Phys. Conf. Ser. 2020, 1684, 012109. [Google Scholar] [CrossRef]

- Thakur, T.; Bhatia, S.; Kaur, G.; Thakur, T.; Bhatia, S.; Kaur, G. Influence of Virtual Reality as a Tool to Revolutionize Industry Education. Available online: https://www.igi-global.com/gateway/chapter/www.igi-global.com/gateway/chapter/349422 (accessed on 13 February 2025).

- Akpan, I.J.; Offodile, O.F. The Role of Virtual Reality Simulation in Manufacturing in Industry 4.0. Systems 2024, 12, 26. [Google Scholar] [CrossRef]

- Keswani, B.; Mohapatra, A.G.; Mishra, T.C.; Keswani, P.; Mohapatra, P.C.G.; Akhtar, M.M.; Vijay, P. World of Virtual Reality (VR) in Healthcare. In Advanced Computational Intelligence Techniques for Virtual Reality in Healthcare; Gupta, D., Hassanien, A.E., Khanna, A., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–23. ISBN 978-3-030-35252-3. [Google Scholar]

- Johansson, M.; Roupé, M. Real-World Applications of BIM and Immersive VR in Construction. Autom. Constr. 2024, 158, 105233. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, W.; Quach, S.; Thaichon, P.; Li, Q. Examining the Moderating Effects of Shopping Orientation, Product Knowledge and Involvement on the Effectiveness of Virtual Reality (VR) Retail Environment. J. Retail. Consum. Serv. 2024, 78, 103713. [Google Scholar] [CrossRef]

- Turner, C.J.; Hutabarat, W.; Oyekan, J.; Tiwari, A. Discrete Event Simulation and Virtual Reality Use in Industry: New Opportunities and Future Trends. IEEE Trans. Hum.-Mach. Syst. 2016, 46, 882–894. [Google Scholar] [CrossRef]

- Effectiveness of Immersive VR in STEM Education | IEEE Conference Publication | IEEE Xplore. Available online: https://ieeexplore.ieee.org/abstract/document/9320779 (accessed on 13 February 2025).

- Hsieh, M.C.; Lee, J.J. Preliminary Study of VR and AR Applications in Medical and Healthcare Education. J. Nurs. Health Stud. 2018, 3, 100030. [Google Scholar] [CrossRef]

- Publié le 24 Juillet 2022 par Brahim Habriche. Available online: https://www.lavieeco.com/affaires/carriere/limmersive-learning-fait-son-chemin/ (accessed on 24 July 2022).

- Available online: https://www.enssup.gov.ma/en/actualites/lancement-des-seances-d-ecoute-et-de-consultation-pour-la-co-construction-du-plan-national-d-acceleration-de-la-transformation-de-l-ecosysteme-de-l-enseignement-superieur-de-la-recherche-scientifique-et-de-l-innovation (accessed on 16 February 2022).

- Available online: https://www.mmsp.gov.ma/fr/actualites/la-vision-%C3%A9clair%C3%A9e-de-sa-majest%C3%A9-le-roi-mohammed-vi-que-dieu-le-glorifie-plac%C3%A9-le-num%C3%A9rique-au-centre-des-priorit%C3%A9s-nationales (accessed on 5 September 2024).

- Talbi, K.; Aithaddouchane, Z.; Zergout, I.; Ajana, S. Virtual Reality in Moroccan Higher Education: Swot Analysis. Int. J. Inf. Sci. Technol. 2024, 8, 26–35. [Google Scholar] [CrossRef]

- Handbook of Qualitative Research—ProQuest. Available online: https://www.proquest.com/openview/5d9ea365c771fc82a1945ef79e7cd533/1?pq-origsite=gscholar&cbl=1816610 (accessed on 14 February 2025).

- Pareto Diagrams Get to the Root of Process Problems—ProQuest. Available online: https://www.proquest.com/openview/61594e91f7a64c8abd547df03b6de8fd/1?pq-origsite=gscholar&cbl=35812 (accessed on 14 February 2025).

- Haddouchane, Z.A.; Faraj, K.; Bakkali, S.; Ajana, S. Etude Critique Des Référentiels de Compétences Du Génie Mécanique. J. Qual. Educ. 2017, 6, 12. [Google Scholar] [CrossRef]

- Eppes, T.A.; Milanovic, I.; Jamshidi, R.; Shetty, D. Engineering Curriculum in Support of Industry 4.0. Int. J. Online Biomed. Eng. (iJOE) 2021, 17, 4–16. [Google Scholar] [CrossRef]

- Laad, M.; Renedo, M. Skill Requirement in Industry 4.0. In Industry 4.0 in Small and Medium-Sized Enterprises (SMEs); Laad, M., Renedo, M., Eds.; CRC Press: Boca Raton, FL, USA, 2022; ISBN 978-1-00-320085-7. [Google Scholar]

- Sundar, R.; Balaji, A.N.; Kumar, R.M.S. A Review on Lean Manufacturing Implementation Techniques. Procedia Eng. 2014, 97, 1875–1885. [Google Scholar] [CrossRef]

- Gupta, S.; Jain, S.K. A Literature Review of Lean Manufacturing. Int. J. Manag. Sci. Eng. Manag. 2013, 8, 241–249. [Google Scholar] [CrossRef]

- Hadek, A.; Bakkali, S.; Ajana, S. Evaluation of the Lean Approach Implementation in Engineering Education. Emerg. Sci. J. 2023, 7, 1126–1137. [Google Scholar] [CrossRef]

- Hawkins, I.; Phelps, A.J. Virtual Laboratory vs. Traditional Laboratory: Which Is More Effective for Teaching Electrochemistry? Chem. Educ. Res. Pract. 2013, 14, 516–523. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).