Experimental Investigation on Mechanical and Free Vibration Characteristics of Elastomer-Embedded Natural-Rubber-Filled GFRP Laminates for Anti-Vibration Mounts †

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials Preferred

2.2. Fabrication of Elastomer Unit Centered NR Filled GFRP Laminates

3. Testing of Preferred Elastomeric-Unit-Centered NR-Filled GFRP Composite Laminates

3.1. Tensile Test

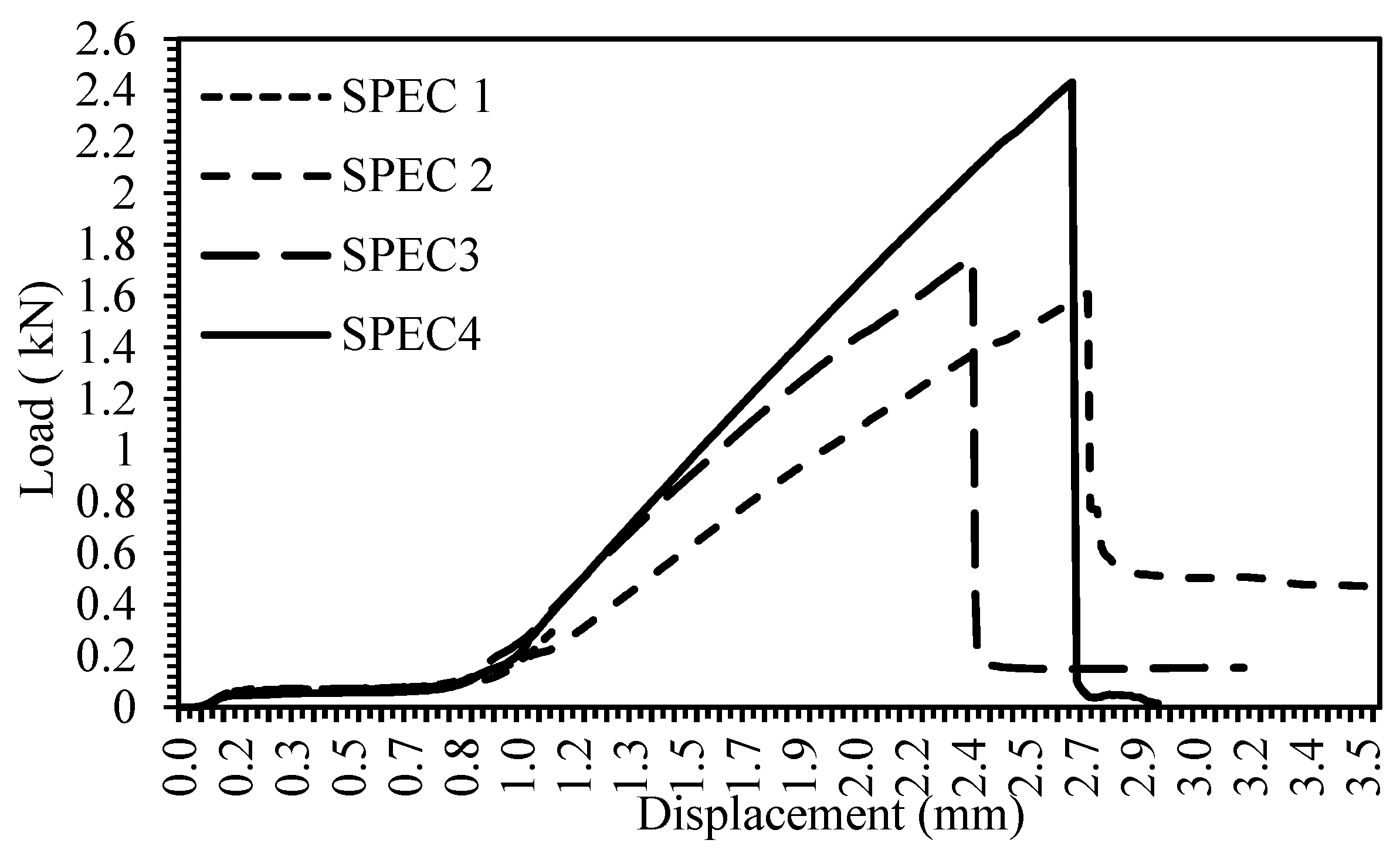

3.2. Flexural Test

3.3. Impact Test

3.4. Free Vibration Study

4. Results and Discussion

4.1. Mechanical Properties of Elastomeric-Unit-Centered NR-Filled GFRP Laminates

4.2. Free Vibration Analysis of Elastomeric-Unit-Centered NR-Filled GFRP Laminates

5. Conclusions

- The tensile strength of the preferred elastomer composite laminates varies according to the wt% of NR particles blended with the epoxy matrix, since the inclusion of NR particles in the epoxy matrix marginally improves the tensile modulus of the laminate.

- The introduction of NR particles in the epoxy resin effectively increases the flexural modulus, and therefore the variation in the flexural strength among the preferred elastomer composite laminates is more significant.

- Since the impact strength of the composite laminates is majorly governed by the strength of the reinforced fiber, the inclusion of NR particles at different wt% in the matrix material caused no variation in the impact strength of the various types of elastomer composite laminates considered.

- The addition of NR particles to the epoxy matrix aids in the improvement of the overall stiffness of the laminates, and therefore the modal frequency and damping values of the preferred elastomer hybrid laminates marginally vary according to the variation in the wt% of NR particles in the epoxy resin.

- The increase in the mechanical strength and overall dynamic stiffness of the preferred elastomer-unit-centered and NR-filled GFRP laminates proves that the present form of hybrid laminate arrangement is suitable for making AV mounts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kurna, S.; Jain, R.; Mathur, A.; Parwal, M.; Legala, A. Design Optimization of Engine Mounts for Commercial Vehicle Application to Avoid Failures. SAE Technical Paper, 10 January 2017. [Google Scholar]

- Azammi, A.N.; Sapuan, S.M.; Ishak, M.R.; Sultan, M.T. Conceptual design of automobile engine rubber mounting composite using TRIZ-Morphological chart-analytic network process technique. Def. Technol. 2018, 14, 268–277. [Google Scholar] [CrossRef]

- Jaiswal, P.; Barve, S. Utilization of composite materials for engine mounts & different vehicle structures: A review. AIP Conf. Proc. 2022, 2421, 040007. [Google Scholar] [CrossRef]

- Mago, J.; Negi, A.; Pant, K.K.; Fatima, S. Development of natural rubber-bamboo biochar composites for vibration and noise control applications. J. Clean. Prod. 2022, 373, 133760. [Google Scholar] [CrossRef]

- Malinova, P.; Ilieva, N.; Metodiev, V. Investigation of elastomers ratio influence in the composites for truck tires treads production. J. Chem. Technol. Metall. 2022, 57, 232–240. [Google Scholar]

- Sokolova, M.D.; Davydova, M.L.; Shadrinov, N.V. The modification of surface of dispersed fillers for their application in polymer–elastomer composites. Prot. Met. Phys. Chem. Surf. 2018, 54, 845–852. [Google Scholar] [CrossRef]

- Barrera, C.S.; Tardiff, J.L. Static and dynamic properties of eggshell filled natural rubber composites for potential application in automotive vibration isolation and damping. J. Clean. Prod. 2022, 353, 131656. [Google Scholar] [CrossRef]

- Akmal, S.A.; Bharathiraja, G. Analysis of engine mount material for automotive vibration and noise reduction. Mater. Today Proc. 2022, 62, 2235–2239. [Google Scholar] [CrossRef]

- Hu, S.; He, S.; Wang, Y.; Wu, Y.; Shou, T.; Yin, D.; Mu, G.; Zhao, X.; Gao, Y.; Liu, J.; et al. Self-repairable, recyclable and heat-resistant polyurethane for high-performance automobile tires. Nano Energy 2022, 95, 107012. [Google Scholar] [CrossRef]

- Murugan, R.; Ramesh, R.; Padmanabhan, K. Investigation of the mechanical behavior and vibration characteristics of thin walled glass/carbon hybrid composite beams under a fixed-free boundary condition. Mech. Adv. Mater. Struct. 2016, 23, 909–916. [Google Scholar] [CrossRef]

- Ganesan, G.; Muthunadar, S.; Ramasamy, M. Experimental investigation on mechanical properties and free vibration characteristics of epoxy-based glass/flax laminates. Polym. Compos. 2022, 43, 6004–6012. [Google Scholar] [CrossRef]

- Liu, J.; Tian, S.; Ren, J.; Huang, J.; Luo, L.; Du, B.; Zhang, T. Improved Interlaminar Properties of Glass Fiber/Epoxy Laminates by the Synergic Modification of Soft and Rigid Particles. Materials 2023, 16, 6611. [Google Scholar] [CrossRef] [PubMed]

- Rajini, N.; Jappes, J.W.; Rajakarunakaran, S.; Jeyaraj, P. Mechanical and free vibration properties of montmorillonite clay dispersed with naturally woven coconut sheath composite. J. Reinf. Plast. Compos. 2012, 31, 1364–1376. [Google Scholar] [CrossRef]

- Rajkumar, K.; Ramraji, K.; Rajesh, M.; Rajiv kumar, M. Dynamic mechanical analysis of flax fiber stacked polyurethane blend epoxy composites. In Trends in Manufacturing and Engineering Management: Select Proceedings of ICMechD 2019; Springer: Berlin/Heidelberg, Germany, 2020; pp. 475–484. [Google Scholar]

- Rajkumar, K.; Selvaraj, M. Study of hexagonal boron nitride particulate as vibration behaviour modifier of alternate stacked glass–natural fibre polymer composite laminate. In Trends in Manufacturing and Engineering Management: Select Proceedings of ICMechD 2019; Springer: Berlin/Heidelberg, Germany, 2021; pp. 451–460. [Google Scholar]

- Selvaraj, M.; Murugan, R. Static and dynamic analysis of silicone/polyurethane embedded GFRP composite for magnetorheological elastomer. Mater. Today Proc. 2024, in press. [CrossRef]

| Layering Arrangement | Photograph Showing the Four Types of Specimen Prepared | Description |

|---|---|---|

|  | (a) SPEC 1—1 Wt% NR filled Epoxy (b) SPEC 2—2 Wt% NR filled Epoxy (c) SPEC 3—3 Wt% NR filled Epoxy (d) SPEC 4—4 Wt% NR filled Epoxy |

| Specimen | Tensile Strength (MPa) | Flexural Strength (MPa) |

|---|---|---|

| SPEC 1 | 20.70667 | 42.33 |

| SPEC 2 | 21.45333 | 47.41 |

| SPEC 3 | 23.33333 | 71.12 |

| SPEC 4 | 32.42667 | 88.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Selvaraj, M.; Murugan, R. Experimental Investigation on Mechanical and Free Vibration Characteristics of Elastomer-Embedded Natural-Rubber-Filled GFRP Laminates for Anti-Vibration Mounts. Eng. Proc. 2025, 93, 26. https://doi.org/10.3390/engproc2025093026

Selvaraj M, Murugan R. Experimental Investigation on Mechanical and Free Vibration Characteristics of Elastomer-Embedded Natural-Rubber-Filled GFRP Laminates for Anti-Vibration Mounts. Engineering Proceedings. 2025; 93(1):26. https://doi.org/10.3390/engproc2025093026

Chicago/Turabian StyleSelvaraj, Muthunadar, and Ramasamy Murugan. 2025. "Experimental Investigation on Mechanical and Free Vibration Characteristics of Elastomer-Embedded Natural-Rubber-Filled GFRP Laminates for Anti-Vibration Mounts" Engineering Proceedings 93, no. 1: 26. https://doi.org/10.3390/engproc2025093026

APA StyleSelvaraj, M., & Murugan, R. (2025). Experimental Investigation on Mechanical and Free Vibration Characteristics of Elastomer-Embedded Natural-Rubber-Filled GFRP Laminates for Anti-Vibration Mounts. Engineering Proceedings, 93(1), 26. https://doi.org/10.3390/engproc2025093026