Abstract

The tunnel oxide passivated contact (TOPCon) solar cell utilizes an ultra-thin tunnel oxide layer in its passivation layer structure. The performance difference between TOPCon and passivated emitter and rear cell (PERC) solar cells is obvious due to differences in their structure and operational characteristics. Compared with PERC, TOPCon involves additional processes such as boron diffusion, tunnel oxide deposition, polysilicon doping, and cleaning, while eliminating the need for laser grooving. PERC production lines can be converted to TOPCon production lines which reduces equipment investment costs. Therefore, it is beneficial to replace PERC products in the future. On two different manufacturing technologies for TOPCon and PERC solar modules, we conducted electroluminescence (EL) tests to analyze power degradation in the solar modules.

1. Introduction

Solar energy is a viable renewable energy resource due to its abundance, environmental benefits, and economic potential. It stands out among renewable energy sources for its accessibility and affordability, making it an important global energy source. Solar energy is harvested using various technologies, including photovoltaic systems and concentrated solar power whose efficiency is continuously improved [1,2]. Solar energy contributes to sustainable development by creating jobs, reducing greenhouse gas emissions, and promoting energy independence [3,4]. The declining costs of solar panel installation bolster its attractiveness as a clean energy source, particularly in regions with unreliable power supply [5]. The Bureau of Energy under Taiwan’s Ministry of Economic Affairs announced the Renewable Energy Development Act [6] to advance solar photovoltaic power generation. This act outlines the necessary regulatory framework for the development of renewable energy sources, such as geothermal, wind, and solar energy. Specifically, Article 12-1, inspired by Berlin’s Solar Energy Law, requires developers to install solar photovoltaic systems with a minimum designated capacity for newly constructed, expanded, or renovated buildings exceeding a certain size unless insufficient sunlight or other qualifying conditions are confirmed. This legislation has significantly increased the demand for rooftop solar installations. In the installation, factors such as return on investment (ROI), feed-in tariffs, sunlight hours, construction costs, energy conversion efficiency, and degradation rates are considered for investment decisions. Given the increasing difficulty in securing land at reasonable costs, the energy efficiency of solar modules must be increased for a higher ROI. Currently, most solar modules in the market utilize passivated emitter and rear cells (PERCs). However, the industry has replaced PN junction-based diodes with NP junction technology. Therefore, tunnel oxide passivated contact (TOPCon) solar cells have been the leading technology using the N-type solar cell. We conducted a comparative analysis between TOPCon and PERC modules, employing the electroluminescence (EL) test method. We examined the power degradation behavior of solar components after prolonged exposure.

2. PERC and TOPCon Solar Module

2.1. PERC

PERC solar modules have significantly advanced, offering enhanced efficiency and reduced costs. The module employs a dielectric layer for rear surface passivation, which minimizes charge carrier recombination and results in higher power conversion efficiency than traditional aluminum back surface field (Al-BSF) cells. PERC has achieved a record-high efficiency of 22.8% in industrial applications, and its market share has increased from 40 to 70% [7]. Incorporating high-k materials such as oxides for passivation further reduces interface trap density and enhances overall efficiency [8]. Additionally, its bifacial designs boost energy output by capturing light from both sides of the module [7]. Overall, PERC dominates the solar panel market due to its efficiency, adaptability, and suitability for a wide range of applications [9].

2.2. TOPCon

The TOPCon module represents a significant advancement in solar cell technology, particularly for crystalline silicon (c-Si) solar cells. This technology enhances efficiency by incorporating a tunnel oxide layer to improve interface passivation and reduce recombination losses. The conversion efficiency of TOPCon solar cells exceeds 25% [10]. N-type TOPCon cells, using monocrystalline Czochralski wafers [11], achieve an efficiency of 25.19%. Additionally, its manufacturing process is compatible with existing PERC, facilitating seamless integration into current production lines [11]. Although TOPCon technology has made significant manufacturing progress, challenges remain in scaling production and ensuring the quality of p-type wafers, which limits its widespread adoption within the industry.

3. Methods

3.1. Maximum Power Measurement

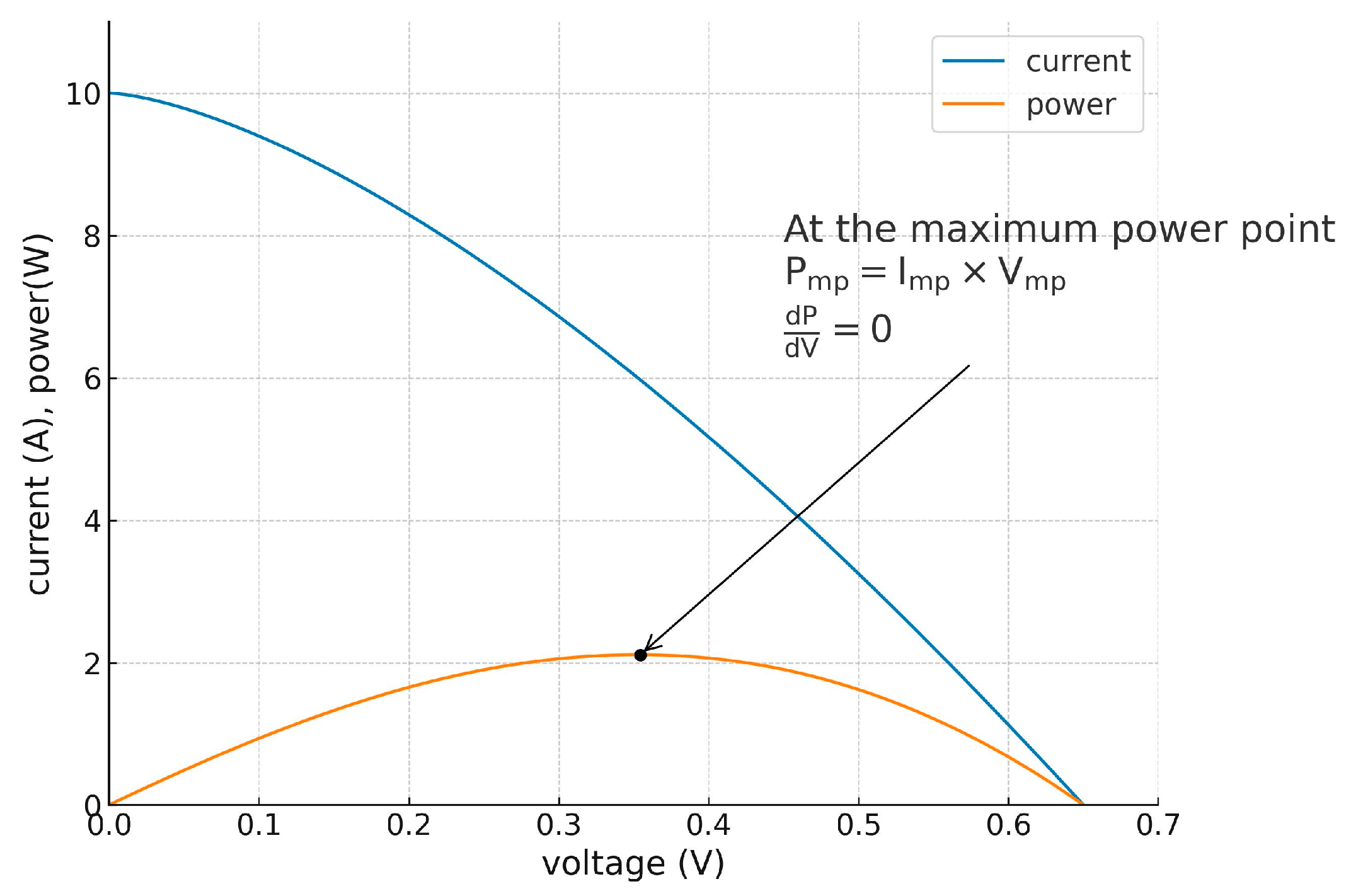

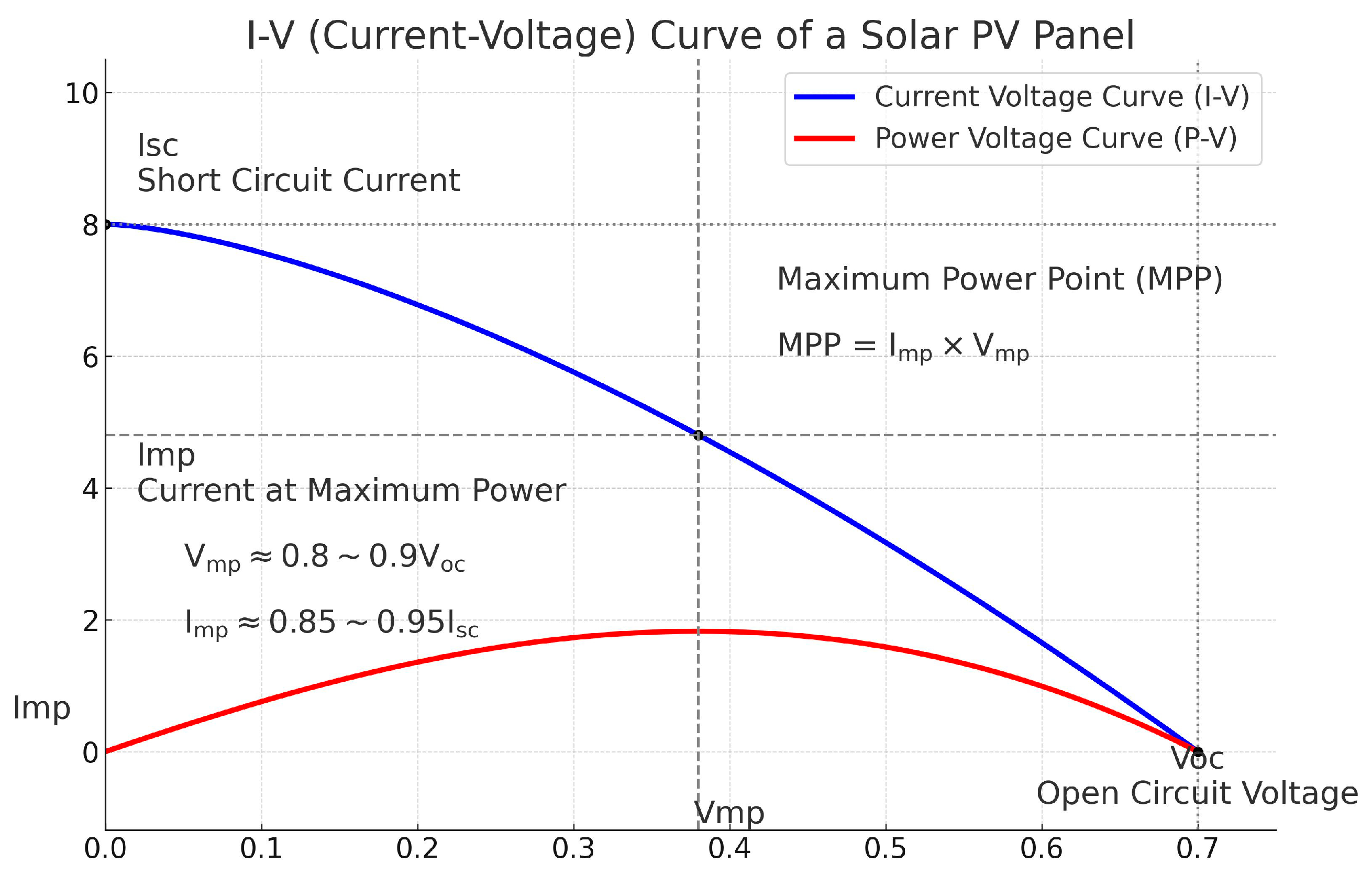

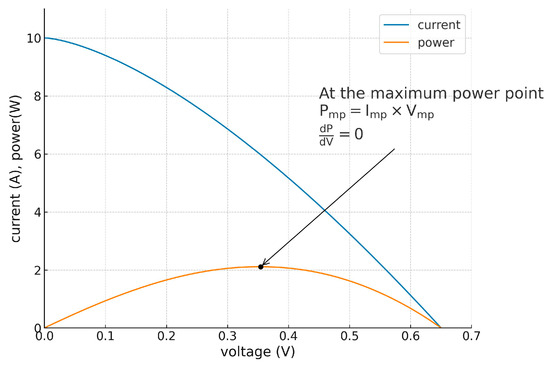

Vmp refers to the voltage at which a solar panel operates most efficiently (Figure 1), corresponding to its maximum power point (MPP). At this voltage, the panel delivers the highest power output under given irradiance and temperature conditions. Vmp is a crucial parameter in system design and optimization, as it is used to determine the voltage requirements for inverters and charge controllers. Operating solar cells at the maximum power point voltage enables system efficiency to increase for optimal energy harvesting.

Figure 1.

Voltage at maximum power. (Figure created by the authors).

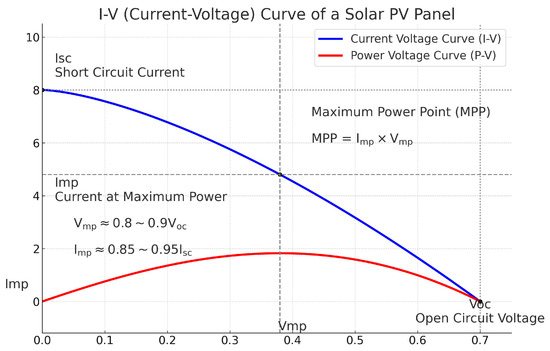

Imp denotes the current output of the solar panel when operating at the maximum power point voltage (Figure 2). Vmp and Vmp are used to determine the maximum power output of the panel under specific operating conditions. Imp is influenced by solar irradiance, temperature, and the internal resistance of the solar cells. It also represents the maximum current the panel can supply to an external load while operating at peak efficiency.

Figure 2.

Current at maximum power. (Figure created by the authors).

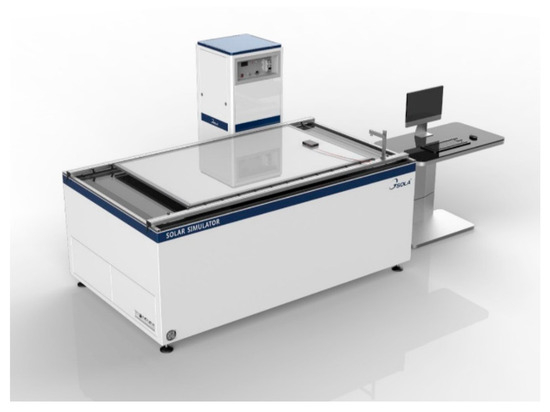

3.2. Solar Simulator

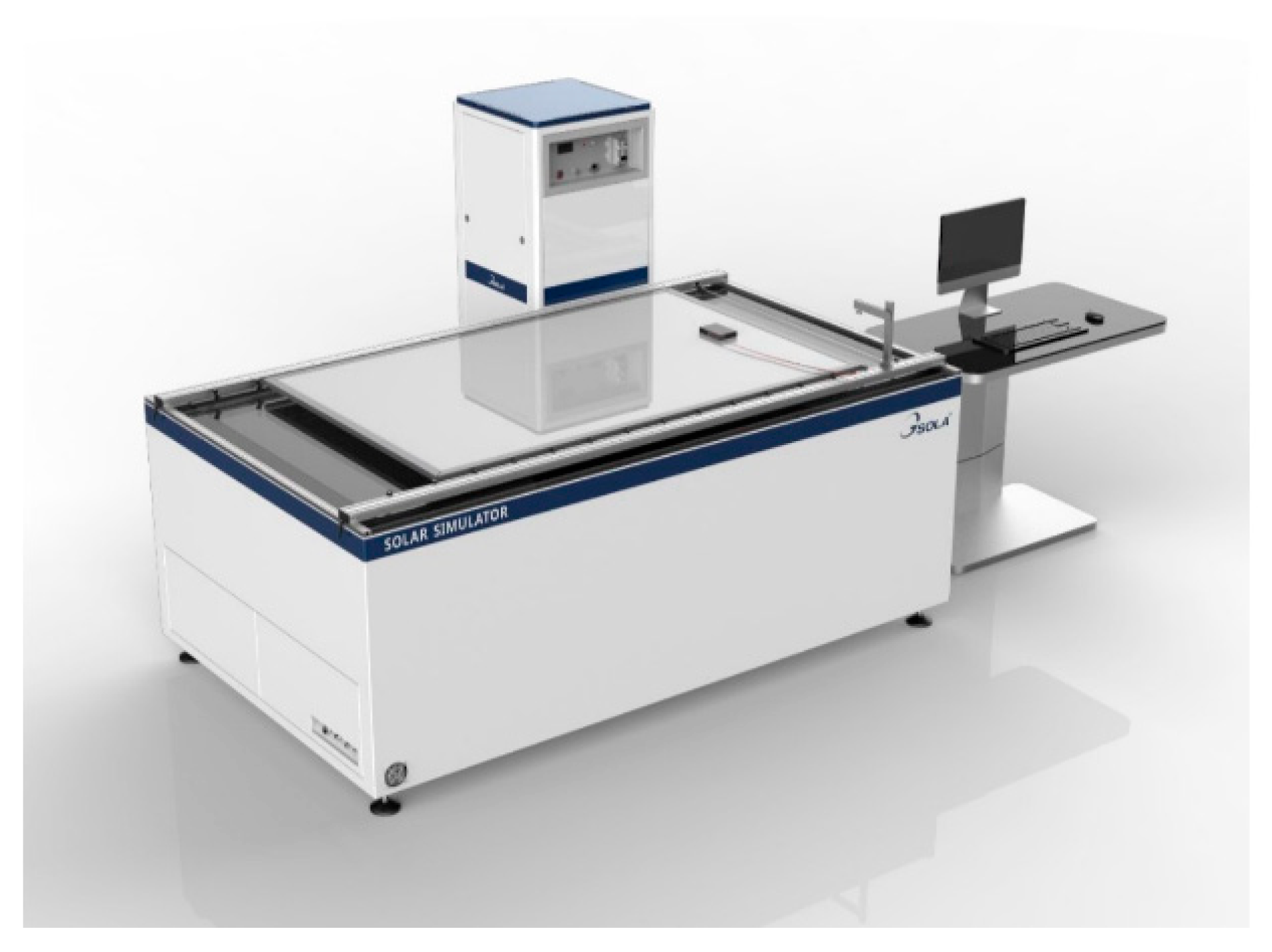

The solar simulator used in this study was designed to cover a spectral wavelength range from 380 to 1100 nm for all flat-panel photovoltaic modules. This simulator enables the accurate measurement of module power output even in the absence of standard reference modules, making it ideal for testing or quality control for manufacturers. The AAA-grade steady-state solar simulator ensures high performance with an A-grade classification in spectral match, irradiance uniformity, and temporal stability. By using a xenon lamp array as the light source, the simulator’s unique optical design ensures uniformity within 2% without requiring frequent adjustments. Each lamp unit maintains stable uniformity and spectral characteristics, enabling rapid testing by selectively activating or shielding individual lamps without compromising spectral match or uniformity. This simulator provides the most accurate artificial light source that mimics outdoor sunlight conditions. In this research, the solar modules were tested using the 3A-grade steady-state solar simulator (Figure 3). The 3A classification refers to the simulator’s performance: A-grade spectral match with the solar spectrum, A-grade uniformity, and A-grade temporal stability. The experiments were conducted under specific irradiance and temperature conditions to evaluate the performance of the modules.

Figure 3.

Solar simulator (Class 3A).

3.3. EL Test

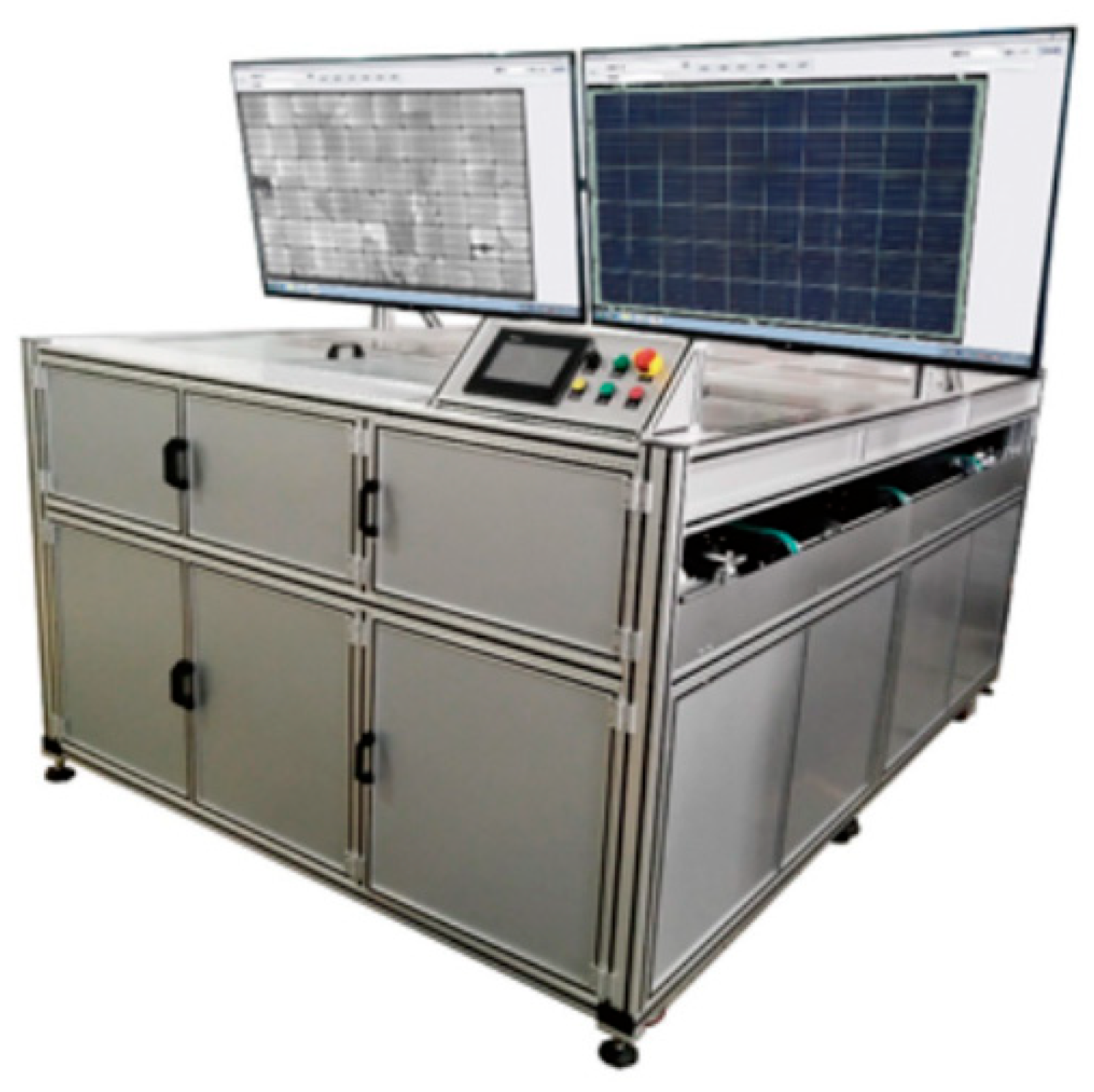

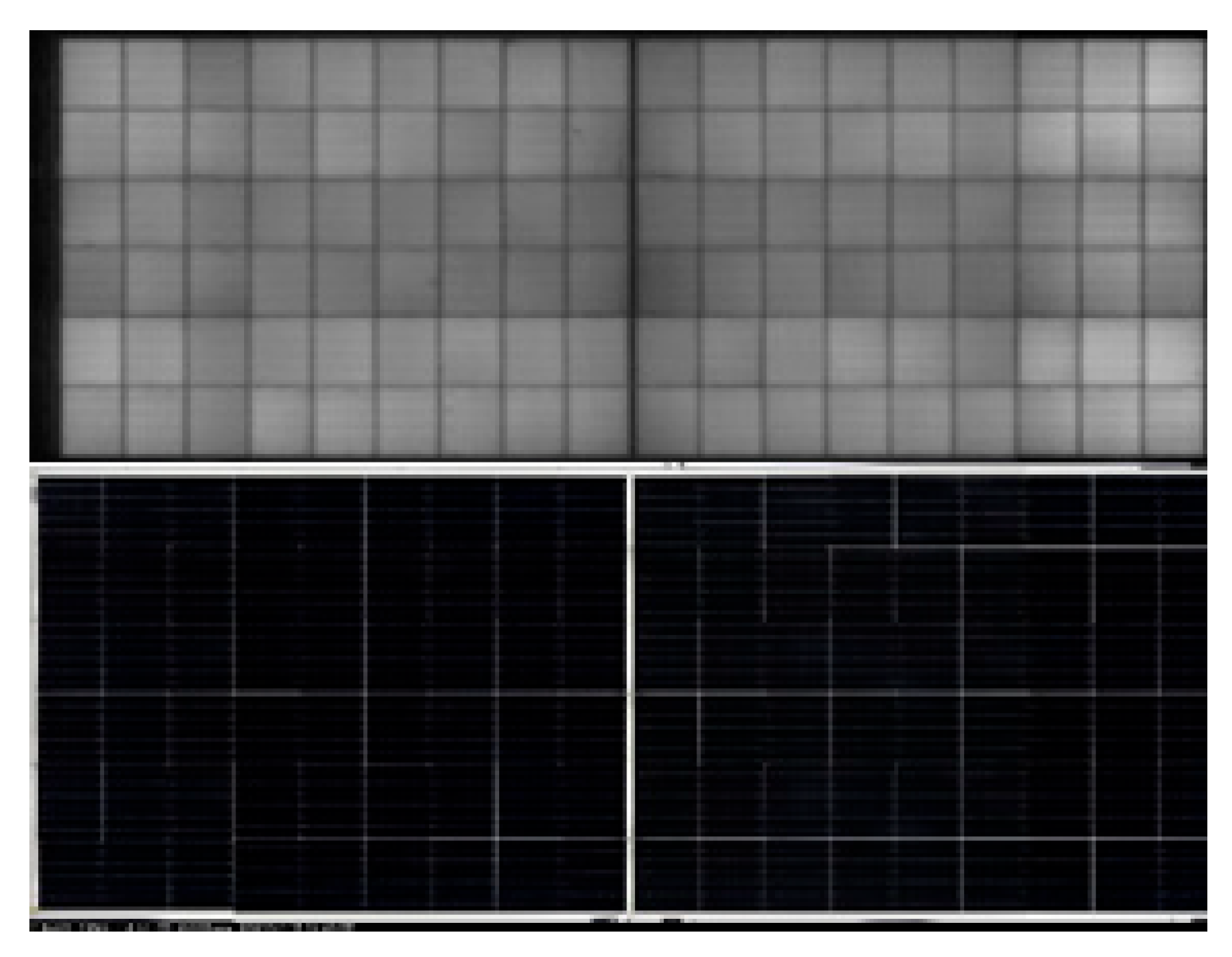

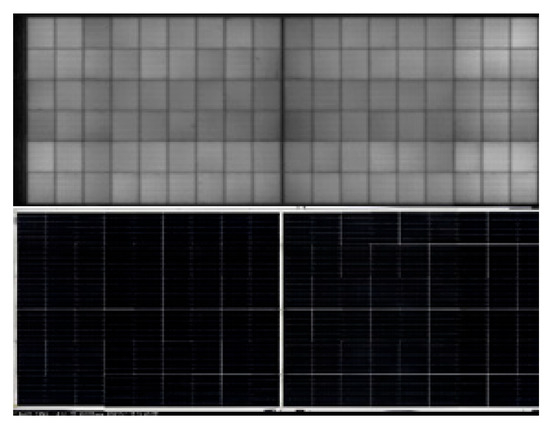

After solar modules are manufactured, producers conduct EL testing to ensure the final product’s quality. Since defects in solar cells are not visible to the human eye, EL testing functions similarly to light-emitting diodes (LEDs) used in semiconductors. In silicon-based solar modules, near-infrared light is emitted, which is invisible to the human eye. By utilizing charge-coupled device (CCD) cameras, defects are identified in solar photovoltaic modules using various operational methods in EL testing. Such defects include microcracks, electrode disconnections, and other flaws. Additionally, cells appearing visibly dimmer and indicating lower efficiency and weaker light emission are detected as those suggest performance degradation. Other than detecting manufacturing defects, EL testing equipment is important in assessing the internal changes in solar cells following accelerated aging and reliability tests. This method helps manufacturers understand how the internal structure of solar modules evolves under stress while the results are used to ensure long-term durability and performance stability. The equipment used in this study is shown in Figure 4 and Figure 5.

Figure 4.

EL testing machine.

Figure 5.

Image of EL testing result.

3.4. Outdoor Exposure Power Degradation Test

The principle of solar photovoltaic technology is to convert solar energy into electricity on photovoltaic cells. Various climatic conditions and environmental factors affect the power output of PV modules. Once manufactured, solar modules inherently begin to degrade. Without exposure to sunlight, the rate of power degradation is relatively slow; however, once exposed to sunlight, the power output decreases more significantly. In the initial phase, the degradation shows a measurable pattern before gradually stabilizing. We evaluated the power degradation of solar modules after every 10 kWh/m2 of accumulated irradiance in outdoor conditions in Pingtung. The irradiance levels for accumulation range from 600 to 1000 W/m2 under direct sunlight. Outdoor exposure is performed to understand cumulative degradation effects and environmental deterioration that laboratory testing cannot detect. The process is critical in module performance assessment. In this study, irradiance levels were measured using an irradiance monitoring instrument, and PERC and TOPCon modules were tested to estimate potential differences in degradation behavior. The irradiance accumulation in this study reached 100 kWh/m2 for a comparative analysis of the degradation patterns between the two modules under identical outdoor conditions.

4. Results and Discussion

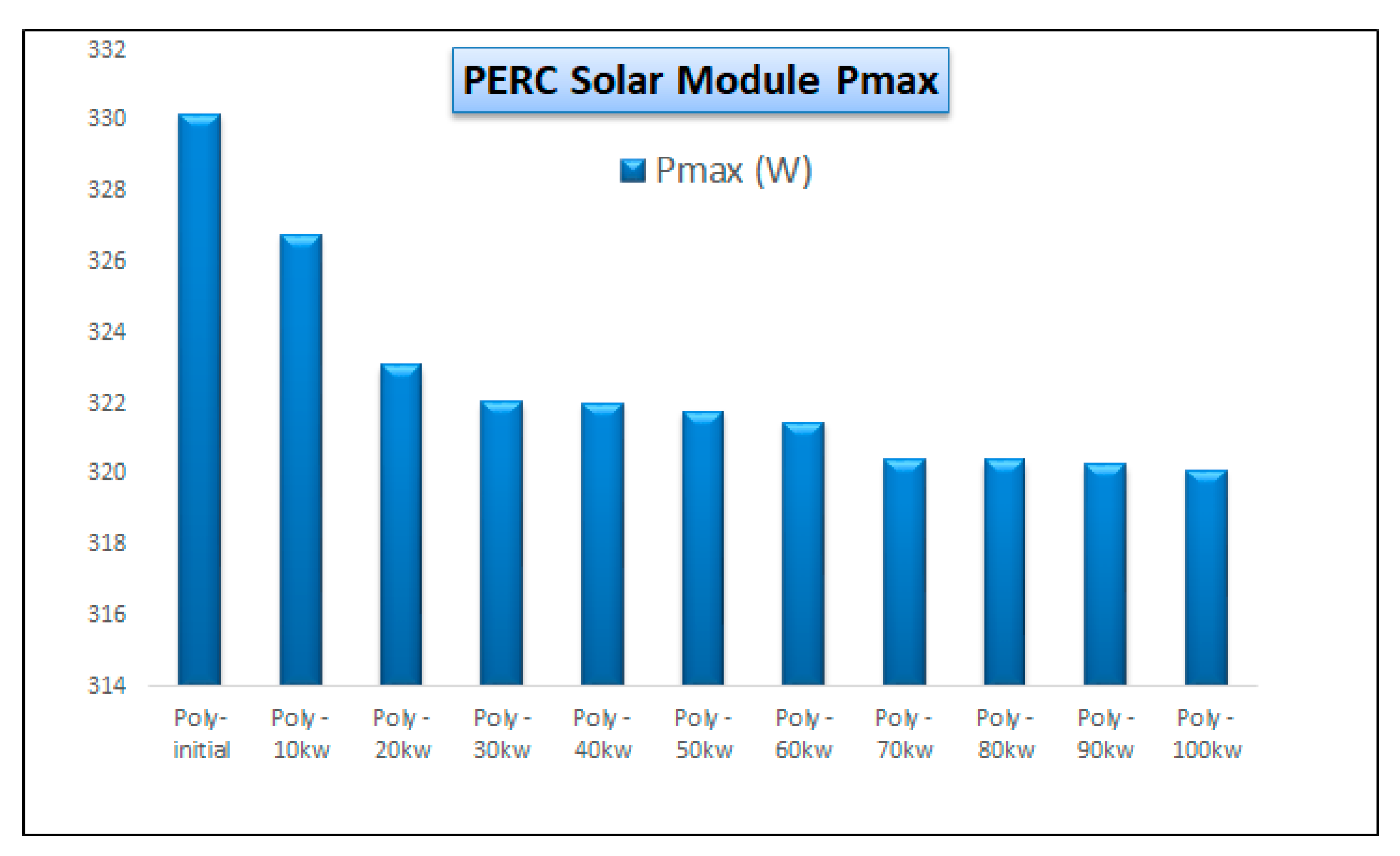

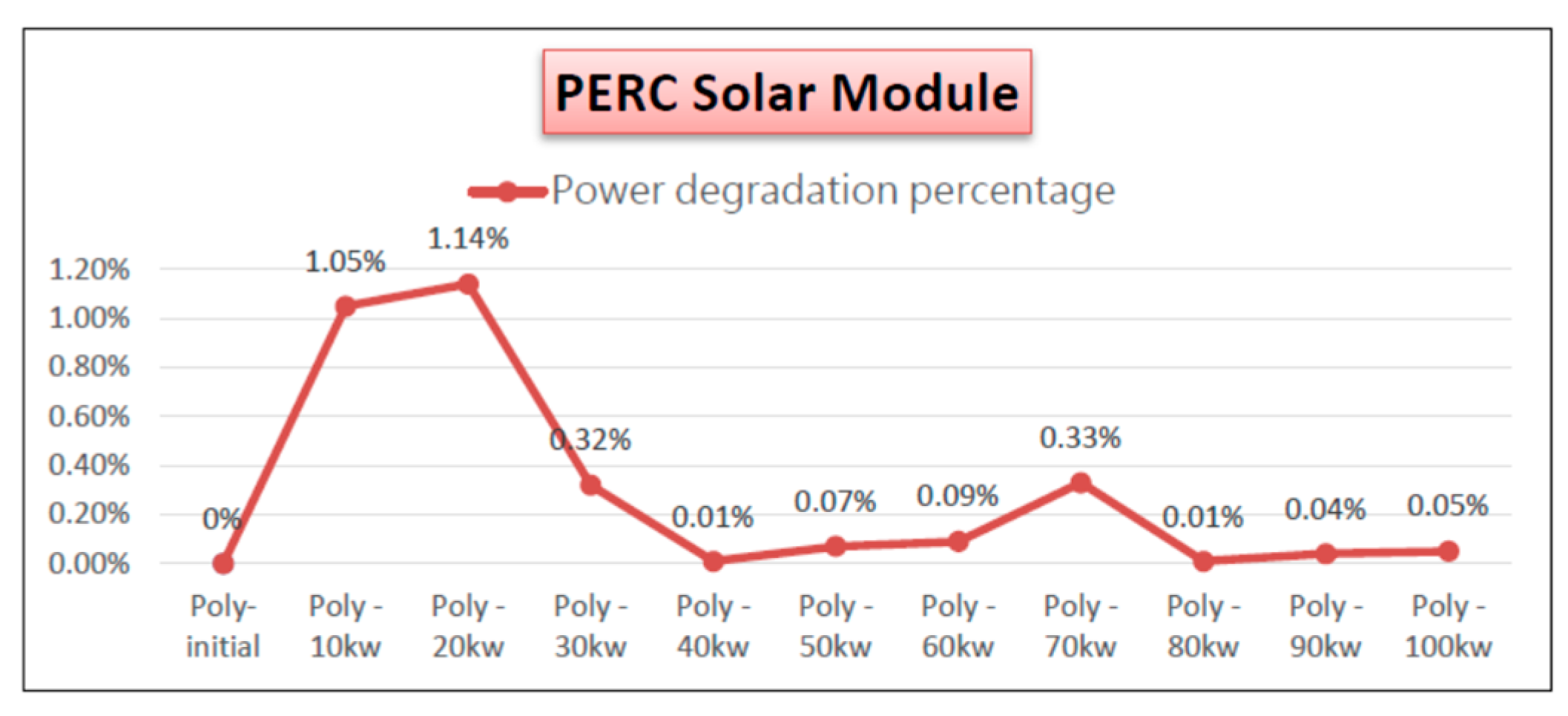

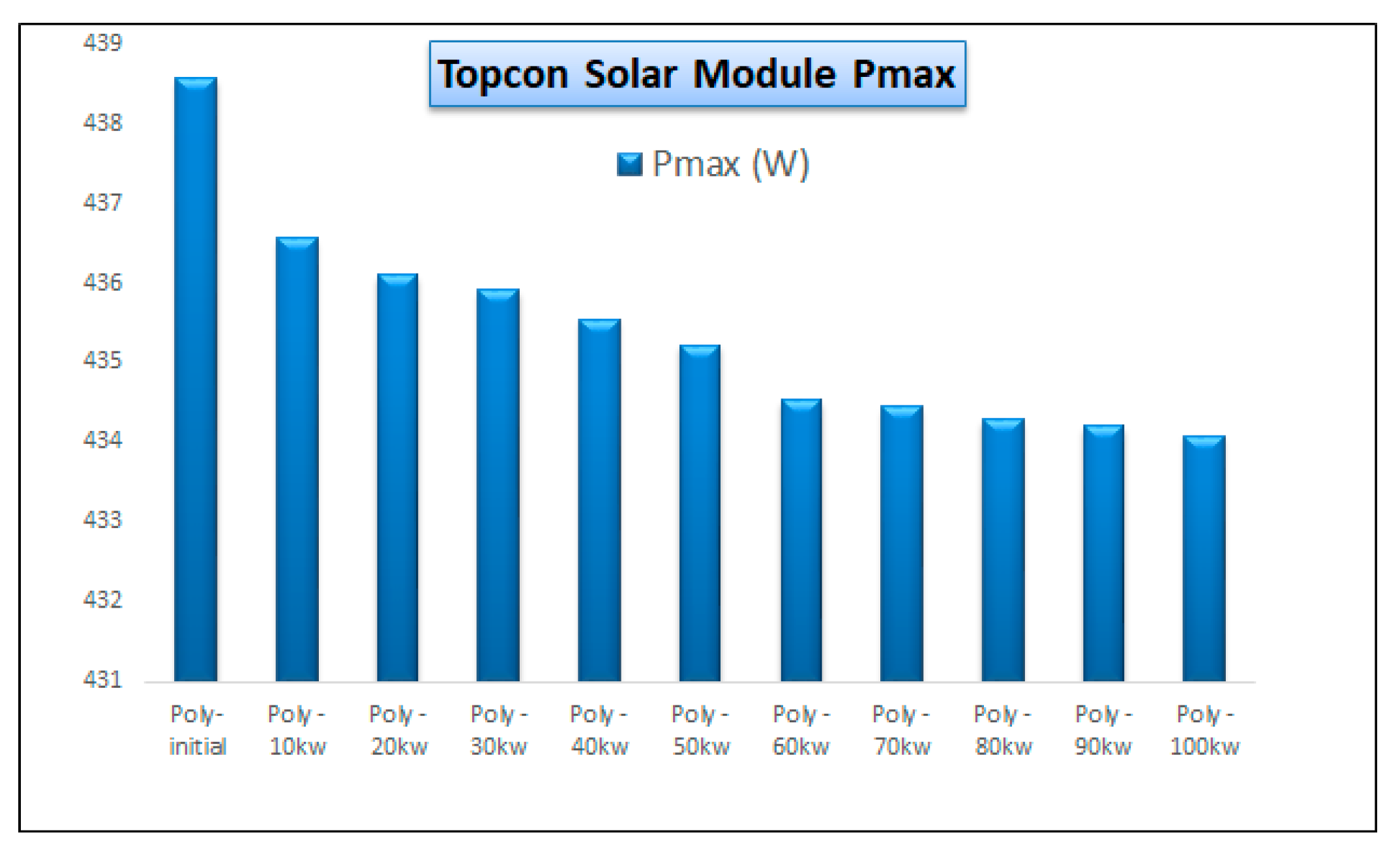

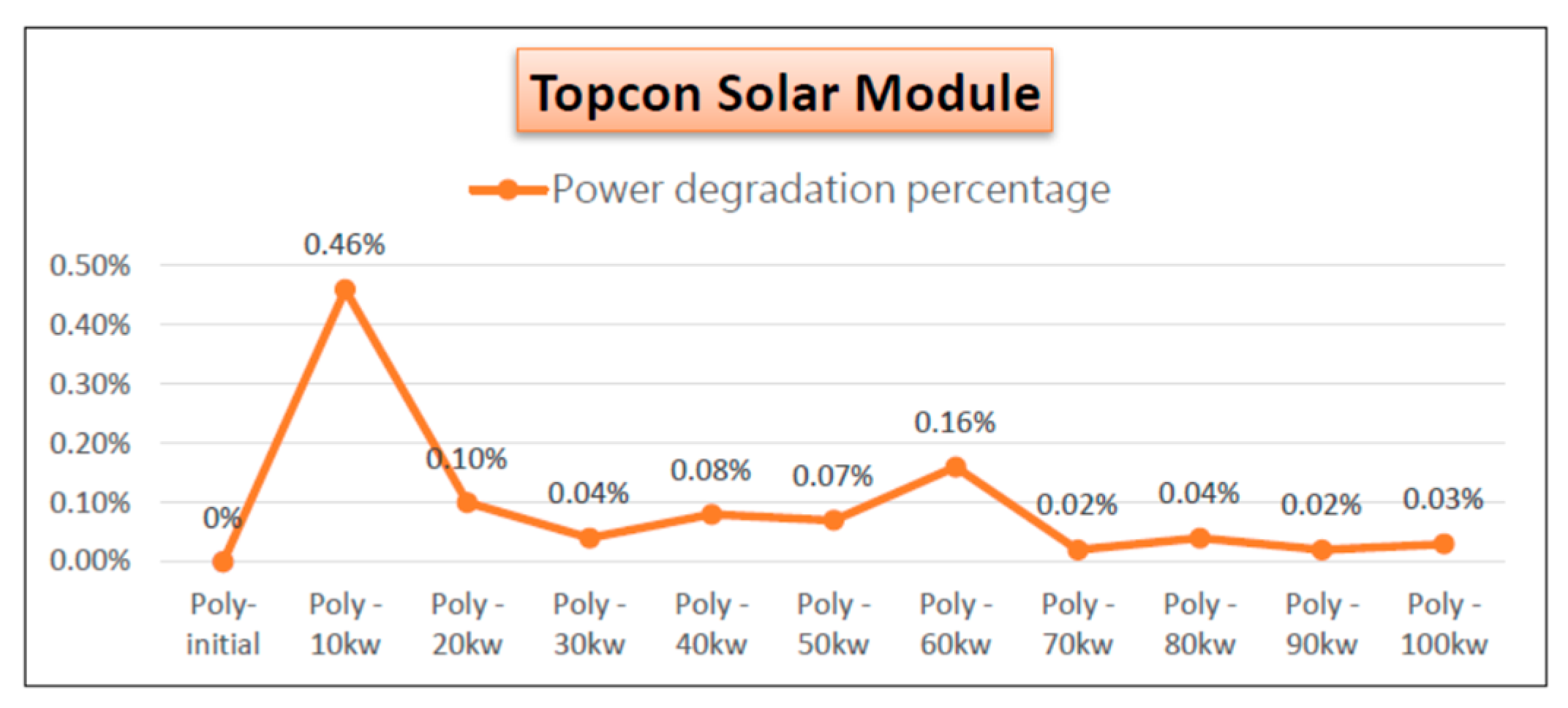

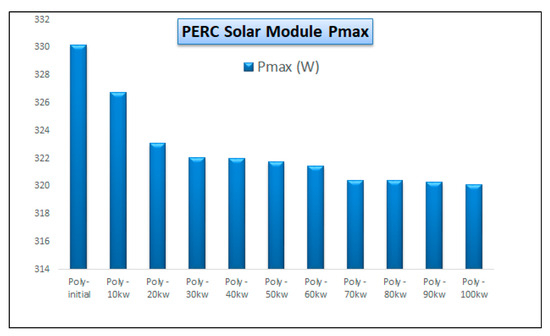

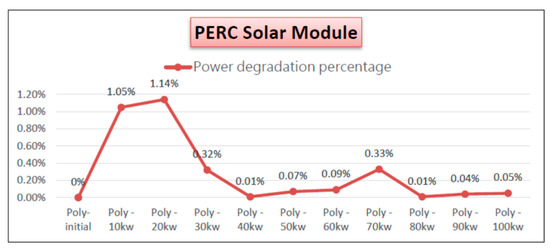

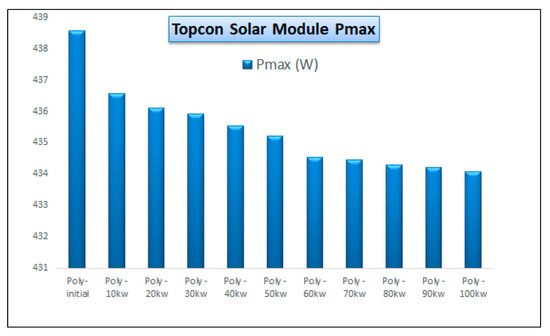

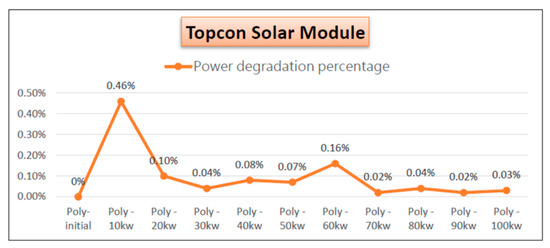

The maximum power (Pmax) of solar modules was calculated after 100 kWh/m2 of irradiance based on the standard formula for testing the maximum power efficiency of solar panels: Imp (current at maximum power) × Vmp (voltage at maximum power) = Pmax (maximum power) [12]. The initial Pmax of the PERC solar module was 330.19 W, and after exposure to 100 kWh/m2 of irradiance, it decreased to 320.13 W, indicating a power degradation of 3.14% (Table 1, Figure 6 and Figure 7). The initial Pmax of the TOPCon solar module was 438.56 W, and after the same irradiance exposure, it decreased to 434.09 W, representing 1.03% power degradation (Table 2, Figure 8 and Figure 9). The TOPCon solar module exhibited superior performance, with only a 1.03% decline in the maximum power, compared with a 3.14% decline of the PERC solar module.

Table 1.

Degradation of PERC solar modules (Adapted from [12]).

Figure 6.

Pmax (W) of PERC solar modules.

Figure 7.

Power degradation percentage of PERC solar modules.

Table 2.

Degradation of TOPCon solar modules.

Figure 8.

Pmax (W) of TOPCon solar modules.

Figure 9.

Power degradation percentage of TOPCon solar modules.

Author Contributions

Conceptualization, T.-J.T. and M.-H.L.; methodology, J.-Y.L. and M.-H.L.; software, J.-Y.L.; validation, T.-J.T., J.-Y.L. and M.-H.L.; formal analysis, T.-J.T. and J.-Y.L.; investigation, T.-J.T. and J.-Y.L.; resources, T.-J.T. and M.-H.L.; data curation, J.-Y.L. and M.-H.L.; writing—original draft preparation, M.-H.L. and J.-Y.L.; writing—review and editing, M.-H.L. and T.-J.T.; visualization, T.-J.T. and M.-H.L.; supervision, T.-J.T. and M.-H.L.; project administration, M.-H.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- El-afifi, M.I. Solar energy: Our future for sustainable energy. Nile J. Commun. Comput. Sci. 2024, 7, 67–83. [Google Scholar] [CrossRef]

- Utility of Solar Energy in Sustainable Development. Available online: https://iipseries.org/assets/docupload/rsl2024FAEC06966F025F5.pdf (accessed on 10 October 2024).

- Bello, K.A.; Nwagwu, G.T.; Emmanuel, A.; Amoko, B.T.; Adediran, A.A.; Elewa, R.L.; Ariyo, W.J.; Ajogu, N.O.; Ibikunle, R.A.; Adeodu, A. A promising renewable source to help nigeria meet its energy demand. In Proceedings of the 2024 International Conference on Science, Engineering and Business for Driving Sustainable Development Goals (SEB4SDG), Omu-Aran, Nigeria, 2–4 April 2024; pp. 1–10. [Google Scholar] [CrossRef]

- Jafarov, E. Potential opportunities for using solar energy: Example of light industrial enterprises. Sci. Collect. «InterConf+» 2024, 44, 372–383. [Google Scholar] [CrossRef]

- Srivastava, S.K. A comparative study on grid energy and renewable solar energy system. Int. J. Humanit. Eng. Sci. Manag. 2023, 4, 14–18. [Google Scholar] [CrossRef]

- Renewable Energy Development Act. Available online: https://reurl.cc/dy3W86 (accessed on 10 October 2024).

- Dullweber, T. High-Efficiency Industrial PERC Solar Cells for Monofacial and Bifacial Applications. In High-Efficient Low-Cost Photovoltaics; Petrova-Koch, V., Hezel, R., Goetzberger, A., Eds.; Springer Series in Optical Sciences; Springer: Cham, Switzerland, 2020; Volume 140, pp. 65–94. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.; Chowdhury, S.; Yi, J. A brief review of passivation materials and process for high efficiency PERC Solar Cell. Trans. Electr. Electron. Mater. 2022, 23, 1–5. [Google Scholar] [CrossRef]

- Kashyap, S.; Madan, J.; Pssssssandey, R.; Sharma, R. Comprehensive Study on the Recent Development of PERC Solar Cell. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; pp. 2542–2546. [Google Scholar] [CrossRef]

- Rahman, R.U.; Khokhar, M.Q.; Hussain, S.Q.; Mehmood, H.; Yousuf, H.; Jony, J.A.; Park, S.; Yi, J. Progress in TOPCon Solar Cell Technology: Investigating Hafnium Oxide Through Simulation. Curr. Appl. Phys. 2024, 63, 96–104. [Google Scholar] [CrossRef]

- Khokhar, M.Q.; Yousuf, H.; Jeong, S.; Kim, S.; Fan, X.; Kim, Y.; Dhungel, S.K.; Yi, J. A Review on p-Type Tunnel Oxide Passivated Contact (TOPCon) Solar Cell. Trans. Electr. Electron. Mater. 2023, 24, 169–177. [Google Scholar] [CrossRef]

- Tsai, N.-C. Discussion on the Characteristics of Single Crystal/Polysilicon Solar Module and Single Crystal/Polysilicon PREC Solar Module. Master’s Thesis, Institute of Electrical Engineering, Kao Yuan University, Kaohsiung City, Taiwan, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).