Molding Characteristics and Impact Strength of Polypropylene with Different Numbers of Recycling Cycles †

Abstract

1. Introduction

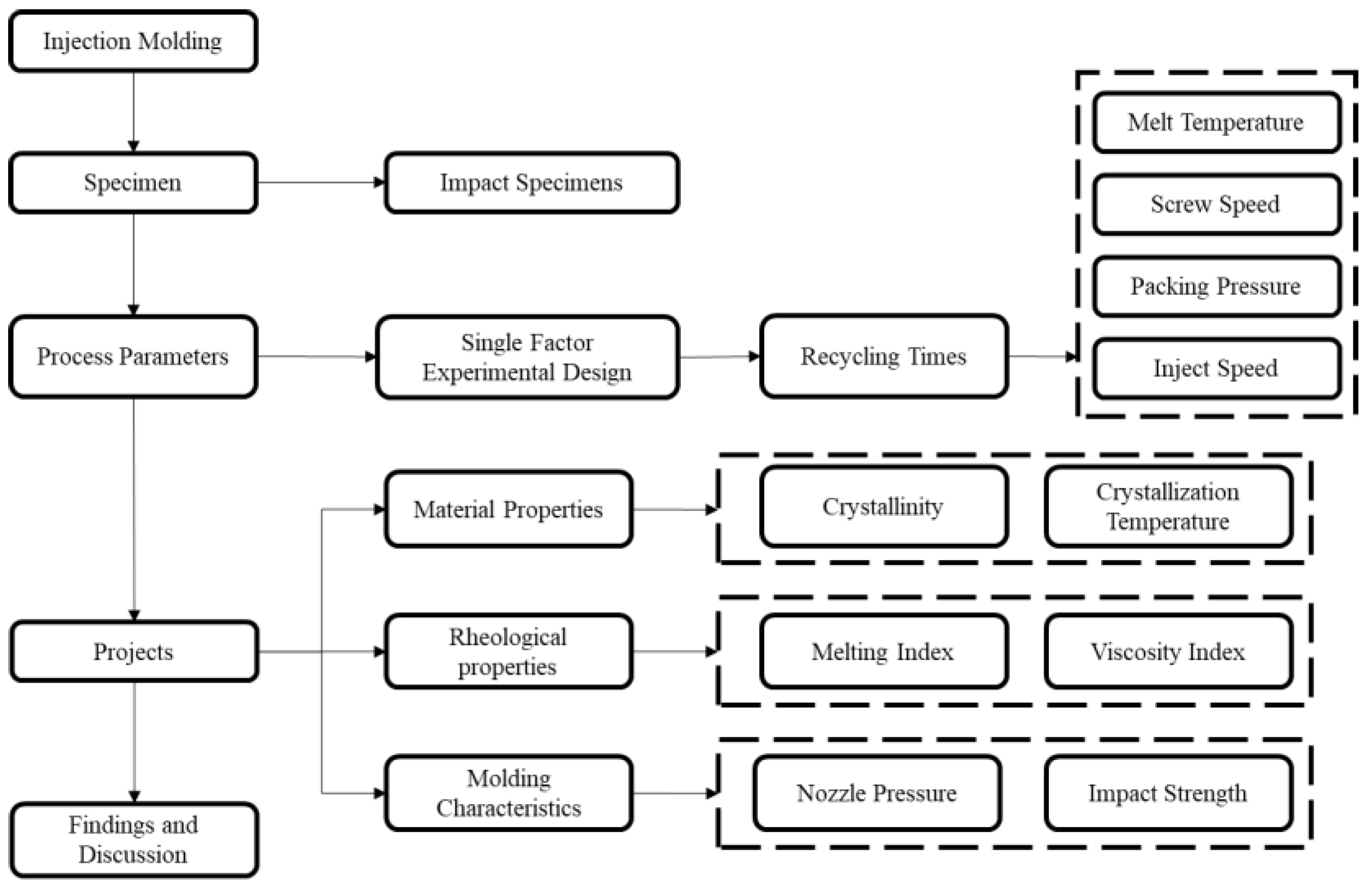

2. Methods

2.1. Material

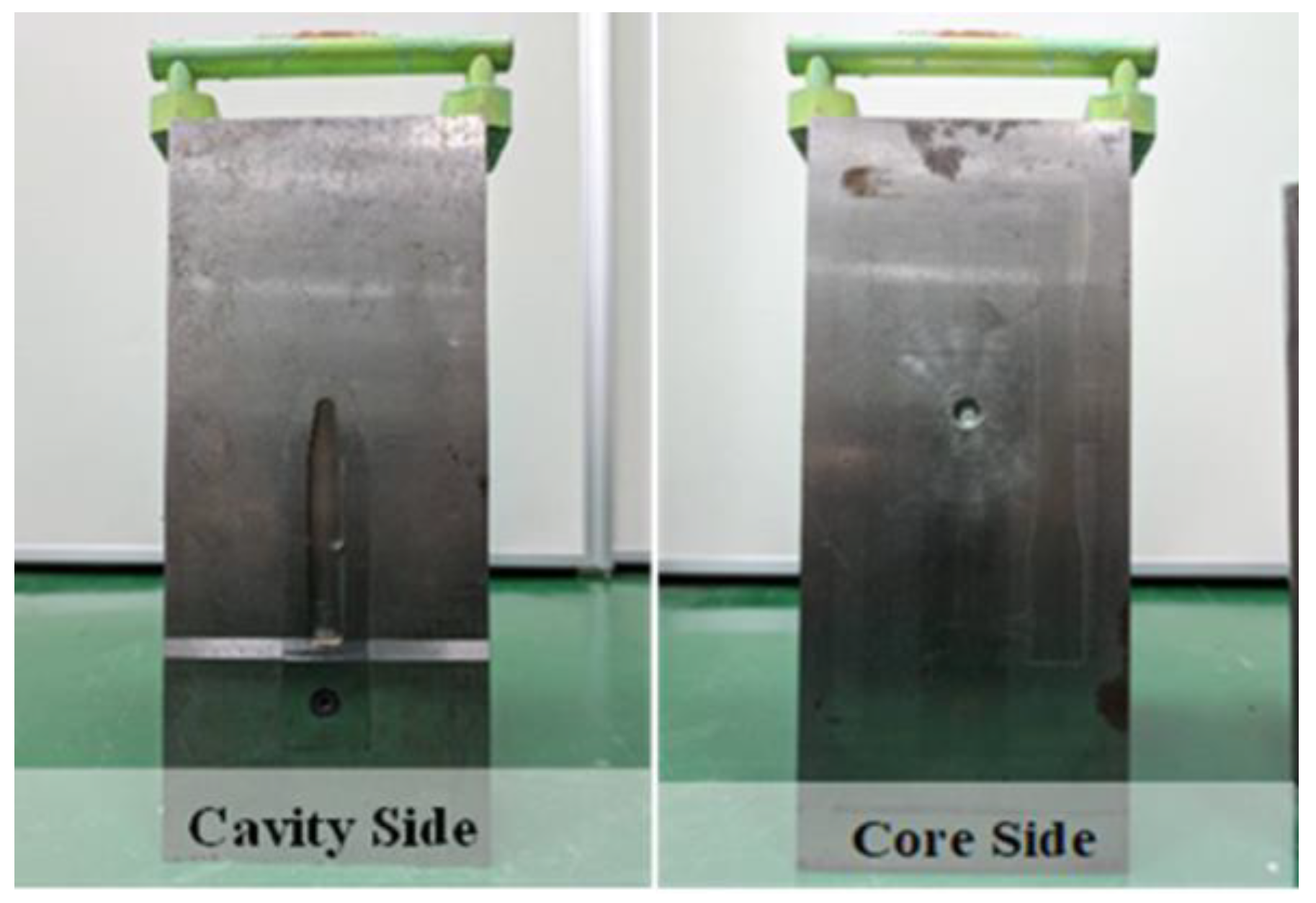

2.2. Mold and Molded Specimen

2.3. Injection Molding Machine

2.4. Plastic Crusher

2.5. Experiments

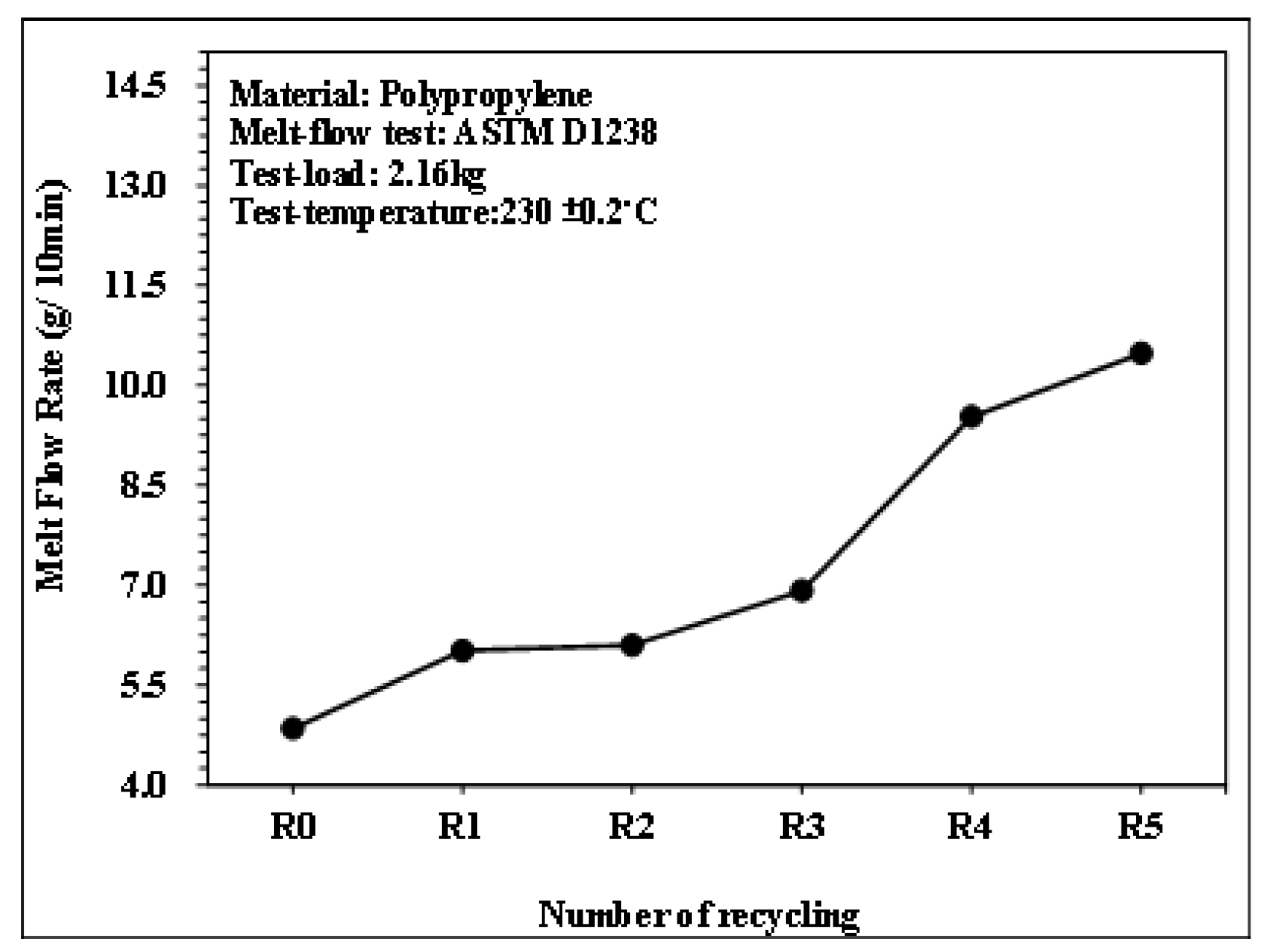

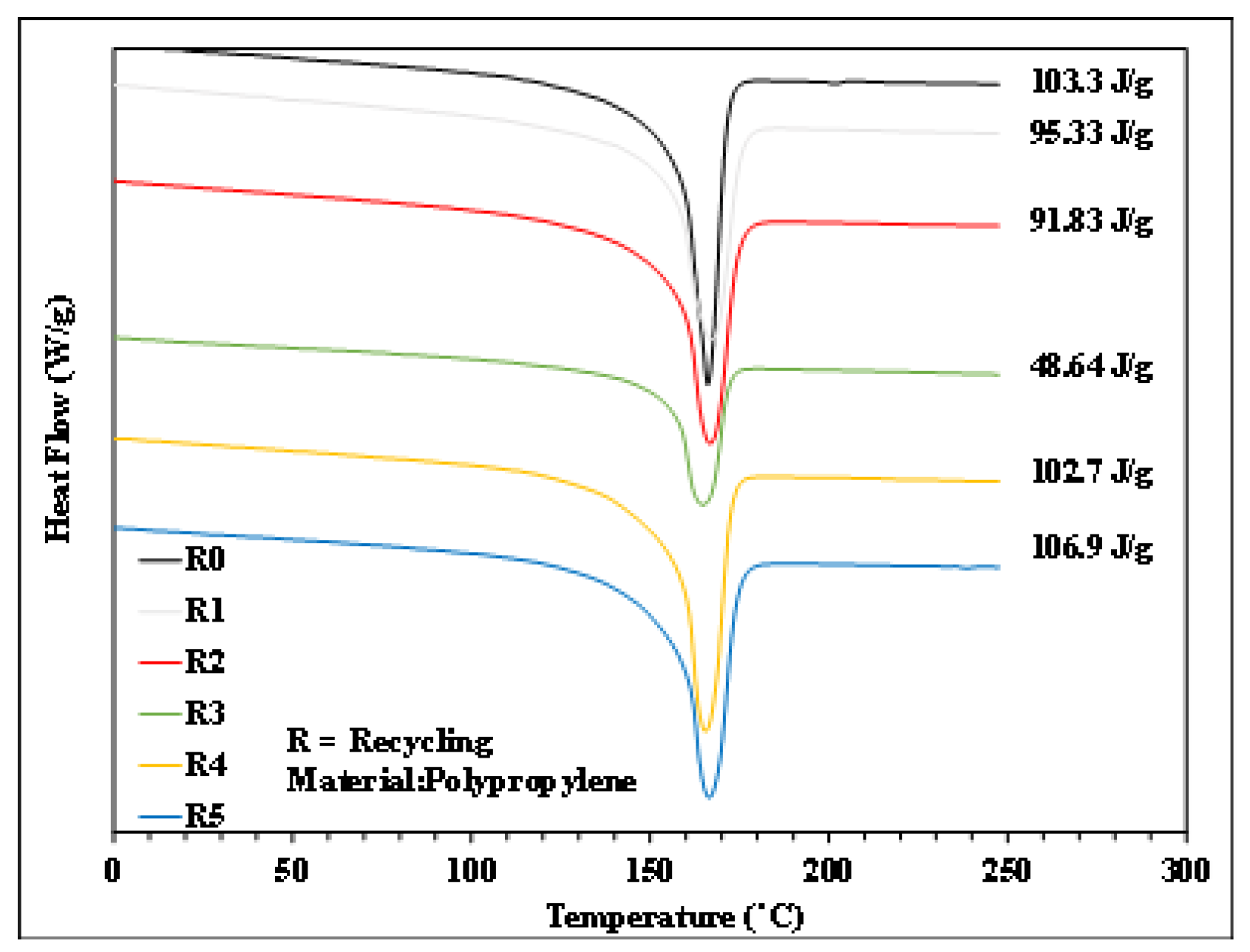

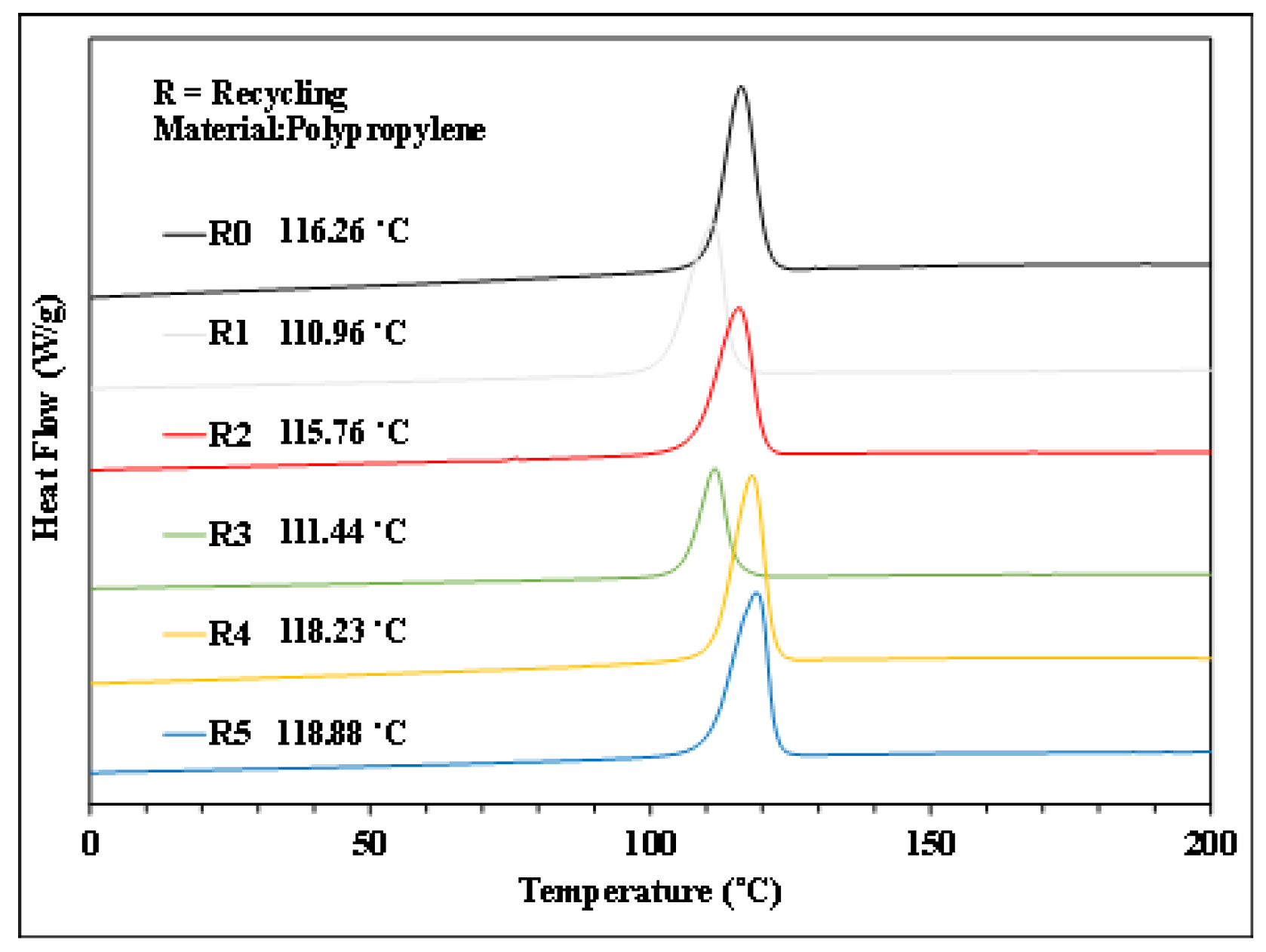

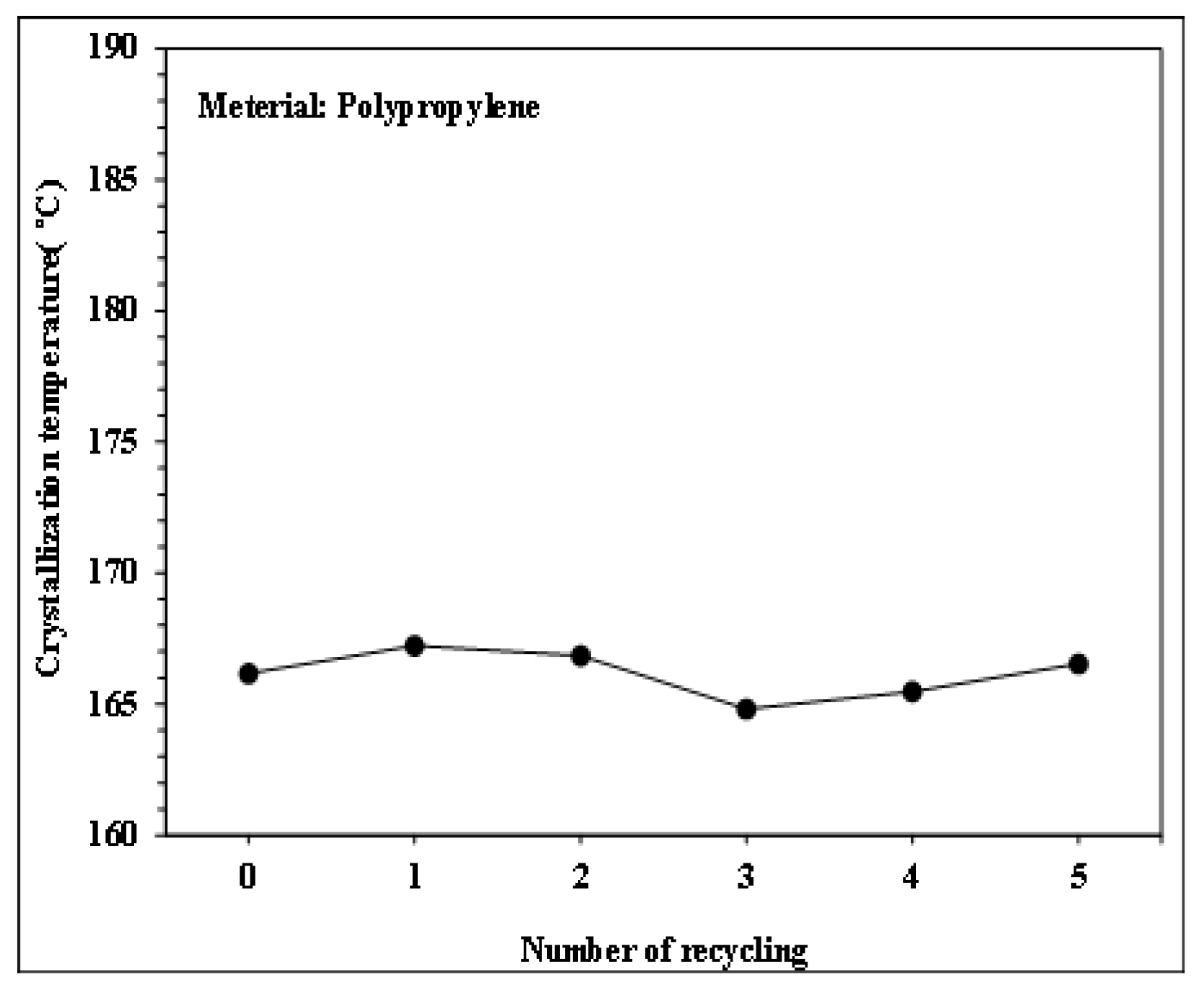

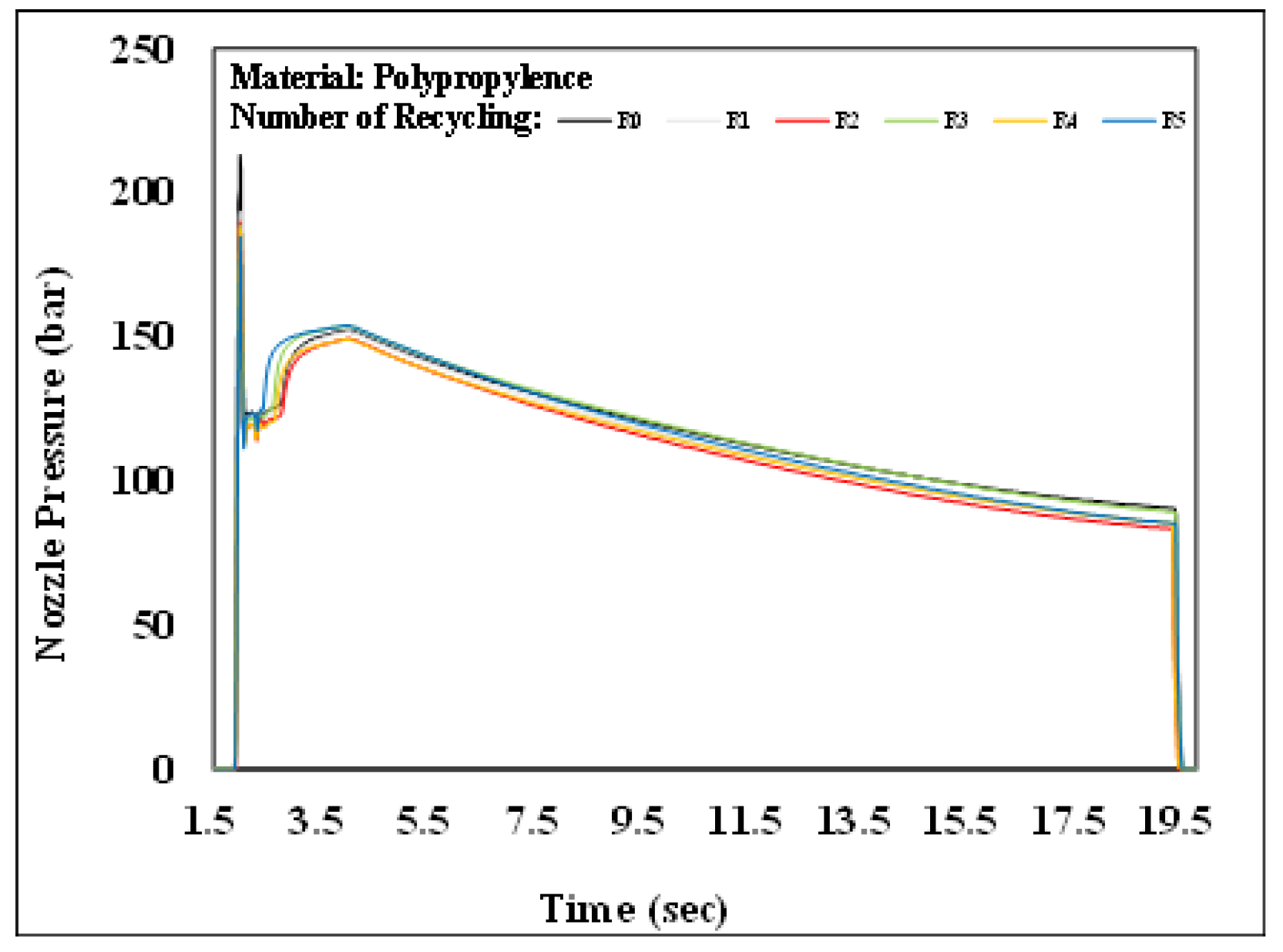

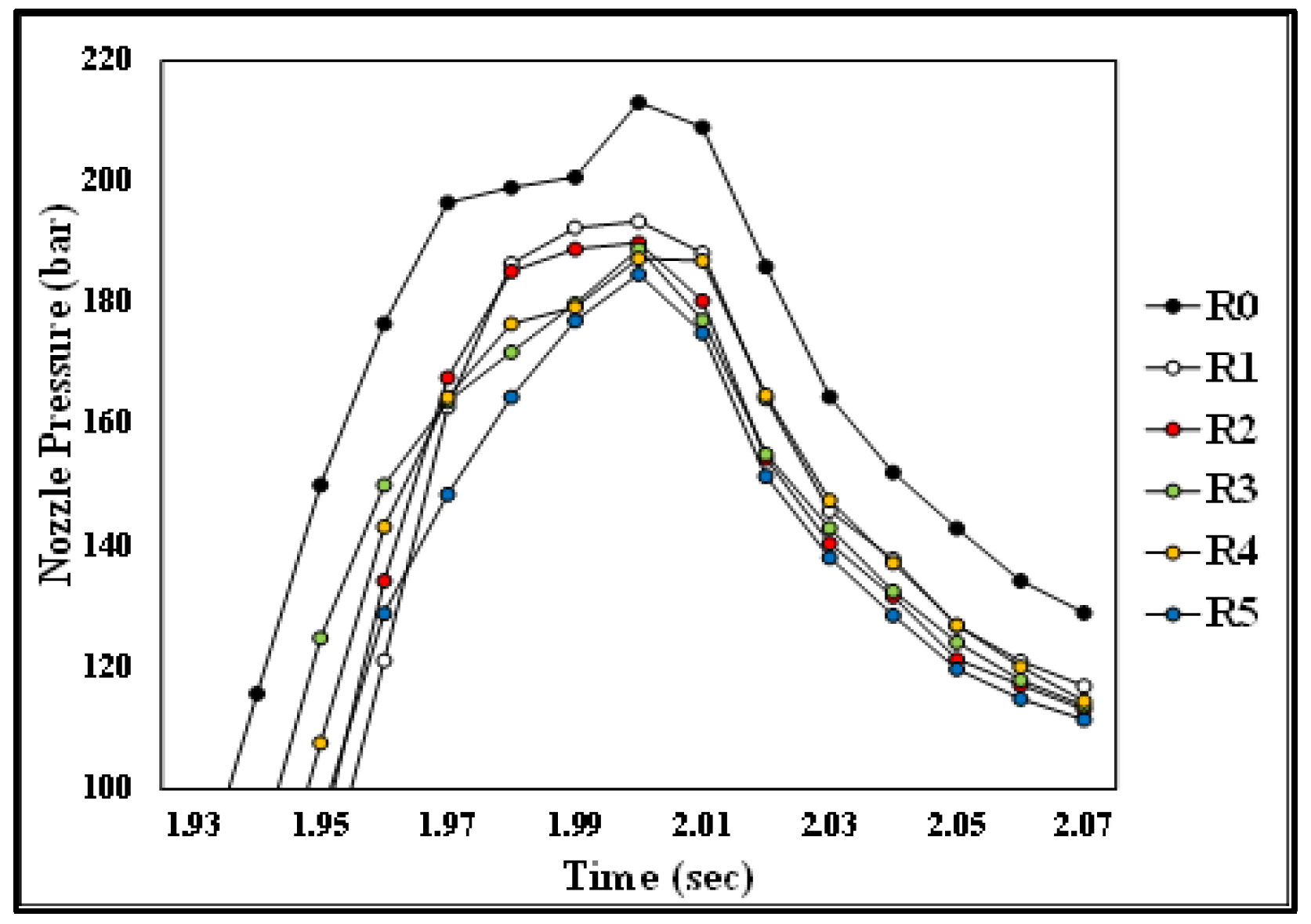

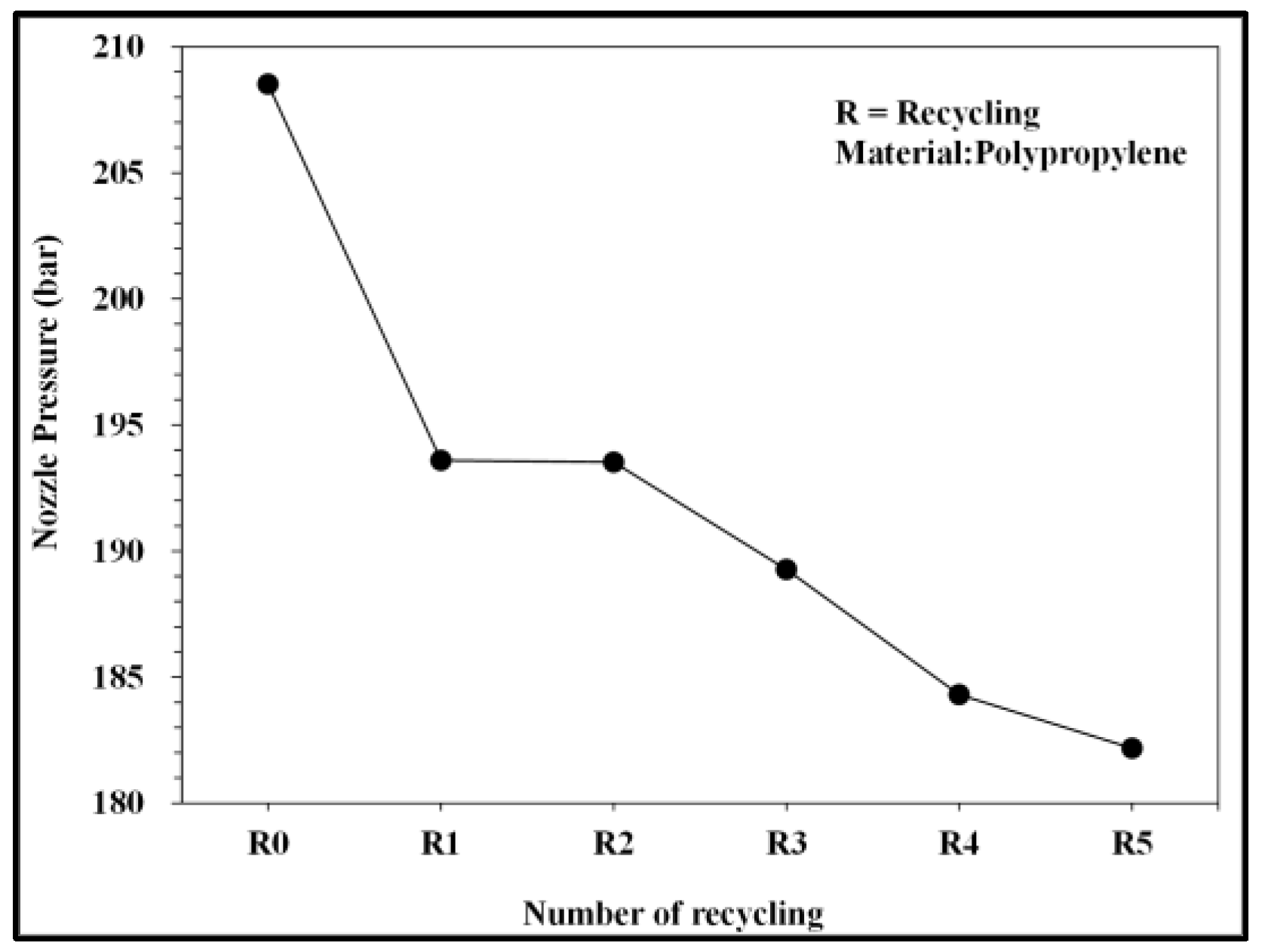

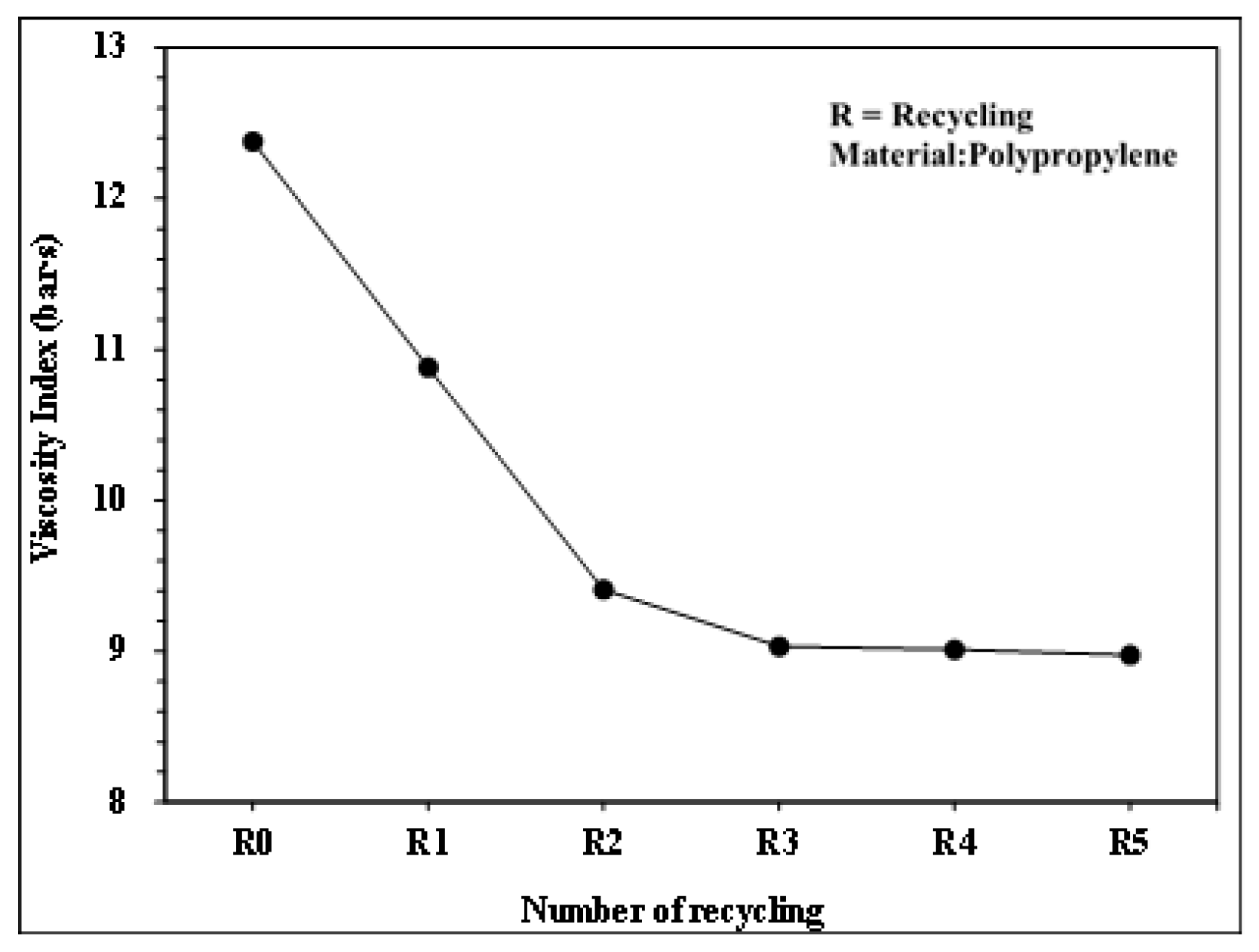

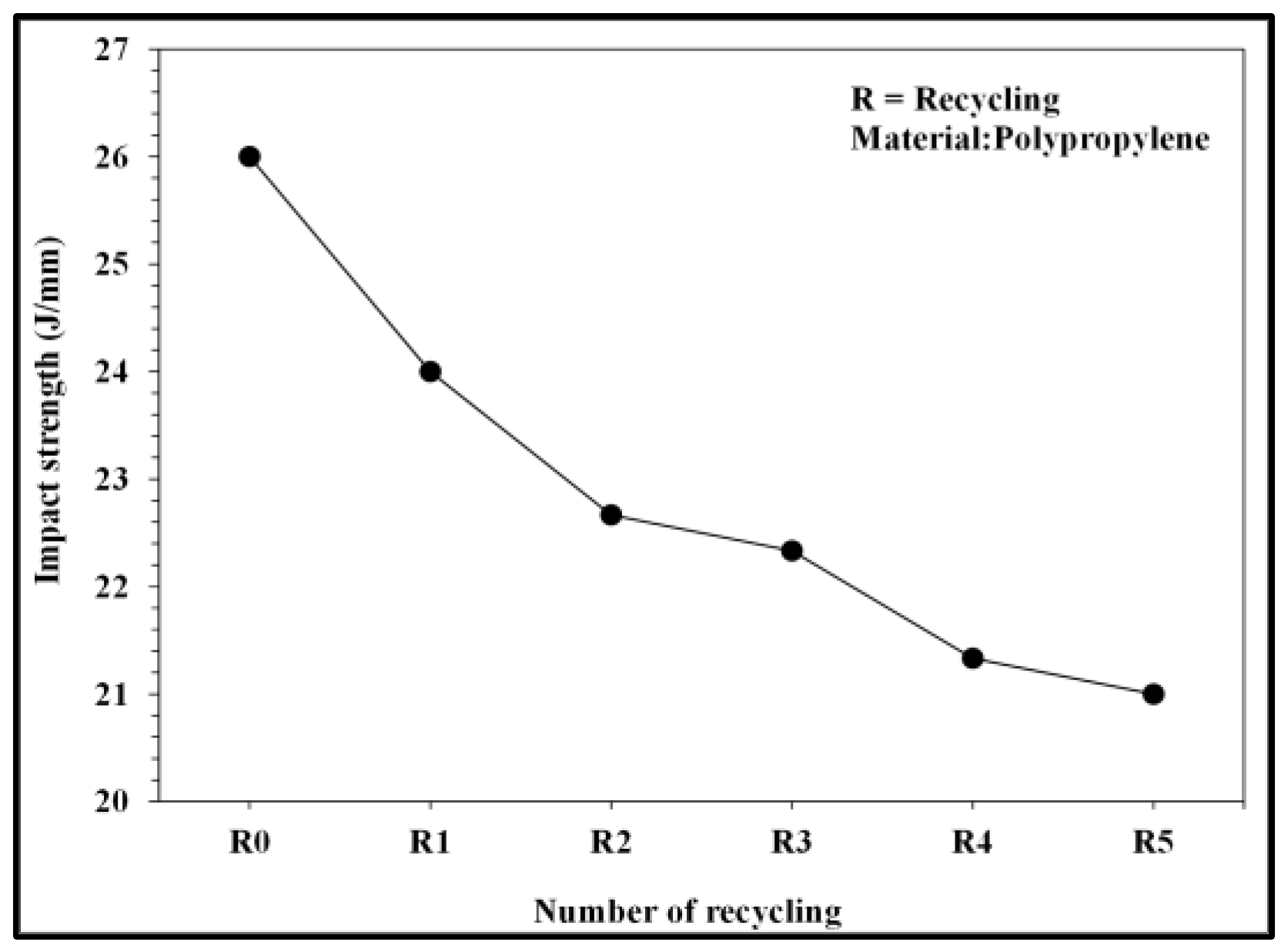

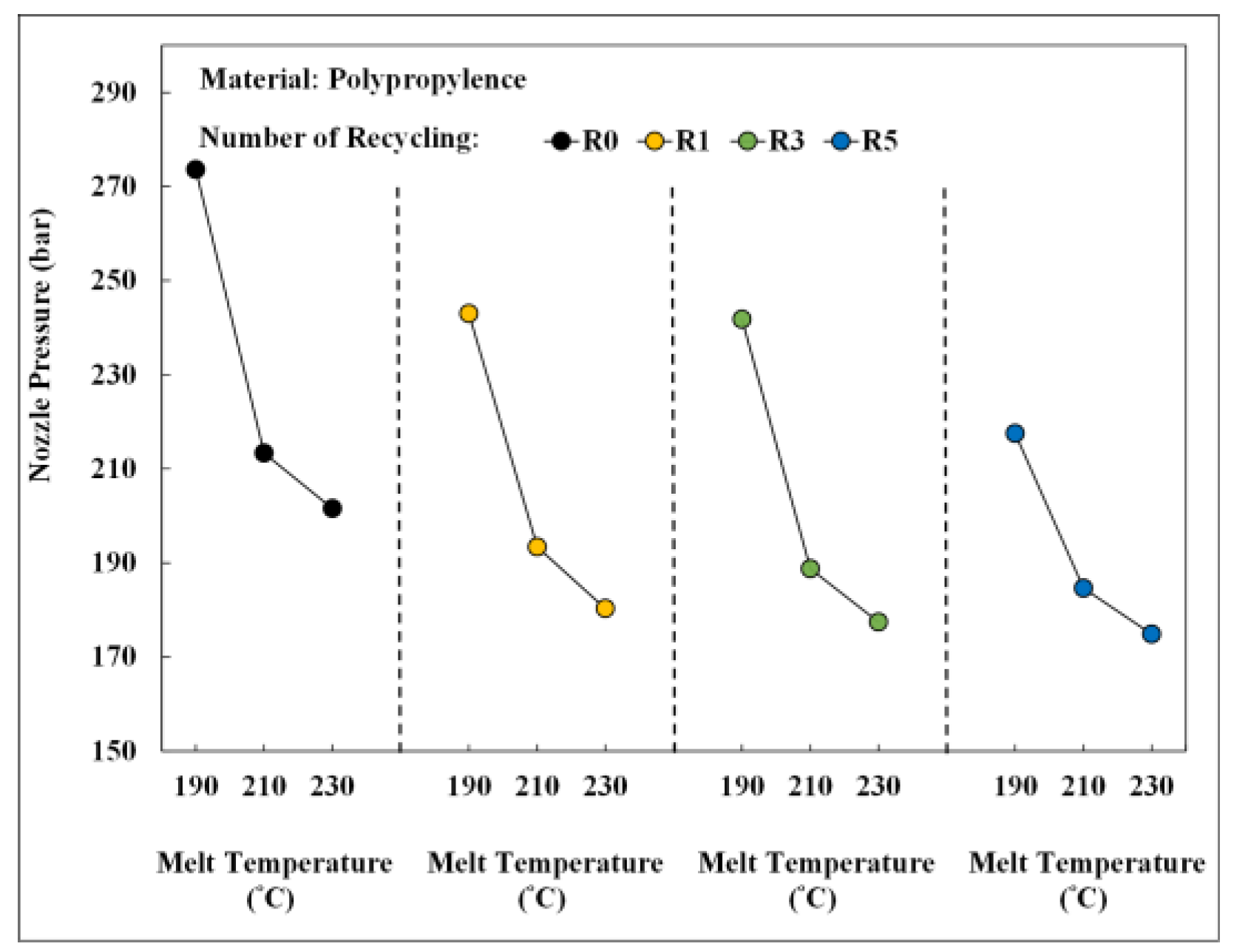

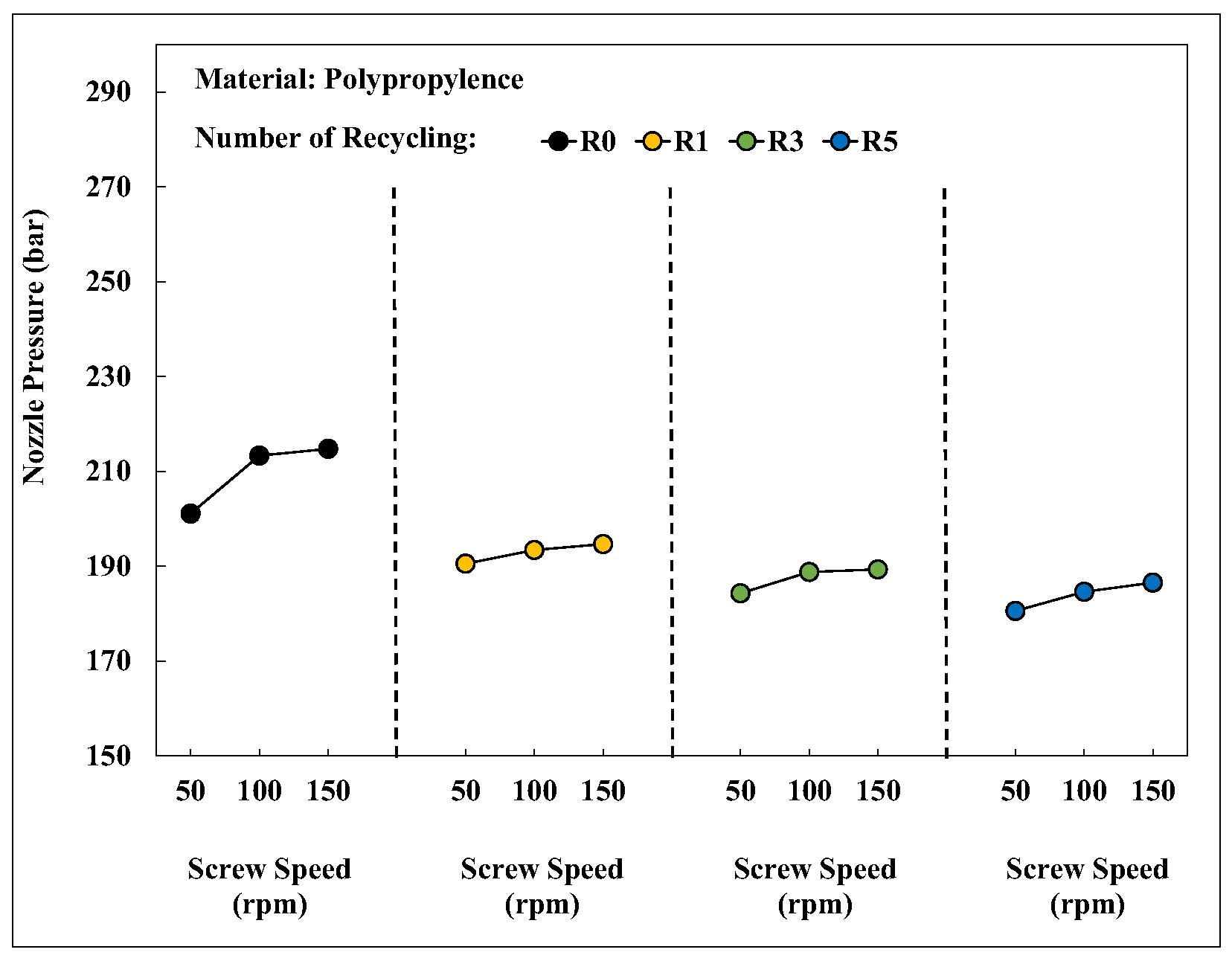

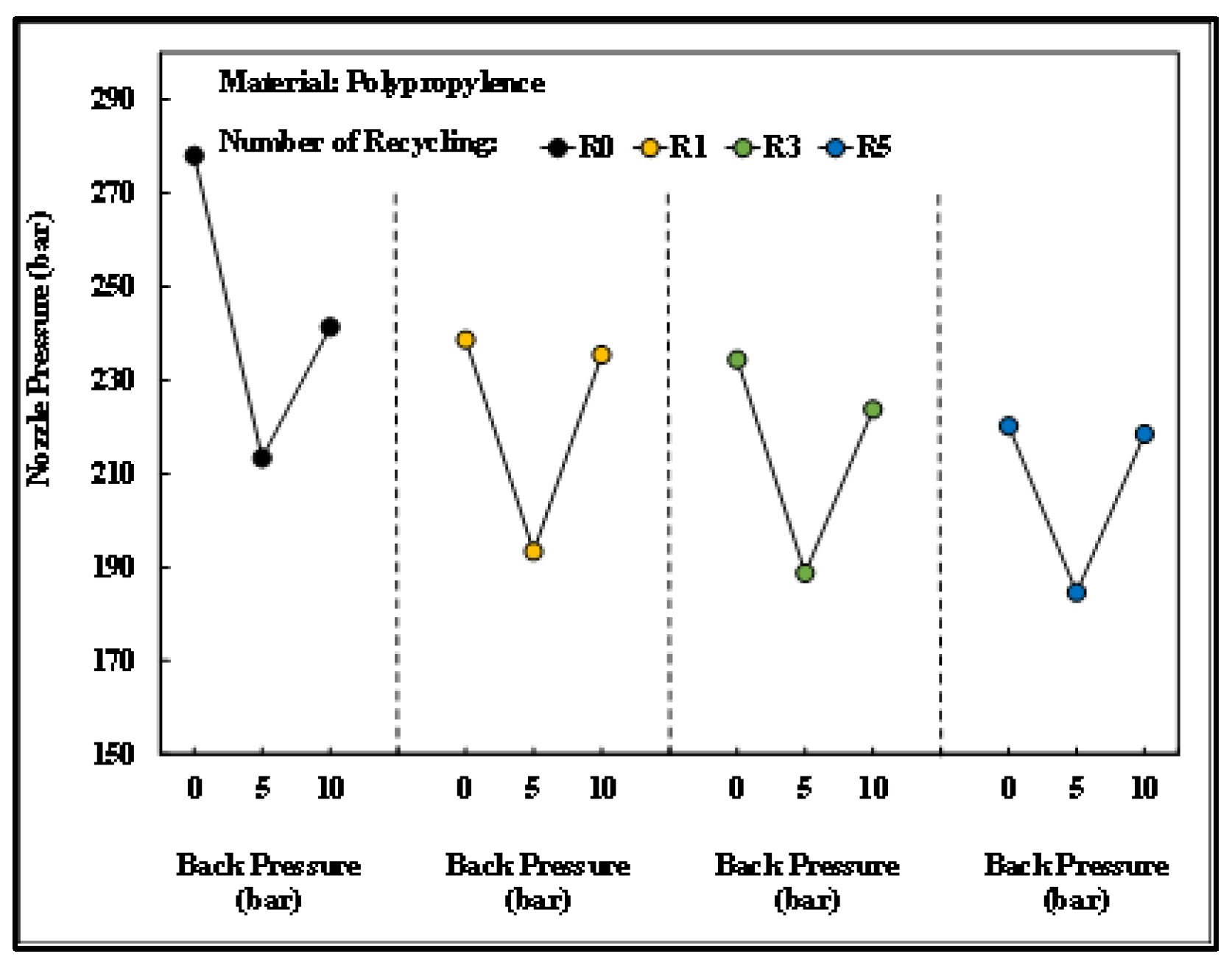

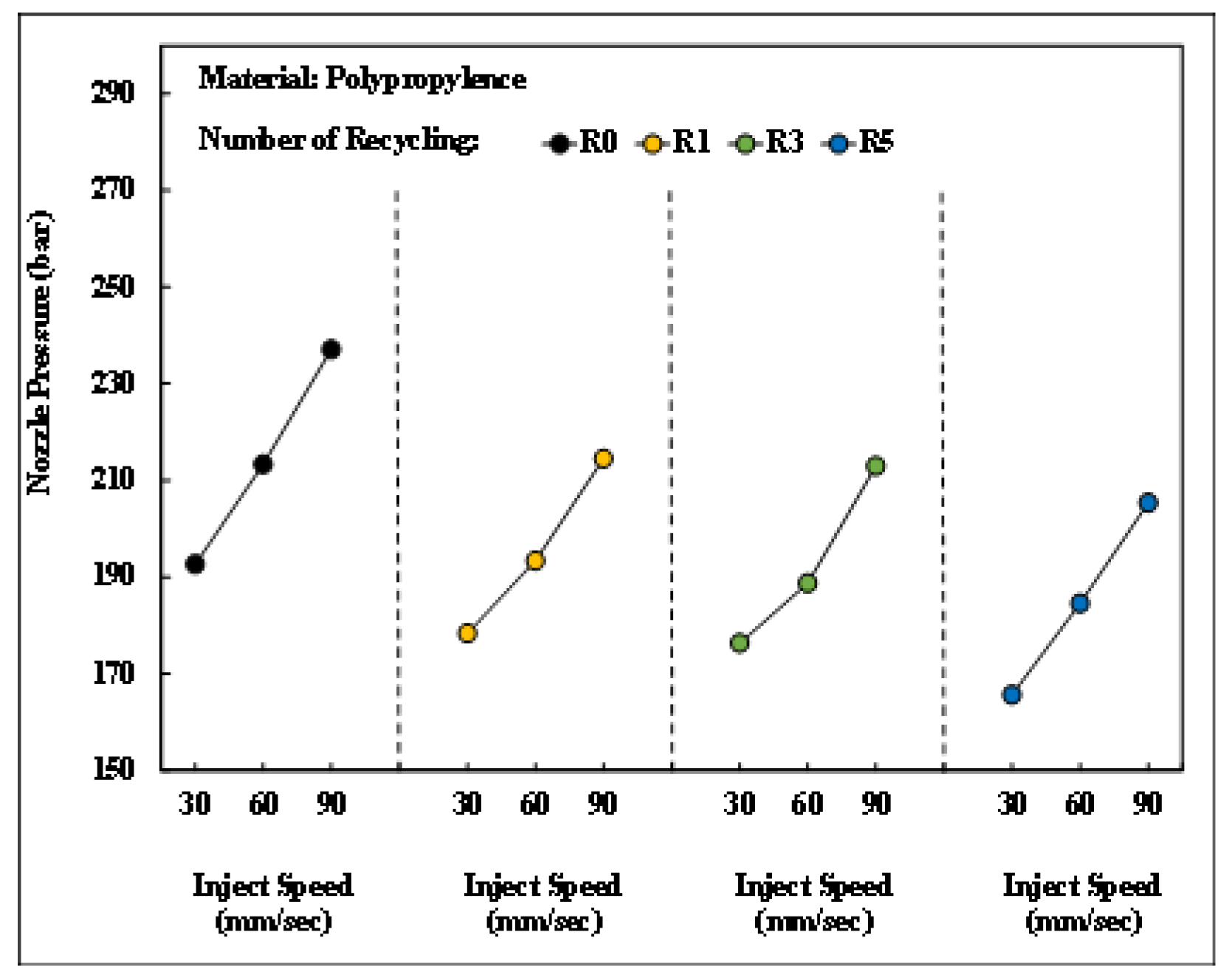

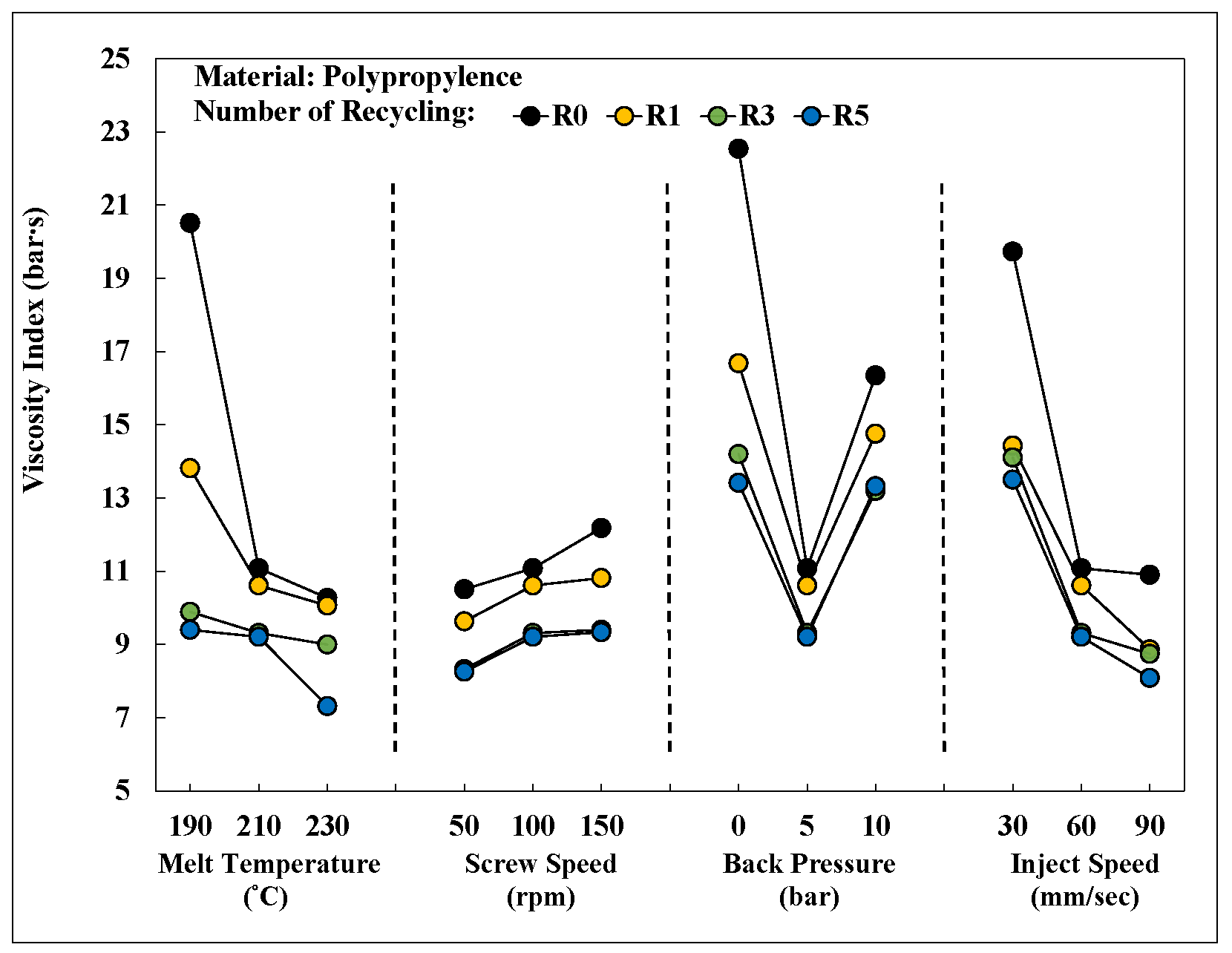

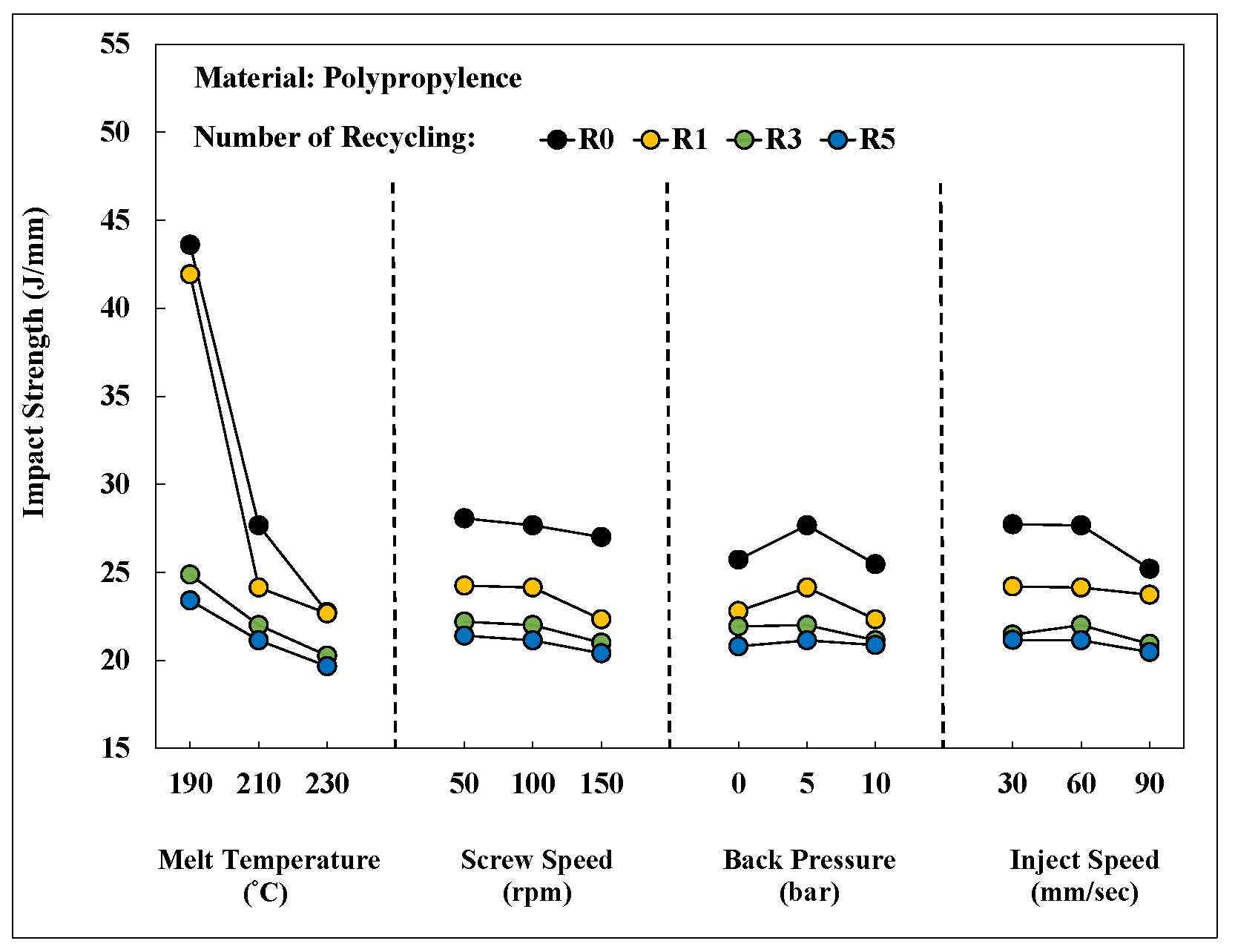

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aurrekoetxea, J.; Sarrionandia, M.A.; Urrutibeascoa, I.; Maspoch, M.L. Effects of recycling on the microstructure and the mechanical properties of isotactic polypropylene. J. Mater. Sci. 2001, 36, 2607–2613. [Google Scholar] [CrossRef]

- Huang, P.-W.; Peng, H.-S. Number of Times Recycled and Its Effect on the Recyclability, Fluidity and Tensile Properties of Polypropylene Injection Molded Parts. Sustainability 2021, 13, 11085. [Google Scholar] [CrossRef]

- Hou, H.-Y. A Study on the Properties of Repeated Recycle Polypropylene. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2010. [Google Scholar]

- Hsu, B.-A. A Study of Relationships Between Physical Properties of Polypropylene Plastic and Its Reprocessed Cycle with Various Blending Ratios. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2017. [Google Scholar]

- Kuo, C.-Y. An Evaluation on the Physical Properties of Recycled High Density Polyethylene Plastic. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2008. [Google Scholar]

- Lin, C.-D. Online Monitoring the Products Quality by Measuring Cavity Pressure During Injection Molding. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2010. [Google Scholar]

- Lu, W.-Y. Application of Cavity Pressure Monitoring Technology to Improve the Differential Shrinkage of Injection Products. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2014. [Google Scholar]

- Liou, G.-Y.; Cheng, F.-J.; Su, W.-J.; Hwang, S.-J.; Peng, H.-S.; Chu, H.-Y. Nozzle Pressure and Clamping Force Based Injection Molding Process Parameter Optimization and Adaptive Process Quality Control. In Proceedings of the 2022 25th International Conference on Mechatronics Technology (ICMT), Kaohsiung, Taiwan, 18–21 November 2022; pp. 1–4. [Google Scholar]

- Liew, K.-F.; Peng, H.-S.; Huang, P.-W.; Su, W.-J. Injection Barrel/Nozzle/Mold-Cavity Scientific Real-Time Sensing and Molding Quality Monitoring for Different Polymer-Material Processes. Sensors 2022, 22, 4792. [Google Scholar] [CrossRef] [PubMed]

- Lee, M.-R. A Cavity Pressure Based Quality Control Method for Injection Molding. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2003. [Google Scholar]

- Su, P.-L. Measurement of Cavity Pressure and Investigation on Manufacturing Characteristics of an Injection Molding Process. J. Chung Chou Inst. Technol. 2002, 16, 117–126. [Google Scholar]

- Tseng, C.-C. A Novel Methodology for Online Quality Monitoring during Injection Molding. Master’s Thesis, National Kaohsiung University of Science and Technology, Kaohsiung, Taiwan, 2018. [Google Scholar]

- Kruppa, S.; Holzinger, G.P. In Situ Characterization of Polymer Melt and Molded Part Quality; KraussMaffei Technologies GmbH: Munich, Germany, 2013. [Google Scholar]

| NO. | Injection Speed (mm/sec) | Back Pressure (bar) | Screw Speed (rpm) | Melt Temperature (°C) |

|---|---|---|---|---|

| 1 | 30 | 5 | 100 | 210 |

| 2 | 60 | 5 | 100 | 210 |

| 3 | 90 | 5 | 100 | 210 |

| 4 | 60 | 0 | 100 | 210 |

| 5 | 60 | 10 | 100 | 210 |

| 6 | 60 | 5 | 50 | 210 |

| 7 | 60 | 5 | 150 | 210 |

| 8 | 60 | 5 | 100 | 190 |

| 9 | 60 | 5 | 100 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, H.-M.; Li, J.-C.; Wang, Y.-K.; Liew, K.-F.; Peng, H.-S. Molding Characteristics and Impact Strength of Polypropylene with Different Numbers of Recycling Cycles. Eng. Proc. 2025, 92, 88. https://doi.org/10.3390/engproc2025092088

Zheng H-M, Li J-C, Wang Y-K, Liew K-F, Peng H-S. Molding Characteristics and Impact Strength of Polypropylene with Different Numbers of Recycling Cycles. Engineering Proceedings. 2025; 92(1):88. https://doi.org/10.3390/engproc2025092088

Chicago/Turabian StyleZheng, Hui-Mei, Jui-Chan Li, Yen-Kai Wang, Kai-Fu Liew, and Hsin-Shu Peng. 2025. "Molding Characteristics and Impact Strength of Polypropylene with Different Numbers of Recycling Cycles" Engineering Proceedings 92, no. 1: 88. https://doi.org/10.3390/engproc2025092088

APA StyleZheng, H.-M., Li, J.-C., Wang, Y.-K., Liew, K.-F., & Peng, H.-S. (2025). Molding Characteristics and Impact Strength of Polypropylene with Different Numbers of Recycling Cycles. Engineering Proceedings, 92(1), 88. https://doi.org/10.3390/engproc2025092088