Abstract

We developed a fully automated key production line for smart manufacturing technologies based on the Internet of Things (IoT) and automatic optical inspection (AOI) to enable efficient and consistent production. The production line consists of seven processing stations: raw materials uploading, groove milling, laser marking, key tooth cutting, deburring, defects inspection, and a discharge station. IoT technology enables real-time monitoring and data transmission through a visual panel that displays the operational status of each station and provides immediate alerts in case of abnormalities for quick intervention. The defects inspection station ensures comprehensive quality checks, automatically stops the production line for detected defects, and prevents defective products from proceeding to subsequent stages. Chronological data are used to support predictive maintenance, production parameter optimization, and energy efficiency improvements. Overall, the system effectively integrates automation, real-time monitoring, and quality control to ensure stable production and high product quality.

1. Introduction

With the rapid development of manufacturing technology, improving product quality and production efficiency has become a key goal. Traditional manufacturing processes are dependent on manual operations, leading to inconsistent quality and limited data integration, which causes various issues such as tool wear, operational inconsistencies, lack of real-time monitoring, and low equipment utilization. These problems reduce product consistency and cost-effectiveness and cause difficulty in resource and waste control. Moreover, traditional production lines are slow to respond to rapid changes in market demand, hindering flexible production and real-time adjustments.

To address these challenges, smart manufacturing technology is proposed. Smart manufacturing integrates the IIoT (IIoT), cloud computing, big data analytics, and automation technology to construct flexible, efficient, and stable production lines. Smart manufacturing enables real-time production monitoring, reduces defect rates, and improves energy efficiency. The related technologies are integrated with production equipment to autonomously detect and respond to abnormalities in production. Scheduling and production plans are optimized through data-driven decision-making, ultimately enhancing product quality, reducing production costs, minimizing material waste, and maintaining competitiveness in the market.

Peres et al. [1] proposed a smart manufacturing framework that highlights the role of Industrial Artificial Intelligence (AI) in enhancing the connectivity between production machines and final products, thereby enabling intelligent optimization of manufacturing processes. Kusiak [2] outlined the six foundational pillars of smart manufacturing—manufacturing technologies and processes, materials, data, predictive engineering, sustainability, and resource sharing and networking—providing essential guidelines for the design of intelligent production systems. Wang et al. [3] introduced a smart factory architecture for the food processing industry by integrating the Industrial Internet of Things (IIoT) and cloud computing, demonstrating significant improvements in production efficiency and energy consumption. Oesterreich and Teuteberg [4] investigated the implementation of smart factory technologies in the automotive sector, showcasing the advantages of digital twin technology for real-time monitoring and production line optimization. Lee et al. [5] applied machine learning techniques to predictive maintenance, aiming to reduce equipment downtime and enhance the operational efficiency of manufacturing lines. Lastly, Nagorny et al. [6] explored the role of big data analytics in smart manufacturing, helping manufacturers identify production bottlenecks, streamline workflows, and improve overall productivity.

This study aims to establish a fully automated key production line, incorporating advanced smart manufacturing technologies to improve production efficiency and product quality. By utilizing technologies such as automated optical inspection (AOI) and the Industrial IoT (IIoT), the production line can be fully automated for real-time quality control and an efficient and intelligent manufacturing system.

2. Fully Automated Key Production Line

The fully automated key production line is applied from raw material feeding to product output. This production line includes seven key processing stations, with each responsible for a different step to ensure the quality and precision of the keys throughout the production process. These seven stations demonstrate examples of the application of smart manufacturing technology in fully automated production.

Chao and Lee [7] proposed a fully automated key production line, including six original processing stations: raw materials uploading, groove milling, laser marking, key tooth cutting, deburring, and a discharge station. They designed the defects inspection station for quality checks and a visual panel to display the manufacturing status via the IoT. The manufacturing data included smart meter data, work order details, and operator information and were transmitted to the cloud using IoT technology.

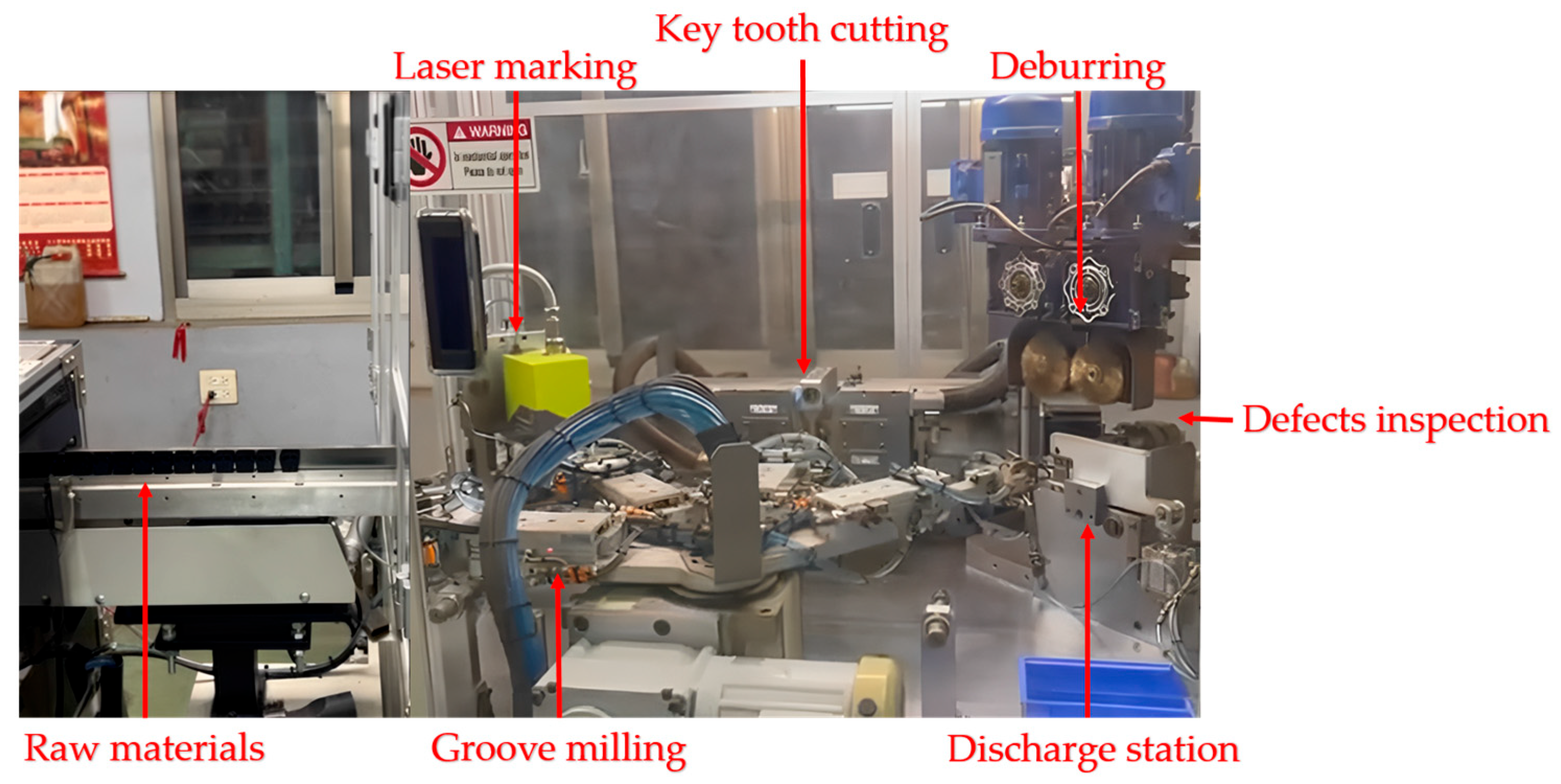

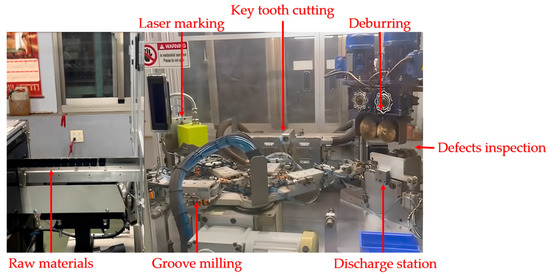

We have added a defects inspection station after the deburring station to further enhance quality control in this study. The new station identified remaining defects after deburring to meet the required quality standards before proceeding to the discharge station. The structure of the key processing is shown in Figure 1, which includes raw materials uploading, groove milling, laser marking, key tooth cutting, deburring, defects inspection, and the discharge station. The operational details of these seven stations are introduced in the following sections with the detailed processing of the AOI defects inspection station.

Figure 1.

Key production line and its process.

Feeding is the first step in the production process. Raw materials are fed into the production line through automated conveyors, with one key processing them every 2 s. This initial inspection and classification must meet the standards for subsequent processing. The design of feeding one key at a time maintains production rhythm and precision. The degree of automation in the feeding station is crucial for the smooth progress of the entire production process, ensuring quality from the very start.

In the groove milling process, the key blank is fixed on the milling machine’s workbench for slot milling. To ensure processing stability and precision, a specially designed jig is used to accurately position and secure the key, preventing displacement during processing. This fixture is designed to hold each angle and position of the key accurately, ensuring no movement during the process. In the milling of the groove, the feed rate and milling speed need to be precisely adjusted to produce consistent processing results and ensure that each slot meets the designated dimensions. Operators also periodically check the operation of the milling equipment to ensure it is functioning properly.

The laser marking station is responsible for engraving serial numbers and other identification information on the key surface. These markings are crucial for product traceability and quality management. High-precision laser equipment marks the keys, ensuring the depth and clarity of the markings meet design standards. Accurate positioning and fixation are crucial in the marking process to prevent blurring or errors caused by vibrations. The laser power and marking speed must be precisely controlled to avoid damaging the key surface and keep each marking visible.

Cutting the key teeth is another critical processing step. In this step, high-precision cutting tools are used to cut the key’s teeth, ensuring that the shape and dimensions of each tooth meet design specifications. In the cutting process, the feed rate and cutting speed of the tool must be finely adjusted to ensure stability and consistency. The stability of the working environment must also be maintained to prevent dimensional errors caused by external disturbances. Tools need to be regularly checked and replaced to prevent wear from affecting product quality and to ensure the accuracy and precision of each cut.

The deburring process is designed to remove burrs produced during previous processing steps and enhance product quality and user safety. The deburring equipment is equipped with rotary polishing tools that precisely treat every edge of the key and make a smooth surface free of sharp edges. The speed and feed path of the polishing tools are adjusted according to different processing requirements to ensure consistent deburring effects. It is also important to monitor the wear of the polishing tools to ensure they are always in optimal condition, achieving high-quality deburring.

After all the processing steps, the keys enter the discharging station. Products that pass quality inspection are automatically sorted and packaged, ready for storage or transport to the next phase. The automation of the discharging station improves the efficiency of output while reducing manual intervention and ensures a smooth and efficient production process. A final visual inspection is conducted before discharge to ensure that all products meet quality standards before packaging.

The AOI defect inspection station is responsible for quality monitoring of products from the previous six processing stations, ensuring that each step meets design standards. The AOI system uses AOI technology combined with high-resolution cameras to accurately detect defects such as dimensional deviations, surface flaws, and burrs. If a product is found to be non-conforming (e.g., exceeding tolerance limits), the system automatically alarms and marks the product, while stopping the production line to prevent defective products from advancing to subsequent stages. Additionally, the AOI system provides detailed reports on different defect types to assist operators in identifying the root causes of issues and making timely adjustments to production. These functions ensure high product quality and consistency, significantly reducing the occurrence of defective products.

The integration and automated operation of these processing stations ensure the fully automated key production line that consistently and efficiently produces products that meet high quality and precision standards from raw materials to finished products.

3. AOI Defects Inspection Station

The AOI defects inspection station plays a crucial role in the fully automated key production line. Utilizing IoT technology, the station ensures that the system automatically stops the production line and displays an error message on the visual panel for operator intervention and repair. This integration allows for real-time monitoring and prompt handling of defects, minimizing the impact on subsequent production steps. The station’s primary task is to conduct comprehensive quality checks on the keys processed at each station, ensuring that each step meets design requirements and promptly providing feedback on production issues. A detailed explanation of the potential errors at each processing station and their causes is as follows.

At the groove milling station, common errors include insufficient groove depth, irregular groove shape, or misalignment. These errors are caused by tool wear, improper key fixation by the jig, or incorrect feed rate. Improper jig design or incorrect positioning of the key can directly affect the precision of groove milling. At the laser marking station, potential errors occur for unclear markings, misaligned positions, or incorrect marking depth. These issues are caused by improper laser power, incorrect placement of the key, or vibration during the process affecting the accuracy of positioning. Environmental factors, such as insufficient lighting or unstable vibrations during the marking process, can impact marking quality. At the key tooth cutting station, potential errors such as overcutting or undercutting of grooves, irregular shapes, or incorrect tooth spacing occur. These issues are usually caused by tool wear, incorrect feed or cutting speed settings, or improper positioning of the key blank during processing. Strict monitoring of tool wear is essential to maintain the accuracy of the tooth cutting. At the deburring station, errors occur due to incomplete burr removal, rough edges, or scratches on the surface. These issues are related to inappropriate operational parameters (e.g., rotational speed) of the polishing tools, excessive wear of the polishing tools, or unstable clamping of the key during deburring, leading to uneven processing. At the discharging station, incorrect product classification, packaging errors, or jammed products are common issues, causing the production line to stop. These problems are often caused by malfunctioning conveyor equipment, sensors failing to accurately detect product positions, or disorganized product stacking during packaging.

At the AOI defects inspection station, possible issues include the failure to detect defects accurately, blurred images, or incorrect quality assessments. These errors are caused by inappropriate camera focus, uneven lighting causing insufficient or excessive illumination, or inaccurate positioning. When the AOI system detects non-conforming products, it automatically marks and alerts, and, if necessary, it stops the entire production line to ensure that defective products do not proceed to subsequent processes. Additionally, the AOI station utilizes IoT technology to transmit real-time data to a cloud-based system to monitor the production line status. When an issue is detected, the AOI system stops the production line and displays an error message on the visual panel for operator intervention and repair. This ensures prompt addressing of defects and minimizing the impact on subsequent production steps.

The AOI defects inspection station is critical to the stable operation of the entire production line. Its inspection results help operators address current issues promptly and optimize production parameters through data analysis. By thoroughly analyzing the errors at each processing station, the system effectively reduces the defect rate during production, enhancing the overall quality of the products.

The integration and automated operation of these processing stations ensure that the fully automated key production line consistently and efficiently manufactures products that meet high-quality and high-precision standards through full automation and intelligence from raw materials to finished products.

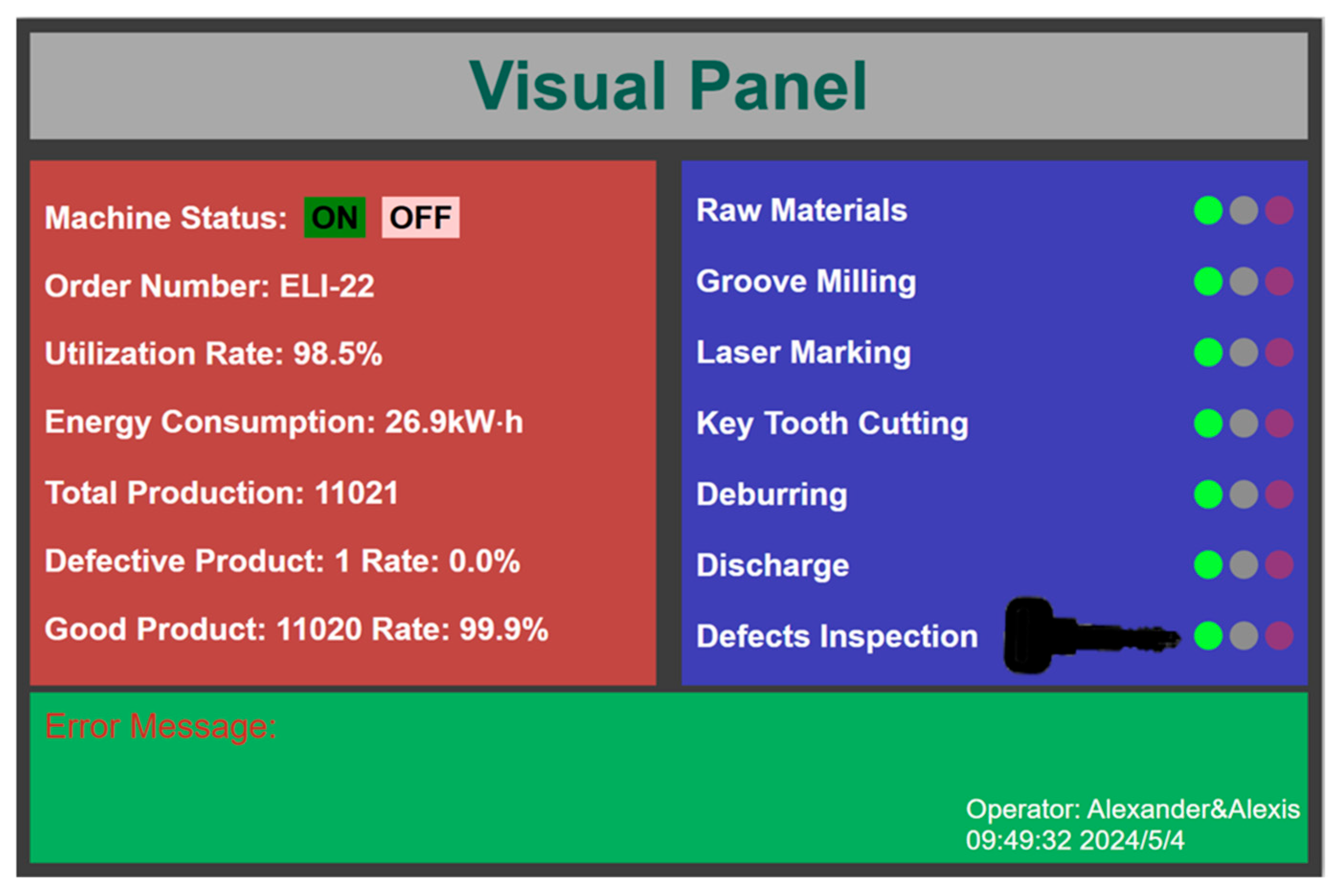

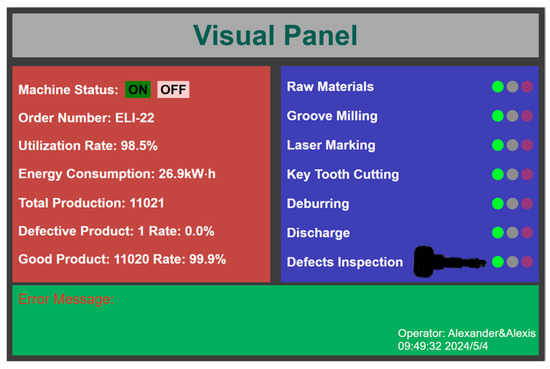

4. Visual Panel of Production Line

In the fully automated key production line, the visual panel of the production line is essential in realizing intelligent production management. Through IoT technology, processing information is automatically transmitted to a cloud database and displayed on visual panels at both remote and local controllers. These statuses include operator name, production part number, work order status, messages from each station (such as operating normally, waiting, or error messages), production quantity, production time, yield rate, and energy consumption. The visual panel integrates multiple key production indicators and provides an intuitive and easy-to-understand interface (Figure 2). The status of each station, including “Feeding Station”, “Groove Milling Station”, “Laser Marking Station”, “Key Tooth Cutting Station”, “Deburring Station”, “AOI Defects Inspection Station”, and “Discharge Station”, is displayed in three colors: “ON” (green), “WAITING” (yellow), and “ERROR” (red), allowing operators to quickly interpret the machine status.

Figure 2.

The visual panel of the production line.

The energy consumption data displayed on the visual panel enable the understanding of the energy usage of each processing station, identifying areas of energy waste, and optimizing the production plan. The real-time display of yield rate and production quantity also allows operators to promptly adjust production parameters to maintain a high level of production quality. The display of work-order status and production part numbers helps trace the production process, ensuring that the information of each production batch is recorded accurately. Furthermore, when a station experiences an anomaly (e.g., frequent error messages), the panel immediately displays the specific error cause, and the equipment stops immediately to prevent further damage and allow operators to quickly troubleshoot and solve the problem. The recording and analysis of historical data are used to automatically generate production reports, providing management with effective decision support, such as the need for preventive maintenance of equipment, thereby avoiding unnecessary downtime. The visual panel plays a dual role in monitoring and managing smart manufacturing for production transparency and data-driven management. It also helps effectively improve production efficiency, reduce production costs, and ensures the consistency and stability of product quality.

5. Conclusions

To the fully automated key production line, smart manufacturing technologies are successfully integrated to achieve high-quality, high-precision production. By featuring automated feeding, processing, inspection, and discharging, the line ensures stable and efficient production. The AOI defects inspection station, combined with IoT integration, performs real-time quality checks, automatically stops the line for defect handling, and prevents defective products from proceeding, maintaining product consistency and reliability. The visual panel provides real-time production data for operators to monitor key indicators and quickly address issues, with the IoT enabling both remote and local monitoring to enhance transparency and decision support. Historical data support predictive maintenance, production optimization, and energy efficiency improvements. The production line achieves high efficiency, quality, and smart manufacturing objectives through advanced AOI and IoT technologies, demonstrating a reliable and data-driven production environment.

Author Contributions

Conceptualization, G.-C.L. and K.-C.L.; methodology, G.-C.L.; software, G.-C.L.; validation, G.-C.L. and Y.-H.C.; formal analysis, G.-C.L.; investigation, G.-C.L.; resources, K.-C.L.; data curation, G.-C.L.; writing—original draft preparation, G.-C.L.; writing—review and editing, Y.-H.C. and K.-C.L.; visualization, G.-C.L.; supervision, K.-C.L.; project administration, K.-C.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0—Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Wang, L.; Törngren, M.; Onori, M. Current Status and Advancement of Cyber-Physical Systems in Manufacturing. J. Manuf. Syst. 2015, 37, 517–527. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the Implications of Digitisation and Automation in the Context of Industry 4.0: A Triangulation Approach and Elements of a Research Agenda for the Construction Industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems Architecture for Industry 4.0-Based Manufacturing Systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Nagorny, K.; Lima-Monteiro, P.; Barata, J.; Colombo, A. Big Data Analysis in Smart Manufacturing: A Review. Int. J. Commun. Netw. Syst. Sci. 2017, 10, 31–58. [Google Scholar] [CrossRef]

- Chao, W.H.; Lee, K.C. Smart Manufacturing Scheme for Automated Production Line of Key. In Proceedings of the 2023 IEEE 5th Eurasia Conference on IoT, Communication and Engineering (ECICE), Yunlin, Taiwan, 27–29 October 2023. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).