Identifying Barong Tagalog Textile Using Convolutional Neural Network and Support Vector Machine with Structural Pattern Segmentation †

Abstract

:1. Introduction

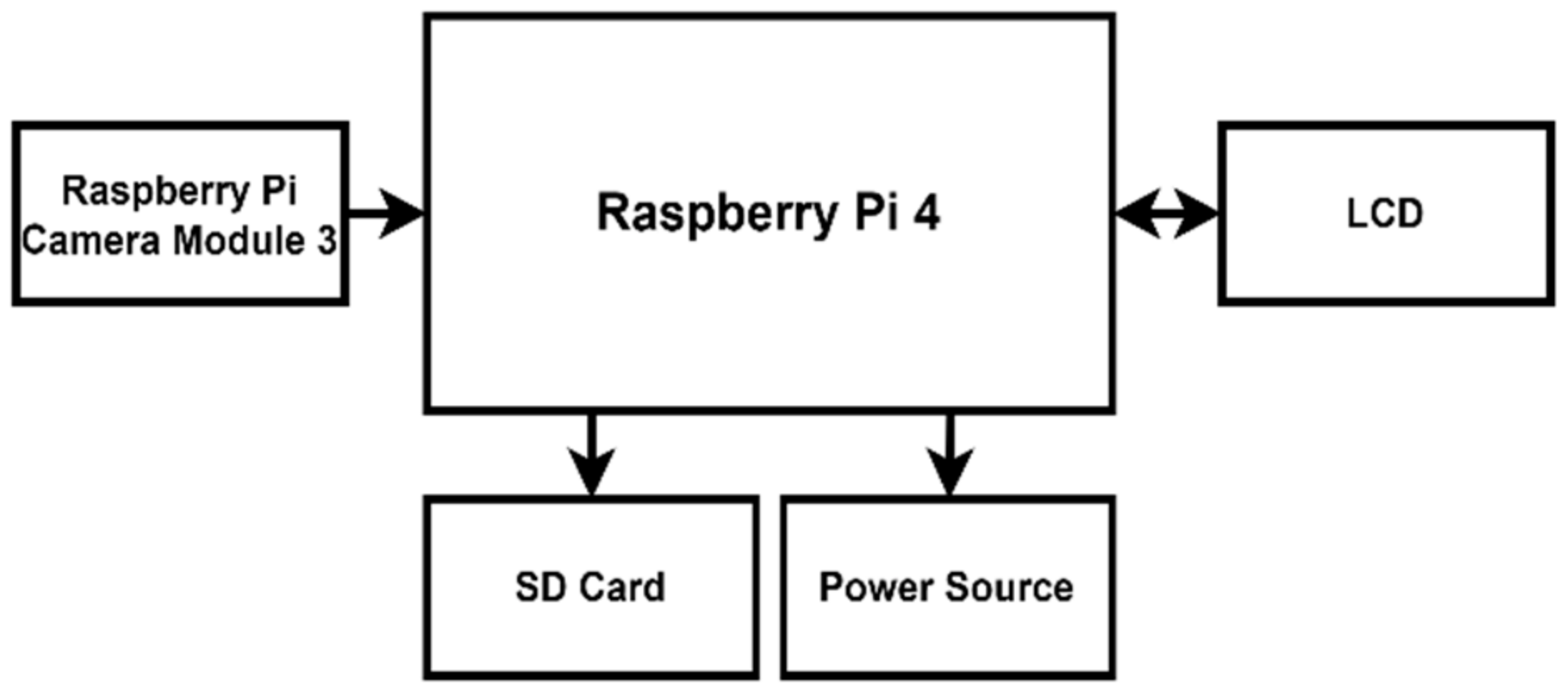

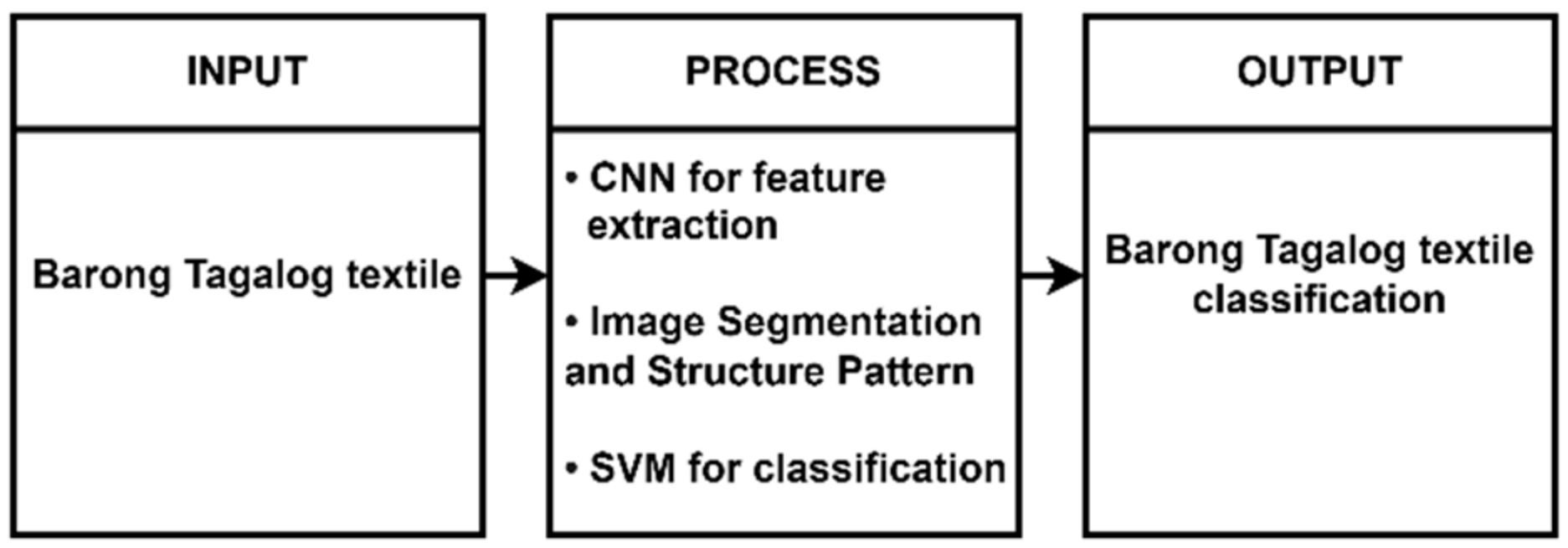

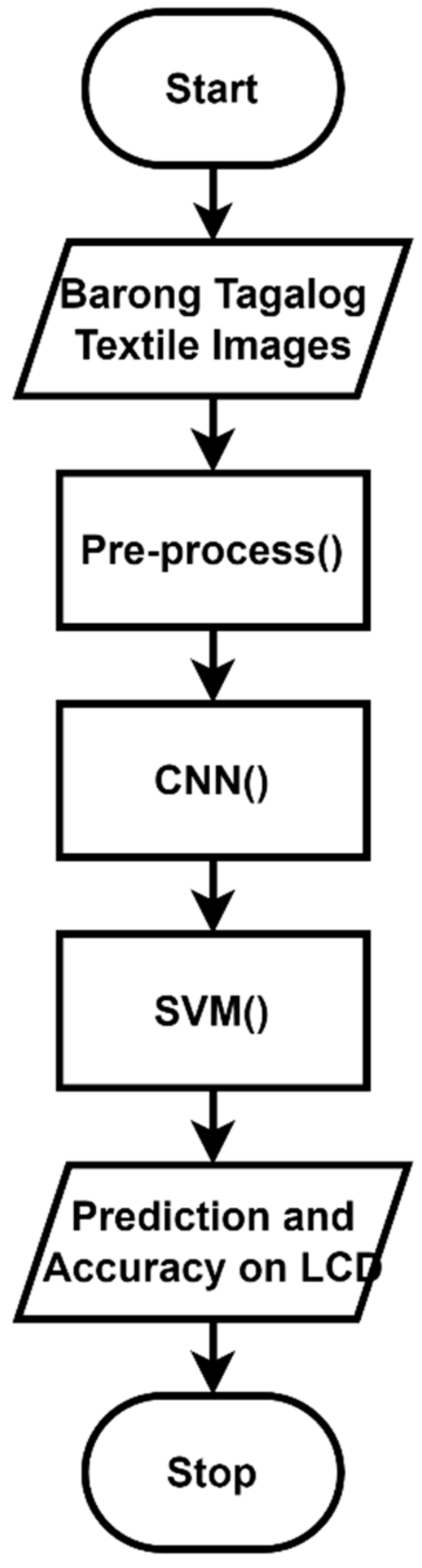

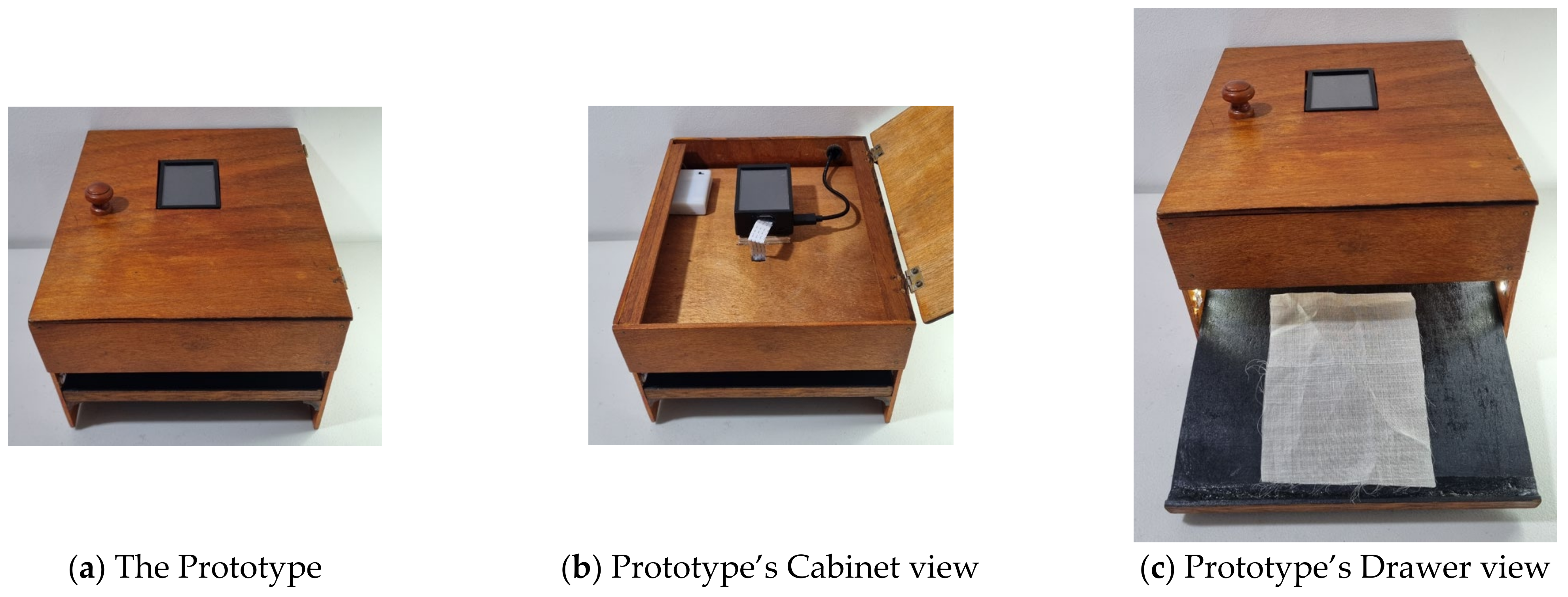

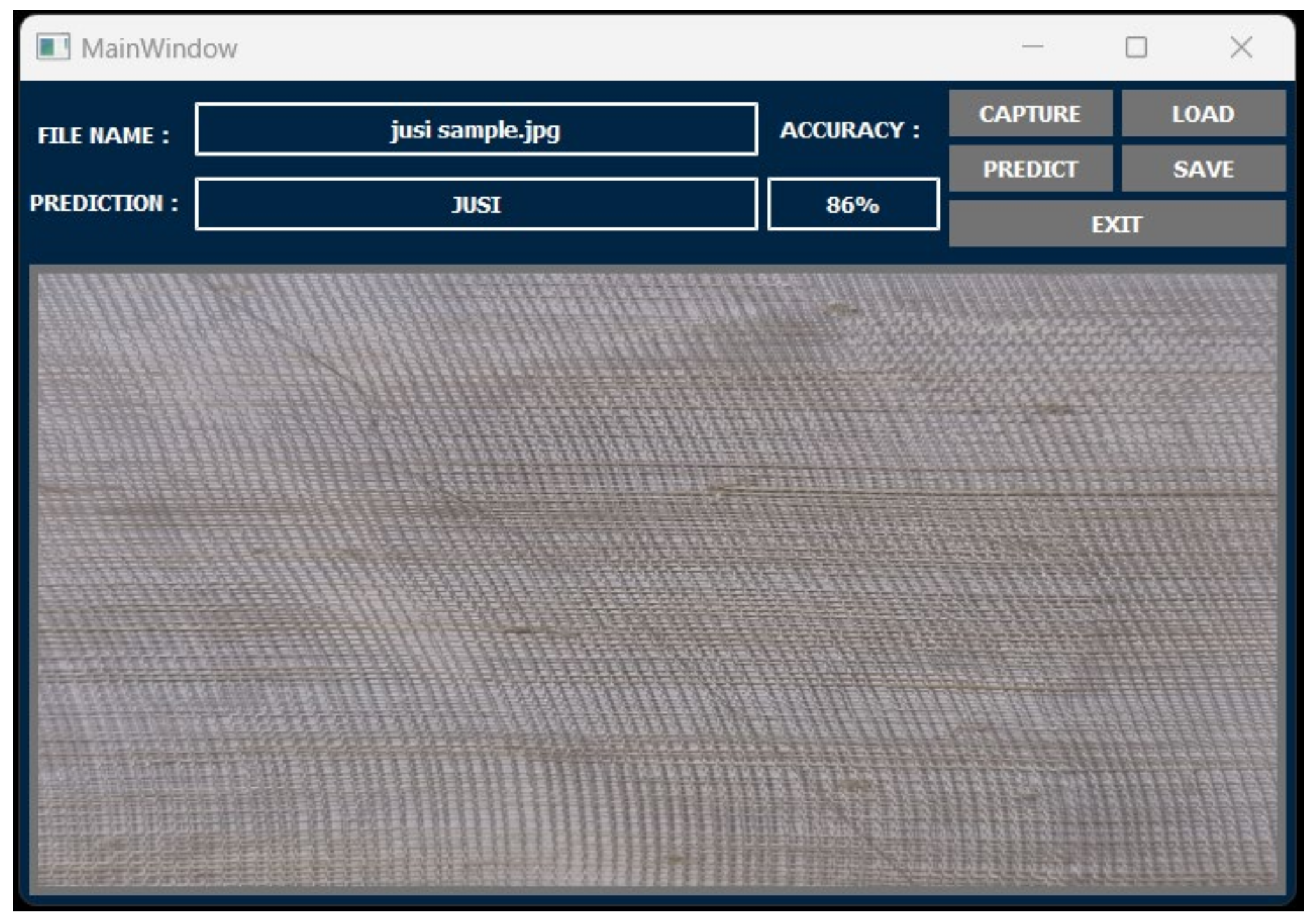

2. Methodology

System Flowchart

3. Results and Discussion

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sorilla, F., IV. Barong Tagalog: The History of the Traditional Filipino Attire. Available online: https://www.tatlerasia.com/style/fashion/barong-tagalog-the-traditional-filipino-mens-attire (accessed on 28 October 2024).

- Hussain, M.A.I.; Khan, B.; Wang, Z.; Ding, S. Woven fabric pattern recognition and classification based on deep convolutional neural networks. Electronics 2020, 9, 1048. [Google Scholar] [CrossRef]

- Patil, S.S.; Gaikwad, V.T. Defect Detection in Fabric using Image Process Technique. Int. Res. J. Eng. Technol. 2008, 5, 904. [Google Scholar]

- Rani, N. Image Processing Techniques: A Review. J. Today’s Ideas—Tomorrow’s Technol. 2017, 5, 40–49. [Google Scholar] [CrossRef]

- Chowdhary, C.L.; Acharjya, D. Segmentation and feature extraction in Medical Imaging: A Systematic Review. Procedia Comput. Sci. 2020, 167, 26–36. [Google Scholar] [CrossRef]

- Ngan, H.Y.; Pang, G.K.; Yung, S.; Ng, M.K. Wavelet-based methods on patterned fabric defect detection. Pattern Recognit. 2005, 38, 559–576. [Google Scholar] [CrossRef]

- Fan, Z.; Mei, J.; Zhang, S.; Liu, M. Recognition of Woven Fabric based on Image Processing and Gabor Filters. In Proceedings of the 2017 IEEE 7th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 31 July–4 August 2017. [Google Scholar]

- Liu, P.; Choo, K.-K.R.; Wang, L.; Huang, F. SVM or deep learning? A comparative study on remote sensing image classification. Soft Comput. 2017, 21, 7053–7065. [Google Scholar] [CrossRef]

- Tuazon, G.L.H.; Duran, H.M.; Villaverde, J.F. Portable Sigatoka Spot Disease Identifier on Banana Leaves Using Support Vector Machine. In Proceedings of the 2021 IEEE 13th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Manila, Philippines, 28–30 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Aguilar, E.J.L.; Borromeo, G.K.P.; Villaverde, J.F. Determination of Pineapple Ripeness Using Support Vector Machine for Philippine Standards. In Proceedings of the 2021 7th International Conference on Control Science and Systems Engineering, ICCSSE 2021, Qingdao, China, 30 July–1 August 2021; pp. 283–287. [Google Scholar] [CrossRef]

- Arceo, A.J.C.; Borejon, R.Y.N.; Hortinela, M.C.R.; Ballado, A.H.; Paglinawan, A.C. Design of an e-attendance checker through facial recognition using histogram of oriented gradients with support vector machine. In Proceedings of the 2020 IEEE 8th International Conference on Smart City and Informatization, iSCI 2020, Guangzhou, China, 31 December 2020–1 January 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Xin, R.; Zhang, J.; Shao, Y. Complex Network Classification with Convolutional Neural Network. Tsinghua Sci. Technol. 2020, 25, 447–457. [Google Scholar] [CrossRef]

- Sardogan, M.; Tuncer, A.; Ozen, Y. Plant Leaf Disease Detection and Classification Based on CNN with LVQ Algorithm. In Proceedings of the 2018 3rd International Conference on Computer Science and Engineering (UBMK), Sarajevo, Bosnia and Herzegovina, 20–23 September 2018; pp. 382–385. [Google Scholar] [CrossRef]

- Tenorio, A.; Desiderio, J.; Manlises, C. Classification of Rincon Romaine Lettuce Using convolutional neural networks (CNN). In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Ibarra, N.C.; Rivera, M.P.; Manlises, C.O. Determination of Leaf Degradation Percentage for Banana leaves with Panama Disease Using Image Segmentation of Color Spaces and OpenCV. In Proceedings of the 2023 15th International Conference on Computer and Automation Engineering, ICCAE 2023, Sydney, Australia, 3–5 March 2023; pp. 269–275. [Google Scholar] [CrossRef]

- Legaspi, K.R.B.; Sison, N.W.S.; Villaverde, J.F. Detection and Classification of Whiteflies and Fruit Flies Using YOLO. In Proceedings of the 2021 13th International Conference on Computer and Automation Engineering, ICCAE 2021, Melbourne, Australia, 20–22 March 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Balangue, R.D.; Padilla, C.D.M.; Linsangan, N.B.; Cruz, J.P.T.; Juanatas, R.A.; Juanatas, I.C. Ear Recognition for Ear Biometrics Using Integrated Image Processing Techniques via Raspberry Pi. In Proceedings of the 2022 IEEE 14th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Boracay Island, Philippines, 1–4 December 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Desiderio, J.M.H.; Tenorio, A.J.F.; Manlises, C.O. Health Classification System of Romaine Lettuce Plants in Hydroponic Setup Using Convolutional Neural Networks (CNN). In Proceedings of the 4th IEEE International Conference on Artificial Intelligence in Engineering and Technology, IICAIET 2022, Kota Kinabalu, Malaysia, 13–15 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Mateo, K.C.H.; Navarro, L.K.B.; Manlises, C.O. Identification of Macro-Nutrient Deficiency in Onion Leaves (Allium cepa L.) Using Convolutional Neural Network (CNN). In Proceedings of the 2022 5th International Seminar on Research of Information Technology and Intelligent Systems, ISRITI 2022, Yogyakarta, Indonesia, 8–9 December 2022; pp. 419–424. [Google Scholar] [CrossRef]

- Blonder, B.; Violle, C.; Bentley, L.P.; Enquist, B.J. Venation networks and the origin of the leaf economics spectrum. Ecol. Lett. 2011, 14, 91–100. [Google Scholar] [CrossRef] [PubMed]

| Barong Tagalog Fabric Types | Number of Images |

|---|---|

| Cocoon | 30 |

| Jusi | 30 |

| Pina-Silk | 30 |

| PREDICTED | ||||

|---|---|---|---|---|

| Cocoon | Jusi | Pina-Silk | ||

| ACTUAL | Cocoon | 19 | 11 | 0 |

| Jusi | 0 | 30 | 0 | |

| Pina-Silk | 5 | 0 | 25 | |

| PREDICTED | TOTAL | |||||

|---|---|---|---|---|---|---|

| TP | TN | FP | FN | |||

| ACTUAL | Cocoon | 14 | 5 | 7 | 4 | 30 |

| Jusi | 30 | 0 | 0 | 0 | 30 | |

| Pina-Silk | 20 | 5 | 1 | 4 | 30 | |

| TOTAL | 64 | 10 | 8 | 8 | 90 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Totesora, J.B.; Torralba, E.C.; Manlises, C.O. Identifying Barong Tagalog Textile Using Convolutional Neural Network and Support Vector Machine with Structural Pattern Segmentation. Eng. Proc. 2025, 92, 2029. https://doi.org/10.3390/engproc2025092029

Totesora JB, Torralba EC, Manlises CO. Identifying Barong Tagalog Textile Using Convolutional Neural Network and Support Vector Machine with Structural Pattern Segmentation. Engineering Proceedings. 2025; 92(1):2029. https://doi.org/10.3390/engproc2025092029

Chicago/Turabian StyleTotesora, Jeff B., Edward C. Torralba, and Cyrel O. Manlises. 2025. "Identifying Barong Tagalog Textile Using Convolutional Neural Network and Support Vector Machine with Structural Pattern Segmentation" Engineering Proceedings 92, no. 1: 2029. https://doi.org/10.3390/engproc2025092029

APA StyleTotesora, J. B., Torralba, E. C., & Manlises, C. O. (2025). Identifying Barong Tagalog Textile Using Convolutional Neural Network and Support Vector Machine with Structural Pattern Segmentation. Engineering Proceedings, 92(1), 2029. https://doi.org/10.3390/engproc2025092029