Proportion of Fly Ash in Producing Roller-Compacted Concrete †

Abstract

1. Introduction

2. Experiments

Mixing Ratio

- Water–cementitious material ratio.The target design strength (f’c) was interpolated to determine the water–cementitious material ratio of W/(C + P).

- Minimum paste volume (Pv).For mass concrete, Pv ≈ 0.38; for surface mixtures, Pv ≈ 0.46.

- Absolute volume of coarse aggregate (Vca).

- Volume of cement–sand mortar (Vm).Assuming an air content of 2%, a unit concrete volume of 1 was used as (1):Vm = Cv × 0.98 − Vca

- Volume of cement paste (Vp).

- Volume of fine aggregates (VFA).

- Water volume (Vw).

- Cement volume (Vc)

- Volume of mineral admixtures (VF).

- Material volumes to weights.

- Material properties.The specific gravity of cement was 3.15, the specific gravity of fly ash was 2.08, and the specific gravity of coarse aggregate (SSD) was 2.64.

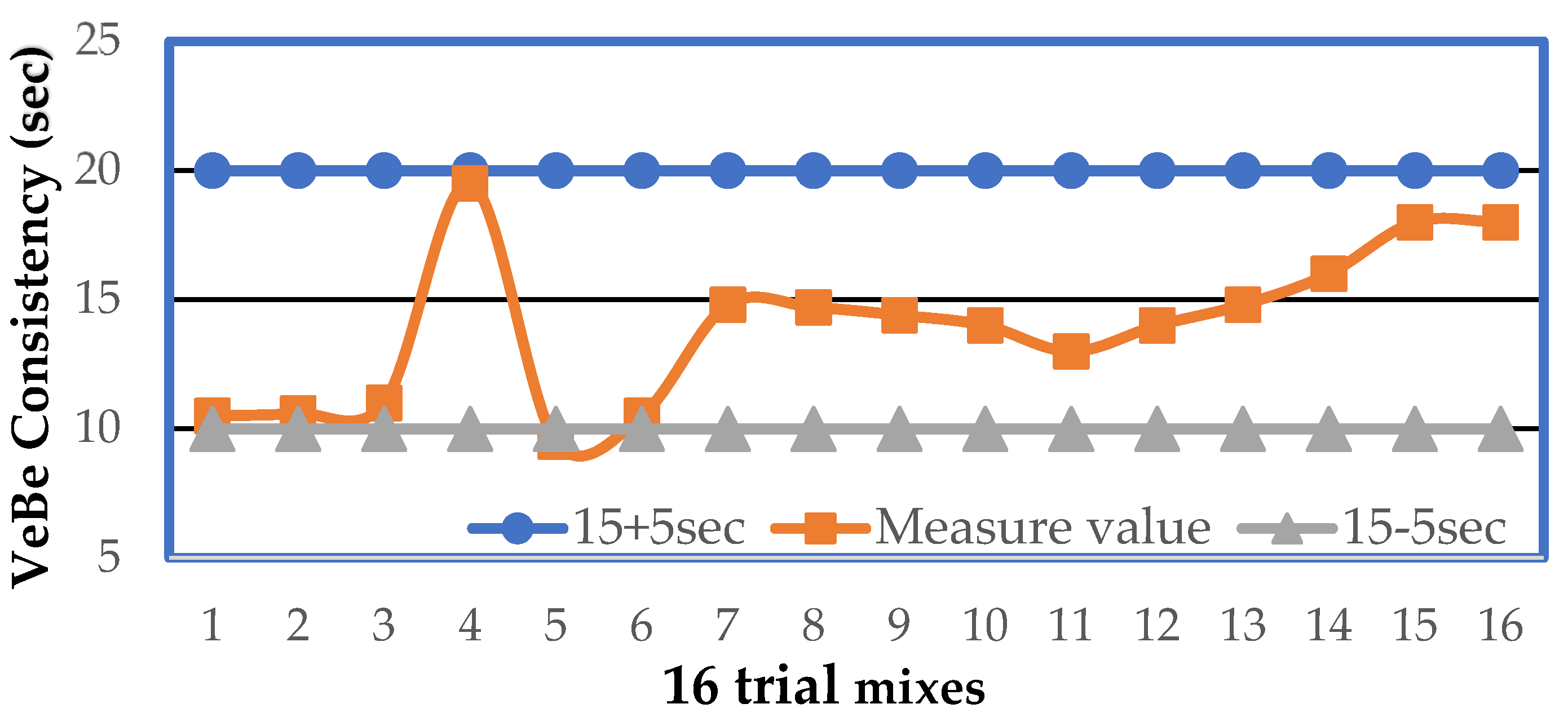

- Design conditions.The VC value was 15 ± 5 s, the air content was 3%, and the ratio of sand (S/A) was 30%.

- The fixed water volume was 120 kg/m3.

- Cement and fly ash contents.The water–cementitious ratio was 0.4, the weight of cement was 120/0.4 = 300 kg, the weight of fly ash (30%) was 300 × 30% = 90 kg, and the weight of cement was 300 − 90 = 210 kg.

- Absolute volume of aggregates.Va+s = 1 − Vair − Vw − Vc − Vf .Vs = 0.74 × 0.3 (S/A) = 0.22 Ws = 0.22 × 2.64 × 1000 = 580 kg.Va = 0.74 − 0.22 = 0.52 Wa = 0.52 × 2.64 × 1000 = 1373 kg.

- Mix proportions per m3 of roller-compacted concrete.Cement: 210 kg, fly ash: 90 kg, fine aggregate: 580 kg, coarse aggregate: 1373 kg, and water: 120 kg.The mixing ratio is presented in Table 3.

3. Results and Discussion

3.1. VeBe Consistency Test [5,7,11]

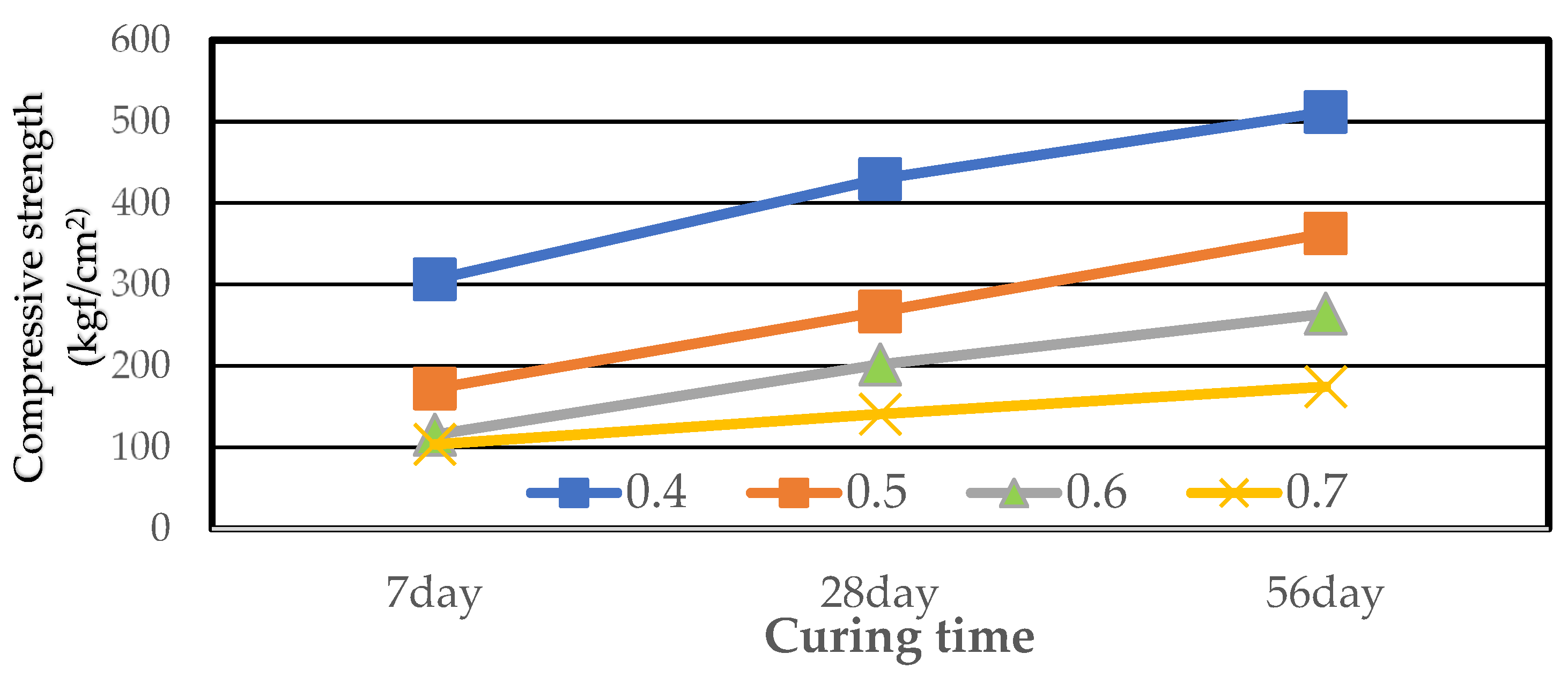

3.2. Compressive Strength Test

3.2.1. Water–Cement Ratio

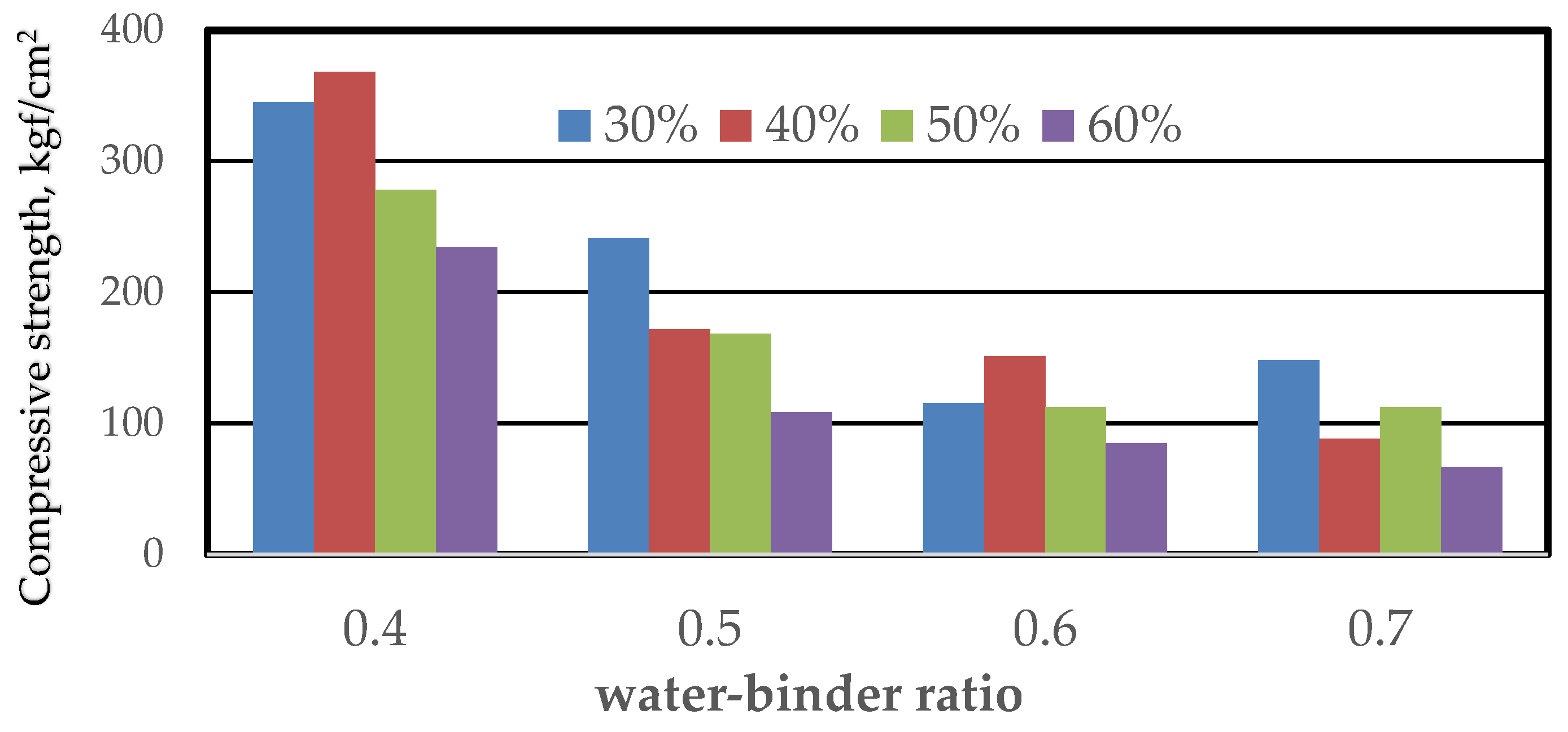

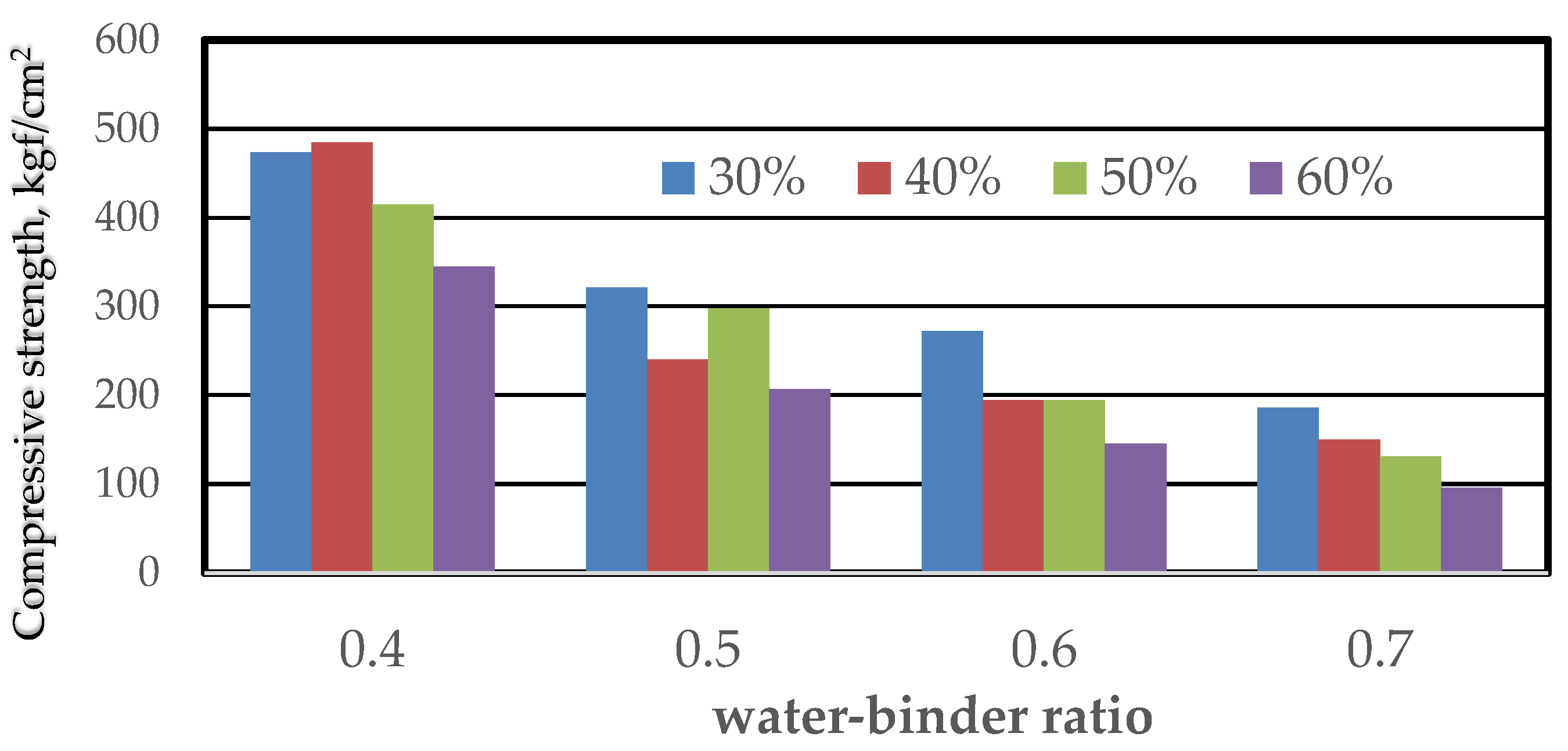

3.2.2. S/A

3.2.3. Coarse Aggregate Replacement with Stone Material

3.2.4. Fly Ash Replacement

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Report on Roller-Compacted Mass Concrete; ACI 207.5R-11; American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Portland Cement Association. Roller-Compacted Concrete for Dams; Portland Cement Association: Skokie, IL, USA, 2009. [Google Scholar]

- Abdel-Halim, M.A.; Al-Omari, M.A.; Iskender, M.M. Rehabilitation of the Spillway of Sama EI—Serhan Dam in Jordan, Using RCC. Eng. Struct. 1999, 21, 497–506. [Google Scholar] [CrossRef]

- Selvam, M.; Debbarma, S.; Singh, S.; Shi, X. Utilization of alternative aggregates for roller compacted concrete pavements—A state-of-the-art review. Constr. Build. Mater. 2022, 317, 125838. [Google Scholar] [CrossRef]

- Macias, A. RCC (RCC) for Pavement Construction. Concr. Int. 2011, 33, 37–42. [Google Scholar]

- Meyer, C. RCC: Design and Construction; ASCE Press Collection: Reston, VA, USA, 2006. [Google Scholar]

- Saluja, S.; Kaur, K.; Goyal, S. Achievement of RCC Incorporating GGBS by Using Soil Compaction Approach. In Lecture Notes in Civil Engineering; Springer: Singapore, 2024; Volume 371. [Google Scholar]

- State-of-the-Art Report on Roller-Compacted Concrete Pavements; ACI 325.10R; American Concrete Institute: Farmington Hills, MI, USA, 2011.

- Guide to Roller-Compacted Concrete Pavements; ACI 327R-14; American Concrete Institute: Farmington Hills, MI, USA, 2015.

- Hesami, S.; Modarres, A.; Soltaninejad, M.; Madani, H. Mechanical properties of RCC pavement containing coal waste and lime stone powder as partial replacement of cement. Constr. Build. Mater. 2016, 111, 625–636. [Google Scholar] [CrossRef]

| KERRYPNX | Property | Slump (mm) | VC Value (s) |

|---|---|---|---|

| RCC | Extremely Dry | — | 18–32 |

| Very Dry and Hard | — | 10–18 | |

| Dry and Hard | 0–25 | 5–10 | |

| OPC | Stiff Plastic | 25–50 | 3–5 |

| Plastic | 75–100 | 0–3 | |

| Flowable | 150–175 | — |

| Sieve Number | Passing Percentage (%) | ||

|---|---|---|---|

| RCC Dam | RCC Pavement | OPC | |

| 3 in | 98–100 | — | — |

| 2 ½ in | 98–99 | — | — |

| 2 in | 86–96 | — | — |

| 1 ½ in | 75–90 | — | — |

| 1 in | 63–77 | — | — |

| ¾ in | 56–69 | 100 | — |

| 3/8 in | 43–53 | 60–85 | 100 |

| No.4 | 33–43 | 40–60 | 95–100 |

| No.8 | 25–35 | 35–55 | 80–100 |

| No.16 | 19–29 | 20–40 | 50–85 |

| No.30 | 14–24 | 15–35 | 25–60 |

| No.50 | 20–18 | 8–20 | 10–30 |

| No.100 | 6–13 | 6–18 | 2–10 |

| No.200 | 4–10 | 2–8 | — |

| No. | W/C | Water | Cement | Fly Ash | Stone1 | Stone2 | Stone3 | Sand |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.40 | 120 | 210 | 90 | 477 | 477 | 409 | 584 |

| 2 | 180 | 120 | 428 | 428 | 460 | 619 | ||

| 3 | 150 | 150 | 381 | 381 | 507 | 654 | ||

| 4 | 120 | 180 | 336 | 336 | 550 | 687 | ||

| 5 | 0.50 | 120 | 144 | 96 | 419 | 419 | 559 | 598 |

| 6 | 468 | 72 | 375 | 375 | 613 | 642 | ||

| 7 | 96 | 144 | 456 | 456 | 391 | 671 | ||

| 8 | 120 | 120 | 413 | 413 | 445 | 715 | ||

| 9 | 0.60 | 120 | 100 | 100 | 390 | 390 | 638 | 608 |

| 10 | 80 | 120 | 412 | 412 | 549 | 646 | ||

| 11 | 140 | 60 | 438 | 438 | 472 | 695 | ||

| 12 | 120 | 80 | 456 | 456 | 391 | 733 | ||

| 13 | 0.70 | 120 | 68 | 103 | 466 | 466 | 502 | 615 |

| 14 | 85 | 86 | 490 | 490 | 420 | 658 | ||

| 15 | 102 | 69 | 375 | 375 | 613 | 702 | ||

| 16 | 120 | 51 | 398 | 398 | 530 | 746 |

| Type | RCC | OPC |

|---|---|---|

| Aggregate Size | Uses more coarse aggregates with less surface area, requiring less cement. Requires less cement (about 10–20% less), with similar water–cement ratio. Reduced mixing and transport time, less vibration during compaction, lower energy consumption. Lower CO2 emissions due to less cement usage (approximately 10–15% reduction). Longer lifespan, lower maintenance frequency, less need for repairs. Can further reduce CO2 emissions through alternative materials like fly ash and slag. Lower carbon footprint, especially when cement usage is reduced. | Uses more fine aggregates, requiring more cement. |

| Cement Usage | Uses more cement. | |

| Energy Consumption in Production | Requires more mixing, transport, and vibration, resulting in higher energy consumption. | |

| CO2 Emissions | Higher CO2 emissions due to greater cement demand. | |

| Durability of Construction | Higher maintenance frequency, more indirect energy consumption. | |

| Potential for Carbon Emission Reduction Overall Carbon Footprint | Although alternative materials are used, CO2 emissions are harder to significantly reduce. Higher carbon footprint due to high cement consumption. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.-J.; Lee, M.-G.; Chuo, S.-F. Proportion of Fly Ash in Producing Roller-Compacted Concrete. Eng. Proc. 2025, 91, 5. https://doi.org/10.3390/engproc2025091005

Chen H-J, Lee M-G, Chuo S-F. Proportion of Fly Ash in Producing Roller-Compacted Concrete. Engineering Proceedings. 2025; 91(1):5. https://doi.org/10.3390/engproc2025091005

Chicago/Turabian StyleChen, How-Ji, Ming-Gin Lee, and Shang-Fei Chuo. 2025. "Proportion of Fly Ash in Producing Roller-Compacted Concrete" Engineering Proceedings 91, no. 1: 5. https://doi.org/10.3390/engproc2025091005

APA StyleChen, H.-J., Lee, M.-G., & Chuo, S.-F. (2025). Proportion of Fly Ash in Producing Roller-Compacted Concrete. Engineering Proceedings, 91(1), 5. https://doi.org/10.3390/engproc2025091005