1. Introduction

In recent years, both national space agencies and private ventures have intensified their efforts to advance lunar accessibility, exploration, and resource utilization [

1]. The use of unmanned robotic rover systems is becoming vital in exploring the moon’s challenging terrain. While the lunar rovers of recent decades have typically been large, complex, and heavy, research is increasingly shifting towards smaller, lightweight micro rovers [

2]. Even though compact designs promise comparably low launch costs and the opportunity for swarm exploration, unique challenges are imposed by the harsh lunar thermal environment. As a consequence, the majority of state-of-the-art micro rover developments are designed for a mission lifetime of the lunar day exclusively [

3]. The SAMLER-KI project seeks to unlock new opportunities for rover missions by advancing designs with the capability to survive the lunar night within the micro rover class. Autonomous exploration tasks should be executable in a mission, with a total mission lifetime of at least 1.5 lunar cycles. This endeavor is further intensified by the planned landing site near the lunar equator at the Reiner Gamma swirls

https://science.nasa.gov/resource/lunar-swirl-reiner-gamma/ (accessed on 25 November 2024) in the Oceanus Procellarum, where immense discrepancies in the environmental conditions between the lunar day and night are present. During the mission, a trajectory of around 900 m is planned to be traversed [

4].

2. Environmental Conditions and Requirements

As the moon is tidally locked to the Earth, its sidereal period equals its day–night cycle. This implies a 14-Earth-day time period of lunar day and an equally long lunar night. With the absence of any significant atmosphere, the temperatures vary drastically during these periods depending on the latitude and the local topography. For a planned mission landing site in the equatorial region, a thermal design for the rover is required which is able to cope with environmental temperatures of up to 390 K during the lunar day and 95 K [

5] during the lunar night. While such a design might be achievable using delicate structures and low-conducting material, it must also be coherent with the other rover subsystems, such as the global structure. To this end, the thermal and mechanical design must go hand in hand for a rover to survive both the lunar environment and rocket launch. The vibration environment during launch is characterized by severe sine and random vibrations [

6]. As these specifications are highly dependent on the superordinate lander system, the vibration characteristics of a current launch provider were considered. For confidential reasons, neither the name of the provider nor the exact specification itself can be shown here. However, it can be stated that the maximal sine acceleration applied is 9 g, and the maximal random level is around 11 grms.

An extensive requirement catalog was defined for the SAMLER-KI mission, representing a framework for the design, as well as providing a measure for the evaluation. For the sake of clarity, the requirements shown in

Table 1 represent a condensed form of only some of the key requirements for the structural and thermal evaluation. Thermally, the temperatures of the electronic components and the batteries are in focus. It is assumed that these are most sensitive, with the narrowest allowable temperature range in the system design, and are thus focused on for evaluation. The key task for the thermal subsystem is to provide an adequate temperature regime for these components. Structurally, the margin of safety (MOS) is the main evaluation criterion for the performed sine and random vibrations. It considers the current design stress

, the material limit stress

, and a factor of safety (FOS) and is defined as follows.

For all of the structural components, the calculated MOS should be greater than 0, meaning that the current design’s stress after considering a specified margin is still lower than the material’s stress limits. To also comply with the lander interface requirements and stay below the dictated limit loads, primary notching should be applied to the vibration specifications.

3. Thermal–Structural Concepts

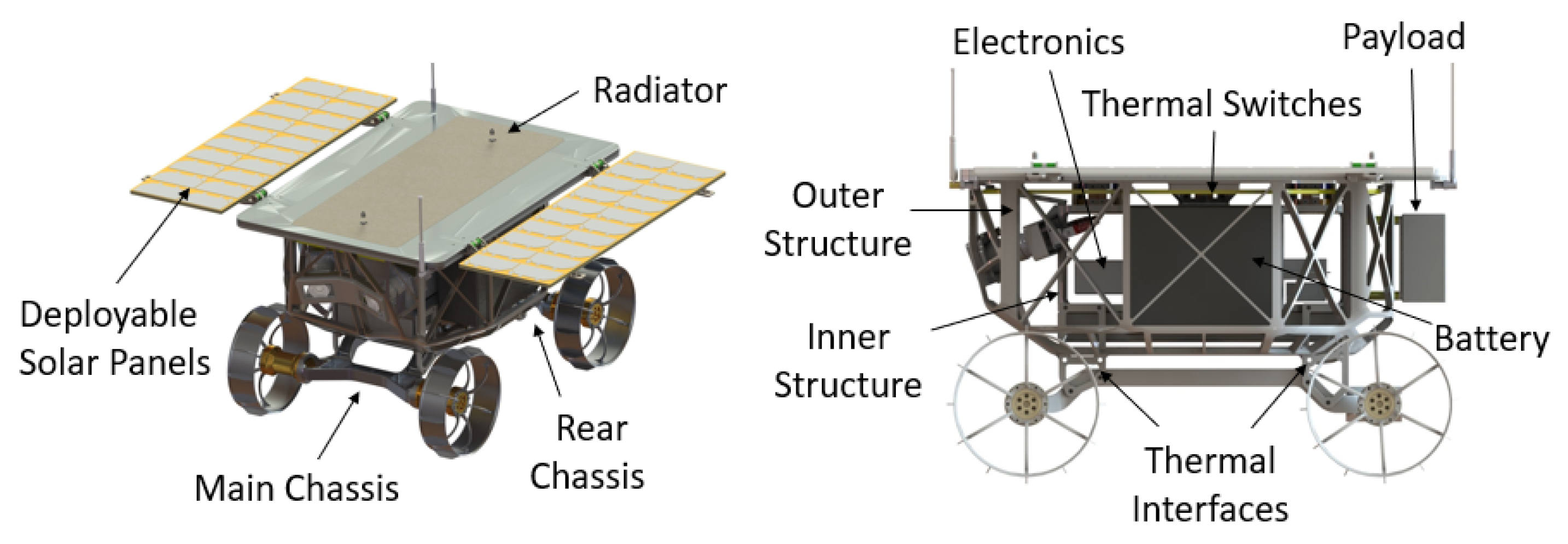

As the environmental temperature around the rover shows extreme differences depending on the time of the lunar cycle and sensitive components must be kept at a relatively constant temperature, insulation is the key word in the global thermal concept for the rover. This guideline is followed by implementing a dual-compartment concept. In this design, a smaller electronic compartment is housed inside of a bigger external compartment that is subjected to the environment. All of the remaining primary structural components, such as the locomotion chassis and the top panel assembly, are mounted onto the outer compartment to prevent parasitic heat flows between the inner compartment and the environment. Radiative insulation is achieved by mounting one sheet of multi-layer insulation (MLI) around each compartment. Low-conducting interfaces are introduced for the connection between each structural subassembly.

Throughout the lunar day, waste heat generated by the rover’s electronic components must be effectively dissipated. By positioning the radiator on the horizontal top panel, efficient heat rejection can be achieved against deep space without parasitic infrared irradiation from the environment. The need for heat rejection during the lunar day stands in harsh contrast to the heat-saving necessity at night. These high discrepancies in the desire for heat rejection and retention, respectively, imply the introduction of a variable heat path to the radiator (i.e., thermal switches). Heat generation during the night survival mission mode exclusively relies on electrical heating from the rover’s core.

On the structural side, the aim is to support the thermal concept while at the same time implementing resilience against the launch vibrations. Monolithic and lightweight frames are implemented for the compartment structures to support this philosophy. As launch loads are introduced via four interface points on the locomotion system, a strong chassis with an H-profile and stiffening rips is introduced. High resistance to bending for flat structures is supported by the honeycomb construction found for the radiator and the solar panels. One of the main challenges is the design of the low-conduction interface structures between the locomotion system, the outer compartment, and the inner compartment. These structures represent the main structural load paths to the rover’s inside during launch while at the same time posing one of the most high-potential sources of heat leakage from the rover’s core to the outside. The thermal requirements in terms of slender geometries and low-conducting material in these parts result in the need for a compromise, which is to be justified and supported by both thermal and structural analyses. In the current design status, this is implemented in the form of multiple interface brackets connecting the structures at specific points. A schematic overview of this concept is presented in

Figure 1.

4. Rover Design

For the SAMLER-KI project, the DFKI (German Research Institut for Artificial Intelligence), under the assistance of FH Aachen (University of Applied Sciences Aachen), developed the first iteration of an initial rover system based on which the structural and thermal assessments in this work were conducted. The use of nuclear power sources was not considered due to regulatory, safety, and public policy considerations.

Based on the requirements, the system design visible in

Figure 2 was developed. The outcome was a four-wheeled system that relies on solar energy as a power source, in combination with a set of batteries for energy storage. The solar panels for power harvesting fold on top of the rover in the launch configuration and are released right before the mission operation, entailing different configurations for thermal and structural analysis cases. Optimal contact between the wheels and the ground is granted by the implementation of a rear chassis axle that is passively connected to the main chassis via a rotation joint.

For the operational mission phase, a total maximum peak power dissipation of around 35 W in the form of heat was calculated for a worst-case scenario. During the night, when the rover is switched to sleep mode, this amount is highly reduced down to 5.6 W.

Aluminum and titanium are the main materials used for the primary structure of the system. Glass-fiber-reinforced plastic (GFRP) was considered the best-suited material to all of the low-conduction interfaces. A total system mass of 20.6 kg for the rover, including a margin for the neglected harness in the CAD modeling, was calculated.

5. Thermal Analysis Results

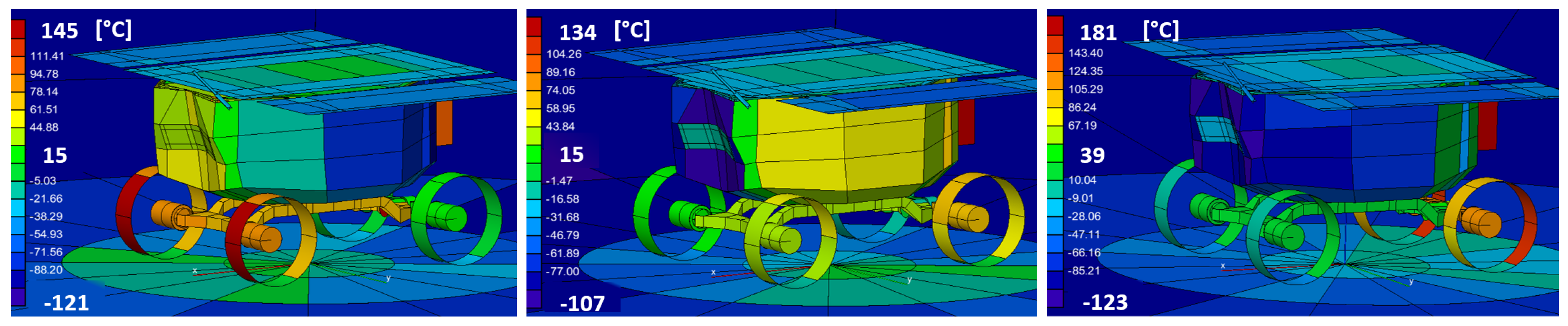

A finite difference model was derived following the thermal concept and the system design. The analyses were based on multiple different steady-state load cases. These replicated the possible rover–Sun orientations during the entire mission considered to be most severe. For this article, we focused on five cases with extreme inclination values.

Case 1: Lunar dusk/dawn, shallow solar inclination angle (3°), three rover orientations;

Case 2: Lunar noon, high solar angle (90°, zenith), one rover orientation;

Case 3: Lunar night, no sun present, one rover orientation.

During the presence of sunlight, the worst-case maximum internal power dissipation is applied, while at night, sleep-mode heat is considered.

Materials corresponding to the system design and thermo-optical properties most beneficial to support the insulation concept were applied. Most mentionable is a white Kapton coating for the MLI on the outer structure and a barium sulfate coating for the radiator. Based on the fact that finding a functioning thermal design was considered quite a challenging task, high-performance values for the thermal hardware were set from the beginning. Even though they are not yet flight-proven, barium sulfate coatings promise advantageous

/

ratios, leading to high independence from the surrounding environmental conditions. The current state-of-the-art values for the MLI properties [

7] and a thermal switch turn-down ratio of 1:100 were considered and applied to the model. The lunar surface was modeled based on the work of Hager [

8]. Additionally, it should be mentioned that begin-of-life (BOL) conditions were applied, and no dust coverage on the optical surfaces was accounted for. The resulting temperatures for the dusk/dawn cases are shown in

Figure 3 and

Table 2.

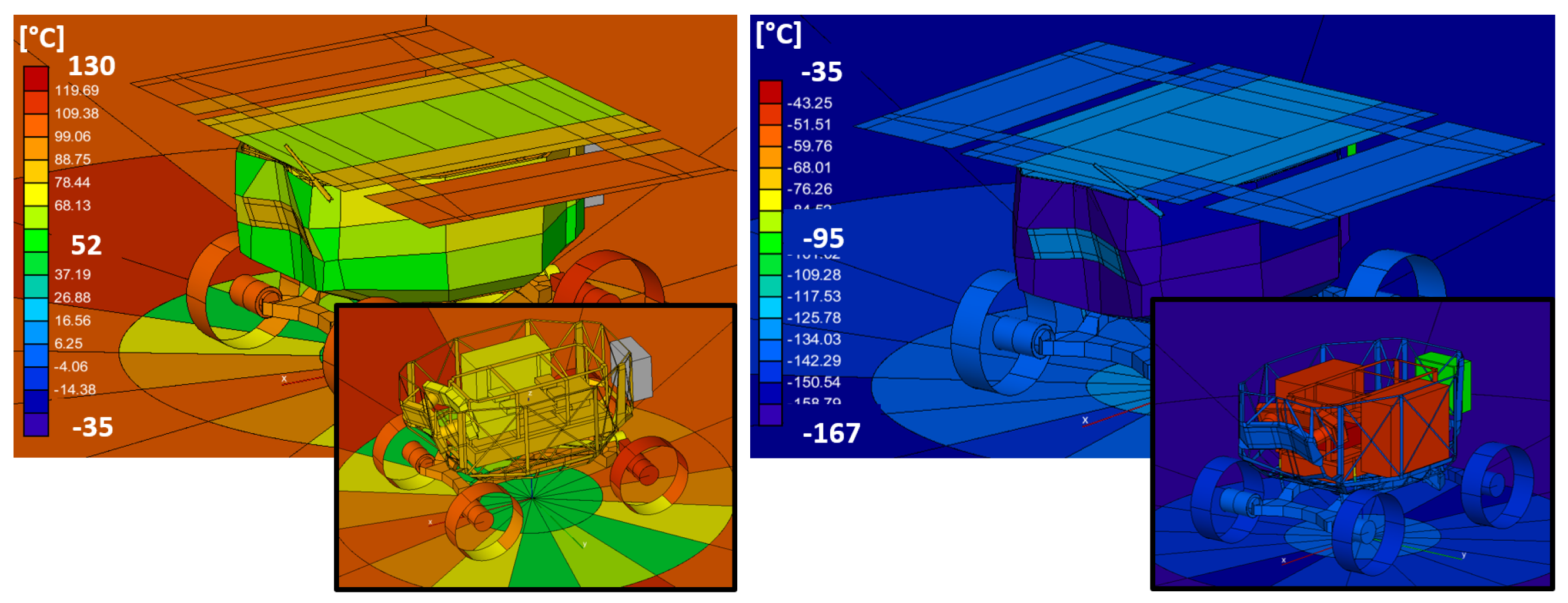

It becomes apparent that the ‘side’ and ‘back’ load cases show more severe temperatures than those for illumination from the front. While for most of the components the temperatures are tolerable, the battery temperatures are outside of the acceptable region for all three scenarios. The offset to the set requirement is, however, considered to be manageable with future adaptations. The thermal performance for the noon and night load cases is presented in

Figure 4 and

Table 3. The insulation concepts work out, as the temperatures inside the rover differ significantly from those in the environment for both load cases, but with the addition that the electronics and battery temperatures were not able to be kept within the bounds of the set requirement. The temperatures exceed the set limits during noon and undercut them during the night.

Taking the most temperature-sensitive rover components as an example, it already becomes apparent that the current design is not able to deal with the environmental conditions during any of the defined load cases. Even though the insulation concept is working in principle, the results suggest that significant unintended heat paths over the wheels and the top panel are still present, leading to parasitic bridges to the outside during the night. In addition, the high power dissipation during operations leads to noticeable overheating of the rover’s internal electronics under high solar incidence angles.

6. Structural Analysis Results

A precise representation of the rover’s geometry was also achieved using the finite element model derived from the system design, which represented the CAD model’s mass within a precision of 1%. Dedicated components are considered as mass points or as non-structural masses and are thus not geometrically visible in the results. As a simplification, at this early design iteration stage, the GFRP structures were considered to be isotropic. Distinct element quality and model checks in compliance with the European Cooperation for Space Standardization (ECSS) [

9] were performed to guarantee a correct starting point for the analysis. Significant global eigenmodes of the rover system were calculated and are depicted in

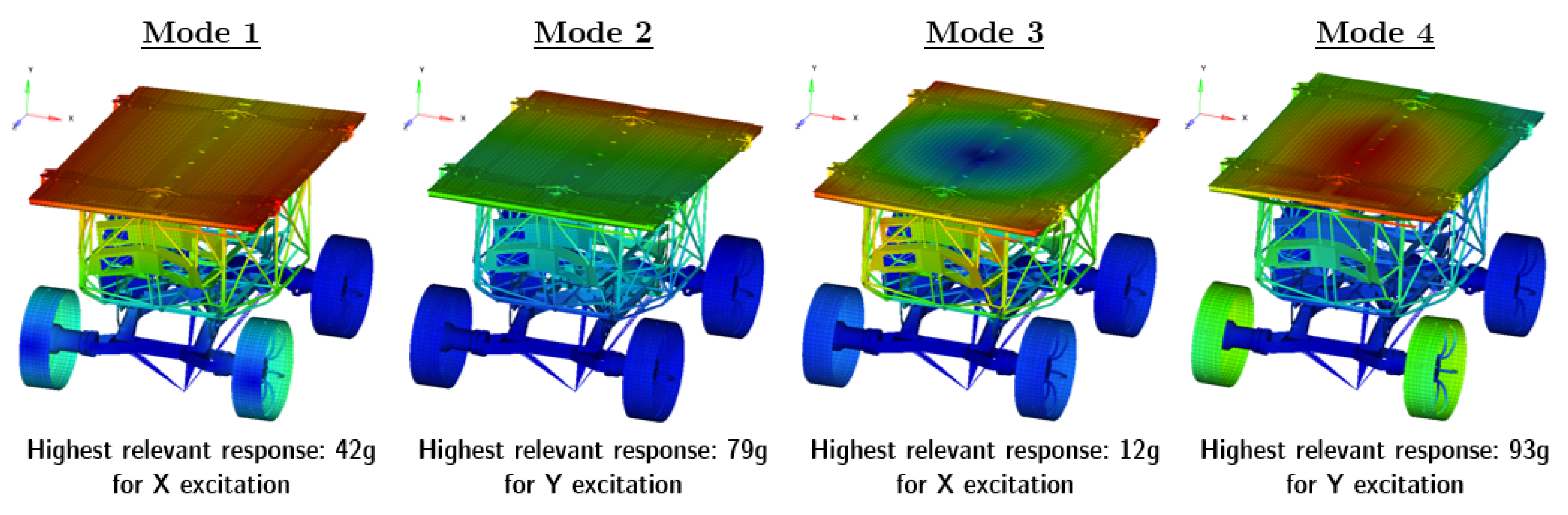

Table 4. These are defined as modes that excite more than 5% of the overall system mass. The current system design shows multiple global modes within the sine-equivalent region up to 100 Hz that have the potential to be excited during launch.

The corresponding mode shapes and the maximal acceleration amplification predicted by the frequency response analyses are shown in

Figure 5. The global modes become heavily excited, especially for the load cases in the X and Y directions. High responses from the majority of the components are present, based on which high stresses in the dedicated components and corresponding interfaces can be expected.

A stress evaluation was performed under consideration of the actual lander specifications for sine and random load cases and excitation in all three spatial directions. The results include a factor of safety of 1.74 for the material yield and 1.98 for the ultimate limits. These were calculated under consideration of the specific project, modeling, and local design factors [

10]. To comply with the interface requirements, primary notching was applied. The stress results and corresponding MOSs were obtained for every component and direction and for both sine and random vibration load cases.

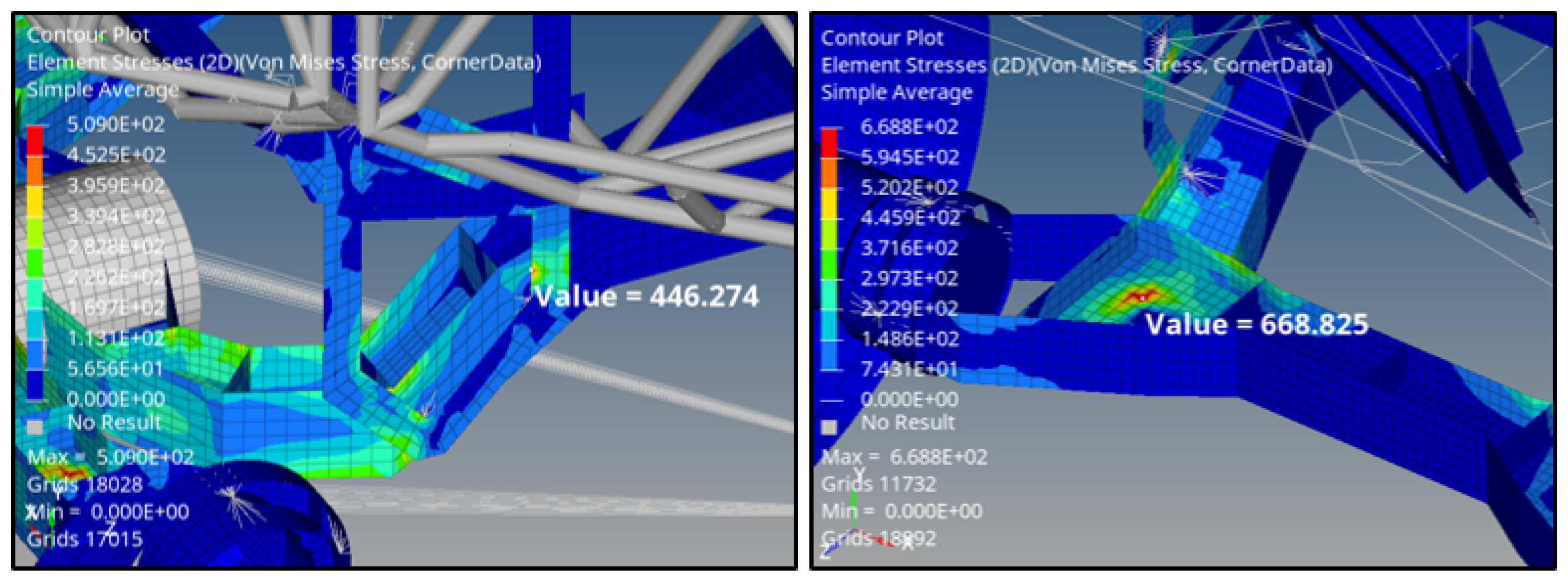

Table 5 represents a condensed form of the overall table of the margin of safety results with only the most critical failing components and maximal sine vibration stresses present. It is shown that sine vibrations impact the structure way more severely compared to random input, which is heavily impacted by the primary notching. Color plots of the stress calculations for two of the critical components are shown in

Figure 6.

Significant negative MOS were calculated for three specific structures, which were the box interfaces, the chassis main structure, and the chassis rear structure, predicting structural failure when exposed to the applied launch conditions. While it is believed that other MOS close to 0, e.g., that for the outer structure, could be raised quite easily, the abovementioned components are identified as most critical and might require a more elaborative redesign.

7. Conclusions

The current design status of the SAMLER-KI rover was successfully modeled and analyzed in terms of its thermal and structural performance. The analyses demonstrated that the initial conceptual design is neither capable of withstanding the environmental conditions of rocket launch nor the lunar thermal environment. Despite these predicted failures, the results are considered to be a significant success, as they have identified the most critical areas requiring improvement. These findings serve as a starting point for future design adaptations and iterations towards a compliant structural and thermal rover design. The analyses revealed that structurally, the chassis of the locomotion system and the interfaces between the compartments and the chassis are the primary weak points in the current design. Localized adjustments, such as increasing the component thicknesses or implementing geometric modifications, are expected to address these areas effectively. At this stage, major changes in the structural concept are not considered necessary.

From a thermal perspective, reducing the power dissipation during the lunar day and enhancing the insulation of the top panel are identified as the key areas for improvement. Modifying the mission profiles to alternate high-power operations with frequent low-power intervals could help mitigate excessive daytime temperatures. Additionally, improving the insulation between the radiator and the adjacent top panel structure is expected to significantly reduce the heat leakage during the lunar night, thereby shifting the temperatures into an acceptable range. A critical challenge remains in the system’s overall mass limit of 20 kg, which the current design exceeds. While weight minimization is anticipated to be a crucial trade-off parameter in subsequent subsystem iterations, it may be necessary to reconsider the feasibility of the 20 kg limit. Softly relaxing this requirement—while incorporating a suitable uncertainty margin—is expected to allow the system to meet all of the functional and performance criteria. In conclusion, the findings indicate that with targeted design improvements and careful relaxation of the mass requirements, a feasible rover system can be achieved in future iterations.

Author Contributions

Conceptualization: L.S. and J.G. Analysis: L.S., J.G., and D.Z. Investigation: L.S., J.G. and D.Z. Writing—original draft preparation: L.S. Writing—review and editing: J.G., M.C. and D.Z. Project administration: M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was carried out within the scope of the project SAMLER-KI (grant No. 50RA2203B), which is funded by the German space agency DLR with federal funds from the Federal Ministry of Economic Affairs and Climate Action in accordance with the parliamentary resolution of the German parliament.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The analyses conducted were partially carried out using third-party data. Access to the data and the corresponding results is restricted due to proprietary considerations, and thus they cannot be made available. The other datasets generated during the current study will be made available upon the conclusion of the project and the publication of the final results.

Acknowledgments

The authors would like to thank the German Research Center for Artificial Intelligence DFKI as the consortium leader of the SAMLER-KI project. Special thanks go to the collaborators who developed and provided the mechanical and functional design of the rover.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Schonfeld, J. Summary of the Contracted Deliveries of NASA Payloads to the Moon Via Commercial Lunar Payload Services (CLPS). In Proceedings of the 2023 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Honolulu, Oahu, HI, USA, 1–4 October 2023. [Google Scholar]

- NASA—Jet Propulsion Laboratory. NASA’s Trio of Mini Rovers Will Team Up to Explore the Moon. Latest Update on Oct 2023. Available online: https://www.nasa.gov/centers-and-facilities/jpl/nasas-trio-of-mini-rovers-will-team-up-to-explore-the-moon/ (accessed on 25 November 2024).

- Schweitzer, L. Micro Rover Mission for Measuring Lunar Polar Ice. In Proceedings of the 2021 IEEE Aerospace Conference (50100), Big Sky, MT, USA, 6–13 March 2021; pp. 1–13. [Google Scholar] [CrossRef]

- Yüksel, M. Development of a semi-autonomous microrover for lunar night survival. In Proceedings of the International Astronautical Congress (IAC), Milan, Italy, 14–18 October 2024. [Google Scholar]

- Williams, J.-P. The global surface temperatures of the Moon as measured by the Diviner Lunar Radiometer Experiment. Icarus 2017, 283, 300–325. [Google Scholar]

- European Cooperation for Space Standardization. Space Engineering: Spacecraft Mechanical Loads Analysis Handbook, ECSS-E-HB-32-26A, ESA-ESTEC, Noordwijk, The Netherlands, February 2013. Available online: https://ecss.nl/standard (accessed on 25 November 2024).

- Peyrou-Lauga, R. JUICE (Jupiter Icy Moon Explorer) Spacecraft Thermal Control. In Proceedings of the 50th International Conference on Environmental Systems, Lisbon, Portugal, 12–14 July 2021. [Google Scholar]

- Hager, P.B. Dynamic Thermal Modeling for Moving Objects on the Moon; Technische Universität München (TUM): München, Germany, 2013; p. 81. [Google Scholar]

- European Cooperation for Space Standardization. Space Engineering: Structural Finite Element Method, ECSS-E-ST-32-03C, ESA-ESTEC, Noordwijk, The Netherlands, July 2008. Available online: https://ecss.nl/standard (accessed on 25 November 2024).

- European Cooperation for Space Standardization. Space Engineering: Structural Factors of Safety for Spaceflight Hardware, ECSS-E-ST-32-10C Rev.2 Corrigendum 1, ESA-ESTEC, Noordwijk, The Netherlands, August 2019. Available online: https://ecss.nl/standard (accessed on 25 November 2024).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).