Abstract

This paper presents a comprehensive approach aimed at optimizing the design of aircraft components from a cradle-to-grave sustainability perspective. Central to this approach is a rigorous sustainability assessment, which evaluates environmental, cost, and performance criteria using the TOPSIS multi-criteria decision-making method. Environmental criteria are derived through a Life Cycle Assessment, while cost criteria are determined via Life Cycle Costing, both facilitated by the SimaPro software. Performance is evaluated in terms of mass and specific stiffness. To account for the complex relationship of these criteria, objective weighting methods are employed to determine the weights for each criterion. The methodology is applied to a case study of a fuselage panel. By maximizing the sustainability of the component, optimal designs—considering material selection, component thickness, and manufacturing methods—are identified to minimize environmental impact, reduce costs, and enhance performance.

1. Introduction

Next-generation air transportation plays a critical role in influencing the environment, safety, and economy. The growing demand for air travel, the increasing number of retired aircraft, and the depletion of energy resources have made this a pressing area requiring immediate attention. Numerous projects are focused on developing innovative technologies to address today’s environmental challenges while aligning with the EU’s goal of achieving net-zero flights by 2050 [1]. This ambitious goal can be approached from multiple perspectives, including airport operations, air traffic management, maintenance services, and more. For example, optimizing air traffic involves managing flight routes and schedules based on weather conditions and aircraft movements to reduce flight times, as well as minimizing the LTO (landing and take-off) cycle and fleet size [2,3]. Additionally, sustainable alternative fuels (SAFs) are being tested to lower CO2 emissions during aircraft operations [4]. Significant attention is also being directed toward the development of hydrogen-powered aircraft, supported by several European initiatives such as FASTER-H2, H2elios, and ACAP, which are contributing to research in this area. Parallel efforts are advancing novel propulsion systems, optimizing wing configurations, and enhancing overall aircraft design to achieve weight reductions and improvements in fuel efficiency [2,5].

This paper focuses on the aircraft level, particularly on fuselage design from a sustainable perspective that emphasizes the structural integrity of the aircraft components. Several studies have investigated optimal fuselage panel designs (e.g., [6]) aimed at minimizing both cost and weight. Key variables in these studies include materials, geometric characteristics (such as the cross-sectional dimensions of stiffeners and the thickness of panel sub-components), and manufacturing processes, which affect design, material waste, and cost [7]. The concept of sustainability in aviation, aimed at achieving net-zero emissions, requires balancing environmental, economic, and performance metrics. To this end, nine panel scenarios were evaluated for sustainability from a cradle-to-grave perspective. The criteria used to assess the sustainability of the panels were divided into three main categories: environmental, cost, and performance. Life Cycle Assessment (LCA), Life Cycle Costing (LCC) using SimaPro 9.6.0.1 software, and finite element analysis (FEA) using Ansys Workbench 2023R1 were performed for each scenario to collect comprehensive data for analysis. Finally, the TOPSIS multi-criteria decision-making method was applied to identify the optimal panel configuration.

2. Technological Problem

The primary objective of this study is to develop a methodology for assessing aircraft components in terms of sustainability from a cradle-to-grave perspective. Different designs of fuselage panels, incorporating variations in materials, manufacturing processes, geometric characteristics (such as thickness), and joining methods, were evaluated to determine the most sustainable option. Adjusting these parameters affects several critical factors, including the weight of the fuselage panel, waste scenarios, energy consumption throughout the panel’s lifecycle, from production to End-of-Life (EoL) performance, and more. The numerous variables influenced by these adjustments significantly increase the complexity of the problem. Therefore, a robust methodology is required as a supporting tool to enable designers to make informed, sustainable decisions.

Geometry and Materials

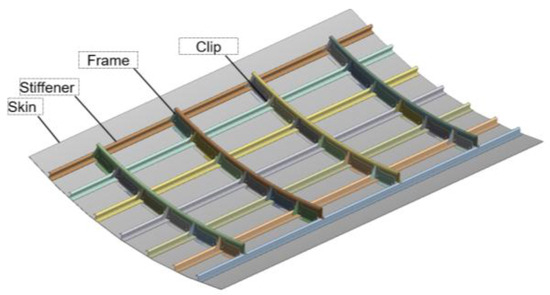

The case study analyzed focuses on the design of a fuselage panel, as illustrated in Figure 1, which is provided within the framework of the EU program FASTER-H2. The panel is composed from a curved skin, 7 stringers, 4 frames and 24 clips. Eight panel scenarios are developed, which are alternatives of the baseline scenario S0, formed by changing the materials, the manufacturing processes, the thicknesses of the sub-parts and the joining method. A detailed overview of the nine scenarios is provided in Table 1.

Figure 1.

Fuselage panel sketch.

Table 1.

Panel scenarios characteristics.

3. Sustainability Assessment Methodology

The sustainability assessment methodology proposed in this study consists of four main steps: LCA, LCC, FE Analysis (FEA), and the TOPSIS MCDM method. The first three steps generate the necessary data for addressing the decision-making problem of selecting the most sustainable panel design. Following this, the TOPSIS method is applied to integrate the environmental, cost, and performance attributes of the alternatives, ultimately identifying the optimal design. The criteria categories reflecting sustainability in the aviation context are environment, cost, and performance. The criteria are detailed in Table 2. Six objective weighting methods were employed to calculate the importance of the criteria.

Table 2.

Criteria selected for the sustainability assessment.

3.1. Life Cycle Assessment (LCA)—Environmental Criteria

A Life Cycle Assessment of the nine panel scenarios was conducted using SimaPro software in order to collect the data for the environmental criteria. In detail, the Life Cycle Assessment framework according to ISO14040 [8] and ISO14044 [9] for this study was as follows:

- A.

- Goal and Scope: The aim of this study is to compare different fuselage panel designs from a sustainability perspective. As a functional unit, a single panel is considered. The analysis is cradle to grave and covers all production and manufacturing stages, from raw material extraction until the end of life of the panel including its use phase. As the use phase is considered to be the panel’s transportation, as a part of the fuselage of an A319 aircraft, which has a lifetime of 30 years [10].

- B.

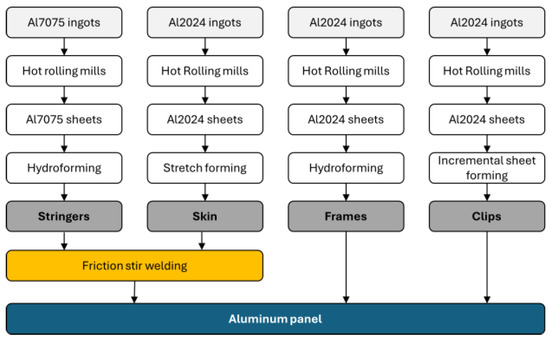

- Inventory Analysis: The data were mainly derived from the literature and the Ecoinvent library, while the design of the panel (geometry and materials for the baseline scenario) was provided by the FASTER-H2 project. For the aluminum panels (S0 to S2), it is assumed that the aluminum alloys are initially produced in ingot form and subsequently converted into sheets through a hot rolling mill process. The stringers and frames are manufactured using a hydroforming process, the skin is formed through stretch forming, and the clips are produced using incremental sheet forming. No material loss or consumables were considered in the manufacturing processes. For the composite panels (S3 to S8), thermoplastic and thermoset CFRP prepregs were produced, and an autoclave process was used to manufacture the sub-parts of the panel. The waste scenario for the aluminum panels assumes 85% recycling and 15% landfill, whereas for the composite panels, it is 100% landfill. The joining method for the aluminum and thermoplastic CFRP panels is an appropriate welding process, while bonding is used for the thermoset CFRP panels. Transportation is not included, and electricity is assumed to be provided from Europe. The process tree diagram for the aluminum panel model is depicted in Figure 2.

Figure 2. Process tree diagram for the aluminum panel model.

Figure 2. Process tree diagram for the aluminum panel model.

- C.

- Impact assessment: The methods selected for the assessment are the ReCiPe 2016 Endpoint (H) and the IPCC 2021 GWP100. And their impact categories, human health, ecosystems, resources, and global warming potential (GWP), are considered the environmental criteria of the study [11].

- D.

- Interpretation: In this study, the interpretation of the results comes from the final ranking through the TOPSIS process, combining cost and performance attributes too.

3.2. Life Cycle Costing—Cost Criteria

A method for the environmental Life Cycle Costing assessment was developed using SimaPro software. The impact categories considered include material, energy, use, and End-of-Life (EoL) costs associated with all phases of the panel’s lifecycle, which were and the cost criteria of the study. Revenue costs were not taken into account.

3.3. Finite Element Analysis—Performance Criteria

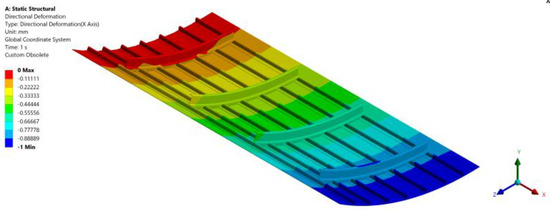

A FE model was developed in Ansys in order to compute the specific stiffness of the panel, an essential structural design parameter, which was considered one of the performance criteria. Solid elements were used to represent all the panel sub-parts except for clips, and unit axial compressive displacement was applied to one end of the panel, while the opposite one was fully constrained. In Figure 3, the axial deformation of the panel is shown.

Figure 3.

The directional deformation of the panel.

The other performance criterion considered is mass, which is the most important attribute in aviation for the reason that it affects almost all the other criteria (production energy, fuel consumption, cost, etc.)

3.4. The TOPSIS MCDM Method

The TOPSIS method [12,13] is a widely utilized MCDM method that ranks alternatives based on relative closeness to a positive ideal solution (PIS) and a negative ideal solution (NIS). TOPSIS is carried out through the following for a normalized decision matrix :

First, calculate the weighted normalized matrix by applying the criteria weights to each normalized value:

The positive ideal solution () and negative ideal solution () are then determined as follows:

The separation between each alternative is measured by the Euclidean distances and calculated as

to quantify how close each alternative is to the PIS and NIS. Finally, the relative closeness coefficient of each alternative to the ideal solution is given by

A higher indicates that the alternative is closer to the PIS and further from the NIS, thus being more desirable; therefore, the alternatives are ranked in descending order of values.

Objective Weighting Methods

The weighting of the criteria in the decision-making process is critical as it determines the importance of each criterion in the assessment and directly affects the final results. The weights can be defined either with objective methods or subjective methods. Subjective methods rely on expert opinions, where weights are assigned either through formal methodologies or based on individual expertise without a standardized approach. Due to the large number of experts needed, objective methods were selected for this study. Objective weighting methods derive weights using statistical measures from the data. Six methods were applied in this study to analyze their impact on the final results: Standard Deviation (Std), the Coefficient of Variation (COV), Entropy, CRITIC, CRITIC–Entropy, and MEREC. The Standard Deviation method assigns weights based on variability among the criteria, while the Coefficient of Variation method considers the relationship between criteria. The CRITIC method [14] uses correlation analysis to identify contrasts between criteria. The Entropy method [15] measures the uncertainty of information, while the CRITIC–Entropy method is a combination of these two methods. The MEREC method [16] determines weights by evaluating the effect of removing each criterion on the overall performance of alternatives, using a logarithmic calculation with equal initial weights.

4. Results

Using the methodology outlined in Section 3, a decision matrix was developed based on the data from SimaPro and finite element analysis, as shown in Table 3.

Table 3.

Decision matrix of the panel.

Six objective weighting methods were applied, yielding varying results regarding the importance of the criteria. The CRITIC method identifies C6 as the most important criterion, followed by C5 and C8, while the MEREC method ranks the same criteria differently. For the Entropy method, C6 remains the most important, followed by C10. The Standard Deviation method prioritizes C4, C7, and C3, while the CRITIC–Entropy and COV methods highlight C5, C6, and C8 in differing orders. Criteria C1 to C9, associated with cost, environmental impacts, and mass, need to be minimized, whereas C10, representing the specific strength of the panel, is a benefit criterion to be maximized. These criteria types influence the normalization formula applied, thereby affecting the results. Using this decision matrix, the TOPSIS method is implemented in Python 3.12 with six weighting methods, and the rankings of the alternatives are presented in Table 4.

Table 4.

Criteria weights derived from the six different objective weighting methods.

The final rankings that are depicted in Table 5 show that the TOPSIS method, regardless of the weighting method used, identifies the same optimal solution. Additionally, the MEREC, Entropy, CRITIC–Entropy, and COV methods produce identical results for the top three solutions. However, differences in rankings arise when using various weighting methods in the main methodology. Another factor influencing the final results is the normalization method applied in both the TOPSIS approach and the weighting methods requiring normalization.

Table 5.

The ranking of alternatives using the TOPSIS method for the six different weighting approaches.

5. Conclusions and Next Steps

The importance of criteria defined by objective methods is based on statistical metrics derived from the data for each criterion. However, this does not necessarily align with the purpose of the analysis. For example, if criteria were prioritized subjectively, we might select Global Warming Potential (GWP), use life cost, and performance as the most significant factors driving the final ranking of alternatives. This discrepancy could potentially be addressed by applying subjective weighting methods.

Regarding the final rankings, all methods consistently identify the same best alternative, with four weighting methods also agreeing on the top three alternatives. This indicates that while the choice of weighting method significantly influences the methodology, the first-ranked alternative remains consistent across all approaches. Notably, the results tend to converge more effectively when the same normalization method is used for both the TOPSIS and weighting methods.

This analysis evaluated different panel designs by varying materials, geometric parameters, and joining methods to assess their sustainability. The methodology provides a foundation for an eco-design approach for aircraft components.

The next steps in developing the eco-design approach are as follows:

- Define Governing Parameters: For the specific application, the most suitable governing parameters are the material and the mass of the panel.

- Develop Functional Relationships: Establish functions between the governing parameters and the criteria using mathematical methods, such as regression analysis, or AI techniques, such as neural networks.

- Identify Physical Constraints: Define physical constraints, such as minimum stiffness requirements and geometric restrictions.

- Perform Optimization: Use the established functions between governing parameters and criteria to perform optimization with an appropriate MCDM method.

Author Contributions

Conceptualization, K.T., A.A. and D.S.; methodology, K.T., A.A. and D.S.; software, A.A., G.F. and D.S.; investigation, K.T., A.A. and D.S.; writing—original draft preparation, K.T., A.A. and D.S.; writing—review and editing, K.T., A.A. and D.S.; visualization, A.A., G.F. and D.S.; supervision, K.T.; funding acquisition, K.T. All authors have read and agreed to the published version of the manuscript.

Funding

The work described in the paper has been financially supported by the Clean Aviation project FASTER-H2 (Project: 101101978). The views and opinions expressed in the paper are those of the author(s) only and do not necessarily reflect those of the European Union or Clean Aviation Joint Undertaking.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Dray, L.; Schäfer, A.W.; Grobler, C.; Falter, C.; Allroggen, F.; Stettler, M.E.J.; Barrett, S.R.H. Cost and Emissions Pathways towards Net-Zero Climate Impacts in Aviation. Nat. Clim. Change 2022, 12, 956–962. [Google Scholar] [CrossRef]

- Dhara, A.; Muruga Lal, J. Sustainable Technology on Aircraft Design: A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 889, 012068. [Google Scholar] [CrossRef]

- Guimarans, D.; Arias, P.; Tomasella, M.; Wu, C.-L. A Review of Sustainability in Aviation. In Sustainable Transportation and Smart Logistics; Elsevier: Amsterdam, The Netherlands, 2019; pp. 91–121. ISBN 978-0-12-814242-4. [Google Scholar]

- Bicer, Y.; Dincer, I. Life Cycle Evaluation of Hydrogen and Other Potential Fuels for Aircrafts. Int. J. Hydrogen Energy 2017, 42, 10722–10738. [Google Scholar] [CrossRef]

- Henderson, R.P.; Martins, J.R.R.A.; Perez, R.E. Aircraft Conceptual Design for Optimal Environmental Performance. Aeronaut. J. 2012, 116, 1–22. [Google Scholar] [CrossRef]

- Filippatos, A.; Markatos, D.; Tzortzinis, G.; Abhyankar, K.; Malefaki, S.; Gude, M.; Pantelakis, S. Sustainability-Driven Design of Aircraft Composite Components. Aerospace 2024, 11, 86. [Google Scholar] [CrossRef]

- Kassapoglou, C. Simultaneous Cost and Weight Minimization of Composite-Stiffened Panels under Compression and Shear. Compos. Part A Appl. Sci. Manuf. 1997, 28, 419–435. [Google Scholar] [CrossRef]

- ISO 14040; Environmental Management: Life Cycle Assessment; Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management, Life Cycle Assessment; Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Liu, Z. Life Cycle Assessment of Composites and Aluminium Use in Aircraft Systems. Ph.D. Thesis, Cranfield University, Wharley End, England, 2013. [Google Scholar]

- SimaPro | Methods Manual. Available online: https://support.simapro.com/s/article/SimaPro-Methods-manual (accessed on 26 April 2024).

- Hwang, C.-L.; Yoon, K. Multiple Attribute Decision Making; Lecture Notes in Economics and Mathematical Systems; Springer: Berlin/Heidelberg, Germany, 1981; Volume 186, ISBN 978-3-540-10558-9. [Google Scholar]

- Triantaphyllou, E. Multi-Criteria Decision Making Methods: A Comparative Study; Applied Optimization; Springer: Boston, MA, USA, 2000; Volume 44, ISBN 978-1-4419-4838-0. [Google Scholar]

- Diakoulaki, D.; Mavrotas, G.; Papayannakis, L. Determining Objective Weights in Multiple Criteria Problems: The Critic Method. Comput. Oper. Res. 1995, 22, 763–770. [Google Scholar] [CrossRef]

- Chen, C.-H. A Novel Multi-Criteria Decision-Making Model for Building Material Supplier Selection Based on Entropy-AHP Weighted TOPSIS. Entropy 2020, 22, 259. [Google Scholar] [CrossRef] [PubMed]

- Keshavarz-Ghorabaee, M.; Amiri, M.; Zavadskas, E.K.; Turskis, Z.; Antucheviciene, J. Determination of Objective Weights Using a New Method Based on the Removal Effects of Criteria (MEREC). Symmetry 2021, 13, 525. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).